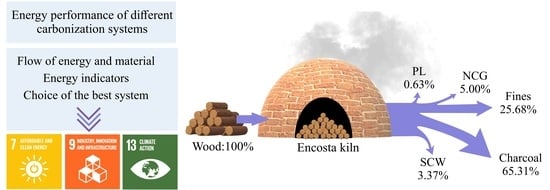

Energy Performance of Different Charcoal Production Systems

Abstract

:1. Introduction

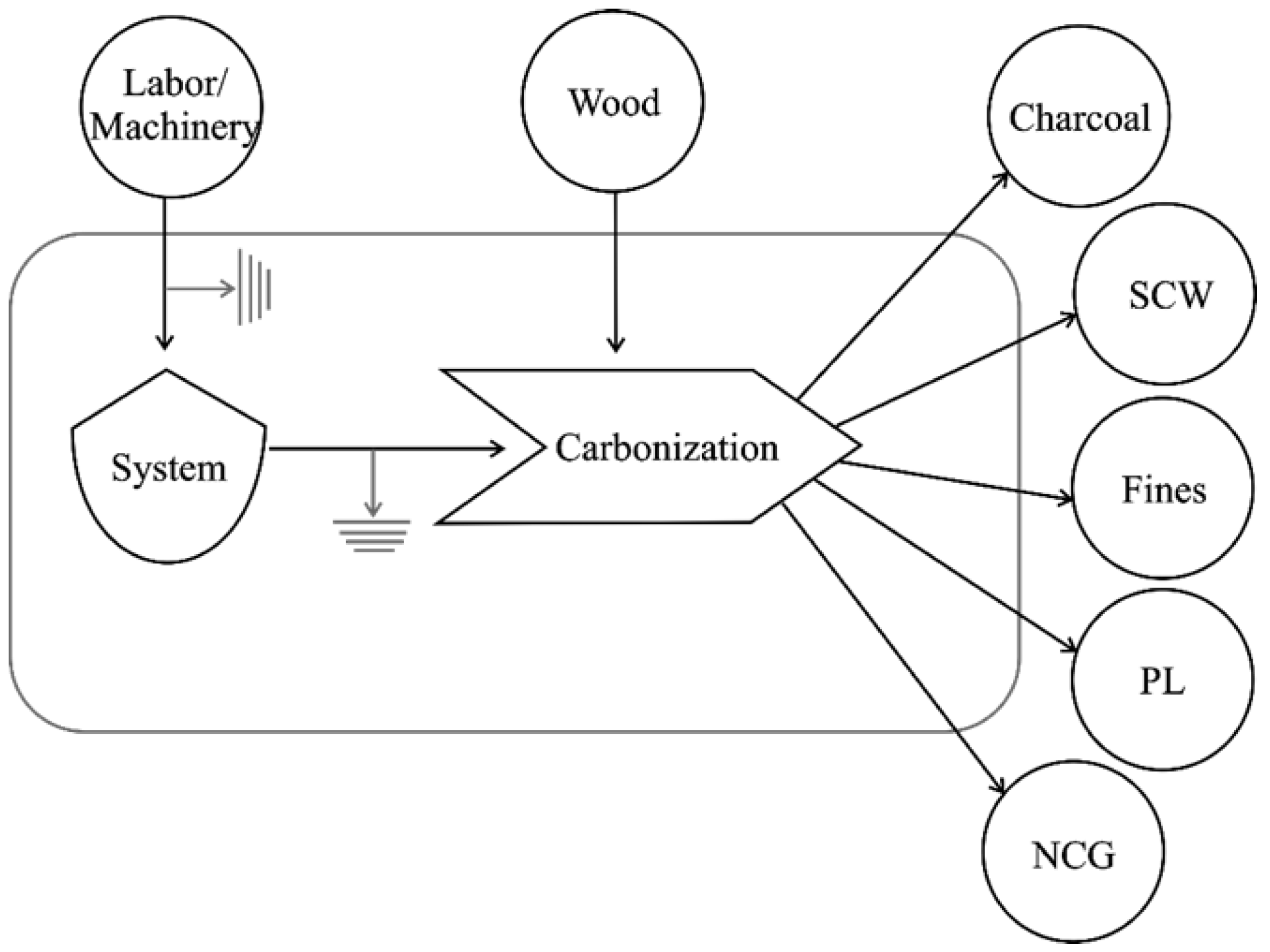

2. Materials and Methods

2.1. Description and Selection of Charcoal System Variables

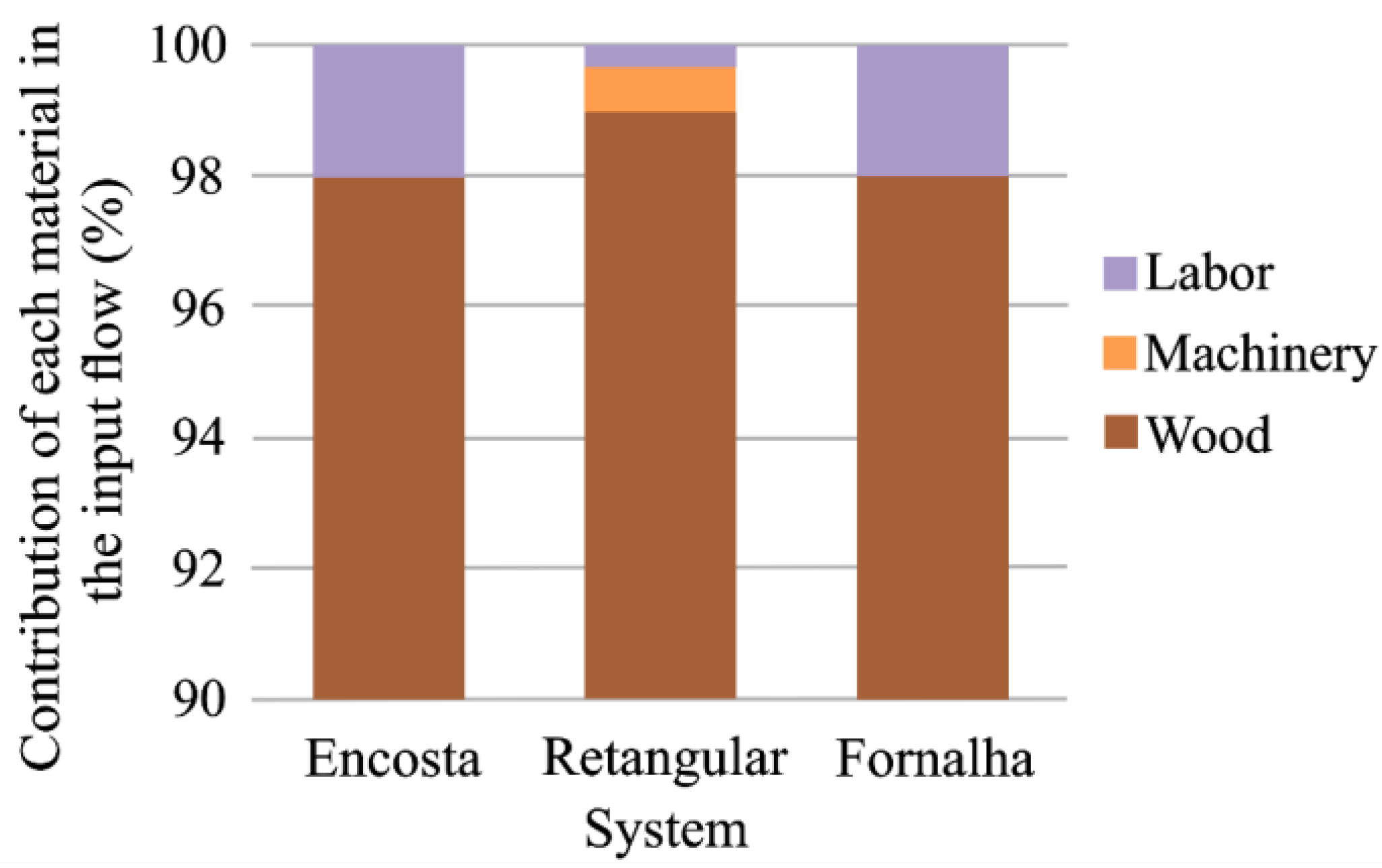

2.2. Determination of Material and Energy Flows

2.3. Sensitivity Analysis of Carbonization Systems

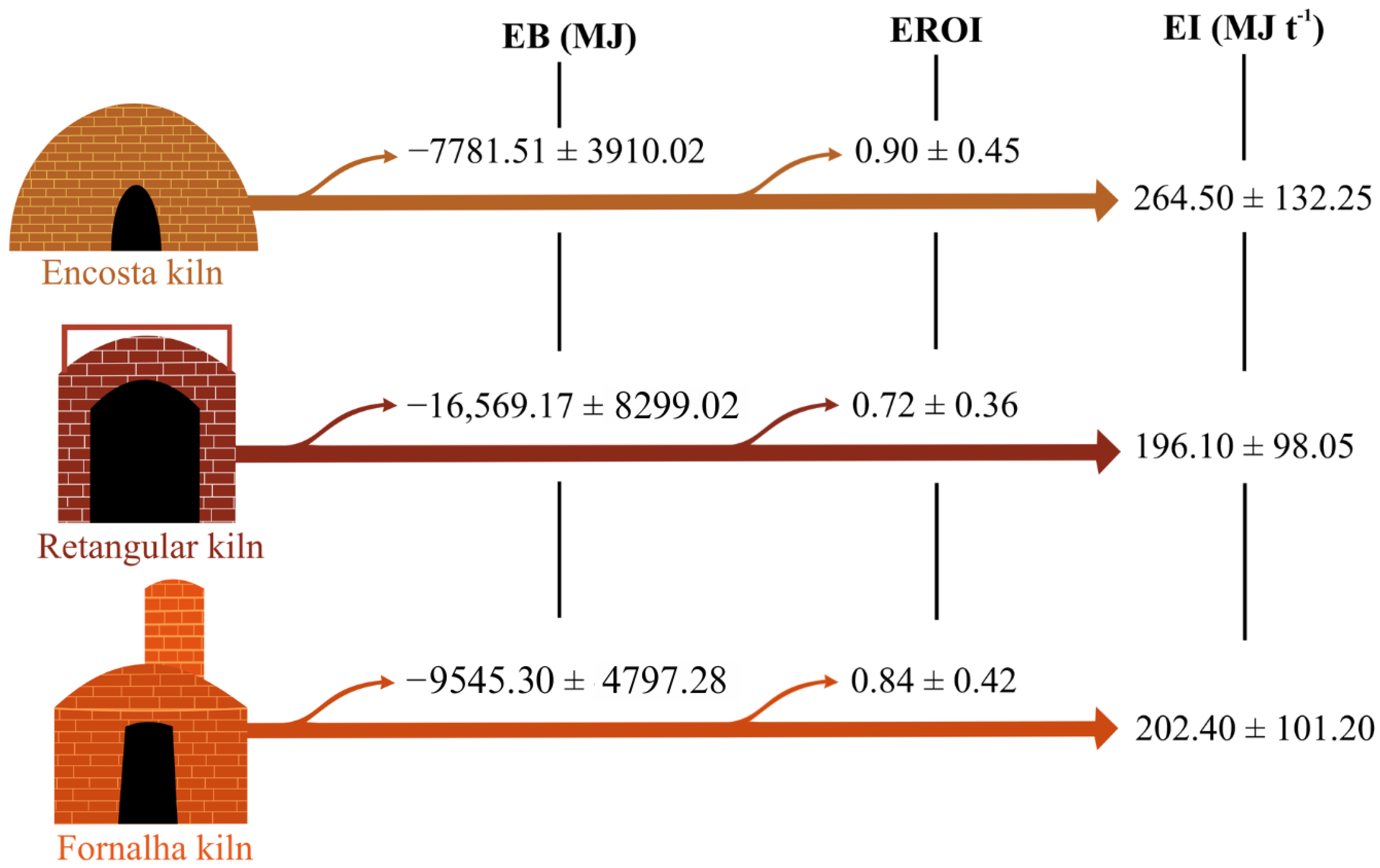

3. Results and Discussion

3.1. Energy Performance of Systems

3.2. Sensitivity Analysis

3.3. Practical and Social Implications and Research Difficulties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dam, J.V. The Charcoal Transitions: Greening the Charcoal Value Chain to Mitigate Climate Change and Improve Local Livelihoods; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2017. [Google Scholar]

- Muller, E. Enhancing Sustainability and Efficiency of Woodfuel Production and Consumption. In Proceedings of the African Forestry and Wildlife Commission, Nairobi, Kenya, 1–5 February 2016. [Google Scholar]

- Indústria Brasileira de Árvores. Relatório Anual. 2020. Available online: https://iba.org/datafiles/publicacoes/relatorios/relatorio-iba-2020.pdf (accessed on 20 February 2023).

- Bustos-Vanegas, J.D.; Martins, M.A.; Carneiro AD, C.O.; Freitas, A.G.; Barbosa, R.C. Thermal Inertia Effects of the Structural Elements in Heat Losses during the Charcoal Production in Brick Kilns. Fuel 2018, 226, 508–515. [Google Scholar] [CrossRef]

- Rodrigues, T.; Braghini Junior, A. Charcoal: A Discussion on Carbonization Kilns. J. Anal. Appl. Pyrolysis 2019, 143, 104670. [Google Scholar] [CrossRef]

- Zola, F.C.; Colmenero, J.C.; Aragão, F.V.; Rodrigues, T.; Junior, A.B. Multicriterial Model for Selecting a Charcoal Kiln. Energy 2020, 190, 116377. [Google Scholar] [CrossRef]

- de Oliveira Vilela, A.; Lora, E.S.; Quintero, Q.R.; Vicintin, R.A.; Pacceli da Silva e Souza, T. A New Technology for the Combined Production of Charcoal and Electricity through Cogeneration. Biomass Bioenergy 2014, 69, 222–240. [Google Scholar] [CrossRef]

- Adedayo, H.B.; Adio, S.A.; Oboirien, B.O. Energy Research in Nigeria: A Bibliometric Analysis. Energy Strategy Rev. 2021, 34, 100629. [Google Scholar] [CrossRef]

- Romanelli, T.L.; Nardi, H.D.S.; Saad, F.A. Material Embodiment and Energy Flows as Efficiency Indicators of Soybean (Glycine Max) Production in Brazil. Eng. Agrícola 2012, 32, 261–270. [Google Scholar] [CrossRef]

- Sangaletti-Gerhard, N.; Romanelli, T.L.; de Souza Vieira, T.M.F.; Navia, R.; Regitano-d’Arce, M.A.B. Energy Flow in the Soybean Biodiesel Production Chain Using Ethanol as Solvent Extraction of Oil from Soybeans. Biomass Bioenergy 2014, 66, 39–48. [Google Scholar] [CrossRef]

- Ilyushin, Y.V.; Kapostey, E.I. Developing a Comprehensive Mathematical Model for Aluminium Production in a Soderberg Electrolyser. Energies 2023, 16, 6313. [Google Scholar] [CrossRef]

- Schettini, B.L.S.; Jacovine, L.A.G.; Torres, C.M.M.E.; Carneiro, A.D.C.O.; Villanova, P.H.; da Rocha, S.J.S.S.; Rufino, M.P.M.X.; Silva, L.B.; Castro, R.V.O. Furnace-Kiln System: How Does the Use of New Technologies in Charcoal Production Affect the Carbon Balance? Ind. Crops Prod. 2022, 187, 115330. [Google Scholar] [CrossRef]

- Vicente Leme, M.M.; Venturini, O.J.; Silva Lora, E.E.; de Almeida, W.; Rocha, M.H.; Andrade da Cunha Dias, T. Life Cycle Assessment of Charcoal Production and Electricity Generation from Eucalyptus in an Industrial Batch Kiln. Renew. Energy 2021, 180, 232–244. [Google Scholar] [CrossRef]

- Oliveira, A.C.; Ramos, D.C.; Pereira, B.L.C.; de Cássia Oliveira Carneiro, A. Temperatura de Carbonização e Propriedades Do Carvão Vegetal Ao Longo de Um Forno Retangular. Rev. Bras. Ciências Agrárias 2020, 15, 1–8. [Google Scholar] [CrossRef]

- Serra, G.E.; Moreira, J.R.; Goldenberg, J.; Heezen, A.M. Avaliação da Energia Investida Na Fase Agrícola de Algumas Culturas; Planalsucar: Brasília, Brazil, 1979. [Google Scholar]

- Lana, G.C. Efeito Na Dimensão de Toras No Processo de Colheita Florestal e Seus Impactos No Custo e Na Qualidade Do Carvão Vegetal; Universidade Federal do Paraná: Paraná, Argentina, 2012. [Google Scholar]

- Seixas, F.; Marquesini, M. Determinação Do Esforço Físico de Trabalhadores Na Colheita de Caixeta (Tabebuia Cassinoides) Workers Physical Stress Determination on “caixeta” Harvesting (Tabebuia Cassinoides). Sci. For. 2001, 59, 145–151. [Google Scholar]

- de Arruda, T.P.M.; Pimenta, A.S.; Vital, B.R.; Lucia, R.M.D.; Acosta, F.C. Avaliação de Duas Rotinas de Carbonização Em Fornos Retangulares. Rev. Árvore 2011, 35, 949–955. [Google Scholar] [CrossRef]

- Ricky Chan, W.C.; Kelbon, M.; Krieger-Brockett, B. Single-Particle Biomass Pyrolysis: Correlations of Reaction Products with Process Conditions. Ind. Eng. Chem. Res. 1988, 27, 2261–2275. [Google Scholar] [CrossRef]

- Blake, S.T.; Cristina Setúbal Queiroz, S.; Lívio Gomide, J.; Luiz Colodette, J.; Chaves de Oliveira, R. Influência Da Densidade Básica Da Madeira Na Qualidade Da Polpa Kraft de Clones Hibrídos de Eucalyptus Grandis W. Hill Ex Maiden X Eucalyptus Urophylla S. T. Blake. Rev. Árvore 2004, 28, 901–909. [Google Scholar] [CrossRef]

- Friedl, A.; Padouvas, E.; Rotter, H.; Varmuza, K. Prediction of Heating Values of Biomass Fuel from Elemental Composition. Anal. Chim. Acta 2005, 544, 191–198. [Google Scholar] [CrossRef]

- Oliveira, A.F.; Bavaresco, A.; Pessuti, C.A.A.; Miyashiro, C.S.; Frank, J. Análise Da Qualidade Do Carvão Para Consumo Doméstico De Quatro Municípios Do Estado Do Paraná. Rev. Bras. Energ. Renov. 2015, 4, 102–111. [Google Scholar] [CrossRef]

- Parikh, J.; Channiwala, S.A.; Ghosal, G.K. A Correlation for Calculating HHV from Proximate Analysis of Solid Fuels. Fuel 2005, 84, 487–494. [Google Scholar] [CrossRef]

- Brand, M.A.; Rodrigues, A.A.; de Oliveira, A.; Machado, M.S.; Zen, L.R. Qualidade Do Carvão Vegetal Para O Consumo Doméstico Comercializado Na Região Serrana Sul De Santa Catarina. Rev. Árvore 2015, 39, 1165–1173. [Google Scholar] [CrossRef]

- Kumar, M.; Gupta, R.C.; Sharma, T. Effects of Carbonisation Conditions on the Yield and Chemical Composition of Acacia and Eucalyptus Wood Chars. Biomass Bioenergy 1992, 3, 411–417. [Google Scholar] [CrossRef]

- Trugilho, P.F.; Da Silva, D.A. Influência Da Temperatura Final de Carbonização Nas Características Físicas e Químicas Do Carvão Vegetal de Jatobá (Himenea Courbaril L.). Sci. Agrar. 2001, 2, 45. [Google Scholar] [CrossRef]

- Urkan, M.K.; Arikol, M. Burning Times of Volatiles from Turkish Coals during Fluidized Bed Combustion. Fuel 1994, 73, 768–772. [Google Scholar] [CrossRef]

- do Vale, A.T.; Dias, Í.S.; Santana, M.A.E. Relações entre propriedades químicas, físicas e energéticas da madeira de cinco espécies de cerrado. Ciência Florest. 2010, 20, 137–145. [Google Scholar] [CrossRef]

- Santos, S.D.F.D.O. Modelo Ambiental e Econômico de Produção de Carvão Vegetal; Universidade Tecnológica Federal do Paraná: Ponta Grossa, Brazil, 2017. [Google Scholar]

- Costa, J.M.F.N. Temperatura Final de Carbonização e Queima Dos Gases Na Redução de Metano, Como Base à Geração de Créditos de Carbono; Universidade Federal de Viçosa: Viçosa, Brazil, 2017. [Google Scholar]

- Romanelli, T.L.; Milan, M. Energy Performance of a Production System of Eucalyptus. Rev. Bras. Eng. Agrícola Ambient. 2010, 14, 896–903. [Google Scholar] [CrossRef]

- Kittner, N.; Gheewala, S.H.; Kammen, D.M. Energy Return on Investment (EROI) of Mini-Hydro and Solar PV Systems Designed for a Mini-Grid. Renew. Energy 2016, 99, 410–419. [Google Scholar] [CrossRef]

- Bailis, R.; Rujanavech, C.; Dwivedi, P.; de Oliveira Vilela, A.; Chang, H.; de Miranda, R.C. Innovation in Charcoal Production: A Comparative Life-Cycle Assessment of Two Kiln Technologies in Brazil. Energy Sustain. Dev. 2013, 17, 189–200. [Google Scholar] [CrossRef]

- Ronix, A.; Cazetta, A.L.; Ximenez, G.R.; Spessato, L.; Silva, M.C.; Fonseca, J.M.; Yokoyama, J.T.C.; Lopes, G.K.P.; Zanella, H.G.; Almeida, V.C. Biochar from the Mixture of Poultry Litter and Charcoal Fines as Soil Conditioner: Optimization of Preparation Conditions via Response Surface Methodology. Bioresour. Technol. Rep. 2021, 15, 100800. [Google Scholar] [CrossRef]

- Rousset, P.; Caldeira-Pires, A.; Sablowski, A.; Rodrigues, T. LCA of Eucalyptus Wood Charcoal Briquettes. J. Clean Prod. 2011, 19, 1647–1653. [Google Scholar] [CrossRef]

- Assis, M.R.; Brancheriau, L.; Napoli, A.; Trugilho, P.F. Factors Affecting the Mechanics of Carbonized Wood: Literature Review. Wood Sci. Technol. 2016, 50, 519–536. [Google Scholar] [CrossRef]

- Barcellos, D. Entenda o Conceito de Uma Fábrica de Carvão Ecológico-Daniel Barcellos. Available online: https://danielbarcellos.com/conceito-de-uma-fabrica-de-carvao-ecologico-2/ (accessed on 17 October 2023).

- Jesus, M.S.; Napoli, A.; Trugilho, P.F.; Abreu Júnior, Á.A.; Martinez, C.L.M.; Freitas, T.P. Energy and Mass Balance in the Pyrolysis Process of Eucalyptus Wood. Cerne 2018, 24, 288–294. [Google Scholar] [CrossRef]

- Brownsort, P.A. Biomass Pyrolysis Processes: Performance Parameters and Their Influence on Biochar System Benefits. Master’s Thesis, University of Edinburgh, Edinburgh, UK, 2009. [Google Scholar]

- Artuzo, F.D.; Allegretti, G.; Santos, O.I.B.; da Silva, L.X.; Talamini, E. Emergy Unsustainability Index for Agricultural Systems Assessment: A Proposal Based on the Laws of Thermodynamics. Sci. Total Environ. 2021, 759, 143524. [Google Scholar] [CrossRef]

- Produção e Utilização de Carvão Vegetal; Fundação Centro Tecnológico de Minas Gerais (CETEC): Belo Horizonte, Brazil, 1982.

- Lima, M.D.R.; Patrício, E.P.S.; Junior, U.D.O.B.; Silva, R.D.C.C.; Bufalino, L.; Numazawa, S.; Hein, P.R.G.; de Paula Protásio, T. Colorimetry as a Criterion for Segregation of Logging Wastes from Sustainable Forest Management in the Brazilian Amazon for Bioenergy. Renew. Energy 2021, 163, 792–806. [Google Scholar] [CrossRef]

- Bernardes, F.F. Desempenho Energético de Diferentes Processos de Produção de Carvão Vegetal. Ph.D. Thesis, Universidade de São Paulo, São Paulo, Brazil, 2019. [Google Scholar]

- Ministério do Meio Ambiente. Produção Sustentãvel de Carvão Vegetal: Manual de Construção Sistemas Fornos, Fornalha; MMA: São Paulo, Brazil, 2019. [Google Scholar]

| Wood as Raw Material | System | Carbonization Products |

|---|---|---|

| Clone/Species | Capacity (m³) | Gravimetric yield (%) |

| Moisture (%) | Kiln loading (h) | Ash (%) |

| Density (kg m−3) | Unloading (h) | Semi-carbonized wood (kg) |

| Diameter (cm) | Temperature measurement (h) | Moisture (%) |

| Length (m) | Ignition (h) | Density (kg m−³) |

| Input mass (kg) | Carbonization (h) | Charcoal mass on a dry basis (kg) |

| Higher calorific value (MJ kg−1) | Cooling (h) | Fines of charcoal (%) |

| - | Final temperature (°C) | Higher calorific value (MJ kg−1) |

| - | Machine consumption (L h−1) | Pyroligneous liquid (%) |

| Material | Indicator (MJ) | Encosta Kiln | Rectangular Kiln | Fornalha Kiln | |||

|---|---|---|---|---|---|---|---|

| LCL | UCL | LCL | UCL | LCL | UCL | ||

| Input | |||||||

| Wood | ECwd | 76,366.40 | 84,109.13 | 56,041.40 | 60,958.05 | 58,378.90 | 61,939.29 |

| System | ECmop1 | 15.72 | 30.21 | - | - | 16.71 | 29.81 |

| ECmop2 | 4.21 | 8.09 | 1.62 | 2.68 | 4.47 | 7.99 | |

| ECmop3 | - | - | 0.18 | 0.30 | - | - | |

| ECmec | - | - | 43.32 | 72.02 | - | - | |

| Output | |||||||

| Charcoal | ECch | 27,924.64 | 33,155.44 | 26,048.28 | 29,099.40 | 27,168.57 | 28,486.99 |

| Fines | ECfines | 19,824.58 | 33,479.65 | 8419.97 | 12,634.17 | 10,950.51 | 17,068.07 |

| SCW | ECscw | 8247.03 | 10,445.65 | 820.95 | 1970.93 | 5694.26 | 7396.16 |

| PL | ECpl | 257.37 | 363.39 | 271.17 | 406.47 | 257.07 | 418.43 |

| NCG | ECncg | 2474.18 | 3001.14 | 1839.41 | 2101.27 | 1893.51 | 1991.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bernardes, F.F.; Romanelli, T.L.; Pereira, A.K.S.; Cupertino, G.F.M.; Fernandes, M.A.; Brito, J.O.; de Souza, E.C.; Saloni, D.; Dias Júnior, A.F. Energy Performance of Different Charcoal Production Systems. Energies 2023, 16, 7318. https://doi.org/10.3390/en16217318

Bernardes FF, Romanelli TL, Pereira AKS, Cupertino GFM, Fernandes MA, Brito JO, de Souza EC, Saloni D, Dias Júnior AF. Energy Performance of Different Charcoal Production Systems. Energies. 2023; 16(21):7318. https://doi.org/10.3390/en16217318

Chicago/Turabian StyleBernardes, Francisco Fernandes, Thiago Libório Romanelli, Allana Katiussya Silva Pereira, Gabriela Fontes Mayrinck Cupertino, Márcia Aparecida Fernandes, José Otávio Brito, Elias Costa de Souza, Daniel Saloni, and Ananias Francisco Dias Júnior. 2023. "Energy Performance of Different Charcoal Production Systems" Energies 16, no. 21: 7318. https://doi.org/10.3390/en16217318

APA StyleBernardes, F. F., Romanelli, T. L., Pereira, A. K. S., Cupertino, G. F. M., Fernandes, M. A., Brito, J. O., de Souza, E. C., Saloni, D., & Dias Júnior, A. F. (2023). Energy Performance of Different Charcoal Production Systems. Energies, 16(21), 7318. https://doi.org/10.3390/en16217318