A Survey on Recent Applications of Artificial Intelligence and Optimization for Smart Grids in Smart Manufacturing

Abstract

:1. Introduction

- This survey reviews recent works on the SG as well as the AI and optimization applications using the SG in smart manufacturing.

- To achieve smart manufacturing and sustainability, this survey collects recent works on the applications of AI and optimization technologies for SG in manufacturing operations.

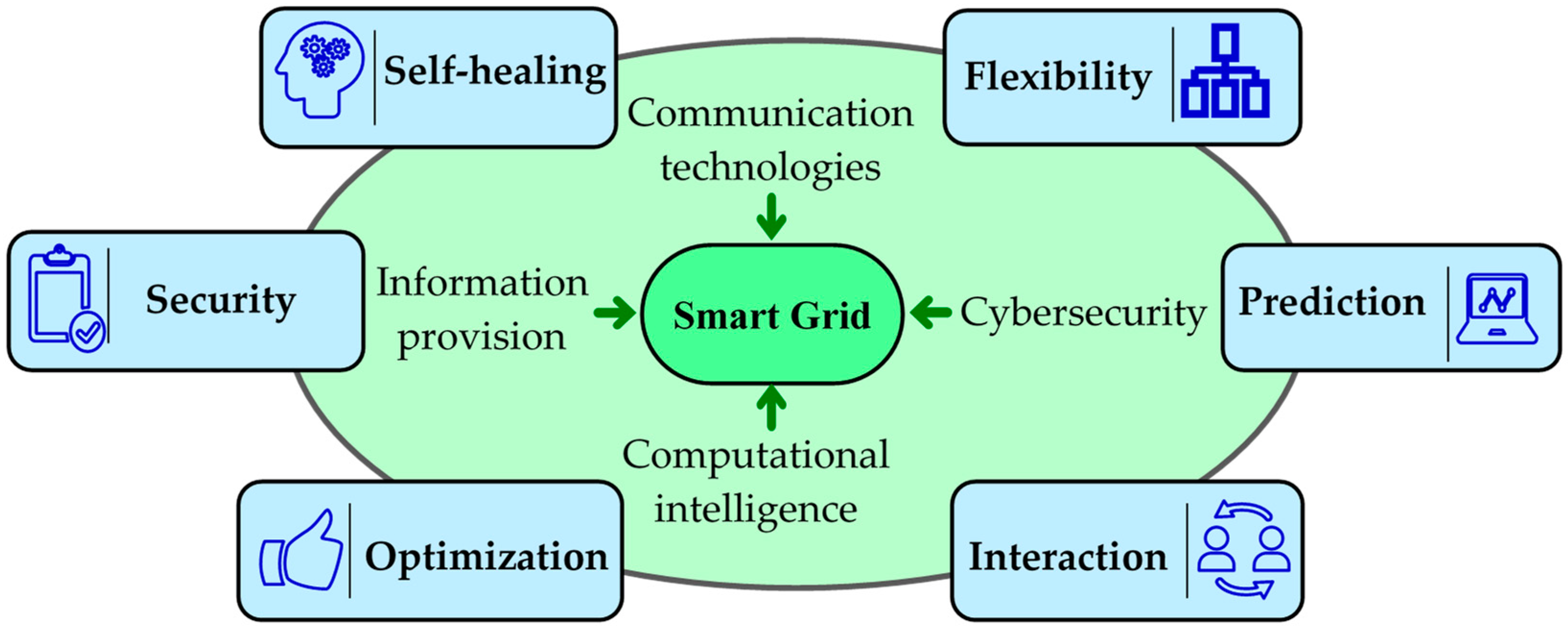

2. Overview of SG Operations for Smart Manufacturing

2.1. Distribution Side Management through SGs

2.2. Demand Side Management through SGs

2.3. Smart Manufacturing Using Distribution and Demand Side Management through SGs

3. AI Applications for SGs in Smart Manufacturing

3.1. Basic Concept of AI

- Step 2 (processing algorithm): The major AI algorithms are classified into supervised learning (i.e., the model is established based on the training dataset in which the label of each instance is known), unsupervised learning (i.e., the label of each instance in the training dataset is unknown), and reinforcement learning (e.g., the agent continuously interacts with the environment to learn how to correctly take actions). According to the required goals and objectives, AI algorithms are chosen to solve the problem or provide actions [39,40,41,42].

- Knowledge database: The knowledge database provides the AI system with the stored experience and decision data to assist the operation.

3.2. AI Applications in SGs for Smart Manufacturing

4. Optimization Applications for SGs in Smart Manufacturing

4.1. Smart Manufacturing Environment and Technology Importing

- Smart manufacturing: The smart manufacturing environment includes human–machine systems, automated guided vehicles (AGVs), automated storage/retrieval systems (AS/RS), and other equipment, which are monitored by smart meters.

- Power supply from power companies: The energy required for manufacturing processes is supplied by hydroelectric energy, wind energy, nuclear energy, and thermal power from the power companies in the SG.

- Self-power supply: A lot of smart factories set up solar panels and energy generators on the SG to control the power supply independently.

4.2. Optimizing SG Systems for Smart Manufacturing

- Energy cost management: Khalid and Powell [86] developed an algorithm for forecasting manufacturing energy load to effectively reduce peak facility power. Lu and Hong [87] proposed an incentive-based demand response algorithm to enable the SG system to have reinforcement learning and deep neural network capabilities. Targeting natural gas demand in the SG, Dababneh and Li [88] proposed a modified simulated annealing algorithm to establish a production scheduling model to allow manufacturers to reduce energy costs. Wu et al. [89] proposed a mixed integer linear programming model to schedule actual multi-tasks to minimize the energy cost.

- Installation of smart meters: To effectively manage energy consumption, Zakariazadeh [90] adopted smart meters and an artificial bee colony-based random forest clustering algorithm for data classification and analysis, and the adopted method was more accurate than other classification methods. Venkatraman et al. [91] developed a smart meter data-driven rate model to recover distribution network-related charges and imported grid-edge technologies to meet the needs of consumers of different power scales and save costs.

- Reliable energy system: Behara and Saha [92] carried out a reliability assessment for SG-integrated distributed power-generating with AI methodology-based search algorithms to ensure the reliability and accuracy of the power system. Rouzbahani et al. [93] simulated the SG system being attacked by the IoT energy network through an attack generator algorithm and used the deep neural network to detect it to establish a safe and reliable energy system.

- Establishment of the digital twin: Wang et al. [94] surveyed the approaches and applications of digital twins for energy systems. Jiang et al. [95] proposed a complex SG system with the digital twin based on data and knowledge for duplication of similar unit-level and management. In view of the large energy consumption and fluctuations in the manufacturing system, Mourtzis et al. [96] developed the stored energy allocation model based on the digital twin technology to optimize energy allocation and reduce CO2 emissions.

- Data-driven optimization: Mourtzis et al. [97] surveyed smart manufacturing energy policies and cases, in which a lot of actual cases used SG data collection and analysis and machine learning methods to control energy consumption and electricity prices, allowing continuous data-driven optimization. To monitor and optimize the energy consumption of manufacturing factories, Bermeo-Ayerbea et al. [98] proposed a data-driven energy prediction model to control machine energy consumption and fault warning and improve energy efficiency. Meng et al. [99] summarized the solutions to energy consumption in the manufacturing industry and explained how to make smart manufacturing move forward toward sustainable development through big data collection and the development of decision-making technologies.

- Quality-of-service (QoS) of communication networks and data collected: Faheem and Gungor [100] considered that electromagnetic interference and multipath effects exist at the manufacturing site due to the use of industrial wireless sensors and IoT, and they would affect the QoS for data collection. They then proposed a QoS-aware data acquisition protocol model to reduce data error rate and improve the quality of manufacturing data communication. Qureshi et al. [101] proposed a software-defined network (SDN) for the energy internet to improve the response time and QoS of the controller, which can also increase the utilization rate of green energy in the SG system. In the complex SG framework, Faheem and Gungor [102] applied dynamic clustering-based energy efficiency and a QoS-aware routing protocol to improve the quality of information transmission.

4.3. Applications Result Summary

5. Discussion and Future Challenges

- Integration of the SG system with renewable energies: As environmental sustainability issues have received increasing attention, more and more renewable energies will be integrated into the SG system in the future [107] so that the system will become more complex, especially when supply and demand of the SC are intermittent, thus, supporting demand-side management in industrial environments becomes key to grid stability and flexibility [108,109]. One of the future challenges is to investigate how to make this complex integrated system more stable and provide manufacturing more efficiently.

- Applications of 5G and B5G network technologies in the SG system: The B5G (beyond 5G) means the next generation of communication technology that has a peak transmission speed dozens of times faster than 5G, and it can solve the energy consumption of 5G and improve coverage by applying low orbit satellites. Smart factories are formed by connecting various devices through the IoT. Therefore, it is important to carry out intelligent energy management [110]. 5G network technologies provide the industrial IoT with better communication quality and smart energy management [111], and it also solves the problem of communication latency in the manufacturing process [112]. Therefore, a line of the future challenge is to investigate how to further optimize the SG system integrated with 5G networks through AI technologies [113].

- Next-generational smart manufacturing: The emergence of Industry 4.0 has initial-ized the fourth industrial evolution. It has driven the development of smart manufacturing processes, including the wide introduction of human–machine systems, communication networks, big data analysis, and so on. It has brought efficient and effective manufacturing models, but some challenges still exist, e.g., circular economy, energy demand management, and net-zero emissions. Therefore, the development of next-generation intelligent manufacturing will increasingly emphasize the human-centered concept. Although the SG effectively has integrated energy into smart manufacturing and had a positive impact on reducing operating costs [114], when smart manufacturing systems are evolving to the next generation, the next-generation smart grid (NGSG) that can reduce nonlinear effects needs to be continuously developed [115]. At the same time, it is also a challenge to effectively integrate the concept of human-oriented to achieve more efficient smart factories [116].

6. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Javaida, M.; Haleema, A.; Singhb, R.P.; Sumanc, R.; Gonzalez, E.S. Understanding the adoption of Industry 4.0 technologies in improving environmental sustainability. Sustain. Oper. Comput. 2022, 3, 203–217. [Google Scholar] [CrossRef]

- Nouiri, M.; Trentesaux, D.; Bekrar, A. Towards energy efficient scheduling of manufacturing systems through collaboration between cyber physical production and energy systems. Energies 2019, 12, 4448. [Google Scholar] [CrossRef]

- Islama, M.M.; Rahmanb, M.; Heidaria, F.; Gudec, V. Optimal onsite microgrid design for net-zero energy operation in manufacturing industry. Procedia Comput. Sci. 2021, 185, 81–90. [Google Scholar] [CrossRef]

- Qarabsh, N.A.; Sabry, S.S.; Qarabash, H.A. Smart grid in the context of Industry 4.0: An overview of communications technologies and challenges. Indones. J. Electr. Eng. Comput. Sci. 2020, 18, 656–665. [Google Scholar] [CrossRef]

- Dileep, G. A survey on smart grid technologies and applications. Renew. Energy 2020, 146, 2589–2625. [Google Scholar] [CrossRef]

- Babayomi, O.; Zhang, Z.; Dragicevic, T.; Hu, J.; Rodriguez, J. Smart grid evolution: Predictive control of distributed energy resources—A review. Int. J. Electr. Power Energy Syst. 2023, 147, 108812. [Google Scholar] [CrossRef]

- Bhattarai, T.N.; Ghimire, S.; Mainali, B.; Gorjian, S.; Treiche, H.; Paudel, S.R. Applications of smart grid technology in Nepal: Status, challenges, and opportunities. Environ. Sci. Pollut. Res. 2022, 30, 25452–25476. [Google Scholar] [CrossRef]

- Rodgers, W.; Cardenas, J.A.; Gemoets, L.A.; Sarfi, R.J. A smart grids knowledge transfer paradigm supported by experts’ throughput modeling artificial intelligence algorithmic processes. Technol. Forecast. Soc. Chang. 2023, 190, 122373. [Google Scholar] [CrossRef]

- Ahmad, T.; Zhang, D.; Huang, C.; Zhang, H.; Dai, N.; Song, Y.; Chen, H. Artificial intelligence in sustainable energy industry: Status Quo, challenges and opportunities. J. Clean. Prod. 2021, 289, 125834. [Google Scholar] [CrossRef]

- Xia, M.; Shao, H.; Ma, X.; de Silva, C.W. A stacked GRU-RNN-Based approach for predicting renewable energy and electricity load for smart grid operation. IEEE Trans. Ind. Inform. 2021, 17, 7050–7059. [Google Scholar] [CrossRef]

- Khalid, R.; Javaid, N.; Al-zahrani, F.A.; Aurangzeb, K.; Qazi, E.; Ashfaq, T. Electricity load and price forecasting using jaya-long short term memory (JLSTM) in smart grids. Entropy 2019, 22, 10. [Google Scholar] [CrossRef] [PubMed]

- Avancini, D.B.; Rodrigues, J.J.P.C.; Martins, S.G.B.; Rabêlo, R.A.L.; Al-Muhtadi, J.; Solic, P. Energy meters evolution in smart grids: A review. J. Clean. Prod. 2019, 217, 702–715. [Google Scholar]

- Jaiswal, D.M.; Thakre, M.P. Modeling & designing of smart energy meter for smart grid applications. Glob. Transit. Proc. 2022, 3, 311–316. [Google Scholar]

- Yang, Y.; Li, W.; Li, W.; Gulliver, T.A.; Li, S. Bayesian deep learning-based probabilistic load forecasting in smart grids. IEEE Trans. Ind. Inform. 2020, 16, 4703–4713. [Google Scholar] [CrossRef]

- Shi, Z.; Yao, W.; Li, Z.; Zeng, L.; Zhao, Y.; Zhang, R.; Tang, Y.; Wen, J. Artificial intelligence techniques for stability analysis and control in smart grids: Methodologies, applications, challenges and future directions. Appl. Energy 2020, 278, 115733. [Google Scholar] [CrossRef]

- Bagdadee, A.H.; Aurangzeb, M.; Ali, S.; Zhang, L. Energy management for the industrial sector in smart grid system. Energy Rep. 2020, 6, 1432–1442. [Google Scholar] [CrossRef]

- Bahaghighat, M.; Abedini, F.; Xin, Q.; Mirjalili, S. Using machine learning and computer vision to estimate the angular velocity of wind turbines in smart grids remotely. Energy Rep. 2021, 7, 8561–8576. [Google Scholar] [CrossRef]

- Alazab, M.; Khan, S.; Krishnan, S.S.R.; Pham, Q.-V.; Reddy, M.P.K.; Gadekallu, T.R. A multidirectional LSTM model for predicting the stability of a smart grid. IEEE Access 2020, 8, 85454–85463. [Google Scholar] [CrossRef]

- Mostafa, N.; Ramadan, H.S.M.; Elfarouk, O. Renewable energy management in smart grids by using big data analytics and machine learning. Mach. Learn. Appl. 2022, 9, 100363. [Google Scholar] [CrossRef]

- Santo, K.G.D.; Santo, S.G.D.; Monaro, R.M.; Saidel, M.A. Active demand side management for households in smart grids using optimization and artificial intelligence. Measurement 2018, 115, 152–161. [Google Scholar]

- Jha, N.; Prashar, D.; Rashid, M.; Gupta, S.K.; Saket, R.K. Electricity load forecasting and feature extraction in smart grid using neural networks. Comput. Electr. Eng. 2021, 96, 107479. [Google Scholar] [CrossRef]

- England, B.S.; Alouani, A.T. Real time voltage stability prediction of smart grid areas using smart meters data and improved thevenin estimates. Electr. Power Energy Syst. 2020, 122, 106189. [Google Scholar] [CrossRef]

- Habib, A.A.; Hasan, M.K.; Alkhayyat, A.; Islam, S.; Sharma, R.; Alkwai, L.M. False data injection attack in smart grid cyber physical system: Issues, challenges, and future direction. Comput. Electr. Eng. 2023, 107, 108638. [Google Scholar] [CrossRef]

- Zhang, G.; Li, J.; Bamisile, O.; Cai, D.; Huang, Q. A novel data-driven time-delay attack evaluation method for wide-area cyber–physical smart grid systems. Sustain. Energy Grids Netw. 2022, 32, 100960. [Google Scholar] [CrossRef]

- Javaid, N.; Jan, N.; Javed, M.U. An adaptive synthesis to handle imbalanced big data with deep siamese network for electricity theft detection in smart grids. J. Parallel Distrib. Comput. 2021, 153, 44–52. [Google Scholar] [CrossRef]

- Ahmad, T.; Chen, H. Potential of three variant machine-learning models for forecasting district level medium-term and long-term energy demand in smart grid environment. Energy 2018, 160, 1008–1020. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, Y.; Liu, B. An artificial intelligence-based electric multiple units using a smart power grid system. Energy Rep. 2022, 8, 13376–13388. [Google Scholar] [CrossRef]

- Halle, P.D.; Shiyamala, S. Secure advance metering infrastructure protocol for smart grid power system enabled by the Internet of things. Microprocess. Microsyst. 2022, 95, 104708. [Google Scholar] [CrossRef]

- Chen, T.; Yin, X.; Wang, G. Securing communications between smart grids and real users; providing a methodology based on user authentication. Energy Rep. 2021, 7, 8042–8050. [Google Scholar] [CrossRef]

- Vallant, H.; Stojanović, B.; Božić, J. Threat modelling and beyond-novel approaches to cyber secure the smart energy system. Appl. Sci. 2021, 11, 5419. [Google Scholar] [CrossRef]

- Gunduz, M.Z.; Das, R. Cyber-security on smart grid: Threats and potential solutions. Comput. Netw. 2020, 169, 107094. [Google Scholar] [CrossRef]

- Lamba, V.; Šimková, N.; Wang, G.; Rossi, B. Recommendations for smart grid security risk management. Cyber-Phys. Syst. 2019, 5, 92–118. [Google Scholar] [CrossRef]

- Turing, A.M. Computing machinery and intelligence. Mind 1950, 59, 433–460. [Google Scholar] [CrossRef]

- Corea, F. AI Knowledge Map: How to Classify AI Technologies. Available online: https://www.forbes.com/sites/cognitiveworld/2018/08/22/ai-knowledge-map-how-to-classify-ai-technologies/#5e99db627773 (accessed on 13 March 2023).

- Canhoto, A.I.; Clear, F. Artificial intelligence and machine learning as business tools: A framework for diagnosing value destruction potential. Bus. Horiz. 2020, 63, 183–193. [Google Scholar] [CrossRef]

- Paschen, U.; Pitt, C.; Kietzmann, C. Artificial intelligence: Building blocks and an innovation typology. Bus. Horiz. 2020, 63, 147–155. [Google Scholar] [CrossRef]

- Albahra, S.; Gorbett, T.; Robertson, S.; D’Aleo, G.; Kumar, S.V.S.; Ockunzzi, S.; Lallo, D.; Hu, B.; Rashidi, H.H. Artificial intelligence and machine learning overview in pathology & laboratory medicine: A general review of data preprocessing and basic supervised concepts. Semin. Diagn. Pathol. 2023, 40, 71–87. [Google Scholar]

- Devlin, M.A.; Hayes, B.P. Non-intrusive load monitoring and classification of activities of daily living using residential smart meter data. IEEE Trans. Consum. Electron. 2019, 65, 339–348. [Google Scholar] [CrossRef]

- Katimbo, A.; Rudnick, D.R.; Zhang, J.; Ge, Y.; DeJonge, K.C.; Franz, T.E.; Shi, Y.; Liang, W.-Z.; Qiao, X.; Heeren, D.M.; et al. Evaluation of artificial intelligence algorithms with sensor data assimilation in estimating crop evapotranspiration and crop water stress index for irrigation water management. Smart Agric. Technol. 2023, 4, 100176. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, J.; Liu, H.; Tong, J.; Sun, Z. Prediction of energy photovoltaic power generation based on artificial intelligence algorithm. Neural Comput. Appl. 2021, 33, 821–835. [Google Scholar] [CrossRef]

- Chen, L.; Qiao, Z.; Wang, M.; Wang, C.; Du, R.; Stanley, H.E. Which artificial intelligence algorithm better predicts the chinese stock market? IEEE Access 2018, 6, 48625–48633. [Google Scholar] [CrossRef]

- Yuana, K.-C.; Tsaib, L.-W.; Lee, K.-H.; Cheng, Y.-W.; Hsu, S.-C.; Lo, Y.-S.; Chen, R.-J. The development an artificial intelligence algorithm for early sepsis diagnosis in the intensive care unit. Int. J. Med. Inform. 2020, 141, 104176. [Google Scholar] [CrossRef] [PubMed]

- Araujo, T.; Helberger, N.; Kruikemeier, S.; de Vreese, C.H. In AI we trust? Perceptions about automated decision-making by artificial intelligence. AI Soc. 2020, 35, 611–623. [Google Scholar] [CrossRef]

- Duan, Y.; Edwards, J.S.; Dwivedi, Y.K. Artificial intelligence for decision making in the era of big data-evolution, challenges and research agenda. Int. J. Inf. Manag. 2019, 48, 63–71. [Google Scholar] [CrossRef]

- Ding, R.-X.; Palomares, I.; Wang, X.; Yang, G.-R.; Liu, B.; Dong, Y.; Herrera-Viedma, E.; Herrera, F. Large-scale decision-making: Characterization, taxonomy, challenges and future directions from an artificial intelligence and applications perspective. Inf. Fusion 2020, 59, 84–102. [Google Scholar] [CrossRef]

- Bini, S.A. Artificial intelligence, machine learning, deep learning, and cognitive computing: What do these terms mean and how will they impact health care? J. Arthroplast. 2018, 33, 2358–2361. [Google Scholar] [CrossRef]

- Zhou, J.; Huang, W.; Chen, F. Facilitating machine learning model comparison and explanation through a radial visualisation. Energies 2021, 14, 7049. [Google Scholar] [CrossRef]

- Dao, D.V.; Ly, H.-B.; Trinh, S.H.; Le, T.-T.; Pham, B.T. Artificial intelligence approaches for prediction of compressive strength of geopolymer concrete. Materials 2019, 12, 983. [Google Scholar] [CrossRef]

- Mohamadou, Y.; Halidou, A.; Kapen, P.T. A review of mathematical modeling, artificial intelligence and datasets used in the study, prediction and management of COVID-19. Appl. Intell. 2020, 50, 3913–3925. [Google Scholar] [CrossRef]

- Wang, Z.; Srinivasan, R.S. A review of artificial intelligence based building energy use prediction: Contrasting the capabilities of single and ensemble prediction models. Renew. Sustain. Energy Rev. 2017, 75, 796–808. [Google Scholar] [CrossRef]

- Połap, D.; Włodarczyk-Sielicka, M.; Wawrzyniak, N. Automatic ship classification for a riverside monitoring system using a cascade of artificial intelligence techniques including penalties and rewards. ISA Trans. 2022, 121, 232–239. [Google Scholar] [CrossRef]

- Huang, Q. Weight-Quantized squeezenet for resource-constrained robot vacuums for indoor obstacle classification. AI 2022, 3, 180–193. [Google Scholar] [CrossRef]

- Juhn, Y.; Liu, H. Artificial intelligence approaches using natural language processing to advance EHR-based clinical research. J. Allergy Clin. Immunol. 2019, 145, 463–469. [Google Scholar] [CrossRef] [PubMed]

- Robaldo, L.; Villata, S.; Wyner, A.; Grabmair, M. Introduction for artificial intelligence and law: Special issue “natural language processing for legal texts”. Artif. Intell. Law 2019, 27, 113–115. [Google Scholar] [CrossRef]

- Vincent, D.R.; Deepa, N.; Elavarasan, D.; Srinivasan, K.; Chauhdary, S.H.; Iwendi, C. Sensors driven AI-based agriculture recommendation model for assessing land suitability. Sensors 2019, 19, 3667. [Google Scholar] [CrossRef]

- Yoon, N.; Lee, H.-K. AI recommendation service acceptance: Assessing the effects of perceived empathy and need for cognition. J. Theor. Appl. Electron. Commer. Res. 2019, 16, 1912–1928. [Google Scholar] [CrossRef]

- Cai, K.; Chen, H.; Ai, W.; Lin, Q.; Feng, Q. Feedback convolutional network for intelligent data fusion based on near-infrared collaborative IoT technology. IEEE Trans. Ind. Inform. 2022, 18, 1200–1209. [Google Scholar] [CrossRef]

- Shim, J.Y. Feature matching synchronized reasoning from energy-based memory network for intelligent data management in cloud computing data center. Electronics 2021, 10, 1900. [Google Scholar] [CrossRef]

- Alkali, Y.; Routray, I.; Whig, P. Study of various methods for reliable, efficient and secured IoT using artificial intelligence. In Proceedings of the International Conference on Innovative Computing & Communication (ICICC 2022), Delhi, India, 19–20 February 2022. [Google Scholar]

- Nauman, A.; Nguyen, T.N.; Qadri, Y.; Nain, Z.; Cengiz, K.; Kim, S.W. Artificial intelligence in beyond 5G and 6G reliable communications. IEEE Internet Things Mag. 2022, 5, 73–78. [Google Scholar] [CrossRef]

- Khan, M.Z.; Alhazmi, O.H.; Javed, M.A.; Ghandorh, H.; Aloufi, K.S. Reliable Internet of things: Challenges and future trends. Electronics 2021, 10, 2377. [Google Scholar] [CrossRef]

- Omitaomu, O.A.; Niu, H. Artificial intelligence techniques in smart grid: A survey. Smart Cities 2021, 4, 548–568. [Google Scholar] [CrossRef]

- Ali, S.S.; Choi, B.J. State-of-the-Art artificial intelligence techniques for distributed smart grids: A review. Electronics 2020, 9, 1030. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar] [CrossRef]

- Boza, P.; Evgeniou, T. Artificial intelligence to support the integration of variable renewable energy sources to the power system. Appl. Energy 2021, 290, 116754. [Google Scholar] [CrossRef]

- Das, S.R.; Ray, P.K.; Sahoo, A.K.; Singh, K.K.; Dhiman, G.; Singh, A. Artificial intelligence based grid connected inverters for power quality improvement in smart grid applications. Comput. Electr. Eng. 2021, 93, 107208. [Google Scholar] [CrossRef]

- Jahangir, H.; Tayarani, H.; Gougheri, S.S.; Golkar, M.A.; Ahmadian, A.; Elkamel, A. Deep learning-based forecasting approach in smart grids with microclustering and bidirectional LSTM network. Comput. Electr. Eng. 2021, 68, 8298–8309. [Google Scholar] [CrossRef]

- Antonopoulos, I.; Robu, V.; Couraud, B.; Kirli, D.; Norbu, S.; Kiprakis, A.; Flynn, D.; Elizondo-Gonzalez, S.; Wattam, S. Artificial intelligence and machine learning approaches to energy demand-side response: A systematic review. Renew. Sustain. Energy Rev. 2020, 130, 109899. [Google Scholar] [CrossRef]

- Khan, M.A.; Saleh, A.M.; Waseem, M.; Sajjad, I.A. Artificial intelligence enabled demand response: Prospects and challenges in smart grid environment. IEEE Access 2022, 11, 1477–1505. [Google Scholar] [CrossRef]

- Fenza, G.; Gallo, M.; Loia, V. Drift-aware methodology for anomaly detection in smart grid. IEEE Access 2019, 7, 9645–9657. [Google Scholar] [CrossRef]

- Bose, B.K. Artificial intelligence techniques in smart grid and renewable energy systems-some example applications. Proc. IEEE 2017, 105, 2262–2273. [Google Scholar] [CrossRef]

- Khan, Z.A.; Khalid, A.; Javaid, N.; Haseeb, A.; Saba, T.; Shafiq, M. Exploiting nature-inspired-based artificial intelligence techniques for coordinated day-ahead scheduling to efficiently manage energy in smart grid. IEEE Access 2019, 7, 140102–140125. [Google Scholar] [CrossRef]

- Ma, K.; Liu, X.; Li, G.; Hu, S.; Yang, J.; Guan, X. Resource allocation for smart grid communication based on a multi-swarm artificial bee colony algorithm with cooperative learning. Eng. Appl. Artif. Intell. 2019, 81, 29–36. [Google Scholar] [CrossRef]

- Kotsiopoulos, T.; Sarigiannidis, P.; Ioannidis, D.; Tzovaras, D. Machine learning and deep learning in smart manufacturing: The smart grid paradigm. Comput. Sci. Rev. 2021, 40, 100341. [Google Scholar] [CrossRef]

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S.D. Smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 118–128. [Google Scholar] [CrossRef]

- Zheng, P.; Wang, H.; Sang, Z.; Zhong, R.Y.; Liu, Y.; Liu, C.; Mubarok, K.; Yu, S.; Xu, X. Smart manufacturing systems for Industry 4.0: Conceptual framework, scenarios, and future perspectives. Front. Mech. Eng. 2018, 13, 137–150. [Google Scholar] [CrossRef]

- Kumar, N.; Lee, S.C. Human-machine interface in smart factory: A systematic literature review. Technol. Forecast. Soc. Chang. 2022, 174, 121284. [Google Scholar] [CrossRef]

- Abderrahim, M.; Bekrar, A.; Trentesaux, D.; Aissani, N.; Bouamrane, K. Manufacturing 4.0 operations scheduling with AGV battery management constraints. Energies 2020, 13, 4948. [Google Scholar] [CrossRef]

- Fernandes, J.; Silva, F.J.G.; Campilho, R.D.S.G.; Pinto, G.F.L.; Baptista, A. Intralogistics and Industry 4.0: Designing a novel shuttle with picking system. Procedia Manuf. 2019, 38, 1801–1832. [Google Scholar] [CrossRef]

- Ferreira, J.J.; Lopes, J.M.; Gomes, S.; Rammal, H.G. Industry 4.0 implementation: Environmental and social sustainability in manufacturing multinational enterprises. J. Clean. Prod. 2023, 404, 136841. [Google Scholar] [CrossRef]

- Dragicevic, N.; Ullrich, A.; Tsui, E.; Gronau, N. A conceptual model of knowledge dynamics in the Industry 4.0 smart grid scenario. Knowl. Manag. Res. Pract. 2019, 18, 199–213. [Google Scholar] [CrossRef]

- Colak, I.; Kabalci, E.; Fulli, G.; Lazarou, S. A survey on the contributions of power electronicsto smart grid systems. Renew. Sustain. Energy Rev. 2015, 47, 562–579. [Google Scholar] [CrossRef]

- Lu, R.; Li, Y.-C.; Li, Y.; Jiang, J.; Ding, Y. Multi-agent deep reinforcement learning based demand response for discrete manufacturing systems energy management. Appl. Energy 2020, 276, 115473. [Google Scholar] [CrossRef]

- Phuyal, S.; Bista, D.; Bista, R. Challenges, opportunities and future directions of smart manufacturing: A state of art review. Sustain. Futures 2020, 2, 100023. [Google Scholar] [CrossRef]

- Roesch, M.; Linder, C.; Zimmermann, R.; Rudolf, A.; Hohmann, A.; Reinhart, G. Smart grid for industry using multi-agent reinforcement learning. Appl. Sci. 2020, 10, 6900. [Google Scholar] [CrossRef]

- Machalek, D.; Powell, K. Automated electrical demand peak leveling in a manufacturing facility with short term energy storage for smart grid participation. J. Manuf. Syst. 2019, 52, 100–109. [Google Scholar] [CrossRef]

- Lu, R.; Hong, S.H. Incentive-based demand response for smart grid with reinforcement learning and deep neural network. Appl. Energy 2019, 236, 937–949. [Google Scholar] [CrossRef]

- Dababneh, F.; Li, L. Integrated electricity and natural gas demand response for manufacturers in the smart grid. IEEE Trans. Smart Grid 2019, 10, 4164–4174. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, K.; Yang, J.; Cao, Y.; Gan, Y. Energy-efficiency-oriented scheduling in smart manufacturing. J. Ambient Intell. Humaniz. Comput. 2019, 10, 969–978. [Google Scholar] [CrossRef]

- Zakariazadeh, A. Smart meter data classification using optimized random forest algorithm. ISA Trans. 2022, 126, 361–369. [Google Scholar] [CrossRef]

- Venkatraman, A.; Thatte, A.A.; Xie, L. A smart meter data-driven distribution utility rate model for networks with prosumers. Util. Policy 2021, 70, 101212. [Google Scholar] [CrossRef]

- Behara, R.K.; Saha, A.K. Artificial intelligence methodologies in smart grid-integrated doubly fed induction generator design optimization and reliability assessment: A review. Energies 2022, 15, 7164. [Google Scholar] [CrossRef]

- Rouzbahani, H.M.; Karimipour, H.; Lei, L. Multi-layer defense algorithm against deep reinforcement learning-based intruders in smart grids. Int. J. Electr. Power Energy Syst. 2023, 146, 108798. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, X.; Chen, Z. A survey of digital twin techniques in smart manufacturing and management of energy applications. Green Energy Intell. Transp. 2022, 1, 1000014. [Google Scholar] [CrossRef]

- Jiang, Z.; Lv, H.; Li, Y.; Guo, Y. A novel application architecture of digital twin in smart grid. J. Ambient Intell. Humaniz. Comput. 2021, 13, 3819–3835. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Development of a PSS for smart grid energy distribution optimization based on digital twin. Procedia CIRP 2022, 107, 1138–1143. [Google Scholar] [CrossRef]

- Ahmad, T.; Madonski, R.; Zhang, D.; Huang, C.; Mujeeb, A. Data-driven probabilistic machine learning in sustainable smart energy/smart energy systems: Key developments, challenges, and future research opportunities in the context of smart grid paradigm. Renew. Sustain. Energy Rev. 2022, 160, 112128. [Google Scholar] [CrossRef]

- Bermeo-Ayerbea, M.A.; Ocampo-Martineza, C.; Diaz-Rozo, J. Data-driven energy prediction modeling for both energy effciency and maintenance in smart manufacturing systems. Energy 2022, 238, 121691. [Google Scholar] [CrossRef]

- Meng, Y.; Yang, Y.; Chung, H.; Lee, P.; Shao, C. Enhancing sustainability and energy efficiency in smart factories: A review. Sustainability 2018, 10, 4779. [Google Scholar] [CrossRef]

- Faheem, M.; Gungor, V.C. MQRP: Mobile sinks-based QoS-aware data gathering protocol for wireless sensor networks-based smart grid applications in the context of Industry 4.0-based on internet of things. Future Gener. Comput. Syst. 2018, 82, 358–374. [Google Scholar] [CrossRef]

- Qureshi, K.N.; Hussain, R.; Jeon, G. A distributed software defined networking model to improve the scalability and quality of services for flexible green energy internet for smart grid systems. Comput. Electr. Eng. 2020, 84, 106634. [Google Scholar] [CrossRef]

- Faheem, M.; Gungor, V.C. Energy efficient and QoS-aware routing protocol for wireless sensor network-based smart grid applications in the context of Industry 4.0. Appl. Soft Comput. 2018, 68, 910–922. [Google Scholar] [CrossRef]

- Akkad, A.; Wills, G.; Rezazadeh, A. An information security model for an IoT-enabled Smart Grid in the Saudi energy sector. Comput. Electr. Eng. 2023, 105, 108491. [Google Scholar] [CrossRef]

- Ghiasi, M.; Niknam, T.; Wang, Z.; Mehrandezh, M.; Dehghani, M.; Ghadimi, N. A comprehensive review of cyber-attacks and defense mechanisms for improving security in smart grid energy systems: Past, present and future. Electr. Power Syst. Res. 2023, 215, 108975. [Google Scholar] [CrossRef]

- Nti, I.K.; Adekoya, A.F.; Weyori, B.A.; Nyarko-Boateng, O. Applications of artificial intelligence in engineering and manufacturing: A systematic review. J. Intell. Manuf. 2022, 33, 1581–1601. [Google Scholar] [CrossRef]

- Pan, Y.; Froese, F.J. An interdisciplinary review of AI and HRM: Challenges and future directions. Hum. Resour. Manag. Rev. 2023, 33, 100924. [Google Scholar] [CrossRef]

- Olabi, A.G.; Abdelkareem, M.A. Renewable energy and climate change. Renew. Sustain. Energy Rev. 2022, 158, 112111. [Google Scholar] [CrossRef]

- Boehm, R.; Buerner, J.; Franke, J. Smart factory meets smart grid: Cyber-physical compressed air systems enable demand side management in industrial environments. Appl. Mech. Mater. 2015, 805, 25–31. [Google Scholar] [CrossRef]

- Billings, W.B.; Powell, M.K. Grid-responsive smart manufacturing: A perspective for an interconnected energy future in the industrial sector. AIChE J. 2022, 68, e17920. [Google Scholar] [CrossRef]

- Shrouf, F.; Ordieres, J.; Miragliotta, G. Smart factories in Industry 4.0: A review of the concept and of energy management approached in production based on the Internet of things paradigm. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Selangor Darul Ehsan, Malaysia, 9–12 December 2014; pp. 697–701. [Google Scholar]

- Huseien, G.F.; Shah, K.W. A review on 5G technology for smart energy management and smart buildings in Singapore. Energy AI 2022, 7, 100116. [Google Scholar] [CrossRef]

- Mourtzis, D. Smart Manufacturing and Tactile Internet Powered by 5G: Investigation of Current Developments, Challenges, and Future Trends. Procedia CIRP 2021, 104, 1960–1969. [Google Scholar] [CrossRef]

- Velasquez, K.; Abreu, D.P.; Curado, M.; Monteiro, E. Resource orchestration in 5G and beyond: Challenges and opportunities. Comput. Commun. 2022, 192, 311–315. [Google Scholar] [CrossRef]

- Chen, Y.; Billings, B.W.; Powell, K.M. Industrial processes and the smart grid: Overcoming the variability of renewables by using built-in process storage and intelligent control strategies. Int. J. Prod. Res. 2023, in press. [Google Scholar] [CrossRef]

- Ahsan, F.; Dana, N.H.; Sarker, S.K.; Li, L.; Muyeen, S.M.; Ali, M.F.; Tasneem, Z.; Hasan, M.M.; Abhi, S.H.; Islam, M.R.; et al. Data-driven next-generation smart grid towards sustainable energy evolution: Techniques and technology review. Prot. Control Mod. Power Syst. 2023, 8, 43. [Google Scholar] [CrossRef]

- Pandey, V.; Sircar, A.; Bist, N.; Solanki, K.; Yadav, K. Accelerating the renewable energy sector through Industry 4.0: Optimization opportunities in the digital revolution. Int. J. Innov. Stud. 2023, 7, 171–188. [Google Scholar] [CrossRef]

- Smadi, A.A.; Ajao, B.T.; Johnson, B.K.; Lei, H. A comprehensive survey on cyber-physical smart grid testbed architectures: Requirements and challenges. Electronics 2021, 10, 1043. [Google Scholar] [CrossRef]

| Category | Technology | Application | Reference |

|---|---|---|---|

| Communication technologies | Cyber-physical system | Predicting stability | [18,23,24] |

| Information provision | Smart meter | Power generation and distribution, power sector, forecasting | [12,13,14,22] |

| Big data | Power load management, predicting stability | [16,19,25] | |

| Computational intelligence | Neural network | Power load, forecasting | [10,11,21] |

| Machine learning | Power demand, forecasting, predicting stability | [17,18,26] | |

| AI | Predicting stability, power load management, power demand management, forecasting | [15,20,27] | |

| Cybersecurity | Cybersecurity | Security of Internet operations | [28,29,30,31,32] |

| Optimization Application | Technology and Implementation | Reference | Note |

|---|---|---|---|

| Energy cost management | Machine learning, deep learning, algorithm, linear programming | [86,87,88,89] | To effectively reduce the cost of energy use in smart manufacturing, AI technology is introduced into the SG for optimizing load control and power scheduling. |

| Implementation of smart meters | Algorithm, grid-edge technologies, smart meter | [90,91] | Smart meters are implemented in the SG, and the measured data is analyzed by AI algorithms and models to manage power consumption more accurately. |

| Reliable energy system | Machine learning, deep learning, deep neural network | [92,93] | AI technologies are used to evaluate the reliability of SGs and simulate possible attacks on IoT-based energy networks to ensure a reliable energy system. |

| Establishment of the digital twin | Digital twin technology, algorithm | [94,95,96] | The digital twin was established to provide an effective configuration and solution for the energy consumption of complex smart manufacturing systems. |

| Big data-driven optimization | Machine and deep learning, sensor | [97,98,99] | Big data from manufacturing is collected and analyzed by deep learning to control energy consumption and achieve sustainable development of the manufacturing process. |

| QoS of communication networks and data collected | Controller, sensor | [100,101,102] | To ensure QoS communication quality in the complex smart manufacturing framework based on the SG, sensors and controllers are used for data collection to improve energy utilization and energy saving. |

| Problem | Method | Result | Reference |

|---|---|---|---|

| The factory consumed a lot of energy and could not achieve the goal of green manufacturing. | Efficient energy usage scheduling of SGs with dynamic mechanisms | The energy efficiency equaled 129%, and the electricity cost saving equaled 28%. | [2,89] |

| Power voltage instability affected manufacturing and generated high carbon emissions. | Smart meters replaced conventional electricity meters. Stability index with smart meters was implemented to predict voltage in SG. | Achieving overload current protection to maintain effective manufacturing and have 30 min early to take action to avoid blackouts. | [13,22] |

| High electricity prices increased production costs. | Integrated smart grid solution was implemented. | The manufacturing efficiency increased by 84%. | [85] |

| Unstable power quality affected client operations | The AI technology was applied to improve power supply quality. | The total harmonic distortion for electricity was under 2.8%. | [66] |

| Production line equipment consumed too much energy and had inefficient energy scheduling. | AI multi-agent deep deterministic method was proposed for equipment scheduling and manufacturing scheduling model with SG. | The electricity cost equaled 90.92%, and the energy cost saving equaled 66–68%. | [83,88] |

| How to optimize manufacturing systems to comply with Industry 4.0 was concerned. | Optimization of the digital twin for SG energy distribution | The average power saving was 18.6%. | [96] |

| Low reliability of SG affected manufacturing. | Big data communication and data exchange power prediction model | The accuracy rate for predicting energy usage was 96%. | [19] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, C.-C.; Jiang, B.-H.; Lin, C.-C. A Survey on Recent Applications of Artificial Intelligence and Optimization for Smart Grids in Smart Manufacturing. Energies 2023, 16, 7660. https://doi.org/10.3390/en16227660

Hsu C-C, Jiang B-H, Lin C-C. A Survey on Recent Applications of Artificial Intelligence and Optimization for Smart Grids in Smart Manufacturing. Energies. 2023; 16(22):7660. https://doi.org/10.3390/en16227660

Chicago/Turabian StyleHsu, Chao-Chung, Bi-Hai Jiang, and Chun-Cheng Lin. 2023. "A Survey on Recent Applications of Artificial Intelligence and Optimization for Smart Grids in Smart Manufacturing" Energies 16, no. 22: 7660. https://doi.org/10.3390/en16227660