Technological Alternatives for Electric Propulsion Systems in the Waterway Sector

Abstract

:1. Introduction

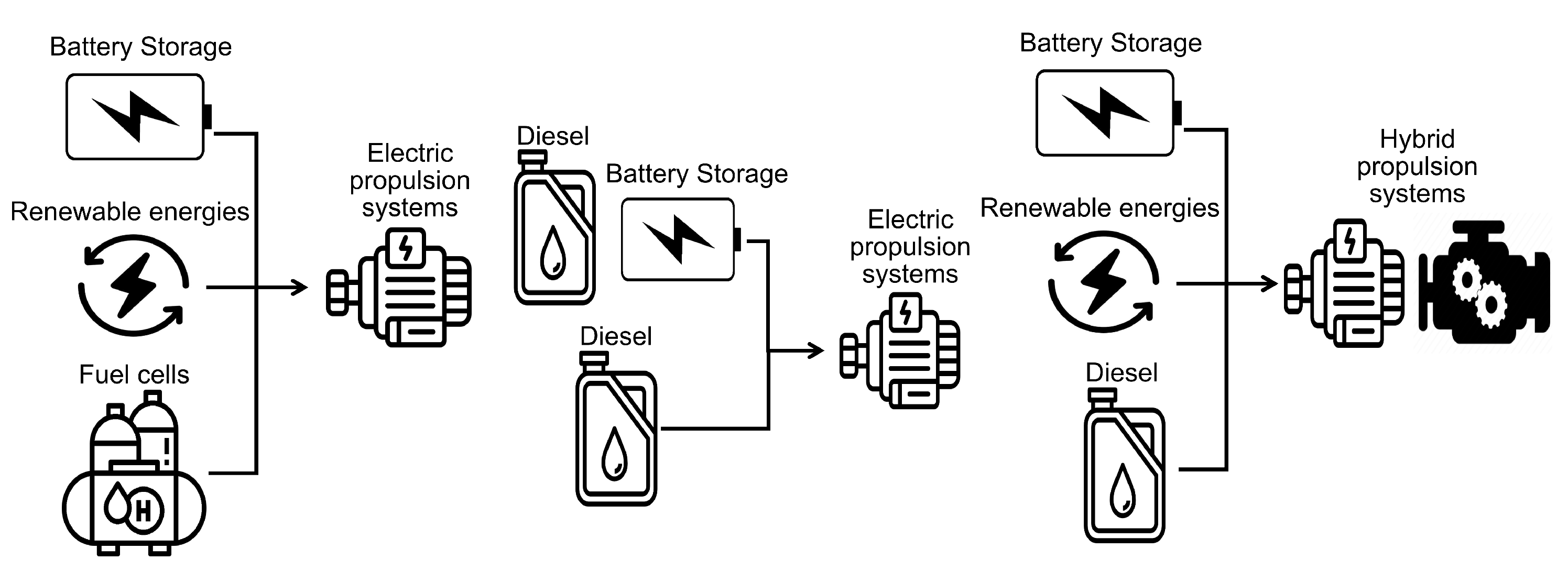

2. Technological Alternative for Boats with Electromobility

3. Technological Alternatives for Propulsion

3.1. Battery-Powered Propulsion System

3.2. Renewable Energy Propulsion System

3.3. Fuel Cell Generation Propulsion System

3.4. Electric Propulsion System with Power Generation from Internal Combustion Engines and Batteries

3.5. Electric Propulsion System, Powered by Generation from Internal Combustion Engines without Batteries

3.6. Hybrid Propulsion System with Generation from Internal Combustion Engines

4. Characterization and Topologies of River Electromobility

4.1. Battery Storage with Fully Electric Propulsion Systems

4.2. Self-Generation from Renewable Alternatives with Fully Electric Propulsion Systems

- 1.

- Bypass and blocking diode. The bypass diode will come into operation when a photovoltaic panel is shaded to such an extent that its voltage drop exceeds 0.7 V; consequently, the panel will be protected. In addition, the unidirectional conductivity of the blocking diode will also prevent the reverse current. The topology of the structure of the bypass and blocking diode topology can be found in [46].

- 2.

- Chain and multichain. In this topology, several panels are connected in series at the beginning and each PV string is connected to a separate inverter. Similarly, in the multichain structure, each PV string is connected to a DC/DC converter at the beginning and then 4–5 converters are connected to an inverter [46]. Taking into account the available technologies, solar boats need to maximize the PV surface area and battery capacity to increase the range for long-distance trips.

4.3. Fuel Cell Generation with Fully Electric Propulsion Systems

4.4. Generation from Internal Combustion Engines and Battery Energy Storage with All-Electric Propulsion Systems

4.5. Generation from Internal Combustion Engines without Energy Storage by Batteries with Fully Electric Propulsion Systems

4.6. Generation from Internal Combustion Engines with Hybrid Propulsion Systems

5. Advantages and Disadvantages of Propulsion Systems

6. Conclusions

- The review of the different existing and operating vessels made it possible to identify the main characteristics of the different vessels. This allows the reader to have an overview of the most common sizes, speeds, autonomy, energy sources, operation areas, and predominant manufacturing countries of boats.

- Most commercial vessels offered by the industry are designed for operating at sea. However, considering the specific activities performed by communities on waterways, new considerations must be taken to implement these vessels according to local conditions. This is a great topic for research and provides an opportunity to develop this sector.

- Implementing small electric vessels on navigable waterways with rechargeable docks longer than 50 miles could be a challenging task. Propulsion systems that depend entirely on batteries are difficult to implement, as autonomy is limited and the distances between docks exceed their travel capacity. Some navigable waterways are located in areas with difficult access to electricity due to geographical conditions.

- The different technological alternatives offer a variety of options to implement electromobility in the sector of navigable waterways. This allows the selection of different configurations that best adapt to the requirements of the vessel in terms of travel distances, load capacity, speed navigation, size, and maneuverability.

- The literature showed that there are different possibilities for selecting power sources. Some of them are completely battery-based systems, thermal generators, hydrogen cells, and renewable resources. These sources can be combined with the propulsion train, which can be electrical, mechanical, or hybrid systems. Technologies can be implemented in combination with each other to achieve optimal performance according to the use of the vessel.

- From the table of advantages and disadvantages, it can be seen that the hybrid system is the best alternative. This system improves efficiency by implementing electric propulsion systems and batteries, reduces emissions by utilizing renewable energy, and maintains autonomy by employing fossil resources. This alternative is presented as a short-term solution to the energy transition in the waterway sector.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rodrigue, J.P. The Geography of Transport Systems; Routledge: Oxfordshire, UK, 2020. [Google Scholar]

- Kreps, B.H. The rising costs of fossil-fuel extraction: An energy crisis that will not go away. Am. J. Econ. Sociol. 2020, 79, 695–717. [Google Scholar] [CrossRef]

- Perera, F.; Nadeau, K. Climate Change, Fossil-Fuel Pollution, and Children’s Health. N. Engl. J. Med. 2022, 386, 2303–2314. [Google Scholar] [CrossRef]

- Shang, Y.; Han, D.; Gozgor, G.; Mahalik, M.K.; Sahoo, B.K. The impact of climate policy uncertainty on renewable and non-renewable energy demand in the United States. Renew. Energy 2022, 197, 654–667. [Google Scholar] [CrossRef]

- Maruga Salas, L.; Saravia Arenas, J. Navegando hacia embarcaciones sostenibles: Estado de la industria y los ODS. In Proceedings of the VIII Congreso Nternacional De Diseño e Ingeniería Naval (CIDIN), Cartagena, Colombia, 8–10 March 2023. [Google Scholar]

- Rodríguez Vidal, C.G. Soluciones a las Emisiones de Gases Contaminantes en Motores Diésel Marinos. Ph.D. Thesis, University of Coruña, Coruña, Spain, 2022. [Google Scholar]

- Bigerna, S.; Micheli, S.; Polinori, P. Willingness to pay for electric boats in a protected area in Italy: A sustainable tourism perspective. J. Clean. Prod. 2019, 224, 603–613. [Google Scholar] [CrossRef]

- Kaśkosz, K. Analysis and Evaluation of Ferry Services in the Baltic Sea Region in the Context of Environmental Solutions. Conf. Qual. Prod. Improv. CQPI 2021, 3, 357–368. [Google Scholar]

- Breucker, S.D.; De Breucker, S.; Peeters, E.; Driesen, J. Possible applications of plug-in hybrid electric ships. In Proceedings of the 2009 IEEE Electric Ship Technologies Symposium, Baltimore, MD, USA, 20–22 April 2009. [Google Scholar]

- Traut, M.; Gilbert, P.; Walsh, C.; Bows, A.; Filippone, A.; Stansby, P.; Wood, R. Propulsive power contribution of a kite and a Flettner rotor on selected shipping routes. Appl. Energy 2014, 113, 362–372. [Google Scholar] [CrossRef]

- Ihrfelt, F. Electric Leisure Boats: Enablers and Barriers: A Case Study of Leisure Boat Manufacturers. Ph.D. Thesis, KTH Royal Institute Of Technology, Stockholm, Sweden, 2023. [Google Scholar]

- Medina, I.I.A.; Castillo, S.M.C.; Pasqualino, J.C.; Mendoza, C.D. Viabilidad de electromovilidad náutica en el distrito de Cartagena-Colombia. Investig. Innov. Ing. 2019, 7, 20–46. [Google Scholar] [CrossRef]

- Janjevic, M.; Ndiaye, A.B. Inland waterways transport for city logistics: A review of experiences and the role of local public authorities. Urban Transp. XX 2014, 138, 279–290. [Google Scholar]

- Ammar, N.R.; Almas, M.A.; Nahas, Q.H. Overview of the main benefits and challenges of different ship propulsion systems. Int. J. Multidiscip. Curr. Res. 2023, 11, 314–320. [Google Scholar]

- Pratt, J.W.; Klebanoff, L.E. Feasibility of the SF-BREEZE: A Zero-Emission, Hydrogen Fuel Cell, High-Speed Passenger Ferry; Sandia National Laboratories: Albuquerque, NM, USA, 2016. [Google Scholar]

- Kifune, H.; Satou, M.; Oode, T. A Study on Battery System Design for Battery Ships Conforming to CHAdeMO. Mar. Eng. 2016, 51, 879–886. [Google Scholar] [CrossRef]

- Giraldo-Pérez, E.; Gaviria, G.; Betancur, E.; Osorio-Gómez, G.; Mejía-Gutiérrez, R. Influence of energy consumption on battery sizing of electric fluvial vessels: A Colombian Case Study. In Proceedings of the 2020 Fifteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 10–12 September 2020; pp. 1–8. [Google Scholar]

- Geertsma, R.D.; Negenborn, R.R.; Visser, K.; Hopman, J.J. Design and control of hybrid power and propulsion systems for smart ships: A review of developments. Appl. Energy 2017, 194, 30–54. [Google Scholar] [CrossRef]

- Bennabi, N.; Charpentier, J.F.; Menana, H.; Billard, J.Y.; Genet, P. Hybrid Propulsion Systems for Small Ships: Context and Challenges. In Proceedings of the 2016 XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016. [Google Scholar]

- Obaid, W.; Hamid, A.K.; Ghenai, C. Wind-Fuel-Cell-Solar Hybrid Electric Boat Power Design with MPPT System. In Proceedings of the 2019 8th International Conference on Modeling Simulation and Applied Optimization (ICMSAO), Manama, Bahrain, 15–17 April 2019; pp. 1–5. [Google Scholar]

- Tercan, Ş.H.; Eid, B.; Heidenreich, M.; Kogler, K.; Akyürek, Ö. Financial and Technical Analyses of Solar Boats as A Means of Sustainable Transportation. Sustain. Prod. Consum. 2021, 25, 404–412. [Google Scholar] [CrossRef]

- Madsen, R.T.; Klebanoff, L.E.; Caughlan, S.A.M.; Pratt, J.W.; Leach, T.S.; Appelgate, T.B.; Kelety, S.Z.; Wintervoll, H.C.; Haugom, G.P.; Teo, A.T.Y.; et al. Feasibility of the Zero-V: A zero-emissions hydrogen fuel-cell coastal research vessel. Int. J. Hydrogen Energy 2020, 45, 25328–25343. [Google Scholar] [CrossRef]

- Shakeri, N.; Zadeh, M.; Bremnes Nielsen, J. Hydrogen Fuel Cells for Ship Electric Propulsion: Moving Toward Greener Ships. IEEE Electrif. Mag. 2020, 8, 27–43. [Google Scholar] [CrossRef]

- Prevljak, N. World’s first all-electric fast ferry named in Norway. Offshore Energy. 2022. Available online: https://www.offshore-energy.biz/worlds-first-all-electric-fast-ferry-named-in-norway/ (accessed on 31 October 2023).

- Xshore. Eelex 8000. 2022. Available online: https://xshore.com/eelex-8000/ (accessed on 26 March 2023).

- Rocha, C.H.; Silva, G.L.; Abreu, L.M.d. Analysis of the evolution of Brazilian ports’ environmental performances. Rev. Gest. Costeira Integr. 2018, 18, 103–109. [Google Scholar] [CrossRef]

- Park, C.; Jeong, B.; Zhou, P.; Jang, H.; Kim, S.; Jeon, H.; Nam, D.; Rashedi, A. Live-Life cycle assessment of the electric propulsion ship using solar PV. Appl. Energy 2022, 309, 118477. [Google Scholar] [CrossRef]

- Hemez, C.; Chiu, J.; Ryan, E.C.; Sun, J.; Dubrow, R.; Pascucilla, M. Environmental and health impacts of electric service vessels in the recreational boating industry. Water Pract. Technol. 2020, 15, 781–796. [Google Scholar] [CrossRef]

- Q Yachts. 2017. Available online: https://q-yachts.com/ (accessed on 27 March 2023).

- Hynova. Hynova 40. 2022. Available online: https://www.hynova-yachts.fr/hynova-40/ (accessed on 1 September 2023).

- Silent. Silent 60. 2022. Available online: https://www.silent-yachts.com/es/silent-60/ (accessed on 27 March 2023).

- Vision—Marine Technologies. Volt 180 Electric Boat. 2021. Available online: https://visionmarinetechnologies.com/volt-en/ (accessed on 27 March 2023).

- INMEDIA. SAY E. 2023. Available online: https://www.seyachting.com/es/new-boats/say-29e-electric-silent-boat/ (accessed on 28 March 2023).

- Candela. Candela C-8. 2022. Available online: https://candela.com/candela-c-8/ (accessed on 31 October 2023).

- Catamaran, P. Premium Catamaran. Obtenido de 2022.

- Freire, T.; Sousa, D.M.; Costa Branco, P.J. Modeling the electric chain of an electric boat. In Proceedings of the 2011 IEEE EUROCON—International Conference on Computer as a Tool, Lisbon, Portugal, 27–29 April 2011; pp. 1–4. [Google Scholar]

- Haxhiu, A.; Kyyrä, J.; Chan, R.; Kanerva, S. Improved Variable DC Approach to Minimize Drivetrain Losses in Fuel Cell Marine Power Systems. IEEE Trans. Ind. Appl. 2021, 57, 882–893. [Google Scholar] [CrossRef]

- Chai, M.; Bonthapalle, D.R.; Sobrayen, L.; Panda, S.K.; Wu, D.; Chen, X. Alternating current and direct current-based electrical systems for marine vessels with electric propulsion drives. Appl. Energy 2018, 231, 747–756. [Google Scholar] [CrossRef]

- Alacano, A. Modelado y Análisis de Sistemas de Distribución en DC Orientado a Buques con Propulsión eléctrica. Ph.D. Thesis, Mondragon Unibertsitatea, Mondragon, Spain, 2017. [Google Scholar]

- Nuchturee, C.; Li, T.; Xia, H. Energy efficiency of integrated electric propulsion for ships—A review. Renew. Sustain. Energy Rev. 2020, 134, 110145. [Google Scholar] [CrossRef]

- Shagar, V.; Gamini, S.; Enshaei, H. Effect of load changes on hybrid electric ship power systems. In Proceedings of the 2016 IEEE 2nd Annual Southern Power Electronics Conference (SPEC), Auckland, New Zealand, 5–8 December 2016; pp. 1–5. [Google Scholar]

- López, M.A.G.; Sanabria, E.G.P.; Cortes, J.A.Z.; Bedoya, Á.R.V.; Restrepo, Y.A.; Montoya, D.G. El Transporte Férreo y Fluvial Colombiano: Una Perspectiva Hacia la Electromovilidad; Fondo Editorial CEIPA: Sabaneta, Colombia, 2023. [Google Scholar]

- Tummakuri, V.; Chelliah, T.R.; Ramesh, U.S. Sizing of Energy Storage System for A Battery Operated Short Endurance Marine Vessel. In Proceedings of the 2020 IEEE International Conference on Power Electronics, Smart Grid and Renewable Energy (PESGRE2020), Cochin, India, 2–4 January 2020; pp. 1–6. [Google Scholar]

- Chen, C.J.; Su, C.L.; Teng, J.H. Determination of Load Characteristics for Electrical Load Analysis in Shipboard Microgrids. In Proceedings of the 2019 IEEE/IAS 55th Industrial and Commercial Power Systems Technical Conference (I&CPS), Calgary, AB, Canada, 5–8 May 2019 ; pp. 1–9. [Google Scholar]

- Mutarraf, M.U.; Guan, Y.; Xu, L.; Su, C.L.; Vasquez, J.C.; Guerrero, J.M. Electric cars, ships, and their charging infrastructure—A comprehensive review. Sustain. Energy Technol. Assessments 2022, 52, 102177. [Google Scholar] [CrossRef]

- Tang, R. Large-scale photovoltaic system on green ship and its MPPT controlling. Sol. Energy 2017, 157, 614–628. [Google Scholar] [CrossRef]

- International Maritime Organization. OMI 2020: El Límite de Azufre en el Combustible Entra en Vigor el 1 de Enero. 2020. Available online: https://www.imo.org/es/MediaCentre/PressBriefings/Paginas/34-IMO-2020-sulphur-limit-.aspx (accessed on 23 October 2023).

- Nyanya, M.N.; Vu, H.B.; Schönborn, A.; Ölçer, A.I. Wind and solar assisted ship propulsion optimisation and its application to a bulk carrier. Sustain. Energy Technol. Assessments 2021, 47, 101397. [Google Scholar] [CrossRef]

- Jestin, Y.; Chandra, S.; Cass, B.; Ahmed, H.; McCormack, S.J. Down-Shifting of the Incident Light for Photovoltaic Applications; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Klebanoff, L.E.; Pratt, J.W.; Leffers, C.M.; Sonerholm, K.T.; Escher, T.; Burgard, J.; Ghosh, S. Comparison of the greenhouse gas and criteria pollutant emissions from the SF-BREEZE high-speed fuel-cell ferry with a diesel ferry. Transp. Res. Part D Trans. Environ. 2017, 54, 250–268. [Google Scholar] [CrossRef]

- Corbett, J.J.; Farrell, A. Mitigating air pollution impacts of passenger ferries. Transp. Res. Part D Trans. Environ. 2002, 7, 197–211. [Google Scholar] [CrossRef]

- Monti, A.; Molinas, M. A Ship Is a Microgrid and a Microgrid Is a Ship: Commonalities and Synergies [About This Issue]. IEEE Electrif. Mag. 2019, 7, 2–5. [Google Scholar] [CrossRef]

- Chasiotis, I.D.; Karnavas, Y.L. A Generic Multi-Criteria Design Approach Toward High Power Density and Fault-Tolerant Low-Speed PMSM for Pod Applications. IEEE Trans. Transp. Electrif. 2019, 5, 356–370. [Google Scholar] [CrossRef]

- ABB. Azipod Electric Propulsion. 2023. Available online: https://new.abb.com/marine/systems-and-solutions/azipod (accessed on 1 September 2023).

- ISO 8217:2017; Petroleum Products Fuels (Class F) Specifications of Marine Fuels. ISO: Geneva, Switzerland. 2020. Available online: https://www.iso.org/standard/64247.html (accessed on 23 October 2023).

- Myclebust, T.A. Llegar a buen puerto: Propulsión eléctrica en buques AHTS. Revista ABB 2010, 3, 19–23. [Google Scholar]

- Hernández Rodríguez, P. Baterías y Propulsión Híbrida. Ph.D. Thesis, Universidad de la Laguna, San Cristobal de La Laguna, España, 2021. [Google Scholar]

- Bolvashenkov, I.; Herzog, H.G.; Rubinraut, A.; Romanovskiy, V. Possible Ways to Improve the Efficiency and Competitiveness of Modern Ships with Electric Propulsion Systems. In Proceedings of the 2014 IEEE Vehicle Power and Propulsion Conference (VPPC), Coimbra, Portugal, 27–30 October 2014; pp. 1–9. [Google Scholar]

| Boat | Power Source | Length (m) | Beam Width (m) | Maximum Speed (kN) | Cruising Speed (kN) | Country | Operation | Auto Generation |

|---|---|---|---|---|---|---|---|---|

| Eelex 8000 | Batteries | 8.00 | 2.50 | 30.0 | 20.0 | Switzerland | Maritime | No |

| Yachts Q30 | Batteries | 9.30 | 2.20 | 15.0 | 9.0 | Finland | Maritime | No |

| Hynova 40 | FC | 12.00 | 3.80 | 25.0 | 15.0 | France | Maritime | FC |

| Silent 60 | Diesel + RE | 17.99 | 8.99 | 20.0 | 15.0 | Austria | Maritime | Diesel + PV |

| Volt 180 | Batteries | 5.40 | 2.13 | 5.6 | 3.4 | Canada | Maritime/dam | No |

| Say 29E | Batteries | 8.86 | 2.76 | 52.0 | 52.0 | Spain | Maritime | No |

| Candela C-8 | Batteries | 8.50 | 2.45 | 30.0 | 25.0 | Switzerland | Maritime | No |

| Soelcat 12 | RE | 11.80 | 5.80 | 15.0 | 8.0 | Spain | Maritime | PV |

| Technology | Advantages | Disadvantages | Ref. |

|---|---|---|---|

| Battery | No pollution during operation. High energy efficiency in propulsion due to stored energy. It can withstand overloads due to the storage system. It occupies less volume in the vessel than in other systems. | The autonomy in navigation is limited and batteries can increase weight. Specialized charging infrastructure is required, and the supply of propulsion systems is focused on boats with low power requirements. At the end of the useful life of the batteries, they must be disposed of either to a second useful life or to a recycling process. This implies reinvestment into the vessel. | [36] |

| REs | It has a high-energy efficiency in propulsion due to the self-generation of energy and its use. It can withstand overloads due to the energy stored in batteries. | It generates a weight increase in the vessel due to the use of batteries. The system is dependent on environmental conditions and geopositioning of the vessel. Including self-generation systems implies the use of deck space, especially with self-generation through photovoltaic systems. At the end of the useful life of the batteries, they must be disposed of either through a second useful life or through a recycling process. This implies reinvestment in the vessel each time a second useful life is reached. | [40] |

| Fuel cell | It does not generate pollution during operation. It could withstand overloads because of the energy storage system. If the hydrogen used as a fuel is produced from renewable sources, then its environmental impact is much lower than that of any fossil fuel. | The extraction of hydrogen from fossil fuels generates a larger environmental footprint than the extraction of diesel or LNG; however, this is mitigated by the GHG emissions generated by using diesel or LNG as propulsion fuel. Hydrogen storage on ships is one of the major limitations of its use as it presents losses, and specialized containers are required for safe storage. It requires a hydrogen refueling infrastructure to support the needs of vessels. This drawback implies not only having hydrogen sources but also having the necessary loading infrastructure to transport and/or store it safely in port. At the end of the useful life, batteries must be disposed of either for a second useful life or for a recycling process. This implies reinvestment in the vessel each time the life cycle of a battery module is fulfilled. | [40] |

| Internal combustion engines with energy storage by batteries. | The system withstands overloads due to the energy storage system. Allows for greater autonomy than all-electric systems with or without self-generation and can run on both diesel and LNG. GHG emissions are reduced when running on LNG, compared to the same system that runs on diesel. | When using systems such as internal combustion engines or turbines for generation, the efficiency of the system is low compared to fuel cell or all-electric generation systems with or without self-generation, and the GHG emissions generated are high. Due to the use of batteries, the volume occupied by the system is larger than that of a system with direct generation by an internal combustion engine or turbine. It requires refueling infrastructure to support the needs of the vessels. This drawback implies not only having fuel sources but also that it requires charging infrastructure to transport and store it safely in port. At the end of the useful life of the batteries, they must be disposed of either to a second useful life or to a recycling process. This implies reinvestments in the vessel each time the life cycle of a battery module is fulfilled. | [58] |

| Internal combustion engines without energy storage by batteries. | Greater navigation autonomy compared to all-electric systems with or without self-generation. It runs on both diesel and LNG; in the case of running on LNG, GHG emissions are significantly reduced compared to the same system running on diesel. | When using systems such as internal combustion engines or turbines for generation, the energy efficiency of the system is low compared to fuel cell or all-electric generation systems with or without self-generation, and the GHG emissions generated are high. It requires refueling infrastructure to support the needs of the vessels. This implies having available fuel sources and loading infrastructure to transport and store them safely in port. | [40] |

| Hybrid propulsion | The constant low speed of the diesel engine in combined propulsion reduces pollutant gas emissions and fuel consumption. Versatility between the different operating modes and flexibility in operation. | It requires refueling infrastructure to support the needs of the vessels. This implies having available fuel sources and loading infrastructure to transport and store them safely in port. | [58] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Candelo-Beccera, J.E.; Maldonado, L.B.; Sanabria, E.P.; Pestana, H.V.; García, J.J. Technological Alternatives for Electric Propulsion Systems in the Waterway Sector. Energies 2023, 16, 7700. https://doi.org/10.3390/en16237700

Candelo-Beccera JE, Maldonado LB, Sanabria EP, Pestana HV, García JJ. Technological Alternatives for Electric Propulsion Systems in the Waterway Sector. Energies. 2023; 16(23):7700. https://doi.org/10.3390/en16237700

Chicago/Turabian StyleCandelo-Beccera, John E., Leonardo Bohórquez Maldonado, Edwin Paipa Sanabria, Hernán Vergara Pestana, and José Jiménez García. 2023. "Technological Alternatives for Electric Propulsion Systems in the Waterway Sector" Energies 16, no. 23: 7700. https://doi.org/10.3390/en16237700

APA StyleCandelo-Beccera, J. E., Maldonado, L. B., Sanabria, E. P., Pestana, H. V., & García, J. J. (2023). Technological Alternatives for Electric Propulsion Systems in the Waterway Sector. Energies, 16(23), 7700. https://doi.org/10.3390/en16237700