1. Introduction

Charcoal is the product obtained from the pyrolytic process of organic material (mainly wood) conducted at low oxygen concentrations and temperatures to avoid the complete combustion of biomass into ashes [

1,

2,

3,

4,

5]. Based on the heating rate, residence time, and temperature used, pyrolysis can be distinguished into slow (carbonization), intermediate, and fast [

3]. For charcoal production, carbonization is preferred, involving the use of low temperatures, heating rates, and extended residence times [

6]. In addition to charcoal, the carbonization of biomass also produces liquids and gases with various proportions according to the temperature used [

6,

7,

8,

9,

10].

Charcoal offers several advantages compared to woody raw materials. It has a higher heating value and energy density while being lightweight, making it easier to transport [

11,

12]. These characteristics have established charcoal as a significant energy source for cooking worldwide. While it has traditionally been a primary fuel in low- and middle-income countries [

13], its usage is also rising in high-income countries, driven by the recent increase in the popularity of charcoal grilling. This trend is evident both in household barbecues and professional charcoal restaurants, due to its distinctive smoky flavor and aroma [

14].

Data from the Food and Agriculture Organization (FAO) underscores a significant increase in charcoal imports to North America and Europe since 2000 [

15]. In Europe, only a quarter of the charcoal is produced on the continent [

15,

16]. The annual charcoal consumption exceeds one million tons, with the majority of the material being imported from non-EU countries, particularly subtropical, tropical, and Eastern European regions [

15]. In these areas, a lack of adequate controls and corruption may result in environmental issues due to the overexploitation of local forests [

17,

18], the use of illegally wood-harvested material [

16,

18], and the employment of inefficient production processes. These factors collectively contribute to heightened demand for wood, intensifying the strain on local forests, threatening biodiversity, and releasing high polluting emissions [

19,

20,

21].

In the literature, numerous works have systematically analyzed the technical and operational features characterizing various charcoal production systems on a worldwide scale [

22,

23,

24,

25]. However, it is essential to recognize that charcoal production systems are influenced by different variables based on geographical origin, economic feasibility, and the characteristics of the raw materials used [

22]. As a consequence, the panorama of charcoal production remains profoundly heterogeneous on an international scale, with several production systems not yet investigated.

Few works in literature have evaluated the possible charcoal production systems that can be implemented in high-income countries. The development of new charcoal production systems in high-income countries would guarantee advantages in terms of the sustainability of the charcoal supply chain by reducing the imports of illegal material and, at the same time, favoring new socioeconomic opportunities, especially in marginal mountain areas [

26].

Given the rising demand in Europe for charcoal imports, the establishment of a local charcoal production chain in these countries holds the potential to significantly reduce these imports. To explore the possible solutions within this context, Italy was chosen as a case study. This selection is justified by the coexistence in the country of traditional production methods with modern and innovative systems that have emerged in recent years. This study aims to conduct a comprehensive comparative assessment of the technical and operational attributes of various charcoal production systems in current use, evaluate charcoal quality according to international standards, and formulate recommendations for future operational improvements. The outcomes of this research can offer valuable insights to local forestry enterprises and policymakers, serving as a relevant resource for the establishment and advancement of charcoal production chains.

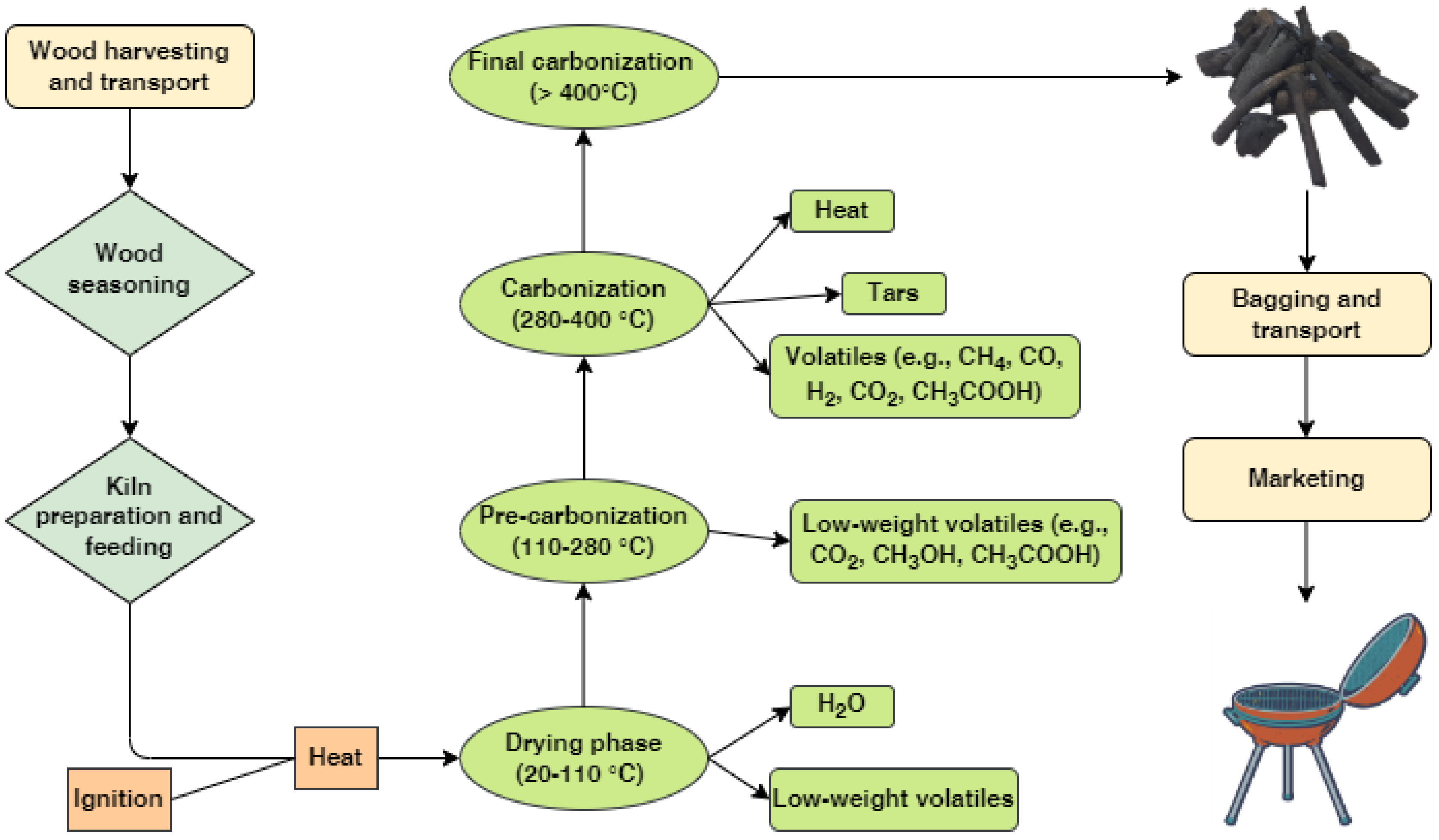

2. Carbonization Process

The temperature increase occurring during the pyrolytic process determines a chemical modification of the biomass [

9] which begins with the pyrolysis of cellulose and hemicellulose contained in the raw material, followed by the slow decomposition of the lignin, producing a porous material rich in carbon and with low volatiles [

27,

28,

29]. The carbonization process can differ depending on the kiln type and the operating conditions used. However, according to temperature, it can be distinguished into five main stages (

Figure 1) [

1,

2,

28,

30,

31,

32,

33,

34,

35,

36,

37,

38]:

Drying phase (20–110 °C): The carbonization process starts after the ignition of the material, leading to a temperature increase. This temperature increase causes the evaporation of water and the release of a small portion of the volatiles contained in the raw material. The time necessary for completing this phase is proportional to the biomass moisture content.

Pre-carbonization (endothermic reactions, 110–280 °C): The dominance of endothermic reactions leading to the release of low-molecular-weight volatile compounds including carbon dioxide (CO2), carbon monoxide (CO), methanol (CH3OH), and acetic acid (CH3COOH).

Carbonization (exothermic reactions, 280–400 °C): The thermal degradation process of the wood starts, determining the onset of exothermic reactions and releasing the last water residues (H2O), methane (CH4), carbon monoxide (CO), hydrogen (H2), carbon dioxide (CO2), acetone (CH3COH), other non-condensable gases and tars. A strong mass loss of the material occurs.

Final carbonization (>400 °C): The wood material is completely carbonized in charcoal containing a high carbon content. The fixed carbon content increases and its final value depends on the final carbonization temperature. Charcoal still contains the ashes present in the raw material and it could also contain some tarry residues.

Cooling phase: The carbonization process is completed, and the charcoal temperature is progressively reduced using different methods according to the production process used.

2.1. Factors Affecting the Carbonization Process and Charcoal Quality

The carbonization process previously described can be affected by several factors that determine yield and final quality variations:

Wood moisture content: A high moisture content of the raw material (>20% dry basis) negatively affects the carbonization process as a greater amount of energy will be required to remove the water, reducing the process yield [

3,

39,

40,

41]. Furthermore, a high moisture content can cause a strong vapor pressure causing internal cracks in the material, increasing charcoal friability, and reducing its mechanical properties [

40].

Woody raw material properties: The wood species, timber type (hardwood or softwood) [

3,

4,

42,

43,

44,

45,

46], and initial characteristics of the material (e.g., ash content, size, density, presence or absence of bark, lignin content, and extractives) will affect the charcoal properties [

37,

43,

44,

45,

47].

Skill and experience of the operators (for traditional charcoal-making processes): Since they monitor the process development and air entrance, they will affect the carbonization process yield and charcoal quality [

13,

34].

Kiln type (earth, metal, or brick kiln) and characteristics: If the carbonization process is not homogeneous, charcoals with different qualitative characteristics can be obtained depending on the position inside the kiln [

10].

Carbonization conditions: Final carbonization temperature, temperature rate, residence time, oxygen concentration, and pressure during the process affect the charcoal yield and its qualitative characteristics. Temperature and residence time are the main factors affecting the carbonization process and charcoal properties. In the literature, several authors have highlighted how high carbonization temperature and residence time determine a charcoal yield reduction but improving the product quality by modifying the charcoal structure, porosity, and density, as well as increasing the fixed carbon content [

3,

5,

12,

24,

28,

30,

42,

45,

47,

48,

49,

50]. Low carbonization temperatures would result in a poor-quality product with irregular and smoky combustion [

35,

51]. High temperatures determine the release of a higher concentration of volatiles from the biomass, increasing the gas yield [

10,

12,

28,

49,

50,

52]. According to Antal and Grønli [

45], Assis et al. [

37], and Wang et al. [

43] an increase in pressure inside the kiln determines a reorganization of the structure of the material due to the establishment of secondary reactions leading to process yield improvement.

Meteorological conditions: Precipitation impacts the carbonization process by reducing the internal kiln temperature, both in traditional techniques and non-insulated kilns [

38,

53,

54]. Even the ambient temperature and air humidity can affect both the yield of the process, influencing the initial wood moisture content, and the duration of the carbonization process.

2.2. Determination of Charcoal Quality

Due to the large number of factors affecting the carbonization process, charcoal quality is widely variable [

52,

55]. Although the same production technique is used, the final characteristics of the product could be different due to the variation of the raw material or the carbonization conditions [

22,

44].

In Europe, the quality of charcoal used for cooking food is determined by referring to the EN 1860-2:2023 standard [

56]. However, the products on the market do not always meet the required characteristics and may have unacceptable traces of contaminants (e.g., mineral matter, plastic, glass, metals), which can be emitted during grilling, spread to food, and/or inhaled by the users [

55,

57,

58].

Table 1 shows the primary physical–energy parameters required by the standard, along with the corresponding standard procedures and the established limits. These measures are designed to enhance performance in charcoal barbecuing while minimizing associated health risks [

27,

56]. However, the standard does not present some fundamental parameters for the characterization of charcoal-based products, including the heating value, bulk density, and the main chemical elements (C, H, N, and O). Although not required by the standard, it was decided to include them among the quality parameters of the charcoals analyzed in this work.

3. Technical–Operational Characteristics of Charcoal Production Systems

Traditional charcoal production remains a small-scale activity predominantly practiced in local mountain areas. In recent years, novel prototypes of modern charcoal-making systems have emerged to address the limitations associated with traditional techniques, ultimately enhancing efficiency and productivity. This section outlines the primary technical and operational characteristics of carbonization systems currently available in Italy (

Figure 2).

3.1. Traditional System (Charcoal Pile)

Although on a local scale, the setting up of the charcoal pile presents little difference based on the traditions and experience of the operators, the process is performed according to the following procedures.

The production of charcoal using the traditional technique involves the initial preparation of the area where the charcoal pile will be built. In the past, these were located inside the forest to reduce the distance of wood transportation and near a watercourse to facilitate the extinguishing of the charcoal pile. To create a flat surface on slopes, the ground is leveled by removing the portion of land uphill and repositioning it on the downhill side [

65]. The base of the charcoal pile typically has a circular or, more frequently, elliptical shape to facilitate charcoal harvesting [

66], developing vertically up to presenting a conical or hemispherical shape (

Figure 3). The size of the charcoal pile is proportional to the amount of stacked wood material.

In the structure center, a chimney is made by arranging the larger logs horizontally and creating a square structure or, even more simply, tying poles together vertically of variable height, usually around 2–3 m [

38,

65,

67]. The chimney is filled with easily combustible material to speed up and facilitate the ignition of the carbonization process. Around the chimney, the larger logs (diameter > 15 cm) are stacked in the internal part of the structure, while the external part is filled using small-sized material arranged perpendicularly (diameter < 5 cm) [

38]. The progressive deposition of the wood determines the typical final hemispherical shape. To prevent contact between oxygen and the material and the entry of water from rainfall, the pile is covered with a mixture of earth, branches, and leaves for a thickness ranging from 5 to 20 cm [

13,

30,

65,

67].

The carbonization process is started by pouring embers through the chimney [

65,

68]. Being an artisanal process, the monitoring of the carbonization process is based exclusively on the experience of the operators. To control the air inside the pile, which regulates the combustion process, holes are opened and closed at the base of the charcoal pile [

30] (

Figure 4). The wrong aeration could lead to the development of flames causing the combustion of the material, while insufficient aeration could cause the process to stop.

The duration of carbonization is proportional to the volume of wood material used and is conditioned by climatic conditions, the moisture content of the material, and the experience and skill of the operators. For small charcoal piles, the production cycle takes at least one day, but, more frequently, it takes from 3 to 4 days, while for large piles, the process can take from 10 to 20 days [

13,

65,

67,

68,

69]. The end of the carbonization process is regulated by the color change of the exhaust fumes [

68]. In the first phase of the carbonization process, the smoke coming out of the chimney and the holes is white, indicating the evaporation of the water contained inside the wood [

70]. As the process progresses, the structure gradually loses volume and shrinks in size. The presence of light blue smoke indicates the end of the carbonization process and the beginning of the cooling phase [

25,

65,

70]. In this phase, the temperature of the material gradually decreases naturally, requiring a lot of time depending on the geometry and dimensions of the pile, the quantity of material, and the atmospheric conditions [

25]. Long times are needed to stabilize the charcoal, as a sudden entry of air could cause the combustion of the material [

36]. To speed up the process, earth or water is used to lower the temperature and extinguish any embers still present [

38]. Finally, the charcoal produced is collected and, once the earth has been removed, packaged for transport.

3.2. Modern Charcoal Kilns

3.2.1. Ukrainian Mobile Kiln

The paper by Picchio et al. [

32] describes the characteristics and performance of a modern Ukrainian mobile horizontal kiln for charcoal production. The kiln presents a metal structure placed on a sled for facilitating transport using a tractor or truck. The woody raw material is manually loaded inside the carbonization chamber through a front hatch. At the rear of the kiln, there is a system for collecting the liquids resulting from the pyrolysis, preventing their dispersion in the soil, and a chimney for the release of the gases used for monitoring the process. As for the traditional charcoal kiln, the carbonization process is controlled based on the observation of the color of the smoke. In the front part of the kiln, there is a small combustion chamber where firewood is loaded, whose combustion is used for heating the material igniting the process. The oxygen entry inside the chamber is regulated by opening and closing appropriate vents positioned on the kiln sides. Once the process is complete, the charcoal produced is unloaded manually from the front hatch. Moreover, in this case, the carbonization must be monitored by the operator for the entire duration of the process, but its presence can be discontinuous.

3.2.2. Mobile Cylindrical Kiln

Based on the previous kiln, the same authors developed a new prototype of a cylindrical steel charcoal kiln [

38]. Like the previous one, the kiln is installed on a sled to facilitate transport. The kiln structure is insulated to reduce heat loss during the process and improve the circulation of the pyrolysis gases, allowing for more homogeneous carbonization. The kiln has a loading capacity of approximately 5 m

3. In the front and rear parts of the cylindrical structure, there are two loading doors with hermetic closures that can be opened in both directions, facilitating the loading and unloading operations. The kiln structure was designed to mechanically facilitate the insertion of wood using a tractor or forklift, allowing for a significant speeding up of loading operations and increasing productivity. Similarly, to the Ukrainian mobile kiln, in the front part of the kiln, there is a small combustion chamber fueled by firewood to provide the required heat for the whole process. The oxygen entry into the carbonization chamber is regulated by opening and closing vents located on the kiln sides and in the closing compartment of the ash collection chamber. The pyrolysis liquids are collected inside a tank whose unloading is facilitated by the presence of a tap, preventing their dispersion on the ground. In the rear part of the kiln, a condensation chamber equipped with a chimney is present. An operator must be discontinuously present during the process. The carbonization is monitored using laser thermometers to measure the temperatures inside the kiln. The visual analysis of the fume color resulting from the chimney further supports the monitoring of the process trend.

3.2.3. Vertical Mobile Kiln

Different from the previous ones, Picchio et al. [

71] have developed a new prototype of a vertical mobile kiln. The kiln consists of a cylindrical steel carbonization chamber that performs both direct carbonization of the material loaded inside the chamber and indirect carbonization by inserting special cylindrical containers into the chamber. The carbonization chamber is closed at the top by a lid where a chimney is positioned centrally. On the side is present an additional chimney for collecting the gases released during the carbonization coming from three ducts placed below the carbonization chamber when using the cylindrical containers. In the front part, there is a combustion chamber where firewood is loaded, whose combustion is used to provide the heat necessary for the ignition of the process. Like the previous one, ash and liquids generated during charcoal production are collected in dedicated structures, while fumes are released into the atmosphere.

The direct carbonization of the raw biomass guarantees greater productivity as it exploits the full volume of the carbonization chamber. Inside, there can be stowed about 450–600 kg of logs of dimensions between 100–120 cm, which are arranged vertically and uniformly to ensure regular carbonization. To prevent the combustion of the material deriving from flames generated in the ignition chamber, the carbonization chamber is shielded by a fire-cutting plate. During indirect carbonization, three cylindrical containers are positioned inside the carbonization chamber. This is to further prevent direct contact with the flames generated by the thermal unit. In this case, the ignition of the process occurs through an airflow that circulates in the material using a vacuum system without direct contact with the flame. In addition to logs, containers can be filled with smaller materials, such as wood chips. Compared to the direct process, it has a lower load capacity, ranging between 190–280 kg.

Direct carbonization allows for the greater production of charcoal despite a greater energy consumption and a longer production duration. According to the authors, this process is better suited to the production of barbecue charcoal, while the indirect one is better suited to the production of biochar to be used in agriculture. In both processes, the loading and unloading of the material is conducted manually.

As for the previous ones, the carbonization process is monitored using the visual support of the color of the fumes. It is possible to measure the temperature inside the combustion chamber or cylindrical containers by inserting a probe or laser thermometer through an inspection hole. The process progress and oxygen entry are regulated by the operator by opening and closing the inlets present in the kiln.

3.2.4. Continuous Reactor

The development of highly technological kilns requires huge investments that are often not compatible with the financial resources of small and medium-sized Italian forestry enterprises. To provide a further tool for the energy valorization of biomass, RE-CORD

® has developed a biomass carbonization reactor (CarbOn, patent IT1429282) for charcoal production [

51,

72,

73]. The material obtained can be used in agriculture as a soil amendment [

74], as active carbon [

75], for the metallurgical industry [

49], and for barbecue [

72]. The kiln is composed of a vertical steel cylinder reactor with a capacity of 50 kg h

−1 of biomass. The carbonization process is conducted continuously at atmospheric pressure with controlled oxygen concentration and with a temperature range between 450–700 °C [

72].

Wood is manually loaded through a gate valve placed in the top part of the reactor. After the ignition of the process, the carbonized material and the pyrolysis gases are deposited in the lower part of the reactor. The charcoal is removed through a hopper placed below the reactor, which involves the carbonized material on a screw. Its rotation regulates the residence time of the material. The screw is cooled with water to reduce the charcoal temperature, conveying the materials into barrels with a capacity of 0.2 m3 for the collection. Since the removal of the pyrolysis gases does not take place at the bottom of the solid bed but above it, this leads to the presence of an oxygen-rich zone above the gas extraction point and, below it, a zone with a lower oxygen concentration. The temperature of the zones is monitored using thermocouples equipped with probes distributed both in the oxygen-rich zone (three probes) and the low oxygen concentration zone. The extracted gases, whose temperature is monitored with additional thermocouples to avoid tar condensation, pass through a cyclone for dust removal, an ejector, and finally burn in a torch.

4. Kilns Comparison

4.1. Technical–Operational Characteristics

Table 2 shows the technical operating characteristics of the kilns. The yield, expressed as %, represents the ratio between the quantity of charcoal produced and the quantity of raw material input. All the processes have a wide yield range because of the condition variability described previously in

Section 2.1. The charcoal pile has a wider range of values as it is more exposed to factors that alter the final yield, resulting in much lower potential yields than metal kilns and the CarbOn system.

4.1.1. Carbonization Process

The carbonization process can be classified as continuous, semi-continuous, or discontinuous (batch-type) [

12,

22]. The traditional technique has the longest process duration compared to other kilns, negatively affecting productivity. The metal kilns are batch-type, resulting in a similar production process time, longer than that of the CarbOn system. Different production systems can result in different material residence times and heating rates [

12]. In the CarbOn system, charcoal is produced continuously, and the biomass remains on average for three hours inside the reactor and two hours in the cooling zone [

73]. A low process duration of the continuous process allows for a significant production increase.

4.1.2. Portability, Mechanization, and Monitoring of the Production Process

The CarbOn system is the only stationary system. The possibility of movement guaranteed by the portable metal kilns and charcoal piles reduces the time and costs of processes. Moreover, transport allows them to operate directly inside the forest [

25,

32,

76].

The use of machines is a crucial factor that greatly affects both production costs and production time. The cylindrical kiln is the only kiln that allows for the mechanization of the process, obtaining a considerable improvement in loading and unloading operations [

38]. On the contrary, Ukrainian-type and vertical kilns require manual loading and unloading. In the CarbOn system, the operator is involved only in the initial feeding of the reactor. Moreover, being equipped with sensors for monitoring the process, the CarbOn system does not require the presence of operators since it is an automated process. In metal kilns, process monitoring is based on operator monitoring for several hours.

4.1.3. Management of Pyrolysis Liquids and Gases

The management of pyrolysis co-products is a crucial factor that influences the environmental impact of the process and presents opportunities, as these by-products can be utilized for various purposes. Metal kilns and CarbOn are equipped with systems for collecting the liquids deriving from pyrolysis, preventing their dispersion on the soil as occurs in traditional techniques. The composition of the liquids varies according to the final temperature but generally, they contain water, different aromatic compounds, organic acids, phenols, aromatics, methanol, PAHs, and other minor compounds [

50,

72]. Collecting liquids allows a reduction of the environmental impact of the process, with the possibility of using them in industrial processes [

12,

38]. In addition to the liquids, it is necessary to provide systems for reducing the gaseous compounds released during the carbonization of the material. Pyrolysis gases are composed of condensable and non-condensable gases [

77], mainly containing H

2, CO

2, CO, CH

4, and other compounds in minor concentrations, including ammonia (NH

3), nitrogen oxides (NOx), sulfur oxides (SOx), methanol (CH

3OH), propane (C

3H

8), ethane (C

2H

6), and ethylene (C

2H

4) [

4,

6,

10,

12,

50,

72], whose direct release into the atmosphere can contribute to air pollution as well as represent a potential health risk for the operators [

78]. However, the CarbOn system is the only one equipped with emission abatement systems using a cyclone for dust abatement and a torch, reducing the environmental impact of the process [

39,

72]. Although the developed mobile kilns have a higher carbonization efficiency and consequently lower emissions [

38], real abatement systems are not installed as in the previous one.

Table 2.

Comparison of the technical–operational characteristics of the charcoal production processes.

Table 2.

Comparison of the technical–operational characteristics of the charcoal production processes.

| | Carbonization Process | Portability, Mechanization, and Monitoring | Pyrolysis Co-Product Management |

|---|

| Carbonization Kiln | Yield (%) | Carbonization Time | Operation Mode | Cooling Process | Portability | Labor

Intensity * | Chamber Loading | Carbonization Monitoring | Liquid Collecting Systems | Emission Abatement Systems |

|---|

| Charcoal pile [65,66,69] | 10–25 | 24–480 | Batch | Natural | Mobile | High | Manual | Fume color | No | No |

| Ukrainian metal mobile kiln [32] | 20–35 | 30–85 | Batch | Natural | Mobile | Medium | Manual | Fume color | Yes | No |

Mobile

cylindrical kiln [38] | 20–35 | 24–80 | Batch | Natural | Mobile | Medium-Low | Mechanical | Fume color + Sensors | Yes | No |

| Vertical mobile kiln (direct carbonization) [71] | 20–26 | 8–14 | Batch | Natural | Mobile | Medium-Low | Manual | Fume color + Sensors | Yes | No |

| Vertical mobile kiln (indirect carbonization) [71] | 22–26 | 6–9 | Batch | Natural | Mobile | Medium-Low | Manual | Fume color + Sensors | Yes | No |

| Continuous reactor [72] | 25–30 | 3 | Continuous | Water-cooled screw | Stationary | Low | Manual | Sensors | Yes | Yes |

4.2. Charcoal Quality

Table 3 shows the mean values of the qualitative characteristics of the charcoals produced using the techniques previously described. For the charcoals produced with the Ukrainian mobile kiln and the cylindrical mobile kiln, since three different values were provided by the authors, the range of values has been reported. The values relating to the charcoal produced with the charcoal pile technique were obtained from previous work by the same authors [

55]. The samples are produced using the same technique but with different origins (Veneto, Marche, and Calabria regions) and using different wood species.

Table 4 shows the wood species used for charcoal production. The species used are those available in the vicinity of the kiln location. Therefore, all the analyzed charcoals present different species. However, all the samples are made using hardwood since, for barbecue uses, they are more appreciated by consumers due to the greater density associated with a longer duration of combustion [

21,

47,

76].

4.2.1. Proximate Analysis

According to the opinion of barbecue charcoal users, the low moisture content is one of the most important characteristics [

79] since high values can cause problems during the ignition and combustion of fuel [

48]. The higher moisture content values for charcoal were produced using holm oak (Calabria) and the deciduous mix (Veneto). This could be due to greater absorption of humidity during storage as well as a greater porosity of the material [

48,

80].

The ash content is closely linked to the quality of the raw biomass [

30,

45] since most of the mineral content will remain after the carbonization process, increasing in concentration compared to the initial values [

9,

10,

42,

47,

48]. Good-quality charcoals generally have values between 0.5 and 5.0% [

30,

45]. The charcoals produced with charcoal piles in the Marche and in Calabria have mean values above this threshold, but in any case, lower than the limits set by the standard. This may be due to a greater presence of bark in the raw material, the use of branches and tops, or the contamination with earth or other residues deriving from the traditional production process and transportation [

30,

54,

76,

81]. High ash contents could cause problems during cooking by depositing on food as well as requiring more frequent cleaning of the barbecue [

47,

81,

82,

83].

Although the standard does not indicate any limits in terms of volatiles, good-quality barbecue charcoal should have values below 30% to prevent excessive smoke release as well as irregular combustion of the product [

30,

35,

47,

82]. All the charcoals considered have values lower than this threshold. The charcoals produced with the traditional technique have slightly lower values compared to other production processes. This could be due to the longer residence time of the material, which determines a higher loss of volatiles [

12], or from higher temperatures during the pyrolysis of the biomass [

52].

The charcoal heating value is more determined by the initial characteristics of the biomass used than by the pyrolysis conditions [

52]. Up to a temperature of about 600 °C the heating value does not show significant variations, but after this threshold, it begins to decrease as the temperature increases due to the loss of hydrogen and extractives [

12,

52]. Apart from the charcoal produced with the CarbOn system, all samples have LHV values greater than 30.0 MJ kg

−1. High values of LHV lead to elevated temperatures in the embers, guaranteeing faster cooking of foods and lower charcoal consumption [

47].

All charcoals produced through the various production processes exhibit high quality, with fixed carbon values above 75%, as required by the standard [

29,

30]. As discussed in

Section 2.1, as the pyrolysis temperature and residence time increase during the process, an increase in the fixed carbon content of the charcoal occurs. Low fixed carbon values, combined with high ash and moisture content, can cause problems in terms of ignition and determining an irregular combustion of charcoal [

83].

4.2.2. Physical–Mechanical Properties

Bulk density values exhibit considerable variability among charcoals produced using different production systems. Specifically, vertically mobile kilns yield charcoal with the highest bulk density values, whereas the continuous carbonization system produces charcoal with the lowest values. According to Charvet et al. [

47], bulk density is a parameter characterized by high heterogeneity, closely tied to the characteristics of the initial feedstock. The greater the bulk density of the feedstock, the higher the corresponding value of the relative charcoal [

45]. Furthermore, the bulk density value is influenced by the shape and dimensions of the charcoal, stemming from differences in spatial occupation and the relative presence of voids [

83].

4.2.3. Ultimate Analysis

Carbon is the main chemical element present in charcoal, with values above 80%. The carbonization process determines a strong increase in the carbon and nitrogen content compared to the starting material [

5,

9,

25,

28,

42,

72,

73,

84], while the hydrogen and oxygen content decrease since they are removed during the carbonization process mainly in the form of CO, CO

2, CH

4, and H

2O [

9,

24,

28,

42,

84].

Table 3.

Mean values of the main characteristics of the charcoals produced using different carbonization processes.

Table 3.

Mean values of the main characteristics of the charcoals produced using different carbonization processes.

| Parameter | Standard Limits | Charcoal Pile (Veneto) [55] | Charcoal Pile (Marche) [55] | Charcoal Pile (Calabria) [55] | Ukrainian Mobile Kiln [32,38] | Mobile Cylindrical Kiln [38] | Vertical

Mobile Kiln (Direct Carbonization) [71] | Vertical Mobile Kiln (Indirect Carbonization) [71] | Continuous

Reactor [72] |

|---|

| Proximate analysis (dry basis, wt.%) | | | | | | | | | |

| Moisture content | <8% | 7.3 | 4.7 | 7.2 | 4.5 | 4.5 | / | / | 3.0 |

| Ash content | <8% | 4.8 | 5.5 | 5.2 | 1.6–2.1 | 1.7–2.0 | 3.1 | 2.2 | 2.2 |

| Volatile matter | / | 7.3 | 13.9 | 10.5 | 16.0–19.0 | 16.0–19.0 | 14.0 | 14.0 | 17.0 |

| Fixed carbon | >75% | 88.0 | 80.7 | 84.3 | 82.0–87.0 | 82.0–87.0 | 83.0 | 84.0 | 80.8 |

| Heating value (dry basis, MJ kg−1) | | | | | | | | | |

| LHV | / | 32.0 | 30.4 | 30.7 | 31.5–33.0 | 31.5–33.5 | 32.1 | 30.4 | 29.9 |

| Physical–mechanical properties | | | | | | | | | |

| Bulk density (kg m−3) | / | / | / | / | 235–270 | 235–302 | 472 | 465 | 136.9 |

| Ultimate analysis (dry basis, wt. %) | | | | | | | | | |

| C | / | 92.0 | 84.5 | 90.5 | / | / | / | / | 84.9 |

| H | / | 1.6 | 2.6 | 1.7 | / | / | / | / | 2.3 |

| N | / | 0.6 | 0.6 | 0.4 | / | / | / | / | 0.4 |

| O (calc.) | / | 1.0 | 6.8 | 2.2 | / | / | / | / | 10.1 |

Table 4.

Wood species used for charcoal production.

Table 4.

Wood species used for charcoal production.

| Carbonization Kiln | Unit of Measure |

|---|

| Charcoal pile (Veneto) [55] | Beech (Fagus sylvatica), European hop-hornbeam (Ostrya carpinifolia), common hornbeam (Carpinus betulus), manna ash (Fraxinus ornus), and hazel (Corylus avellana) |

| Charcoal pile (Marche) [55] | European hop-hornbeam (Ostrya carpinifolia) and manna ash (Fraxinus ornus) |

| Charcoal pile (Calabria) [55] | Holm oak (Quercus ilex) |

| Ukrainian mobile kiln [32] | Beech (Fagus sylvatica) |

| Mobile cylindrical kiln [38] | Beech (Fagus sylvatica), Turkey oak (Quercus cerris), and chestnut (Castanea sativa) |

| Vertical mobile kiln [71] | Chestnut (Castanea sativa) |

| CarbON pilot plant [72] | Chestnut (Castanea sativa) |

5. Future Developments and Limitations

To implement an efficient charcoal production chain, it is necessary to invest in the development of new modern technologies capable of increasing productivity and product quality while at the same time reducing the required labor, process, and logistic costs and environmental impacts.

Both metal kilns and the CarbOn system have advantageous characteristics compared to the traditional technique. However, some limitations still emerge that future technological developments will have to address. Below are the main aspects to consider, briefly listed, and in which it is necessary to invest.

5.1. Kiln Construction Characteristics

The kiln dimensions are a crucial aspect, with repercussions for the carbonization process, investment costs, mobility, and productivity.

The use of too-large kilns could determine the presence of non-homogeneous temperatures inside the carbonization chamber, affecting the yield and quality of the products [

22]. As evidenced by Charvet et al. [

10] in a traditional Portuguese brick kiln, different temperatures in the carbonization chamber will result in different quality products. On the contrary, the use of small kilns would cause a drastic drop in productivity and an increase in costs. Therefore, it is necessary to calibrate the kiln dimensions according to the expected volume of material to be subjected to carbonization.

The use of insulating material allows a reduction of energy waste and dispersion, obtaining a stable temperature inside the kiln [

25,

38], lower energy consumption, and higher internal temperatures, improving the quality of the final product [

1,

2,

35].

Mobile kilns that can be easily moved by tractors or trucks reduce the costs of raw material transport and guarantee the possibility of use in different areas [

34]. However, having more compact dimensions than a stationary kiln, the charcoal production capacity will be limited. Stationary kilns can be advantageous if they are located not too far from the biomass supply areas and are fed using diversified sources, not relying only on forest wood but also using energy plantations such as short-rotation forestry [

34,

73,

78,

85]. Therefore, among the factors affecting the choice of the most suitable kilns, the availability of investment, the quantity of material to carbonize, and the distance from the biomass sources should be considered.

5.2. Mechanization, Automation, and Control of the Production Process

The low mechanization of the loading and unloading operation still determines a strong labor demand, causing high physical work required by the operators, increasing costs, and lowering productivity [

21,

22,

25,

36]. The use of mechanical means, as already used in the cylindrical kiln described by Picchio et al. [

38] and the screw present in the CarbOn system [

72], will reduce labor costs and process time.

Monitoring the carbonization process is a fundamental aspect of the correct management of temperatures and heating rates inside the kiln [

25] since they affect the yield and final charcoal quality [

23]. The control of the carbonization process based on the observation of the smoke color represents an empirical method based on the experience of the operator, with difficulties in monitoring the process, especially during the night and on weekends [

10]. The use of probes allows for constant real-time monitoring of the kiln temperature, not requiring the presence of the operator. The collected data can be used by dedicated software capable of managing the control of the entire charcoal production process, obtaining an increase in productivity and quality of the final product [

10].

In summary, the implementation of automatic systems for process monitoring and procedure mechanization during the charcoal production process, despite higher investment costs and system complexity, would allow for an increase in production yields, product quality, and profitability by reducing costs and production times [

2,

25,

86].

5.3. Improvement in the Carbonization Process

To enhance the productivity of the carbonization process, improvements in the procedure itself are essential.

Pyrolysis can be carried out using various types of reactors, whether discontinuous, semi-continuous, or continuous, depending on the raw material used, the pyrolysis type (slow, intermediate, or fast), and the production target (solid, liquid, gaseous, heat, and electricity) [

3,

31]. The simplest and most traditional systems are batch-type [

22], in which the pyrolysis is discontinuous. This process is better suited to be used in portable systems due to the necessity of compact dimensions and reducing the number of components. However, these types of processes lead to long production times [

24]. The use of continuous or semi-continuous production systems, as adopted by the CarbOn system, allows for numerous operational advantages.

Among the continuous processes, Campuzano et al. [

31] reviewed the main types of auger reactors (screw reactors), underscoring their technical and economic advantages and disadvantages. These are versatile systems of simple design characterized by continuous feeding, heating, and cooling devices suitable for working with different types of biomasses and pyrolysis [

12,

31]. In addition to charcoal production, auger reactors can also generate heat and energy, reducing fuel consumption and air emissions [

25,

87].

Continuous processes guarantee lower labor requirements and production times, increasing yield, energy efficiency, charcoal quality, ease of control of the whole production cycle, and productivity [

3,

22,

88]. However, they require high initial investments and physical–thermal pre-treatments of the raw biomass, focusing particularly on addressing moisture content and reducing the size of the raw material [

88]. Given the reduced carbonization time in continuous reactors, utilizing small-sized materials enhances heat and mass transfer by providing a larger surface area for exchange and maintaining a uniform temperature during pyrolysis [

4]. Overall, most continuous-type systems are better suited to medium-large stationary industrial-type systems [

3], but those with a compact design could also be installed in mobile systems.

Further improvements to the pyrolysis process involve the use of multi-stage pyrolysis. During the pyrolytic process, thermal energy is continuously supplied until the final temperature is reached, ignoring the different reaction mechanisms that involve both endothermic and exothermic reactions [

35,

89]. To decrease the energy consumption in the process, one effective solution involves adopting multistage pyrolysis. This method employs varying temperatures, heating rates, and residence times at different stages [

90]. Oyedun et al. [

35] developed a three-stage pyrolysis characterized by a rapid initial stage of temperature increase and a slow and gradual heating stage to uniformize the biomass temperature followed by a final cooling stage. According to the authors, this type of pyrolysis reduces energy consumption and saves time. In contrast, Elyounssi et al. [

29] used a two-step pyrolysis, in which the first step was conducted at low temperatures followed by a second step at high temperatures (950 °C). Based on the results, this type of approach is economically advantageous, saving energy, reducing production times, and increasing charcoal quality due to its high fixed carbon values.

The cooling phase represents one of the most time-consuming phases of the entire charcoal production cycle, with a duration similar to the carbonization process [

35,

91]. The natural cooling of the product requires a long time, drastically reducing productivity [

1,

22,

24,

25]. Given that the qualitative characteristics of the charcoal are not affected by cooling, this must take place as quickly as possible [

25,

92]. In the literature, several solutions are presented to accelerate the cooling process. Among the most common systems adopted are the use of water, inert gases, heat exchangers, the removal of insulation, and the use of different materials and thicknesses for the construction of kiln walls [

22,

72,

78,

91]. However, the implementation of additional components for cooling the material could cause an increase in investment costs and the use of natural resources such as water [

22].

5.4. Reuse of Pyrolysis Gases Resulting from the Carbonization Process

Different product proportions will be obtained depending on the temperature inside the kiln during the carbonization process. An increase in temperature is associated with a reduction in charcoal yield against an increase in the concentration of pyrolysis gases [

5,

12]. The latter represents a co-product of charcoal production that, if properly exploited, gives benefits both in economic and environmental terms [

78]. It is estimated that about 50% of the initial energy of the biomass is lost during the carbonization process in the form of pyrolysis gasses which, rather than being released into the atmosphere, can be exploited to recover energy and produce heat [

4,

36,

77,

78].

During the carbonization process, part of the heat inside the kiln is inevitably lost. In traditional systems, the increase in temperature is due to the combustion of a part of the biomass, reducing the yield of the process [

39]. Using pyrolysis gas recirculation systems inside the carbonization chamber, an improvement is obtained in the production process by reducing the request for energy inputs through the increase in the internal kiln temperature due to the presence of combustible gases, including methane [

1,

2]. The heat obtained from the use of pyrolysis gases can be used both for drying the raw material during the initial endothermic phases of the production process, obtaining advantages in economic and production terms, and reducing greenhouse gas emissions (GHG) [

25,

77]. The reuse of pyrolysis gases is better suited to systems operating continuously since in batch-type systems, the gas composition varies over time, determining a different energy content [

77].

Furthermore, it is possible to produce electricity by burning non-condensable pyrolysis gases (e.g., H

2 and CH

4) to produce a flow that drives a turbine that generates electricity. Before using pyrolytic gases, they must be treated to remove or reduce the concentrations of components such as tars, dust, water vapor, ammonia, and hydrogen sulfide (H

2S) [

4]. The amount of electricity produced depends on the composition and heating value of the pyrolysis gases [

36,

78]. The energy produced can be used to self-power the plant or sold on the electrical grid. Furthermore, if the electricity generated replaces or avoids the use of fossil fuels, it produces carbon credits, increasing the sustainability of the process [

77]. Therefore, the use of pyrolysis gases for producing electricity drastically reduces the GHGs emitted during charcoal production.

The reuse of pyrolysis gases represents a more suitable solution in medium-large stationary plants operating continuously or semi-continuously in which the composition and heating value of the gases are homogeneous [

36]. Moreover, the structural characteristics of stationary systems allow for the easier installation of additional components compared to mobile kilns.

6. Limitations

In this paper, only the production processes present in the literature were described and compared; further small-scale production processes may be present, and their inclusion in the paper would be able to provide a more complete state of the art of charcoal production in Italy. However, because of the lack of information about them, it was not possible to consider them in this paper.

In the charcoal qualitative characteristics comparison, additional physical–mechanical properties required by the EN 1860-2:2023 standard were not taken into consideration due to a lack of data. Nevertheless, the characteristics considered represent the main physical–energy characteristics of the material, capable of providing comprehensive knowledge regarding charcoal quality.

This study solely assessed the technical and operational aspects of various charcoal production systems. Therefore, no economic evaluations were conducted. Further research is needed to identify optimal solutions for local contexts and assess cost-effectiveness for forestry enterprises.

7. Conclusions

The global charcoal trade is steadily increasing, and high-income countries are importing significant quantities of charcoal, often associated with environmental issues in the production regions. To address these challenges, promoting the development of a local charcoal production chain in high-income countries is crucial. This study involved conducting a comprehensive comparison of five distinct charcoal production systems within European and, specifically, Italian contexts. The comparison considered both traditional and modern methods and included an assessment of the resulting quality of charcoal. The evaluation of traditional and modern charcoal production systems highlighted notable inefficiencies in traditional methods concerning manpower, costs, time, and yield. On the other hand, recent innovations, particularly mobile and stationary kiln prototypes, have demonstrated promising solutions. Mobile kilns, while providing flexibility and cost savings, demand specialized expertise, have limited automation, and involve longer cycles. In contrast, despite higher initial costs, stationary systems operate continuously, leading to increased productivity and efficiency. Interestingly, charcoal quality showed minimal variations among the production methods, underscoring the potential of new technologies. However, certain limitations persist, particularly in terms of mechanization, process monitoring, and environmental impact. In light of the findings, we recommend a targeted focus on research and development initiatives aimed at improving current technologies. Specifically, efforts should concentrate on enhancing automation, mechanization, efficiency, and reducing environmental impact. This information is essential for industry stakeholders, forestry enterprises, policymakers, and researchers, providing crucial insights for the enhancement and implementation of sustainable charcoal production chains.

Author Contributions

Conceptualization, A.M., R.C., R.G. and S.G.; investigation, A.M.; resources, R.C. and S.G.; data curation, A.M.; writing—original draft preparation, A.M.; writing—review and editing, R.C., R.G. and S.G.; visualization, A.M.; supervision, R.C. and S.G.; project administration, S.G.; funding acquisition, S.G. All authors have read and agreed to the published version of the manuscript.

Funding

This study was carried out within the Agritech National Research Center and received funding from the European Union Next-GenerationEU (PIANO NAZIONALE DI RIPRESA E RESILIENZA (PNRR)—MISSIONE 4 COMPONENTE 2, INVESTIMENTO 1.4—D.D. 1032 17/06/2022, CN00000022).

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Manatura, K. Novel Performance Study of Recirculated Pyro-Gas Carbonizer for Charcoal Production. Energy Sustain. Dev. 2021, 64, 8–14. [Google Scholar] [CrossRef]

- Ayass, W.W.; Kobeissi, H.; Mokdad, R.; Shammas, E.; Asmar, D.; Zeaiter, J. Process Design and Operation of a Wood Charcoal Retort. Waste Biomass Valorization 2018, 9, 2211–2220. [Google Scholar] [CrossRef]

- Panwar, N.L.; Pawar, A.; Salvi, B.L. Comprehensive Review on Production and Utilization of Biochar. SN Appl. Sci. 2019, 1, 168. [Google Scholar] [CrossRef]

- Kan, T.; Strezov, V.; Evans, T.J. Lignocellulosic Biomass Pyrolysis: A Review of Product Properties and Effects of Pyrolysis Parameters. Renew. Sustain. Energy Rev. 2016, 57, 1126–1140. [Google Scholar] [CrossRef]

- Demirbas, A.; Ahmad, W.; Alamoudi, R.; Sheikh, M. Sustainable Charcoal Production from Biomass. Energy Sources A Recovery Util. Environ. Eff. 2016, 38, 1882–1889. [Google Scholar] [CrossRef]

- Ingram, L.; Mohan, D.; Bricka, M.; Steele, P.; Strobel, D.; Crocker, D.; Mitchell, B.; Mohammad, J.; Cantrell, K.; Pittman, C.U. Pyrolysis of Wood and Bark in an Auger Reactor: Physical Properties and Chemical Analysis of the Produced Bio-Oils. Energy Fuels 2008, 22, 614–625. [Google Scholar] [CrossRef]

- Sangsuk, S.; Suebsiri, S.; Puakhom, P. The Metal Kiln with Heat Distribution Pipes for High Quality Charcoal and Wood Vinegar Production. Energy Sustain. Dev. 2018, 47, 149–157. [Google Scholar] [CrossRef]

- Khan, M.S.; Min, Y.; Broumand, M.; Yun, S.; Hong, Z.; Thomson, M.J. Advancing the Application of Pyrolysis Liquid (Bio-Oil) by the Improvement of Its Fuel Properties by Thermo-Catalytic Reforming. Energy Fuels 2022, 36, 4381–4395. [Google Scholar] [CrossRef]

- Kazimierski, P.; Hercel, P.; Januszewicz, K.; Kardaś, D. Pre-Treatment of Furniture Waste for Smokeless Charcoal Production. Materials 2020, 13, 3188. [Google Scholar] [CrossRef]

- Charvet, F.; Matos, A.; da Silva, J.F.; Tarelho, L.; Leite, M.; Neves, D. Charcoal Production in Portugal: Operating Conditions and Performance of a Traditional Brick Kiln. Energies 2022, 15, 4775. [Google Scholar] [CrossRef]

- Bailis, R. Wood in Household Energy Use. In Encyclopedia of Energy; Cleveland, C.J., Ed.; Elsevier: Amsterdam, The Netherlands, 2004; pp. 509–526. [Google Scholar]

- Ningbo, G.; Baoling, L.; Aimin, L.; Juanjuan, L. Continuous Pyrolysis of Pine Sawdust at Different Pyrolysis Temperatures and Solid Residence Times. J. Anal. Appl. Pyrolysis 2015, 114, 155–162. [Google Scholar] [CrossRef]

- Seboka, Y. Charcoal Production: Opportunities and Barriers for Improving Efficiency and Sustainability. In Bio-Carbon Opportunities in Eastern & Southern Africa; Harnessing Carbon Finance to Promote Sustainable Forestry, Agro-Forestry and Bio-Energy; United Nations Development Programme: New York, NY, USA, 2009; pp. 102–126. [Google Scholar]

- Allais, F. The Chemistry behind Cooking on a Barbecue. In Handbook of Molecular Gastronomy: Scientific Foundations, Educational Practices, and Culinary Applications; Lavelle, C., This, H., Kelly, A.L., Burkle, R., Eds.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Forestry Production and Trade-Wood Charcoal. Available online: https://www.fao.org/faostat/en/#data/FO (accessed on 17 April 2023).

- Zahnen, J.; Haag, V.; Lewandrowski, T.; Hirschberger, P. 2020 Analysis of the EU Charcoal Market; WWF Germany: Berlin, Germany, 2020. [Google Scholar]

- Haag, V.; Zemke, V.T.; Lewandrowski, T.; Zahnen, J.; Hirschberger, P.; Bick, U.; Koch, G. The European Charcoal Trade. IAWA J. 2020, 41, 463–477. [Google Scholar] [CrossRef]

- Nabukalu, C.; Gieré, R. Charcoal as an Energy Resource: Global Trade, Production and Socioeconomic Practices Observed in Uganda. Resources 2019, 8, 183. [Google Scholar] [CrossRef]

- Sedano, F.; Mizu-Siampale, A.; Duncanson, L.; Liang, M. Influence of Charcoal Production on Forest Degradation in Zambia: A Remote Sensing Perspective. Remote Sens. 2022, 14, 3352. [Google Scholar] [CrossRef]

- Kiruki, H.M.; van der Zanden, E.H.; Kariuki, P.; Verburg, P.H. The Contribution of Charcoal Production to Rural Livelihoods in a Semi-Arid Area in Kenya. Environ. Dev. Sustain. 2020, 22, 6931–6960. [Google Scholar] [CrossRef]

- Hido, A.; Teka, A.; Alemayehu, A. Analysis of Charcoal Producers Perceptions of Its Production, Forest Degradation, and Governance in Wolaita, Southern Ethiopia’s Dry Afromontane Forests. Int. J. For. Res. 2023, 2023, 3352702. [Google Scholar] [CrossRef]

- Rodrigues, T.; Braghini Junior, A. Charcoal: A Discussion on Carbonization Kilns. J. Anal. Appl. Pyrolysis 2019, 143, 104670. [Google Scholar] [CrossRef]

- Kajina, W.; Junpen, A.; Garivait, S.; Kamnoet, O.; Keeratiisariyakul, P.; Rousset, P. Charcoal Production Processes: An Overview. J. Sustain. Energy Environ. 2019, 10, 19–25. [Google Scholar]

- Pyshyev, S.; Miroshnichenko, D.; Malik, I.; Bautista Contreras, A.; Hassan, N.; Abd Elrasoul, A. State of the Art in the Production of Charcoal: A Review. Chem. Chem. Technol. 2021, 15, 61–73. [Google Scholar] [CrossRef]

- Rodrigues, T.; Junior, A.B. Technological Prospecting in the Production of Charcoal: A Patent Study. Renew. Sustain. Energy Rev. 2019, 111, 170–183. [Google Scholar] [CrossRef]

- Rogelja, T.; Ludvig, A.; Weiss, G.; Prah, J.; Shannon, M.; Secco, L. Analyzing Social Innovation as a Process in Rural Areas: Key Dimensions and Success Factors for the Revival of the Traditional Charcoal Burning in Slovenia. J. Rural. Stud. 2023, 97, 517–533. [Google Scholar] [CrossRef]

- de Meira, A.M.; Nolasco, A.M.; Klingenberg, D.; de Souza, E.C.; Dias Júnior, A.F. Insights into the Reuse of Urban Forestry Wood Waste for Charcoal Production. Clean Technol. Environ. Policy 2021, 23, 2777–2787. [Google Scholar] [CrossRef]

- Demirbas, A. Relationships between Carbonization Temperature and Pyrolysis Products from Biomass. Energy Explor. Exploit. 2004, 22, 411–420. [Google Scholar] [CrossRef]

- Elyounssi, K.; Blin, J.; Halim, M. High-Yield Charcoal Production by Two-Step Pyrolysis. J. Anal. Appl. Pyrolysis 2010, 87, 138–143. [Google Scholar] [CrossRef]

- FAO. Industrial Charcoal Making; Food and Agriculture Organization of the United Nations: Rome, Italy, 1985. [Google Scholar]

- Campuzano, F.; Brown, R.C.; Martínez, J.D. Auger Reactors for Pyrolysis of Biomass and Wastes. Renew. Sustain. Energy Rev. 2019, 102, 372–409. [Google Scholar] [CrossRef]

- Picchio, R.; Pari, L.; Venanzi, R.; Latterini, F.; Picchio, R.; Pari, L.; Venanzi, R.; Latterini, F.; Suardi, A.; Alfano, V.; et al. A New Mobile Kiln Prototype for Charcoal Production. In Proceedings of the 28th European Biomass Conference and Exhibition, Online, 6–9 July 2020. [Google Scholar]

- Zola, F.C.; Colmenero, J.C.; Aragão, F.V.; Rodrigues, T.; Junior, A.B. Multicriterial Model for Selecting a Charcoal Kiln. Energy 2020, 190, 116377. [Google Scholar] [CrossRef]

- Van Dam, J. The Charcoal Transition: Greening the Charcoal Value Chain to Mitigate Climate Change and Improve Local Livelihoods; Food and Agriculture Organization of the United Nations: Rome, Italy, 2017. [Google Scholar]

- Oyedun, A.O.; Lam, K.L.; Hui, C.W. Charcoal Production via Multistage Pyrolysis. Chin. J. Chem. Eng. 2012, 20, 455–460. [Google Scholar] [CrossRef]

- de Oliveira Vilela, A.; Lora, E.S.; Quintero, Q.R.; Vicintin, R.A.; Pacceli da Silva e Souza, T. A New Technology for the Combined Production of Charcoal and Electricity through Cogeneration. Biomass Bioenergy 2014, 69, 222–240. [Google Scholar] [CrossRef]

- Assis, M.R.; Brancheriau, L.; Napoli, A.; Trugilho, P.F. Factors Affecting the Mechanics of Carbonized Wood: Literature Review. Wood Sci. Technol. 2016, 50, 519–536. [Google Scholar] [CrossRef]

- Picchio, R. Guidelines for Wood Carbonization with Mobile Kilns (Linee Guida per la Carbonizazione di Legna con Forni Mobili), Viterbo, 2018.

- Adam, J.C. Improved and More Environmentally Friendly Charcoal Production System Using a Low-Cost Retort-Kiln (Eco-Charcoal). Renew. Energy 2009, 34, 1923–1925. [Google Scholar] [CrossRef]

- Canal, W.D.; Carvalho, A.M.M.; Figueiró, C.G.; de Cássia Oliveira Carneiro, A.; de Freitas Fialho, L.; Donato, D.B. Impact of Wood Moisture in Charcoal Production and Quality. Floresta Ambiente 2020, 27, e20170999. [Google Scholar] [CrossRef]

- Sparrevik, M.; Cornelissen, G.; Sparrevik, M.; Adam, C.; Martinsen, V.; Cornelissen, G.; Cornelissen, G. Emissions of Gases and Particles from Charcoal/Biochar Production in Rural Areas Using Medium-Sized Traditional and Improved “Retort” Kilns. Biomass Bioenergy 2015, 72, 65–73. [Google Scholar] [CrossRef]

- Kumar, R.; Gunjal, J.; Chauhan, S. Effect of Carbonization Temperature on Properties of Natural Fiber and Charcoal Filled Hybrid Polymer Composite. Compos. B Eng. 2021, 217, 108846. [Google Scholar] [CrossRef]

- Wang, L.; Skreiberg, Ø.; Van Wesenbeeck, S.; Grønli, M.; Antal, M.J. Experimental Study on Charcoal Production from Woody Biomass. Energy Fuels 2016, 30, 7994–8008. [Google Scholar] [CrossRef]

- Costa, A.C.P.R.; Ramalho, F.M.G.; Ribeiro, L.C.; Trugilho, P.F.; Hein, P.R.G. Classification of Commercial Charcoal for Domestic Use by Near Infrared Spectroscopy. Biomass Bioenergy 2019, 127, 105280. [Google Scholar] [CrossRef]

- Antal, M.J.; Grønli, M. The Art, Science, and Technology of Charcoal Production. Ind. Eng. Chem. Res. 2003, 42, 1619–1640. [Google Scholar] [CrossRef]

- Kammen, D.M.; Lew, D.J. Review of Technologies for the Production and Use of Charcoal; Energy and Resources Group & Goldman School of Public Policy, University of California: Berkeley, CA, USA, 2005. [Google Scholar]

- Charvet, F.; Silva, F.; Ruivo, L.; Tarelho, L.; Matos, A.; da Silva, J.F.; Neves, D. Pyrolysis Characteristics of Undervalued Wood Varieties in the Portuguese Charcoal Sector. Energies 2021, 14, 2537. [Google Scholar] [CrossRef]

- Dias Júnior, A.F.; Pirola, L.P.; Takeshita, S.; Lana, A.Q.; Brito, J.O.; de Andrade, A.M. Higroscopicity of Charcoal Produced in Different Temperatures. Cerne 2016, 22, 423–430. [Google Scholar] [CrossRef]

- Dufourny, A.; Van De Steene, L.; Humbert, G.; Guibal, D.; Martin, L.; Blin, J. Influence of Pyrolysis Conditions and the Nature of the Wood on the Quality of Charcoal as a Reducing Agent. J. Anal. Appl. Pyrolysis 2019, 137, 1–13. [Google Scholar] [CrossRef]

- Solar, J.; Caballero, B.M.; De Marco, I.; López-Urionabarrenechea, A.; Gastelu, N. Optimization of Charcoal Production Process from Woody Biomass Waste: Effect of Ni-Containing Catalysts on Pyrolysis Vapors. Catalysts 2018, 8, 191. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Prussi, M.; Nistri, R.; Pettorali, M.; Rizzo, A.M. Biomass Carbonization: Process Options and Economics for Small Scale Forestry Farms. Energy Procedia 2014, 61, 1515–1518. [Google Scholar] [CrossRef]

- Dias Junior, A.F.; Esteves, R.P.; da Silva, Á.M.; Sousa Júnior, A.D.; Oliveira, M.P.; Brito, J.O.; Napoli, A.; Braga, B.M. Investigating the Pyrolysis Temperature to Define the Use of Charcoal. Eur. J. Wood Wood Prod. 2020, 78, 193–204. [Google Scholar] [CrossRef]

- Tintner, J.; Fierlinger, R.; Gerzabek, H.; Pfeifer, C.; Smidt, E. Pyrolysis Profiles of a Traditional Circular Kiln in Austria and a Drum Kiln in Namibia. J. Anal. Appl. Pyrolysis 2020, 150, 104865. [Google Scholar] [CrossRef]

- Neves, D.; Charvet, F.R.; Ruivo, L.; Matos, M.A.A.; Tarelho, L.; da Silva, F.J. Current Practices of Charcoal Production in Southern Portugal: A Case-Study in a Large Production Site. In Proceedings of the 29th European Biomass Conference and Exhibition, Online, 26–29 April 2021. [Google Scholar]

- Mencarelli, A.; Cavalli, R.; Greco, R. Variability on the Energy Properties of Charcoal and Charcoal Briquettes for Barbecue. Heliyon 2022, 8, e10052. [Google Scholar] [CrossRef]

- EN 1860-2:2023; Appliances, Solid Fuels and Firelighters for Barbecueing—Part 2: Barbecue Charcoal and Barbecue Charcoal Briquettes-Requirements and Test Methods. European Standard: Plzen, Czech Republic, 2023.

- Jelonek, Z.; Drobniak, A.; Mastalerz, M.; Jelonek, I. Environmental Implications of the Quality of Charcoal Briquettes and Lump Charcoal Used for Grilling. Sci. Total Environ. 2020, 747, 141267. [Google Scholar] [CrossRef]

- Mencarelli, A.; Greco, R.; Balzan, S.; Grigolato, S.; Cavalli, R. Charcoal-Based Products Combustion: Emission Profiles, Health Exposure, and Mitigation Strategies. Environ. Adv. 2023, 13, 100420. [Google Scholar] [CrossRef]

- EN ISO 18122:2022; Solid Biofuels—Determination of Ash Content. ISO: Geneva, Switzerland, 2022.

- EN ISO 18134-2:2017; Solid Biofuels—Determination of Moisture Content. Oven Dry Method. Total Moisture. Simplified Method. ISO: Geneva, Switzerland, 2017.

- EN ISO 18123:2023; Solid Biofuels—Determination of Volatile Matter. ISO: Geneva, Switzerland, 2023.

- EN ISO 18125:2017; Solid Biofuels—Determination of Calorific Value. ISO: Geneva, Switzerland, 2017.

- EN ISO 17828:2015; Solid Biofuels—Determination of Bulk Density 2015. ISO: Geneva, Switzerland, 2015.

- EN ISO 16948:2015; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. ISO: Geneva, Switzerland, 2015.

- Benatti, A.; Bal, M.; Allée, P.; Bosi, G.; Dallai, D.; Mercuri, A.M. Charcoal Kilns in the Northern Apennines (Italy): Forest Exploitation by Past Societies in Mountain Areas. IANSA 2018, 9, 169–178. [Google Scholar] [CrossRef]

- Carrari, E.; Ampoorter, E.; Bottalico, F.; Chirici, G.; Coppi, A.; Travaglini, D.; Verheyen, K.; Selvi, F. The Old Charcoal Kiln Sites in Central Italian Forest Landscapes. Quat. Int. 2017, 458, 214–223. [Google Scholar] [CrossRef]

- Menemencioglu, K. Traditional Wood Charcoal Production Labour in Turkish Forestry (Çankırı Sample). J. Food Agric. Environ. 2013, 11, 1136–1142. [Google Scholar]

- Berrocal-Mendéz, N.; Moya, R. Production, Cost and Properties of Charcoal Produced after Logging and Sawing, by the Earth Pit Method from Tectona Grandis Wood Residues. J. Indian Acad. Wood Sci. 2022, 19, 121–132. [Google Scholar] [CrossRef]

- Di Fazio, S.; Laudari, L.; Modica, G. Heritage Interpretation and Landscape Character in the Forestry District of Serra San Bruno (Calabria, Italy). In Proceedings of the XVIIth World Congress of the International Commission of Agricultural Engineering (CIGR), Québec City, QC, Canada, 13–17 June 2010. [Google Scholar]

- Foley, G. Charcoal Making in Developing Countries; Earthscan Pubns Ltd.: London, UK, 1986. [Google Scholar]

- Picchio, R.; Venanzi, R.; Lo Monaco, A.; Tocci, D.; Di Marzio, N.; Mercurio, R. Diversification of Production and By-Products. In The Fruit Chestnut. Ecology, Parasitic Adversities, Innovative Mechanization; 2022; pp. 110–126.

- Rizzo, A.M.; Pettorali, M.; Nistri, R.; Chiaramonti, D. Mass and Energy Balances of an Autothermal Pilot Carbonization Unit. Biomass Bioenergy 2019, 120, 144–155. [Google Scholar] [CrossRef]

- Rizzo, A.M.; Pettorali, M.; Prussi, M.; Nistri, R.; Pari, L.; Chiaramonti, D. Integration of SRF and Carbonization Plant for Small Forestry Farms. Energy Procedia 2017, 105, 212–217. [Google Scholar] [CrossRef]

- Casini, D.; Barsali, T.; Rizzo, A.M.; Chiaramonti, D. Production and Characterization of Co-Composted Biochar and Digestate from Biomass Anaerobic Digestion. Biomass Convers. Biorefinery 2021, 11, 2271–2279. [Google Scholar] [CrossRef]

- Duan, D.; Chen, D.; Huang, L.; Zhang, Y.; Zhang, Y.; Wang, Q.; Xiao, G.; Zhang, W.; Lei, H.; Ruan, R. Activated Carbon from Lignocellulosic Biomass as Catalyst: A Review of the Applications in Fast Pyrolysis Process. J. Anal. Appl. Pyrolysis 2021, 158, 105246. [Google Scholar] [CrossRef]

- Straka, T.J. Historic Charcoal Production in the US and Forest Depletion: Development of Production Parameters. Adv. Hist. Stud. 2014, 03, 104–114. [Google Scholar] [CrossRef][Green Version]

- de Miranda, R.C.; Bailis, R.; de Oliveira Vilela, A. Cogenerating Electricity from Charcoaling: A Promising New Advanced Technology. Energy Sustain. Dev. 2013, 17, 171–176. [Google Scholar] [CrossRef]

- Bailis, R.; Rujanavech, C.; Dwivedi, P.; de Oliveira Vilela, A.; Chang, H.; de Miranda, R.C. Innovation in Charcoal Production: A Comparative Life-Cycle Assessment of Two Kiln Technologies in Brazil. Energy Sustain. Dev. 2013, 17, 189–200. [Google Scholar] [CrossRef]

- Dias Júnior, A.F.; Andrade, C.R.; Milan, M.; Brito, J.O.; de Andrade, A.M.; de Souza, N.D. Quality Function Deployment (QFD) Reveals Appropriate Quality of Charcoal Used in Barbecues. Sci. Agric. 2020, 77, e20190021. [Google Scholar] [CrossRef]

- Wang, L.; Barta-Rajnai, E.; Hu, K.; Higashi, C.; Skreiberg, O.; Grønli, M.; Czégény, Z.; Jakab, E.; Myrvågnes, V.; Várhegyi, G.; et al. Biomass Charcoal Properties Changes during Storage. Energy Procedia 2017, 105, 830–835. [Google Scholar] [CrossRef]

- Drobniak, A.; Jelonek, Z.; Mastalerz, M.; Jelonek, I. Atlas of Charcoal-Based Grilling Fuel Components. Indian J. Earth Sci. 2021, 3, 1–6. [Google Scholar] [CrossRef]

- Guo, Z.; Guo, F.; Guo, Y.; Miao, Z.; Feng, Y.; Wu, J.; Zhang, Y. Preparation of Barbecue Charcoal Using Residue Produced after Biomass Gasification and Pollutant Emission Test during Combustion. J. Environ. Chem. Eng. 2022, 10, 107074. [Google Scholar] [CrossRef]

- Dias Júnior, A.F.; Andrade, C.R.; Lana, A.Q.; da Silva, Á.M.; Brito, J.O.; Milan, M. Tips on the Variability of BBQ Charcoal Characteristics to Assist Consumers in Product Choice. Eur. J. Wood Wood Prod. 2021, 79, 1017–1026. [Google Scholar] [CrossRef]

- Tintner, J.; Preimesberger, C.; Pfeifer, C.; Soldo, D.; Ottner, F.; Wriessnig, K.; Rennhofer, H.; Lichtenegger, H.; Novotny, E.H.; Smidt, E. Impact of Pyrolysis Temperature on Charcoal Characteristics. Ind. Eng. Chem. Res. 2018, 57, 15613–15619. [Google Scholar] [CrossRef]

- GIZ. Towards Sustainable Modern Wood Energy Development. Stocktaking Paper on Successful Initiatives in Developing Countries in the Field of Wood Energy Development; Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ): Bonn, Germany, 2014. [Google Scholar]

- Vis, M.; Uitdewilligen, L.; Vos, J. Charcoal Production from Alternative Feedstocks; NL Agency—Ministry of Economic Affairs: Utrecht, The Netherlands, 2013. [Google Scholar]

- Zanli, B.L.G.L.; Gbossou, K.C.; Tang, W.; Kamoto, M.; Chen, J. A Review of Biochar Potential in Cote d’Ivoire in Light of the Challenges Facing Sub-Saharan Africa. Biomass Bioenergy 2022, 165, 106581. [Google Scholar] [CrossRef]

- Qureshi, K.M.; Kay Lup, A.N.; Khan, S.; Abnisa, F.; Wan Daud, W.M.A. A Technical Review on Semi-Continuous and Continuous Pyrolysis Process of Biomass to Bio-Oil. J. Anal. Appl. Pyrolysis 2018, 131, 52–75. [Google Scholar] [CrossRef]

- Oyedun, A.O.; Lam, K.L.; Gebreegziabher, T.; Hui, C.W. Optimization of Multi-Stage Pyrolysis. Appl. Therm. Eng. 2013, 61, 123–127. [Google Scholar] [CrossRef]

- Cheung, K.Y.; Lee, K.L.; Lam, K.L.; Chan, T.Y.; Lee, C.W.; Hui, C.W. Operation Strategy for Multi-Stage Pyrolysis. J. Anal. Appl. Pyrolysis 2011, 91, 165–182. [Google Scholar] [CrossRef]

- García-Quezada, J.; Musule-Lagunes, R.; Prieto-Ruíz, J.A.; Vega-Nieva, D.J.; Carrillo-Parra, A. Evaluation of Four Types of Kilns Used to Produce Charcoal from Several Tree Species in Mexico. Energies 2023, 16, 333. [Google Scholar] [CrossRef]

- Valentim, A.R.; Behainne, J.R.; Junior, A.B. Thermal Performance Analysis of Materials and Configurations for Cylindrical Sidewalls of Charcoal Kilns. Energies 2022, 15, 5872. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).