1. Introduction

The transition towards carbon neutrality and peak carbon emissions has emerged as the pivotal trajectory guiding global energy development. Among the array of primary energy sources, natural gas, lauded for its environmentally friendly attributes, has garnered significant attention and promotion in China’s energy matrix. Over the past two decades, China has witnessed an exponential surge in natural gas consumption. In 2005, the consumption stood at 46.8 billion cubic meters, soaring to 194.7 billion cubic meters in 2015, and further reaching 375.7 billion cubic meters in 2022. During this period, the contribution of natural gas to China’s primary energy consumption burgeoned from 2.4% in 2005 to 8.4% in 2022 [

1].

Figure 1 shows the consumption of natural gas in China from 2011 to 2022, with an average growth rate of 9.86%. The trend underscores the tremendous potential natural gas holds in China’s energy market. However, this promising outlook is accompanied by intricacies stemming from regional disparities in production and consumption. While the primary natural gas reserves are concentrated in the southwestern regions of China, the major centers of consumption are dispersed across the southeastern provinces. Furthermore, pronounced seasonality characterizes natural gas consumption, with demand surging during winter, sometimes exceeding summer usage by ratios exceeding 10:1, as observed in Beijing. Large-scale natural gas storage facilities emerge as a crucial element in maintaining a stable supply of natural gas [

2].

Rock salt, characterized by favorable rheology [

4,

5], ultra-low permeability [

6,

7], and self-healing property [

8], have gained attention as ideal reservoirs for CO

2 geologic storage, hydrocarbon underground reserves, and underground waste disposal [

9,

10,

11]. Salt cavern UGS employs water solution mining techniques to create caverns within deep geological formations of salt rock. Freshwater is injected into the salt layer through wells, dissolving the salt rock in the process, and brine is subsequently extracted. This cyclic process continues, leading to the gradual dissolution of the underground salt layer and the formation of a cavern. Finally, a debring process is carried out through gas injection and brine removal to store natural gas within the salt cavern [

12], as shown in

Figure 2a. However, layered salt rock formations are prevalent in China, often exhibiting a typical interlayered structure with rock layers such as mudstone, dolomite, and anhydrite [

13]. During the construction of salt caverns, exceeding a certain threshold of exposed interlayer surface area can result in collapse [

14]. Fragments of these interlayers accumulate at the cavern base, forming what is referred to as sediment. In the case of the Dawenkou salt mine in China, for example, the cumulative thickness of the interlayers can account for up to 50% of the thickness of the salt-bearing strata, and when the bulking-expansion effect is taken into account [

15], the accumulation volume of the sediment can even exceed 80% of the volume of the salt cavern. From the experience of traditional salt cavern UGSs, the volume filled with sediment is rendered unusable. Consequently, to minimize the volume occupied by sediment, it is generally recommended to establish salt cavern UGSs within salt-bearing formations with as low an interlayer proportion as possible. In order to overcome the limitations imposed by geological conditions on salt cavern UGS construction, the concept of utilizing the voids within the sediment for natural gas storage has been proposed. In this approach, the debring process still involves injecting gas and removing brine, but due to the hindrance posed by the sediment, the brine removal process must rely on a well directly connected to the base of the salt cavern, as depicted in

Figure 2b.

A large number of scholars have carried out studies on the stability of underground caves under various conditions [

16,

17,

18]. Studies on the effect of filled bulk on the stability of the surrounding rock are common in the field of mining [

19,

20]. It is generally accepted that force transfer between the filled bulk and the surrounding rock is achieved through point contact and that the bulk increases the stability of the surrounding rock. Similarly, sediment is generally believed to suppress the creep contraction of salt caverns due to the support it provides to the surrounding rock. Similarly, it is this aspect that suggests sediment-filled salt cavern UGS could potentially reduce the minimum internal gas pressure of salt cavern, thus enhancing UGS operational capabilities. In summary, sediment is thought to influence the stability of salt cavern, yet targeted research in this area is lacking. Presently, research on sediment within salt caverns primarily focuses on characterizing the physical state of sediment. For instance, Li et al. [

21] employed fractal theory to predict the porosity of insoluble materials, observing that porosity decreases with an increase in fractal dimension. Zheng et al. [

22] found that the porosity of accumulated insoluble materials was approximately 50% and conducted simulation experiments to demonstrate the drainage of brine from sediment voids. Li et al. [

23] employed a coupled model to analyze interlayer failure patterns and sediment accumulation forms. Liang et al. [

24] proposed a method for predicting sediment void volume based on brine compression and salt cavern deformation. However, research on the stability of sediment-filled salt caverns remains limited. In previous stability assessments of salt cavern UGS, the effect of sediment on caverns was often simplified as fluid pressure applied to the interior walls of the salt cavern or the shape and size of sediment were entirely neglected and simplified as spheres [

25]. These simplifications hinder a realistic portrayal of the interaction between sediment and salt cavern, thus preventing an accurate assessment of sediment’s impact on cavern stability.

To investigate the influence of sediment on salt cavern stability, we first examined the interaction process between sediment and salt cavern, identifying the conditions for equilibrium in this process. Furthermore, a new method for modeling sediment-filled salt caverns using the discrete element software 3DEC 5.0 is presented. The sediment and salt caverns are modeled as rigid and deformable blocks, respectively. We utilized an ellipsoidal elemental framework to simulate sediment blocks, meeting the desired requirements for simulation. We separately simulated the 30-year operation of salt cavern UGS without sediment and sediment-filled salt cavern UGS at various internal gas pressures using 3DEC. We compared and analyzed the impact of sediment on salt cavern stability using five indicators: deformation, effective volume contraction rate, plastic zone, equivalent strain, and safety factor. The results demonstrate that sediment can effectively inhibit cavern volume contraction, reduce the cavern’s plastic zone, and improve the creep damage and expansion failure phenomena in salt rock during operation. In conclusion, sediment-filled salt cavern UGS offers a more stable and secure gas storage condition compared to salt cavern UGS without sediment. This study contributes as a reference for the stability assessment of sediment-filled salt cavern UGS.

2. Interaction between Sediment and Salt Cavern

Salt rock exhibits remarkable rheological behavior, manifesting creep phenomena when there is non-zero deviatoric stress within the salt rock. Traditional salt cavern UGS relies on adjusting internal gas pressure to control the ultimate deformation of caverns during their design service life. The internal gas pressure diminishes the deviatoric stress within the cavern rock, resulting in smaller creep deformation over the specified time period. Internal gas pressure merely imparts a fixed force to the surrounding rock, rendering it a flexible constraint on cavern deformation. In contrast, sediment within the cavern can be considered a rigid constraint. Sediment transmits force to the cavern rock through contact (as depicted in

Figure 3), and the interaction between sediment and the salt cavern changes as both entities deform. Moreover, as an actual entity within the cavern, sediment establishes a definitive boundary for cavern deformation. This boundary is reached when the cavern contracts to a point where further compression of sediment is not feasible. At this juncture, both the force and displacement between sediment and the cavern achieve a stable state. These are the primary characteristics of deformation in sediment-filled salt caverns.

The spatial arrangement of sediment particles dictates the upper limit of external pressure it can withstand, termed the system resistance of sediment. We denote the existing system resistance of sediment as

. This is due to the overall compressive force exerted on sediment resulting from cavern contraction, denoted as

. Rock salt creep is governed by deviatoric stress, represented by

, the in-situ stress of salt rock. Given the reduction in deviatoric stress within the salt rock due to sediment support, represented by

, the interplay between sediment and the cavern can be visually illustrated through a process diagram, as depicted in

Figure 4.

3. Computational Principles

In this paper, the simulation of sediment-filled salt caverns is carried out using 3DEC, a 3-dimensional discrete element method software. 3DEC is widely used in the analysis of rock engineering projects and is particularly suited to the study of potential damage patterns directly related to discontinuity features. The basic unit in 3DEC is the block, which can be either rigid or deformable (by subdivision into elements). There are 20 built-in material models available for deformable blocks, including creep models, shear yield models, etc. 3DEC is based on a dynamic (time-domain) algorithm that solves the equations of motion of the block system by an explicit finite difference method.

In this paper, we simulate the sediment using rigid blocks, and the surrounding rock of the salt cavern is simulated with deformable blocks, whose deformation is controlled by the creep constitutive equations, which mainly take into account the remarkable rheological property of the rock salt. The basic logic of 3DEC for computing the motion of rigid blocks, deformable blocks and the interaction between different blocks through contact is briefly described, which references the manuscript of 3DEC [

26].

3.1. Motion of a Rigid Block

The translational and rotational equations of motion for a single block can be expressed as Equation (1) and Equation (2), respectively.

where

the acceleration of the block centroid,

take the values 1 to 3, and denote components of a vector or tensor in the global coordinate system;

the velocity of the block centroid;

the viscous (mass-proportional) damping constant;

sum of forces acting on the block (from block contacts and applied external forces);

is the block mass; and

is the gravity acceleration vector,

is the angular velocity of the

-axis,

is the angular accelerations of the

-axis,

is a component of torque of the

-axis applied to the block,

is the moment of inertia of the block.

A central finite-difference procedure is used to integrate the equations of motion. Then the translational and rotational velocities of the block at time

can be expressed by Equation (3):

Equation (4) represents the translational and angular acceleration of the block:

The velocities at time

can be obtained via Equations (1)–(4). Further, the increment of translation

and increment of rotation

are given by Equation (5):

The position of the block centroid is updated as Equation (6):

The new locations of the block vertices are given by Equation (7):

where,

is the value of the coordinates of the vertex

at moment

,

is the permutation matrix,

are the coordinates of the centroid of the block,

,

take the values 1 to 3, and denote components of a vector or tensor.

3.2. Motion of a Deformable Block

The vertices of the tetrahedral elements are gridpoints, and the equations of motion for each gridpoint are formulated as:

where

is the surface enclosing the mass

, lumped at the gridpoint;

is the unit normal to

;

is the resultant of all external forces applied to the gridpoint (from block sub-contacts or otherwise); and

is the gravitational acceleration.

where

is the externally applied force and

is the sub-contact force, which exists only at the gridpoints along the block boundary,

results from the contribution of the internal stresses in the zones adjacent to the gridpoint.

When the force at the node is not zero, the acceleration of the gridpoint is denoted by Equation (10):

within each timestep, the strains and rotations are expressed in terms of the nodal displacement as Equation (11):

The constitutive relations for deformable blocks are used in an incremental form so that implementation on nonlinear problems can be accomplished easily. The actual form of the equations is expressed as Equation (12).

where

and

are the lame constants;

are the elastic increments of the stress tensor;

are the incremental strains;

is the increment of volumetric strain; and

is the Kronecker delta function.

3.3. Interaction between Blocks

At each time step, the laws of motion and constitutive equations are applied. Sub-contact force-displacement relationships are specified for both rigid and deformable blocks. Integration of the laws of motion provides the new block position and, therefore, the contact displacement increment (or velocity). The new sub-contact force is then obtained using the sub-contact force-displacement law and applied to the block in the next timestep. The mechanical calculation cycle is shown in

Figure 5.

The interaction between blocks relies on contact. The first thing that needs to be known is the relative velocity of the motions of block A and block B when contact occurs, i.e., the relative contact velocity, which determines the relative displacement increment at the sub-contact in the next time step. For a rigid block, the relative contact velocity can be expressed as Equation (13):

where

,

, are the position vectors of the centers of blocks

and

, respectively, and

is the reference point of the common plane, which is determined by the relative positions of blocks

and

, and is used to judge the contact relationship between

and

.

For deformable blocks, it is necessary to calculate the velocity at the contact using linear interpolation, as shown in Equation (14). To compute the weight factor, the coordinates of the three points on the face need to be transformed into a local reference system, which is located in the face plane. The coordinates of vertex

can be expressed within this coordinate system as

and

.

where,

, The other two factors can be obtained by circular permutation of the superscripts

,

, and

.

The relative velocity of the contact involving the deformable block is expressed as Equation (15):

The contact displacement

can be expressed as Equation (16):

Using the constitutive equations of contact (the elastic constitutive equations are used here as an example), it is possible to calculate the normal and shear force increments at the contact by Equation (17):

The updated normal and shear forces at the sub-contact are expressed as Equation (18):

For a rigid block, the sum of forces and moments is updated, as shown in Equation (19):

For deformable blocks, on the vertex side of the sub-contact, this force is added to the other gridpoint forces. On the face side, the force is distributed among the three vertices (

,

,

), using the interpolation factors defined as Equation (20):

6. Results and Analysis

6.1. Deformation

Controlling deformation is crucial for the safety and gas storage capacity of salt cavern UGS facilities. At present, a common approach to control deformation is by setting an appropriate internal gas pressure for the salt cavern UGS, and it is generally observed that higher gas pressure leads to reduced deformation [

25]. Hence, various internal gas pressures were applied in our study to investigate the influence of sediment on salt cavern deformation.

Figure 8 illustrates the deformation contours of sediment-filled salt cavern UGS and salt cavern UGS without sediment after 30 years of operation under different internal gas pressures. From the simulated results, it is evident that sediment significantly diminishes cavern deformation, particularly at lower internal gas pressures. Monitoring points were placed at the midpoint of the top, bottom, and side walls of the salt cavern, as depicted in

Figure 9.

The restraining effect of sediment on deformation is most prominent at the bottom and side walls of the salt cavern. Under internal pressures of 2 MPa, 6 MPa, 10 MPa, and 14 MPa, the deformation of the bottom center point of the salt cavern without sediment was 22.1 m, 16.3 m, 11 m, and 6.5 m, respectively. In contrast, for the sediment-filled salt cavern under corresponding internal gas pressure conditions, the displacement at the bottom center was 3.8 m, 3.6 m, 3.2 m, and 2.8 m. Thus, the presence of sediment reduced the displacement by 82.8%, 77.9%, 70.9%, and 56.9%, respectively. Similar trends were observed for the side wall center point. For instance, in a salt cavern without sediment, the displacement of the side wall center point at internal gas pressures of 2 MPa, 6 MPa, 10 MPa, and 14 MPa was −26.4 m, −20.2 m, −13.1 m, and −7 m. However, in the sediment-filled cavern, the displacement ranged from −5 m to 4 m, resulting in reductions of 81.1%, 77.7%, 66.4%, and 42.9% compared to the salt cavern without sediment. Moreover, smaller internal gas pressures accentuated the creep phenomenon of the salt cavern, leading to the compression of the sediment, and the increase in the height of the sediment top surface. However, the location of maximum deformation on the side wall of the sediment-filled cavern remained near the height of the sediment top surface. Notably, in the model including sediment, the salt cavern’s top was not filled with sediment. Contrary to the model without sediment, the displacement at the top monitoring point showed no significant reduction. This observation underscores the importance of considering the stability of the unfilled portion in the salt cavern when determining operational pressures for sediment-filled salt cavern UGS. In conclusion, sediment fill effectively mitigates deformation in the sediment-filled portion of the salt cavern, with a more pronounced effect at lower internal gas pressures. This stands as an advantage of sediment-filled salt cavern UGS compared to the conventional salt cavern UGS without sediment.

6.2. Plastic Zone

In the simulation of the two types of salt cavern UGS facilities, we employed the Mohr–Coulomb criterion to assess the development of plastic zones.

Figure 10 illustrates the distribution of plastic zones in the two types of salt cavern UGS facilities after 30 years of operation under different internal pressure conditions. Regardless of the type of salt cavern UGS, the plastic zones decreased as the internal gas pressure increased. However, there is a significant distinction between the distribution of plastic zones between the two types of salt cavern UGS. As evident from

Figure 10g–l, plastic zones are mainly concentrated in the areas that are not filled with sediment. This distinctly indicates that sediment assists in reducing the plastic zones around the salt cavern. To provide a clearer comparison of the impact of sediment on the development of plastic zones in salt cavern UGS, we plotted the ratio of plastic zone volume to salt cavern volume (RPC), as shown in

Figure 11.

The trend in the development of the RPC is consistent for both types of salt cavern UGS facilities. It experiences an initial rapid growth phase, followed by a gradual slowdown in the growth rate, eventually reaching a relatively stable RPC level. Evidently, under different internal gas pressure conditions, particularly lower internal gas pressures, the sediment-filled cavern UGS exhibits a significantly lower final RPC compared to the unfilled salt cavern UGS. At internal gas pressures of 2 MPa, 6 MPa, 10 MPa, and 14 MPa after 30 years of operation, the RPC for the unfilled salt cavern UGS is 2.07, 1.88, 1.58, and 0.93, respectively. In contrast, under the same conditions, the RPC for the sediment-filled cavern UGS is 0.74, 0.71, 0.59, and 0.48. The percentage reduction in RPC is 64.3%, 62.2%, 62.7%, and 48.4%, respectively. Furthermore, for the established sediment-filled cavern UGS, the time taken to reach a stable RPC is notably shorter. As indicated in

Figure 11, under various simulated internal gas pressure conditions, the sediment-filled cavern UGS takes approximately 5 years to achieve a stable RPC, while the unfilled cavern UGS requires around 10 years.

In summary, sediment fill aids in controlling the development of plastic zones in the surrounding rock of salt cavern. This not only significantly reduces the volume of plastic zones but also accelerates the sediment-filled cavern UGS toward a stable development stage of plastic zones compared to the unfilled cavern UGS.

6.3. Shrinkage of Effective Volume

Rock salt exhibits pronounced creep characteristics, and under the influence of in-situ stresses, the volume of salt cavern UGS facilities will continue to contract. The volume of the salt cavern dictates its operational capacity; excessive volume contraction can severely undermine its economic viability and safety. In sediment-filled salt cavern UGS, gas is mainly stored in the voids between sediment particles. Therefore, we define the volume inside the salt cavern, excluding the sediment, as the effective gas storage volume. For unfilled salt cavern UGS, the effective volume is equivalent to the cavern’s volume. We define the reduction in effective volume within the salt cavern and its initial effective volume ratio as the effective volume shrinkage ratio.

Figure 12 presents the effective volume changes over 30 years for the two types of salt cavern UGS facilities under varying internal gas pressures. The curves depicting the change in effective volume over time exhibit a pattern of rapid decline followed by stabilization. At the same internal pressure, the effective volume shrinkage ratio of the sediment-filled salt cavern UGS is consistently lower than that of the unfilled salt cavern UGS. However, the difference in effective volume shrinkage ratio between the two diminishes with increasing internal gas pressure. As the internal gas pressure approaches the in-situ stress of the salt cavern’s surrounding rock, the effective volume shrinkage ratios of the two types gradually converge.

For instance, at internal pressures of 2 MPa, 6 MPa, 10 MPa, 14 MPa, 18 MPa, and 22 MPa, the effective volume shrinkage ratios for the sediment-filled salt cavern UGS and the unfilled salt cavern UGS are 56.8%, 49.5%, 41.7%, 29.9%, 17.7%, 7.4%, and 84.4%, 71.2%, 53.2%, 33.5%, 17.5%, 7.4%, respectively. This indicates that even at lower internal gas pressures, sediment can still assist in restraining the shrinkage of the effective volume within the salt cavern, and this effect becomes more pronounced with decreasing internal gas pressure. Furthermore, after undergoing a rapid volume shrinkage phase, the growth in the effective volume shrinkage ratio of sediment-filled salt cavern UGS is slower compared to unfilled salt cavern UGS due to the restraining influence of sediment on cavern deformation. This implies that sediment-filled caverns can achieve a more stable effective volume level more quickly. For salt cavern UGS, this characteristic is highly advantageous for extending the lifespan of salt cavern UGS, maintaining relatively stable operational capacity over an extended period, and enhancing economic viability.

6.4. Equivalent Strain

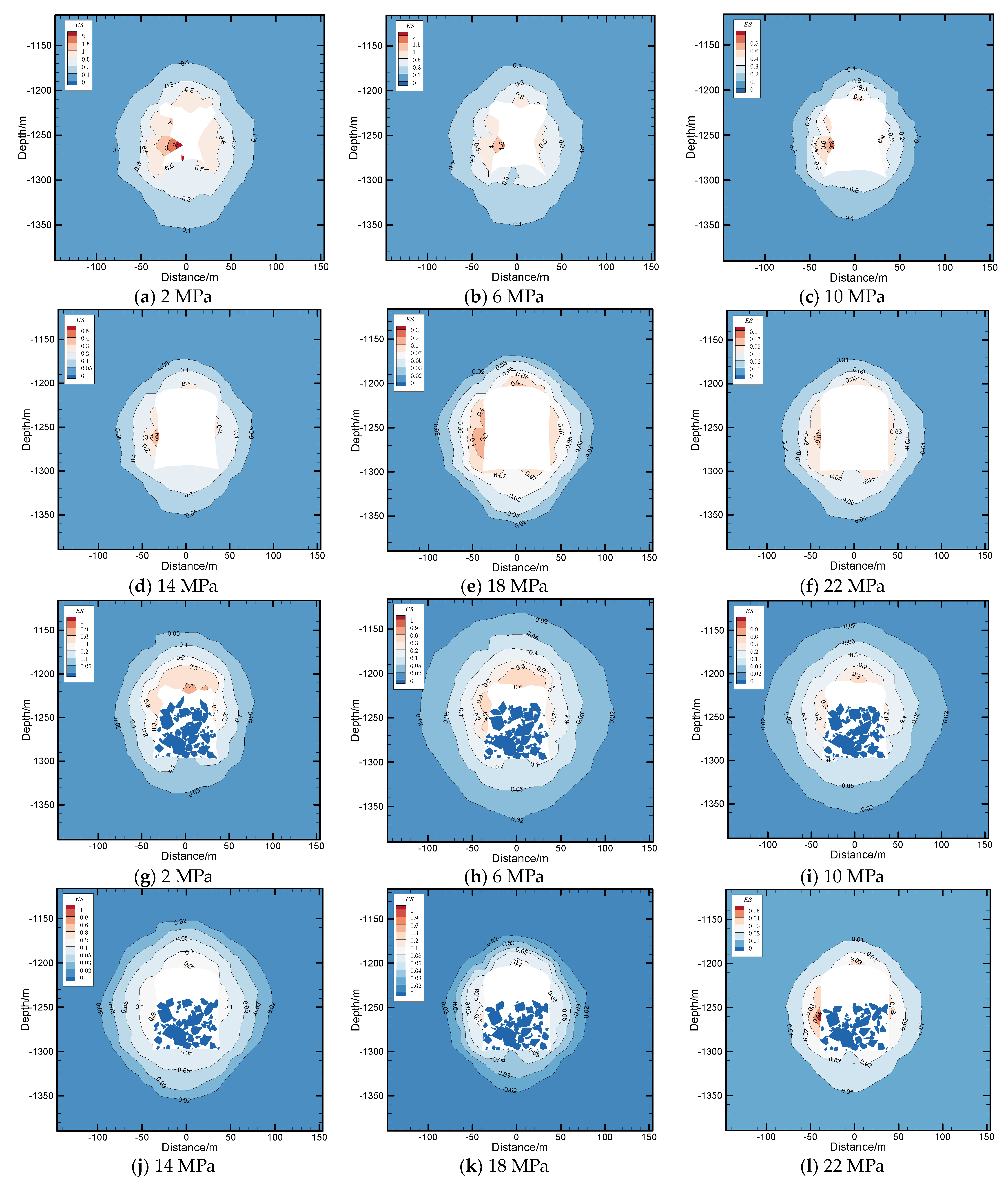

The equivalent strain contours, presented in

Figure 13, offer valuable insights into the behavior of the two types of salt cavern UGS after 30 years of operation. For the unfilled salt cavern UGS, prominent zones of elevated equivalent strain are evident around the cavern, with the top and mid-sections of the cavern walls exhibiting relatively higher equivalent strain values compared to other areas. The maximum equivalent strain occurs slightly below the center of the cavern wall. Notably, as the internal gas pressure increases, there is a corresponding decrease in the overall equivalent strain. In this context, elevating the internal gas pressure remains the sole strategy for mitigating equivalent strain around the cavern periphery in the case of unfilled salt cavern UGS. However, it is important to acknowledge that this approach concurrently results in a reduction in the operational gas capacity of the salt cavern UGS.

In contrast, the equivalent strain contours for sediment-filled salt cavern UGS reveal distinct behaviors. Under varying internal gas pressures, larger regions of equivalent strain primarily encompass areas around the salt cavern that do not directly interface with sediment. Specifically, the cavern’s top section consistently demonstrates considerable equivalent strain. On the salt cavern walls in contact with sediment, the equivalent strain values progressively decrease as sediment depth increases. Remarkably, the location of the maximum equivalent strain aligns closely with the top surface of the sediment. This observation underscores the vital role of sediment in providing effective support to balance deviatoric stresses within the surrounding rock, consequently leading to reduced strain in the rock directly interfacing with the sediment.

Consequently, for sediment-filled salt cavern UGS, a focal point should be the safety of regions outside the sediment-filled zone. This consideration takes precedence when designing the minimum internal gas pressure for the cavern. Decreasing internal gas pressure implies greater compression on the sediment. As the sediment’s top surface rises, the position of maximum equivalent strain on the cavern wall also ascends. In scenarios where potential weak layers, such as micro-permeable interlayers, exist within the cavern’s depth range, it is imperative to mitigate the occurrence of maximum equivalent strain in such areas. This concern is paramount when crafting the design of sediment-filled salt cavern UGS.

6.5. Safety Factor

Figure 14 illustrates the safety factor (SF) contours for unfilled salt cavern UGS and sediment-filled salt cavern UGS after 30 years of operation under varying internal gas pressures. Previous studies have indicated that SF < 1.5 signifies localized damage, SF < 1.0 denotes material failure, and SF < 0.6 indicates the onset of collapse [

35]. The SF contours reveal that the bottoms of unfilled salt cavern UGS consistently exhibit the lowest SF values, a phenomenon particularly pronounced with lower internal gas pressures. At an internal gas pressure of 2 MPa, extensive collapse areas have already emerged at the cavern bottom after 30 years of operation. While increasing internal gas pressure significantly enhances SF within the surrounding rock, this comes at the cost of sacrificing the gas-supplying capacity of the salt cavern UGS.

Figure 14g–l showcases the safety factor contours for sediment-filled salt cavern UGS under different internal pressures after 30 years of operation. It is evident that sediment exerts a substantial influence on the SF of the cavern’s surrounding rock. Regions filled with sediment exhibit SF predominantly exceeding 1.5, implying that sediment inhibits the dilatant behavior of the adjacent salt rock.

This observation underscores sediment’s role in curtailing the escalation of damage resulting from salt rock deformation. Preserving the low permeability of the salt rock and maintaining the sealing integrity of the cavern are highly advantageous consequences of sediment-induced suppression of salt rock deformation and associated damage. This further affirms the positive influence of sediment in bolstering the stability of sediment-filled salt cavern UGS, emphasizing their potential for enhancing both safety and gas-storage efficiency.