Experimental Investigation of IOR Potential in Shale Oil Reservoirs by Surfactant and CO2 Injection: A Case Study in the Lucaogou Formation

Abstract

:1. Introduction

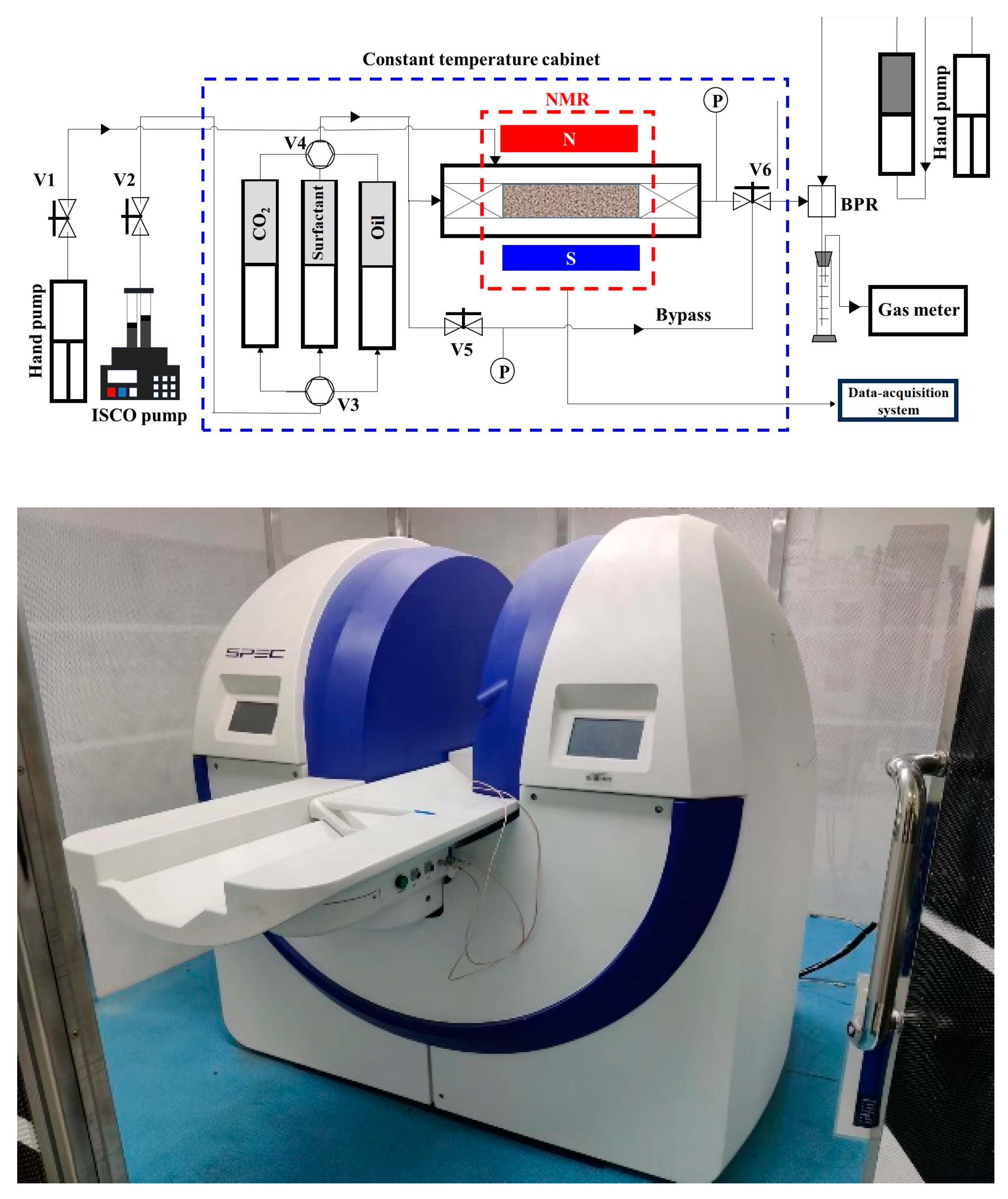

2. Methodology

2.1. Experimental Materials

2.1.1. Core Samples

2.1.2. Surfactant

2.2. Experimental Methods

2.3. Experimental Procedure

- (1)

- The sample was placed into a core holder. The outlet end of the core holder was connected with the back-pressure valve. And the core pore pressure is increased to 15 MPa by pump under the condition of formation temperature.

- (2)

- For one-step depletion development, the outlet pressure of the core was reduced to atmospheric pressure at one time, and the T2 spectrum of samples was tested by the NMR online displacement system.

- (3)

- For multi-step depletion development, the pressure was reduced by one-third at a time until the outlet pressure was reduced to atmospheric pressure. Each stage was maintained for 30 min.

- (4)

- When the core sample was replaced, the pressure changed to 20 MPa and 30 MPa, respectively. Steps (2) and (3) were repeated to analyze the influence of different reservoir pressure on one-step depletion development.

- (5)

- Under the condition of reservoir temperature, the core pore pressure is controlled to 20 MPa. Further, 0.2 PV of supercritical CO2 was injected by a high-pressure constant speed pump for X3 and S70. The injection rate of CO2 was 0.05 mL/min, and 0.2% AES surfactant was injected for X2 and S9. Then, the pressure was sustained for a duration of two hours.

- (6)

- The injection port was opened. After the oil in the rocks was no longer produced, the NMR T2 signals were measured. The NMR imaging of X2 and X3 was measured.

- (7)

- Procedures (1) and (2) were repeated. NMR T2 and imaging signals were measured in different cycles. This experiment comprised a total of four cycles.

- (8)

- After four stages of CO2 huff-n-puff for S70, three more cycles of surfactant imbibition were conducted. And for S9, three more cycles of CO2 huff-n-puff were conducted.

3. Results and Discussion

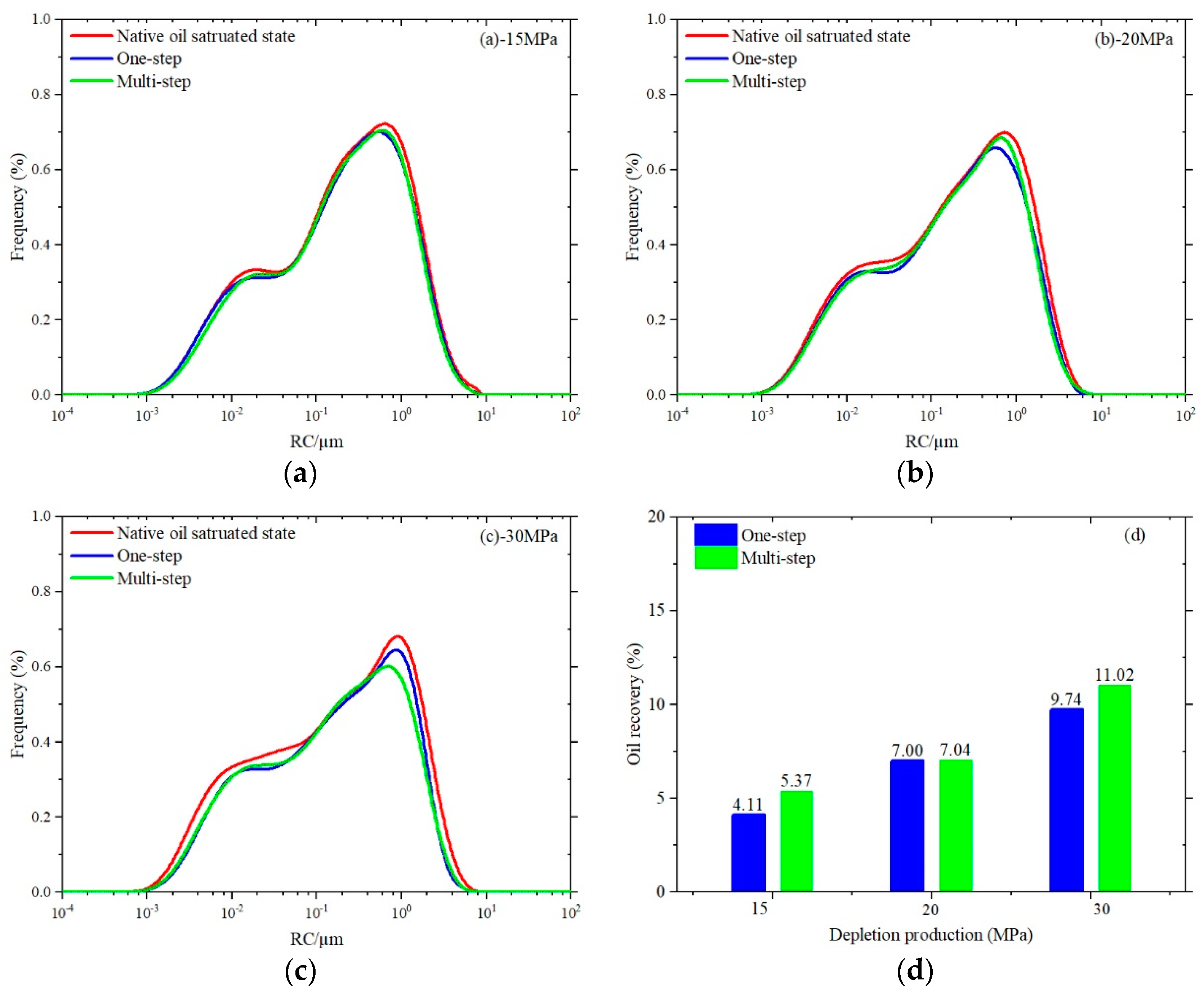

3.1. Performance of One-Step and Multi-Step Depletion

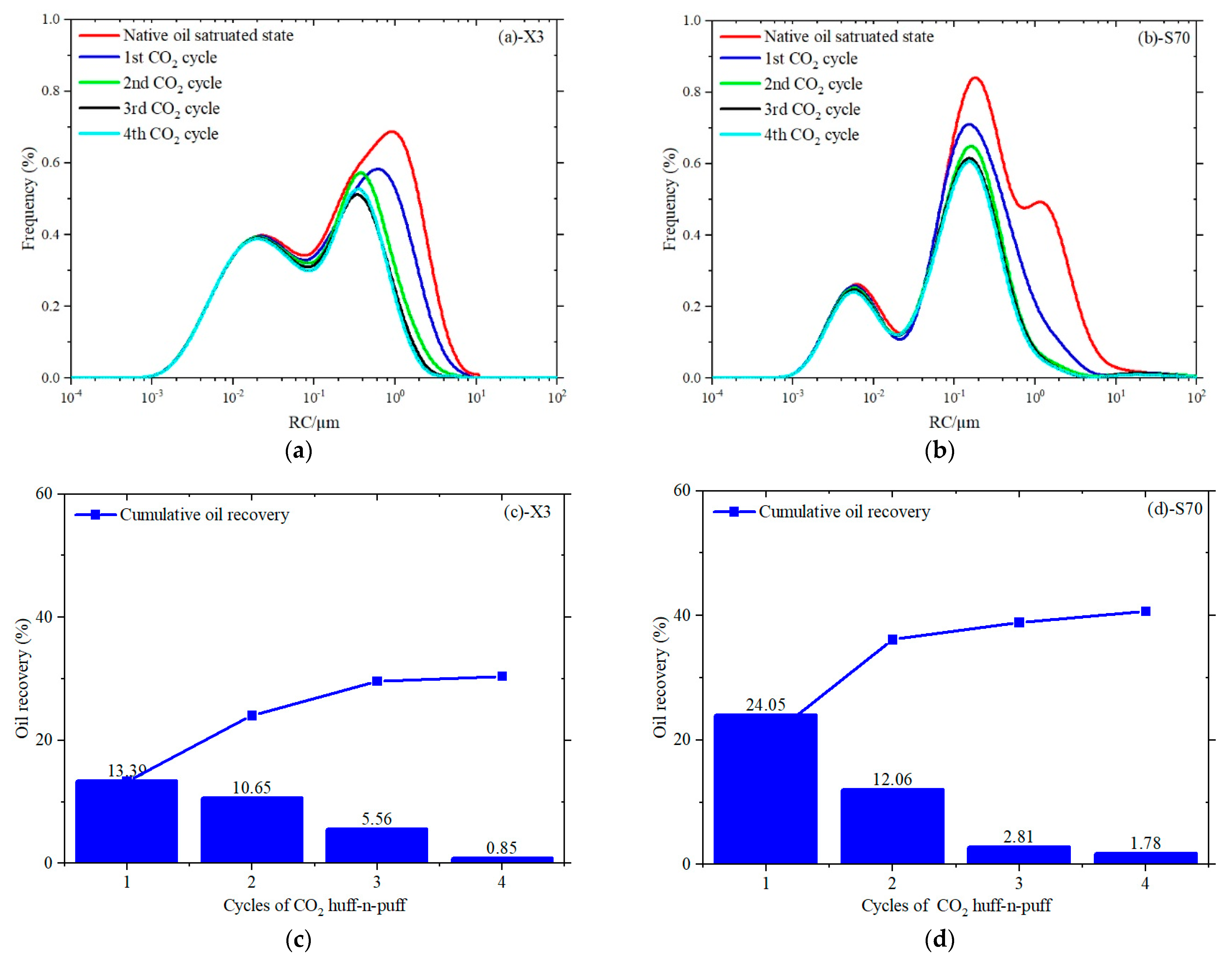

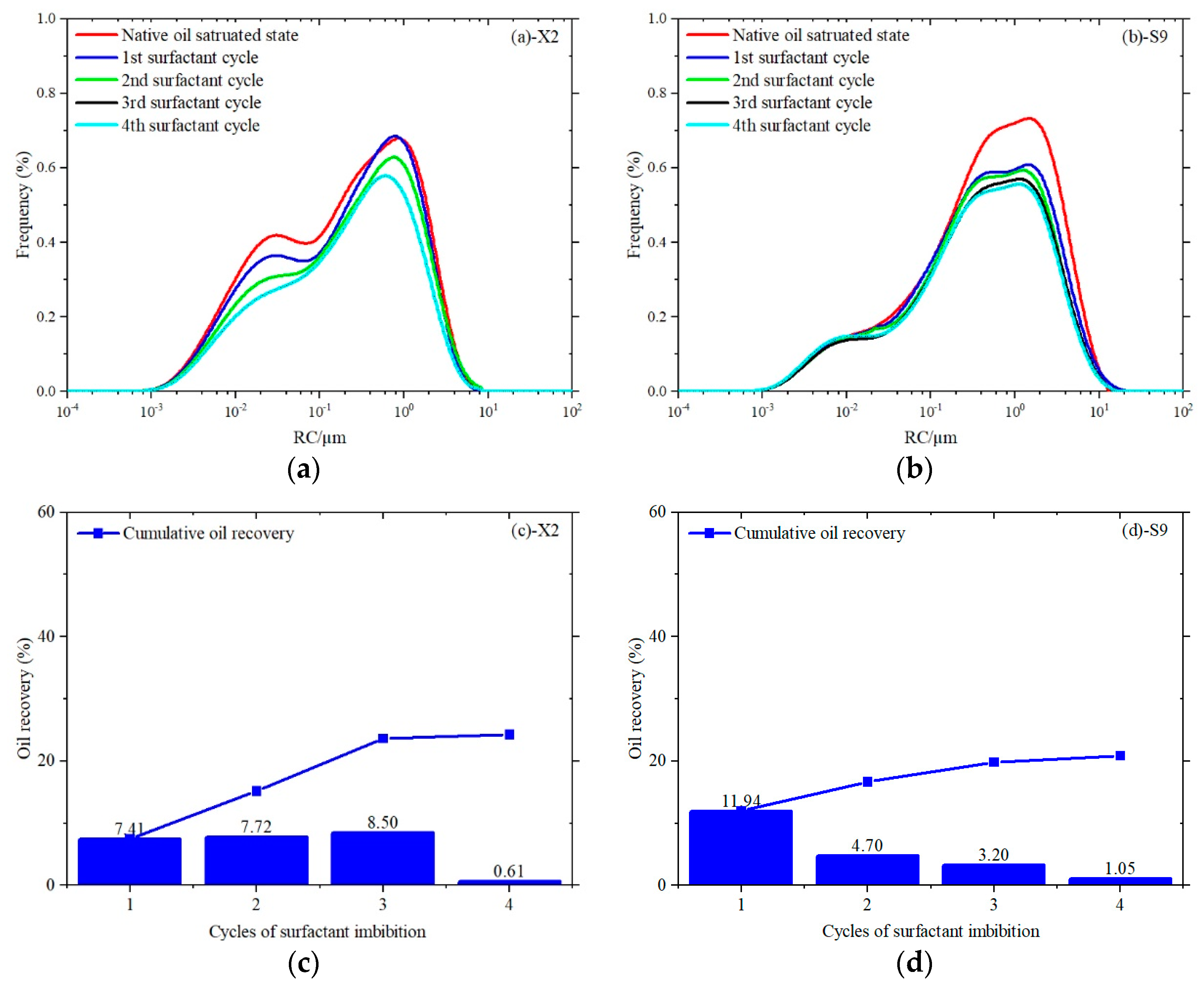

3.2. Performance of CO2 Huff-n-Puff and Surfactant Imbibition

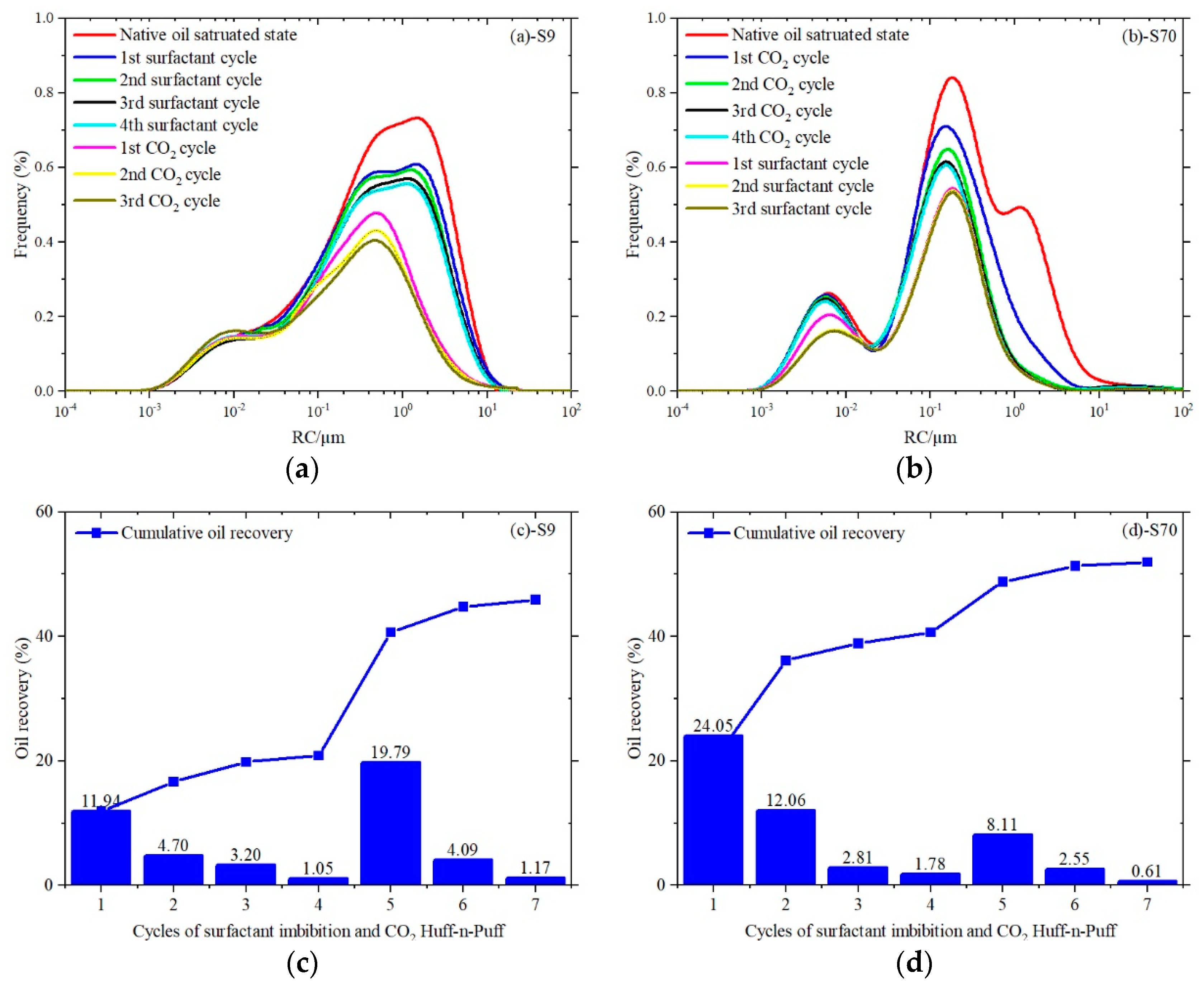

3.3. Performance of Combination CO2 with Surfactant

3.4. Contribution of Different Scale Pores

3.5. Sweep Area and Efficiency of CO2 and Surfactant

4. Conclusions

- (1)

- The ultimate oil recoveries for 15 MPa, 20 MPa, and 30 MPa one-step depletion production are 4.11%, 7.0%, and 9.74%, respectively. And for multi-step depletion production, the oil recovery rate at the same pressure is increased by 1.26%, 0.04%, and 1.28%, respectively. Higher initial pressure shows higher oil recovery. And multi-step depletion production can improve the degree of oil utilization in different pores.

- (2)

- The ultimate oil recoveries of the X3 and S70 samples are 30.45% and 40.70% by CO2 huff-n-puff. Two or three cycles of CO2 injection should be sufficient for shale formations. Pore size distribution is an important factor for CO2 huff-n-puff. Oil in large pores is mainly produced. The ultimate oil recoveries of the X2 and S9 samples are 24.24% and 20.89% by surfactant imbibition. Pore size distribution is also an important factor for surfactant imbibition. And surfactant has a wider production range of pore sizes than CO2 huff-n-puff.

- (3)

- Combining the surfactant with the gas huff-n-puff approach can represent a viable method for enhancing oil recovery. After three more cycles of surfactant imbibition and CO2 huff-n-puff, the ultimate recovery rate can be increased by 11.27% and 26.27%, respectively. We should pay more attention to the effect of CO2 on a specific oil reservoir. Surfactant imbibition after CO2 huff-n-puff is the greater IOR.

- (4)

- The NMR imaging results show that the sweep area and efficiency of CO2 huff-n-puff are larger. Oil utilization is different in the first two cycles by CO2 huff-n-puff due to the heterogeneity. In the third and fourth cycles, the degree of oil utilization is barely noticeable. Oil in the whole X2 sample was partly produced by surfactant imbibition. The effect of the flowback stage is limited.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AES | Sodium Alcohol Ether Sulphate |

| BS−12 | Dodecyl dimethyl betaine |

| BS−18 | Octadecyl dimethyl betaine |

| DPS−2 | Dimethyldithioformamide propylsolfonic acid sodium |

| KPS | Karamay petroleum sulfonate |

| OP | Alkylphenol polyoxyethylene |

| IFT | Interfacial tension |

| IOR | Improved oil recovery |

| MIP | Mercury intrusion porosimetry |

| NMR | Nuclear magnetic resonance |

| NEA | National Energy Administration |

| TOC | Total organic carbon |

| Pore shape factor | |

| Content of oil in the rocks | |

| Change of oil | |

| Oil recovery | |

| surface relaxation rate (µm/ms) | |

| r | Pore radius (µm) |

| S(T2) | Function of the area of the T2 spectrum |

| S/V | surface–volume ratio (µm−1) |

| surface relaxation |

References

- Energy Information Administration. U.S. Energy Facts—Energy Explained; 2019. Available online: https://www.eia.gov/energyexplained/?page=us_energy_home (accessed on 17 May 2019).

- Zhi, D.M.; Song, Y.; He, W.J.; Jia, X.Y.; Zhou, Y.; Huang, L.L. Geological Characteristics, Resource Potential and Exploration Direction of Shale Oil in Middle−Lower Permian, Junggar Basin. Xinjiang Pet. Geol. 2019, 40, 389–402. [Google Scholar]

- Ang Li, A.; Zhang, L.Y.; Yang, J.G.; Li, S.C.; Fei, X.; Yao, Y.L.; Huang, Y.M.; Liu, N. Study on Anisotropic Petrophysical Modeling of Shale: A Case Study of Shale Oil in Qingshankou Formation in Sanzhao Sag, Songliao Basin, China. Geofluids 2023, 2023, 6236986. [Google Scholar] [CrossRef]

- Hou, L.H.; Luo, X.; Lin, S.H.; Li, Y.X.; Zhang, L.J. Assessment of recoverable oil and gas resources by in−situ conversion of shale−Case study of extracting the Chang 73 shale in the Ordos Basin. Pet. Sci. 2022, 19, 441–458. [Google Scholar] [CrossRef]

- National Energy Administration. Ten Landmark Achievements in National Oil and Gas Exploration and Development in 2022. Available online: http://www.nea.gov.cn/2023−01/20/c_1310692197.htm (accessed on 20 January 2023).

- Toshev, S.; Rakhimov, B. Well production increased when drilling horizontal wells. J. Phys. Conf. Ser. 2022, 2388, 012171. [Google Scholar] [CrossRef]

- Liu, W.; Liu, H.; Wang, S.L.; Dong, K.X. A multi−fracture balanced extension control method for horizontal wells in anisotropic shale. Eng. Fract. Mech. 2023, 281, 109102. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Yan, L.; Ge, H.K.; Liu, S.; Zhou, D.S. Experimental Study on Connection Characteristics of Rough Fractures Induced by Multi−Stage Hydraulic Fracturing in Tight Reservoirs. Energies 2022, 15, 2377. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. Drilling Productivity Report. Available online: https://www.eia.gov/petroleum/drilling (accessed on 16 August 2021).

- Hawthorne, S.B.; Gorecki, C.D.; Sorensen, J.A.; Steadman, E.N.; Harju, J.A.; Melzer, S. Hydrocarbon Mobilization Mechanisms from Upper, Middle, and Lower Bakken Reservoir Rocks Exposed to CO2. In SPE Unconventional Resources Conference Canada; OnePetro: Richardson, TX, USA, 2013. [Google Scholar] [CrossRef]

- Malozyomov, B.V.; Martyushev, N.V.; Kukartsev, V.V. Overview of Methods for Enhanced Oil Recovery from Conventional and Unconventional Reservoirs. Energies 2023, 16, 4907. [Google Scholar] [CrossRef]

- Tian, H.; He, K.; Huangfu, Y.H.; Liao, F.R.; Wang, X.M.; Zhang, S.C. Oil content and mobility in a shale reservoir in Songliao Basin, Northeast China: Insights from combined solvent extraction and NMR methods. Fuel 2024, 357, 129678. [Google Scholar] [CrossRef]

- Zhu, D.; Li, B.F.; Zheng, L.; Lei, W.S.; Li, B.L.; Li, Z.M. Effects of CO2 and surfactants on the interface characteristics and imbibition process in low−permeability heavy oil reservoirs. Colloids Surf. A Physicochem. Eng. Asp. 2023, 657, 130538. [Google Scholar] [CrossRef]

- Alfarge, D.; Wei, M.Z.; Bai, B.J. CO2-EOR mechanisms in huff-n-puff operations in shale oil reservoirs based on history matching results. Fuel 2018, 226, 112–120. [Google Scholar] [CrossRef]

- Alfarge, D.; Wei, M.; Bai, B. Factors affecting CO2−EOR in shale−oil reservoirs: Numerical simulation study and pilot tests. Energy Fuel 2017, 31, 8462–8480. [Google Scholar] [CrossRef]

- Wan, T.; Zhang, J.; Jing, Z.Y. Experimental evaluation of enhanced shale oil recovery in pore scale by CO2 in Jimusar reservoir. J. Pet. Sci. Eng. 2022, 208, 109730. [Google Scholar] [CrossRef]

- Ahmadi, M.A.; Pouladi, B.; Barghi, T. Numerical modeling of CO2 injection scenarios in petroleum reservoirs: Application to CO2 sequestration and EOR. J. Nat. Gas Sci. Eng. 2016, 30, 38–49. [Google Scholar] [CrossRef]

- Zhu, J.H.; Chen, J.B.; Wang, X.M.; Fan, L.Y.; Nie, X.R. Experimental Investigation on the Characteristic Mobilization and Remaining Oil Distribution under CO2 Huff-n-puff of Chang 7 Continental Shale Oil. Energies 2021, 14, 2782. [Google Scholar] [CrossRef]

- Li, L.; Wang, C.W.; Li, D.S. Experimental investigation of shale oil recovery from Qianjiang core samples by the CO2 huff-n-puff EOR method. RSC Adv. 2019, 9, 28857–28869. [Google Scholar] [CrossRef] [PubMed]

- Mahzari, P.; Oelkers, E.; Mitchell, T.; Jones, A. An Improved Understanding about CO2 EOR and CO2 Storage in Liquid−Rich Shale Reservoirs. In Proceedings of the 81st EAGE Conference and Exhibition, London, UK, 3–6 June 2019; SPE: Kuala Lumpur, Malaysia, 2019. [Google Scholar]

- Alharthy, N.; Teklu, T.; Kazemi, H.; Graves, R.; Hawthorne, S. Enhanced oil recovery in liquid–rich shale reservoirs: Laboratory to field. SPE Reserv. Eval. Eng. 2022, 21, 137–159. [Google Scholar] [CrossRef]

- Chico, S.; Liu, N.; Shaibu, R.; Ahmed, A. A Technical Review of CO2 for Enhanced Oil Recovery in Unconventional Oil Reservoirs. Geoenergy Sci. Eng. 2023, 221, 111185. [Google Scholar] [CrossRef]

- Sanchez−Rivera, D.; Mohanty, K.; Balhoff, M. Reservoir simulation and optimization of Huff−and−Puff operations in the Bakken Shale. Fuel 2015, 147, 82–94. [Google Scholar] [CrossRef]

- Abouzar, C.; Abbas, H.; David, A.W. Estimation of minimum miscibility pressure of varied gas compositions and reservoir crude oil over a wide range of conditions using an artificial neural network model. Adv. Geo Energy Res. 2019, 3, 52–66. [Google Scholar] [CrossRef]

- Altawati, F.; Sheng, J.; Emadi, H. Investigating Effects of Water on Shale Oil Formation by Using Cyclic Gas Injection Technique−An Experimental Study. In Proceedings of the 54th U.S. Rock Mechanics/Geomechanics Symposium, Golden, CO, USA, 28 June–1 July 2020. [Google Scholar]

- Zeng, T.Z.; Miller, C.S.; Mohanty, K.K. Combination of a chemical blend with CO2 huff-n-puff for enhanced oil recovery in oil shales. J. Pet. Sci. Eng. 2020, 194, 107546. [Google Scholar] [CrossRef]

- Gupta, I.; Rai, C.S.; Sondergeld, C.H. Impact of Surfactants on Hydrocarbon Mobility in Shales. SPE Reserv. Eval. Eng. 2020, 23, 1105–1117. [Google Scholar] [CrossRef]

- Alvarez, J.O.; Schechter, D.S. Altering wettability in Bakken shale by surfactant additives and potential of improving oil recovery during injection of completion fluids. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016. SPE−179688−MS. [Google Scholar] [CrossRef]

- Zhang, F.; Adel, L.A.; Park, K.H.; Saputra, I.W.R.; Schechter, D.S. Enhanced oil recovery in unconventional liquid reservoir using a combination of CO2 Huff-n-Puff and surfactant−assisted spontaneous imbibition. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 24–26 September 2018. [Google Scholar]

- Li, B.F.; Zhang, Q.L.; Li, S.Y.; Li, Z.M. Enhanced heavy oil recovery via surfactant−assisted CO2 huff-n-puff processes. J. Pet. Sci. Eng. 2017, 159, 25–34. [Google Scholar] [CrossRef]

- Negin, C.; Ali, S.; Xie, Q. Most Common Surfactants Employed in Chemical Enhanced Oil Recovery. Petroleum 2016, 3, 197–211. [Google Scholar] [CrossRef]

- Zha, X.J.; Lai, F.Q.; Gao, X.B.; Gao, Y.; Jiang, N.; Luo, L. Characteristics and Genetic Mechanism of Pore Throat Structure of Shale Oil Reservoir in Saline Lake—A Case Study of Shale Oil of the Lucaogou Formation in Jimsar Sag, Junggar Basin. Energies 2021, 14, 8450. [Google Scholar] [CrossRef]

- Ding, X.J.; Qu, J.X.; Imin, A.; Zha, M.; Su, Y.; Jiang, Z.F. Organic matter origin and accumulation in tuffaceous shale of the lower Permian Lucaogou Formation, Jimsar Sag. J. Pet. Sci. Eng. 2019, 179, 696–706. [Google Scholar] [CrossRef]

- Meng, Z.Y.; Liu, Y.Q.; Jiao, X.; Ma, L.T.; Zhou, D.W.; Li, H. Petrological and organic geochemical characteristics of the Permian Lucaogou Formation in the Jimsar Sag, Junggar Basin, NW China: Implications on the relationship between hydrocarbon accumulation and volcanic−hydrothermal activities. J. Pet. Sci. Eng. 2022, 210, 110078. [Google Scholar] [CrossRef]

- Gao, Y.; Ye, Y.P.; He, J.X.; Qian, G.B.; Qin, J.H.; Li, Y.Y. Development practice of continental shale oil in Jimsar sag in the Junggar Basin. China Pet. Explor. 2020, 25, 133–141. [Google Scholar]

- Que, Z.; Lu, B.; Shi, Z.S.; Dong, D.Z.; Wang, H.Y.; Zhou, J. Residual accumulation and resource assessment of shale oil from the Permian Lucaogou Formation in Jimusar Sag. Nat. Gas Geosci. 2016, 27, 1817–1827. [Google Scholar]

- Yao, Z.H.; Qin, J.H.; Gao, Y.; Chen, C.; Liu, Z.P.; Zhang, X.G. Variations of Physical Properties of Shale Oil in Jimsar Sag, Junggar Basin. Xinjiang Pet. Geol. 2022, 43, 72–79. [Google Scholar]

- Shi, Y.; Wu, B.; Wang, H.; Li, Y.; Liu, Z.; Xu, C.; Qin, J.; Li, Y.; Song, Z.; Liu, H. Insights into CO2 huff-n-puff mechanisms from laboratory experiment and single-well pilot test in the Lucaogou tight oil reservoir, Jimsar sag, China. Geoenergy Sci. Eng. 2024, 232, 212456. [Google Scholar] [CrossRef]

| Sample | Length (cm) | Diameter (cm) | Porosity (%) | Permeability (mD) | Experiment |

|---|---|---|---|---|---|

| X1a | 2.6 | 2.5 | 15.1 | 0.65 | 15 MPa depletion |

| X1b | 2.4 | 2.5 | 15.0 | 0.61 | 20 MPa depletion |

| X1c | 2.5 | 2.5 | 15.5 | 0.73 | 30 MPa depletion |

| X3 | 2.6 | 2.5 | 15.2 | 0.68 | CO2 huff-n-puff |

| S70 | 2.6 | 2.5 | 16.8 | 0.67 | CO2 huff-n-puff + surfactant imbibition |

| X2 | 2.6 | 2.6 | 15.2 | 0.69 | surfactant imbibition |

| S9 | 2.5 | 2.5 | 12.8 | 0.12 | surfactant imbibition + CO2 huff-n-puff |

| Number | Surfactant Type | IFT (mN/m) | Number | Surfactant Type | IFT (mN/m) |

|---|---|---|---|---|---|

| 1 | 0.1% OP | 2.408 | 11 | 0.1% binary KPS | 1.081 |

| 2 | 0.2% OP | 0.500 | 12 | 0.2% binary KPS | 0.674 |

| 3 | 0.1% AES | 0.788 | 13 | 0.1% nonionic | 16.149 |

| 4 | 0.2% AES | 0.385 | 14 | 0.2% nonionic | 12.501 |

| 5 | 0.1% BS-12 | 2.922 | 15 | 0.1% anion | 0.345 |

| 6 | 0.2% BS-12 | 3.149 | 16 | 0.2% anion | 0.549 |

| 7 | 0.1% BS-18 | 0.402 | 17 | 0.1% BS-18 + 0.1% AES | 0.179 |

| 8 | 0.2% BS-18 | 0.420 | 18 | 0.1% BS-18 + 0.05% AES | 0.045 |

| 9 | 0.1% DPS-2 | 0.361 | 19 | 0.2% BS-18 + 0.1% AES | 0.287 |

| 10 | 0.2% DPS-2 | 0.403 | 20 | 0.2% BS-18 + 0.05% AES | 0.281 |

| Sample | Formation Water | 0.2% AES | 0.1% DPS-2 | |||

|---|---|---|---|---|---|---|

| Contact Angle | Wettability | Contact Angle | Wettability | Contact Angle | Wettability | |

| 1 | 63.9° | water wet | 37.6° | water wet | 34.1° | water wet |

| 2 | 45.7° | water wet | 76.0° | water wet | 107.8° | oil wet |

| 3 | 115.0° | oil wet | 52.7° | water wet | 126.6° | oil wet |

| 4 | 106.6° | oil wet | 31.0° | water wet | 160.6° | oil wet |

| IOR Method | Pore Size (μm) | Ultimate Oil Recovery (%) | Lower Limit | |||

|---|---|---|---|---|---|---|

| P < 0.1 | 0.1 < P < 1 | 1 < P < 10 | P > 10 | of Pore Size (μm) | ||

| One-step depletion (30 MPa) | 4.64 | 1.29 | 3.81 | 0.00 | 9.74 | 0.05 |

| Multi-step depletion (30 MPa) | 2.92 | 3.16 | 4.93 | 0.00 | 11.01 | 0.05 |

| CO2 huff-n-puff (X3) | 1.42 | 11.48 | 17.53 | 0.03 | 30.45 | 0.10 |

| Surfactant imbibition (X2) | 11.59 | 6.71 | 5.94 | 0.00 | 24.24 | 0.05 |

| CO2 huff-n-puff + Surfactant imbibition (S70) | 3.00 | 21.39 | 15.94 | 0.94 | 51.97 | 0.05 |

| 8.20 | 2.75 | 0.10 | 0.00 | |||

| Surfactant imbibition + CO2 huff-n-puff (S9) | 1.72 | 7.72 | 11.44 | 0.01 | 47.16 | 0.05 |

| 0.15 | 10.47 | 15.60 | 0.05 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Xu, C.; Wang, H.; Liu, H.; He, C.; Qin, J.; Wu, B.; Li, Y.; Song, Z. Experimental Investigation of IOR Potential in Shale Oil Reservoirs by Surfactant and CO2 Injection: A Case Study in the Lucaogou Formation. Energies 2023, 16, 8085. https://doi.org/10.3390/en16248085

Shi Y, Xu C, Wang H, Liu H, He C, Qin J, Wu B, Li Y, Song Z. Experimental Investigation of IOR Potential in Shale Oil Reservoirs by Surfactant and CO2 Injection: A Case Study in the Lucaogou Formation. Energies. 2023; 16(24):8085. https://doi.org/10.3390/en16248085

Chicago/Turabian StyleShi, Yaoli, Changfu Xu, Heng Wang, Hongxian Liu, Chunyu He, Jianhua Qin, Baocheng Wu, Yingyan Li, and Zhaojie Song. 2023. "Experimental Investigation of IOR Potential in Shale Oil Reservoirs by Surfactant and CO2 Injection: A Case Study in the Lucaogou Formation" Energies 16, no. 24: 8085. https://doi.org/10.3390/en16248085