Areas of Fan Research—A Review of the Literature in Terms of Improving Operating Efficiency and Reducing Noise Emissions

Abstract

:1. Introduction

- Ventilation devices (airing rooms), steel mills, power plants, mines, lecture halls, cinemas, foundries, etc.;

- For cooling engines and generators;

- For cooling internal combustion engines;

- Fan cooling towers;

- Air condensers in refrigeration and cooling systems;

- As draft fans;

- In electronic systems intended for cooling components.

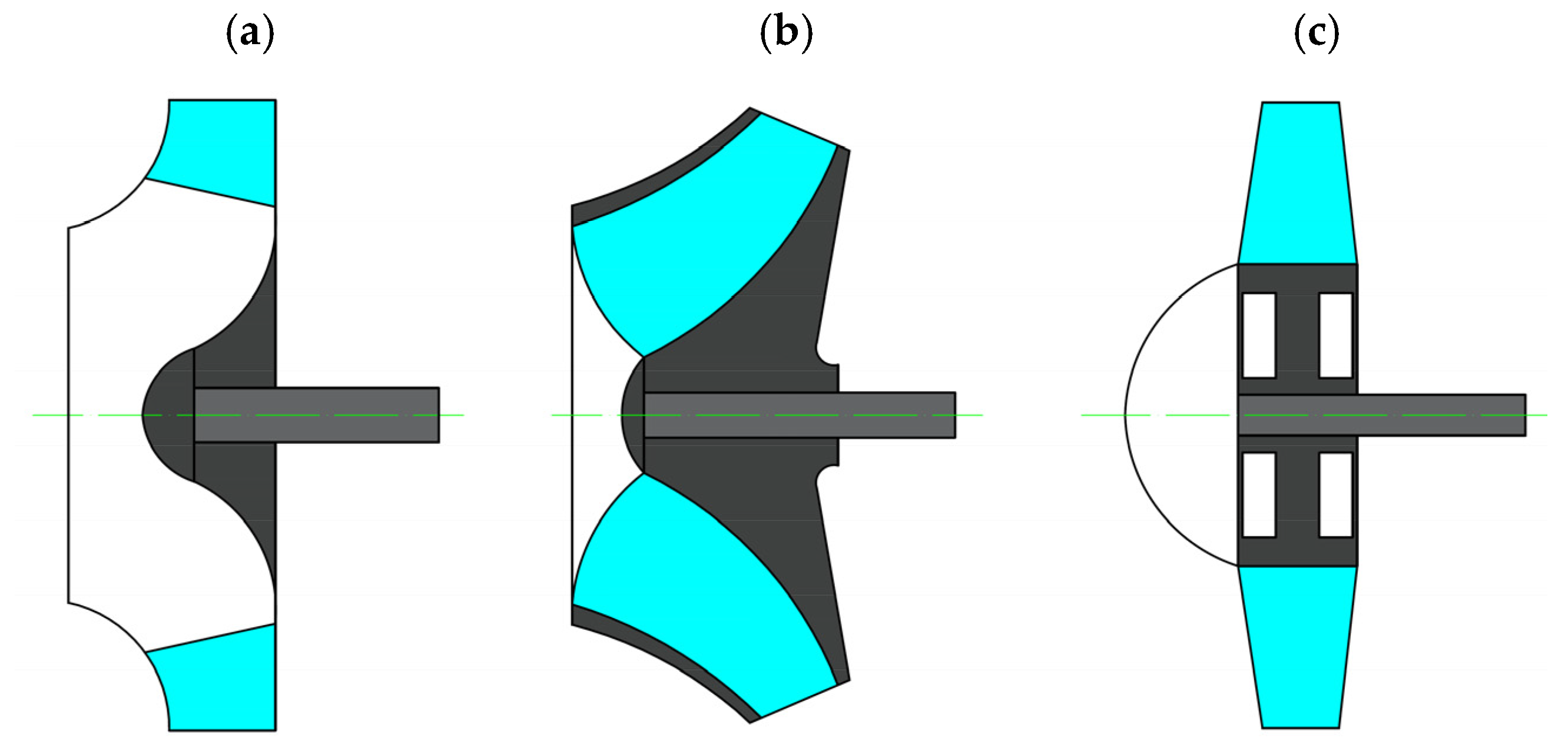

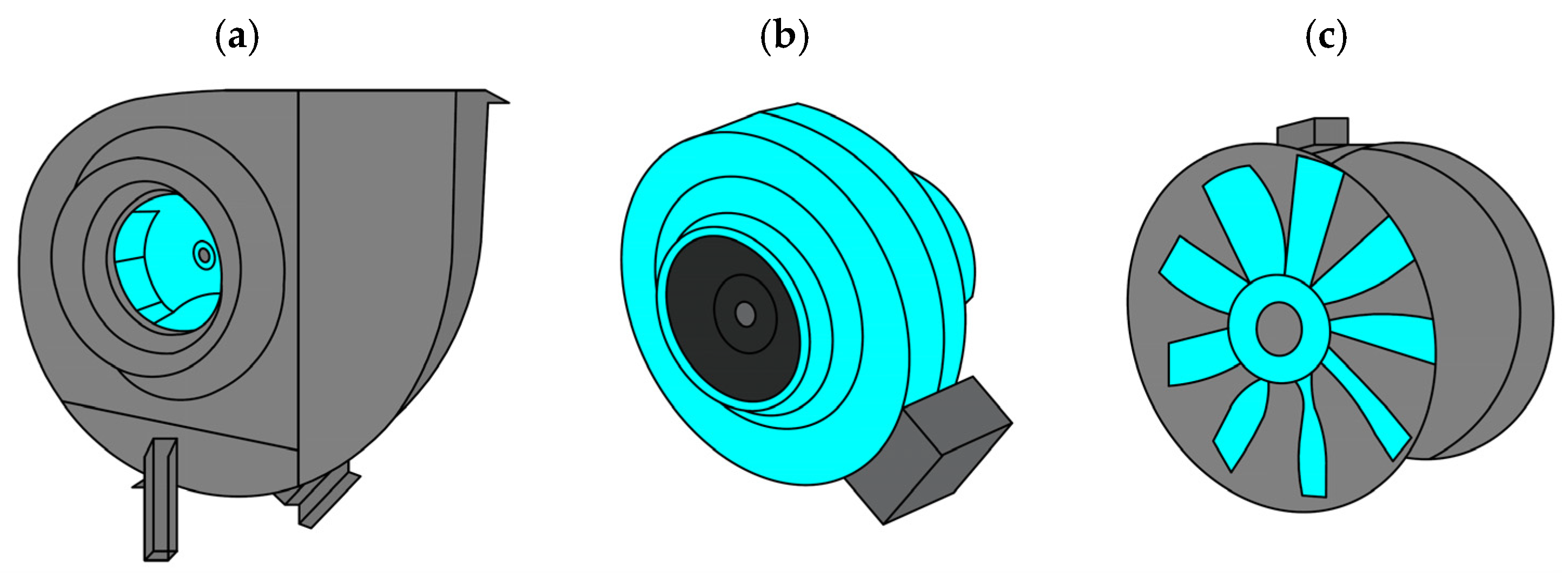

- (a)

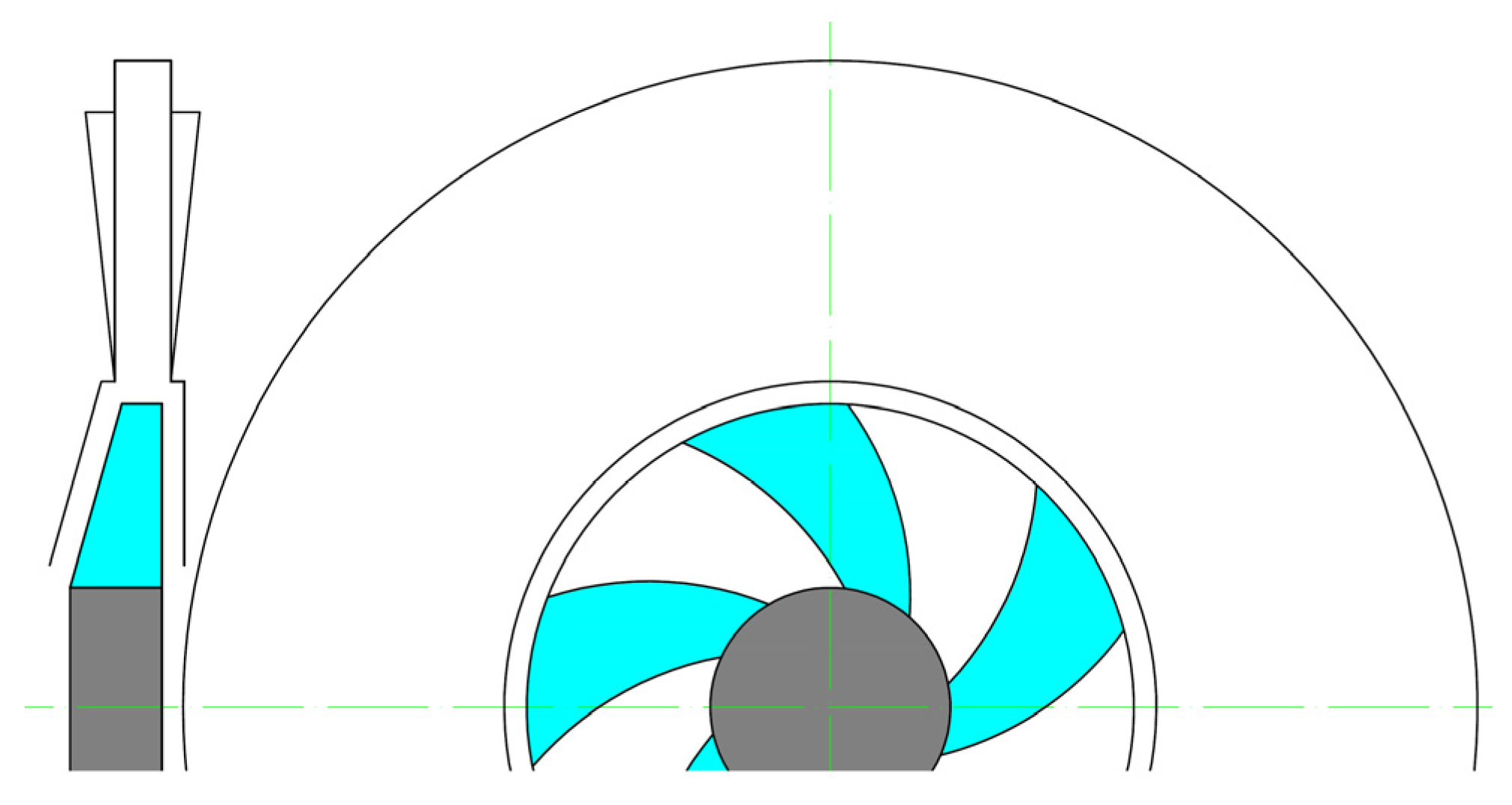

- Axial;

- (b)

- Axial with meridional acceleration;

- (c)

- Semi-axial;

- (d)

- Half-radial;

- (e)

- Semi-radial centrifugal;

- (f)

- Semi-radial centripetal;

- (g)

- Axial-radial;

- (h)

- Peripheral;

- (i)

- Radial disc;

- (j)

- Transverse.

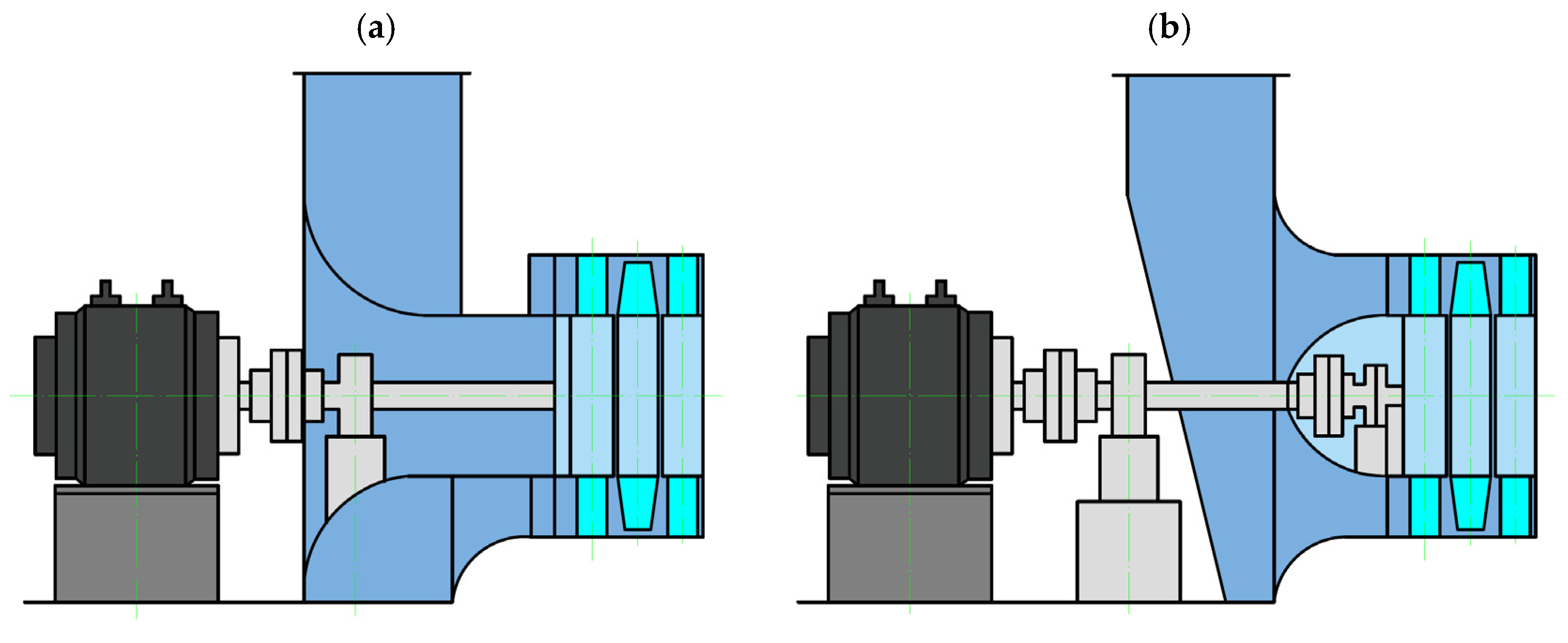

- Intake (intake nozzles, intake boxes, vane diffusers, filters);

- An appropriately selected fan (steering blades, impeller blades, diffusers bladeless, reversing channels, etc.);

- Fan drive (gear, belt, direct) with regulation and control;

- Appropriate fittings and partitions;

- Exhaust (guide vanes, exhaust manifolds, silencers);

- Heat exchangers.

- Determining the current parameters and conditions of work;

- Determining the current state and determining the future state of process production;

- Operational data collection and analysis and workload cycle development;

- Assessment of alternative system implementations and optimization areas,

- Identification of the most economically and technically advantageous variants (necessarily taking into account all subsystems);

- Implementing the best installation option;

- An assessment of energy consumption in relation to working conditions;

- Constant observation and ongoing optimization of the system;

- Operation of the installation aimed at achieving maximum efficiency.

- Improvement of the energy efficiency of the fan itself as a device, including the drive;

- Conducting a series of noise reduction treatments;

- Improving the efficiency of gas transport in the installation.

2. Energy Efficiency—Fan Operation

- -

- Inlet on the funnel;

- -

- Change of flow direction from axial to radial;

- -

- Non-tangential flow to the rim;

- -

- Friction in the interscapular canal.

- -

- Diffusivity of the case;

- -

- Sudden expansion of the flow;

- -

- Stream mixing;

- -

- Friction.

3. Vibrations and Noise

- Design, thermal imbalance (heating unevenness, flow unevenness), operational imbalance (deposition of particles of the working medium, rotor erosion);

- Bending, e.g., due to high permanent forces and material deflection;

- Lost elements, e.g., a spatula;

- Rubbing against body elements as a result of high vibrations, permanent bending of the rotor or axial displacement of the rotor as a whole;

- Blade resonance leads to resonant vibrations and, consequently, fatigue of the material.

- -

- Unbalance of rotating masses;

- -

- Non-axial engagement of clutch parts;

- -

- Work near resonance;

- -

- Aerodynamic flow disturbance;

- -

- Damage to bearings and incorrect clearances;

- -

- Electromagnetic interference affecting the engine;

- -

- Interference from external vibrations.

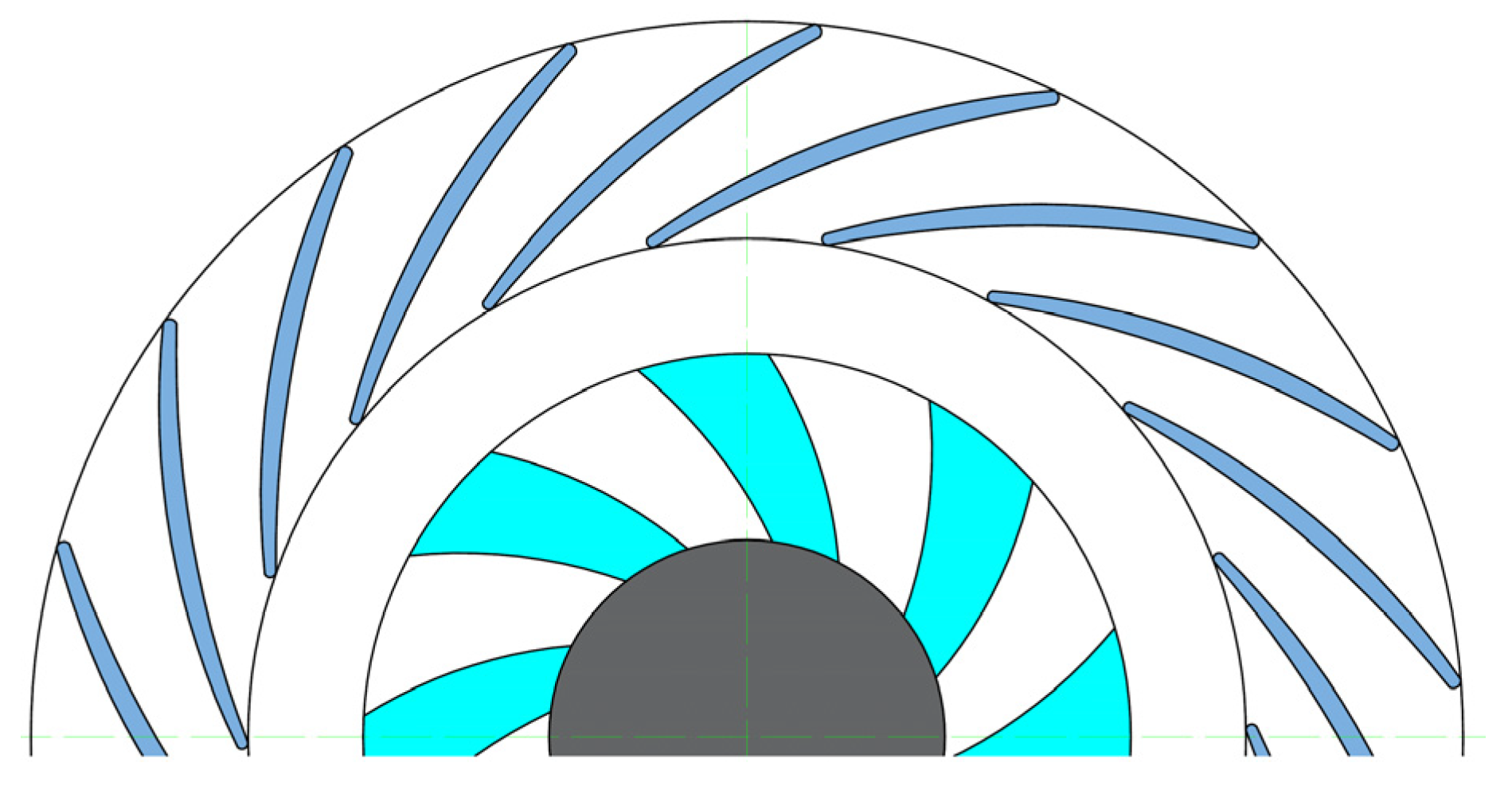

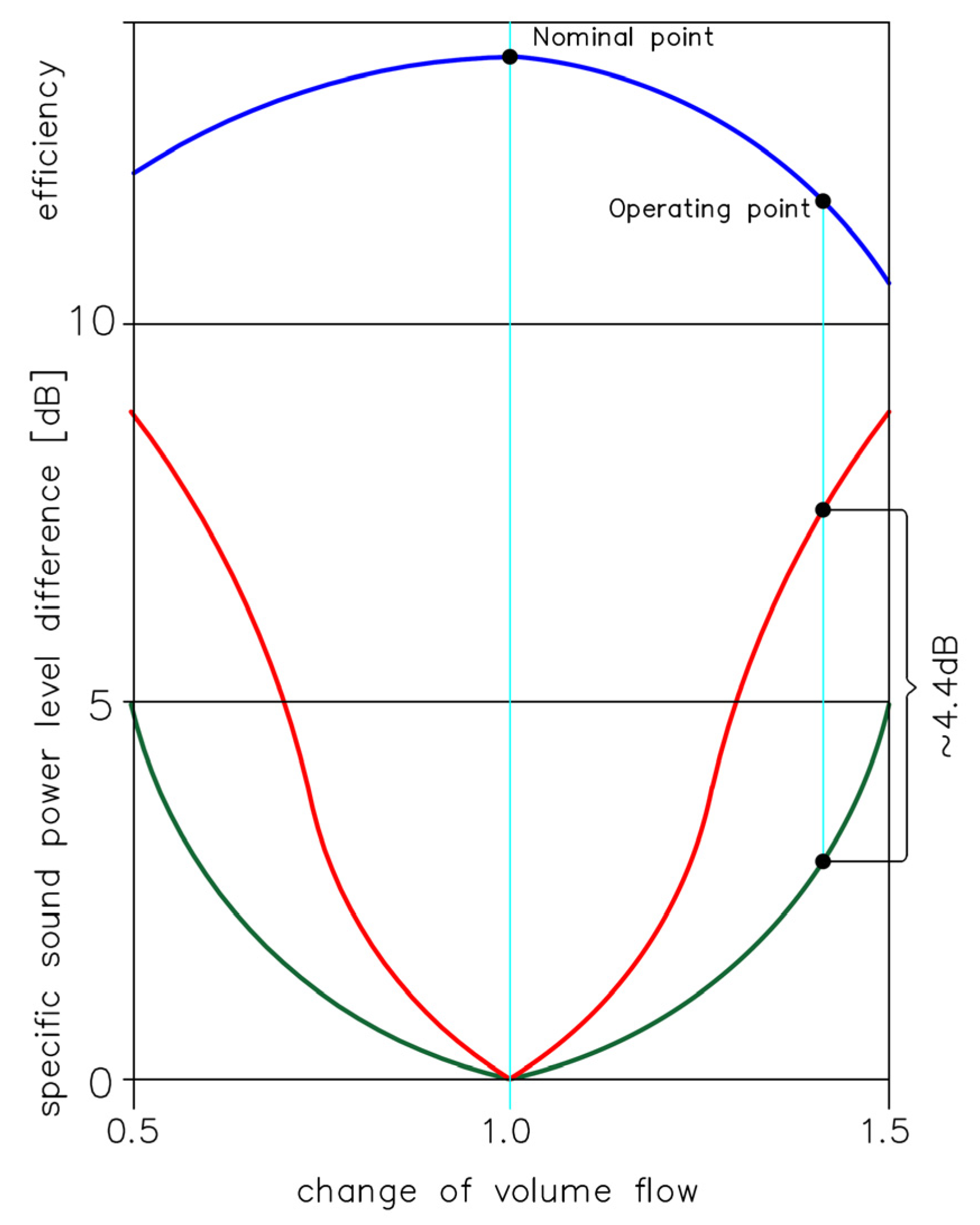

4. Parameters and Areas of Optimization of Plant Components

- Maintaining constant final pressure with variable flow;

- Maintaining constant performance with changing network characteristics.

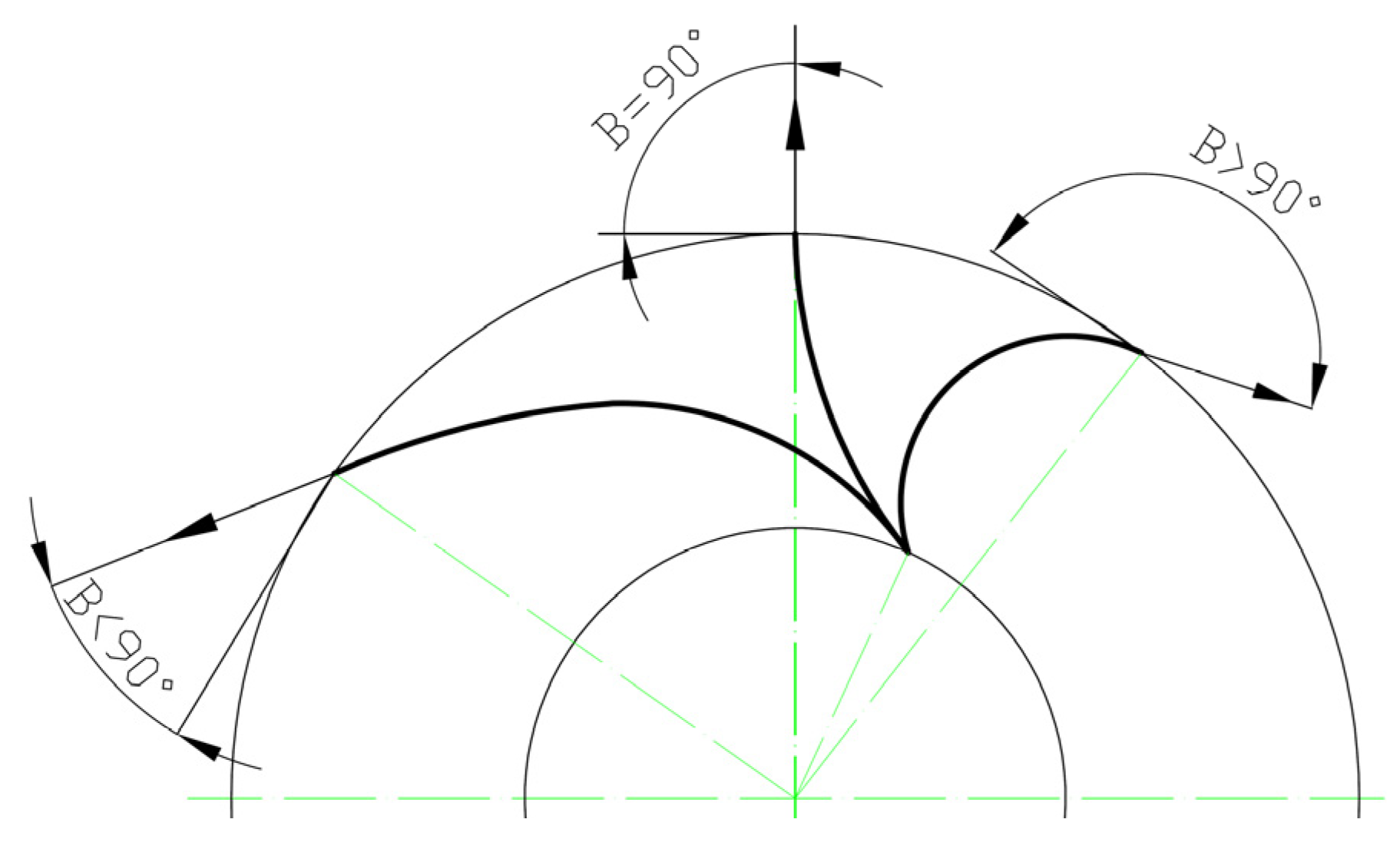

- By changing the rotational speed of the rotor;

- By changing the angles of the impeller blades;

- By changing the angles of the guide vanes (at the inlet or outlet of the rotor);

- By choking the medium on the suction side;

- By choking the medium on the discharge side;

- By blowing gas into the atmosphere or recirculating excess gas to the suction port.

- Internal losses—changing to heat transferred to the flowing factor inside the body. They occur in the impeller blade channel and diffuser. Their value depends on the friction against the walls and intermolecular friction, but also on changes in the flow direction and the channel cross section. Vortices, flows at the walls of the channels, or impacts against the walls, e.g., at the inlet, also have an influence;

- External losses—occurring outside the body do not affect the thermal state of the flowing medium; however, they significantly affect the power supplied to the machine. They appear in, for example, interstage seals. External losses are also mechanical losses.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- 2021 Commission Work Programme—From Strategy to Delivery. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_20_1940 (accessed on 25 October 2022).

- Romik, D.; Czajka, I.; Gołaś, A. Numerical Study of the Effect of Selected Design Parameters on the Aerodynamic Noise of a Radial Fan; Institute of Rock Mechanics Polish Academy of Sciences: Kraków, Poland, 2016; Volume 18, pp. 43–52. (In Polish) [Google Scholar]

- Engel, Z. Environmental Protection against Vibrations and Noise; Polish Scientific Publishers: Warszawa, Poland, 2001; ISBN 83-01-13537-9. (In Polish) [Google Scholar]

- Fortuna, S. Fans. Theoretical Basis, Structural and Operational Issues and Application; Techwent Publishing House: Kraków, Poland, 1999; ISBN 83-912363-0-7. (In Polish) [Google Scholar]

- Majcher, M. Numerical Analysis of Three-Dimensional Flows in Key Components of Axial Fans. Ph.D. Thesis, Military University of Technology, Warsaw, Poland, 2021. (In Polish). [Google Scholar]

- Piwowarski, M.; Ziemiański, P.; Czyżewicz, J.; Bortkiewicz, M.; Laszuk, K.; Galara, I.; Pawłowska, M.; Cybulski, K. Autonomous remote measurement system for industrial fans as a result of an innovative project stage. Instal 2022, 3, 14–21. (In Polish) [Google Scholar] [CrossRef]

- Piwowarski, M. Flow Compressors; Foundation for the Promotion of the Shipbuilding Industry and the Maritime Economy: Gdańsk, Poland, 2017. (In Polish) [Google Scholar]

- Pałucki, Z. Analysis of Real Gas Flow through the Adjustable Vane Diffuser of a Radial Compression Machine. Ph.D. Thesis, Poznan University of Technology, Poznań, Poland, 2014. (In Polish). [Google Scholar]

- Siwek, T. Studies of Flows in an Axially Mounted Radial Impeller Fan. Ph.D. Thesis, Academy of Mining and Technology, Gdańsk, Poland, 2018. (In Polish). [Google Scholar]

- Wettergren, O. In-line Fans: Considerations for Sizing & Selection. Heat. Pip. Air Cond. Eng. 2007, 79, 22–25. [Google Scholar]

- U.S. Department of Energy. Improving Fan System Performance—A Sourcebook for Industry; National Renewable Energy Lab.: Golden, CO, USA, 2003. [Google Scholar]

- Czyżewicz, J.; Jaskólski, P.; Ziemiański, P.; Piwowarski, M.; Bortkiewicz, M.; Laszuk, K.; Galara, I.; Pawłowska, M.; Cybulski, K. Towards Designing an Innovative Industrial Fan: Developing Regression and Neural Models Based on Remote Mass Measurements. Energies 2022, 15, 2425. [Google Scholar] [CrossRef]

- Sathaye, N.; Phadke, A.; Shah, N.; Letschert, V. Potential Global Benefits of Improved Ceiling Fan Energy Efficiency; Tom LBNL Report; Ernest Orlando Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2013. [Google Scholar]

- Yu, J.; Zhang, T.; Qian, J. Electrical Motor Products International Energy-Efficiency Standards and Testing Methods; Woodhead Publishing Limited: Cambridge, UK, 2011. [Google Scholar]

- Schild, P.G.; Mysen, M. Recommendations on Specific Fan Power and Fan System Efficiency; AIVC document AIC-TN65; INIVE EEIG: Oslo, Norway, 2009; ISBN 2-930471-30-1. [Google Scholar]

- Trane, Engineers Newsletter, Volume 43-3. 2014. Available online: https://www.trane.com/content/dam/Trane/Commercial/global/products-systems/education-training/engineers-newsletters/standards-codes/ADMAPN052-EN_100114_final.pdf (accessed on 24 October 2022).

- Waide, P.; Brunner, C. Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems; International Energy Agency: Paris, France, 2011. [Google Scholar]

- Jung, J.H.; Joo, W.G. Effect of tip clearance, winglets, and shroud height on the tip leakage in axial flow fans. Int. J. Refrig. 2018, 93, 195–204. [Google Scholar] [CrossRef]

- Gholamian, M.; Rao, G.K.M.; Panitapu, B. Effect of axial gap between inlet nozzle and impeller on efficiency and flow pattern in centrifugal fans, numerical and experimental analysis. Case Stud. Therm. Eng. 2013, 1, 26–37. [Google Scholar] [CrossRef] [Green Version]

- Azem, A.; Mathis, P.; Stute, F.; Hoffmann, M.; Müller, D.; Hetzel, G. Efficiency increase of free running centrifugal fans through a pressure regain unit used in an air handling unit. Energy Build. 2018, 165, 321–327. [Google Scholar] [CrossRef]

- Hati, A.S. A comprehensive review of energy-efficiency of ventilation system using Artificial Intelligence. Renew. Sustain. Energy Rev. 2021, 146, 111153. [Google Scholar]

- De Souza, E. Improving the energy efficiency of mine fan assemblages. Appl. Therm. Eng. 2015, 90, 1092–1097. [Google Scholar] [CrossRef]

- Lin, Y.; Fan, T.; Zheng, X. Roles of recirculating bubble on the performance of centrifugal compressors. Aerosp. Sci. Technol. 2021, 118, 107073. [Google Scholar] [CrossRef]

- Eszter, L.; Janos, V. Flow topology and loss analysis of a square-to-square sudden expansion. J. Build. Eng. 2021, 41, 102802. [Google Scholar]

- Parpanchi, S.M.; Farsad, S.; Ardekani, M.A.; Farhani, F. Experimental investigation of a diffuser for use in skydiving vertical wind tunnel. Exp. Therm. Fluid Sci. 2021, 125, 110393. [Google Scholar] [CrossRef]

- Ch, S.V.; Anantharaman, K.; Rajasekaran, G. Effect of blade number on the performance of centrifugal fan. Mater. Today Proc. 2022, 72, 1143–1152. [Google Scholar] [CrossRef]

- Hargreaves, J.A. Analysis and Control of Acoustic Modes in Cylindrical Cavities with application to Direct Field Acoustic Noise (DFAN) Testing. In Proceedings of the Internoise 2022, Glasgow, UK, 21–24 August 2022. [Google Scholar]

- Sorgüvena, E.; Doğan, Y. Acoustic optimization for centrifugal fans. Noise Control Eng. J. 2012, 60, 379–391. [Google Scholar] [CrossRef]

- Reitz—Handbook Radial Fans. 2012. Available online: https://www.reitzgroup.com/en/downloads.html (accessed on 26 October 2022).

- Jung, J.H.; Joo, W.G. Analysis on hub vortex and the improvement of hub shape for noise reduction in an axial flow fan. In Proceedings of the Internoise 2019, Madrid, Spain, 16–19 June 2019. [Google Scholar]

- Sunghyun, M.; Namuk, C. An Aeroacoustic Comparison of Centrifugal Fans with Backward-curved and Airfoil Blades. In Proceedings of the Internoise 2019, Madrid, Spain, 16–19 June 2019. [Google Scholar]

- Chen, W.; Kai, M. Aerodynamic and Acoustic Optimization of a Multi Blade Centrifugal Fan. In Proceedings of the Internoise 2019, Madrid, Spain, 16–19 June 2019. [Google Scholar]

- Czwielong, F.; Krömer, F.; Becker, S. Sound Emissions of Axial Fans with Leading-Edge Serrations on different spanwise Locations. In Proceedings of the Internoise 2019, Madrid, Spain, 16–19 June 2019. [Google Scholar]

- Hurtado, M.; Burdisso, R. Axial Fan Design Using Multi-Element Airfoils to Minimize Noise. In Proceedings of the Internoise 2019, Madrid, Spain, 16–19 June 2019. [Google Scholar]

- Kuranaga, T.; Minorikawa, G.; Nakano, T. Experimental Study on Noise Characteristics and Evaluation of Small Ducted Fan. In Proceedings of the Internoise 2018, Chicago, IL, USA, 26–129 August 2018. [Google Scholar]

- Krömer, F.J.; Moreau, S.; Becker, S. Experimental investigation of the interplay between the sound field and the flow field in skewed low-pressure axial fans. J. Sound Vib. 2019, 442, 220–236. [Google Scholar] [CrossRef]

- Tong, F.; Qiao, W.; Xu, K.; Wang, L.; Chen, W.; Wang, X. On the study of wavy leading-edge vanes to achieve low fan interaction noise. J. Sound Vib. 2018, 419, 200–226. [Google Scholar] [CrossRef]

- Chen, H.; Qin, Y.; Wang, R. The optimization and flow diagnoses for a transonic fan with stage flow condition. Aerosp. Sci. Technol. 2018, 80, 247–260. [Google Scholar] [CrossRef]

- Badkar, P.S.; Benal, M.M. Noise reduction in power looms using nitrile rubber polymer. Mater. Today Proc. 2022, 66, 1779–1783. [Google Scholar] [CrossRef]

- Dhamande, L.S.; Bhaurkar, V.S.; Pankaj, N.P. Vibration analysis of induced draught fan: A case study. Mater. Today Proc. 2022, 72, 6657–6663. [Google Scholar] [CrossRef]

- Ottersten, M.; Yao, H.D.; Davidson, L. Inlet gap effect on aerodynamics and tonal noise generation of a voluteless centrifugal fan. J. Sound Vib. 2022, 540, 117304. [Google Scholar] [CrossRef]

- Chen, J.; He, Y.; Gui, L.; Wang, C.; Chen, L.; Li, Y. Aerodynamic noise prediction of a centrifugal fan considering the volute effect using IBEM. Appl. Acoust. 2018, 132, 182–190. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, J.; Yang, X.; Wang, W.; Ding, Y. Tonal noise reduction by unevenly spaced blades in a forward-curved-blades centrifugal fan. Appl. Acoust. 2019, 146, 172–183. [Google Scholar] [CrossRef]

- Wu, Y.; Pan, D.; Peng, Z.; Ouyang, H. Blade force model for calculating the axial noise of fans with unevenly spaced blades. Appl. Acoust. 2019, 146, 429–436. [Google Scholar] [CrossRef]

- Yang, X.; Wu, C.; Wen, H.; Zhang, L. Numerical simulation and experimental research on the aerodynamic performance of large marine axial flow fan with a perforated blade. J. Low Freq. Noise Vib. Act. Control 2018, 37, 410–421. [Google Scholar] [CrossRef]

- NVW Editorial Staff. Reducing noise from fans. NoiseVibration WorldWide 2018, 49, 11–13. [Google Scholar]

- Canepa, E.; Cattanei, A.; Mazzocut Zecchin, F. Leakage Noise and Related Flow Pattern in a Low-Speed Axial Fan with Rotating Shroud. Int. J. Turbomach. Propuls. Power 2019, 4, 17. [Google Scholar] [CrossRef] [Green Version]

- Chen, K.; Liu, Q.P.; Sun, W.L. Experiment Research on the Efficiency of Bionic Blade of Axial Fan. In Proceedings of the 2018 IEEE International Conference on Mechatronics and Automation (ICMA), Changchun, China, 5–8 August 2018. [Google Scholar]

- Kim, S.J.; Sung, H.J.; Wallin, S.; Johansson, A.V. Design of the centrifugal fan of a belt-driven starter generator with reduced flow noise. Int. J. Heat Fluid Flow 2019, 76, 72–84. [Google Scholar] [CrossRef]

- Scheit, C.; Karic, B.; Becker, S. Effect of blade wrap angle on efficiency and noise of small radial fan impellers—A computational and experimental study. J. Sound Vibr. 2012, 331, 996–1010. [Google Scholar] [CrossRef]

- Dong, B.; Jiang, C.; Liu, X.; Deng, Y.; Huang, L. Theoretical characterization and modal directivity investigation of the interaction noise for a small contra-rotating fan. Mech. Syst. Signal Process. 2020, 135, 106362. [Google Scholar] [CrossRef]

- Almeida, V.; Pinheiro, O. Analysis of high frequency noise sources on air conditioning variable speed compressors. In Proceedings of the Internoise 2022, Glasgow, UK, 21–124 August 2022. [Google Scholar]

- Shojiro, K. Multi-Stage Fan Noise Reduction by Cascade Clocking. In Proceedings of the Internoise 2004, Prague, Czech Republic, 22–25 August 2004. [Google Scholar]

- Fukano, T.; Satoh, D.; Jang, C.M. Relation between noise and internal flow characteristics of an axial flow fan. In Proceedings of the Internoise 2004, Prague, Czech Republic, 22–25 August 2004. [Google Scholar]

- Lee, J.; Cho, K.; Lee, S. Analysis of automotive cooling fan noise using free-wake panel method and acoustic analogy. In Proceedings of the Internoise 1999, Fort Lauderdale, FL, USA, 6–18 December 1999. [Google Scholar]

- Lee, S.; Cheong, C.; Park, J.; Lee, J. Development of flow-vibroacoustic coupled numerical methods for prediction of noise radiation due to flow-born vibration of compressor discharge piping system. In Proceedings of the Internoise 2022, Glasgow, UK, 21–124 August 2022. [Google Scholar]

- Hyrynen, J. Sound power dependency on fan speed: Various fans and surrounding structures. In Proceedings of the Internoise 2004, Prague, Czech Republic, 22–25 August 2004. [Google Scholar]

- Wasala, S.; Stevens, L.; Sosseh, R.; Persoons, T. Numerical analysis of acoustic noise from an electronic cooling fan at flow disturbed by an external obstacle. In Proceedings of the Internoise 2022, Glasgow, UK, 21–124 August 2022. [Google Scholar]

- Guo, J.; Qu, R.; Yi, W.; Fang Yi Zhong, S. Broadband noise attenuation in the flow duct using metamaterial-based acoustic liners. In Proceedings of the Internoise 2022, Glasgow, UK, 21–124 August 2022. [Google Scholar]

- Mesquita, A.L.A.; Amarante Mesquita, A.L.; Arthur, E.; Filho, M. Use of Dissipative Silencers for Fan Noise Control; Environmental Noise Control: Curitiba, Brazil, 2005. [Google Scholar]

- Henk, I.; Van der Spek, F. Advanced low noise air cooling fans. In Proceedings of the International Congress and Exposition on Noise Control Engineering, Seogwipo, Korea, 25–28 August 2003. [Google Scholar]

- Jeon, W.H.; Kim, C.J. Analysis of Unsteady Flow Field and Aerodynamic Noise of a Cross Flow Fans. In Proceedings of the International Congress and Exposition on Noise Control Engineering, Seogwipo, Korea, 25–28 August 2003. [Google Scholar]

- Choi, H.L.; Chung, K.H.; Jeon, W.J.; Kim, B.S.; Lee, S.G.; Lee, D.J. Noise Prediction for a Boxed Fan System. In Proceedings of the International Congress and Exposition on Noise Control Engineering, Seogwipo, Korea, 25–28 August 2003. [Google Scholar]

- Papamoschou, D. Modeling of Aft-Emitted Tonal Fan Noise in Isolated and Installed Configurations. In Proceedings of the AIAA SciTech 2021 Forum, Virtual, 11–15 and 19–21 January 2021. [Google Scholar]

- Feng, G.; Lei, S.; Gu, X.; Guo, Y.; Wang, J. Predictive control model for variable air volume terminal valve opening based on back propoagation neutral network. Build. Environ. 2021, 188, 107485. [Google Scholar] [CrossRef]

- Hayashia, H.; Kodama, Y.; Ogino, K.; Fukano, T. Noise Performance of Centrifugal Fan with Inducer. In Proceedings of the Internoise 2004, Prague, Czech Republic, 22–25 August 2004. [Google Scholar]

- Polenghi, A.; Cattaneo, L.; Macchi, M.; Pasanisi, D.; Pesenti, V.; Borgonovo, A. Development of an advanced condidion-based maintenance system for high critical industrial fans in a foundry. IFAC-PapersOnLine 2022, 55, 2–48. [Google Scholar] [CrossRef]

- Song, I.H.; Lhee, J.H.; Jeong, J.W. Energy efficiency and economic analysis of variable frequency drive and variable pitch system: A case study of axial fan in hospital. J. Build. Eng. 2021, 43, 103213. [Google Scholar] [CrossRef]

- Wen, S.; Liu, J.; Zhang, F.; Xu, J. Numerical and experimental study towards a novel torque damper with minimized air flow instability. Build. Environ. 2022, 217, 109114. [Google Scholar] [CrossRef]

- Wen, S.; Gao, R.; Guan, H.; Li, H.; Wang, M.; Zhang, S.; Li, A. Air damper with Controlling Capacity Unrelated to duct system resistance. J. Build. Eng. 2021, 43, 102388. [Google Scholar] [CrossRef]

- Xue, Y.; Li, X.; Li, N.; Zheng, S.; Wang, Z. Experimental analysis and simulation of a centrifugal jet fan for impulse ventilation systems. J. Build. Eng. 2022, 57, 104836. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, F.; Jia, M. A centrifugal fan blade damage identification method based on the multi-level fusion of vibro-acoustic signals and CNN. Measurement 2022, 199, 111475. [Google Scholar] [CrossRef]

- Zhang, H.; Nunayon, S.S.; Jin, X.; Lai, A.C. Pressure drop and nanoparticle deposition characteristics for multiple twisted tape inserts with partitions in turbulent duct flows. Int. J. Heat Mass Transf. 2022, 193, 121474. [Google Scholar] [CrossRef]

- Zhao, X.; Li, H.; Yang, S.; Fan, Z.; Dong, J.; Cao, H. Blade vibration measurement and numerical analysis of a mistuned industrial impeller in a single-stage centrifugal compressor. J. Sound Vib. 2021, 501, 116068. [Google Scholar] [CrossRef]

- Lee, M.; Bolton, J.S.; Yoo, T.; Ido, H.; Sekie, K. Fan Noise Control by Enclosure Modification. In Proceedings of the INTER-NOISE 2005, Rio de Janeiro, Brazil, 7–110 August 2005. [Google Scholar]

- Koo, H.M.; Lee, J.K.; Kim, C.H.; Yoo, K.C. A study on the noise reduction of a cross-flow fan of the air-conditioner using the skewed stabilizers. In Proceedings of the INTER-NOISE 98, Christchurch, New Zealand, 16–118 November 1998. [Google Scholar]

| Publication | Research Area | Research Results |

|---|---|---|

| [18] |

|

|

| [19] |

|

|

| [20] |

|

|

| [21] |

|

|

| [22] |

|

|

| [23] |

|

|

| [24] |

|

|

| [25] |

|

|

| [26] |

|

|

| [27] |

|

|

| Publication | Research Area | Research Results |

|---|---|---|

| [30] |

|

|

| [31] |

|

|

| [32] |

|

|

| [33] |

|

|

| [34] |

|

|

| [35] |

|

|

| [36] |

|

|

| [37] |

|

|

| [38] |

|

|

| [39] |

|

|

| [40] |

|

|

| [41] |

|

|

| [42] |

|

|

| [43] |

|

|

| [44] |

|

|

| [45] |

|

|

| [46] |

|

|

| [47] |

|

|

| [48] |

|

|

| [49] |

|

|

| [50] |

|

|

| [51] |

|

|

| [52] |

|

|

| [53] |

|

|

| [54] |

|

|

| [55] |

|

|

| [56] |

|

|

| [57] |

|

|

| [58] |

|

|

| [59] |

|

|

| [60] |

|

|

| [61] |

|

|

| [62] |

|

|

| [63] |

|

|

| [64] |

|

|

| Publication | Research Area | Research Results |

|---|---|---|

| [41] |

|

|

| [65] |

|

|

| [66] |

|

|

| [67] |

|

|

| [68] |

|

|

| [69] |

|

|

| [70] |

|

|

| [71] |

|

|

| [72] |

|

|

| [73] |

|

|

| [74] |

|

|

| [75] |

|

|

| [76] |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piwowarski, M.; Jakowski, D. Areas of Fan Research—A Review of the Literature in Terms of Improving Operating Efficiency and Reducing Noise Emissions. Energies 2023, 16, 1042. https://doi.org/10.3390/en16031042

Piwowarski M, Jakowski D. Areas of Fan Research—A Review of the Literature in Terms of Improving Operating Efficiency and Reducing Noise Emissions. Energies. 2023; 16(3):1042. https://doi.org/10.3390/en16031042

Chicago/Turabian StylePiwowarski, Marian, and Damian Jakowski. 2023. "Areas of Fan Research—A Review of the Literature in Terms of Improving Operating Efficiency and Reducing Noise Emissions" Energies 16, no. 3: 1042. https://doi.org/10.3390/en16031042

APA StylePiwowarski, M., & Jakowski, D. (2023). Areas of Fan Research—A Review of the Literature in Terms of Improving Operating Efficiency and Reducing Noise Emissions. Energies, 16(3), 1042. https://doi.org/10.3390/en16031042