Numerical Study of Heat and Mass Transfer in the Original Structure and Homogeneous Substitution Model for Three Dimensional Porous Metal Foam

Abstract

1. Introduction

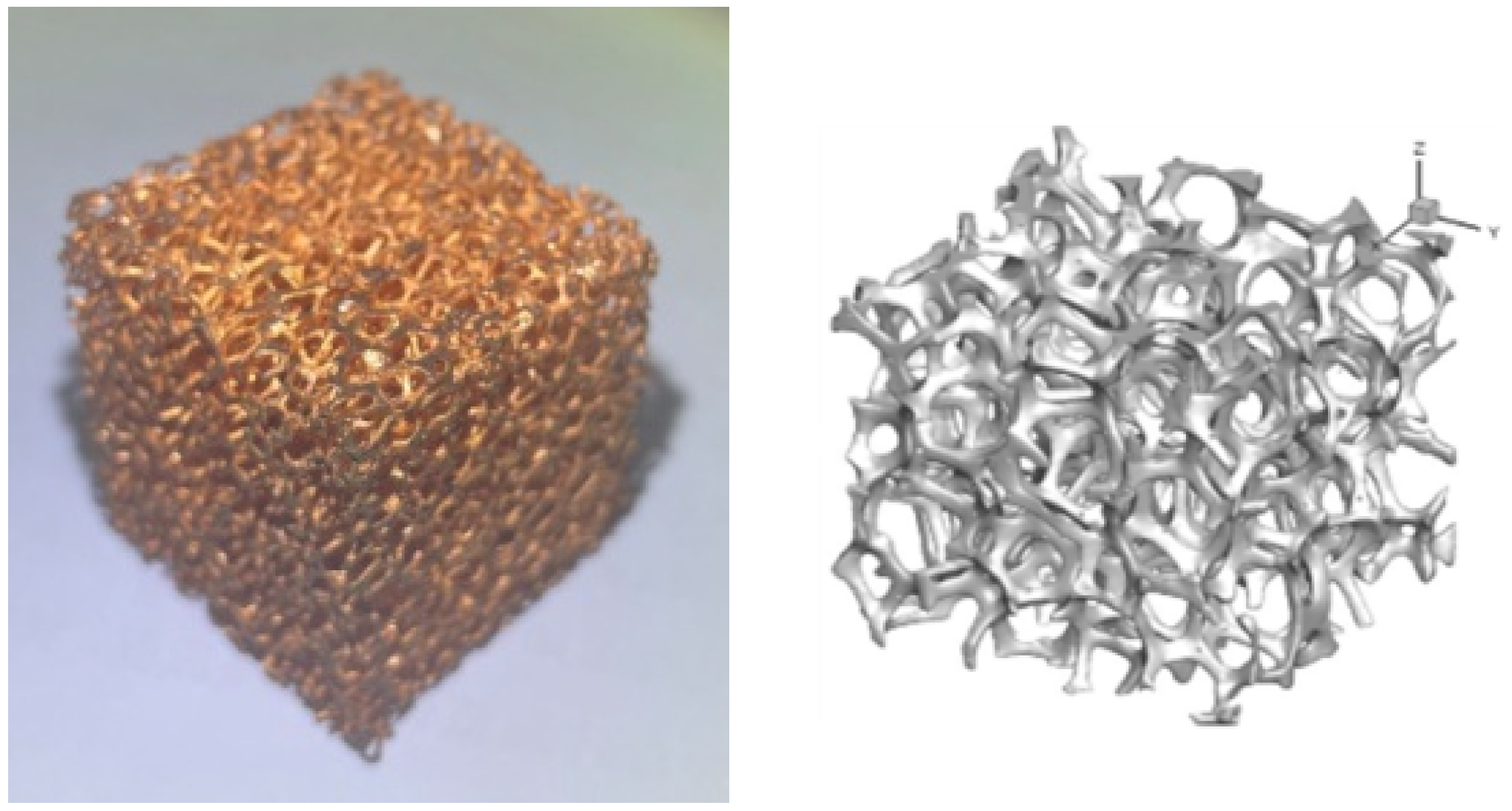

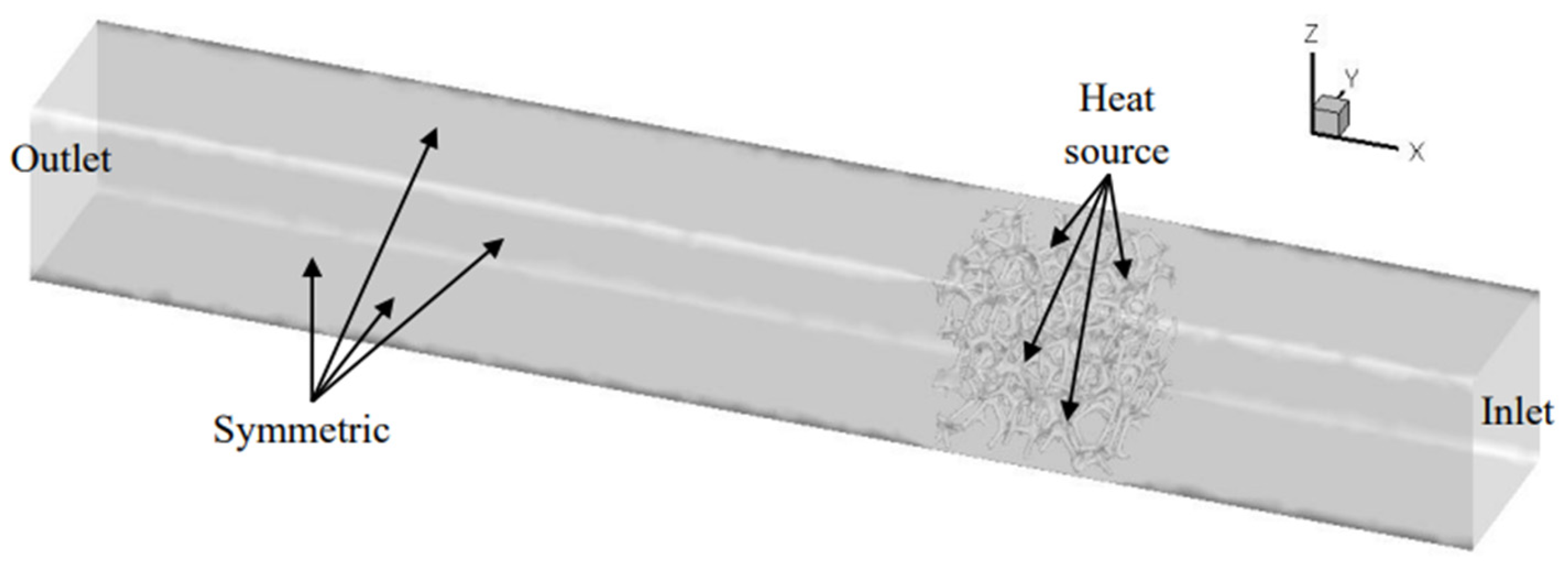

2. Physical Model and Reconstruction Method

3. Mathematical Model

3.1. Governing Equations

3.2. Boundary Conditions

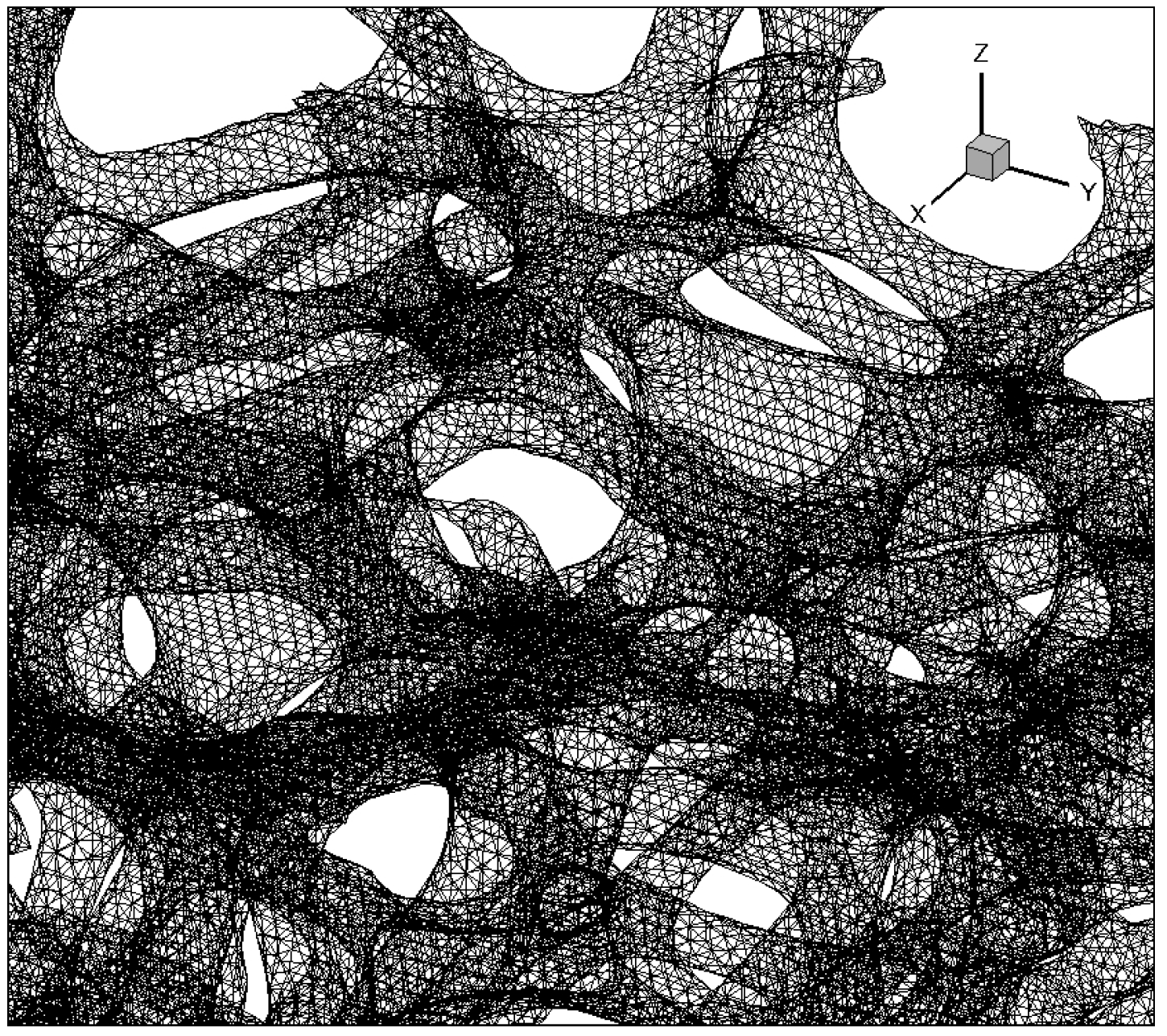

3.3. Numerical Methods

3.4. Grid Independence

4. Results and Discussion

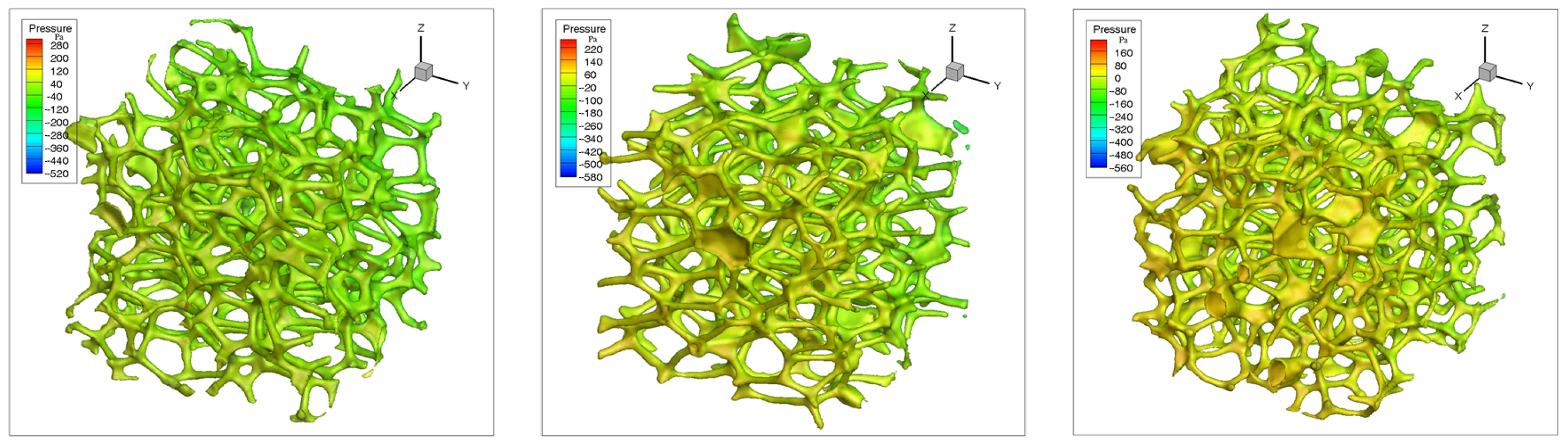

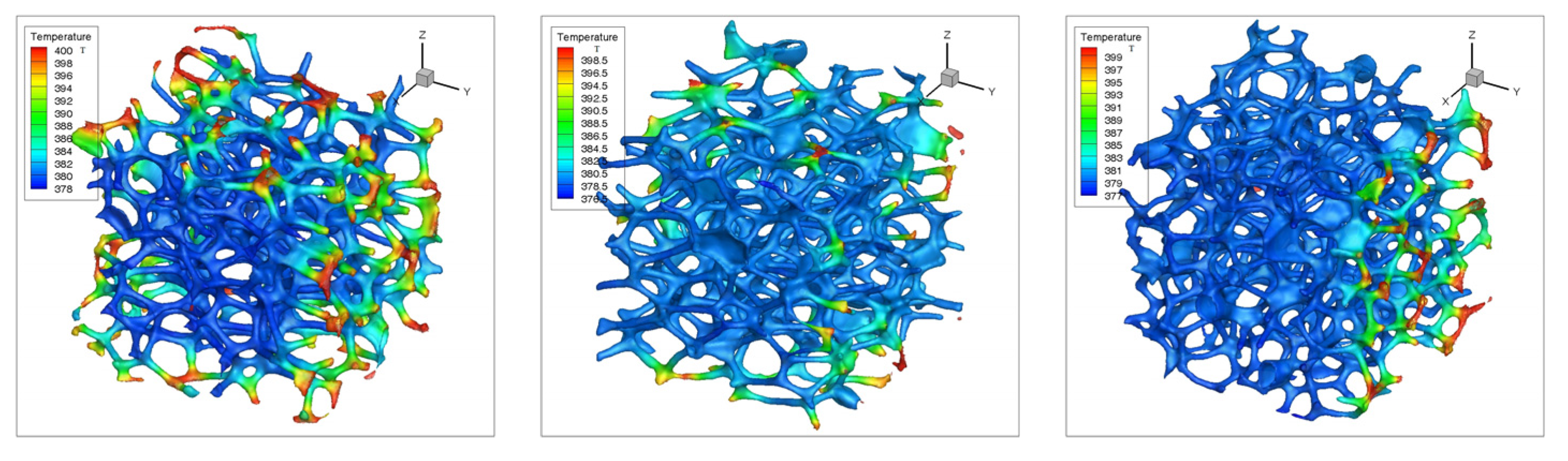

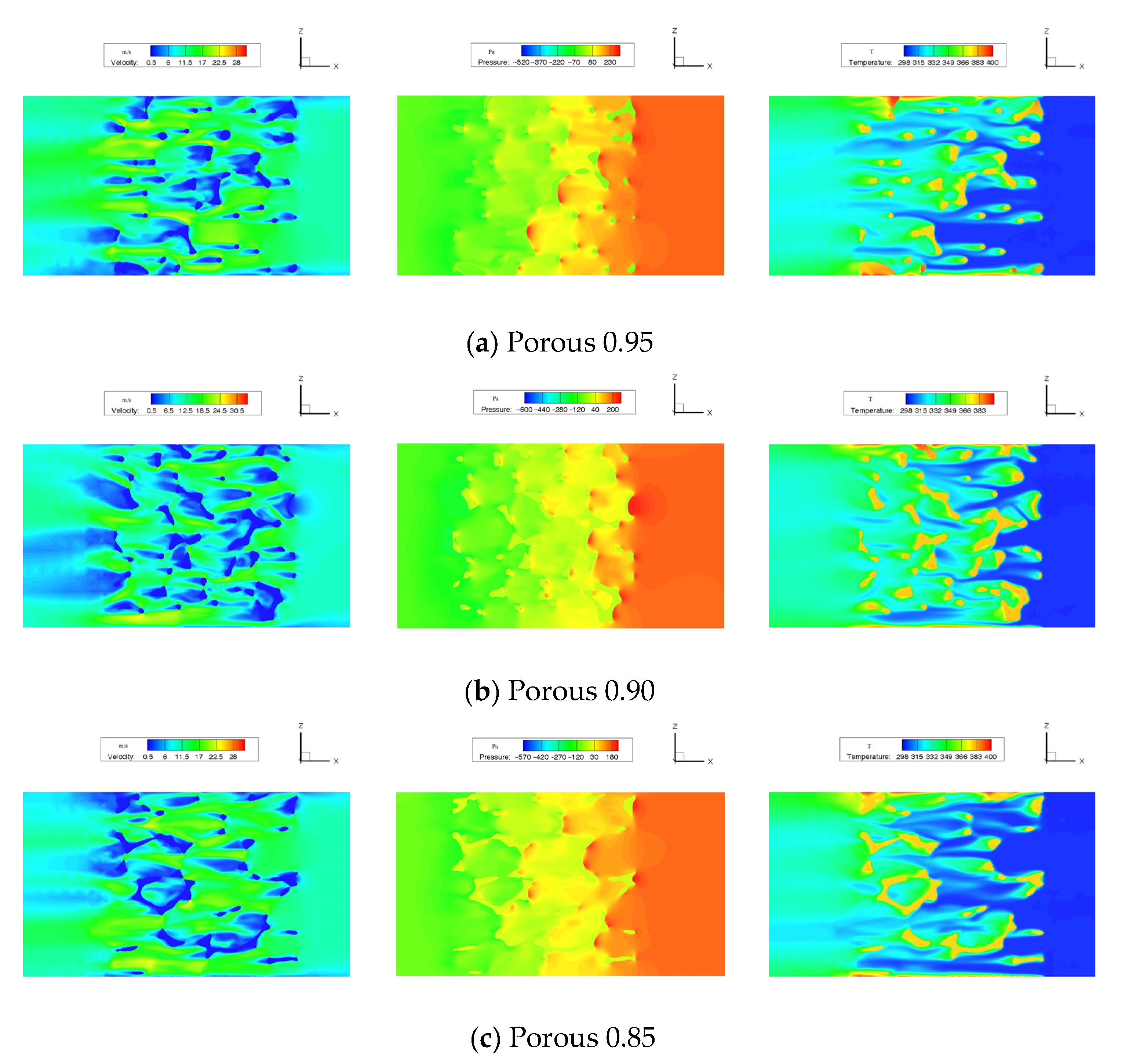

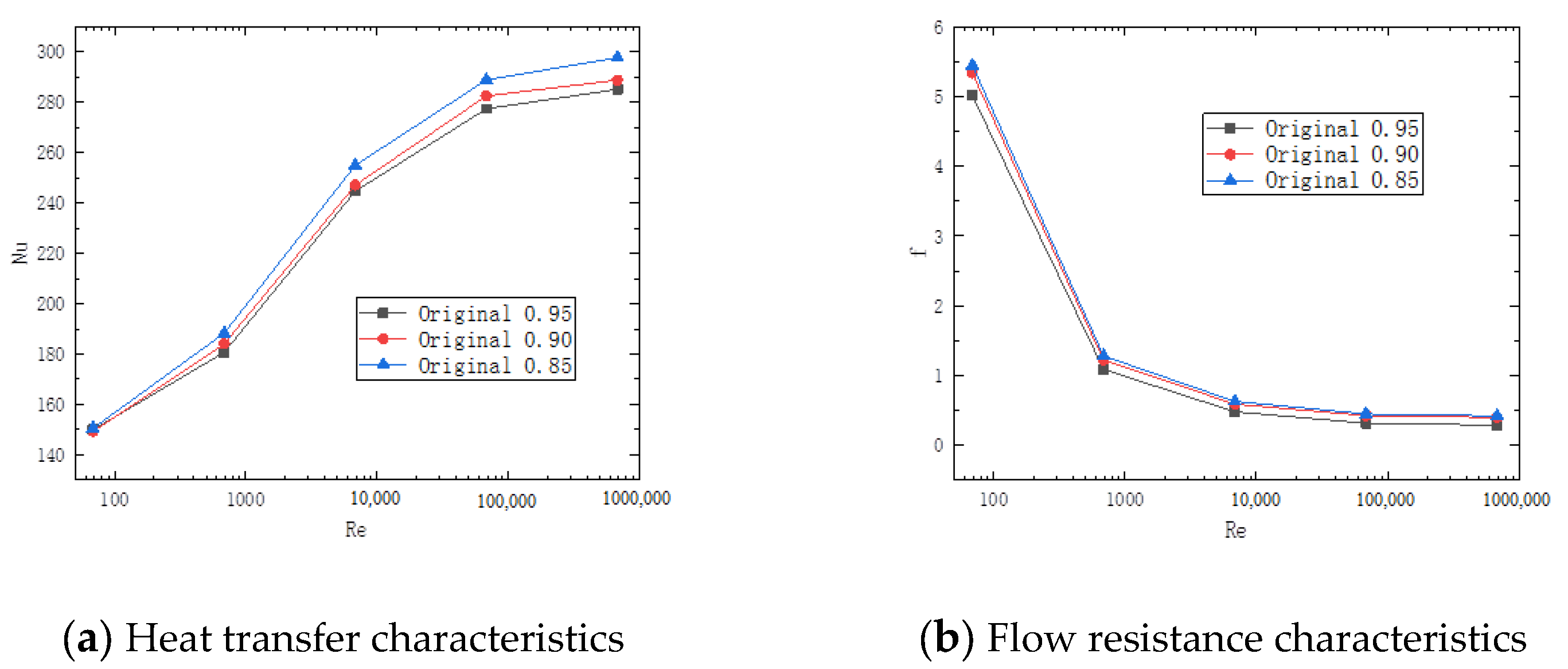

4.1. Flow and Heat Transfer of Original Structures

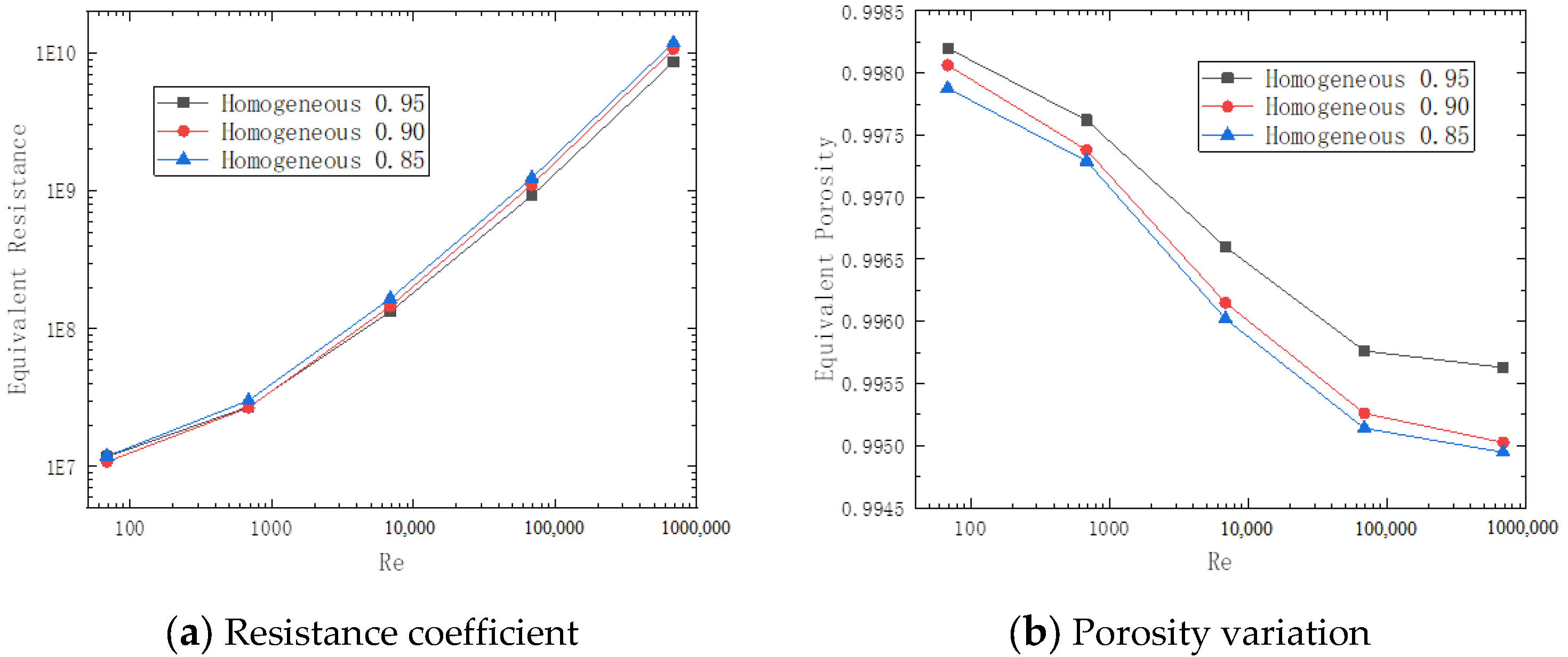

4.2. Comparison of Equivalent Homogenization Models

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| f | Friction resistance value |

| Nu | Nusselt number |

| p | Static pressure (Pa) |

| T | Temperature (K) |

| V | Velocity (m/s) |

| Greek symbols | |

| ρ | Density (kg/m3) |

| λ | Effective thermal conductivity [W/(m∙K)] |

| μ | Work medium dynamic viscosity [kg/(m∙s)] |

| τ | Stress tensor |

| φ | Volumetric concentration (%) |

References

- Gangapatnam, P.; Kurian, R.; Venkateshan, S.P. Numerical simulation of heat transfer in metal foams. Heat Mass Transf. 2018, 54, 553–562. [Google Scholar] [CrossRef]

- Dukhan, N. Equivalent Parallel Strands Modeling of Highly-Porous Media for Two-Dimensional Heat Transfer: Application to Metal Foam. Energies 2021, 14, 6308. [Google Scholar] [CrossRef]

- Xu, H.J.; Gong, L.; Huang, S.B. Flow and heat transfer characteristics of nanofluid flowing through metal foams. Int. J. Heat Mass Transf. 2015, 83, 339–407. [Google Scholar] [CrossRef]

- Yao, Y.P.; Wu, H.Y. Interfacial heat transfer in metal foam porous media (MFPM) under steady thermal conduction condition and extension of Lemlich foam conductivity theory. Int. J. Heat Mass Transf. 2021, 169, 120974. [Google Scholar] [CrossRef]

- Arbak, A.; Dukhan, N. Performance and heat transfer measurements in asymmetrically-heated metal foam cooled by water. Therm. Sci. Eng. Prog. 2020, 20, 100688. [Google Scholar] [CrossRef]

- Bagci, O.; Dukhan, N.; Ozdemir, M.; Kavurmacioglu, L.A. Experimental heat transfer due to oscillating water flow in open-cellmetal foam. Int. J. Therm. Sci. 2016, 101, 48–58. [Google Scholar] [CrossRef]

- Kuruneru, S.T.W.; Saha, S.C.; Sauret, E.; Gu, Y.T. Transient heat transfer and non-isothermal particle-laden gas flows through porous metal foams of differing structure. Appl. Therm. Eng. 2019, 150, 888–903. [Google Scholar] [CrossRef]

- Xia, X.L.; Chen, X.; Sun, C.; Li, Z.H.; Liu, B. Experiment on the convective heat transfer from airflow to skeleton in open-cell porous foams. Int. J. Heat Mass Transf. 2017, 106, 83–90. [Google Scholar] [CrossRef]

- Chen, K.; Wang, X.; Chen, P.F.; Wen, L. Numerical simulation study on heat transfer enhancement of a heat exchanger wrapped with metal foam. Energy Rep. 2022, 8, 103–110. [Google Scholar] [CrossRef]

- Xu, H.; Yao, F.; Zhang, C.B. Numerical study on melting heat transfer in fractal metal foam. Fractals-Complex Geom. Parrtens Scaling Nat. Soc. 2019, 27, 1950106. [Google Scholar] [CrossRef]

- Jang, H.; Kim, M.H.; Park, S.K.; Kim, Y.S.; Choi, B.C. Simulation of Heat and Mass Transfer Characteristics for the Optimal Operating Conditions of a Gas-to-Gas Membrane Humidifier with Porous Metal Foam. Energies 2020, 13, 5110. [Google Scholar] [CrossRef]

- Li, Y.Z.; Wang, S.X.; Zhao, Y.L. Experimental study on heat transfer enhancement of gas tube partially filled with metal foam. Exp. Therm. Fluid Sci. 2018, 97, 408–416. [Google Scholar] [CrossRef]

- Slimani, L.; Hamadouche, A.; Bousri, A.; Ben Hamed, H. Heat transfer enhancement using 40 kHz ultrasound and metal foams inside a horizontal mini-channel. Appl. Therm. Eng. 2022, 216, 119039. [Google Scholar] [CrossRef]

- Vazifeshenas, Y.; Sedighi, K.; Shakeri, M. Heat transfer in PEM cooling flow field with high porosity metal foam insert. Appl. Therm. Eng. 2019, 147, 81–89. [Google Scholar] [CrossRef]

- Chen, W.; Li, L.X. Analysis of heat transfer in a bilayer metal foam block subjected to an impinging air jet. Heat Transf. Res. 2017, 48, 1281–1298. [Google Scholar] [CrossRef]

- Rabbani, P.; Hamzehpour, A.; Ashjaee, M.; Najafi, M.; Houshfar, E. Experimental investigation on heat transfer of MgOnanofluid in tubes partially filled with metal foam. Power Technol. 2019, 354, 734–742. [Google Scholar] [CrossRef]

- Deng, Z.L.; Liu, X.D.; Zhang, C.B.; Huang, Y.P.; Chen, Y.P. Melting behaviors of PCM in porous metal foam characterized by fractal geometry. Int. J. Heat Mass Transf. 2017, 113, 1031–1042. [Google Scholar] [CrossRef]

- Nilpueng, K.; Asirvatham, L.G.; Dalkilic, A.S.; Mahian, O.; Ahn, H.S.; Wongwises, S. Heat transfer and fluid flow characteristics in a plate heat exchanger filled with copper foam. Heat Mass Transf. 2020, 56, 3261–3271. [Google Scholar] [CrossRef]

- Arasteh, H.; Salimpour, M.R.; Tavakoli, M.R. Optimal distribution of metal foam inserts in a double-pipe heat exchanger. Intern. J. Numer. Methods Heat Fluid 2019, 29, 1322–1342. [Google Scholar] [CrossRef]

- Mohammadpour-Ghadikolaie, M.; Saffar-Avval, M.; Mansoori, Z.; Alvandifar, N.; Rahmati, N. Heat Transfer Investigation of a Tube Partially Wrapped by Metal Porous Layer as a Potential Novel Tube for Air Cooled Heat Exchangers. J. Heat Transf.-Trans. ASME 2019, 141, 011802. [Google Scholar] [CrossRef]

- Huisseune, H.; De Schampheleire, S.; Ameel, B.; De Paepe, M. Comparison of metal foam heat exchangers to a finned heat exchanger for low Reynolds number applications. Int. J. Heat Mass Transf. 2015, 89, 1–9. [Google Scholar] [CrossRef]

- Zhang, C.B.; Wu, L.Y.; Chen, Y.P. Study on solidification of phase change material in fractal porous metal foam. Fractals- Complex Geom. Patterns Scaling Nat. Soc. 2015, 3, 1540003. [Google Scholar] [CrossRef]

- Wang, G.Q.; Qi, C.; Pan, Y.H.; Li, C.Y. Experimental study on heat transfer and flow characteristics of two kinds of porous metal foam tubes filled with water. Therm. Sci. 2018, 22, 497–505. [Google Scholar] [CrossRef]

- Li, H.W.; Chang, T.L.; Du, C.H.; Fu, D.W.; Hong, W.P. Experimental study on flow boiling heat transfer characteristics of multi-channel modified filled foam metal small channel. Int. Commun. Heat Mass Transf. 2021, 127, 105588. [Google Scholar] [CrossRef]

- Bianco, N.; Iasiello, M.; Mauro, G.M.; Pagano, L. Multi-objective optimization of finned metal foam heat sinks: Tradeoff between heat transfer and pressure drop. Appl. Therm. Eng. 2021, 182, 116058. [Google Scholar] [CrossRef]

- Trilok, G.; Kurma, E.S.S.; Devika, H.; Gnanasekaran, N.; Moghtada, M. Correlations and Numerical Modeling of Stacked Woven Wire-Mesh Porous Media for Heat Exchange Applications. Energies 2022, 15, 237. [Google Scholar]

- Shi, J.; Du, H.Y.; Chen, Z.Q.; Lei, S.Y. Review of phase change heat transfer enhancement by metal foam. Appl. Therm. Eng. 2023, 219, 119427. [Google Scholar] [CrossRef]

- Moghimi, M.A.; Craig, K.J.; Meyer, J.P. A novel computational approach to combine the optical and thermal modelling of Linear Fresnel Collectors using the finite volume method. Sol. Energy 2015, 216, 407–427. [Google Scholar] [CrossRef]

| Dimension (mm3) | Porosity | Pore Diameter (mm) | Structure Thickness (mm) |

|---|---|---|---|

| 20 × 20 × 20 | 0.85, 0.90, 0.95 | 1.6~2.0 | 0.45~0.65 |

| Medium | (kg/m3) | (W/m.K) | (kg/m.s) | |

|---|---|---|---|---|

| Solid | Copper | 1800 | 245 | / |

| Fluid | liquid medium | 1.225 | 0.0242 | 1.7894 × 10−5~1.7894 × 10−9 |

| Grid Number | 1.228 × 107 | 1.351 × 107 | 1.486 × 107 | 1.635 × 107 |

|---|---|---|---|---|

| Nu | 237.51 | 244.98 | 247.12 | 247.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ke, H.; Zhou, X.; Liu, T.; Wang, Y.; Wang, H. Numerical Study of Heat and Mass Transfer in the Original Structure and Homogeneous Substitution Model for Three Dimensional Porous Metal Foam. Energies 2023, 16, 1114. https://doi.org/10.3390/en16031114

Ke H, Zhou X, Liu T, Wang Y, Wang H. Numerical Study of Heat and Mass Transfer in the Original Structure and Homogeneous Substitution Model for Three Dimensional Porous Metal Foam. Energies. 2023; 16(3):1114. https://doi.org/10.3390/en16031114

Chicago/Turabian StyleKe, Hanbing, Xuzhi Zhou, Tao Liu, Yu Wang, and Hui Wang. 2023. "Numerical Study of Heat and Mass Transfer in the Original Structure and Homogeneous Substitution Model for Three Dimensional Porous Metal Foam" Energies 16, no. 3: 1114. https://doi.org/10.3390/en16031114

APA StyleKe, H., Zhou, X., Liu, T., Wang, Y., & Wang, H. (2023). Numerical Study of Heat and Mass Transfer in the Original Structure and Homogeneous Substitution Model for Three Dimensional Porous Metal Foam. Energies, 16(3), 1114. https://doi.org/10.3390/en16031114