A Model Predictive Control Based Optimal Task Allocation among Multiple Energy Storage Systems for Secondary Frequency Regulation Service Provision

Abstract

:1. Introduction

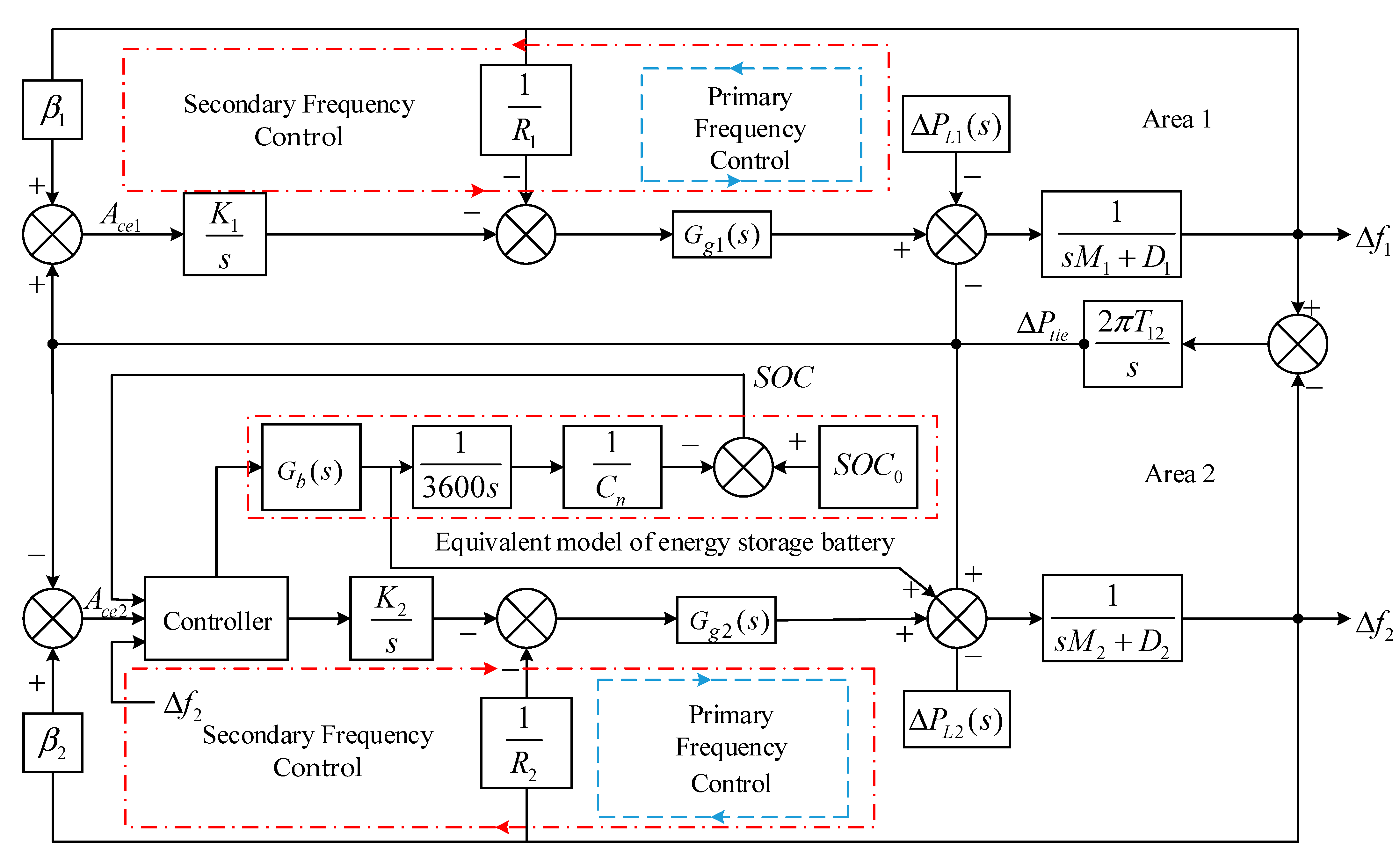

2. Dynamic Model of Secondary Frequency Control with Energy Storage

2.1. Frequency Control Model of Two Area Interconnection Systems

2.2. Equivalent Model of Battery Energy Storage Systems in Power Grid Frequency Control

3. Dynamic Model of Secondary Frequency Control with Energy Storage

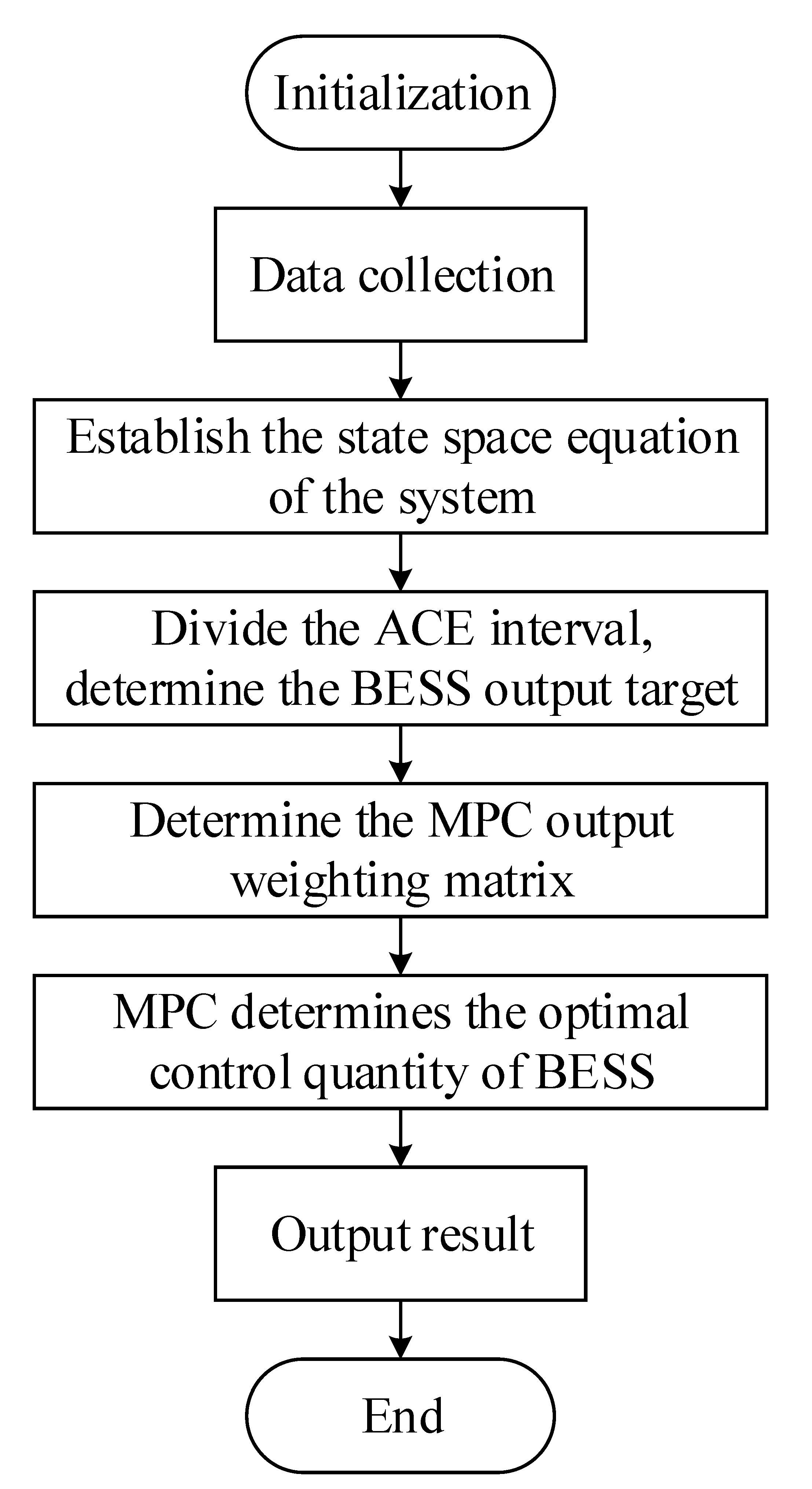

3.1. Model Predictive Control

3.2. Application of MPC in Secondary Frequency Control

3.2.1. System Prediction Model

3.2.2. Rolling Optimization

3.2.3. Feedback Correction

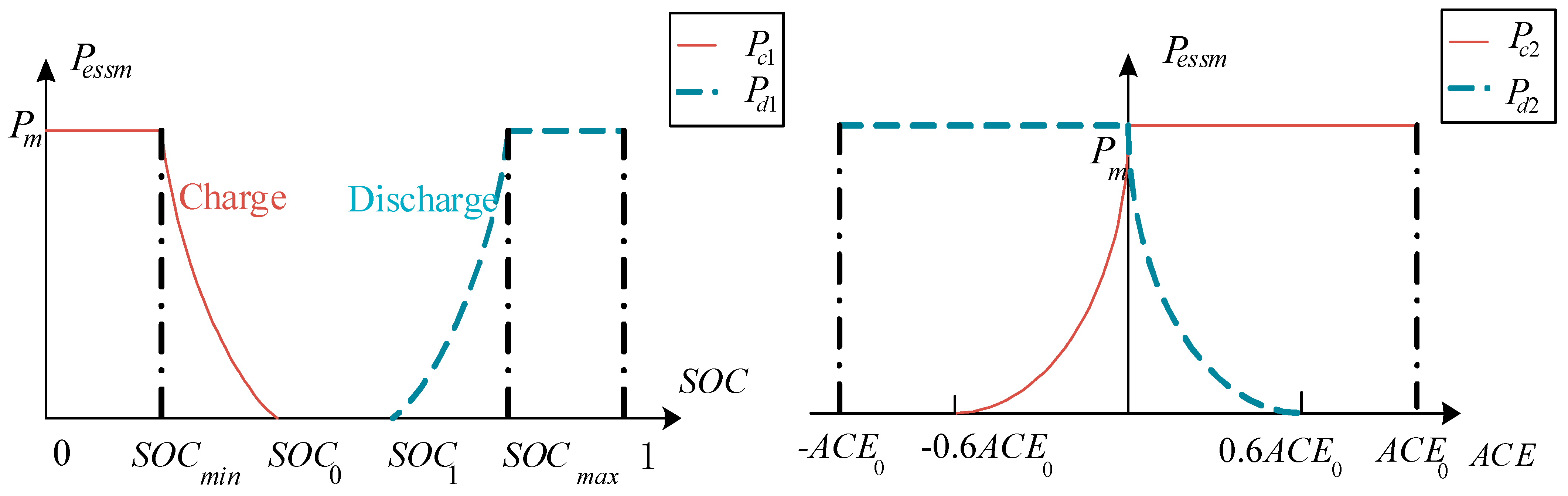

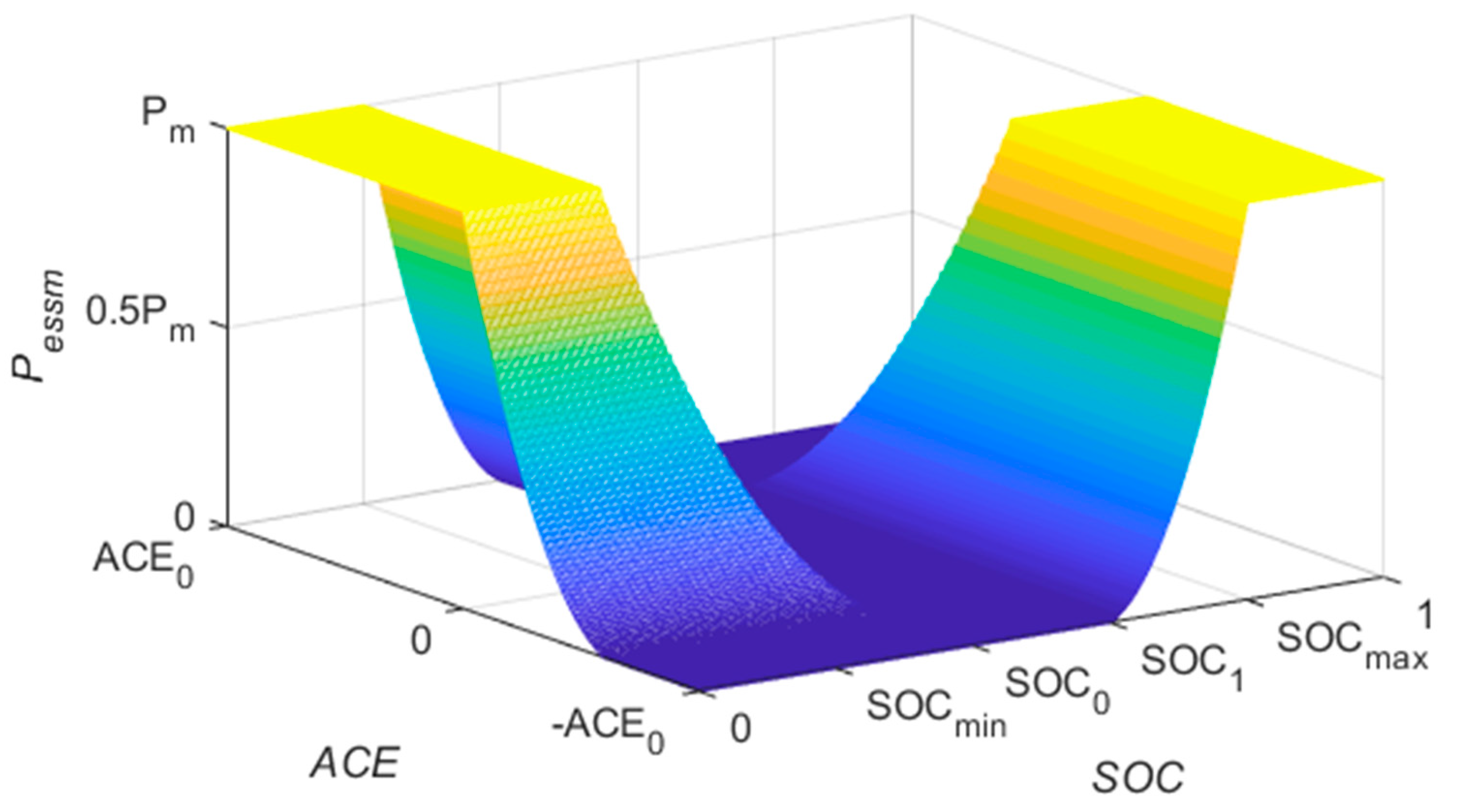

4. Control Strategy of Battery Energy Storage System

4.1. Output Strategy of Battery Energy Storage System

4.1.1. Dead Zone

4.1.2. Normal State Zone

4.1.3. Sub-Emergency State Zone

4.1.4. Emergency State Zone

4.2. Self-Recovery Strategy of Battery Energy Storage System

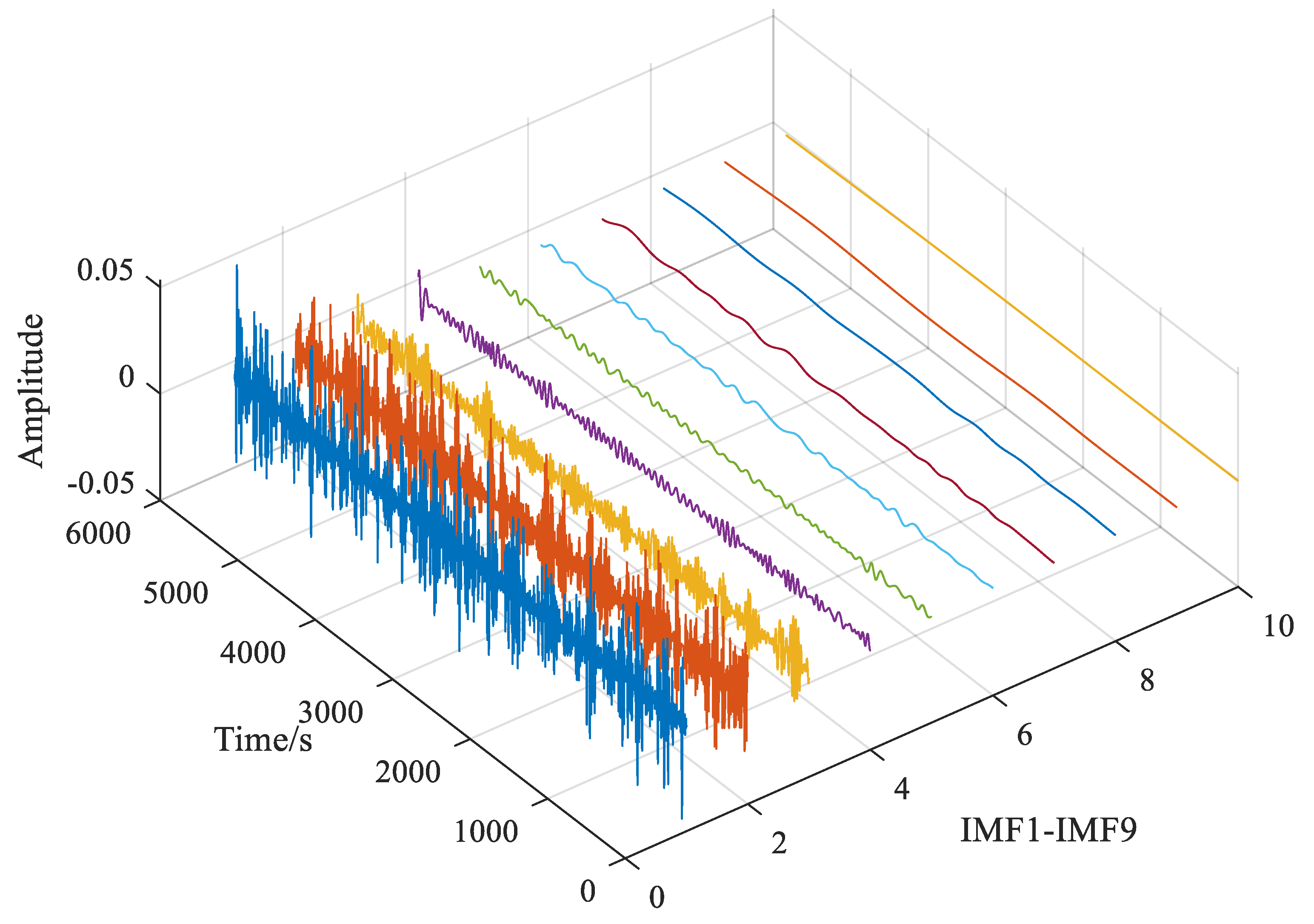

4.3. Decomposition of ACE Signal

5. The Simulation Verification

5.1. The Simulation Parameters

5.2. Analysis of Simulation Results

5.2.1. Scene under Step Load Disturbance

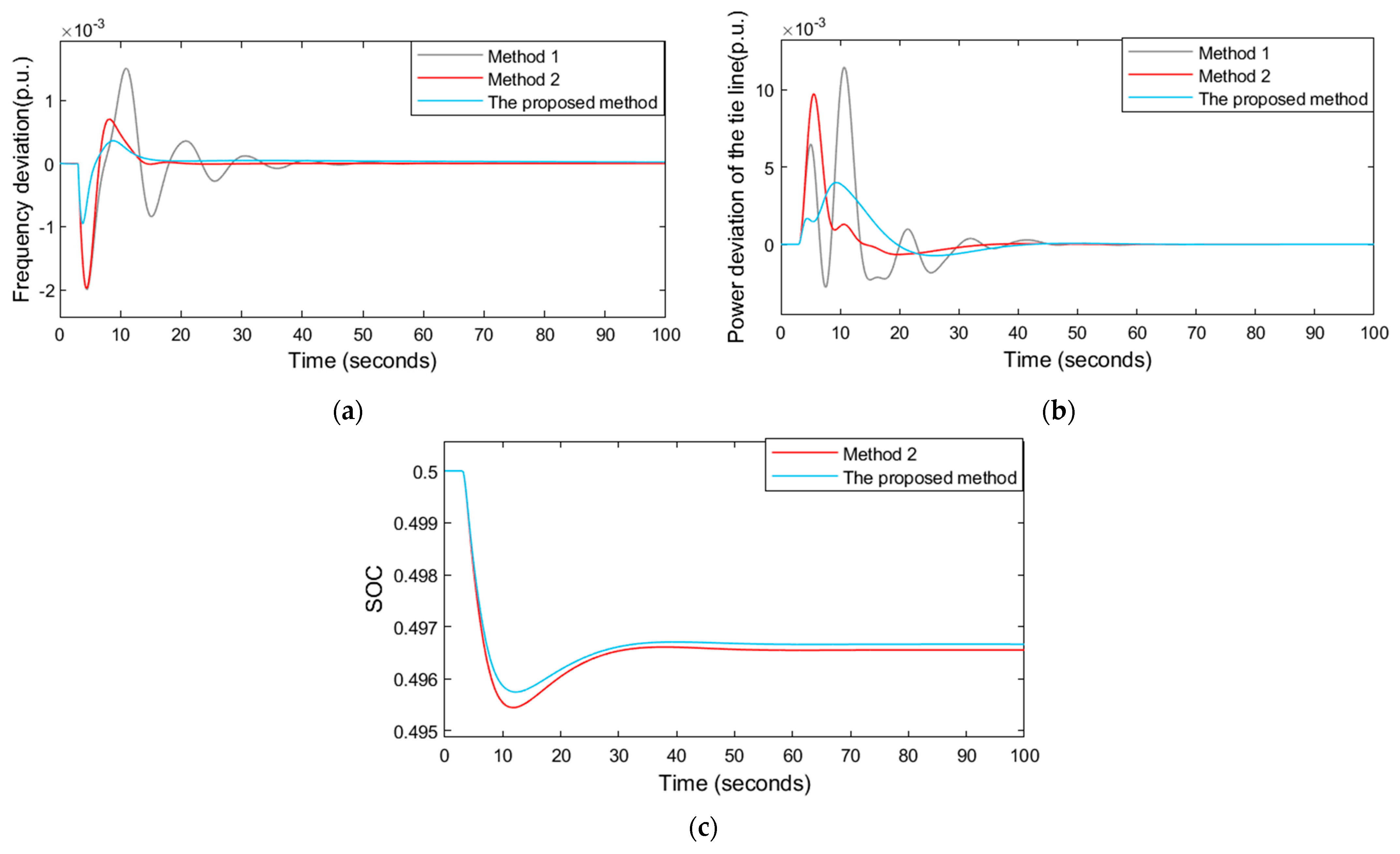

- (1)

- In Figure 7a,b, and Table 3, we compare the proposed method with Method 1(without BESS) and Method 2 (PI). From the results, we obtained the maximum values and root mean square values of system frequency deviation, the maximum values and root mean square values of tie-line power deviation, and the adjustment time, all of which decreased with our proposed method and Method 2. The overshoot of the proposed scheme is the smallest, indicating that the dynamic stability is superior to the other two methods.

- (2)

- The system’s response time is significantly faster in the MPC method than in Method 2, which fully uses the rapid response characteristics of the BESS. Figure 7c shows that SOC has a better maintenance effect.

5.2.2. Scene under Continuous Load Disturbance

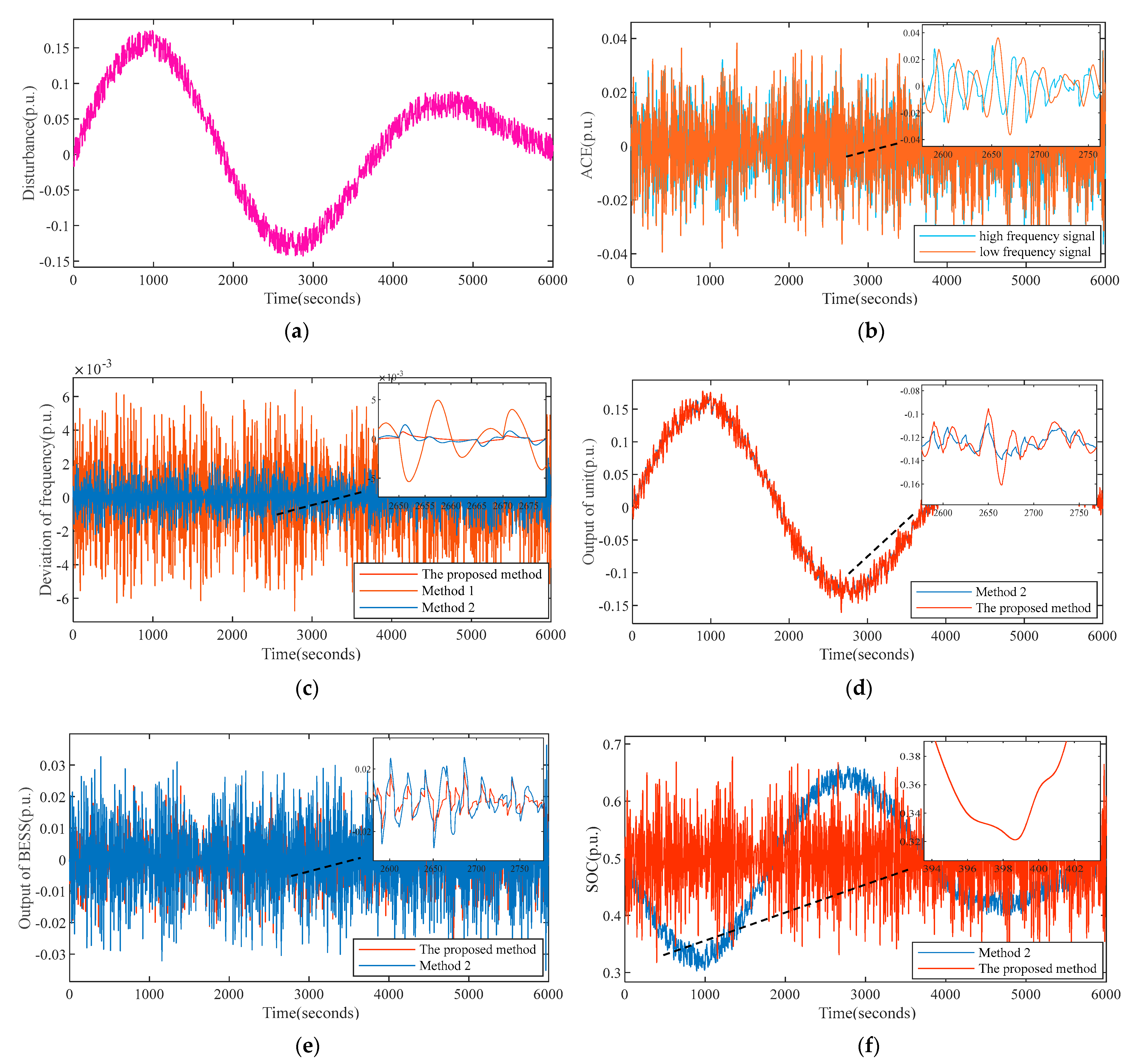

- (1)

- The maximum value of frequency deviation and the root mean square value of frequency deviation for the proposed method are the minimum values compared to the other two methods, and the frequency control effect is significantly improved. In addition, the frequency decline rate of the proposed method is minor, and the recovery speed is faster.

- (2)

- Figure 8b shows the final ACE signal allocation. The high-frequency component is assigned to the BESS and the traditional unit bears the low-frequency component of the ACE. According to Figure 8d,e and Table 4, the operation frequency of the unit is reduced and the operation loss is reduced. Moreover, the unit can contribute more energy, which is beneficial to frequency control. At the same time, the output of BESS is reduced, which reduces the frequency control capacity configuration requirements of BESS.

- (3)

- In Figure 8f, the SOC fluctuation range of our strategy is between 0.3 and 0.7, the state-keeping effect is better, and the burden of BESS is reduced. In addition, it can be seen that when SOC is lower than 0.3, the SOC falling speed is significantly reduced and the rising speed is increased. It is proven that changing the component of high frequency for energy storage in real time is beneficial to maintain SOC state. The ACE signal’s high-frequency component has the characteristics of zero mean value and small amplitude. Assuming the ACE signal’s high-frequency component by the BESS has its advantages of fast response speed and maintaining SOC.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Chen, L.; Han, X. Analysis on key issues of new energy substitution in China under energy transformation. J. Proc. CSEE 2022, 42, 515–524. [Google Scholar]

- Zhang, J.; Li, Q.; Wang, X. Power supply planning method for large-scale new energy grid-connected system. J. Proc. CSEE 2020, 40, 3114–3124. [Google Scholar]

- Li, J.; Feng, X.; Yan, G. Review on research of power system under high wind power permeability. J. Power Syst. Prot. Control 2018, 46, 163–170. [Google Scholar]

- Yao, L.; Yang, B.; Cui, H. Challenges and progresses of energy storage technology and its application in power systems. J. Mod. Power Syst. Clean Energy 2016, 4, 519–528. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Huang, J.; Yang, Y. Review on frequency control of large-scale energy storage power supply. J. Power Syst. Prot. Control 2016, 44, 145–153. [Google Scholar]

- Sun, B.; Yang, S.; Liu, Z. Analysis and enlightenment of current status of frequency control demonstration and application of megawatt energy storage at home and abroad. J. Autom. Electr. Power Syst. 2017, 41, 8–16. [Google Scholar]

- Xie, X.; Guo, Y.; Wang, B. Improving AGC performance of coal-fueled thermal generators using multi-mw scale BESS: A Practical Application. J. IEEE Trans. Smart Grid 2018, 9, 1769–1777. [Google Scholar] [CrossRef]

- Cheng, Y.; Tabrizi, M.; Sahni, M. Dynamic available AGC based approach for enhancing utility scale energy storage performance. IEEE Trans Smart Grid. 2014, 5, 1070–1078. [Google Scholar] [CrossRef]

- Ma, Z.; Li, X.; Tan, Z. The primary frequency regullation control method of energy storage frequency modulation dead zone is considered. J. Trans. China Electrotech. Soc. 2019, 34, 2102–2115. [Google Scholar]

- Meng, G.; Chang, Q.; Sun, Y. Energy storage auxiliary frequency modulation control Strategy Considering ACE and SOC of Energy Storage. J. IEEE Access 2021, 9, 26271–26277. [Google Scholar]

- Cui, H.; Yang, B.; Jiang, Y. Based on fuzzy control and SOC self-recovery energy storage participating in secondary frequency control control strategy. J. Power Syst. Prot. Control 2019, 47, 89–97. [Google Scholar]

- Zhao, T.; Parisio, A.; Milanovicj, V. Distributed control of battery energy storage systems for improved frequency control. J. IEEE Trans. Power Syst. 2020, 35, 3729–3738. [Google Scholar] [CrossRef]

- Li, R.; Li, X.; Tan, Z. Integrated control strategy considering energy storage battery participating in secondary frequency control. J. Autom. Electr. Power Syst. 2018, 42, 74–82. [Google Scholar]

- Liu, Q.; He, S.; Lu, W. Model predictive control method for secondary frequency control assisted by battery energy storage. J. Electr. Meas. Instrum. 2020, 57, 119–125. [Google Scholar]

- Yan, G.; Liu, Y.; Duan, S. Battery energy storage unit group participates in power distribution strategy of secondary frequency control in power system. J. Autom. Electr. Power Syst. 2020, 44, 26–34. [Google Scholar]

- Lv, L.; Chen, S.; Zhang, X. Secondary frequency modulation control strategy for power system considering SOC consistency of large-scale battery storage. J. Therm. Power Gener. 2021, 50, 108–117. [Google Scholar]

- Le, J.; Liao, X.; Zhang, Y. Review and prospect of distributed model predictive control methods for power system. J. Autom. Electr. Power Syst. 2020, 44, 179–191. [Google Scholar]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Power reference/MW | 300 | 0.2, 0.3 | |

| Frequency reference/Hz | 50 | 10, 8 | |

| Energy storage capacity/MW·h | 4.5 | 0.25, 0.37 | |

| Energy storage power/MW | 9 | 0.05 | |

| 0.1, 0.08 | 35, 21 | ||

| 0.03, 0.05 | 2.75, 2 | ||

| 0.5, 0.5 | 10, 12 |

| Parameters | Value | Parameters | Value | Parameters | Value |

|---|---|---|---|---|---|

| 0.2 | 0.35 | 0.4 | |||

| 0.8 | 0.65 | 0.6 | |||

| 1 × 10−7 | 0.03 | 0.05 |

| Evaluation Index | The Proposed Method | Method 1 | Method 2 |

|---|---|---|---|

| 9.560 × 10−4 | 1.998 × 10−3 | 1.690 × 10−3 | |

| 2.084 × 10−4 | 5.722 × 10−4 | 4.365 × 10−4 | |

| 7.298 × 10−4 | 2.776 × 10−2 | 9.718 × 10−3 | |

| 1.016 × 10−3 | 1.995 × 10−3 | 1.483 × 10−3 | |

| 9.560 × 10−4 | 1.998 × 10−3 | 1.690 × 10−3 |

| Evaluation Index | The Proposed Method | Method 1 | Method 2 |

|---|---|---|---|

| 1.100 × 10−3 | 6.463 × 10−3 | 2.316 × 10−3 | |

| 2.763 × 10−4 | 1.933 × 10−3 | 6.015 × 10−4 | |

| 0.242 | 0.274 | 0.265 | |

| 0.021 | _ | 0.0189 | |

| 0.019 | _ | 0.038 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Li, X.; Ni, W.; Wen, F. A Model Predictive Control Based Optimal Task Allocation among Multiple Energy Storage Systems for Secondary Frequency Regulation Service Provision. Energies 2023, 16, 1228. https://doi.org/10.3390/en16031228

Wang X, Li X, Ni W, Wen F. A Model Predictive Control Based Optimal Task Allocation among Multiple Energy Storage Systems for Secondary Frequency Regulation Service Provision. Energies. 2023; 16(3):1228. https://doi.org/10.3390/en16031228

Chicago/Turabian StyleWang, Xiuli, Xudong Li, Weidong Ni, and Fushuan Wen. 2023. "A Model Predictive Control Based Optimal Task Allocation among Multiple Energy Storage Systems for Secondary Frequency Regulation Service Provision" Energies 16, no. 3: 1228. https://doi.org/10.3390/en16031228

APA StyleWang, X., Li, X., Ni, W., & Wen, F. (2023). A Model Predictive Control Based Optimal Task Allocation among Multiple Energy Storage Systems for Secondary Frequency Regulation Service Provision. Energies, 16(3), 1228. https://doi.org/10.3390/en16031228