Abstract

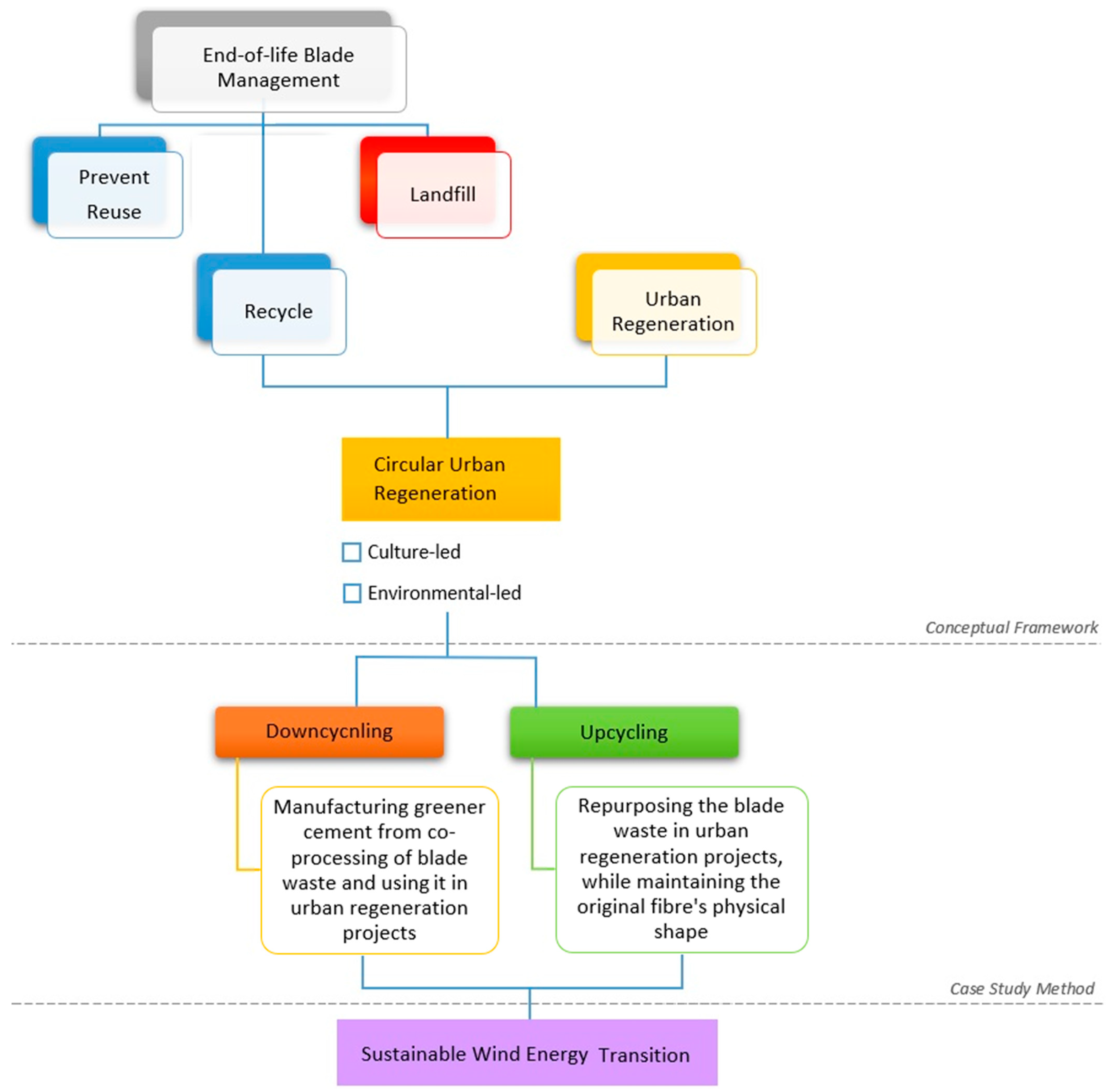

With the vast majority of scientists agreeing that the only hope in mitigating the adverse effects of climate change is to drop our carbon emissions to net zero by 2050, the decarbonization of the electricity sector is an environmental emergency. Wind energy can be a leader in the energy transition to a carbon emission-free economy. However, the wind energy transition must be carefully implemented to mitigate the economic, environmental, and social consequences of this change. Blade waste from end-of-life wind turbines is the Achilles’ heel of this energy transition and the main impediment to its full acceptance. Aiming to support efficient blade waste management and therefore to ensure sustainable wind energy transition, we conduct a two-fold methodology. In the first part, we propose a novel conceptual framework of upcycling and downcycling end-of-life solutions in an urban regeneration setting. In the second part, we use the case study method to illustrate the aspects of our conceptual framework by analyzing real life case studies. This study suggests that end-of-life blades are used in the cement coprocessing of waste and in architectural projects under urban regeneration transformation processes, closing the material loop according to the circular economy and sustainability principles.

1. Introduction

Recognizing the necessity for an effective and progressive response to climate change’s urgent threat, it is vital to maintain global warming within 1.5° above pre-industrial average levels. To hold the average global temperature below this threshold and avoid the devastating impacts on the planet, it is essential to reach net-zero CO2 emissions globally by 2050 [1]. The EU has committed to net-zero greenhouse gas emissions with the European Green Deal and its commitment to global climate action under the Paris Agreement [2]. During COP27, UN Secretary-General António Guterres said that more needs to be done to drastically reduce emissions now “The world still needs a giant leap on climate ambition [3]”.

Given that the energy sector, which traditionally relies on the combustion of fossil fuels, is the largest and primary contributor to global greenhouse gas emissions [4], the decrease of fossil fuels has been the focus of climate policies and regulations. Electricity supply underwent considerable change over the last few years, with renewable sources increasingly gaining ground against fossil fuels [5]. Nevertheless, the aim of zero carbon emissions is far from becoming a reality in the next 30 years. Wind energy is one of the fastest-growing renewable energy sources worldwide. Using wind to generate electricity emits far less GHG in comparison with the use of fossil fuels. In addition, a wind turbine offsets the emissions produced by its manufacture and dismantling within six months of its function and, the resulting emissions represent around 1% of those it will avoid during its useful life in replacing production from coal, gas, or fuel oil power stations [6]. The transition to wind energy systems, except from cutting down on GHG emissions, can also bring socio-economic benefits by creating direct and indirect employment opportunities in manufacturing, installation, maintenance, and monitoring [7].

Nevertheless, wind energy is not developing as fast as it is deemed necessary in order to achieve zero carbon targets by 2050. One of the main reasons is that wind energy must compete with more traditional sectors that use fossil fuels, and some locations may not be windy enough to be cost-competitive. In addition, the societal acceptance of wind turbines is lagging behind their development, as they might cause noise and aesthetic disturbances, and interfere with wildlife. However, the main challenge of the transition to wind energy is to find a sustainable solution to recycle blades from decommissioned wind turbines. Estimations show that there will be 43 million tons of used blades by 2050. Research shows that the end-of-life waste stream will generate more than 2 Mt of global waste annually in 2050 and cumulative blade waste in 2050 will be between 21.4 Mt and 69.4 Mt with the most probable scenario being a waste level of 43.4 Mt [8]. Different projections considering the time of availability of end-of-life wind turbine blades, the geographical location of future end-of-life wind turbine blades, and the material specifications facilitate the future management of blade waste [9].

The outputs of these projections make apparent the need to adopt and adapt a roadmap for a sustainable transition to wind energy including circularity technologies and practices and end-of-life solutions. This study sets the pathway to wind energy transition through a novel conceptualization of solutions that would render end-of-life blade-suitable material for urban regeneration projects, aiming to ensure sustainability. The novelty of this study relies on the coupling of upcycling and downcycling end-of-life solutions with the urban regeneration concept. By illuminating different aspects of our theoretical conceptualization of blade waste circularity coupled with urban regeneration, we analyze and compare real case studies of recycling blade waste projects.

The remainder of this study is organized as follows. In Section 2 we analyze the current end-of-life options of the blades. Section 3 constitutes the methodological part of the study wherein Section 3.1 we analyze, explain, and provide the novel conceptual framework of blade waste management coupled with urban regeneration under the broader concept of the circular economy. By shedding light on the different aspects and dimensions of our conceptual framework, we analyze and compare real-life case studies of recycling blade waste projects in Section 3.2. In Section 4 we then discuss the key points and main challenges for the transition to sustainable wind energy, as well as the main limitations related to the proposed conceptualization’s implementation. Lastly, in Section 5 we present the main conclusions of the study.

2. Background: End-of-Life Blades

Large numbers of the first-generation wind turbines installed in Europe and North America are coming to their end-of-life (EoL). A life expectancy of a wind turbine is 20 years which can be extended to 25, but repowering projects alter their lifetime, and replacing them with newer technologies available on the market alter their life expectancy even more [10].

Wind turbine blades are composite structures, made of a variety of materials with varying qualities. Blades vary depending on the type of blade and the manufacturer but generally, they are manufactured with reinforcement fibers (glass, carbon, aramid, or basalt), polymer matrix (thermosets such as epoxies, polyesters, vinyl esters, polyurethane, or thermoplastics), sandwich core (balsa wood or foams such as polyvinyl chloride and polyethylene terephthalate), coatings (polyethylene and polyurethane), and metals (copper wiring and steel bolts). This combination of fibres and polymers is known as fibre reinforced polymer (FRP) composites and represents the majority of the blades’ material composition by weight: 60–70% reinforcing fibers and 30–40% resin [11]. A schematic representation of a blade is shown in Figure 1 below.

Figure 1.

Schematic representation of the methodological framework for end-of-life blade management.

The blades must be detached from the rest of the wind turbine as a first step in decommissioning and cut into smaller sections before being transported for waste treatment. In the waste treatment facility, they are treated depending on their intended EoL application. Currently, the most typical method of dealing with wind blade waste is to discard it in landfills; however, many landfills are saturated and in some countries such as Germany the method has been banned [12]. In addition, material recovery is not possible with this method. The process of pyrolysis can be utilized, where the blades are cut into suitable dimensions and decomposed using conventional heating in an inert atmosphere (450–700 °C). In this way, material recovery is achieved in the form of fibers which can be used as reinforcements (glues, paints, and concrete), and the by-products syngas and char can be combusted for electricity and heat recovery and recycled as fertilizer, respectively [13]. The method of solvolysis and high voltage pulse fragmentation allows the recovery of clean fibers in their full length and the recovery of resin that can be reused. However, it demands high energy due to the high temperature and high pressure involved and the use of large quantities of solvents. In addition, the method has adverse impacts on human health and ecotoxicity [14,15]. Biotechnological methods have also been tested where microorganisms are used to degrade the matrix, but the availability of this method is limited even at a laboratory scale [16]. The same applies to electrochemical solutions, where an electrical current is applied through an electrolyte solution to degrade the composite matrix. Another option is to incinerate the blades at 800 °C for energy recovery, although this has a number of disadvantages, such as the non-flammability of the glass fibres and the large volume of non-combustible by-products. Alternatively, the blades can be burnt in cement kilns and a few businesses in Germany have lately inserted mechanically recycled fibres into concrete, boosting the material’s structural integrity [17].

Other newly proposed solutions include using the blades as thermal insulation or noise-canceling screens. Even while mechanical and thermal treatment technologies exist, there is currently no connection to end users, and the low cost of virgin material and landfilling reduces the incentive for recycling [12]. Some of the wind turbines that have been dismantled have been sold to intermediaries who sell them for recommissioning in countries of eastern Europe and north Africa [18]. Last but not least, the practice of repurposing blades into second-life constructions is becoming increasingly common, for example, the Re-Wind Network is exploring civic buildings such as pedestrian bridges and transmission towers, among others [19].

3. Research Method

In this theoretical research, we use a two-fold methodology for wind turbine blade end-of-life management, as shown in Figure 1. The first part of the methodology comprises the novel conceptual framework of blade waste circularity coupled with urban regeneration. In our conceptualization, we prove how wind energy transitions can be sustainable through urban regeneration processes stressing the importance of integrating the cultural and the environmental dimension of these transformative processes. For the second part of the methodology, we used the case study method where we analyzed real-life case studies demonstrating the core drivers, the aspects, the dimensions, and the importance of our conceptual framework to the field of sustainable energy transitions. The specific case studies were chosen due to their relevance to our conceptual framework. They were considered excellent examples of projects that demonstrate how the waste of wind turbine blades can be efficiently used in an urban regeneration setting, thus ensuring sustainability.

3.1. Repurposing Wind Turbine Blades Coupled with Urban Regeneration

In the previous section, we demonstrated current methods of disposal of composite materials of wind turbines’ blades. The blades’ disposal at the landfill at the end-of-their-life still remains the most economically affordable option but at the same time, brings severe environmental pressure and causes energy and material waste. In this section, moving the focus to the management of blades after their end-of-life, we elaborate on repurposing them under the broader context of urban regeneration as an alternative to landfill disposal. Urban regeneration is a tool that includes a wide range of transformation processes placed in urban voids and deprived areas aiming to ensure simultaneously economic, social, and environmental sustainability. However, in most empirical cases, urban regeneration processes have been instrumentalized to attract investments, enhancing the urban area’s economic competitiveness without facing the current local urban challenges [20]. In our work, we recognize two main dimensions of equal importance for urban regeneration processes: culture-driven, and environment driven. We argue that through a holistic integration of both dimensions in the planning, design, and implementation of urban regeneration projects, we are able to achieve urban sustainability, tackling current challenges. In the next two paragraphs, we present how culture and environment have been used to support urban regeneration and how we perceive these dimensions. At the end of this section, we theoretically conceptualize how repurposing wind turbine blades through integrated urban regeneration ensures three-dimensional sustainability.

A part of urban regeneration literature has focused on how the cultural dimension plays a critical role in these transformation processes for sustainable urban redevelopment [21,22,23,24]. A study published in 2017 states that cultural urban regeneration processes renew the image of a city and its neighborhoods, foster a sense of belonging in its inhabitants, attract investments and tourism, create jobs in cultural and creative sectors, and improve the quality of life and social cohesion [25]. However, when it comes to the impact of the cultural regeneration processes on the social and human capital, strong critics argue that the current implemented top-down instrumental initiatives lead to relentless gentrification, creating urban areas of consumption [24,26]. In line with multiple comparative analyses found in the literature, we support that culture-led urban regeneration applying mixed top-down/bottom-up initiatives can ensure social efficacy, encouraging community participation in the decision-making processes [22,27,28,29]. In this way, the interests of different stakeholders are communicated and considered in the transformation processes, resulting in urban economic revitalization, and reinforcing the identity of the urban area. Hence, this culture-led regeneration driven by community fulfills the need for place identity and a sense of belonging and, therefore, leads to community coherence and wellbeing.

Analyzing the environmental dimension of urban regeneration, we recognize that priority was given to facing three main challenges related to urban growth: climate change, pollution, and waste. In doing so, scholars have studied urban regeneration consistent with circular economy (CE) principles contributing to sustainable growth [30,31,32]. The concept of CE appears in the literature mostly related to waste management, without fully exploring the circularity of its R-principles (reduction, repair, reuse, recover, remanufacturing, and recycling [33,34]. The Circular Economy (CE) model is a systematic approach to economic development that can benefit businesses, society, and the environment. CE can be explained as an economic model with the main aim of resource efficiency through long-term value creation, waste minimization, and reduction of closed-loop products considering environmental protection [35].

The elimination of waste and thoughtful product design are among the key tenets of the circular economy, as is the separation of a product’s consumables from its durable components, the use of renewable energy, and the replacement of the term “consumer” with “user.” Disassembly or reuse is successful in eliminating waste. Recycling and waste disposal are regarded as energy- and labor-intensive processes. A product’s durable components are built to be upgraded or reused. Consumable parts can be safely disposed of in nature because they are made of organic, non-polluting materials. The users will either be provided with the products, or they will be leased to them. The user will be liable for their return following their end-of-life if they are sold [36].

A recent study overviewed the six main principles of CE and studied the transition to CE business models of several organization typologies of different sizes and economic sectors [37]. Their study points out that recycling is the most preferred practice among the different organizations applied in the entire supply chain. Repair, reuse, and remanufacturing are evolving well, mostly in small companies, and some companies also promote CE culture, moving the focus from recycling to the dissemination of all the principles and practices of the CE concept. The authors found that implementing CE has the potential to achieve more sustainable development at a local and global scale, helping the better direct and indirect use of resources [38]. We support that implementing CE principles through circular urban regeneration processes establishing social, cultural, technological, and ecological synergies increases the resilience of an urban place and therefore ensures its sustainability.

In our theoretical conceptualization for the management of end-of-life wind turbine blades, we adopt an integrated approach to circular urban regeneration using culture-led and environment-led transformation processes. Core drivers of this approach are related to circular economy principles, mainly the primary recycling (upcycling), and the secondary recycling (downcycling) of the blades, as well as to the three-dimensional sustainability (social–economic–environmental). The blade waste is converted into products with equal or higher properties without undergoing any chemical damage through upcycling, while downcycling converts blade waste into products not as structurally strong as the original product and/or with lower quality [34]. Taking advantage of the durability and strength of the blades’ composite materials, the recycled products can be used in various urban regeneration projects ensuring sustainability. For instance, projects related to architecture, spatial planning, and design can regenerate an urban place, reducing the projects’ ecological footprint, and creating economic opportunities in addition to cultural and social benefits for the local community. In our theoretical conceptualization, we emphasize the circularity of the transformation processes related to this kind of urban regeneration project. The circularity is related not just to the upcycling of the materials per se but also to the coevolutionary synergies among different (transformation) processes and actors. Urban regeneration projects require the involvement of different actors, expertise, and a diversity of approaches to ensure their sustainability. The collaboration between the public and private sectors is essential to provide financial resources and governance structure. Moreover, through this collaboration, a supportive regulatory framework with guidelines and legislation is provided to ensure health and safety and to overpass technical challenges regarding project implementation. Community participation is necessary to ensure that these projects reflect the place’s identity and cover the community’s needs. In other words, the focus of circularity remains on the reuse, recycling, and recovery of natural resources but also on how to achieve social–cultural–economic prosperity via transformation processes (Table 1).

Table 1.

Circular urban regeneration framework for recycling wind blades.

3.2. Case Studies

In this section, we analyze and compare real life case studies of recycling blade waste projects, illuminating different aspects of our theoretical conceptualization of circular urban regeneration. By enabling an in-depth examination of these case studies, we investigate how we can maximize the benefits of wind power, capturing the complexity of circular regeneration. The series of case studies under analysis and testing concerns projects of the downcycling and upcycling of decommissioned and dismantled wind turbine blades as an alternative method of landfill disposal, tackling unnecessary waste pollution, and increasing resource efficiency.

3.2.1. Downcycling Wind Turbine Blades

Most of the components of wind turbines are recyclable with a recyclability rate of 85% to 90%, but the blades present a special challenge due to the complex nature of their composite materials. Currently, there are several downcycling technologies for this composite waste including physical, thermal, and chemical processes, and/or combinations of them [38]. Examples of these technologies include mechanical grinding (physical), pyrolysis and gasification (thermal), solvolysis (thermo-chemical), and high voltage pulse fragmentation (electro-mechanical). These different processing methods affect the quality of the fibers and therefore their second-life use. Through physical downcycling methods, long clean fibers, and the general matrix of the polymers cannot be recovered, and the overall material waste is 40%. Thermal processing is not economically viable with short-length recovered fibers out of the market’s demand. Chemical processes can recover clean fibers, but these technologies have not been made available in industrial-scale recycling [37,39].

The downcycling method that we analyze in this study, coupled with circular urban regeneration is cement coprocessing, also referred to as the cement kiln route. Traditional cement production consists of three main stages: the initial raw material preparation, then the clinker burning, and lastly the cement preparation [40]. The raw materials, mostly sand, clay, and limestone, are crushed, homogenized, and placed into a rotary kiln. The produced clinker is burnt at a material temperature of 1450 °C forming new compounds. The cement preparation takes place in a grinding mill where gypsum and other additional material (blast furnace slag, coal fly ash, natural pozzolans, limestones, etc.) are added to the clinker and ground to a fine and homogeneous powder: the cement [41]. During coprocessing, shredded wind turbine blades are used as new materials in cement production, partially substituting fossil fuel and raw material dependency. Specifically, the glass fiber is recycled as a component material of cement clinker and the polymer matrix is burned as fuel (refuse-derived fuel) for cement production. The cement kiln route is considered the optimum way for blade waste recycling providing material and energy recovery; it has a simple supply chain and is cost-effective and efficient [39,41].

The process begins onsite with the dismantling of the wind turbine, where the blades are cut into sections of 10–12 meters with a mobile saw, mainly used in the mining and cement industry, a cable with diamond inserts, and a water mist. The sections are then transported to the reprocessing facility where they are cut into even smaller sections that are fed into a crusher that reduces the size to 50 cm. A shredder then reduces them even further and a hammer mill gives them their final shape before they are mixed with other wet waste to ensure that the fiberglass will be bound properly. The mixture is then added to Solid Recovered Fuel (SRF), an alternative fuel derived from mixed dry waste that is too difficult to separate and would otherwise end up in landfills. SRF is employed as a fossil fuel alternative in the cement and power industries across Europe [42]. The reprocessed blades are then used in cement production as a substitute fuel, replacing coal ash, and as a raw material, displacing some of its need for raw washed sand. The Holcim Lägerdorf cement industry in Northern Germany is currently the sole industry processing blade material on an industrial scale in Europe.

The greener cement produced by repurposing blade waste can be used for various urban regeneration projects adopting circular economy principles. Cement is the binder substance to form concrete which is used as the most common construction material in the urbanized world. Under our holistic theoretical conceptualization of urban regeneration transformations, the production and use of the greener cement and, therefore concrete, creates new business opportunities; safe and affordable housing; workplaces; industrial sites; transportation systems; and infrastructure for sanitation, energy, water, and telecommunication among other life-supporting and wellbeing structures that are commonly made having as base concrete. Replacing traditional cement with green and engaging all stakeholders during the whole design, implementation, and management of the regeneration projects offers essential opportunities for improving the sustainability of the urban space. Starting with the environmental benefits, we achieve CO2 emission savings over the overall life of cement, optimizing its use and maximizing the life of the buildings and infrastructure, resulting in resource salvation, and reducing atmospheric pollution. Improving the service life of those urban regeneration projects, apart from environmental benefits, offers cultural benefits, including social and economic ones. The overall costs of construction, use, and maintenance of the projects are more effective while being energy efficient by reducing the emissions to the environment and improving the energy efficiency regarding cooling and heating costs. Therefore, indirectly the replacement of regular cement with cement produced from wind turbine waste positively influences the quality of life and wellbeing of the users of the regeneration projects.

3.2.2. Upcycling Wind Turbine Blades

Another way to tackle the challenges of wind turbine blade waste is to upcycle them and use them in urban regeneration projects. Repurposing the blades instead of completely deconstructing them via downcycling methods is a less costly option, producing fewer emissions and dust while maintaining the original fiber’s physical shape. Various projects such as the Re-Wind project, companies such as Anmet, and architecture firms, such as Superuse studios, in collaboration with institutes and universities, have been working on repurposing discarded wind turbine blades, thus giving them a second life. The suggested/applied end-of-life solutions offer environmental, social, and economic benefits within the circular economy paradigm.

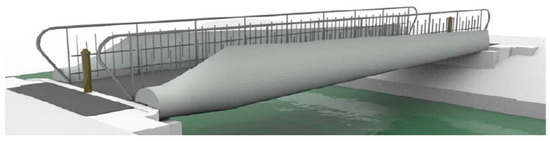

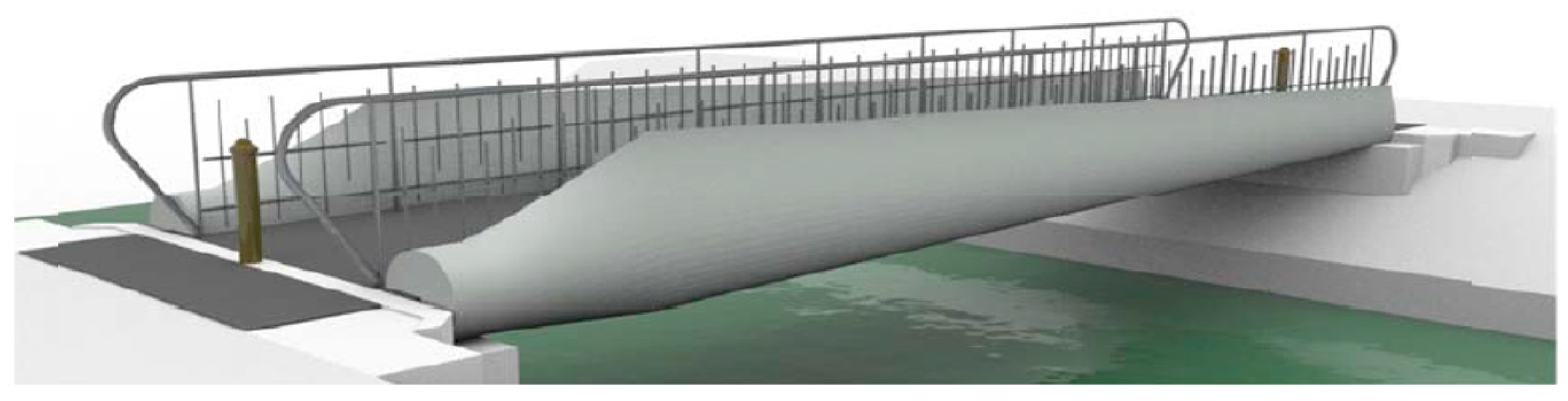

The Re-Wind project is a collaboration between the Georgia Institute of Technology, US; the Queen’s University Belfast, UK; the City University of New York, US; and the University College Cork, IE. Their focus is on sustainable end-of-life strategies for composite material wind turbine blades using data-driven structural modeling coupling geographical information science with environmental, economic, and social Life–Cycle Sustainability Assessments (LCSA) [19,42]. Team members of the Re-Wind project have focused on wind turbine blade reuse options and designed an 8.5 m pedestrian bridge using two A29 wind blades (a modified version of the model from Vestas V27) as girders and proved that the conceptual design fulfills the strength criteria and the recommended Eurocodes serviceability requirements (see Figure A1 in the Appendix A) [43].

A recent study designed a blade bridge for deployment on greenways scheduled for installation, repair, or bridge or culvert replacement on the Midleton-Youghal Greenway in Cork 2021, Ireland (see Figure A2 in the Appendix A) [44]. The bridge will be used for foot passengers and cycling. In case of emergencies, it can support a vehicle of up to 10 t. Greenway blade bridges provide benefits to the environment, society, and the economy by substituting recycled steel for new steel in structural applications, promoting ecotourism and sustainable transportation, and maybe boosting local businesses in blade remanufacturing [44].

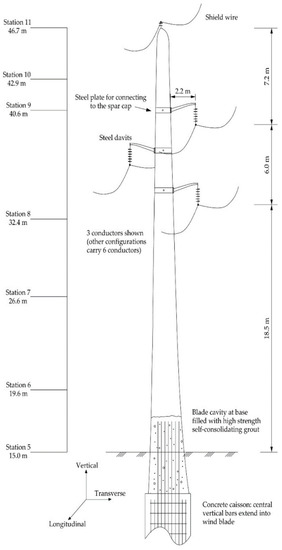

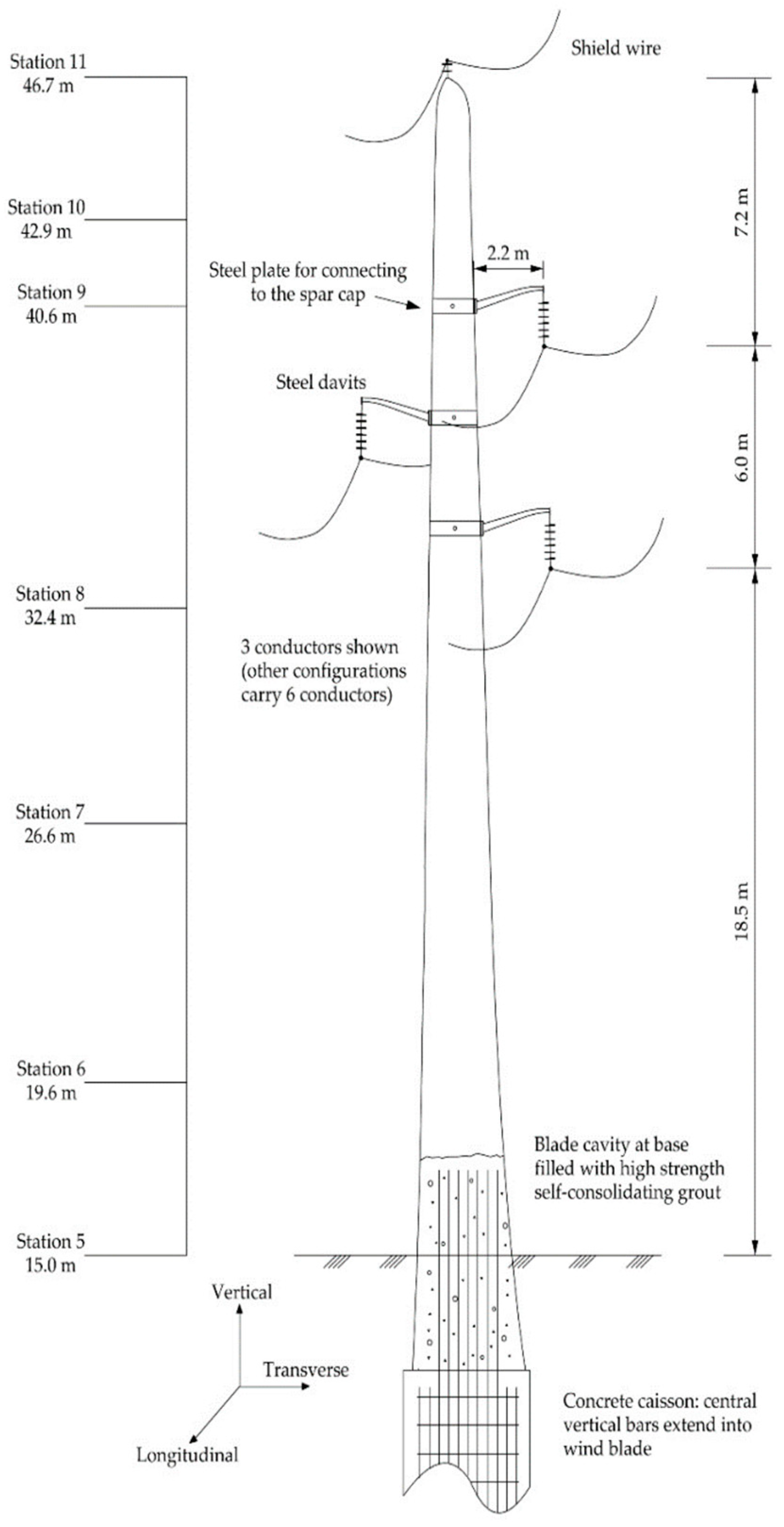

The authors of a recently published study are repurposing a portion of a decommissioned Clipper C96 wind turbine blade as a tangent pole with 230 kV capacity in a power transmission line application (see Figure A3 in the Appendix A) [45]. However, dead-end blade poles and corner blade poles are also possible to design. Fibre-reinforced polymer (FRP) poles are expected to last longer than conventional steel, concrete, or timber poles. The authors have tested the structural analyses for different load cases: extreme wind, concurrent ice, and wind; extreme ice, differential ice, broken conductor, and broken shield; and governing load cases for bending, shear, and torsion. The results showed that the blade pole can resist the expected loads with reasonable safety factors and that the expected deflections are within permissible limits [46].

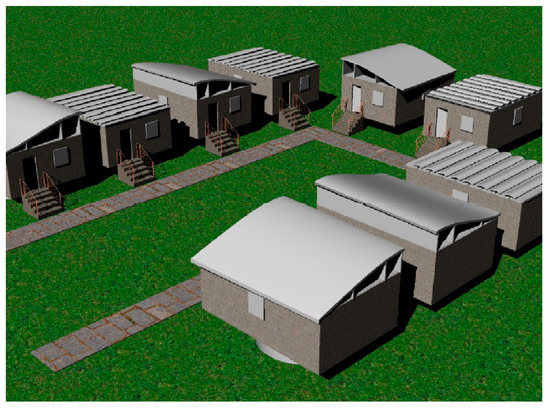

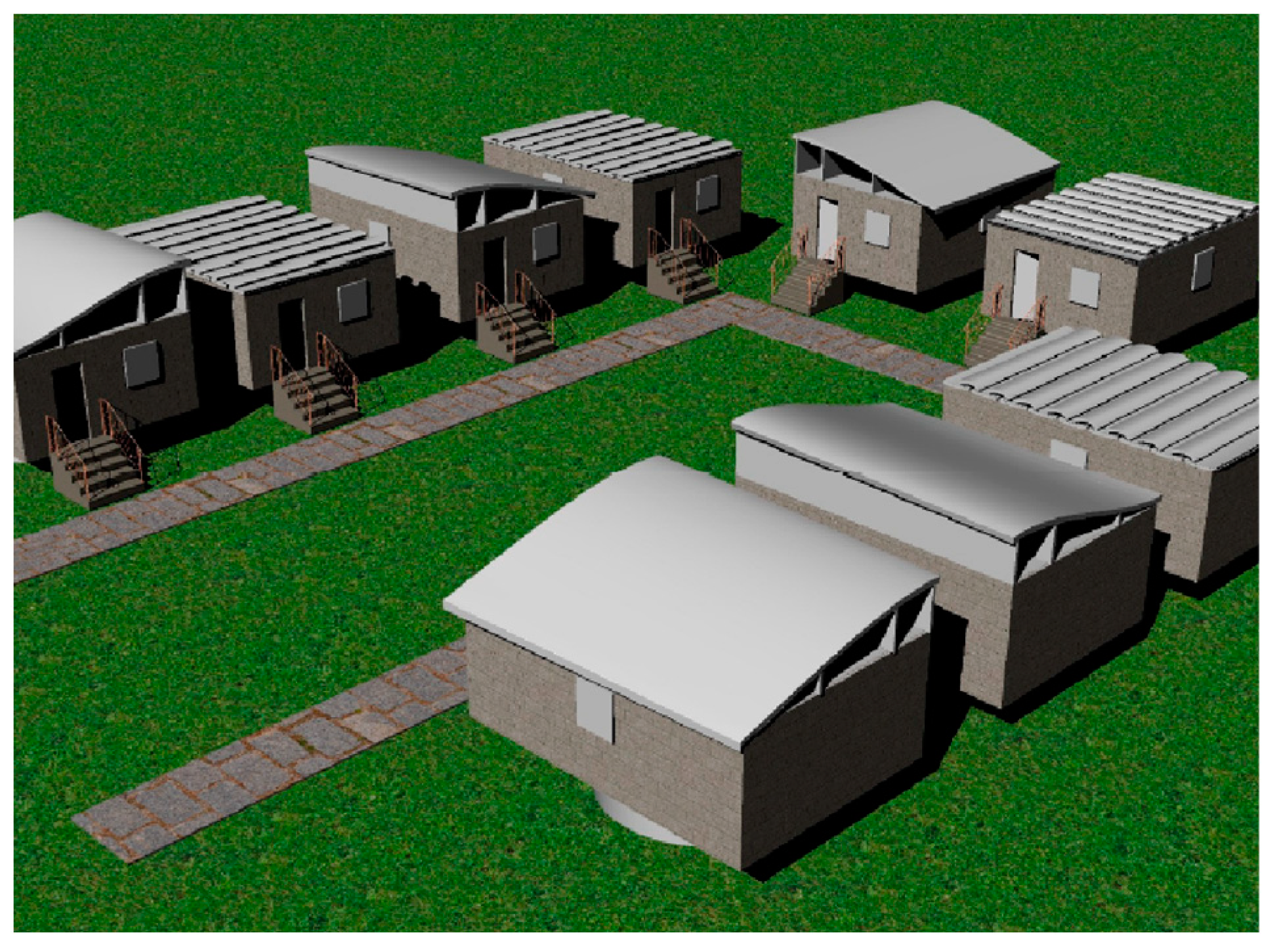

A study published in 2018 [45] discusses conceptual architectural and structural options for repurposing parts from wind turbine blades in new or retrofitted housing projects where harsh environmental conditions exist. Particularly, they studied how large-sized FRP pieces from a decommissioned SNL-100-01 wind blade can be used in affordable housing in coastal regions of the Yucatan province in Mexico on the Gulf of Mexico, where low-quality masonry block housing is vulnerable to severe hurricanes and flooding (see Figure A4 in the Appendix A).

A bike shed made of decommissioned wind turbine blades was implemented by the wind turbine manufacturer Siemens Gamesa in collaboration with the Re-Wind project in Denmark (see Figure A5 in the Appendix A). Denmark has the highest share of wind in the electricity mix globally and is in a leading position in the wind turbine industry, with high technological capability and a significant competitive advantage [47]. Simple repurposing of wind turbine blade projects as such in a country with an important share in wind energy constitutes a paradigm change, applying the principles of circular economy and urban regeneration.

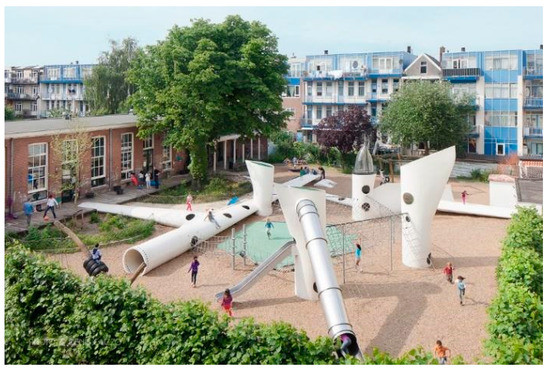

Similarly, in the Netherlands where 200 blades are sent to landfills every year, in 2009 Superuse studios designed a blade-made playground named Wikado covering a 1200 m2 area for the foundation Kinderparadijs Meidoorn in Rotterdam. The old playground required renovation. Superuse studios selected elements that could be reused in the new playground and used five decommissioned rotor blades placed around an existing concrete slab, thereby creating a maze-like space. The base of the blades has been used as four towers, and cut-off parts are spread around the garden connecting the towers (see Figure A6 in the Appendix A). By reusing elements, carbon emissions are reduced up to roughly 90% compared to a conventional playground. At the same time, the abstract shape of the blades allows children to freely imagine where and what they play [48]. Another blade-made project from the same studio is a piece of urban seating furniture placed in Willemsplein square in Rotterdam. It is made using nine blades held by recycled concrete rubble blocks. The blades were initially painted red to give a little more color to the grey surroundings of the area, but in 2020 it was redesigned as a temporary LGBTQI+ monument painted in the rainbow flag colors (see Figure A7 in the Appendix A).

In the municipality of Terneuzen, in the southwestern Netherlands on a small beach next to the harbor, Superuse studios constructed another iconic playground using two blades composited to look like a submarine in 2016. The location of the playground is flood-sensitive and turns from time to time into a swamp-like landscape. The studio took advantage of the durability of the blades to address the high demands of the topography of the area. In the East Pier Terneuzen in 2018, Superuse studios made seating furniture with the blades following the positive response from the residents on the submarine blade-made playground in the same municipality (see Figure A8 in the Appendix A) [48].

In the same line, companies such as Anmet in Poland use blades as load-bearing structural supports for pedestrian bridges and for the strengthening of embankments and landslides (see Figure A9 in the Appendix A). They construct blade-made animal passages, mole poles, and small size structures as lamps, sun loungers, and benches among others (see Figure A10 and Figure A11 in the Appendix A) [49].

The previous paragraphs described various conceptual and applied end-of-life solutions for upcycling blade waste, from small structures such as urban public furniture, to an entire community of blade-made affordable houses. These projects offer circular urban regeneration solutions for sustainable urban growth and resilience. In addition to the environmental benefits related to natural resource efficiency and the reduction of non-biodegradable waste pollution, upcycling blade waste offers social and economic benefits within the circular economy paradigm. Including blade made projects in the transformation processes for the regeneration of critical urban places benefits the local communities in various ways. Taking the conceptual design of affordable houses as an example, it can benefit local inhabitants that live under poor quality housing conditions such as refugees, homeless people, people living in favelas, and populations affected by natural disasters (earthquakes and hurricanes) by improving their living conditions and wellbeing. Smaller structures such as the seating furniture in Willemsplein, Rotterdam, offer a medium for people to rest and socialize but at the same time they can be symbolic and political, enhancing the identity of the urban place. The circularity of these projects in the design process connects the different stakeholders, the wind industry, the wind farm owners, the blade designers, the governments, and the communities. Communities can get involved with social enterprises that remanufacture blade waste supported by the wind industry and enhancement of the local economy by governments. Re-using blades can benefit local communities and offer the prospect of greater acceptance of wind turbines, while addressing wider societal goals linked to the decarbonization of energy systems: change demands an imaginative response [19].

4. Discussion

The transition from fossil-based energy to wind energy can be social, economic, and environmentally beneficial when meeting sustainability principles. To do so, the circular economy model is applied in our conceptualization for end-of-life wind blades solutions coupled with the urban regeneration concept.

End-of-life wind blade solutions coupled with circular urban regeneration ensure the sustainable transition to wind energy, preventing waste and offering economic and environmental benefits. Limitations of this transition can be the lack of legislation that permits the synergies between different actors and sectors along the life cycle of the wind turbine, the lack of modernized network infrastructure that reduces transmission losses, and limitations of the existing recycling technologies such as the limitation of co-processing to maintain the glass fiber shape during the process [50]. Legislation at a global scale that focuses on increasing the recycling rate and resource efficiency is required, as well as investments in research and innovation to develop alternative recycling technologies which produce higher-value recyclates but also high-performance new composites with enhanced circularity [39].

The existing European legislation on waste emphasizes a circular economy. For instance, the Waste Framework Directive is the cornerstone of EU waste policies and establishes a hierarchy in the approaches to waste management that prioritizes the prevention of waste, followed by reuse, recycling, recovery, and disposal. To limit the future waste volume and potential effects, waste prevention can be primarily accomplished during the planning and product development phases. The Commission Decision 2000/532/EC creating the European List of Waste, the Waste Incineration Directive (2000/76/EC), and the Landfill Directive (1999/31/EC) are other legal documents defining waste in the EU and are pertinent for wind turbine blade waste. Countries such as the Netherlands and Germany have banned composite materials from landfills and France has prohibited the disposal of waste containing more than 30% plastic. The end-of-life wind turbine blade waste is impacted by this legislation, which is a component of the anti-waste law. In Europe, the price of composite material landfills varies greatly. The price in Denmark is roughly EUR 120 per ton while in Germany, where composite materials are prohibited from being disposed of in landfills, the cost to treat the waste is EUR 300 per ton, and the pieces of the composite should not exceed 22 m in length [9]. Legislation to decrease blade waste and enhance blade waste regeneration circularity should be established to facilitate synergy between sectors and actors at a multiscale level from local to regional and global allowing sustainable wind energy transitions.

Government investment in innovation and research (R and I) could lead to the development of new smart composites with enhanced circularity that should manifest in the extended lifetime of the blade and improve the aging performance, to improve their separation and recyclability at the end-of-use. Implementing material efficiency in the life cycle of a wind turbine can help the transition towards sustainable wind energy under the circular economy model. Due to production losses, inputs are typically greater than outputs, which is referred to as the material efficiency ratio. In this instance, it means that more than 300 tonnes of materials are needed to create a 300-tonne turbine. Achieving material efficiency reduces the number of materials needed because there are fewer losses. It is crucial to develop material-efficient items, such as lightweight products, in order to minimize material losses. Additionally, products are made to be easier to reuse and recycle and to require less maintenance. This procedure also includes minimizing waste output levels, for instance, by utilizing new processes or the most advanced technology. Designing goods that are simpler to maintain, update, or remanufacture, as well as switching out materials for more sustainable options, will improve life cycle performance [47].

5. Conclusions

Blade waste management is a crucial issue and in order for it to be addressed, circularity must be integrated into the entire value chain from the design stage of next-generation blades to end-of-life solutions. One limitation of this study is that it only addresses end-of-life-related waste and does not take into consideration the waste generated during the manufacturing stage. Furthermore, in this study, we do not consider the cost and the business feasibility of the suggested solutions. Therefore, by focusing on end-of-life blade waste management we provide a novel conceptual framework driven by circular economy and three-dimensional sustainability principles. Specifically, what makes this study pivotal is the coupling of upcycling by repurposing the blade waste and downcycling the blade waste in green cement as part of urban regeneration projects. The main findings of this study indicate that the circularity of the blades does not require a universal approach. Depending on the amount of waste generated in each location and time span, different approaches can be employed. Through the analysis of real-life case studies, we demonstrate how our approach facilitates the circularity of the composite material and at the same time ensures three-dimensional sustainability enabling culture- and environment-transformation processes in an urban context. By coupling blade waste circularity with urban regeneration, an industrial symbiosis scheme could be sustained, where the waste of wind energy could be used on a greater scale as a raw material in the manufacturing sector, closing the loop of the blades and creating an exemplary circular economy community. Simultaneously, it engages a cost-saving policy creating new business and economic opportunities (e.g., new goods and services, job offers) meeting the sustainable development goal seven (“Ensure access to affordable, reliable, sustainable, and modern energy for all”). This study provides a conceptual framework and insights for its implementation in urban planning and design as an alternative to tackle the negative consequences of the current insufficient management of blade waste. By preventing waste and increasing resource-efficient solutions, this study contributes to the wind energy sustainable transition.

Directions for future work would be the life cycle assessment of urban regeneration projects related to upcycling and downcycling of blade waste. Considering that in this study we took into consideration only the end-of-life stage, we suggest that future research examines the entire life cycle, from the design phase and then from cradle to grave. That way, by employing eco-design techniques, part of the waste can be phased out during the design phase, rendering the end-of-life waste easier to handle.

Author Contributions

Conceptualization, S.K. and A.P.; methodology, S.K. and A.P.; resources, S.K. and A.P.; writing—original draft preparation, S.K. and A.P.; writing—review and editing, S.K. and A.P.; project administration, S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

A. Peponi is currently supported by a postdoctoral research scholarship under the project: mainstreaming ecological restoration of freshwater-related ecosystems in a landscape context. Innovation, upscaling, and transformation (101036337—MERLIN—H2020-LC-GD-2020). The Forest Research Centre (CEF) is a research unit funded by FCT(UIDB/00239/2020). The Associate Laboratory TERRA (LA/P/0092/2020) is also funded by FCT.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Figure A1.

A conceptual design of a pedestrian bridge using part of A26 wind blades [44].

Figure A1.

A conceptual design of a pedestrian bridge using part of A26 wind blades [44].

Figure A2.

An existing structure on a greenway route at Roxborough, Midleton, Cork. A conceptual design of a blade bridge at the same location [44].

Figure A2.

An existing structure on a greenway route at Roxborough, Midleton, Cork. A conceptual design of a blade bridge at the same location [44].

Figure A3.

A clipper C96 blade configured as a tangent pole application [42].

Figure A3.

A clipper C96 blade configured as a tangent pole application [42].

Figure A4.

A conceptual housing community made of wind turbine blade waste [46].

Figure A4.

A conceptual housing community made of wind turbine blade waste [46].

Figure A5.

A bike shed in Denmark made from EoL blades [51].

Figure A5.

A bike shed in Denmark made from EoL blades [51].

Figure A6.

Wikado playground [48].

Figure A6.

Wikado playground [48].

Figure A7.

Blade urban seating furniture ReWind at Willemsplein, Rotterdam, © Denis Guzzo 2012 [48].

Figure A7.

Blade urban seating furniture ReWind at Willemsplein, Rotterdam, © Denis Guzzo 2012 [48].

Figure A8.

A blade-made playground and seating furniture in Terneuzen [48].

Figure A8.

A blade-made playground and seating furniture in Terneuzen [48].

Figure A9.

Blade-made load-bearing structural supports for pedestrian bridges [49].

Figure A9.

Blade-made load-bearing structural supports for pedestrian bridges [49].

Figure A10.

Blade-made sun loungers [49].

Figure A10.

Blade-made sun loungers [49].

Figure A11.

A blade-made bench [49].

Figure A11.

A blade-made bench [49].

References

- Masson-Delmotte, V.; Zhai, P.; Pirani, A.; Connors, S.L.; Péan, C.; Berger, S.; Caud, N.; Chen, Y.; Goldfarb, L.; Gomis, M.I.; et al. 2021: Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2021. [Google Scholar]

- United Nations Climate Change The Paris Agreement|UNFCCC. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement/the-paris-agreement (accessed on 16 May 2022).

- COP27: Delivering for People and the Planet|United Nations. Available online: https://www.un.org/uk/node/187664 (accessed on 31 December 2022).

- Kang, J.N.; Wei, Y.M.; Liu, L.C.; Han, R.; Yu, B.Y.; Wang, J.W. Energy Systems for Climate Change Mitigation: A Systematic Review. Appl. Energy 2020, 263, 114602. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The Role of Renewable Energy in the Global Energy Transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Vargas, A.V.; Zenón, E.; Oswald, U.; Islas, J.M.; Güereca, L.P.; Manzini, F.L. Life Cycle Assessment: A Case Study of Two Wind Turbines Used in Mexico. Appl. Therm. Eng. 2015, 75, 1210–1216. [Google Scholar] [CrossRef]

- OECD. Making the Green Recovery Work for Jobs, Income and Growth; OECD: Paris, France, 2020. [Google Scholar]

- Liu, P.; Barlow, C.Y. Wind Turbine Blade Waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef]

- Beauson, J.; Laurent, A.; Rudolph, D.P.; Pagh Jensen, J. The Complex End-of-Life of Wind Turbine Blades: A Review of the European Context. Renew. Sustain. Energy Rev. 2022, 155, 111847. [Google Scholar] [CrossRef]

- Andersen, N.; Eriksson, O.; Hillman, K.; Wallhagen, M. Wind Turbines’ End-of-Life: Quantification and Characterisation of Future Waste Materials on a National Level. Energies 2016, 9, 999. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Lichtenegger, G.; Rentizelas, A.A.; Trivyza, N.; Siegl, S. Offshore and Onshore Wind Turbine Blade Waste Material Forecast at a Regional Level in Europe until 2050. Waste Manag. 2020, 106, 120–131. [Google Scholar] [CrossRef]

- Skelton, K. Discussion Paper on Managing Composite Blade Waste. Aalborg University. 2017. Available online: https://windeurope.org/wp-content/uploads/files/policy/topics/sustainability/Discussionpaper-on-blade-waste-treatment-20170418.pdf (accessed on 29 April 2022).

- Paulsen, E.B.; Enevoldsen, P. A Multidisciplinary Review of Recycling Methods for End-of-Life Wind Turbine Blades. Energies 2021, 14, 4247. [Google Scholar] [CrossRef]

- Ierides, M.; Reiland, J. Wind Turbine Blade Circularity: Technologies and Practices around the Value Chain. Bax and Company. 2019. Available online: https://baxcompany.com/wp-content/uploads/2019/06/wind-turbine-circularity.pdf (accessed on 14 April 2022).

- Purohit, J.; Chattopadhyay, A.; Teli, B. Metagenomic Exploration of Plastic Degrading Microbes for Biotechnological Application. Curr. Genom. 2020, 21, 253–270. [Google Scholar] [CrossRef]

- Gu, L.; Ozbakkaloglu, T. Use of Recycled Plastics in Concrete: A Critical Review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef]

- Windpower Monthly the Complexities of Recycling Begin to Bite|Windpower Monthly. Available online: https://www.windpowermonthly.com/article/1124486/complexities-recycling-begin-bite (accessed on 18 May 2022).

- Gough, F. Engaging Communities on Future Re-Use Options for Decommissioned Wind Turbine Blades”—The Re-Wind Network. 2019. Available online: https://static1.squarespace.com/static/5b324c409772ae52fecb6698/t/5cc4aeeae4966b54dc952a40/1556393709521/Fergal+Gough+Environ+2019.pdf/ (accessed on 19 April 2022).

- Križnik, B. Transformation of Deprived Urban Areas and Social Sustainability: A Comparative Study of Urban Regeneration and Urban Redevelopment in Barcelona and Seoul. Urbani Izziv 2018, 29, 83–95. [Google Scholar] [CrossRef]

- Evans, G.; Shaw, P. The Contribution of Culture to Regeneration in the UK: A Review of Evidence: A Report to the Department for Culture Media and Sport; DCMS: London, UK, 2004. [Google Scholar]

- Heath, S.C.; Rabinovich, A.; Barreto, M. Putting Identity into the Community: Exploring the Social Dynamics of Urban Regeneration. Eur. J. Soc. Psychol. 2017, 47, 855–866. [Google Scholar] [CrossRef]

- Baba, C.; Kearns, A.; McIntosh, E.; Tannahill, C.; Lewsey, J. Is Empowerment a Route to Improving Mental Health and Wellbeing in an Urban Regeneration (UR) Context? Urban Stud. 2017, 54, 1619–1637. [Google Scholar] [CrossRef]

- Yarker, S. Tangential Attachments: Towards a More Nuanced Understanding of the Impacts of Cultural Urban Regeneration on Local Identities. Urban Stud. 2018, 55, 3421–3436. [Google Scholar] [CrossRef]

- Ferilli, G.; Sacco, P.L.; Tavano Blessi, G.; Forbici, S. Power to the People: When Culture Works as a Social Catalyst in Urban Regeneration Processes (and When It Does Not). Eur. Plan. Stud. 2017, 25, 241–258. [Google Scholar] [CrossRef]

- Seo, J.K. Re-Urbanisation in Regenerated Areas of Manchester and Glasgow: New Residents and the Problems of Sustainability. Cities 2002, 19, 113–121. [Google Scholar] [CrossRef]

- Li, X.; Zhang, F.; Hui, E.C.; Lang, W. Collaborative Workshop and Community Participation: A New Approach to Urban Regeneration in China. Cities 2020, 102, 102743. [Google Scholar] [CrossRef]

- della Spina, L. Multidimensional Assessment for “Culture-Led” and “Community-Driven” Urban Regeneration as Driver for Trigger Economic Vitality in Urban Historic Centers. Sustainability 2019, 11, 7237. [Google Scholar] [CrossRef]

- Boussaa, D. Urban Regeneration and the Search for Identity in Historic Cities. Sustainability 2018, 10, 48. [Google Scholar] [CrossRef]

- Williams, J. Circular Cities. Urban Stud. 2019, 56, 2746–2762. [Google Scholar] [CrossRef]

- Cerreta, M.; la Rocca, L. Urban Regeneration Processes and Social Impact: A Literature Review to Explore the Role of Evaluation. In Proceedings of the Computational Science and Its Applications–ICCSA 2021: 21st International Conference, Cagliari, Italy, 13–16 September 2021; Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics). Springer: Cham, Switzerland, 2021; Volume 12954. [Google Scholar]

- Peponi, A.; Morgado, P. Transition to Smart and Regenerative Urban Places (SRUP): Contributions to a New Conceptual Framework. Land 2021, 10, 2. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm. J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a Circular Economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation Completing the Picture—How the Circular Economy Tackles Climate Change|Shared by Climate Change. Available online: https://emf.thirdlight.com/link/w750u7vysuy1-5a5i6n/@/preview/1?o (accessed on 16 May 2022).

- Wu, T.; Zhang, W.; Jin, X.; Liang, X.; Sui, G.; Yang, X. Efficient Reclamation of Carbon Fibers from Epoxy Composite Waste through Catalytic Pyrolysis in Molten ZnCl 2. RSC Adv. 2019, 9, 377–388. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ulgiati, S. Circular economy transition in Italy. Achievements, perspectives and constraints. J. Clean. Prod. 2020, 243, 118360. [Google Scholar] [CrossRef]

- Schmid, M.; Gonzalez Ramon, N.; Dierckx, A.; Wegman, T. Accelerating Wind Turbine Blade Circularity; WindEurope: Brussels, Belgium, 2020. [Google Scholar]

- García-Gusano, D.; Herrera, I.; Garraín, D.; Lechón, Y.; Cabal, H. Life Cycle Assessment of the Spanish Cement Industry: Implementation of Environmental-Friendly Solutions. Clean Technol. Environ. Policy 2015, 17, 59–73. [Google Scholar] [CrossRef]

- Cembureau. The Role of CEMENT in the 2050 LOW CARBON ECONOMY; Cembureau: Bruxelles, Belgium, 2013. [Google Scholar]

- Nagle, A.J.; Delaney, E.L.; Bank, L.C.; Leahy, P.G. A Comparative Life Cycle Assessment between Landfilling and Co-Processing of Waste from Decommissioned Irish Wind Turbine Blades. J. Clean. Prod. 2020, 277, 123321. [Google Scholar] [CrossRef]

- Suhail, R.; Chen, J.-F.; Gentry, R.; Taristro-Hart, B.; Xue, Y.; Bank, L. Analysis and Design of a Pedestrian Bridge with Decommissioned FRP Windblades and Concrete. In Proceedings of the Fiber Reinforced Polymers in Reinforced Concrete Structures FRPRCS14, Belfast, Northern Ireland, 4–7 June 2019. [Google Scholar]

- Leahy, P.; Zhang, Z.; Nagle, A.; Ruane, K.; Delaney, E.; Mckinley, J.; Bank, L.; Gentry, R. Greenway Bridges from Wind Blades Greenway Pedestrian and Cycle Bridges from Repurposed Wind Turbine Blades; Irish Transport Research Network: Sligo, Ireland, 2021. [Google Scholar]

- Bank, L.; Arias, F.; Gentry, R.; Al-Haddad, T.; Chen, J.-F.; Morrow, R. Reusing composite materials from decommissioned wind turbine blades. In Proceedings of the Non-Conventional Materials and Technologies NOCMAT 2017, Merida, Mexico, 26–29 November 2017. [Google Scholar]

- Alshannaq, A.A.; Bank, L.C.; Scott, D.W.; Gentry, R. A Decommissioned Wind Blade as a Second-Life Construction Material for a Transmission Pole. Constr. Mater. 2021, 1, 95–104. [Google Scholar] [CrossRef]

- IRENA. Future of Wind: Deployment, Investment, Technology, Grid Integration and Socio-Economic Aspects (A Global Energy Transformation Paper); International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019. [Google Scholar]

- Superuse Studios Blade Made Playgrounds. Available online: https://www.superuse-studios.com/projectplus/blade-made/ (accessed on 19 May 2022).

- GP Renewables Group. Recycled Urban Architecture; GP Renewables Group: Hamburg, Germany, 2022. [Google Scholar]

- Cholewa, M.; Mammadov, F.; Nowaczek, A. The Obstacles and Challenges of Transition towards a Renewable and Sustainable Energy System in Azerbaijan and Poland. Miner. Econ. 2022, 35, 155–169. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite Material Recycling Technology—State-of-the-Art and Sustainable Development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).