Economic Viability and Engine Performance Evaluation of Biodiesel Derived from Desert Palm Date Seeds

Abstract

:1. Introduction

2. Materials and Methods

2.1. Process Modeling

2.2. Cost Evaluation

2.2.1. Total Capital Cost

2.2.2. Annual Production Cost

2.3. Biodiesel Production

2.4. Experimental Test Rig

3. Results and Discussion

3.1. Profitability of the Proposed DSO Biodiesel Plant

3.2. Engine Performance

3.2.1. Brake Power

3.2.2. Brake Thermal Efficiency

3.2.3. Brake Specific Fuel Consumption

3.2.4. Exhaust Gas Temperature

4. Conclusions

- o

- Based on a DSPP of 70% WPP, the estimated values for NPV, PBT, and ROI were $6.42 million, 5 y, and 14.2%. As the price ratio dropped to 60%, these economic metrics fell sharply, and the investment became unfeasible.

- o

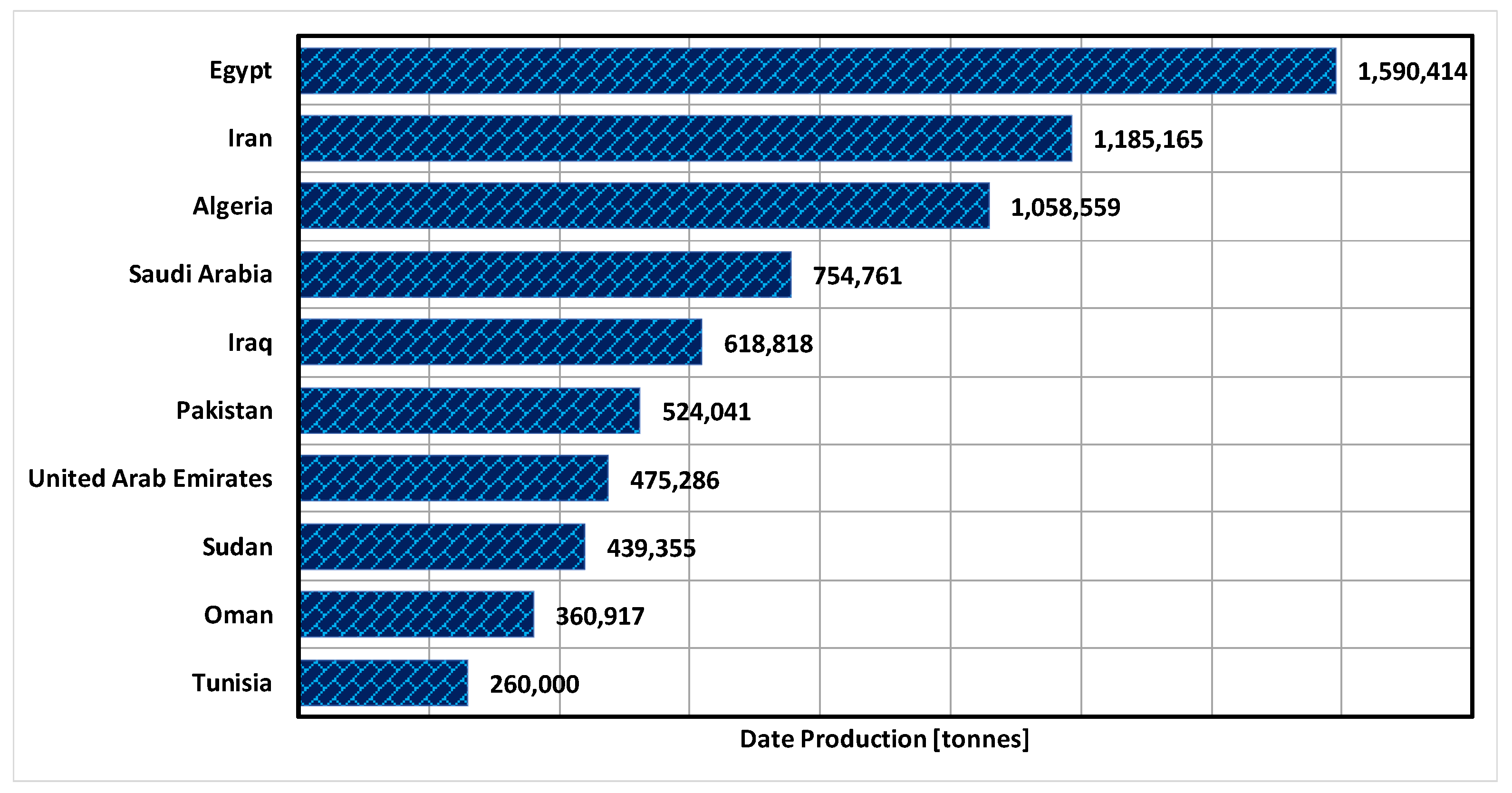

- The economic performance of investment in this project was very sensitive to variations in DSPP, resulting in serious investment risk. Possible solutions include introducing other waste streams (such as coffee waste and tallow) as parent feedstocks or scaling up the plant’s capacity to save on initial investment and use feedstock from neighboring countries.

- o

- BP, BTE, and BSFC values of the DSO biodiesel blends were comparable to those of the baseline diesel, although the latter was superior. On average, the reductions for these metrics at full load for B20 were 4.5%, 7.65%, and 9.84%, respectively. At half load, these reductions for B5 were 0.32%, 1%, and 1.44%, respectively.

- o

- DSO biodiesel blends outperformed the baseline diesel in EGT, with average EGT drops of 29 and 46.7 °C at full load for B5 and B20, respectively. At half load, EGT drops with averages of 10.1% and 14.4% for B10 and B15, respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| DSO | Date seed oil |

| EGT | Exhaust gas temperature |

| ASTM | American Society for Testing and Materials |

| BP | Brake power |

| BSFC | Brake specific fuel consumption |

| BTE | Brake thermal efficiency |

| CI | Compression ignition |

| ISO | International Organization for Standardization |

| EN | European norms |

| Total capital cost | |

| Annual production cost | |

| Fixed capital cost | |

| Working capital cost | |

| Direct costs | |

| Initial construction expenses | |

| Equipment costs | |

| Indirect costs | |

| Engineering expenses | |

| Contractor fees | |

| Contingency allowance | |

| The cost at a reference condition of pressure and materials | |

| Correction factor | |

| Expenditures required to start up the plant | |

| Direct production cost | |

| Indirect production cost | |

| DSPP | Date seed pelletized pellets |

| WPP | Wood pelletized pellets |

| Annual net cash flow at any year | |

| Net annual profit | |

| Total annual expense | |

| CNCF | Cumulative net cash flow |

| NPW | Net present worth |

| ROI | Return on investment |

| PBT | Payback time |

References

- Asokan, M.; Prabu, S.S.; Bade, P.K.K.; Nekkanti, V.M.; Gutta, S.S.G. Performance, combustion and emission characteristics of juliflora biodiesel fuelled DI diesel engine. Energy 2019, 173, 883–892. [Google Scholar] [CrossRef]

- Organization of the Petroleum Exporting Countries (OPEC); World Oil Outlook 2040: Vienna, Austria, 2017.

- Rajak, U.; Nashine, P.; Verma, T.N. Assessment of diesel engine performance using spirulina microalgae biodiesel. Energy 2018, 166, 1025–1036. [Google Scholar] [CrossRef]

- Rosha, P.; Mohapatra, S.K.; Mahla, S.K.; Cho, H.; Chauhan, B.S.; Dhir, A. Effect of compression ratio on combustion, performance, and emission characteristics of compression ignition engine fueled with palm (B20) biodiesel blend. Energy 2019, 178, 676–684. [Google Scholar] [CrossRef]

- Armin, M.; Gholinia, M. Comparative evaluation of energy, performance, and emission characteristics in dual-fuel (CH4/Diesel) heavy-duty engine with RCCI combustion mode. Results Eng. 2022, 16, 100766. [Google Scholar] [CrossRef]

- Madihi, R.; Pourfallah, M.; Gholinia, M.; Armin, M.; Ghadi, A. Thermofluids analysis of combustion, emissions, and energy in a biodiesel (C11H22O2)/natural gas heavy-duty engine with RCCI mode (Part II: Fuel injection time/Fuel injection rate). Int. J. Thermofluids 2022, 16, 100200. [Google Scholar] [CrossRef]

- Madihi, R.; Pourfallah, M.; Gholinia, M.; Armin, M.; Ghadi, A. Thermofluids analysis of combustion, emissions, and energy in a biodiesel (C11H22O2)/natural gas heavy-duty engine with RCCI mode (Part I: Single/two -stage injection). Int. J. Thermofluids 2022, 16, 100200. [Google Scholar] [CrossRef]

- Scheffran, J. The Global Demand for Biofuels: Technologies, Markets and Policies. In Biomass to Biofuels Strategies for Global Industries; Vertes, A.A., Qureshi, N., Blaschek, H.P., Yukawa, H., Eds.; Wiley: West Sussex, UK, 2010; pp. 27–54. [Google Scholar]

- Johnston, M.; Holloway, T. A Global Comparison of National Biodiesel Production Potentials. Environ. Sci. Technol. 2007, 41, 7967–7973. [Google Scholar] [CrossRef]

- Hughes, S.R.; Qureshi, N. Biofuel Demand Realization. In Biomass to Biofuels Strategies for Global Industries; Vertes, A.A., Qureshi, N., Blaschek, H.P., Yukawa, H., Eds.; Wiley: West Sussex, UK, 2010; pp. 55–70. [Google Scholar]

- Luque, R.; Lin, C.S.; Wilson, K.; Clark, J.H. Handbook of Biofuels Production: Processes and Technologies, 2nd ed.; Woodhead Publishing: Duxford, UK, 2016. [Google Scholar]

- Kamil, M.; Ramadan, K.M.; Awad, O.I.; Ibrahim, T.K.; Inayat, A.; Ma, X. Environmental impacts of biodiesel production from waste spent coffee grounds and its implementation in a compression ignition engine. Sci. Total. Environ. 2019, 675, 13–30. [Google Scholar] [CrossRef]

- Aboelazayem, O.; Gadalla, M.; Saha, B. Valorisation of high acid value waste cooking oil into biodiesel using supercritical methanolysis: Experimental assessment and statistical optimisation on typical Egyptian feedstock. Energy 2018, 162, 408–420. [Google Scholar] [CrossRef]

- Azeem, M.W.; Hanif, M.A.; Al-Sabahi, J.N.; Khan, A.A.; Naz, S.; Ijaz, A. Production of biodiesel from low priced, renewable and abundant date seed oil. Renew. Energy 2016, 86, 124–132. [Google Scholar] [CrossRef]

- Afiq, A.; Rahman, A.; Man, C. Date seed and date seed oil. Int. Food Res. J. 2013, 20, 2035–2043. [Google Scholar]

- Besbes, S.; Drira, L.; Blecker, C.; Deroanne, C.; Attia, H. Adding value to hard date (Phoenix dactylifera L.): Compositional, functional and sensory characteristics of date jam. Food Chem. 2009, 112, 406–411. [Google Scholar] [CrossRef]

- FAOSTAT. Statistical databases of the Food and Agriculture Organization of the United Nations. 2020. Available online: http://www.fao.org/faostat/en/#home (accessed on 17 December 2019).

- The British Petroleum Company, BP. BP Statistical Review of World Energy, June 2017. Available online: https://www.bp.com/content/dam/bp/en/corporate/pdf/energy-economics/statistical-review-2017/bp-statistical-review-of-world-energy-2017-full-report.pdf (accessed on 23 August 2018).

- Jamil, F.; Al-Muhtaseb, A.H.; Al-Haj, L.; Al-Hinai, M.A.; Hellier, P.; Rashid, U. Optimization of oil extraction from waste “Date pits” for biodiesel production. Energy Convers. Manag. 2016, 117, 264–272. [Google Scholar] [CrossRef]

- Al-Zuhair, S.; Taher, H.; Al Dhaheri, S.; Wajeeh, S.; Nour, M.; El-Najjar, E. Biodiesel Production from Oils Extracted from Date Pits. Green Sustain. Chem. 2017, 7, 48–56. [Google Scholar] [CrossRef]

- Akaagerger, S.M.; Giwa, S.O.; Ibrahim, M.G.A. Production of biodiesel from desert date seed oil. Int. J. ChemTech Res. 2016, 9, 453–463. [Google Scholar]

- Farooq, M.; Ramli, A.; Naeem, A.; Mahmood, T.; Ahmad, S.; Humayun, M.; Islam, M.G.U. Biodiesel production from date seed oil (Phoenix dactylifera L.) via egg shell derived heterogeneous catalyst. Chem. Eng. Res. Des. 2018, 132, 644–651. [Google Scholar] [CrossRef]

- Xue, J.; Grift, T.E.; Hansen, A.C. Effect of biodiesel on engine performances and emissions. Renew. Sustain. Energy Rev. 2011, 15, 1098–1116. [Google Scholar] [CrossRef]

- Honeywell International. UniSim Design: User Guide; Honeywell International: Rolle, Switzerland, 2017.

- Sheehan, J.; Camobreco, V.; Duffield, J.; Graboski, M.; Shapouri, H. Life Cycle Inventory of Biodiesel and Petroleum Diesel for Use in an Urban Bus; National Renewable Energy Laboratory: Golden, CO, USA, 1998. [Google Scholar]

- Giller, C.; Malkani, B.; Parasar, J. Coffee to Biofuels. University of Pennsylvania. 2017. Available online: http://repository.upenn.edu/cbe_sdr/94 (accessed on 27 November 2018).

- Dimian, A.C.; Bildea, C.S. Chemical Process Design: Computer-Aided Case Studies; Wiley-VCH Verlag GmbH & Co. KgaA: Weinheim, Germany, 2008. [Google Scholar]

- Turton, R.; Bailie, R.C.; Whiting, W.B.; Shaeiwitz, J.A.; Bhattacharyya, D. Analysis, Synthesis and Design of Chemical Processes, 4th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2012. [Google Scholar]

- Sinnott, R.K. Chemical Engineering: Chemical Engineering Design, 4th ed.; Coulson and Richardson’s Chemical Engieering Series; Elsevier Butterworth-Heinemann: Chennai, India, 2005. [Google Scholar]

- Peters, M.S.; Timmerhaus, K.D.; West, R.E. Plant Design and Economics for Chemical Engineers, 5th ed.; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Hill, J.; Nelson, E.; Tilman, D.; Polasky, S.; Tiffany, D. Environmental, economic, and energetic costs and benefits of bio-diesel and ethanol biofuels. Proc. Natl. Acad. Sci. USA 1999, 96, 5903–5907. [Google Scholar]

- National Research Council. Water Implications of Biofuels Production in the United States; National Academies Press: Washington, DC, USA, 2008. [Google Scholar] [CrossRef]

- Skarlis, S.; Kondili, E.; Kaldellis, J. Small-scale biodiesel production economics: A case study focus on Crete Island. J. Clean. Prod. 2012, 20, 20–26. [Google Scholar] [CrossRef]

- Karmee, S.K.; Patria, R.D.; Lin, C.S.K. Techno-Economic Evaluation of Biodiesel Production from Waste Cooking Oil—A Case Study of Hong Kong. Int. J. Mol. Sci. 2015, 16, 4362–4371. [Google Scholar] [CrossRef]

- European Pellet Council. Pellet Market Overview; European Biomass Association: Brussels, Belgium, 2017. [Google Scholar]

- Bart, J.C.; Palmeri, N.; Cavallaro, S. Biodiesel Science and Technology: FROM Soil to Oil; Elsevier Science & Technology: Cornwall, UK, 2010. [Google Scholar]

- Duncan, J. Costs of Biodiesel Production; Energy Efficiency and Conservation Authority: Wellington, New Zealand, 2003. [Google Scholar]

- Methanex. Methanex Methanol Price Sheet. Available online: https://www.methanex.com/our-business/pricing (accessed on 21 February 2019).

- Qingdao Echemi Technology. Sodium Hydroxide Price Analysis. 2019. Available online: http://www.echemi.com/productsInformation/pd20150901041-caustic-soda-pearls.html (accessed on 20 February 2019).

- Apostolakou, A.; Kookos, I.; Marazioti, C.; Angelopoulos, K. Techno-economic analysis of a biodiesel production process from vegetable oils. Fuel Process. Technol. 2009, 90, 1023–1031. [Google Scholar] [CrossRef]

- Green, D.W.; Perry, R.H. Perry’s Chemical Engineers’ Handbook, 8th ed.; McGraw-Hill: New York, NY, USA, 2008. [Google Scholar]

- Sadhukhan, J.; Ng, K.S.; Hernandez, E.M. Biorefineries and Chemical Processes: Design, Intgration and Sustainability Analysis; John Wiley & Sons, Ltd.: West Sussex, UK, 2014. [Google Scholar]

- Towler, G.P.; Sinnott, R.K. Chemical Engineering Design: Principles, Practice, and Economics of Plant and Process Design, 2nd ed.; Butterworth-Heinemann: New York, NY, USA, 2013. [Google Scholar]

- Aydin, H.; Bayindir, H. Performance and emission analysis of cottonseed oil methyl ester in a diesel engine. Renew. Energy 2010, 35, 588–592. [Google Scholar] [CrossRef]

- Hazar, H. Effects of biodiesel on a low heat loss diesel engine. Renew. Energy 2009, 34, 1533–1537. [Google Scholar] [CrossRef]

- Ozsezen, A.N.; Canakci, M.; Turkcan, A.; Sayin, C. Performance and combustion characteristics of a DI diesel engine fueled with waste palm oil and canola oil methyl esters. Fuel 2009, 88, 629–636. [Google Scholar] [CrossRef]

- Carraretto, C.; Macor, A.; Mirandola, A.; Stoppato, A.; Tonon, S. Biodiesel as alternative fuel: Experimental analysis and energetic evaluations. Energy 2004, 29, 2195–2211. [Google Scholar] [CrossRef]

- Reyes, J.; Sepúlveda, M. PM-10 emissions and power of a Diesel engine fueled with crude and refined Biodiesel from salmon oil. Fuel 2006, 85, 1714–1719. [Google Scholar] [CrossRef]

- Utlu, Z.; Koçak, M.S. The effect of biodiesel fuel obtained from waste frying oil on direct injection diesel engine performance and exhaust emissions. Renew. Energy 2008, 33, 1936–1941. [Google Scholar] [CrossRef]

- Lin, B.-F.; Huang, J.-H.; Huang, D.-Y. Experimental study of the effects of vegetable oil methyl ester on DI diesel engine performance characteristics and pollutant emissions. Fuel 2009, 88, 1779–1785. [Google Scholar] [CrossRef]

- Öner, C.; Altun, Ş. Biodiesel production from inedible animal tallow and an experimental investigation of its use as alternative fuel in a direct injection diesel engine. Appl. Energy 2009, 86, 2114–2120. [Google Scholar] [CrossRef]

- Al-Widyan, M.I.; Tashtoush, G.; Abu-Qudais, M. Utilization of ethyl ester of waste vegetable oils as fuel in diesel engines. Fuel Process. Technol. 2002, 76, 91–103. [Google Scholar] [CrossRef]

- Qi, D.; Geng, L.; Chen, H.; Bian, Y.; Liu, J.; Ren, X. Combustion and performance evaluation of a diesel engine fueled with biodiesel produced from soybean crude oil. Renew. Energy 2009, 34, 2706–2713. [Google Scholar] [CrossRef]

- Lapuerta, M.; Herreros, J.M.; Lyons, L.L.; García-Contreras, R.; Briceño, Y. Effect of the alcohol type used in the production of waste cooking oil biodiesel on diesel performance and emissions. Fuel 2008, 87, 3161–3169. [Google Scholar] [CrossRef]

- Ghobadian, B.; Rahimi, H.; Nikbakht, A.; Najafi, G.; Yusaf, T. Diesel engine performance and exhaust emission analysis using waste cooking biodiesel fuel with an artificial neural network. Renew. Energy 2009, 34, 976–982. [Google Scholar] [CrossRef]

- Hull, A.; Golubkov, I.; Kronberg, B.; van Stam, J. Alternative Fuel for a Standard Diesel Engine. Int. J. Engine Res. 2006, 7, 51–63. [Google Scholar] [CrossRef]

- Meng, X.; Chen, G.; Wang, Y. Biodiesel production from waste cooking oil via alkali catalyst and its engine test. Fuel Process. Technol. 2008, 89, 851–857. [Google Scholar] [CrossRef]

- Pal, A.; Verma, A.; Kachhwaha, S.; Maji, S. Biodiesel production through hydrodynamic cavitation and performance testing. Renew. Energy 2010, 35, 619–624. [Google Scholar] [CrossRef]

- da Silva, F.N.; Prata, A.S.; Teixeira, J.R. Technical feasibility assessment of oleic sunflower methyl ester utilisation in Diesel bus engines. Energy Convers. Manag. 2003, 44, 2857–2878. [Google Scholar] [CrossRef]

- Ramadhas, A.; Muraleedharan, C.; Jayaraj, S. Performance and emission evaluation of a diesel engine fueled with methyl esters of rubber seed oil. Renew. Energy 2005, 30, 1789–1800. [Google Scholar] [CrossRef]

- Genzale, C.L.; Pickett, L.M.; Kook, S. Liquid Penetration of Diesel and Biodiesel Sprays at Late-Cycle Post-Injection Conditions. SAE Int. J. Engines 2010, 3, 479–495. [Google Scholar] [CrossRef]

- He, X.; Williams, A.; Christensen, E.; Burton, J.; McCormick, R. Biodiesel Impact on Engine Lubricant Dilution During Active Regeneration of Aftertreatment Systems. SAE Int. J. Fuels Lubr. 2011, 4, 158–178. [Google Scholar] [CrossRef]

- Campbell, M.G.; Martin, E.P. Substrate Selection for a Diesel Catalyst. SAE Trans. 1995, 104, 725–731. [Google Scholar] [CrossRef]

- Pradhan, P.; Raheman, H.; Padhee, D. Combustion and performance of a diesel engine with preheated Jatropha curcas oil using waste heat from exhaust gas. Fuel 2014, 115, 527–533. [Google Scholar] [CrossRef]

- Raheman, H.; Phadatare, A. Diesel engine emissions and performance from blends of karanja methyl ester and diesel. Biomass- Bioenergy 2004, 27, 393–397. [Google Scholar] [CrossRef]

- Arbab, M.; Masjuki, H.; Varman, M.; Kalam, M.; Imtenan, S.; Sajjad, H. Experimental Investigation of Optimum Blend Ratio of Jatropha, Palm and Coconut Based Biodiesel to Improve Fuel Properties, Engine Performance and Emission Characteristics; SAE Technical Paper. 2013. Available online: https://saemobilus.sae.org/content/2013-01-2675/ (accessed on 24 December 2022).

- Ferguson, C.R.; Kirkpatrick, A.T. Internal Combustion Engines: Applied Thermosciences, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Haşimoğlu, C.; Ciniviz, M.; Özsert, I.; Içingür, Y.; Parlak, A.; Salman, M.S. Performance characteristics of a low heat rejection diesel engine operating with biodiesel. Renew. Energy 2008, 33, 1709–1715. [Google Scholar] [CrossRef]

- Armas, O.; Yehliu, K.; Boehman, A.L. Effect of alternative fuels on exhaust emissions during diesel engine operation with matched combustion phasing. Fuel 2010, 89, 438–456. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S. The effect of rapeseed oil methyl ester on direct injection Diesel engine performance and exhaust emissions. Energy Convers. Manag. 2006, 47, 1954–1967. [Google Scholar] [CrossRef]

- Haas, M.J.; Scott, K.M.; Alleman, T.L.; McCormick, R.L. Engine Performance of Biodiesel Fuel Prepared from Soybean Soapstock: A High Quality Renewable Fuel Produced from a Waste Feedstock. Energy Fuels 2001, 15, 1207–1212. [Google Scholar] [CrossRef]

- Luján, J.; Bermúdez, V.; Tormos, B.; Pla, B. Comparative analysis of a DI diesel engine fuelled with biodiesel blends during the European MVEG-A cycle: Performance and emissions (II). Biomass Bioenergy 2009, 33, 948–956. [Google Scholar] [CrossRef]

- Özener, O.; Yüksek, L.; Ergenç, A.T.; Özkan, M. Effects of soybean biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2014, 115, 875–883. [Google Scholar] [CrossRef]

- Al-Lwayzy, S.H.; Yusaf, T. Chlorella protothecoides Microalgae as an Alternative Fuel for Tractor Diesel Engines. Energies 2013, 6, 766–783. [Google Scholar] [CrossRef] [Green Version]

- Heywood, J. Internal Combustion Engine Fundamentals, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2018. [Google Scholar]

| Condition/Parameter/Material | Optimum Selection |

|---|---|

| DSO extraction | |

| Method | Solvent extraction (Soxhlet extraction) |

| Solvent | Hexane |

| Temperature (°C) | 60 |

| Time (h) | 4 |

| Solvent:seed ratio (wt./wt.) | 6 |

| Biodiesel production | |

| Alcohol | Methanol |

| Alcohol:DSO molar ratio | 9:1 |

| Catalyst | NaOH |

| Catalyst mass fraction (wt.%) | 1 |

| Time (h) | 1.5 |

| Temperature (○C) | 55 |

| Specifications | Unit | Description/Value |

|---|---|---|

| Engine | Lombardini 15-LD-225 | |

| Bore | [mm] | 69 |

| Stroke | [mm] | 60 |

| Displacement volume | [L] | 0.224 |

| Compression ratio | 21 | |

| Power @ 3600 rpm | [kW] | 3.5 |

| Torque @ 2400 rpm | [N·m] | 10.4 |

| Intake valve opens at | degrees BTDC | 6 |

| Intake valve closes | degrees ABDC | |

| Exhaust valve opens | degrees BBDC | |

| Exhaust valve closes | degrees ATDC |

| Item | Cost ($) |

|---|---|

| 3,700,000 | |

| 1,110,000 | |

| 4,810,000 | |

| 481,000 | |

| 5,291,000 |

| Item | Unit | Unit Cost ($) | Annual Amount | Annual Cost ($) | Remarks |

|---|---|---|---|---|---|

| DFPDS (Parent feedstock) | t | 70 | 11,363 | 795,410 | Price provided by UAE date producers |

| Alcohol (Methanol, CH3OH) | t | 345 | 170.45 | 58,803 | [38] |

| Catalyst (Sodium hydroxide) | t | 600 | 17 | 10,226 | [39] |

| Water | t | 2 | 2000 | 4000 | [34], cost according to UAE tariff |

| Wastewater treatment | t | 2 | 2000 | 4000 | Cost according to UAE tariff |

| Electricity | kWhe | 0.11 | 60,000 | 6600 | [31], cost according to UAE tariff |

| Thermal energy | kWhth | 0.01 | 440,000 | 4400 | [30], cost according to UAE tariff |

| Operating labor | No. | 18,000 | 5 | 90,000 | Based on 5 employees and UAE labor wages |

| Multifarious items | - | - | - | 5550 | 10% of maintenance; maintenance is 5% of [40]. |

| $978,990 | |||||

| Item | Annual Cost ($) | Remarks |

|---|---|---|

| Laboratories and quality control | 18,000 | 20% of operating labor [41] |

| Operating labor supervision | 18,000 | 20% of operating labor [42] |

| Plant overhead | 45,000 | 50% of operating labor [42] |

| Maintenance | 55,500 | 5% of [40] |

| Capital charges | 111,000 | 10% of [42] |

| Property insurance | 48,100 | 1% of [43] |

| Property taxes | 96,200 | 2% of [41] |

| Royalties | 48,100 | 1% of [28] |

| Research and development | 48,950 | 5% of [42] |

| Selling and marketing costs | 48,950 | 5% of [43] |

| General and administrative costs | 99,450 | 65% of (Operating labor + supervision + overhead) [43] |

| $637,250 | ||

| $1,616,240 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamil, M.; Almarashda, F.M. Economic Viability and Engine Performance Evaluation of Biodiesel Derived from Desert Palm Date Seeds. Energies 2023, 16, 1513. https://doi.org/10.3390/en16031513

Kamil M, Almarashda FM. Economic Viability and Engine Performance Evaluation of Biodiesel Derived from Desert Palm Date Seeds. Energies. 2023; 16(3):1513. https://doi.org/10.3390/en16031513

Chicago/Turabian StyleKamil, Mohammed, and Fatima M. Almarashda. 2023. "Economic Viability and Engine Performance Evaluation of Biodiesel Derived from Desert Palm Date Seeds" Energies 16, no. 3: 1513. https://doi.org/10.3390/en16031513

APA StyleKamil, M., & Almarashda, F. M. (2023). Economic Viability and Engine Performance Evaluation of Biodiesel Derived from Desert Palm Date Seeds. Energies, 16(3), 1513. https://doi.org/10.3390/en16031513