Impact of Primary Air Separation in a Grate Furnace on the Resulting Combustion Products

Abstract

:1. Introduction

1.1. The Role of Combustion Processes in Grate Furnaces

1.2. Advantages and Disadvantages of Combustion Processes in Grate Furnaces

1.3. The Course of the Combustion Process in Selected Grate Furnaces

2. Materials and Methods

2.1. Theoretical Basis of the Conducted Research

2.1.1. Generalization of Air Distribution in Grate Furnaces

- in furnaces with a fixed grate, the following should be assumed: x = t; X = T, min,

- in a furnace with a movable grate: x = l; X = L, m,

2.1.2. Determination of Total Emissions of Gaseous Combustion Products

2.1.3. Determination of the Relative Uncertainty of the Assessment of Gaseous Emissions of Combustion Products

2.1.4. Determination of the Share of Combustible Parts in the Slag

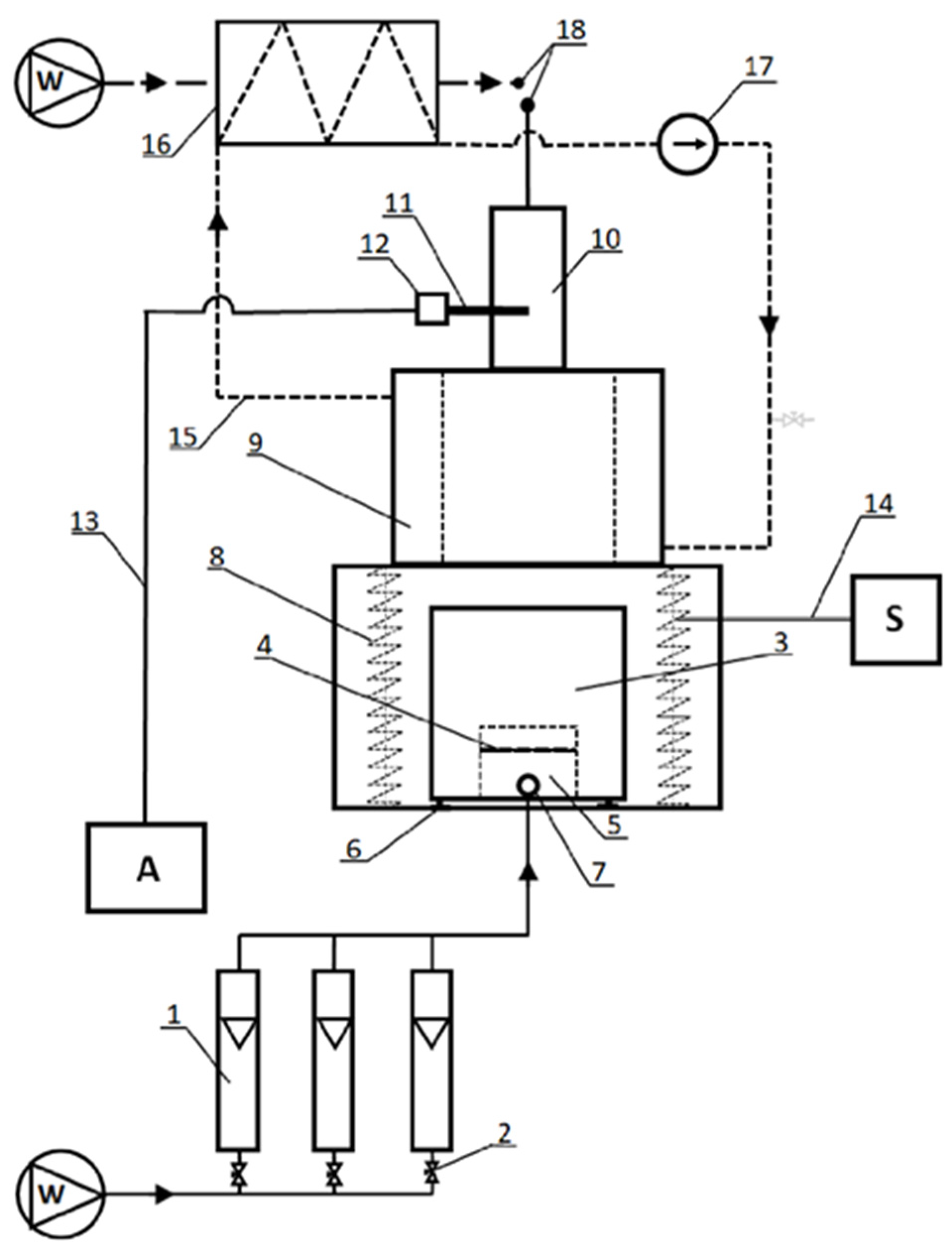

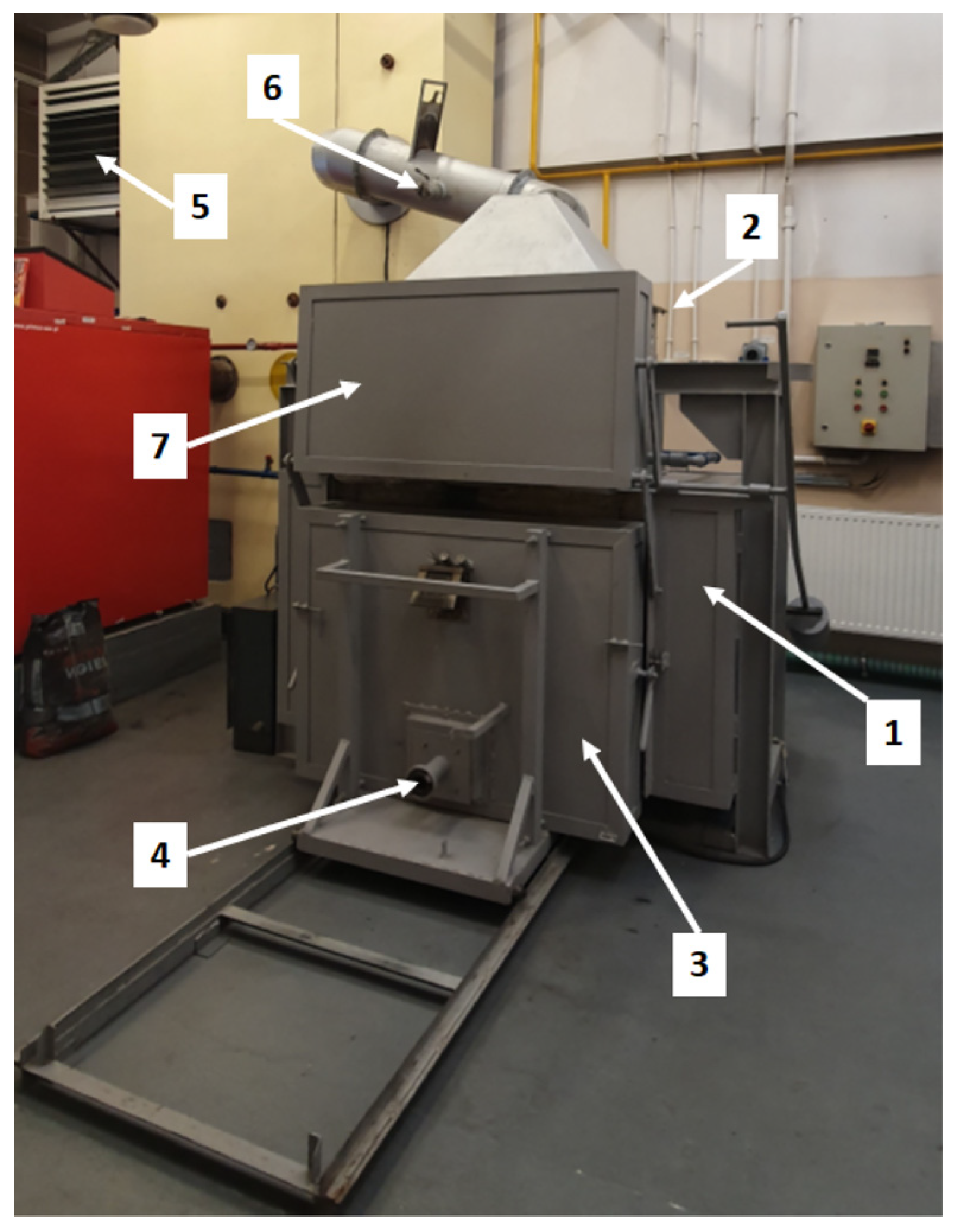

2.2. Research Stand

2.3. Research Material

2.4. Distribution of Primary Air

2.5. Sequence of Procedures in the Determination of Gaseous Products of the Combustion Process

- The following part of the article presents the results of tests carried out in compliance with the following procedure:

- Based on the composition and amount of the tested fuel and on the assumed ratio of excess air, the total amount of supplied air (Vad) was calculated.

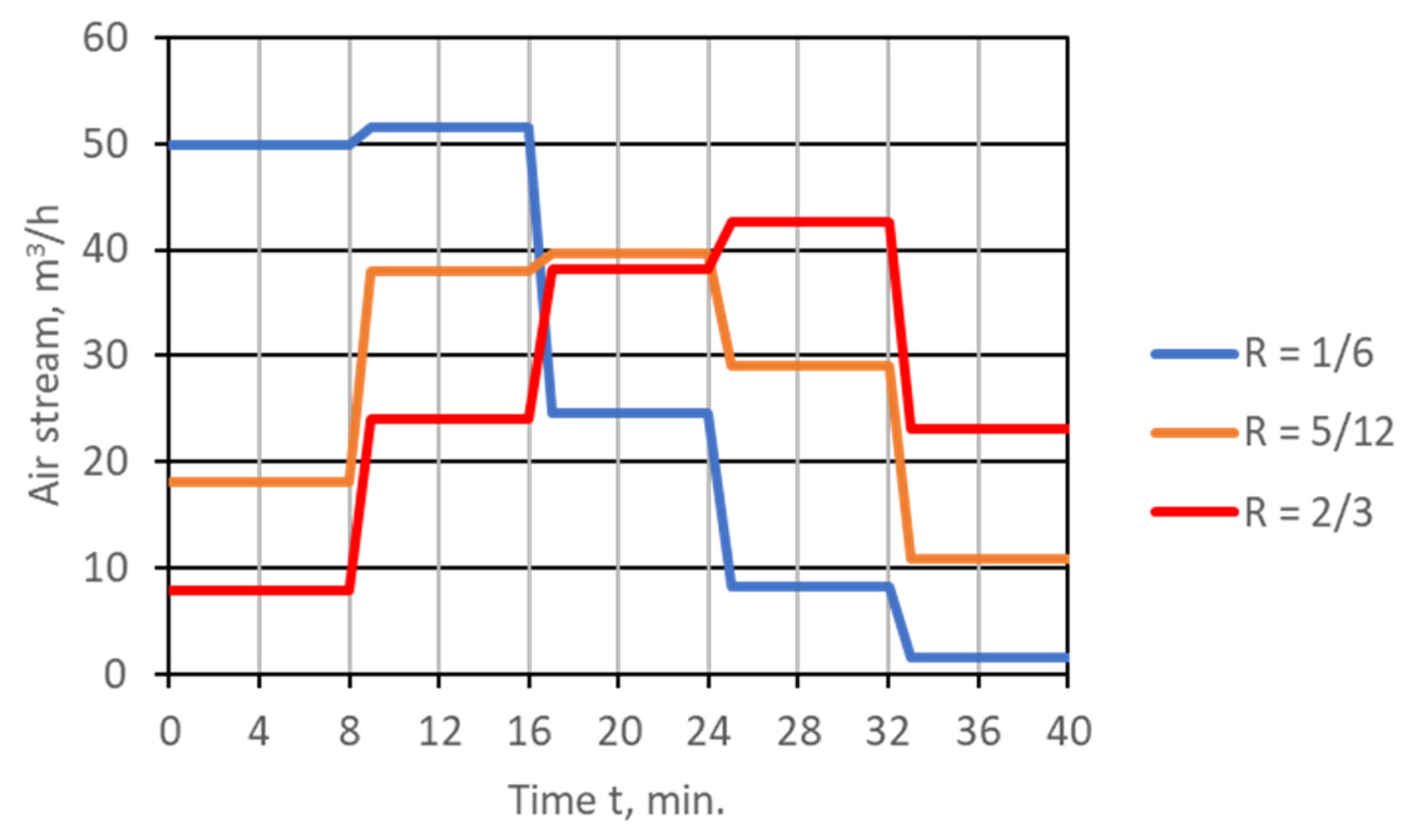

- For the assumed value of R, the air stream distribution in time was determined in line withEquation (2) (Figure 3).

- Based on the Equation (10), the average values of air streams in individual zones were calculated (Figure 4).

- The air streams, equal to the calculated values, were blown into the combustion chamber (they were controlled by means of rotameters).

- During the tests, the concentrations of the analyzed exhaust gas components were measured ; the measurements were made in subsequent time steps in individual zones (using an analyzer).

3. Results

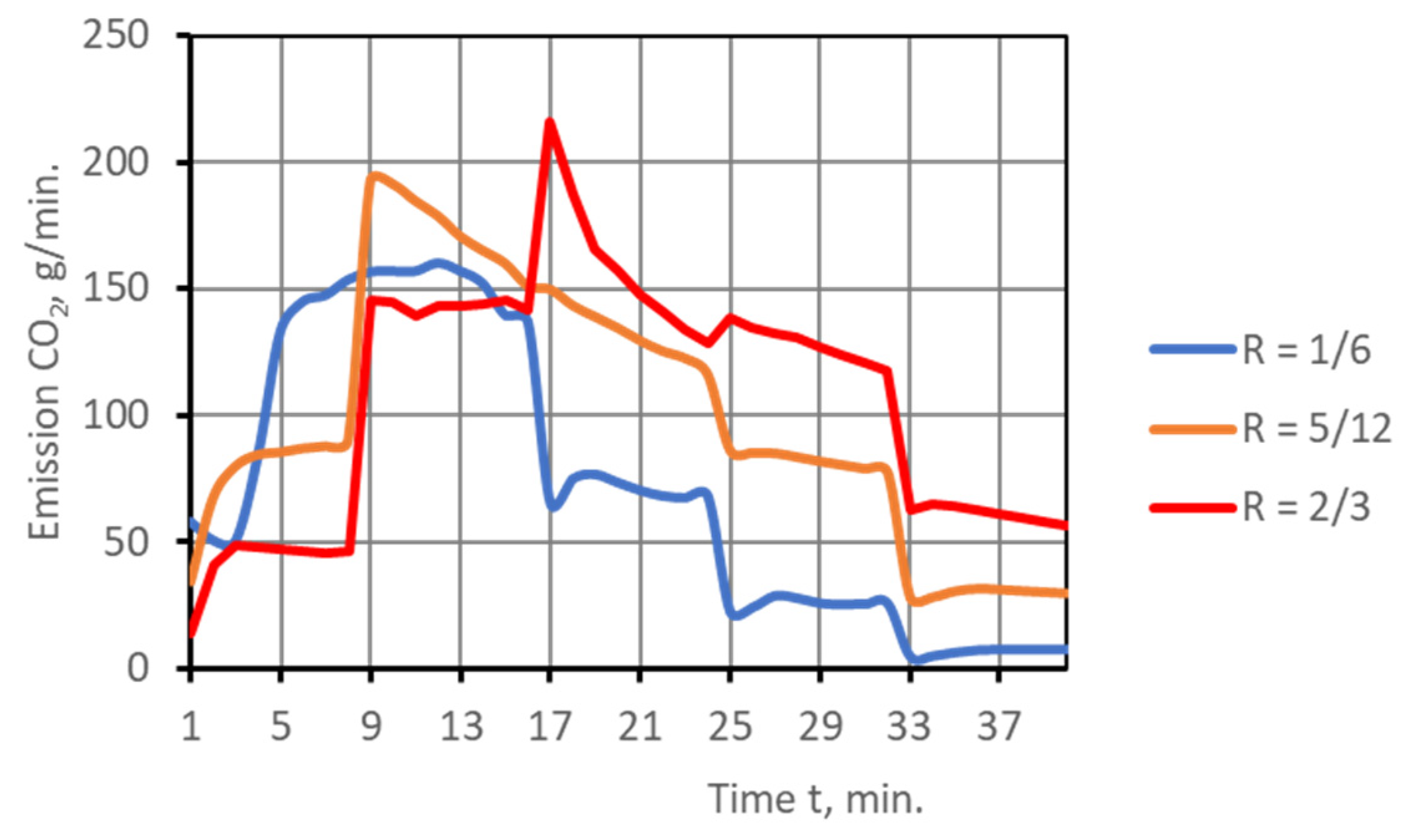

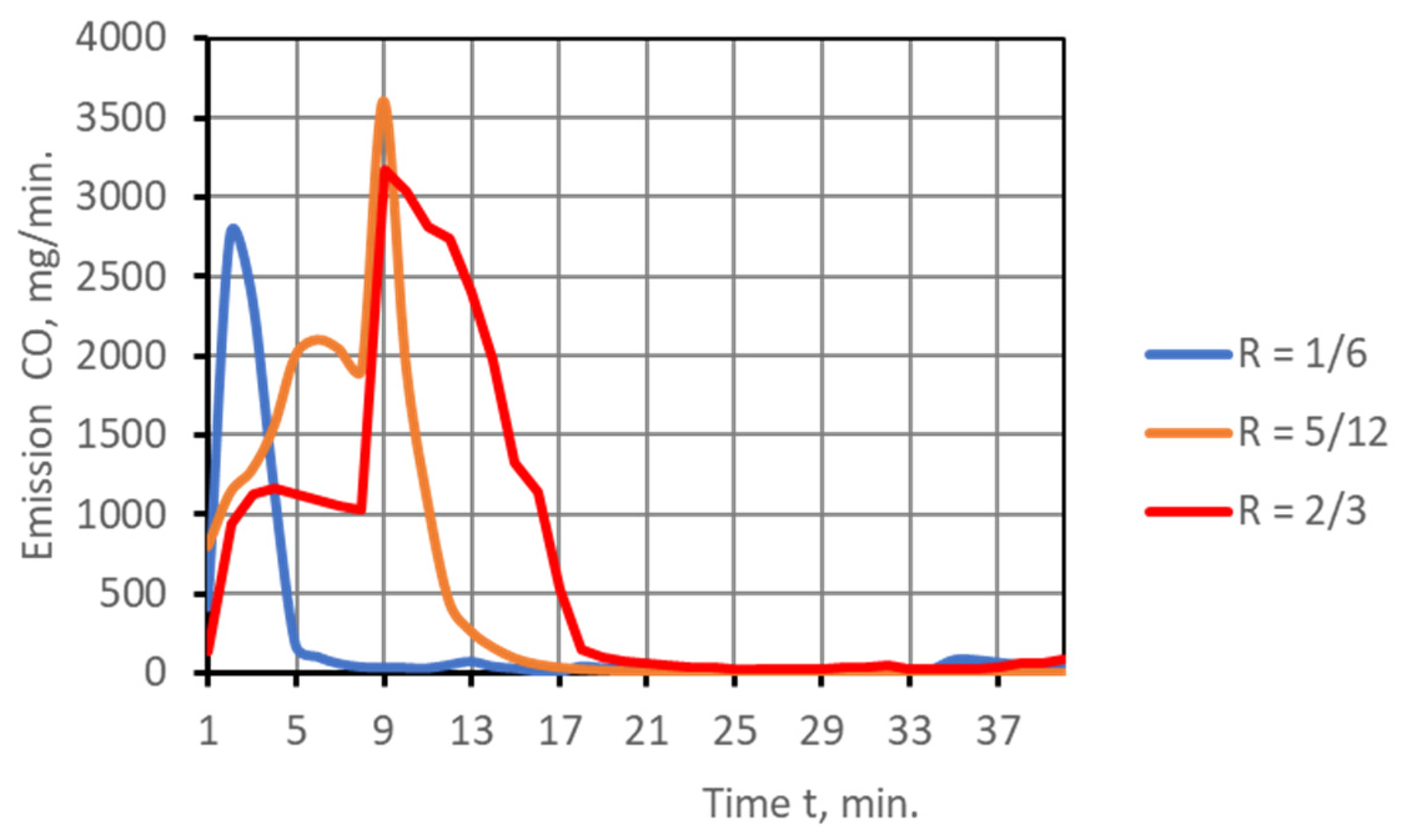

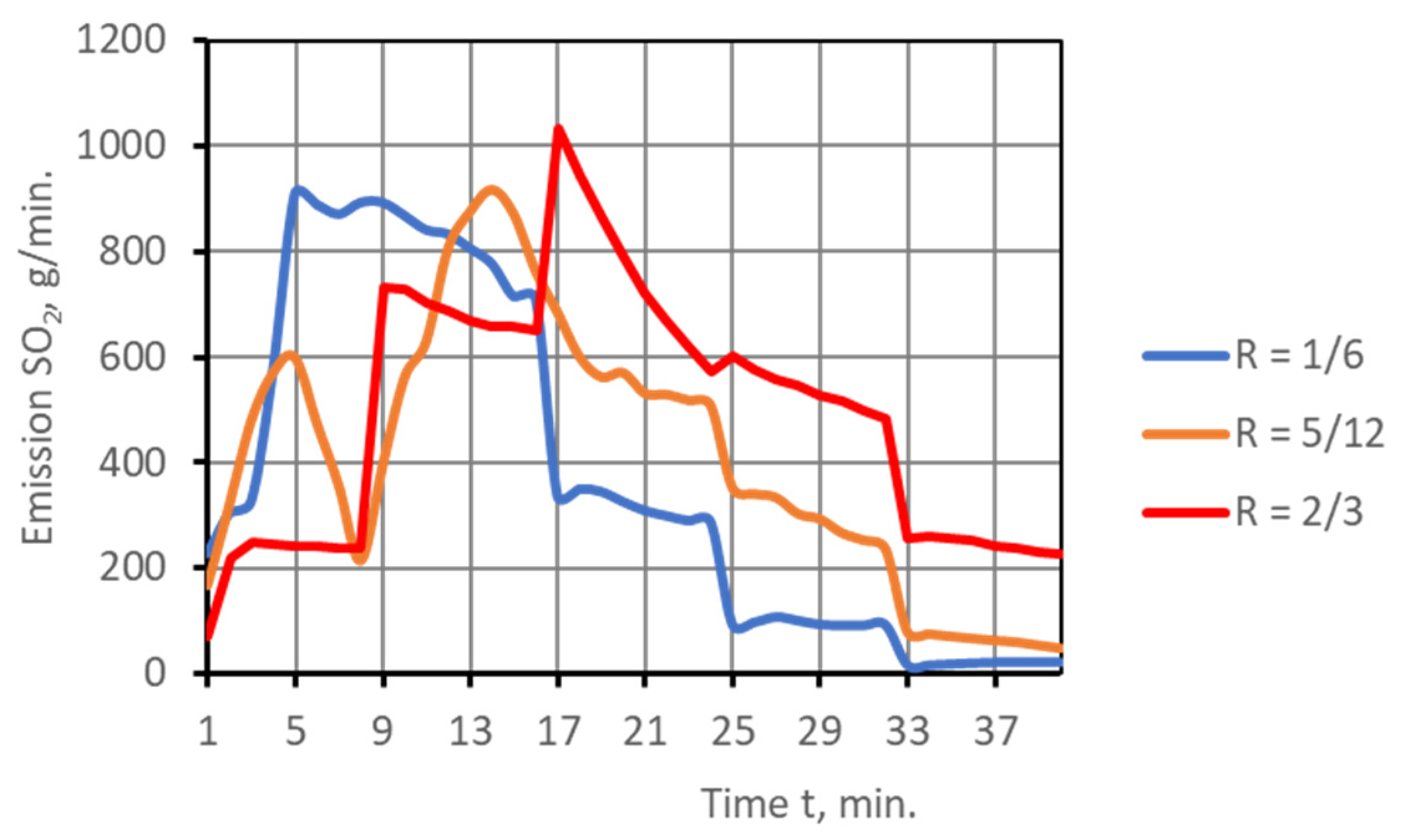

3.1. Emission Streams of Exhaust Gas Components

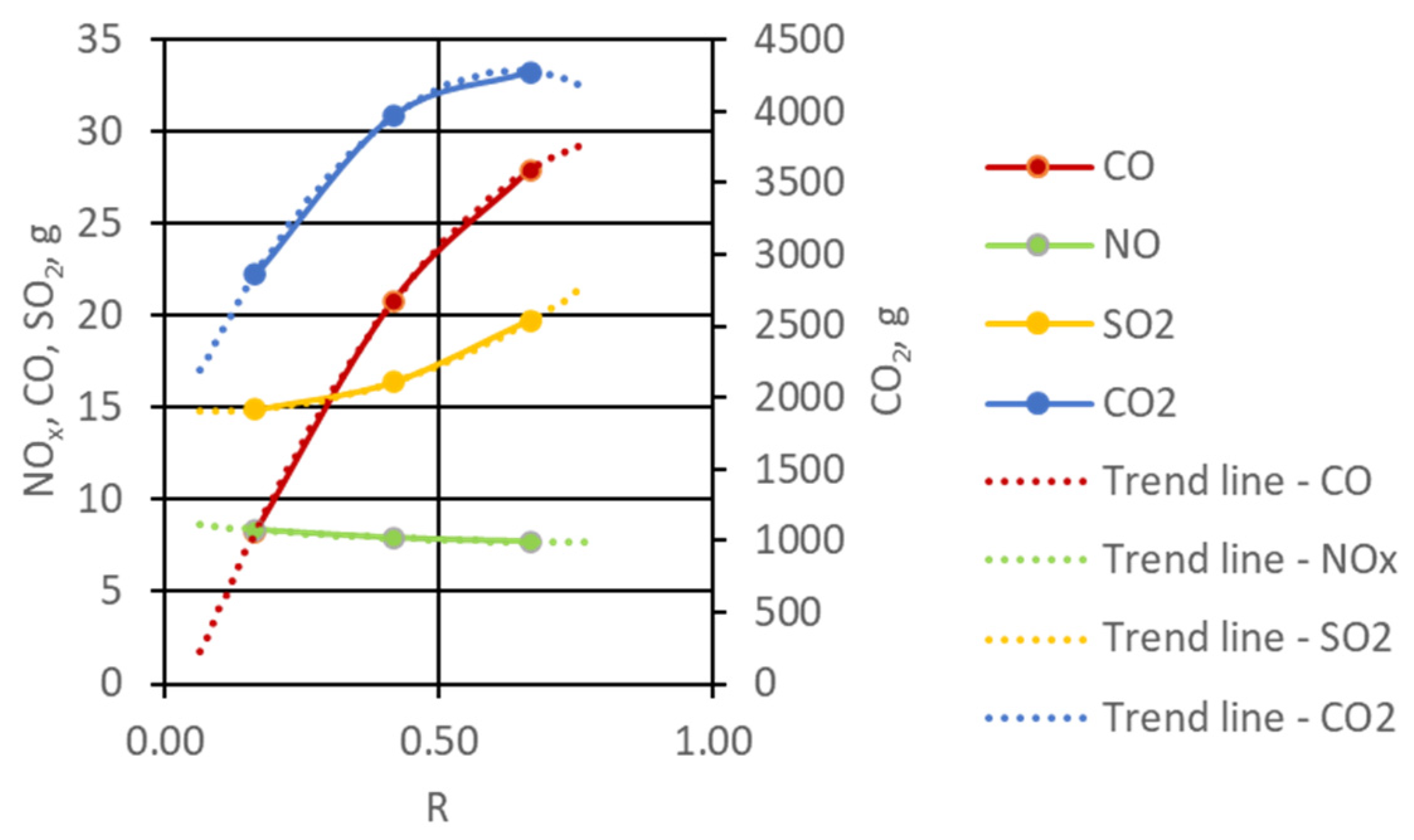

3.2. Total Emissions of Gaseous Combustion Products

3.3. Determination of the Share of Combustible Parts in the Slag

4. Discussion

- The generalized air distribution curve corresponds well with the practical methods of air supply (distribution) in industrial grate furnaces.

- The time or place of supplying the maximum air stream and its total demand are sufficient parameters to determine the shape of the air distribution function.

- Air distribution has a significant impact on the quantity and quality of gaseous and solid products of the combustion process.

- By applying the proper air distribution, it is possible to significantly reduce the emission of selected gaseous substances and to increase the energy efficiency of the furnace operation.

- In order to determine the most advantageous location of the maximum stream, the furnace characteristics should be determined each time for a given fuel (e.g., coal with specific properties).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Madanayake, B.N.; Gan, S.; Eastwick, C.; Ng, H.K. Biomass as an energy source in coal co-firing and its feasibility enhancement via pre-treatment techniques. Fuel Process. Technol. 2017, 159, 287–305. [Google Scholar] [CrossRef]

- Ozawa, M.; Asano, H. (Eds.) Advances in Power Boilers; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Orłowski, P.; Dobrzański, W.; Szwarc, E. Kotły Parowe, Konstrukcja i Obliczenia; Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 1979. [Google Scholar]

- Fang, J.; Li, G.; Aunan, K.; Vennemo, H.; Seip, H.M.; Oye, K.A.; Beér, J.M. A proposed industrial-boiler efficiency program in Shanxi: Potential CO2-mitigation, health benefits and associated costs. Appl. Energy 2002, 71, 275–285. [Google Scholar] [CrossRef]

- Fang, J.; Zeng, T.; Yang, L.I.; Oye, K.A.; Sarofim, A.F.; Beér, J.M. Coal utilization in industrial boilers in China —A prospect for mitigating CO2 emissions. Appl. Energy 1999, 63, 35–52. [Google Scholar] [CrossRef]

- Lin, P.; Ji, J.; Luo, Y.; Wang, Y. A non-isothermal integrated model of coal-fired traveling grate boilers. Appl. Therm. Eng. 2009, 29, 3224–3234. [Google Scholar] [CrossRef]

- Greinert, A.; Mrówczyńska, M.; Grech, R.; Szefner, W. The Use of Plant Biomass Pellets for Energy Production by Combustion in Dedicated Furnaces. Energies 2020, 13, 463. [Google Scholar] [CrossRef]

- Variny, M.; Varga, A.; Rimár, M.; Janošovský, J.; Kizek, J.; Lukáč, L.; Jablonský, G.; Mierka, O. Advances in Biomass Co-Combustion with Fossil Fuels in the European Context: A Review. Processes 2021, 9, 100. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Q.; Bradford, R.; Sharifi, V.; Swithenbank, J. Experimental investigation and mathematical modelling of wood combustion in a moving grate boiler. Fuel Process. Technol. 2010, 91, 1491–1499. [Google Scholar] [CrossRef]

- Yin, C.; Rosendahl, L.A.; Kær, S.K. Grate-firing of biomass for heat and power production. Prog. Energy Combust. Sci. 2008, 34, 725–754. [Google Scholar] [CrossRef]

- Pham, T.P.T.; Kaushik, R.; Parshetti, G.K.; Mahmood, R.; Balasubramanian, R. Food waste-to-energy conversion technologies: Current status and future directions. Waste Manag. 2015, 38, 399–408. [Google Scholar] [CrossRef]

- Jančauskas, A.; Buinevičius, K. Combination of Primary Measures on Flue Gas Emissions in Grate-Firing Biofuel Boiler. Energies 2021, 14, 793. [Google Scholar] [CrossRef]

- Regueiro, A.; Patiño, D.; Porteiro, J.; Granada, E.; Míguez, J.L. Effect of Air Staging Ratios on the Burning Rate and Emissions in an Underfeed Fixed-Bed Biomass Combustor. Energies 2016, 9, 940. [Google Scholar] [CrossRef]

- Kozioł, M. Możliwości Substytucji Węgla Paliwami z Odpadów w Warunkach Polskich. Rynek Energii 2022, 3, 64–70. Available online: http://rynek-energii.pl/pl/RE160 (accessed on 22 September 2022).

- Makarichi, L.; Jutidamrongphan, W.; Techato, K.-A. The evolution of waste-to-energy incineration: A review. Renew. Sustain. Energy Rev. 2018, 91, 812–821. [Google Scholar] [CrossRef]

- Song, J.; Sun, Y.; Jin, L. PESTEL analysis of the development of the waste-to-energy incineration industry in China. Renew. Sustain. Energy Rev. 2017, 80, 276–289. [Google Scholar] [CrossRef]

- Leckner, B.; Lind, F. Combustion of municipal solid waste in fluidized bed or on grate—A comparison. Waste Manag. 2020, 109, 94–108. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Sokhansanj, S.; Grace, J.R.; Bi, X.; Lim, C.J.; Melin, S. Overview and some issues related to co-firing biomass and coal. Can. J. Chem. Eng. 2008, 86, 367–386. [Google Scholar] [CrossRef]

- Xin-Gang, Z.; Gui-Wu, J.; Ang, L.; Yun, L. Technology, cost, a performance of waste-to-energy incineration industry in China. Renew. Sustain. Energy Rev. 2016, 55, 115–130. [Google Scholar] [CrossRef]

- Wilk, R.K. Low-Emission Combustion; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2002. [Google Scholar]

- Nugraha, M.; Saptoadi, H.; Hidayat, M.; Andersson, B.; Andersson, R. Particulate Matter Reduction in Residual Biomass Combustion. Energies 2021, 14, 3341. [Google Scholar] [CrossRef]

- Vakkilainen, E.K. Steam Generation from Biomass. Construction and Design of Large Boilers; Butterworth-Heinemann/Elsevier: Oxford, UK, 2016. [Google Scholar] [CrossRef]

- Hoang, Q.N.; Vanierschot, M.; Blondeau, J.; Croymans, T.; Pittoors, R.; Van Caneghem, J. Review of numerical studies on thermal treatment of municipal solid waste in packed bed combustion. Fuel Commun. 2021, 7, 100013. [Google Scholar] [CrossRef]

- Koziol, J.; Kozioł, M. Determining operating characteristics of co-firing processes in grate furnaces. Fuel 2019, 258, 116164. [Google Scholar] [CrossRef]

- Jiao, L.; Kuang, M.; Chen, Y.; Liu, S.; Wang, X. Detailed measurements of in-furnace gas temperature and species concentration distribution regarding the primary-air distribution mode in a spreader and reversal chain-grate furnace. Energy 2021, 235, 121384. [Google Scholar] [CrossRef]

- Hoang, Q.N.; Van Caneghem, J.; Croymans, T.; Pittoors, R.; Vanierschot, M. A novel comprehensive CFD-based model for municipal solid waste incinerators based on the porous medium approach. Fuel 2022, 326, 124963. [Google Scholar] [CrossRef]

- Zhuang, J.; Tang, J.; Aljerf, L. Comprehensive review on mechanism analysis and numerical simulation of municipal solid waste incineration process based on mechanical grate. Fuel 2022, 320, 123826. [Google Scholar] [CrossRef]

- Frey, H.-H.; Peters, B.; Hunsinger, H.; Vehlow, J. Characterization of municipal solid waste combustion in a grate furnace. Waste Manag. 2003, 23, 689–701. [Google Scholar] [CrossRef] [PubMed]

- Scholz, R.; Beckmann, M.; Schulenburg, F. Entwicklungsmöglichkeiten der Prozeßführung bei Rostsystemen zur Abfallbehandlung; FDBR-Symposium: Rostock, Germany, 1996. [Google Scholar]

- Wissing, F.; Wirtz, S.; Scherer, V. Simulating municipal solid waste incineration with a DEM/CFD method—Influences of waste properties, grate and furnace design. Fuel 2017, 206, 638–656. [Google Scholar] [CrossRef]

- Gu, T.; Ma, W.; Guo, Z.; Berning, T.; Yin, C. Stable and clean co-combustion of municipal sewage sludge with solid wastes in a grate boiler: A modeling-based feasibility study. Fuel 2022, 328, 125237. [Google Scholar] [CrossRef]

- Costa, M.; Massarotti, N.; Mauro, A.; Arpino, F.; Rocco, V. CFD modelling of a RDF incineration plant. Appl. Therm. Eng. 2016, 101, 710–719. [Google Scholar] [CrossRef]

- Tu, Y.; Zhou, A.; Xu, M.; Yang, W.; Siah, K.B.; Prabakaran, S. Experimental and numerical study on the combustion of a 32 MW wood-chip grate boiler with internal flue gas recirculation technology. Energy Procedia 2017, 143, 591–598. [Google Scholar] [CrossRef]

- Rajh, B.; Yin, C.; Samec, N.; Hriberšek, M.; Zadravec, M. Advanced modelling and testing of a 13 MW th waste wood-fired grate boiler with recycled flue gas. Energy Convers. Manag. 2016, 125, 230–241. [Google Scholar] [CrossRef]

- Xia, Z.; Shan, P.; Chen, C.; Du, H.; Huang, J.; Bai, L. A two-fluid model simulation of an industrial moving grate waste incinerator. Waste Manag. 2020, 104, 183–191. [Google Scholar] [CrossRef]

- Karim, R.; Naser, J. CFD modelling of combustion and associated emission of wet woody biomass in a 4 MW moving grate boiler. Fuel 2018, 222, 656–674. [Google Scholar] [CrossRef]

- Jiang, M.; Lai, A.; Law, A. Solid Waste Incineration Modelling for Advanced Moving Grate Incinerators. Sustainability 2020, 12, 8007. [Google Scholar] [CrossRef]

- Zhou, A.; Xu, H.; Tu, Y.; Zhao, F.; Zheng, Z.; Yang, W. Numerical investigation of the effect of air supply and oxygen enrichment on the biomass combustion in the grate boiler. Appl. Therm. Eng. 2019, 156, 550–561. [Google Scholar] [CrossRef]

- Waldner, M.; Halter, R.; Sigg, A.; Brosch, B.; Gehrmann, H.; Keunecke, M. Energy from Waste—Clean, efficient, renewable: Transitions in combustion efficiency and NOx control. Waste Manag. 2013, 33, 317–326. [Google Scholar] [CrossRef] [PubMed]

- PKN. PN-Z-15008-03:1993 Badania Właściwości Paliwowych—Oznaczanie Zawartości Części Palnych i Niepalnych. Available online: https://sklep.pkn.pl/pn-z-15008-03-1993p.html (accessed on 14 July 2021).

- MRU Sp. z o.o.: Instrukcja Obsługi i Serwisu MGA 5 (MGA 5 Flue Gas Analyzer User Manual); MRU GmbH: Neckarsulm, Germany, 2006.

- PKN: PN-ISO 1928:2002 Paliwa Stałe—Oznaczanie Ciepła Spalania Metodą Spalania w Bombie Kalorymetrycznej i Obliczanie Wartości Opałowej. Available online: https://sklep.pkn.pl/pn-iso-1928-2002p.html?options=cart (accessed on 20 July 2021).

- PKN: PN-Z-15008-05:1993 Odpady Komunalne Stałe—Badania Właściwości Paliwowych—Oznaczanie Zawartości Węgla i Wodoru. Available online: https://sklep.pkn.pl/pn-z-15008-05-1993p.html (accessed on 14 July 2021).

- PKN: PN-G-04523:1992 Paliwa Stałe—Oznaczanie Zawartości Azotu Metodą Kjeldahla. Available online: https://sklep.pkn.pl/pn-g-04523-1992p.html?options=cart (accessed on 14 July 2021).

- PKN: PN-ISO 334:1997 Paliwa Stałe—Oznaczanie Siarki Całkowitej—Metoda Eschki. Available online: https://sklep.pkn.pl/pn-iso-334-1997p.html?options=cart (accessed on 14 July 2021).

- PKN: PN-G-04511:1980 Paliwa Stałe—Oznaczanie Zawartości Wilgoci. Available online: https://sklep.pkn.pl/pn-g-04511-1980p.html (accessed on 5 July 2021).

- Kruczek, H.; Modliński, Z.; Ferens, W. Study of NOx formation for lean and rich stirred reactors flames in the presence of sulphur species. In Proceedings of the XIIIth International Symposium on Combustion Processes, Kraków, Poland, 22–24 September 1993. [Google Scholar]

- Scholz, R.; Beckmann, M.; Davidivic, M.; Busch, M.; Schmidt, W. Vergasung von Restabfall auf Rosten; Heft 13; Veröffentlichungen des Zentrums für Abfallforschung der Technischen Universität Braunschweig: Braunschweig, Germany, 1998. [Google Scholar]

| Fuel Type | Calorific Value MJ/kg | α | ||

|---|---|---|---|---|

| λ = 1.0 | λ = 1.4 | λ = 1.6 | ||

| Anthracite | 31.4 | 1.025 | 1.017 | 1.015 |

| Fat coal | 31.8 | 1.037 | 1.027 | 1.023 |

| Gas coal | 31.4 | 1.038 | 1.027 | 1.023 |

| Lean coal | 31.4 | 1.037 | 1.026 | 1.023 |

| Gas coal * | 26.8 | 1.020 | 1.014 | 1.014 |

| Dried peat | 13.5 | 1.029 | 1.020 | 1.018 |

| Lignite | 9.6 | 1.033 | 1.024 | 1.021 |

| Sewage sludge * | 10.3 | 1.043 | 1.030 | 1.025 |

| Mix * of coal + sludge | 24.5 | 1.022 | 1.016 | 1.014 |

| Specification | Unit | Values | Stand. Dev. | Determination Method/Standard |

|---|---|---|---|---|

| Calorific value d.w. | kJ/kg | 10,330 | 680 | PN-ISO 1928:2002 [42] |

| Combustible parts | % d.w. | 62.04 | 0.61 | PN-Z-15008-03:1993 [40] |

| Elementary composition: | ||||

| Carbon | % d.w. | 30.13 | 0.72 | PN-Z-15008-05:1993 [43] |

| Hydrogen | % d.w. | 4.35 | 0.34 | PN-Z-15008-05:1993 [43] |

| Nitrogen | % d.w. | 3.67 | 0.26 | PN-G-04523:1992 [44] |

| Sulphur | % d.w. | 1.41 | 0.16 | PN-ISO 334:1997 [45] |

| Oxygen | % d.w. | 19.30 | 0.85 | Calculation method * |

| Specification | Unit | Values | Stand. Dev. | Determination Method/Standard |

|---|---|---|---|---|

| Calorific value d.w. | kJ/kg | 26,790 | 2040 | PN-ISO 1928:2002 [42] |

| Combustible parts | % d.w. | 93.65 | 0.104 | PN-Z-15008-03:1993 [40] |

| Elementary composition: | ||||

| Carbon | % | 73.01 | 0.97 | PN-Z-15008-05:1993 [43] |

| Hydrogen | % | 4.57 | 0.08 | PN-Z-15008-05:1993 [43] |

| Nitrogen | % | 1.53 | 0.04 | PN-G-04523:1992 [44] |

| Sulphur | % | 0.37 | 0.01 | PN-ISO 334:1997 [45] |

| Oxygen | % | 9.66 | 1.01 | Calculation method * |

| Humidity | % | 4.79 | 0.25 | PN-G-04511:1980 [46] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozioł, M.; Kozioł, J. Impact of Primary Air Separation in a Grate Furnace on the Resulting Combustion Products. Energies 2023, 16, 1647. https://doi.org/10.3390/en16041647

Kozioł M, Kozioł J. Impact of Primary Air Separation in a Grate Furnace on the Resulting Combustion Products. Energies. 2023; 16(4):1647. https://doi.org/10.3390/en16041647

Chicago/Turabian StyleKozioł, Michał, and Joachim Kozioł. 2023. "Impact of Primary Air Separation in a Grate Furnace on the Resulting Combustion Products" Energies 16, no. 4: 1647. https://doi.org/10.3390/en16041647

APA StyleKozioł, M., & Kozioł, J. (2023). Impact of Primary Air Separation in a Grate Furnace on the Resulting Combustion Products. Energies, 16(4), 1647. https://doi.org/10.3390/en16041647