Box-Type Solar Cookers: An Overview of Technological Advancement, Energy, Environmental, and Economic Benefits

Abstract

:1. Introduction

2. Types of Solar Cookers

2.1. Direct Solar Cookers

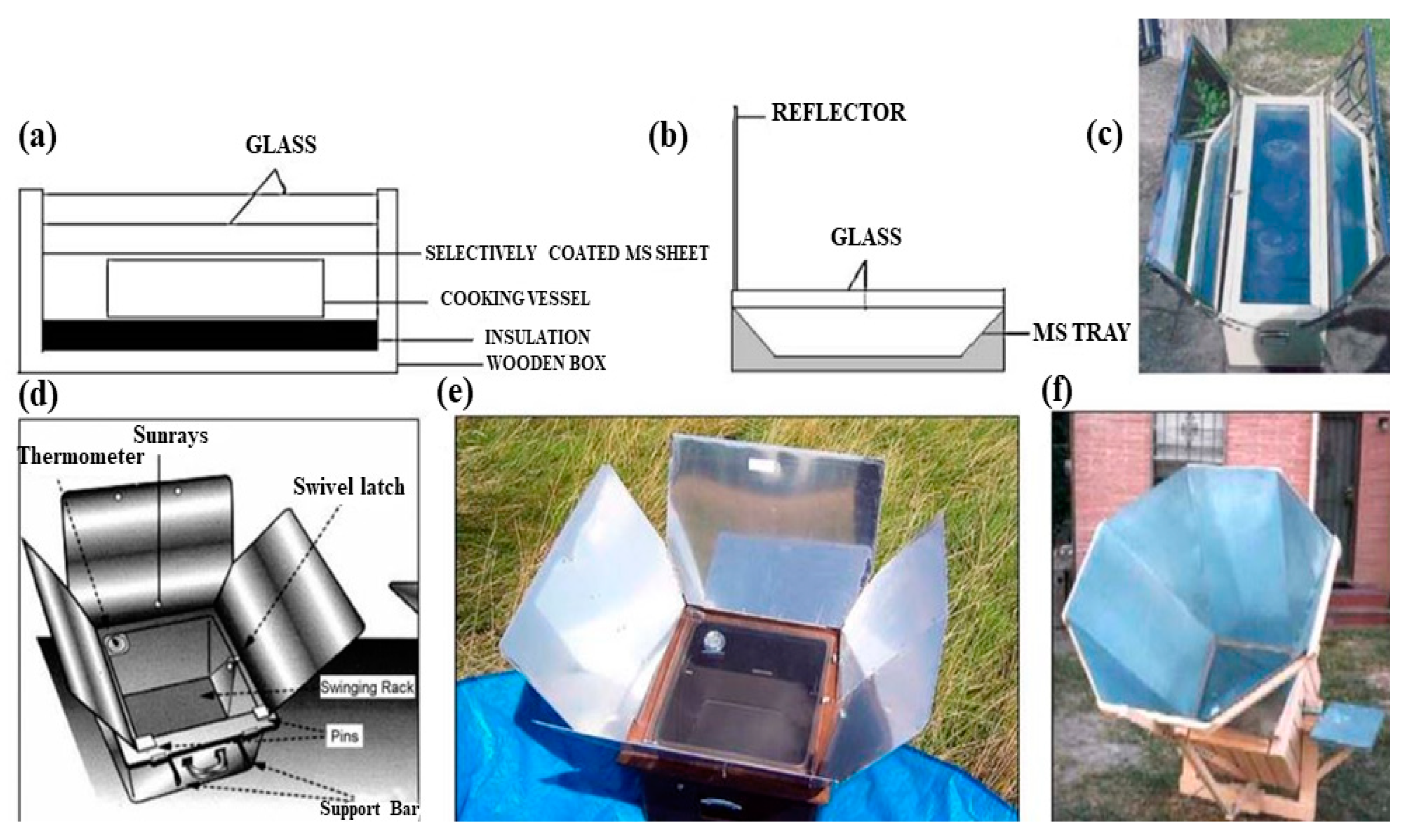

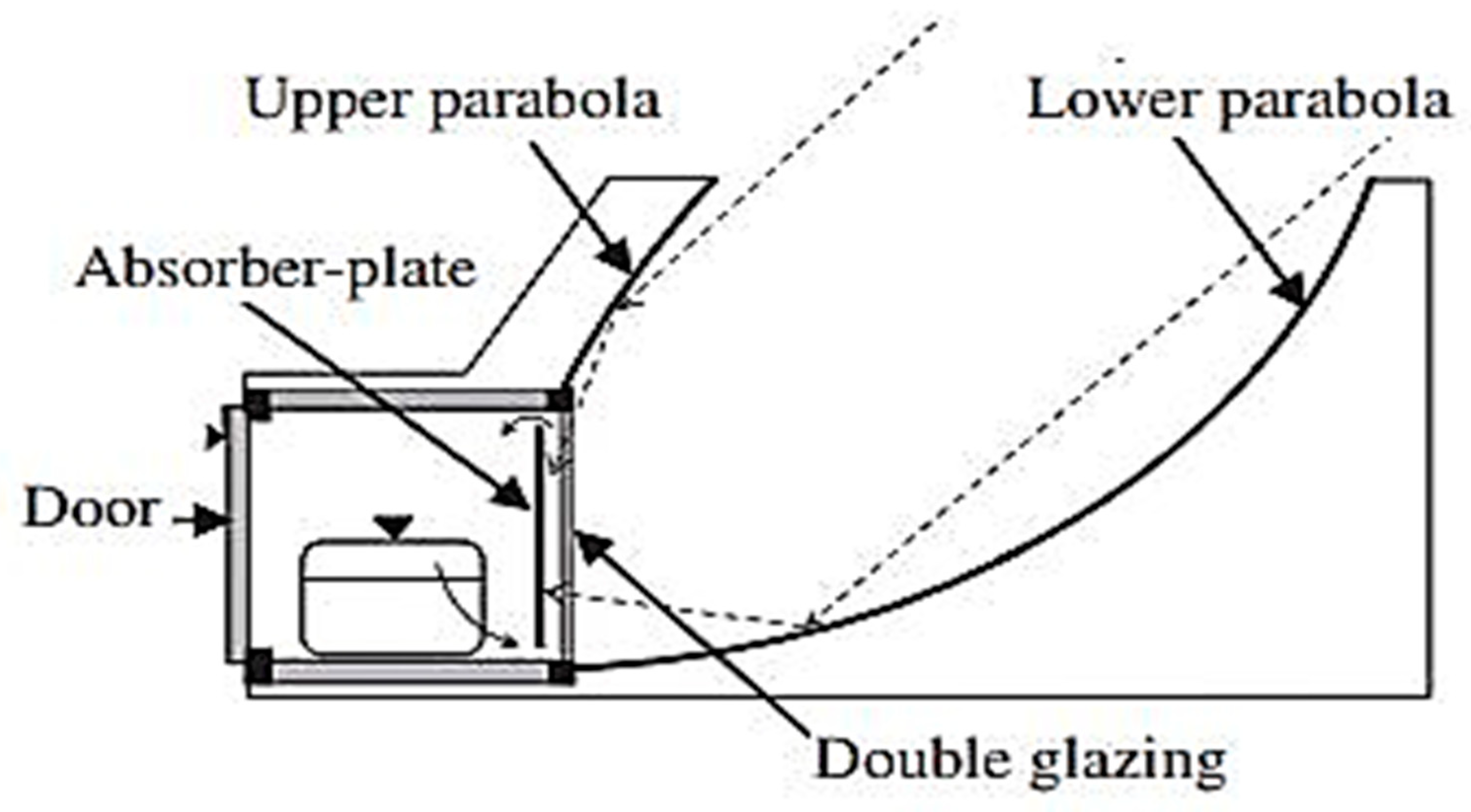

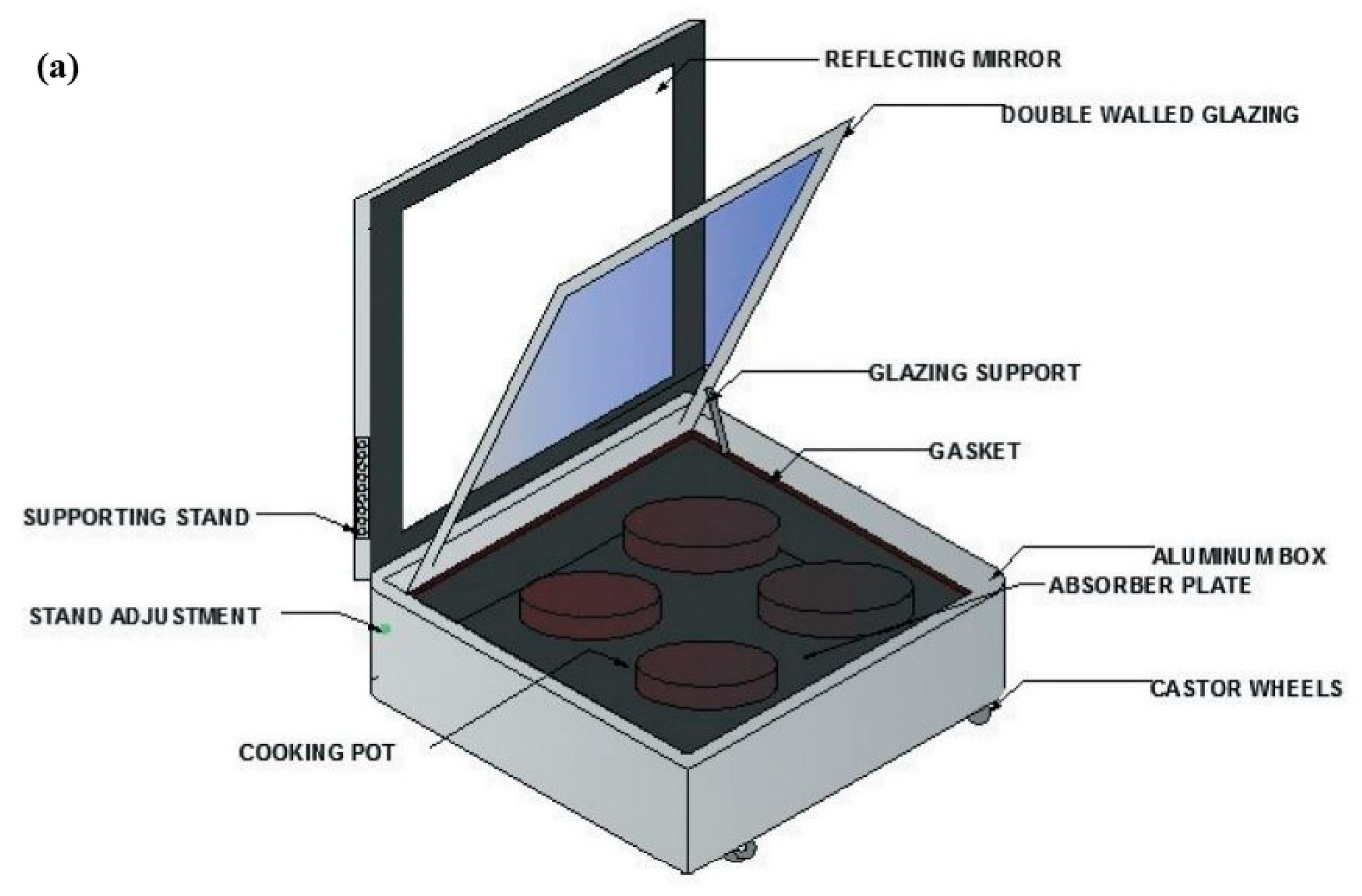

2.1.1. Box-Type Solar Cookers

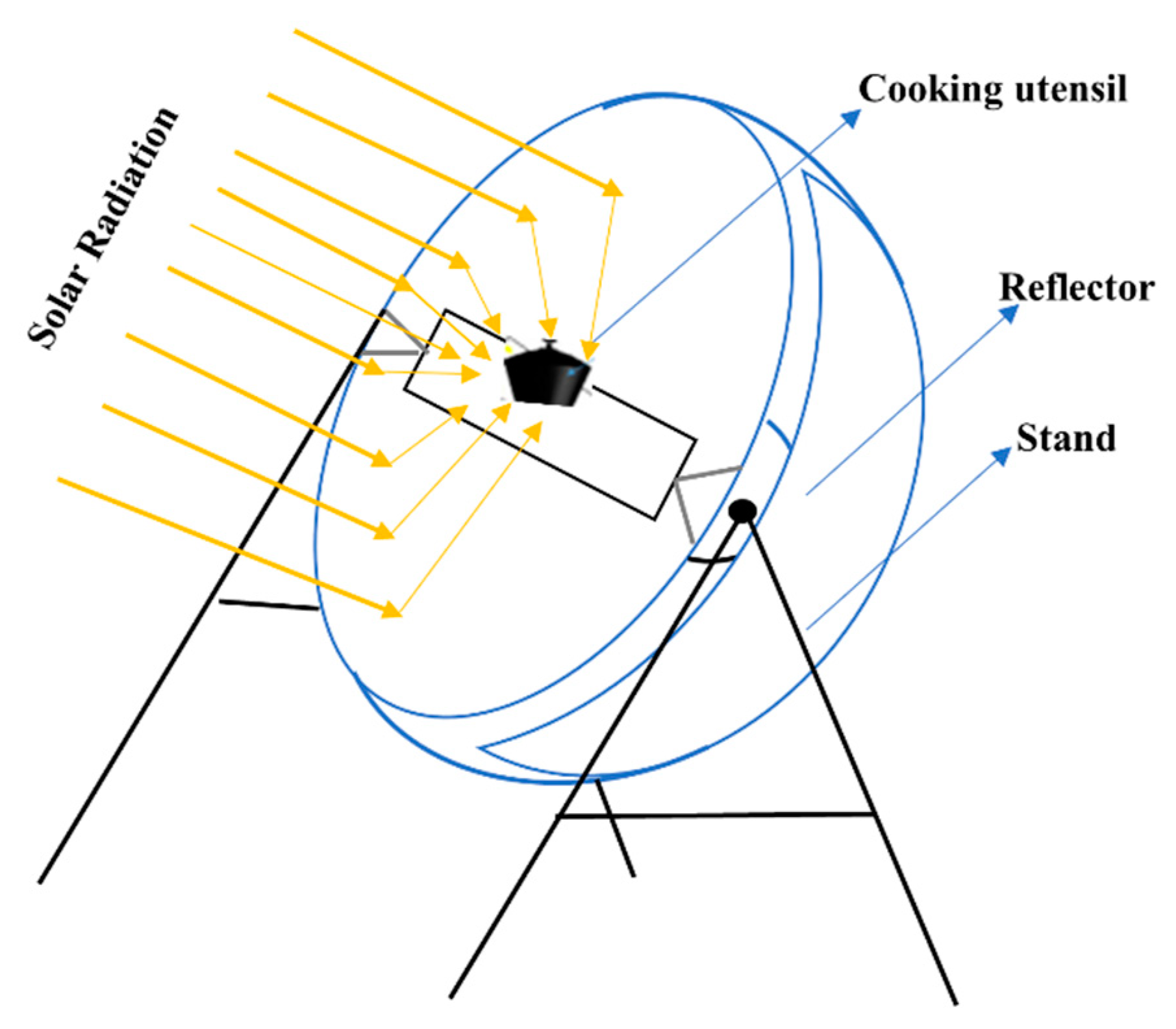

2.1.2. Concentrating Solar Cookers

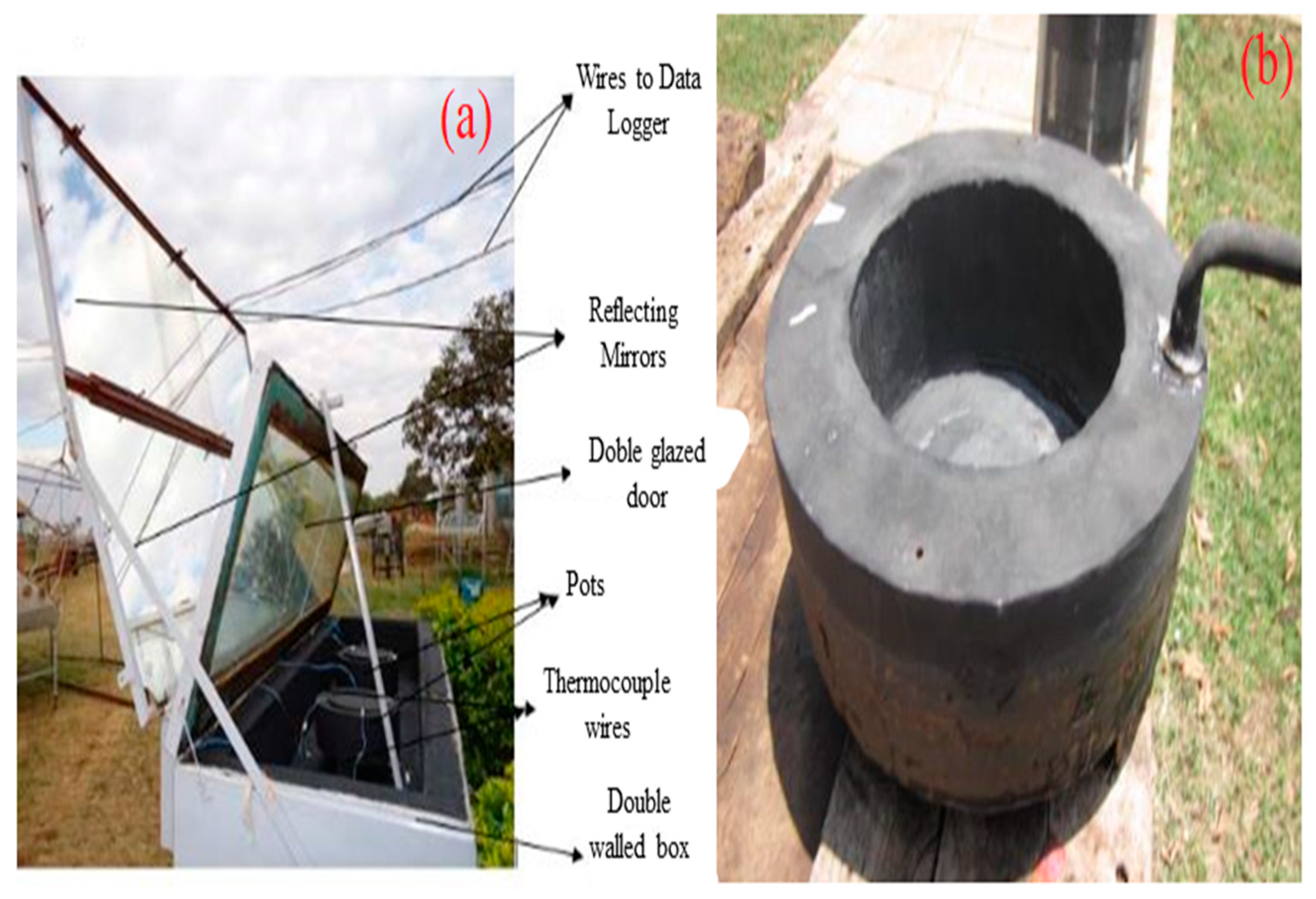

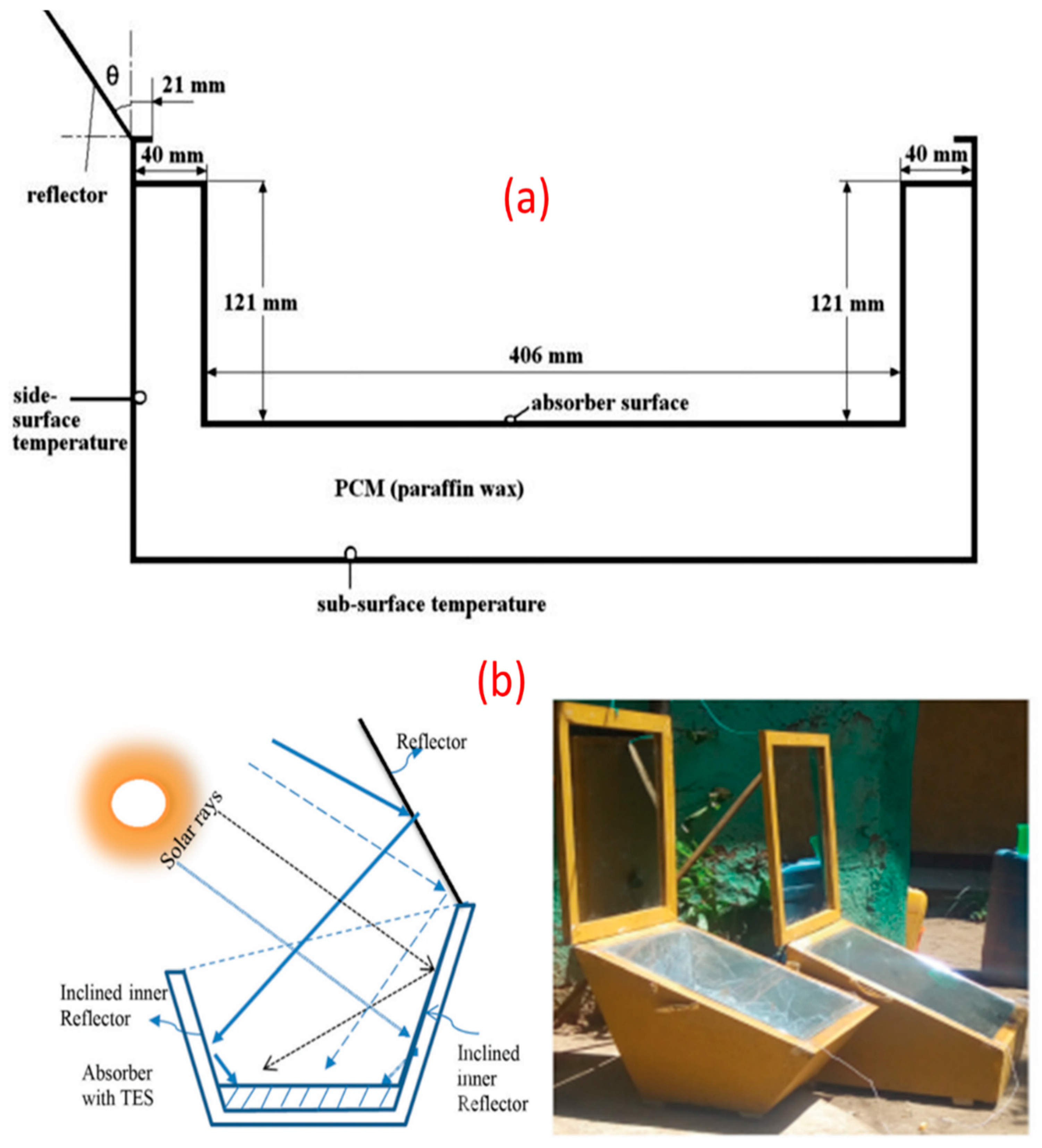

2.2. Indirect Solar Cookers

3. Performance Evaluation of Box-Type Solar Cookers

4. Energy and Exergy Analysis for Box-Type Solar Cookers

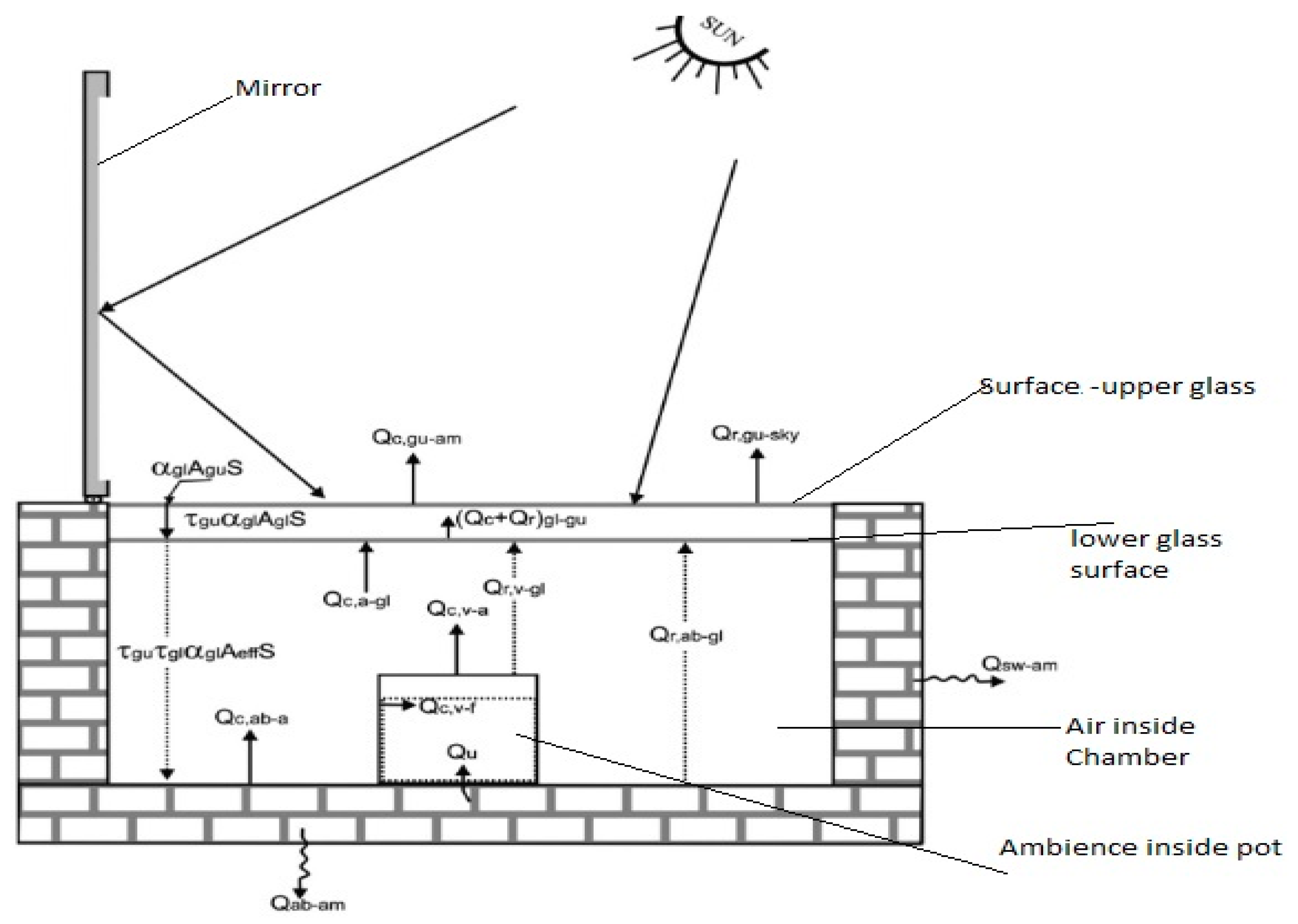

4.1. Heat Transfer in a Box-Type Solar Cooker

- For energy balance at the upper glass surface:

- 2.

- For sun radiation available on the upper glass aperture surface:

- 3.

- For energy balance at the lower glass surface:

- 4.

- For inside the vessel/pot and net energy balance for the vessel/pot:

- 5.

- For energy balance at the absorber base:

- 6.

- For energy balance of air inside the chamber:

4.2. Energy Analysis

4.3. Exergy Analysis

5. Economic Analysis

5.1. Payback Period

5.2. Net Present Value (NPV)

5.3. Benefit–Cost Ratio (B–C Ratio)

5.4. Internal Rate of Return (IRR)

5.5. Levelized Cost of Heat (LCOH)

5.6. Levelized Cost of Cooking a Meal (LCCM)

6. Environmental Analysis

7. Box-Type Solar Cooker without Thermal Energy Storage

8. Box-Type Solar Cooker with Thermal Energy Storage Concept

9. Results and Findings

- It can be seen from the data presented that, in general, the solar cooker with a different type of design improvements has a value of F1 near 0.12 m2 °C/W and successfully meets the BIS standard for cooking food in the given conditions.

- The value of F2 achieved in general for all the cases mentioned in Table 4 for 1 kg of water is from 0.33–0.47, which meets the BIS criteria.

- The stagnant temperature above 100 °C has been achieved for most cases, which shows that solar cooking can be achieved with the design proposed.

- The effect on the environment has been calculated by the amount of wood saved per year for the number of days when the cooking is done with a solar cooker.

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Aeff | Effective aperture area of the solar cooker | Agu | Aperture area of upper glass |

| Ca,m | Cost of yearly savings | Agl | Aperture area of lower glass |

| Clpg | Cost of LPG per kg | Av | Aperture area of vessel |

| Co,m | Operation and maintenance cost | Amr | Aperture area of mirror |

| Csc | Salvage value of the box-type solar cooker | Aab | Area of absorber plate |

| Ci,sc | Capital cost | Avb | Area of vessel base |

| d | Discount rate | αab | Absorptivity of solar radiation on absorber plate |

| Fmr | View factor which is taken unity in this case | αv | Absorptivity of solar radiation on vessel/pot |

| Et | Energy saved | αgu | Absorptivity of solar radiation on upper glass |

| hc.gu-am | Convective heat transfer coefficient of upper glass to ambient | αgl | Absorptivity of solar radiation on lower glass |

| hr.gu-sky | Radiative heat transfer coefficient glass upper to outside air | hc.v-f | Convective heat transfer coefficient vessel to fluid |

| hr.gl-gu | Radiative heat transfer coefficient glass lower to upper | hr.vc-gl | Radiative heat transfer coefficient vessel to lower glass |

| Exergy output | hc.vc-a | Convective heat transfer coefficient vessel to air in SC | |

| H exp | Average solar radiation exposed | hc.a-gl | Convective heat transfer coefficient ambient to lower glass |

| H | Solar radiation | hc.ab-a | Convective heat transfer coefficient ambient to air in SC |

| HCpw | Specific heat of water | hc.ab-gl | Convective heat transfer coefficient ambient to lower glass |

| h | Heat transfer coefficient | hc.gl-gu | Convective heat transfer coefficient lower to upper glass |

| Id | Diffused solar radiation | hr.ab-gl | Radiative heat transfer coefficient ambient to lower glass |

| Is | Solar radiation | MCp | Heat capacity of upper glass |

| IG | Solar radiation on glass | Qr,gl-gu | Radiative heat from lower to upper glass |

| Ib | Beam Solar radiation | Qc, gl-gu | Convective heat from lower to upper glass |

| Mlpg | Mass of LPG consumed per month | Qc,v-a | Heat convective vessel to air in solar cooker |

| Mlt | Meals cooked per year | Qsw | Heat from side wall |

| n | Number of vessels (01 in this sample case) | Qv | Heat from vessel/pot |

| Qf | Heat from fluid in vessel/Pot | Qred CO2 | Quantity of CO2 reduced while using a box-type SC in place of a conventional LPG, |

| η | Optical efficiency | Qam | Ambient heat |

| Thermal exergy | Qgl | Heat on glass lower surface | |

| Qgu | Heat on upper surface of glass | Qtotal CO2 | Total quantity of CO2 produced (in kg/month) conventional LPG |

| Pr | Percentage of the time a solar cooker is used | Qab | Heat at absorber base |

| Tsky | Temperature outside SC | Qc,gu-am | Convective heat from lower glass to ambient air |

| Tab | Stagnation temperature of the absorber plate | Qsw-am | Heat from side wall to ambient air |

| Tv | Temperature of vessel/pot | Qab-am | Heat from absorber to ambient air |

| Tam | Ambient temperature | Qr,gu-sky | Radiative heat from lower glass to sky |

| Tw1 | Lower level of water temperature | Qc, gu-sky | Convective heat from lower glass to sky |

| Tw2 | Upper level of water temperature | (Qc+ Qr)gl-gu | Heat convective and radiative from lower to upper glass |

| t | Time interval when the temperature of water rises from Tw1 to Tw2, | Qc, ab-a | Convective heat from ambient to air |

| texp | Time interval of the experiment | Qu | Heat from absorber plate to vessel |

| Ts | Surface temperature of the sun | Qc,v-f | Convective heat from vessel to fluid |

| Ta | Temperature of air inside solar cooker | Qc, a-gl | Convective heat from ambient to lower glass |

| Tf | Temperature of fluid | Qr,v-gl | Radiative heat from vessel to lower glass |

| Tgu | Temperature of upper surface of glass | Qr,ab-gl | Radiative heat from ambient to lower glass |

| Tgl | Temperature of lower surface of glass | exergy efficiency | |

| ULs | Heat loss factor | S | Solar flux |

| Uvb | Heat loss by vessel base | τgl | Transmissivity of lower glass |

| Usw | Heat loss by side wall | τgu | Transmissivity of upper glass |

| Uab | Heat loss by vessel base | Φ | Angle of incident from mirror to upper glass cover |

References

- Pohekar, S.D.; Kumar, D.; Ramachandran, M. Dissemination of Cooking Energy Alternatives in India—A Review. Renew. Sustain. Energy Rev. 2005, 9, 379–393. [Google Scholar]

- Mani, A.; Rangarajan, S. Solar Radiation Over India; Allied Publishers: Sydney, Australia, 1982. [Google Scholar]

- Sharma, A.; Shukla, A.; Kant, K. Perspective of Solar Energy in India. In Green Energy and Technology; Springer: Berlin/Heidelberg, Germany, 2018; pp. 17–35. ISBN 9789811073250. [Google Scholar]

- Castor, J.; Bacha, K.; Nerini, F.F. SDGs in Action: A Novel Framework for Assessing Energy Projects against the Sustainable Development Goals. Energy Res. Soc. Sci. 2020, 68, 101556. [Google Scholar] [CrossRef]

- Kant, K.; Shukla, A.; Sharma, A.; Rindt, C.C.M.M. Deployment of the Low Carbon Energy Supply Technologies for Sustainable Development. In Low Carbon Energy Supply Technologies and Systems; Sharma, A., Shukla, A., Singh, R., Eds.; CRC Press: London, UK, 2020; pp. 289–304. ISBN 9780367373405. [Google Scholar]

- Al-Yasiri, Q.; Szabó, M. Incorporation of Phase Change Materials into Building Envelope for Thermal Comfort and Energy Saving: A Comprehensive Analysis. J. Build. Eng. 2021, 36, 102122. [Google Scholar]

- Prosekov, A.Y.; Ivanova, S.A. Food security: The challenge of the present. Geoforum 2018, 91, 73–77. [Google Scholar] [CrossRef]

- Muthusivagami, R.M.; Velraj, R.; Sethumadhavan, R. Solar cookers with and without thermal storage—A review. Renew. Sustain. Energy Rev. 2010, 14, 691–701. [Google Scholar] [CrossRef]

- Kant, K.; Pitchumani, R. Advances and Opportunities in Thermochemical Heat Storage Systems for Buildings Applications. Appl. Energy 2022, 321, 119299. [Google Scholar] [CrossRef]

- Kant, K.; Sibin, K.P.; Pitchumani, R. Novel Fractal-Textured Solar Absorber Surfaces for Concentrated Solar Power. Sol. Energy Mater. Sol. Cells 2022, 248, 112010. [Google Scholar] [CrossRef]

- Kant, K.; Shukla, A.; Smeulders, D.M.J.; Rindt, C.C.M. Performance Analysis of a K2CO3-Based Thermochemical Energy Storage System Using a Honeycomb Structured Heat Exchanger. J. Energy Storage 2021, 38, 102563. [Google Scholar] [CrossRef]

- Gorjian, S.; Sharon, H.; Ebadi, H.; Kant, K.; Scavo, F.B.; Tina, G.M. Recent Technical Advancements, Economics and Environmental Impacts of Floating Photovoltaic Solar Energy Conversion Systems. J. Clean. Prod. 2021, 278, 124285. [Google Scholar] [CrossRef]

- Arunachala, U.C.; Kundapur, A. Cost-Effective Solar Cookers: A Global Review. Sol. Energy 2020, 207, 903–916. [Google Scholar] [CrossRef]

- Shukla, A.; Kant, K.; Biwole, P.H.; Pitchumani, R.; Sharma, A. Melting and Solidification of a Phase Change Material with Constructal Tree-Shaped Fins for Thermal Energy Storage. J. Energy Storage 2022, 53, 105158. [Google Scholar] [CrossRef]

- Kant, K.; Shukla, A.; Smeulders, D.M.J.; Rindt, C.C.M. Analysis and Optimization of the Closed-Adsorption Heat Storage Bed Performance. J. Energy Storage 2020, 32, 101896. [Google Scholar] [CrossRef]

- Harmim, A.; Belhamel, M.; Boukar, M.; Amar, M. Experimental investigation of a box-type solar cooker with a finned absorber plate. Energy 2010, 35, 3799–3802. [Google Scholar] [CrossRef]

- Cuce, P.M. Box Type Solar Cookers with Sensible Thermal Energy Storage Medium: A Comparative Experimental Investigation and Thermodynamic Analysis. Sol. Energy 2018, 166, 432–440. [Google Scholar]

- Herez, A.; Ramadan, M.; Khaled, M. Review on Solar Cooker Systems: Economic and Environmental Study for Different Lebanese Scenarios. Renew. Sustain. Energy Rev. 2018, 81, 421–432. [Google Scholar] [CrossRef]

- Omara, A.A.M.; Abuelnuor, A.A.A.; Mohammed, H.A.; Habibi, D.; Younis, O. Improving Solar Cooker Performance Using Phase Change Materials: A Comprehensive Review. Sol. Energy 2020, 207, 539–563. [Google Scholar] [CrossRef]

- Nahar, N. Design, Development and Testing of a Double Reflector Hot Box Solar Cooker with a Transparent Insulation Material. Renew. Energy 2001, 23, 167–179. [Google Scholar] [CrossRef]

- Mahavar, S.; Rajawat, P.; Marwal, V.K.; Punia, R.C.; Dashora, P. Modeling and On-Field Testing of a Solar Rice Cooker. Energy 2013, 49, 404–412. [Google Scholar] [CrossRef]

- Valmiki, M.M.; Li, P.; Heyer, J.; Morgan, M.; Albinali, A.; Alhamidi, K.; Wagoner, J. A Novel Application of a Fresnel Lens for a Solar Stove and Solar Heating. Renew. Energy 2011, 36, 1614–1620. [Google Scholar]

- Munir, A.; Hensel, O.; Scheffler, W. Design Principle and Calculations of a Scheffler Fixed Focus Concentrator for Medium Temperature Applications. Sol. Energy 2010, 84, 1490–1502. [Google Scholar] [CrossRef]

- Lentswe, K.; Mawire, A.; Owusu, P.; Shobo, A. A Review of Parabolic Solar Cookers with Thermal Energy Storage. Heliyon 2021, 7, e08226. [Google Scholar] [CrossRef] [PubMed]

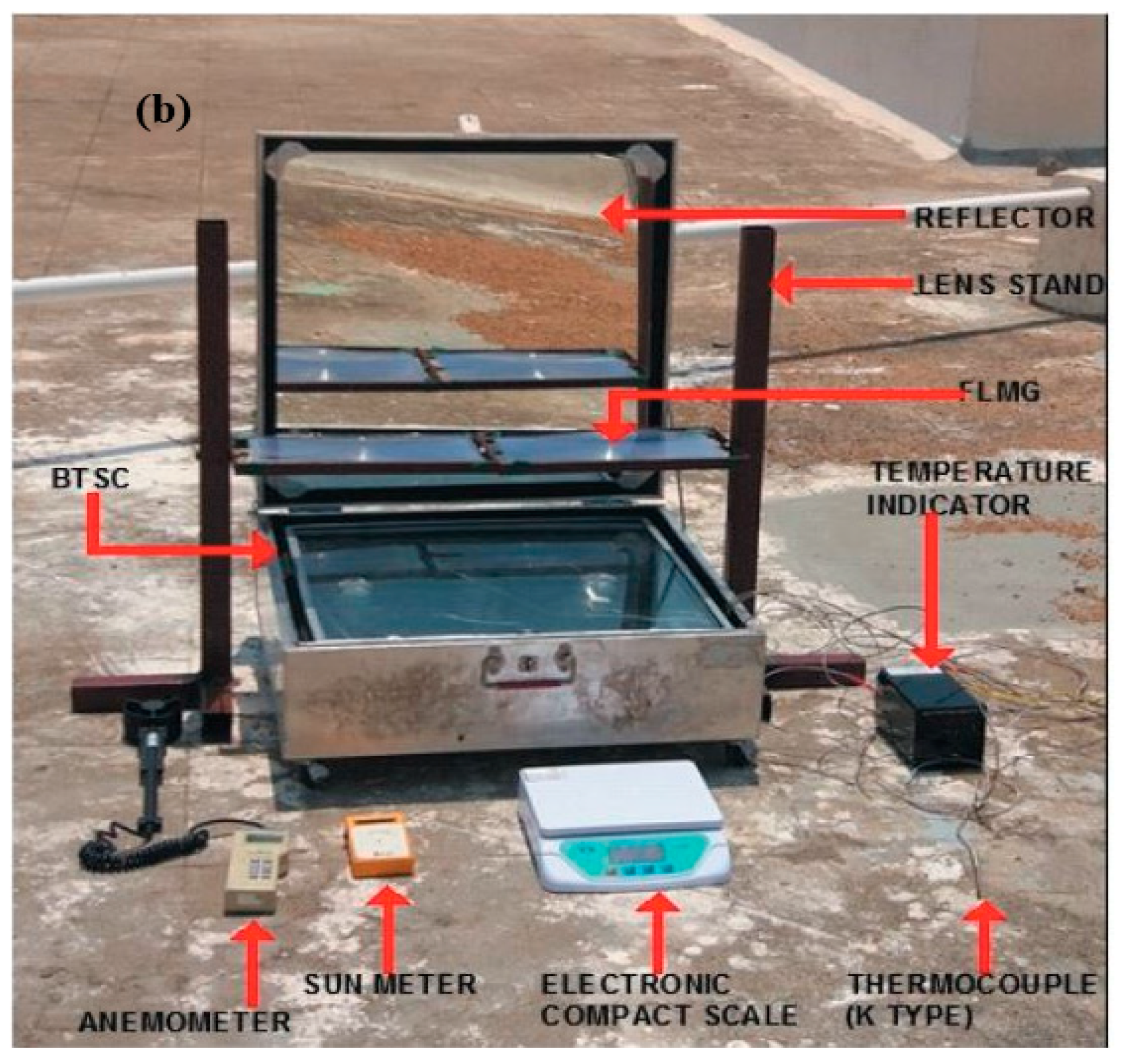

- Tawfik, M.A.; Sagade, A.A.; Palma-Behnke, R.; El-Shal, H.M.; Abd Allah, W.E. Solar Cooker with Tracking-Type Bottom Reflector: An Experimental Thermal Performance Evaluation of a New Design. Solar Energy 2021, 220, 295–315. [Google Scholar] [CrossRef]

- Tawfik, M.A.; Sagade, A.A.; Palma-Behnke, R.; Allah, W.E.A.; El-Shal, H.M. Performance Evaluation of Solar Cooker with Tracking Type Bottom Reflector Retrofitted with a Novel Design of Thermal Storage Incorporated Absorber Plate. J. Energy Storage 2022, 51, 104432. [Google Scholar] [CrossRef]

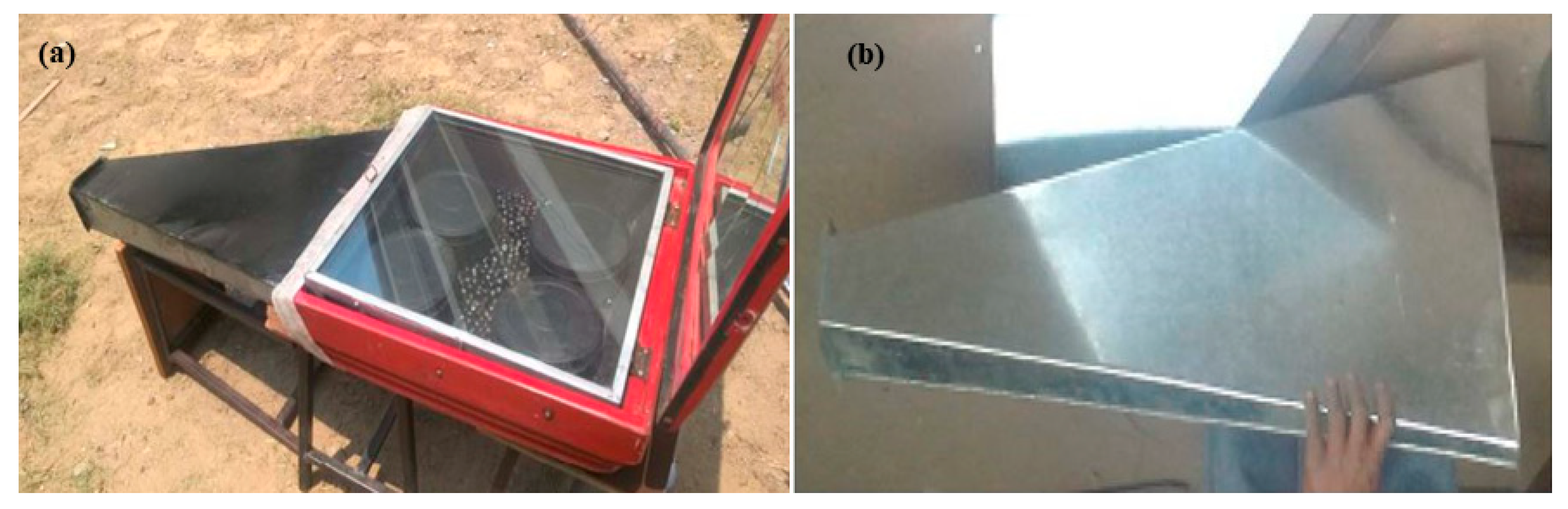

- Guidara, Z.; Souissi, M.; Morgenstern, A.; Maalej, A. Thermal Performance of a Solar Box Cooker with Outer Reflectors: Numerical Study and Experimental Investigation. Sol. Energy 2017, 158, 347–359. [Google Scholar] [CrossRef]

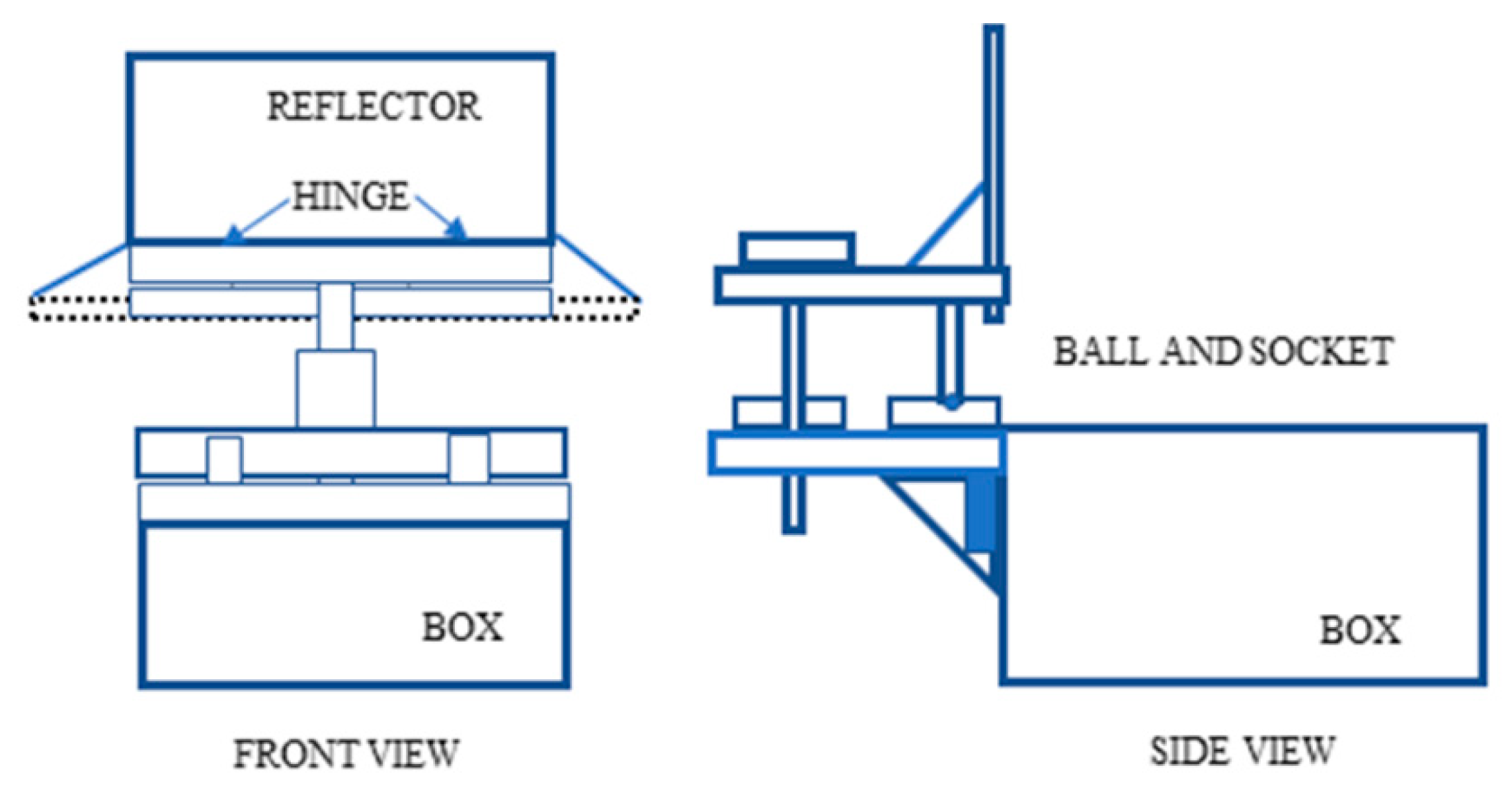

- Al-Nehari, H.A.; Mohammed, M.A.; Odhah, A.A.; Al-attab, K.A.; Mohammed, B.K.; Al-Habari, A.M.; Al-Fahd, N.H. Experimental and Numerical Analysis of Tiltable Box-Type Solar Cooker with Tracking Mechanism. Renew. Energy 2021, 180, 954–965. [Google Scholar] [CrossRef]

- Panwar, N.L. Thermal Modeling, Energy and Exergy Analysis of Animal Feed Solar Cooker. J. Renew. Sustain. Energy 2013, 5, 043105. [Google Scholar] [CrossRef]

- Kandpal, T.C.; Mathur, S.S. The Economics of Box-Type Solar Cookers. Energy Convers. Manag. 1986, 26, 233–235. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kothari, S.; Kaushik, S.C. Techno-Economic Evaluation of Masonry Type Animal Feed Solar Cooker in Rural Areas of an Indian State Rajasthan. Energy Policy 2013, 52, 583–586. [Google Scholar] [CrossRef]

- Indora, S.; Kandpal, T.C. Institutional and Community Solar Cooking in India Using SK-23 and Scheffler Solar Cookers: A Financial Appraisal. Renew. Energy 2018, 120, 501–511. [Google Scholar] [CrossRef]

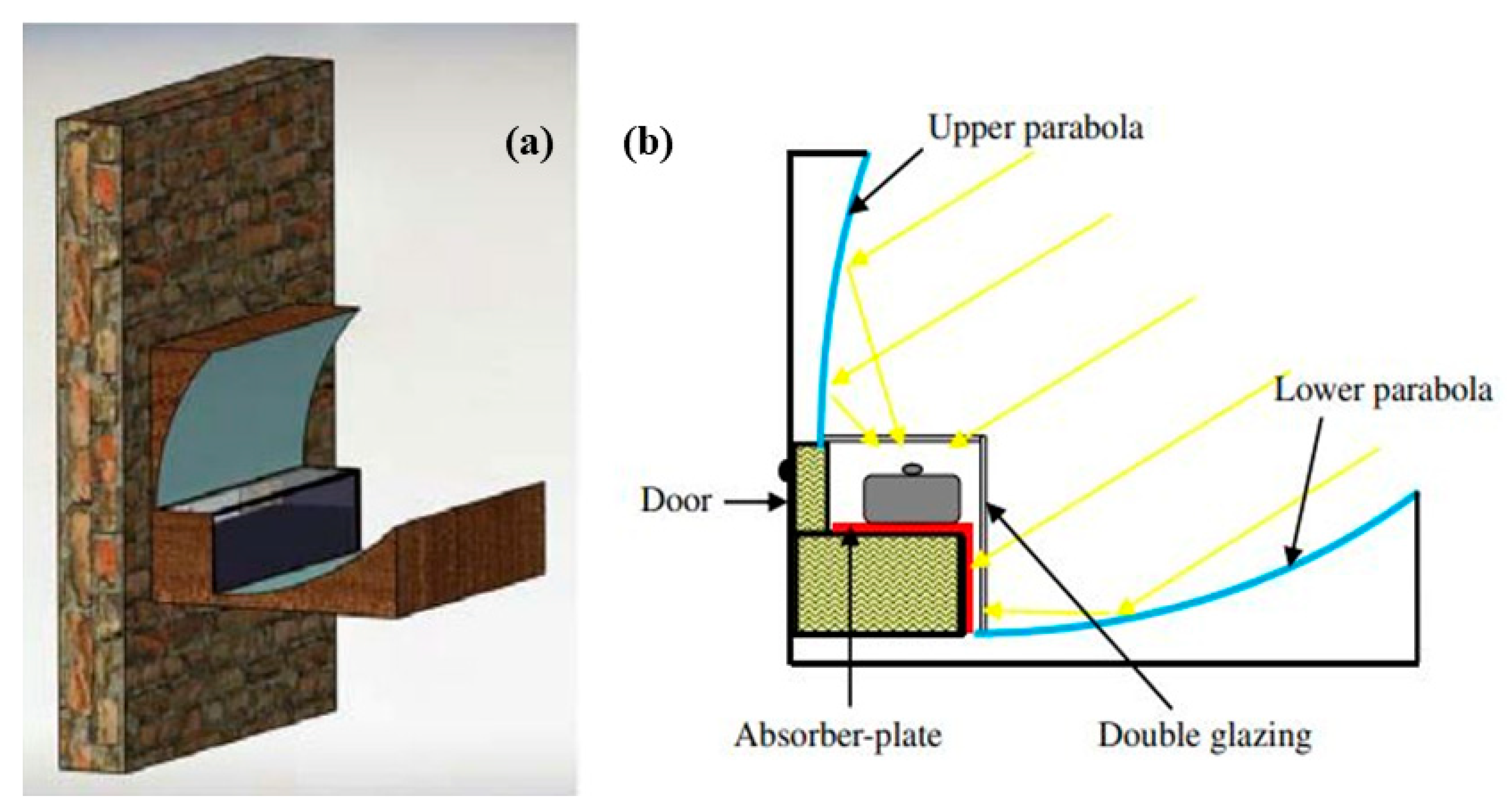

- Harmim, A.; Merzouk, M.; Boukar, M.; Amar, M. Performance Study of a Box-Type Solar Cooker Employing an Asymmetric Compound Parabolic Concentrator. Energy 2012, 47, 471–480. [Google Scholar]

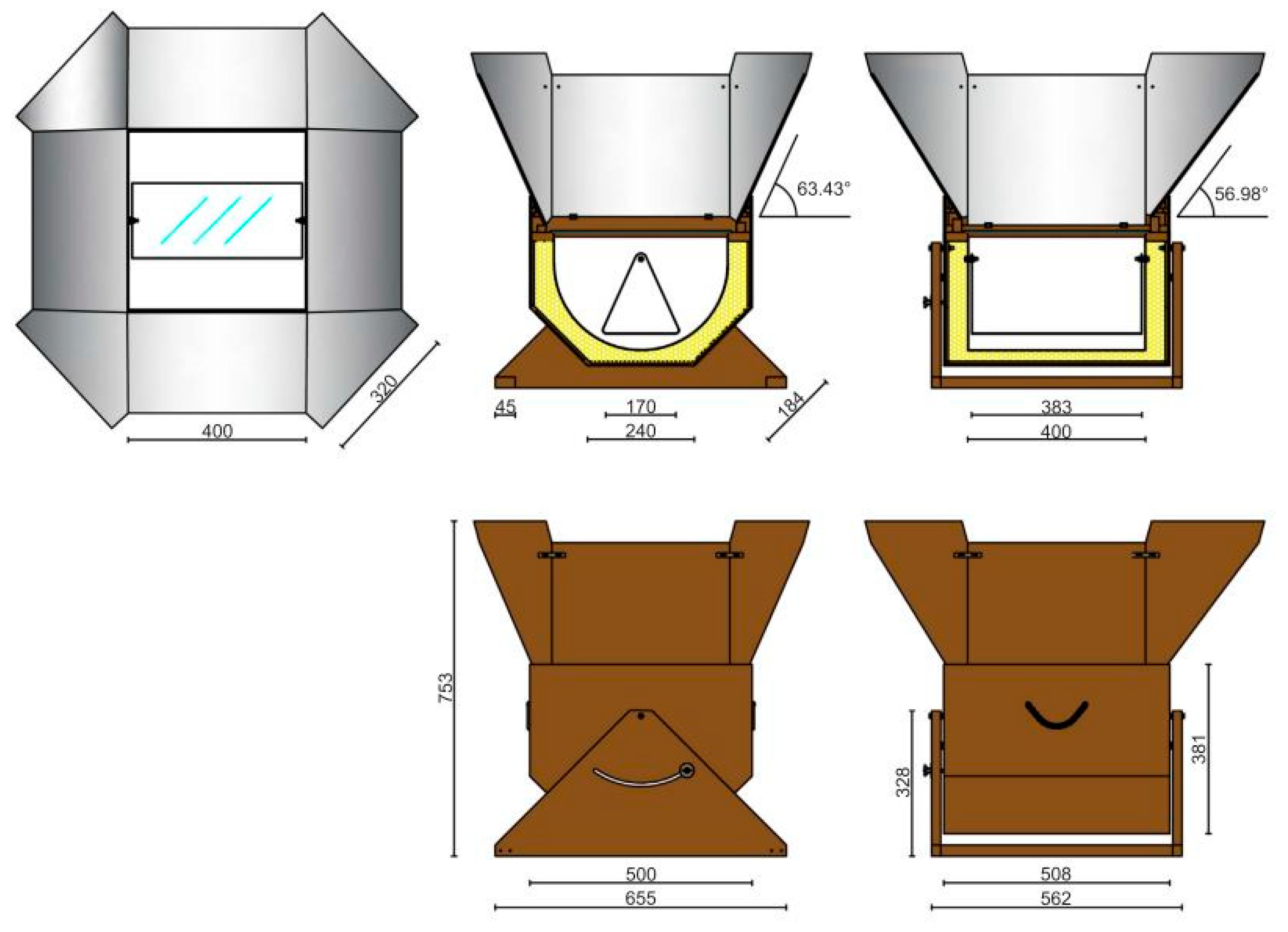

- Harmim, A.; Merzouk, M.; Boukar, M.; Amar, M. Design and Experimental Testing of an Innovative Building-Integrated Box Type Solar Cooker. Sol. Energy 2013, 98, 422–433. [Google Scholar] [CrossRef]

- Misra, R.; Aseri, T.K. Thermal performance enhancement of box-type solar cooker: A new approach. Int. J. Sustain. Energy 2012, 31, 107–118. [Google Scholar] [CrossRef]

- Folaranmi, J. Performance Evaluation of a Double-Glazed Box-Type Solar Oven with Reflector. J. Renew. Energy 2013, 2013, 184352. [Google Scholar] [CrossRef]

- Soria-Verdugo, A. Experimental Analysis and Simulation of the Performance of a Box-Type Solar Cooker. Energy Sustain. Dev. 2015, 29, 65–71. [Google Scholar] [CrossRef]

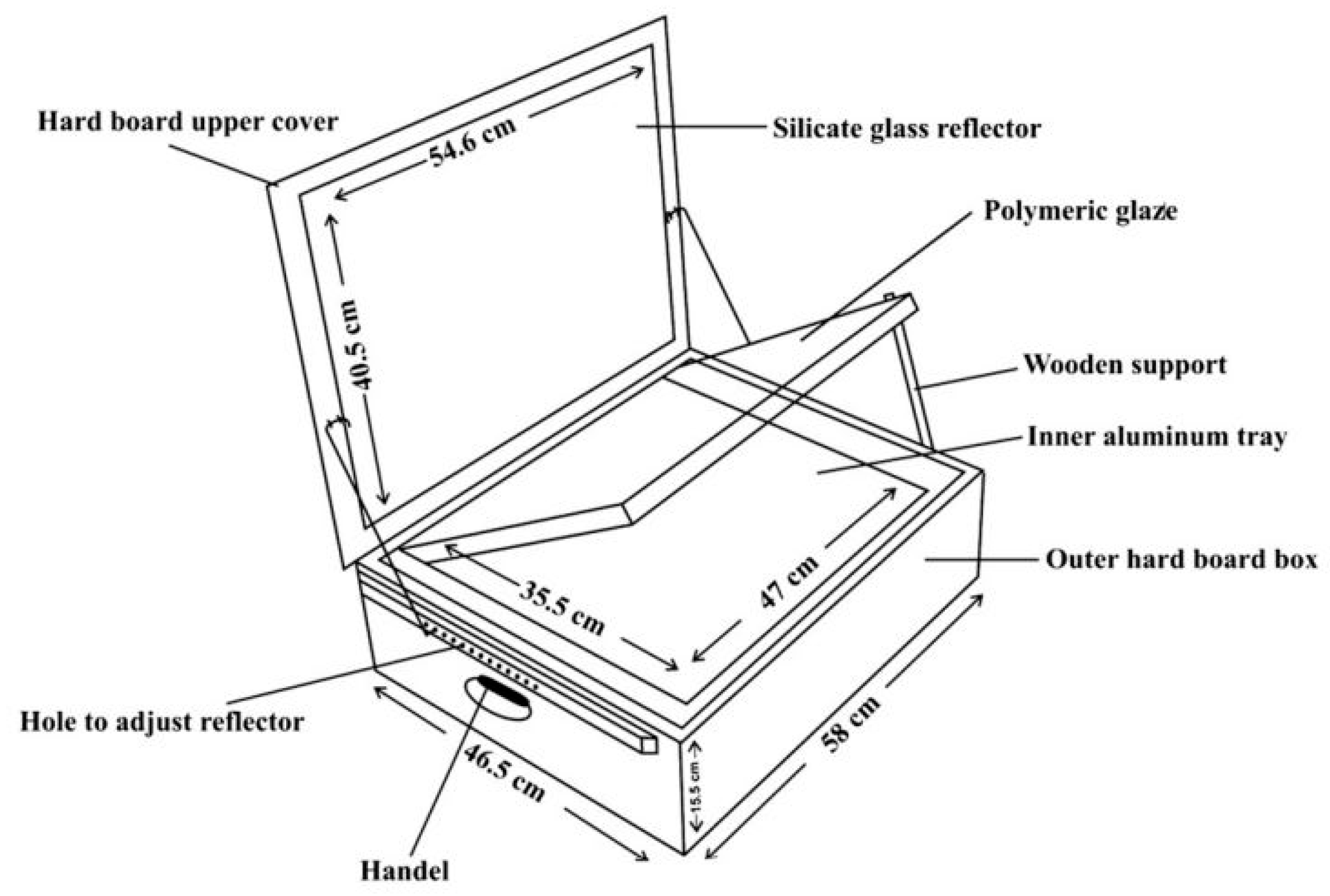

- Mahavar, S.; Sengar, N.; Rajawat, P.; Verma, M.; Dashora, P. Design Development and Performance Studies of a Novel Single Family Solar Cooker. Renew. Energy 2012, 47, 67–76. [Google Scholar] [CrossRef]

- Saxena, A.; Agarwal, N. Performance Characteristics of a New Hybrid Solar Cooker with Air Duct. Sol. Energy 2018, 159, 628–637. [Google Scholar]

- Kolhe, M.L.; Labhasetwar, P.K.; Suryawanshi, H.M. Smart Technologies for Energy, Environment and Sustainable Development: Select Proceedings of ICSTEESD 2018; Springer: Singapore, 2019; ISBN 9811361487. [Google Scholar]

- Engoor, G.G.; Shanmugam, S.; Veerappan, A. Experimental Investigation of a Box-Type Solar Cooker Incorporated with Fresnel Lens Magnifier. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 236, 1–16. [Google Scholar] [CrossRef]

- Khallaf, A.M.; Tawfik, M.A.; El-Sebaii, A.A.; Sagade, A.A. Mathematical Modeling and Experimental Validation of the Thermal Performance of a Novel Design Solar Cooker. Sol. Energy 2020, 207, 40–50. [Google Scholar]

- Hoigebazar, P.; Valder, J. Analysis and Comparison of Compound Parabolic Solar Concentrator Configurations for Box Type Solar Cooker. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2020; Volume 2236, p. 030003. [Google Scholar]

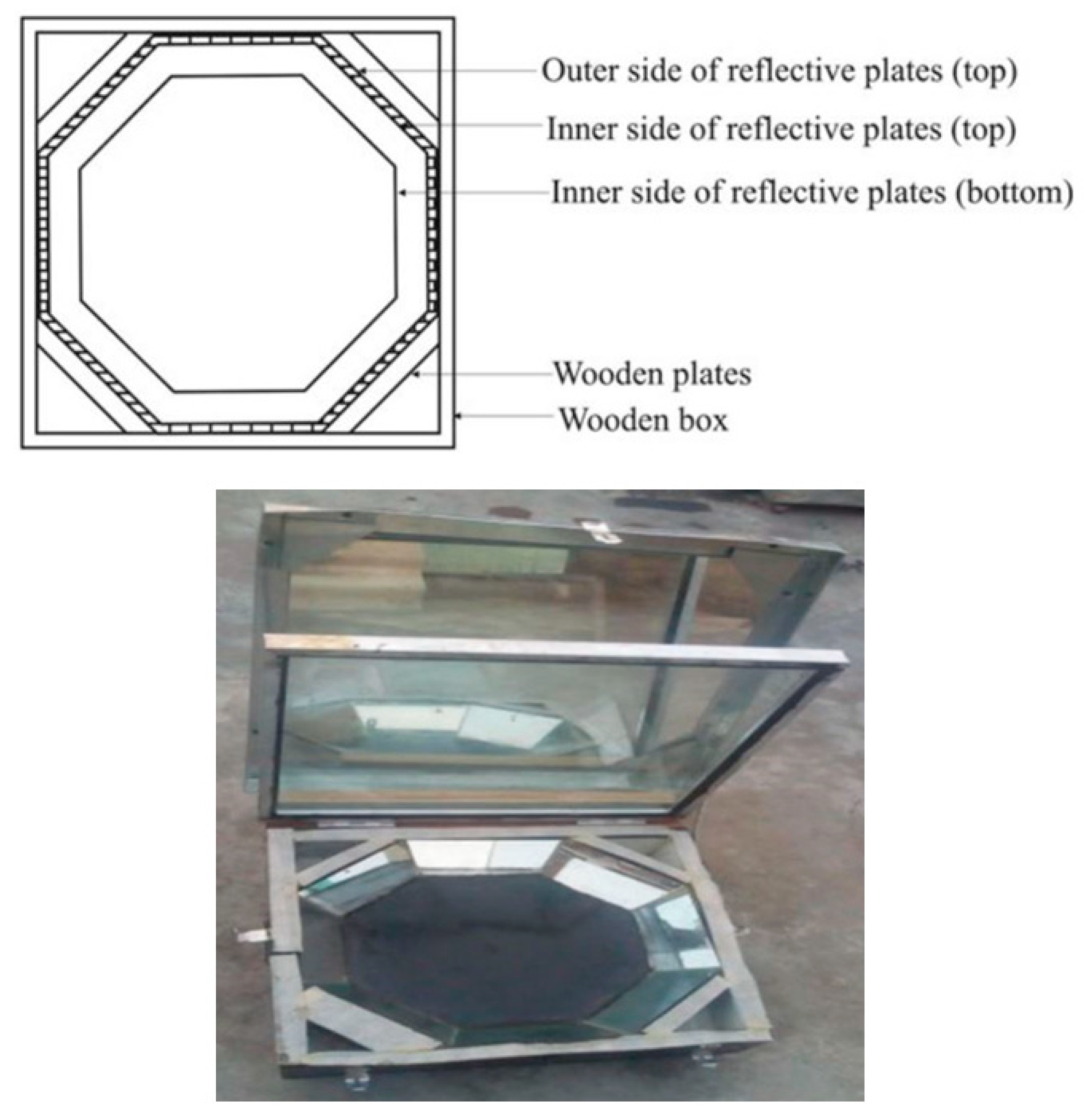

- Terres, H.; Chávez, S.; Lizardi, A.; Alvarez, E. Effect of the Position of the Internal Reflectors on the Thermal Operation of a Solar Cooker Box-Type. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2021; Volume 1723, p. 12031. [Google Scholar]

- Vengadesan, E.; Senthil, R. Experimental Investigation of the Thermal Performance of a Box Type Solar Cooker Using a Finned Cooking Vessel. Renew. Energy 2021, 171, 431–446. [Google Scholar]

- Sharma, A.; Chen, C.R.; Murty, V.V.S.; Shukla, A. Solar Cooker with Latent Heat Storage Systems: A Review. Renew. Sustain. Energy Rev. 2009, 13, 1599–1605. [Google Scholar] [CrossRef]

- Ramadan, M.R.I.; Aboul-Enein, S.; El-Sebaii, A.A. A Model of an Improved Low Cost-Indoor-Solar-Cooker in Tanta. Sol. Wind. Technol. 1988, 5, 387–393. [Google Scholar] [CrossRef]

- Bushnell, D.L. Performance Studies of a Solar Energy Storing Heat Exchanger. Sol. Energy 1988, 41, 503–512. [Google Scholar] [CrossRef]

- Bushnell, D.L.; Sohi, M. A Modular Phase Change Heat Exchanger for a Solar Oven. Sol. Energy 1992, 49, 235–244. [Google Scholar]

- Domanski, R.; El-Sebaii, A.A.; Jaworski, M. Cooking during Off-Sunshine Hours Using PCMs as Storage Media. Energy 1995, 20, 607–616. [Google Scholar]

- Buddhi, D.; Sahoo, L.K. Solar Cooker with Latent Heat Storage: Design and Experimental Testing. Energy Convers. Manag. 1997, 38, 493–498. [Google Scholar] [CrossRef]

- Belghit, A.; Kouhila, M.; Boutaleb, B.C. Experimental Study of Drying Kinetics by Forced Convection of Aromatic Plants. Energy Convers. Manag. 2000, 41, 1303–1321. [Google Scholar]

- Buddhi, D.; Sharma, S.D.; Sharma, A. Thermal Performance Evaluation of a Latent Heat Storage Unit for Late Evening Cooking in a Solar Cooker Having Three Reflectors. Energy Convers. Manag. 2003, 44, 809–817. [Google Scholar]

- Chen, C.R.; Sharma, A.; Tyagi, S.K.; Buddhi, D. Numerical Heat Transfer Studies of PCMs Used in a Box-Type Solar Cooker. Renew. Energy 2008, 33, 1121–1129. [Google Scholar] [CrossRef]

- Yuksel, N.; Arabacıgıl, B.; Avcı, A. The Thermal Analysis of Paraffin Wax in a Box-Type Solar Cooker. J. Renew. Sustain. Energy 2012, 4, 063126. [Google Scholar] [CrossRef]

- Tarwidi, D. Modeling and Numerical Simulation of Solar Cooker with PCM as Thermal Energy Storage. In Proceedings of the 2015 3rd International Conference on Information and Communication Technology (ICoICT), Bali, Indonesia, 27–29 May 2015; IEEE: Piscataway, NJ, USA; pp. 584–589. [Google Scholar]

- Geddam, S.; Dinesh, G.K.; Sivasankar, T. Determination of Thermal Performance of a Box Type Solar Cooker. Sol. Energy 2015, 113, 324–331. [Google Scholar]

- Tarwidi, D.; Murdiansyah, D.T.; Ginanjar, N. Performance Evaluation of Various Phase Change Materials for Thermal Energy Storage of a Solar Cooker via Numerical Simulation. Int. J. Renew. Energy Dev. 2016, 3, 199–210. [Google Scholar]

- Nayak, N.; Abu Jarir, H.; Al Ghassani, H. Solar Cooker Study under Oman Conditions for Late Evening Cooking Using Stearic Acid and Acetanilide as PCM Materials. J. Sol. Energy 2016, 2016, 2305875. [Google Scholar]

- Sharma, S.; Rai, A.K. Study of Box Type Solar Cooker with Energy Storage Medium. Int. J. Adv. Res. Eng. Technol. 2016, 7, 37–42. [Google Scholar]

- Vigneswaran, V.S.; Kumaresan, G.; Sudhakar, P.; Santosh, R. Performance Evaluation of Solar Box Cooker Assisted with Latent Heat Energy Storage System for Cooking Application. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017; Volume 67, p. 12017. [Google Scholar]

- Hebbar, G.; Hegde, S.; Sanketh, B.; Sanith, L.R.; Udupa, R. Design of Solar Cooker Using Evacuated Tube Solar Collector with Phase Change Material. Mater. Today Proc. 2021, 46, 2888–2893. [Google Scholar]

- Coccia, G.; Di Nicola, G.; Tomassetti, S.; Pierantozzi, M.; Chieruzzi, M.; Torre, L. Experimental Validation of a High-Temperature Solar Box Cooker with a Solar-Salt-Based Thermal Storage Unit. Sol. Energy 2018, 170, 1016–1025. [Google Scholar] [CrossRef]

- Coccia, G.; Aquilanti, A.; Tomassetti, S.; Comodi, G.; Di Nicola, G. Design, Realization, and Tests of a Portable Solar Box Cooker Coupled with an Erythritol-Based PCM Thermal Energy Storage. Sol. Energy 2020, 201, 530–540. [Google Scholar]

- Bhandari, S.S.; Pal, D.; Verma, G. Experimental studies on thermal performance evaluation of hybrid solar cooker using phase change materials and PV technology. In Proceedings of the 26thNational and 4th International ISHMT-ASTFE Heat and Mass Transfer Conference, Tamil Nadu, India, 17–20 December 2021; Begel House Inc.: Danbury, CT, USA, 2021. [Google Scholar]

- Mwaura, M.M.; Thoruwa, T.F.N. Phase Change Materials for Energy Storage in Solar Box Cooker: Sustainable Innovations in Energy Technology. In Proceedings of the Sustainable Research and Innovation Conference. 2022, pp. 214–219. Available online: https://sri.jkuat.ac.ke/jkuatsri/index.php/sri/article/view/371/334 (accessed on 8 January 2023).

- Milikias, E.; Bekele, A.; Venkatachalam, C. Performance Investigation of Improved Box-Type Solar Cooker with Sensible Thermal Energy Storage. Int. J. Sustain. Eng. 2021, 14, 507–516. [Google Scholar] [CrossRef]

- Unger, J.B.; Christler, N.R.; Weeman, M.; Strutz, M.E. Insulated Solar Electric Cooker with Phase Change Thermal Storage Medium; Department of Mechanical Engineering, California Polytechnic State University: San Luis Obispo, CA, USA, 2019. [Google Scholar]

- Kanimozhi, B.; Sanandharya, K.; Anand, S.; Kumar, S. Experimental Study on Solar Cooker Using Phase Change Materials. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Zurich, Switzerland, 2015; Volume 766, pp. 463–467. [Google Scholar]

- El-Sebaii, A.A.; Al-Heniti, S.; Al-Agel, F.; Al-Ghamdi, A.A.; Al-Marzouki, F. One Thousand Thermal Cycles of Magnesium Chloride Hexahydrate as a Promising PCM for Indoor Solar Cooking. Energy Convers. Manag. 2011, 52, 1771–1777. [Google Scholar] [CrossRef]

- Mawire, A.; McPherson, M.; Van den Heetkamp, R.R.J. Simulated Energy and Exergy Analyses of the Charging of an Oil–Pebble Bed Thermal Energy Storage System for a Solar Cooker. Sol. Energy Mater. Sol. Cells 2008, 92, 1668–1676. [Google Scholar] [CrossRef]

- Anilkumar, B.C.; Maniyeri, R.; Anish, S. Optimum Selection of Phase Change Material for Solar Box Cooker Integrated with Thermal Energy Storage Unit Using Multi-Criteria Decision-Making Technique. J. Energy Storage 2021, 40, 102807. [Google Scholar] [CrossRef]

| Quantity of LPG (kg/Month) | Quantity of Propane (kg/Month) | Quantity of Butane (kg/Month) | Quantity of CO2 Generated from Propane (kg/Month) | Quantity of CO2 Generated from Butane (kg/Month) | Total Quantity of CO2 from LPG (kg/Month) | |

|---|---|---|---|---|---|---|

| Home | 20 | 4 | 16 | 12 | 48.55 | 60.55 |

| Snack | 300 | 60 | 240 | 180 | 728.28 | 908.28 |

| Hotel | 1320 | 264 | 1056 | 792 | 3204.43 | 3996.43 |

| Restaurant | 2000 | 400 | 1600 | 1200 | 4855.20 | 6055.20 |

| Sl. No. | Phase Change Material (PCM) | Melting Temp (°C) | Latent Heat of Fusion (kJ/kg) | Specific Heat Capacity J/kg.k | Reference |

|---|---|---|---|---|---|

| 1 | Acetanilide | 118.9 | 222 | - | [46] |

| 2 | Stearic Acid | 89 | 162.8 | 1.84 | [50] |

| 3 | Magnesium Nitrate Hexahydrate | 82 | 263 | 1.94 | [51] |

| 4 | Acetamide | 56–60 | 189 | 2.95 | [53] |

| 5 | Paraffin Wax | 67–69 | 202.5 | 2.8 | [55] |

| 6 | Ternary mixture of nitrite and nitrate salts (solar salt: 53 wt% KNO3, 40 wt% NaNO2, 7 wt% NaNO3) | 145.14 | 101.5 | 1.4 | [63] |

| 7 | Coconut Oil | 22 to 26 | 114.6 | 2.1 | [69] |

| 8 | Magnesium chloride hexa- hydrate (MgCl2 6H2O) | 115–117 | 165–169 | - | [70] |

| 9 | Capric Acid | 30.1 | 150–158 | - | |

| 10 | Lauric Acid | 41–43 | 212 | - | |

| 11 | Pentadecane Acid | 52.5 | 159 | - | |

| 12 | Palmitic Acid | 59.9 | 198 | - | |

| 13 | Myristic Acid | 53.8 | 192 | - | |

| 14 | Stearic Acid | 55.1 | 160 | - | |

| 15 | Erythritol | 118 | 340 | - |

| AHP-MOORA | ENTROPY-MOORA | CRITIC-MOORA | COMPROMISED WEIGHS (Wj)—MOORA | |||||

|---|---|---|---|---|---|---|---|---|

| NAV | Rank | NAV | Rank | NAV | Rank | NAV | Rank | |

| Acetanilide | 0.372 | 4 | 0.319 | 4 | 0.283 | 4 | 0.364 | 3 |

| Erythritol | 0.51 | 1 | 0.441 | 1 | 0.342 | 1 | 0.529 | 1 |

| Paraffin wax | 0.266 | 5 | 0.269 | 5 | 0.276 | 5 | 0.246 | 5 |

| MgCl.6H2O | 0.392 | 3 | 0.329 | 3 | 0.285 | 3 | 0.352 | 4 |

| Oxalic acid di-hydrate | 0.509 | 2 | 0.381 | 2 | 0.299 | 2 | 0.521 | 2 |

| Sl No. | Year | Location | Author | First Figure of Merit (F1) | Second Figure of Merit (F2) | Stagnation Temperature | Standardized Cooking Power | Energy Efficiency | Cost | Environmental Effecting Parameter |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2010 | Algeria | Harmim et al. [16] | - | - | 140 °C | - | - | - | - |

| 2 | 2012 | Algeria | Harmim et al. [33] | 0.1681 m2 °C/W | 0.329 at 1 kg of water | 140.5 °C | - | - | - | - |

| 3 | 2012 | India | Misra et al. [35] | 0.1424 m2 °C/W | 0.4077 at 1 kg of water | - | - | - | - | |

| 4 | 2013 | Algeria | Harmima et al. [34] | 0.152 m2 °C/W | 0.47 at 3.5 kg of water without reflector | with reflector maximum absorber-plate temperature 166 °C | 78.9 W | - | - | - |

| 5 | 2013 | Nigeria | Folaranmi et al. [36] | 0.1135 m2 °C/W | 0.3172 for 2 kg of water | 119 °C | - | - | - | - |

| 6 | 2015 | Spain | Soria et al. [37] | - | - | - | 480 kg wood saved for 328 cooking days | |||

| 7 | 2015 | India | Mahavara et al. [38] | 0.116 m2 °C/W | 0.466 at 1 kg of water | for bare plate without reflectors 144 °C | 29.8 W | Rs 1385 per unit | - | |

| 8 | 2018 | India | Saxena et al. [39] | 0.12 m2 °C/W | 0.41 m2 °C/W at 1.2 kg of water | - | 60.20 W | thermal efficiency—45.11% | - | - |

| 9 | 2020 | Egypt | Khallaf et al. [42] | 0.0657 m2/W | 0.085 to 0.76 for the mass of water from 0.5 kg to 4.0 kg | 113.6 °C | - | - | - | - |

| 10 | 2021 | India | Vengadesan et al. [45] | - | - | 102 °C for a fin with max height | - | 56.03% | - | - |

| 11 | 2021 | Egypt | Tawfik et al. [25] | 0.12 m2 °C/W | - | 100 °C | - | overall cooking efficiency 12.5% | reduce the LCOH and LCMM by ~44.1% and ~18%, respectively | - |

| 12 | 2017 | Tunisia | Guidara et al. [27] | 0.14 m2 °C/W | 0.39 | 133.6 °C | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Misra, N.; Anand, A.; Pandey, S.; Kant, K.; Shukla, A.; Sharma, A. Box-Type Solar Cookers: An Overview of Technological Advancement, Energy, Environmental, and Economic Benefits. Energies 2023, 16, 1697. https://doi.org/10.3390/en16041697

Misra N, Anand A, Pandey S, Kant K, Shukla A, Sharma A. Box-Type Solar Cookers: An Overview of Technological Advancement, Energy, Environmental, and Economic Benefits. Energies. 2023; 16(4):1697. https://doi.org/10.3390/en16041697

Chicago/Turabian StyleMisra, Navendu, Abhishek Anand, Saurabh Pandey, Karunesh Kant, Amritanshu Shukla, and Atul Sharma. 2023. "Box-Type Solar Cookers: An Overview of Technological Advancement, Energy, Environmental, and Economic Benefits" Energies 16, no. 4: 1697. https://doi.org/10.3390/en16041697

APA StyleMisra, N., Anand, A., Pandey, S., Kant, K., Shukla, A., & Sharma, A. (2023). Box-Type Solar Cookers: An Overview of Technological Advancement, Energy, Environmental, and Economic Benefits. Energies, 16(4), 1697. https://doi.org/10.3390/en16041697