Numerical Study of the Influence of the Thermal Gas Expansion on the Boundary Layer Flame Flashback in Channels with Different Wall Thermal Conditions

Abstract

:1. Introduction

2. Numerical Approach and Theoretical Background

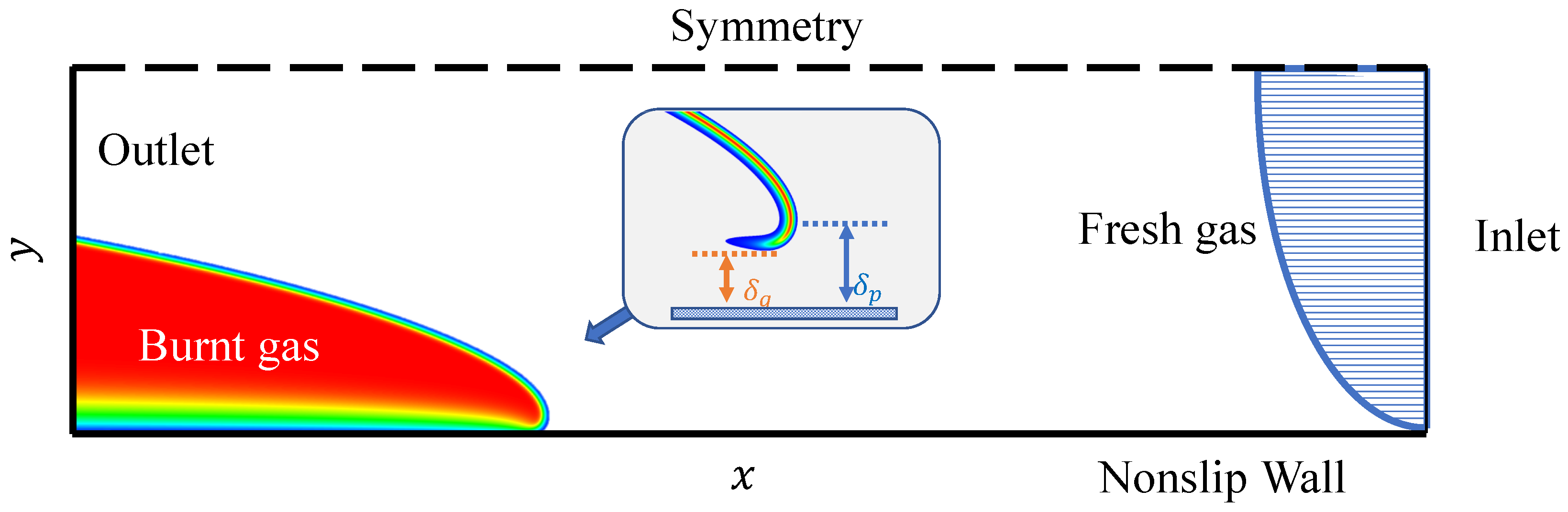

2.1. Basic Equations and Numerical Setup

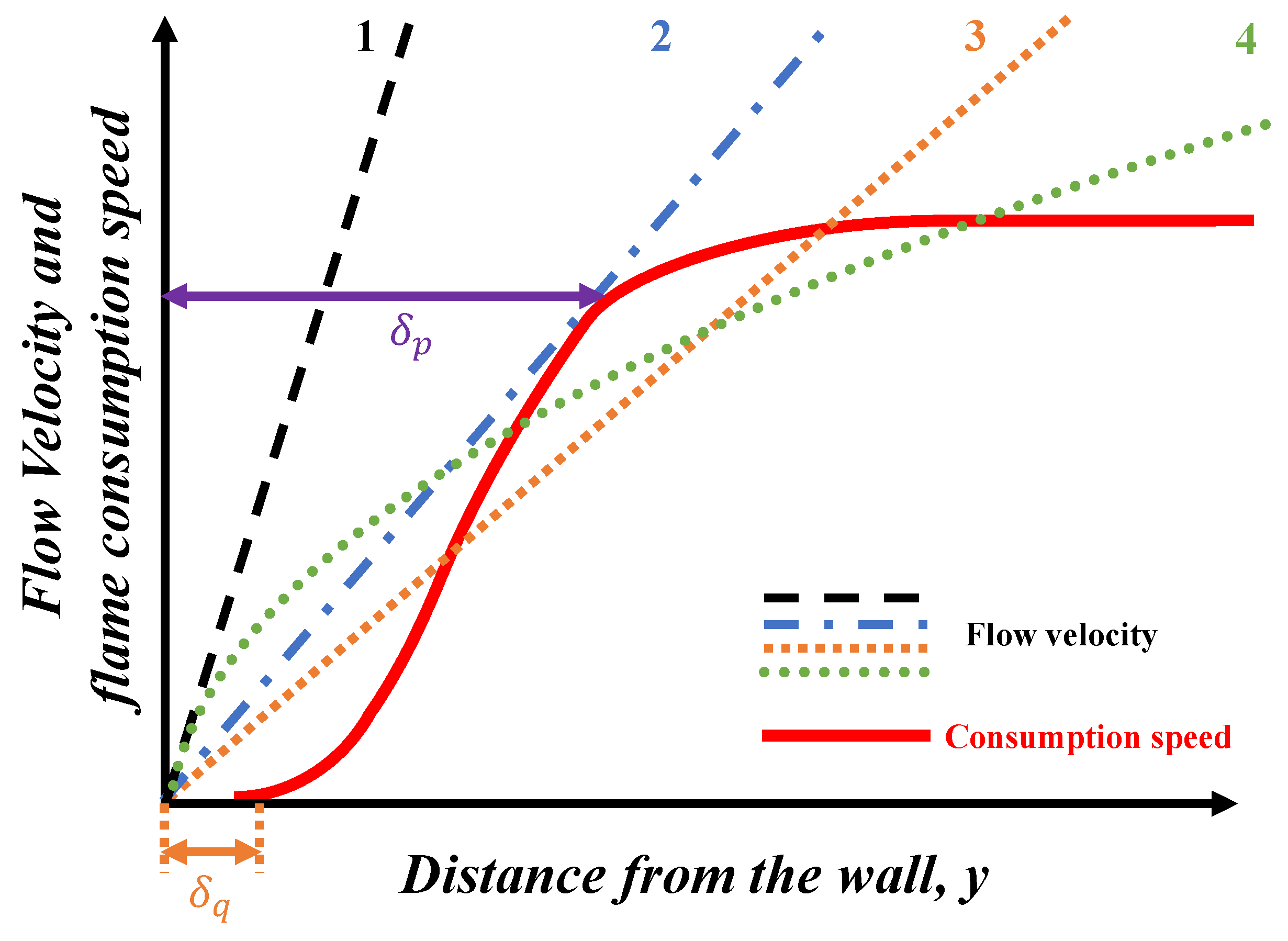

2.2. Critical Condition for the Flame Flashback

2.3. Influence of the Thermal Expansion on the Planar Flame Structure

3. Results and Discussion

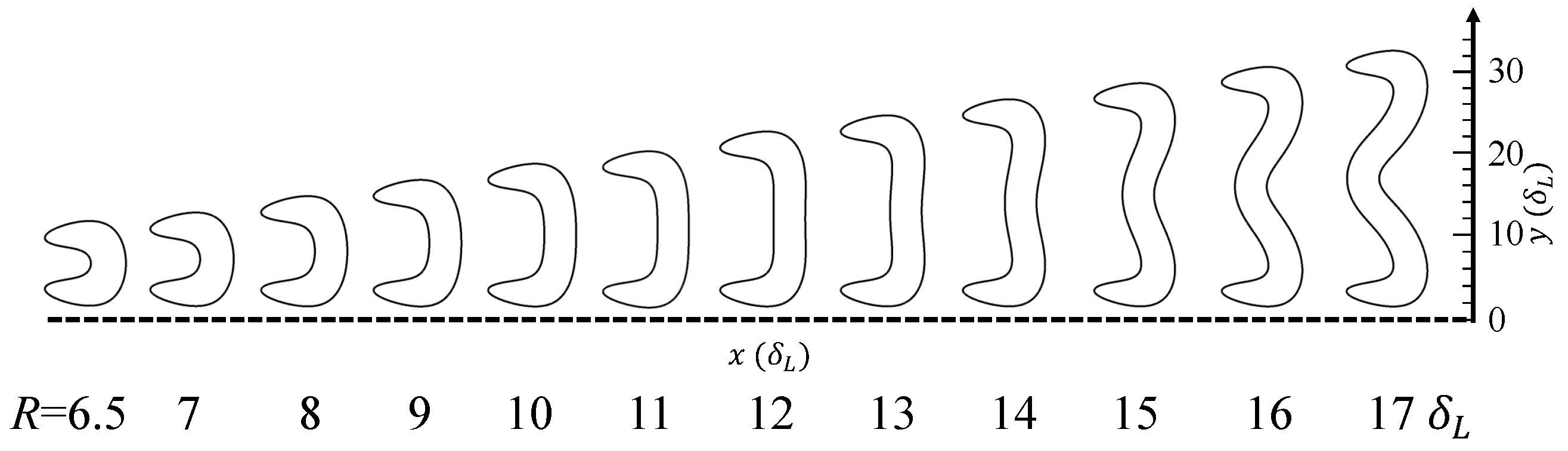

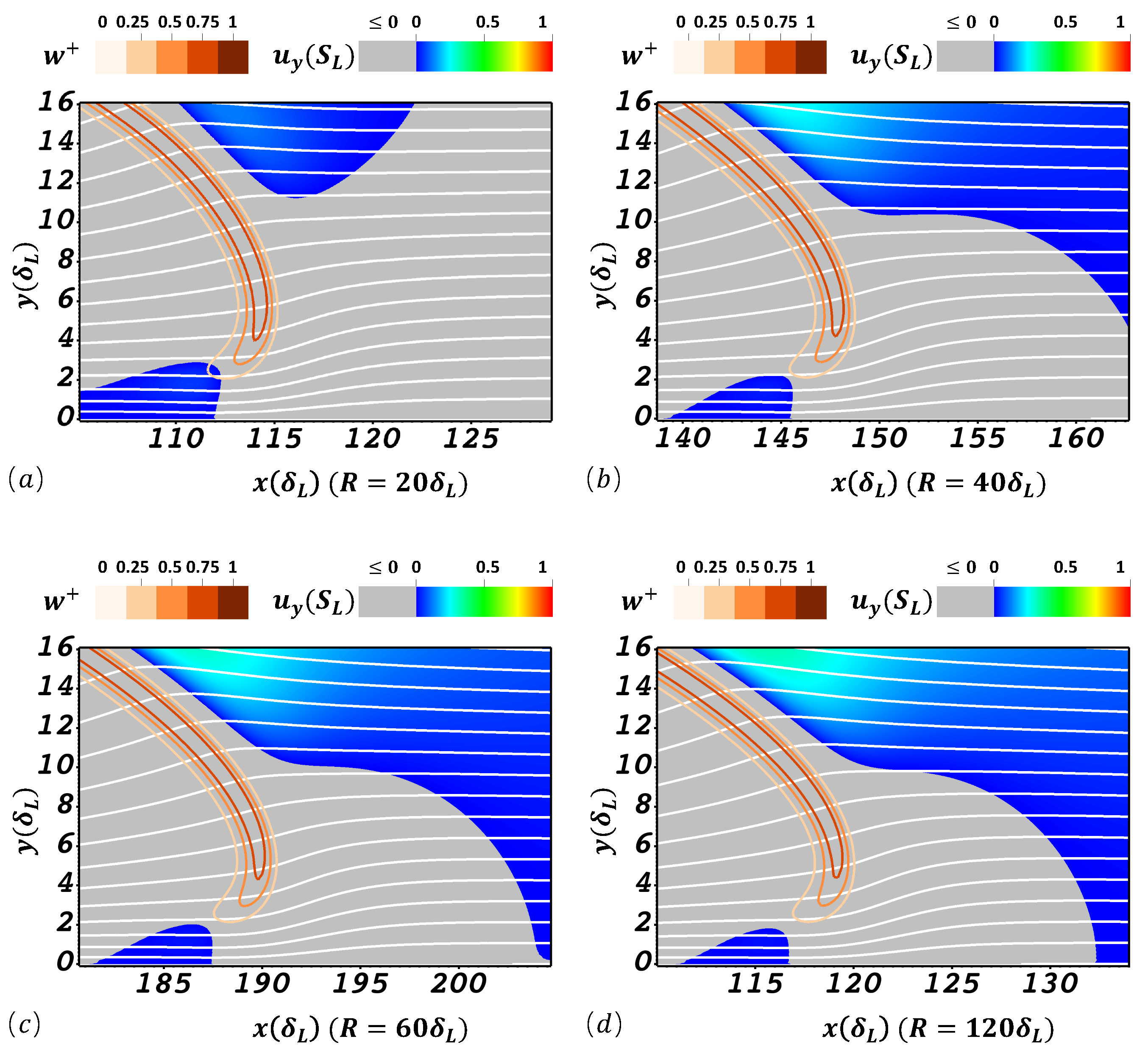

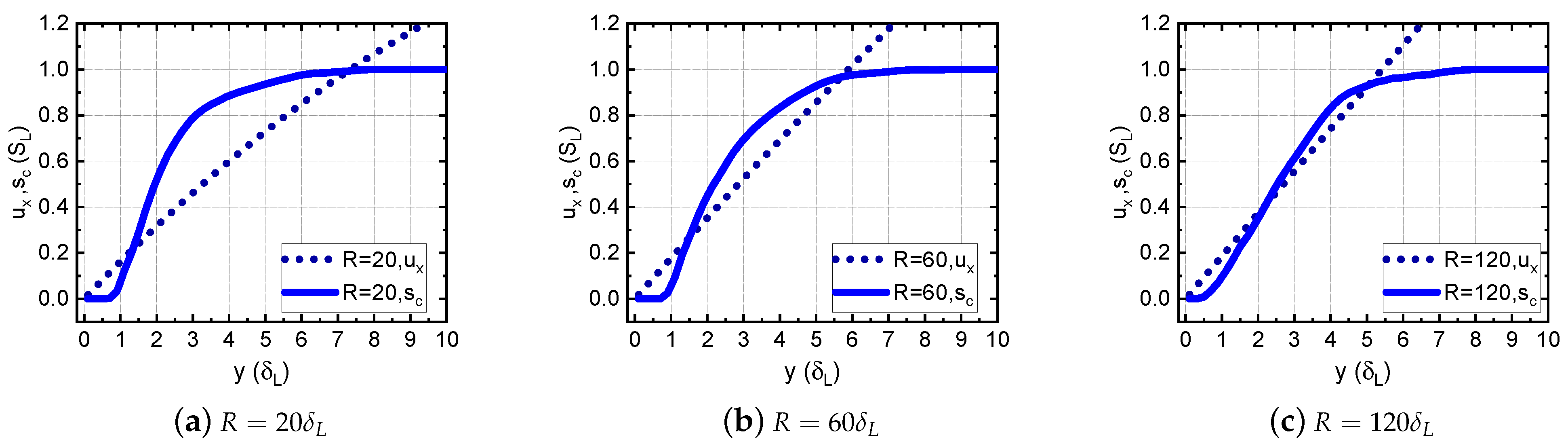

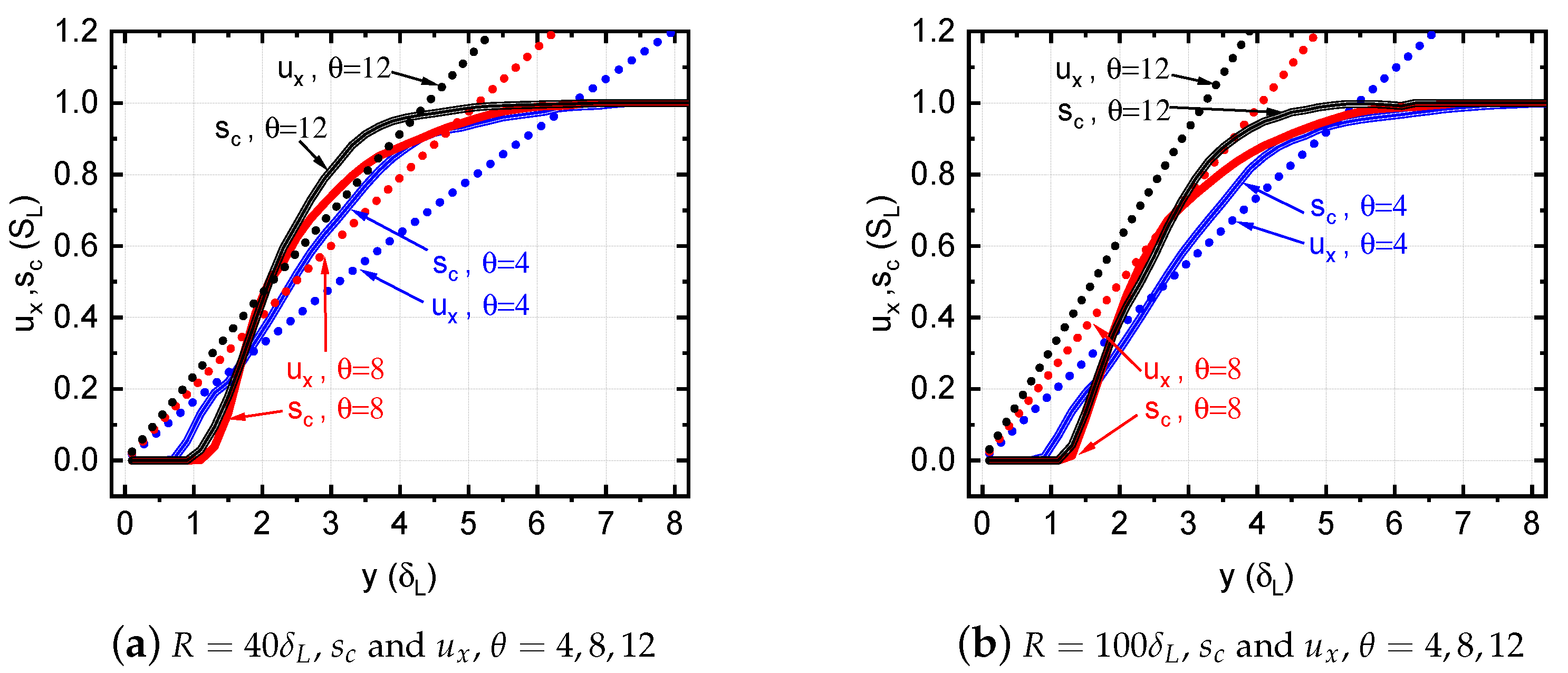

3.1. The Effect of Channel Width

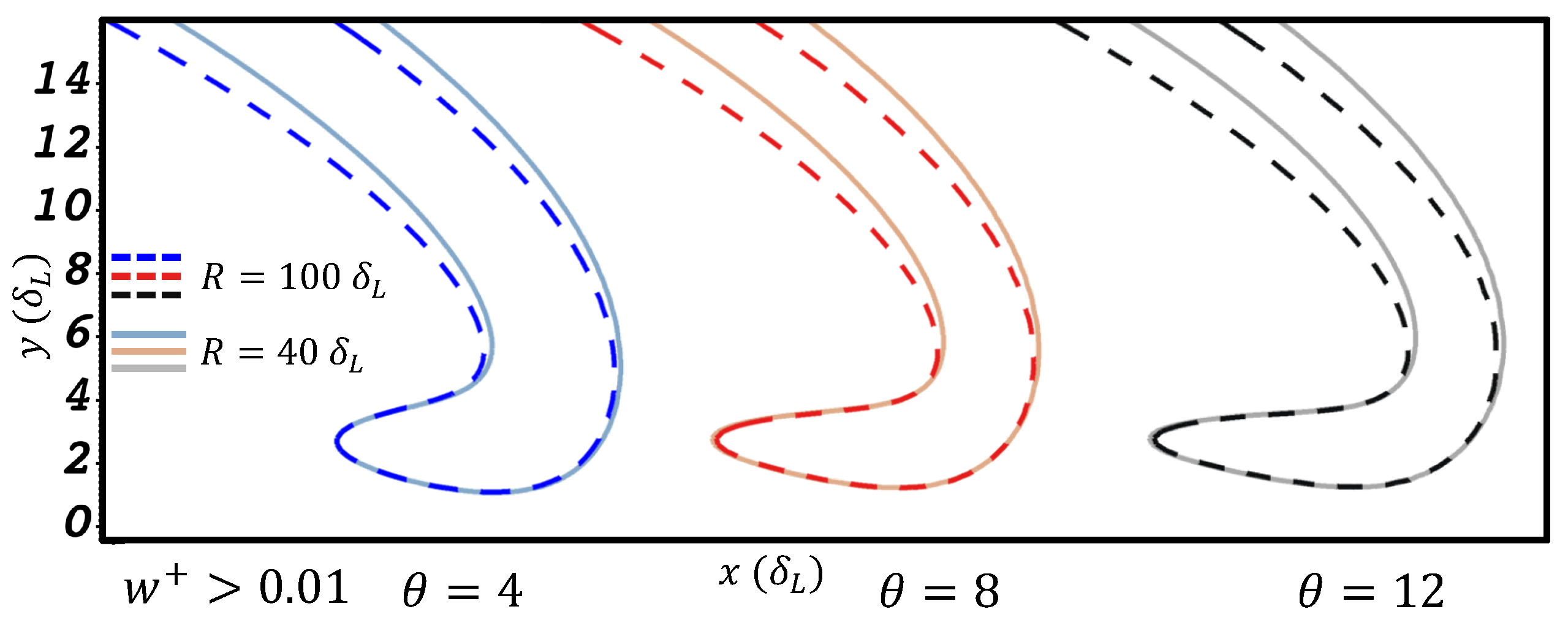

3.1.1. Small Channel Width

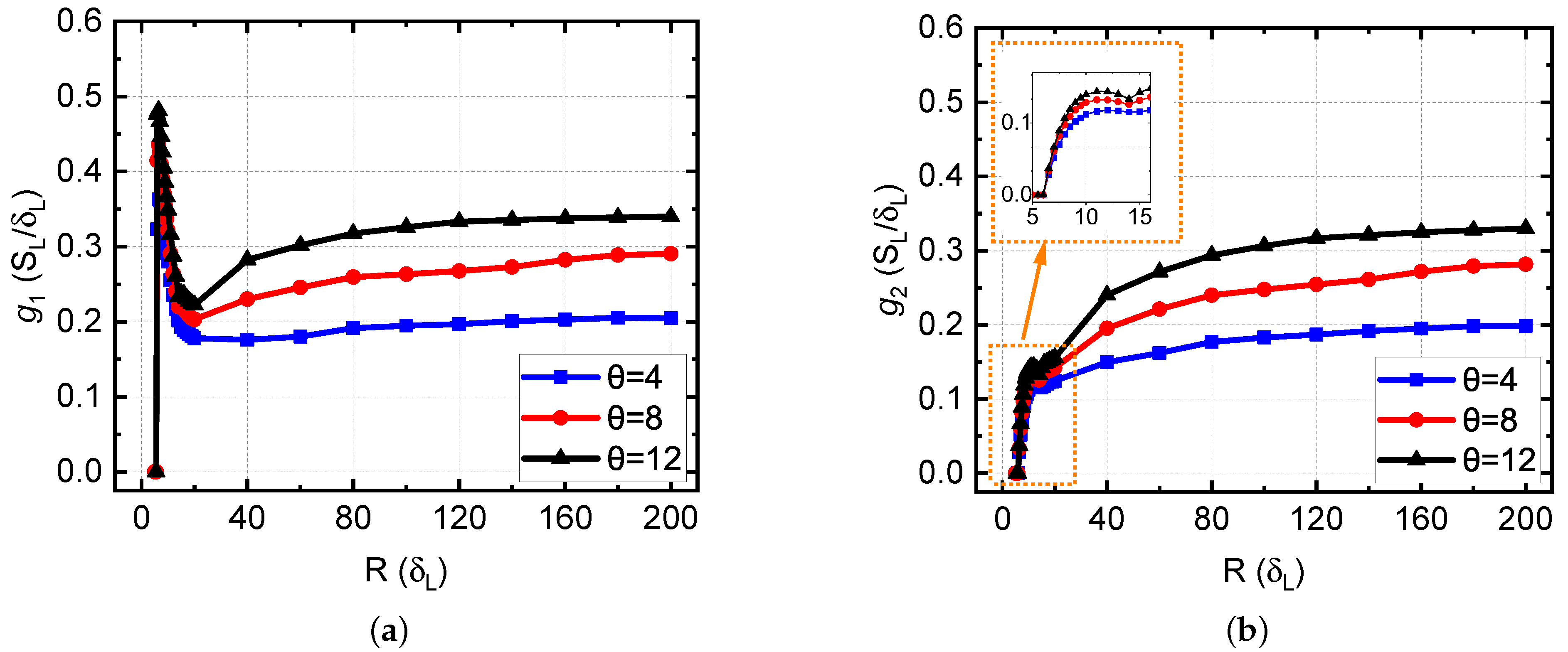

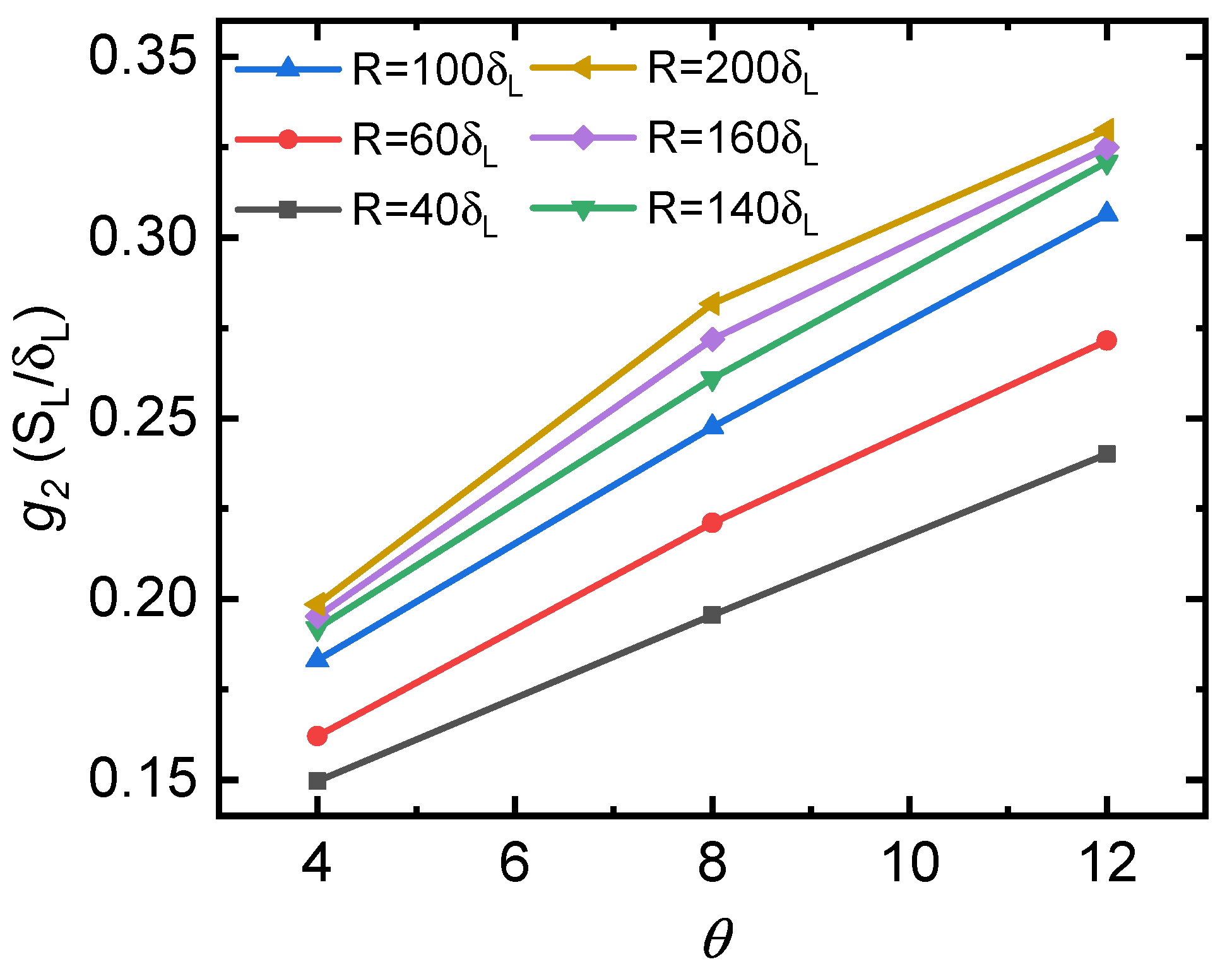

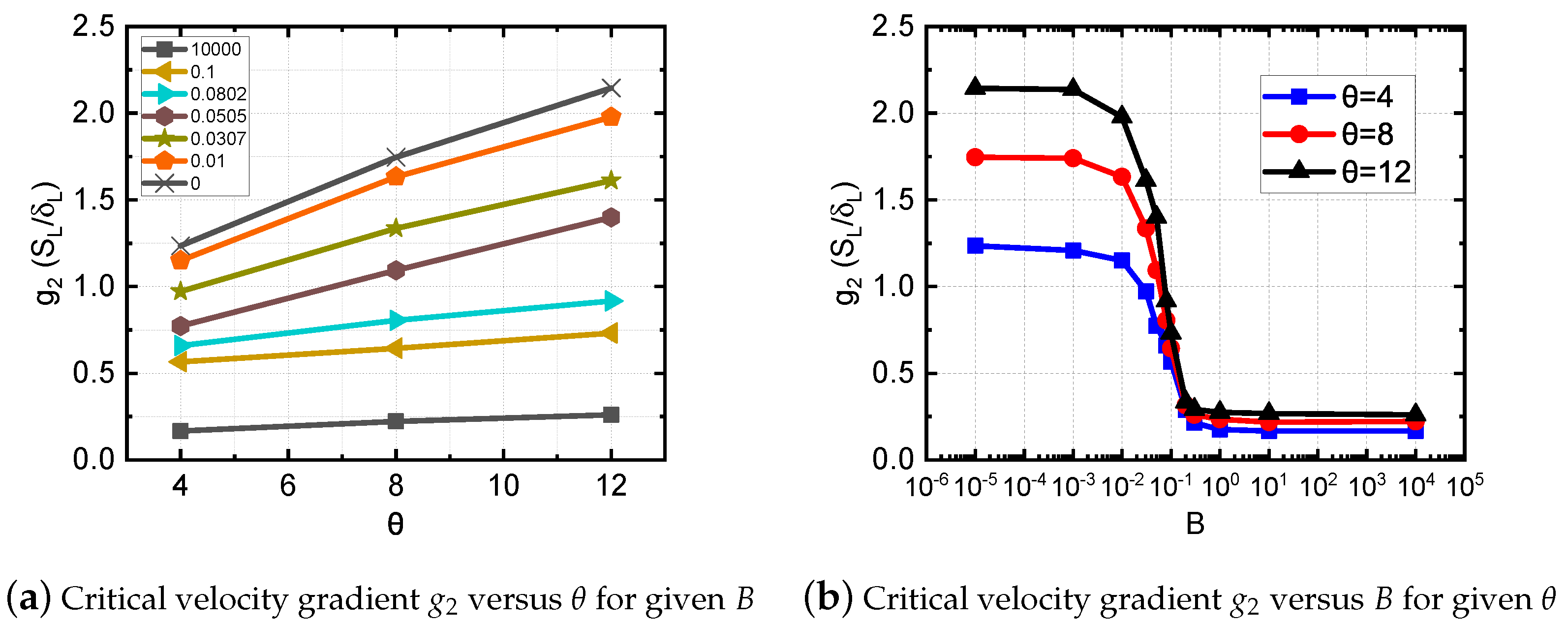

3.1.2. Critical Velocity Gradients for Small to Medium Channel Widths

3.1.3. Effect of Thermal Expansion in Channels of Different Width

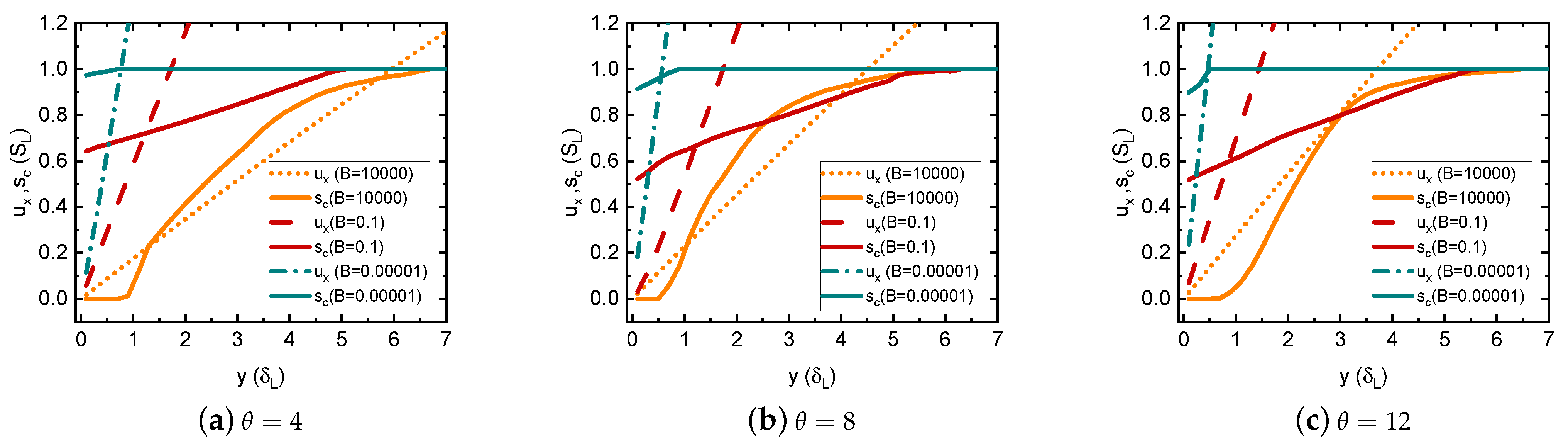

3.2. Effect of Wall Thermal Conditions for Different Thermal Gas Expansion Coefficients

4. Summary

- In narrow channels, with the channel half-width , the centerline velocity at the critical condition depends on the channel width non-monotonically;

- In wider channels, , the critical velocity gradient grows gradually with the channel width, reaching a nearly constant value for a given gas expansion coefficient;

- The critical velocity gradient increases with the gas expansion coefficient for given channel width and wall thermal condition;

- It is confirmed that the critical velocity gradient for the adiabatic wall can be an order of magnitude higher than that for the isothermal wall.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations and Nomenclature

| BLF | boundary layer flashback |

| CGM | critical gradient model |

| CIVB | combustion-induced vortex breakdown |

| B | wall heat transfer parameter |

| sound speed | |

| heat capacity at constant pressure | |

| heat capacity at constant volume | |

| activation energy | |

| g | velocity gradient |

| l | cell size |

| Lewis number | |

| flame propagation Mach number | |

| P | pressure |

| p | order of truncation error decay |

| Prandtl number | |

| energy diffusion vector | |

| Q | energy release from the reaction |

| R | channel half-width |

| universal gas constant | |

| Schmidt number | |

| consumption speed | |

| unstretched laminar burning velocity | |

| t | time |

| T | temperature |

| velocity | |

| w | reaction rate |

| x | axial coordinate |

| y | radial coordinate |

| Y | mass fraction of fuel |

| Zeldovich number | |

| Kronecker delta | |

| laminar flame thickness | |

| quenching distance | |

| penetration distance | |

| total energy per unit volume | |

| Arrhenius number | |

| stress tensor | |

| adiabatic index | |

| gas expansion ratio | |

| dynamic viscosity | |

| density | |

| factor of time dimension in the Arrhenius law | |

| Subscripts | |

| 0 | initial value |

| b | burnt gas |

| c | critical |

| maximum (centerline) | |

| flame tip | |

| Superscripts | |

| + | normalized value |

| Other designations | |

| ∼ | scaled value |

References

- Kalantari, A.; McDonell, V. Boundary layer flashback of non-swirling premixed flames: Mechanisms, fundamental research, and recent advances. Prog. Energy Combust. Sci. 2017, 61, 249–292. [Google Scholar] [CrossRef]

- Leicher, J.; Schaffert, J.; Cigarida, H.; Tali, E.; Burmeister, F.; Giese, A.; Albus, R.; Görner, K.; Carpentier, S.; Milin, P.; et al. The Impact of Hydrogen Admixture into Natural Gas on Residential and Commercial Gas Appliances. Energies 2022, 15, 777. [Google Scholar] [CrossRef]

- Jiang, X.; Tang, Y.; Liu, Z.; Raman, V. Computational Modeling of Boundary Layer Flashback in a Swirling Stratified Flame Using a LES-Based Non-Adiabatic Tabulated Chemistry Approach. Entropy 2021, 23, 567. [Google Scholar] [CrossRef] [PubMed]

- Vigueras-Zuniga, M.O.; Tejeda-del Cueto, M.E.; Vasquez-Santacruz, J.A.; Herrera-May, A.L.; Valera-Medina, A. Numerical Predictions of a Swirl Combustor Using Complex Chemistry Fueled with Ammonia/Hydrogen Blends. Energies 2020, 13, 288. [Google Scholar] [CrossRef]

- Eichler, C.T. Flame Flashback in Wall Boundary Layers of Premixed Combustion Systems. Ph. D. Thesis, Technical University of Munich, Munich, Germany, 2011. [Google Scholar]

- Lewis, B.; von Elbe, G. Stability and structure of burner flames. J. Chem. Phys. 1943, 11, 75–97. [Google Scholar] [CrossRef]

- Von Elbe, G.; Mentser, M. Further studies of the structure and stability of burner flames. J. Chem. Phys. 1945, 13, 89–100. [Google Scholar] [CrossRef]

- Berlad, A.L.; Potter, A.E. Relation of boundary velocity gradient for flash-back to burning velocity and quenching distance. Combust. Flame 1957, 1, 127–128. [Google Scholar] [CrossRef]

- Potter, A.E. 5-Flame Quenching. In Progress in Combustion Science and Technology; Ducarme, J., Gerstein, M., Lefebvre, A.H., Eds.; Pergamon Press: New York, USA, 1960; Volume 1, pp. 145–181. [Google Scholar] [CrossRef]

- Lee, S.T.; T’ien, J.S. A numerical analysis of flame flashback in a premixed laminar system. Combust. Flame 1982, 48, 273–285. [Google Scholar] [CrossRef]

- Mallens, R.M.M.; De Goey, L.P.H. Flash-back of Laminar Premixed Methane/Air Flames on Slitand Tube Burners. Combust. Sci. Technol. 1998, 136, 41–54. [Google Scholar] [CrossRef]

- Kurdyumov, V.; Fernández, E.; Liñán, A. Flame flashback and propagation of premixed flames near a wall. Proc. Combust. Inst. 2000, 28, 1883–1889. [Google Scholar] [CrossRef]

- Kurdyumov, V.N.; Fernandez-Tarrazo, E. Lewis number effect on the propagation of premixed laminar flames in narrow open ducts. Combust. Flame 2002, 128, 382–394. [Google Scholar] [CrossRef]

- Kurdyumov, V.; Fernández-Tarrazo, E.; Truffaut, J.M.; Quinard, J.; Wangher, A.; Searby, G. Experimental and numerical study of premixed flame flashback. Proc. Combust. Inst. 2007, 31, 1275–1282. [Google Scholar] [CrossRef]

- Jiménez, C.; Fernández-Galisteo, D.; Kurdyumov, V.N. DNS study of the propagation and flashback conditions of lean hydrogen-air flames in narrow channels: Symmetric and non-symmetric solutions. Int. J. Hydrogen Energy 2015, 40, 12541–12549. [Google Scholar] [CrossRef]

- Eichler, C.; Baumgartner, G.; Sattelmayer, T. Experimental investigation of turbulent boundary layer flashback limits for premixed hydrogen-air flames confined in ducts. J. Eng. Gas Turbines Power 2012, 134, 011502. [Google Scholar] [CrossRef]

- Wu, M.H.; Wang, C.Y. Reaction propagation modes in millimeter-scale tubes for ethylene/oxygen mixtures. Proc. Combust. Inst. 2011, 33, 2287–2293. [Google Scholar] [CrossRef]

- Kuznetsov, M.; Denkevits, A.; Veser, A.; Friedrich, A. Flame propagation regimes and critical conditions for flame acceleration and detonation transition for hydrogen-air mixtures at cryogenic temperatures. Int. J. Hydrogen Energy 2022, 47, 30743–30756. [Google Scholar] [CrossRef]

- Ebi, D.; Clemens, N.T. Experimental investigation of upstream flame propagation during boundary layer flashback of swirl flames. Combust. Flame 2016, 168, 39–52. [Google Scholar] [CrossRef]

- Ranjan, R.; Clemens, N.T. Insights into flashback-to-flameholding transition of hydrogen-rich stratified swirl flames. Proc. Combust. Inst. 2021, 38, 6289–6297. [Google Scholar] [CrossRef]

- Gruber, A.; Chen, J.H.; Valiev, D.; Law, C.K. Direct numerical simulation of premixed flame boundary layer flashback in turbulent channel flow. J. Fluid Mech. 2012, 709, 516–542. [Google Scholar] [CrossRef] [Green Version]

- Eriksson, L.E. A Third Order Accurate Upwind-Biased Finite-Volume Scheme For Unsteady Compressible Viscous Flow; Volvo Aero Corporation: Trollhättan, Sweden, 1993. [Google Scholar]

- Eriksson, L.E. Flow solution on a dual-block grid around an airplane. Comput. Methods Appl. Mech. Eng. 1987, 64, 79–93. [Google Scholar] [CrossRef]

- Valiev, D.; Bychkov, V.; Akkerman, V.; Law, C.K.; Eriksson, L.E. Flame acceleration in channels with obstacles in the deflagration-to-detonation transition. Combust. Flame 2010, 157, 1012–1021. [Google Scholar] [CrossRef]

- Demirgok, B.; Ugarte, O.; Valiev, D.; Akkerman, V. Effect of thermal expansion on flame propagation in channels with nonslip walls. Proc. Combust. Inst. 2015, 35, 929–936. [Google Scholar] [CrossRef]

- Valiev, D.; Bychkov, V.; Akkerman, V.; Eriksson, L.E.; Law, C.K. Quasi-steady stages in the process of premixed flame acceleration in narrow channels. Phys. Fluids 2013, 25, 096101. [Google Scholar] [CrossRef]

- Han, Y.; Modestov, M.; Valiev, D.M. Effect of momentum and heat losses on the hydrodynamic instability of a premixed equidiffusive flame in a Hele–Shaw cell. Phys. Fluids 2021, 33, 103608. [Google Scholar] [CrossRef]

- Poinsot, T.; Veynante, D. Theoretical and Numerical Combustion; RT Edwards, Inc.: Morningside, QLD, Australia, 2005. [Google Scholar]

- Adebiyi, A.; Abidakun, O.; Akkerman, V. Acceleration of Premixed Flames in Obstructed Pipes with Both Extremes Open. Energies 2020, 13, 4094. [Google Scholar] [CrossRef]

- Feng, R.; Gruber, A.; Chen, J.H.; Valiev, D.M. Influence of gas expansion on the propagation of a premixed flame in a spatially periodic shear flow. Combust. Flame 2021, 227, 421–427. [Google Scholar] [CrossRef]

- Ding, S.; Huang, K.; Han, Y.; Valiev, D. Numerical study of the influence of wall roughness on laminar boundary layer flashback. Phys. Rev. Fluids 2021, 6, 023201. [Google Scholar] [CrossRef]

- Feng, R.; Valiev, D. Influence of gas expansion on the velocity and stability limits of stationary curved flames in channels. Combust. Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Schlichting H, G.K. Boundary-Layer Theory, 9th ed.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Kagan, L. On the transition from deflagration to detonation in narrow channels. Math. Model. Nat. Phenom. 2007, 2, 16. [Google Scholar] [CrossRef] [Green Version]

- Kagan, L.; Sivashinsky, G. On the Transition from Deflagration to Detonation in Narrow Tubes. Flow Turbul. Combust. 2010, 84, 423–437. [Google Scholar] [CrossRef]

- Huang, J.; Han, W.; Gao, X.; Wang, C. Effects of heat loss and viscosity friction at walls on flame acceleration and deflagration to detonation transition. Chin. Phys. B 2019, 28, 074704. [Google Scholar] [CrossRef]

- Zeldovich, I.B.; Barenblatt, G.I.; Librovich, V.B.; Makhviladze, G.M. Mathematical Theory of Combustion and Explosions; Consultants Bureau: New York, NY, USA, 1985. [Google Scholar]

- Law, C.K. Combustion Physics; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Valiev, D.; Bychkov, V.; Akkerman, V.; Eriksson, L.E.; Marklund, M. Heating of the fuel mixture due to viscous stress ahead of accelerating flames in deflagration-to-detonation transition. Phys. Lett. A 2008, 372, 4850–4857. [Google Scholar] [CrossRef]

- Versteeg, H.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; Pearson Education Limited: London, UK, 2007. [Google Scholar]

- AlKhabbaz, M.; Kodakoglu, F.; Valiev, D.; Akkerman, V. Impacts of wall conditions on flame acceleration at the early stages of burning in channels. Phys. Rev. Fluids 2022, 7, 013201. [Google Scholar] [CrossRef]

- Dugger, G.L. Flame stability of preheated propane-air mixtures. Ind. Eng. Chem. 1955, 47, 109–114. [Google Scholar] [CrossRef]

- Harris, M.; Grumer, J.; Elbe, G.V.; Lewis, B. Burning velocities, quenching, and stability data on nonturbulent flames of methane and propane with oxygen and nitrogen 1: Application of theory of ignition, quenching, and stabilizationto flames of propane and air. Symp. Combust. Flame Explos. Phenom. 1948, 3, 80–89. [Google Scholar] [CrossRef]

- Alliche, M.; Haldenwang, P.; Chikh, S. Extinction conditions of a premixed flame in a channel. Combust. Flame 2010, 157, 1060–1070. [Google Scholar] [CrossRef]

- Takizawa, K.; Igarashi, N.; Takagi, S.; Tokuhashi, K.; Kondo, S. Quenching distance measurement of highly to mildly flammable compounds. Fire Saf. J. 2015, 71, 58–68. [Google Scholar] [CrossRef]

- Akkerman, V.; Bychkov, V.; Petchenko, A.; Eriksson, L.E. Flame oscillations in tubes with nonslip at the walls. Combust. Flame 2006, 145, 675–687. [Google Scholar] [CrossRef]

- Hackert, C.; Ellzey, J.; Ezekoye, O. Effects of thermal boundary conditions on flame shape and quenching in ducts. Combust. Flame 1998, 112, 73–84. [Google Scholar] [CrossRef]

- Kim, N.I.; Kataoka, T.; Maruyama, S.; Maruta, K. Flammability limits of stationary flames in tubes at low pressure. Combust. Flame 2005, 141, 78–88. [Google Scholar] [CrossRef]

- Bioche, K.; Vervisch, L.; Ribert, G. Premixed flame-wall interaction in a narrow channel: Impact of wall thermal conductivity and heat losses. J. Fluid Mech. 2018, 856, 5–35. [Google Scholar] [CrossRef]

- Lee, S.T.; Tsai, C.H. Numerical investigation of steady laminar flame propagation in a circular tube. Combust. Flame 1994, 99, 484–490. [Google Scholar] [CrossRef]

| 0.40 | 0.402 | N/A |

| 0.20 | 0.474 | 15.15% |

| 0.10 | 0.486 | 2.46% |

| 0.05 | 0.489 | 0.74% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, K.; Valiev, D.M.; Zhong, H.; Han, W. Numerical Study of the Influence of the Thermal Gas Expansion on the Boundary Layer Flame Flashback in Channels with Different Wall Thermal Conditions. Energies 2023, 16, 1844. https://doi.org/10.3390/en16041844

Huang K, Valiev DM, Zhong H, Han W. Numerical Study of the Influence of the Thermal Gas Expansion on the Boundary Layer Flame Flashback in Channels with Different Wall Thermal Conditions. Energies. 2023; 16(4):1844. https://doi.org/10.3390/en16041844

Chicago/Turabian StyleHuang, Kai, Damir M. Valiev, Hongtao Zhong, and Wenhu Han. 2023. "Numerical Study of the Influence of the Thermal Gas Expansion on the Boundary Layer Flame Flashback in Channels with Different Wall Thermal Conditions" Energies 16, no. 4: 1844. https://doi.org/10.3390/en16041844