Model for Predicting Horizontal Well Transient Productivity in the Bottom-Water Reservoir with Finite Water Bodies

Abstract

1. Introduction

2. Model Building

2.1. Physical Model

2.2. Mathematical Modeling and Solving

3. Typical Curve Analysis

3.1. Model Verification

3.2. Typical Curve

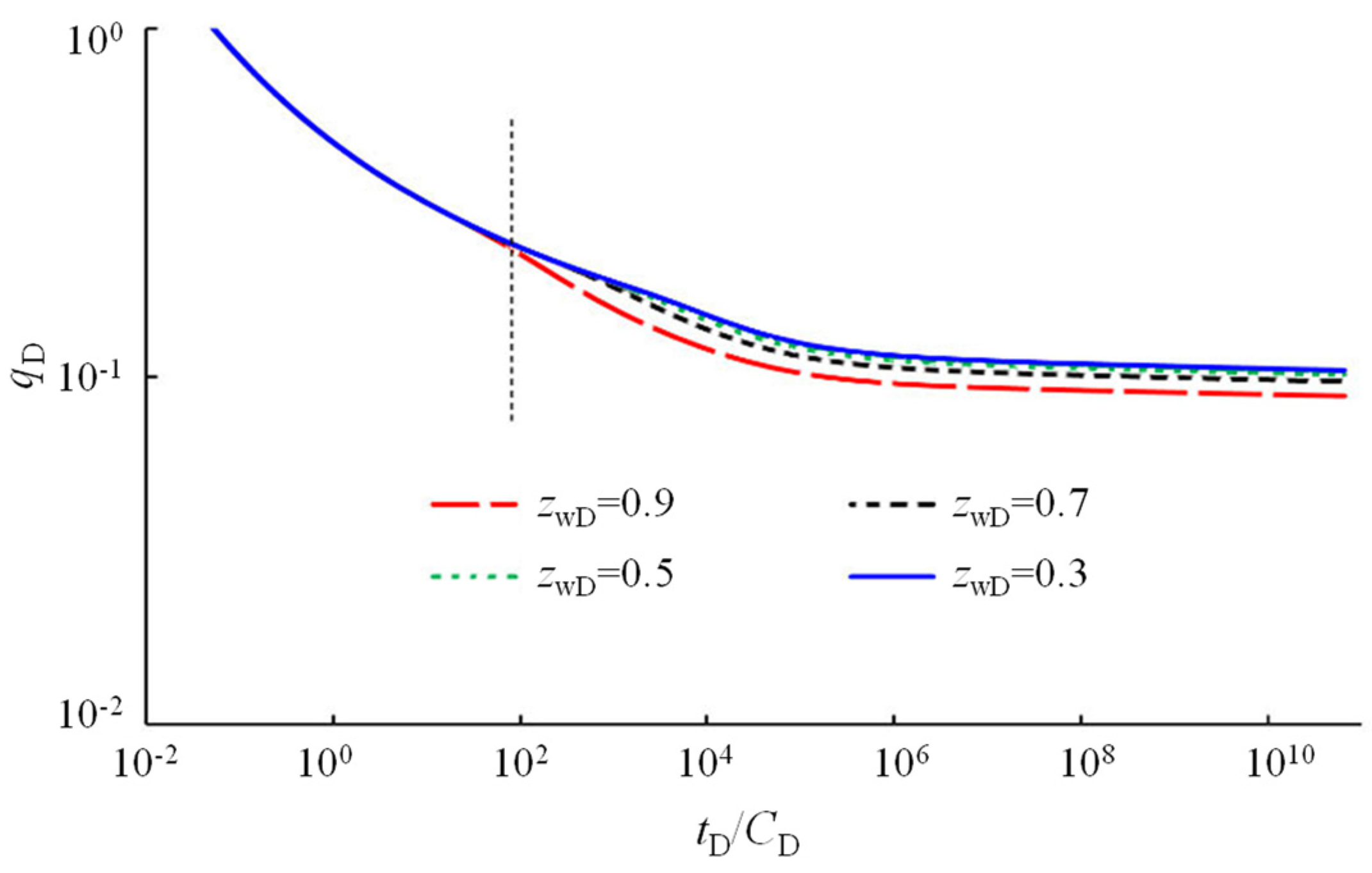

4. Analysis of Factors Influencing Productivity

4.1. Water-Body Multiplier

4.2. Distance between Horizontal Well and Oil–Water Contact

4.3. Skin Factor

4.4. Field Application

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| pi | original formation pressure, MPa |

| t | horizontal well production time, d |

| h1 | thickness of the upper unutilized oil layer, m |

| kh1 | horizontal permeability of the upper unutilized oil layer, 10−3 µm3 |

| kv1 | vertical permeability of the upper unutilized oil layer, 10−3 µm3 |

| Ct1 | integrated compression factor of the upper unutilized oil layer, MPa−1 |

| φ1 | porosity of the upper unutilized oil layer, % |

| p1 | upper unutilized oil layer pressure, MPa |

| h2 | thickness of the sand body in the lower water layer, m |

| Kh2 | horizontal permeability of the sand body in the lower water layer, 10−3 µm3 |

| Kv2 | vertical permeability of the sand body in the lower water layer, 10−3 µm3 |

| Ct2 | the combined compression coefficient of the sand body in the lower water layer, MPa−1 |

| φ2 | porosity of the sand body in the lower water layer, % |

| p2 | pressure of the lower water layer, MPa |

| μw | viscosity of the formation water, mPa·s |

| μo | crude oil viscosity, mPa·s |

| Lh | horizontal well length, m |

| zw | the distance between the horizontal well and oil–water contact, m |

| q | horizontal well production, m3/d |

| C | wellbore storage factor, m3/MPa |

| pD1 | dimensionless pressure of the upper unutilized oil layer, dimensionless |

| pD2 | dimensionless pressure of the lower water layer, dimensionless |

| tD | dimensionless production time of the horizontal well, dimensionless |

| η | conductivity factor, dimensionless |

| hD1 | dimensionless thickness of the upper unutilized oil layer, dimensionless |

| hD2 | the dimensionless thickness of the sand body in the lower water layer, dimensionless |

| xD | the dimensionless variable in the x-direction, dimensionless |

| yD | the dimensionless variable in the y-direction, dimensionless |

| zD | the dimensionless variable in the z-direction, dimensionless |

| zwD | the dimensionless distance between the horizontal well and the oil–water contact, dimensionless |

| CD | the dimensionless wellbore storage factor, dimensionless |

| S | skin factor, dimensionless |

References

- Giger, F.M. Analytic 2-D models of water cresting before the breakthrough of horizontal wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 5 October 1986. [Google Scholar]

- Kuchuk, F.J.; Goode, P.A.; Wikkeson, D.J.; Thambynayagam, R.K.M. Pressure transient behavior of horizontal wells with and without gas cap or aquifer. SPE Form. Eval. 1991, 6, 86–94. [Google Scholar] [CrossRef]

- Zhang, P.; Wen, X.H. Existence of flow barriers improves horizontal well production in bottom-water reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar]

- Yue, P.; Du, Z.M.; Chen, X.F.; Liang, B.S. The critical rate of horizontal wells in bottom-water reservoirs with an impermeable barrier. Petrol. Sci. 2012, 9, 223–229. [Google Scholar] [CrossRef]

- Deng, Y.; Lu, Y.N.; Ma, C.; Sun, B.; Luo, C.Y. A method to calculate the critical production of horizontal wells in bottom water reservoir. Well Test. 2022, 31, 1–5. [Google Scholar]

- Fan, Z.F. Study for horizontal well’s productivity formula in bottom-water drive reservoir. Pet. Explor. Dev. 1993, 20, 71–75. [Google Scholar]

- Fan, Z.F.; Lin, Z.F. A study of critical rate of a horizontal well in a reservoir with bottom-water drive. Pet. Explor. Dev. 1994, 21, 65–70. [Google Scholar]

- Cheng, L.S.; Lang, Z.X.; Zhang, L.H. Reservoir engineering problem of horizontal wells coning in bottom-water driven reservoir. J. China Univ. Pet. 1994, 18, 43–47. [Google Scholar]

- Dou, H. A new method of predicting the productivity of horizontal well. Oil Drill. Prod. Technol. 1996, 18, 76–81. [Google Scholar]

- Dou, H. Calculation of critical production of horizontal well in bottom water reservoir. Oil Drill. Prod. Technol. 1997, 19, 70–75. [Google Scholar]

- Cui, L.P.; He, S.L. Study on production formula for horizontal wells in reservoir with bottom-water. J. Oil Gas Technol. 2009, 31, 110–113. [Google Scholar]

- Chen, Y.Q. New methods to predict critical production rates in horizontal wells with water and gas coning. China Offshore Oil Gas 2010, 22, 22–26. [Google Scholar]

- Dikken, B.J. Pressure drop in horizontal wells and its effect on production performance. J. Pet. Technol. 1990, 42, 1426–1433. [Google Scholar] [CrossRef]

- Landman, M.J.; Goldthorpe, W.H. Optimization of perforation distribution for horizontal wells. In Proceedings of the SPE Asia-Pacific Conference, Perth, Australia, 4–7 November 1991. [Google Scholar]

- Su, Z.; Gudmundsson, J.S. Pressure drop in perforated pipes experiments and analysis. In Proceedings of the SPE Asia Pacific Oil and Gas Conference, Melbourne, Australia, 7–10 November 1994. [Google Scholar]

- Penmatcha, V.R.; Arbabi, S.; Aziz, K. Comprehensive reservoir/wellbore model for horizontal wells. SPE J. 1999, 4, 224–234. [Google Scholar] [CrossRef]

- Ouyang, L.B.; Huang, B. An Evaluation of well completion impacts on the perfomance of horizontal and mutilateral Wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005. [Google Scholar]

- Papatzacos, P.; Herring, T.R.; Marthinsen, R.; Skjæveland, S.M. Cone breakthrough time for horizontal wells. SPE Reserv. Eng. 1991, 6, 311–318. [Google Scholar] [CrossRef]

- Guo, B.Y.; Molinard, J.E.; Lee, R.L. A general solution of gas/water coning problem for horizontal wells. In Proceedings of the European Petroleum Conference, Stavanger, Norway, 24–27 May 1992. [Google Scholar]

- Umnuayponwiwat, S.; Ozkan, E. Water and gas coning toward finite-conductivity horizontal wells: Cone Buildup and Breakthrough. In Proceedings of the SPE Rocky Mountain Regional/Low-Permeability Reservoirs Symposium and Exhibition, Denver, CO, USA, 12–15 March 2000. [Google Scholar]

- Jiang, Y.; Liu, H.Z.; Wang, D.; Wu, H.J.; Huang, L. Study on bottom water reservoir pressure and flow variation regularity. Pet. Geol. Eng. 2018, 32, 72–74. [Google Scholar]

- Liu, X.P.; Guo, C.Z.; Jiang, Z.X.; Liu, X.; Guo, S.P. The model coupling fluid flow in the reservoir with flow in the horizontal wellbore. Acta Pet. Sin. 1999, 20, 82–86. [Google Scholar]

- Xiong, J. Study on Productivity of Horizontal Well Completion in Different Completion Modes in Bottom Water Reservoir; Southwest Petroleum University: Chengdu, China, 2014. [Google Scholar]

- Xiong, J.; Xiong, Y.M.; Zhang, L.; Pang, H.; Wang, H.L. Productivity forecast and influence factors analysis of segmentally perforated horizontal well in bottom water reservoir. Spec. Oil Gas Reserv. 2014, 21, 135–138. [Google Scholar]

- Zheng, Q.; Tian, J.; Li, F.; Ding, Z.P.; Peng, G.H.; Zhang, B. Model of waterflooding along horizontal wellbore in heterogeneous reservoir with bottom-water. Sci. Sin. Technol. 2014, 44, 890–896. [Google Scholar]

- Zhou, D.Y.; Jiang, T.W.; Feng, J.L.; Liu, H.P.; Bian, W.J. A simplified approach for determining the reasonable water-free production of horizontal well with bottom water drive reservoir. Acta Pet. Sin. 2005, 26, 86–89. [Google Scholar]

- Zhao, C.S.; Wang, H.; Lv, J.R. The deliverablitity of horizontal wells of the oil-water fluid in bottom water drive reservoir. Sci. Technol. Eng. 2011, 11, 4433–4435. [Google Scholar]

- Li, X.P. Solution of horizontal well percolation models by orthogonal transformation. China Offshore Oil Gas 1995, 9, 136–140. [Google Scholar]

- Wang, J.L.; Liu, Y.Z.; Jiang, R.Y.; Guan, C.Z. 2-D physical modeling of water coning of horizontal well production in bottom water driving reservoirs. Pet. Explor. Dev. 2007, 34, 590–593. [Google Scholar]

- Liu, X.Y.; Hu, P.; Cheng, L.S. Experimental study of horizontal well with bottom water drive. Pet. Drill. Tech. 2011, 39, 96–99. [Google Scholar]

- Liu, X.Y.; Hu, P. A 3-D visible physical experiment on horizontal wells of heterogeneous reservoirs with bottom water. Acta Pet. Sin. 2011, 32, 1012–1016. [Google Scholar]

- Cui, C.Z.; Zhao, X.Y. Model for predicting horizontal well productivity in the reservoirs with Bottom Water. J. Oil Gas Technol. 2007, 29, 131–134. [Google Scholar]

- Jiang, H.Q.; Li, J.J.; Li, J. Numerical simulation of water flooding law in horizontal wells of reservoirs with bottom water. J. Southwest Pet. Univ. 2009, 31, 172–176. [Google Scholar]

- Wang, J.; Liu, H.Q.; Liu, S.Y.; Gong, R.N. A flooding law in horizontal wells of heterogeneous reservoirs with bottom water. Acta Pet. Sin. 2010, 31, 970–974. [Google Scholar]

- Liu, G.W.; Zhou, D.Y.; Jiang, H.Q.; Wang, T.; Li, J.J. Water-out performance and pattern of horizontal wells for marine sandstone reservoirs in Tarim Basin, NW China. Pet. Explor. Dev. 2018, 45, 128–135. [Google Scholar] [CrossRef]

- Chen, N.; Liu, H.J.; Wei, K. Research on influence factors and economic limits of horizontal well productivity in bottom water reservoir. J. Chongqing Univ. 2019, 21, 38–41. [Google Scholar]

- Du, D.F.; Wang, Y.Y.; Zhao, Y.W.; Sui, P.S.; Xia, X. A new mathematical model for horizontal wells with variable density perforation completion in bottom water reservoirs. Petrol. Sci. 2017, 14, 383–394. [Google Scholar] [CrossRef]

- Kuchuk, F.J.; Habashy, T. Pressure behavior of horizontal wells in multilayer reservoirs with crossflow. SPE Form. Eval. 1996, 11, 55–64. [Google Scholar] [CrossRef]

- Stehfest, H. Numerical inversion of Laplace transforms. Commun. ACM 1970, 13, 47–49. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, X.; Sun, Z.; Lei, G.; Yao, C. Model for Predicting Horizontal Well Transient Productivity in the Bottom-Water Reservoir with Finite Water Bodies. Energies 2023, 16, 1952. https://doi.org/10.3390/en16041952

Jia X, Sun Z, Lei G, Yao C. Model for Predicting Horizontal Well Transient Productivity in the Bottom-Water Reservoir with Finite Water Bodies. Energies. 2023; 16(4):1952. https://doi.org/10.3390/en16041952

Chicago/Turabian StyleJia, Xiaofei, Zhaobo Sun, Guanglun Lei, and Chuanjin Yao. 2023. "Model for Predicting Horizontal Well Transient Productivity in the Bottom-Water Reservoir with Finite Water Bodies" Energies 16, no. 4: 1952. https://doi.org/10.3390/en16041952

APA StyleJia, X., Sun, Z., Lei, G., & Yao, C. (2023). Model for Predicting Horizontal Well Transient Productivity in the Bottom-Water Reservoir with Finite Water Bodies. Energies, 16(4), 1952. https://doi.org/10.3390/en16041952