The Impact of Sewage Sludge-Sweet Sorghum Blends on the Biogas Production for Energy Purposes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Used in the Experiment

2.2. Anaerobic Digestion Process

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| FM | Fresh Matter |

| TS | Total solid |

| VS | Volatile solid |

| Gt | Efficiency of biogas |

| k | Rate Constant |

| T1/2 | Degradation of Half-lives |

| R2 | Coefficient of Determination |

| RMSE | Root Mean Squared Error |

| t | Duration of the Process |

References

- Zsiborács, H.; Hegedűsné Baranyai, N.; Vincze, A.; Zentkó, L.; Birkner, Z.; Máté, K.; Pintér, G. Intermittent Renewable Energy Sources: The Role of Energy Storage in the European Power System of 2040. Electronics 2019, 8, 729. [Google Scholar] [CrossRef]

- Aziz, N.I.H.A.; Hanafiah, M.M.; Gheewala, S.H.; Ismail, H. Bioenergy for a Cleaner Future: A Case Study of Sustainable Biogas Supply Chain in the Malaysian Energy Sector. Sustainability 2020, 12, 3213. [Google Scholar] [CrossRef]

- Barreiro-Vescovo, S.; Barbera, E.; Bertucco, A.; Sforza, E. Integration of Microalgae Cultivation in a Biogas Production Process from Organic Municipal Solid Waste: From Laboratory to Pilot Scale. ChemEngineering 2020, 4, 25. [Google Scholar] [CrossRef]

- Witaszek, K.; Pilarski, K.; Niedbała, G.; Pilarska, A.; Herkowiak, M. Energy Efficiency of Comminution and Extrusion of Maize Substrates Subjected to Methane Fermentation. Energies 2020, 13, 1887. [Google Scholar] [CrossRef]

- Podkówka, Z.; Podkówka, K. Emisja gazów cieplarnianych przez krowy. Przegląd Hod. 2011, 3, 1–4. [Google Scholar]

- Robles-Aguilar, A.; Temperton, V.; Jablonowski, N. Maize Silage Digestate Application Affecting Germination and Early Growth of Maize Modulated by Soil Type. Agronomy 2019, 9, 473. [Google Scholar] [CrossRef]

- Piwowar, A. Agricultural Biogas—An Important Element in the Circular and Low-Carbon Development in Poland. Energies 2020, 13, 1733. [Google Scholar] [CrossRef]

- Koryś, K.; Latawiec, A.; Grotkiewicz, K.; Kuboń, M. The Review of Biomass Potential for Agricultural Biogas Production in Poland. Sustainability 2019, 11, 6515. [Google Scholar] [CrossRef]

- Murphy, J.; Power, N. Technical and economic analysis of biogas production in Ireland utilizing three different crop rotations. Appl. Energy 2009, 86, 25–36. [Google Scholar] [CrossRef]

- Sjöblom, M.; Matsakas, L.; Krige, A.; Rova, U.; Christakopoulos, P. Direct electricity generation from sweet sorghum stalks and anaerobic sludge. Ind. Crops Prod. 2017, 108, 505–551. [Google Scholar] [CrossRef]

- Gennaretti, F.; Ogée, J.; Sainte-Marie, J.; Cuntz, M. Mining ecophysiological responses of European beech ecosystems to drought. Agric. For. Meteorol. 2020, 280, 107780. [Google Scholar] [CrossRef]

- Rolz, C.; de León, R.; Luisa, A.; de Montenegro, M.; Porras, V.; Cifuentes, R. A multiple harvest cultivation strategy for ethanol production from sweet sorghum throughout the year in tropical ecosystems. Renew. Energy 2017, 106, 103–110. [Google Scholar] [CrossRef]

- Léder, I.; Sorghum and Millets. Cultivated Plants, Primarily as Food Sources. 2004. Available online: https://www.eolss.net/sample-chapters/c10/E5-02-01-04.pdf (accessed on 28 December 2022).

- Wilk, A. Characteristics of Sorgo. 2018. Available online: https://portalwysokichplonow.pl/charakterystyka-sorgo/ (accessed on 28 December 2022).

- Available online: http://khbc.pl/sorgo-roslina-energetyczna-i-paszowa-szczegoly-uprawy/ (accessed on 28 December 2022).

- Sowiński, J.; Głąb, L. The effect of nitrogen fertilization management on yield and nitrate content in sorghum biomass and bagasse. Field Crops Res. 2018, 227, 132–143. [Google Scholar] [CrossRef]

- Jiang, D.; Hao, M.; Fu, J.; Liu, K.; Yan, X. Potential bioethanol production from sweet sorghum on marginal land in China. J. Clean. Prod. 2019, 220, 225–234. [Google Scholar] [CrossRef]

- Abdollahi, M.; Ravindran, V.; Wester, T.; Ravindran, G.; Thomas, D. Influence of conditioning temperature on performance, apparent metabolisable energy, ileal digestibility of starch and nitrogen and the quality of pellets, in broiler starters fed maize- and sorghum-based diets. Anim. Feed. Sci. Technol. 2010, 162, 106–115. [Google Scholar] [CrossRef]

- Durdević, D.; Blecich, P.; Jurić, Ž. Energy Recovery from Sewage Sludge: The Case Study of Croatia. Energies 2019, 12, 1927. [Google Scholar] [CrossRef]

- Kominko, H.; Gorazda, K.; Wzorek, Z. Potentiality of sewage sludge-based organo-mineral fertilizer production in Poland considering nutrient value, heavy metal content and phytotoxicity for rapeseed crops. J. Environ. Manag. 2019, 248, 109283. [Google Scholar] [CrossRef]

- Chen, Y. Sewage Sludge Aerobic Composting Technology Research Progress. AASRI Procedia 2012, 1, 339–343. [Google Scholar] [CrossRef]

- Jayaraman, K.; Gökalp, I. Pyrolysis, combustion and gasification characteristics of miscanthus and sewage sludge. Energy Convers. Manag. 2015, 89, 83–91. [Google Scholar] [CrossRef]

- Zhao, J.; Hou, T.; Lei, Z.; Shimizu, K.; Zhang, Z. Effect of biogas recirculation strategy on biogas upgrading and process stability of anaerobic digestion of sewage sludge under slightly alkaline condition. Bioresour. Technol. 2020, 308, 123293. [Google Scholar] [CrossRef]

- Heidrich, Z.; Tiunajtis, K. About quantities of sludge from household wastewater treatment plants and directions of their disposal. Infrastruct. Ecol. Rural. Areas 2008, 5, 191–198. [Google Scholar]

- Głąb, L.; Sowiński, J.; Chmielewska, J.; Prask, H.; Fugol, M.; Szlachta, J. Comparison of the energy efficiency of methane and ethanol production from sweet sorghum (Sorghum bicolor (L.) Moench) with a variety of feedstock management technologies. Biomass Bioenergy 2019, 129, 105332. [Google Scholar] [CrossRef]

- Li, C.; Wang, X.; Zhang, G.; Li, J.; Li, Z.; Yu, G.; Wang, Y. A process combining hydrothermal pretreatment, anaerobic digestion and pyrolysis for sewage sludge dewatering and co-production of biogas and biochar: Pilot-scale verification. Bioresour. Technol. 2018, 254, 187–193. [Google Scholar] [CrossRef]

- Wannasek, L.; Ortner, M.; Kaul, H.; Amon, B.; Amon, T. Double-cropping systems based on rye, maize, and sorghum: Impact of variety and harvesting time on biomass and biogas yield. Eur. J. Agron. 2019, 110, 125934. [Google Scholar] [CrossRef]

- Mu, L.; Zhang, L.; Zhu, K.; Ma, J.; Ifran, M.; Li, A. Anaerobic co-digestion of sewage sludge, food waste, and yard waste: Synergistic enhancement on process stability and biogas production. Sci. Total Environ. 2020, 704, 135429. [Google Scholar] [CrossRef]

- DIN 38414 S-8; German Standard Methods for the Examination of Water, Waste Water and Sludge; Sludge and Sediments (Group S); Determination of the Amenability to Anaerobic Digestion (S 8. DIN Deutches Institut für Normung e. V.: Berlin, Germany, 2012.

- Laval, A.A.; Dzivama, A.U.; Wasinda, M.K. Effect of inoculum to substrate ratio on biogas production of sheep paunch manure. Res. Agric. Eng. 2016, 62, 8–14. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, G.; Li, W.; Li, C.; Zhikai Zhang; Guangyi Zhang; Wangliang Li; Chunxing Li and Guangwen Xu. Enhanced biogas production from sorghum stem by co-digestion with cow manure. Int. J. Hydrog. Energy 2016, 41, 9153–9158. [Google Scholar] [CrossRef]

- Dahunsi, S.; Adesulu-Dahunsi, A.; Osueke, C.; Lawal, A.; Olayanju, T.; Ojediran, J.; Izebere, J. Biogas generation from Sorghum bicolor stalk: Effect of pretreatment methods and economic feasibility. Energy Reports 2019, 5, 584–593. [Google Scholar] [CrossRef]

- Szlachta, J.; Prask, H.; Fugol, M.; Luberański, A. Effect of Mechanical Pre-Treatment of the Agricultural Substrates on Yield of Biogas and Kinetics of Anaerobic Digestion. Sustainability 2018, 10, 3669. [Google Scholar] [CrossRef]

- Nabi, M.; Zhang, G.; Zhang, P.; Tao, X.; Wang, S.; Ye, J.; Zhang, Q.; Zubair, M.; Bao, S.; Wu, Y. Contribution of solid and liquid fractions of sewage sludge pretreated by high-pressure homogenization to biogas production. Bioresour. Technol. 2019, 286, 121378. [Google Scholar] [CrossRef]

- Antonopoulou, G.; Gavala, H.; Skiadas, I.; Lyberatos, G. ADM1-based modeling of methane production from acidified sweet sorghum extract in a two-stage process. Bioresour. Technol. 2012, 106, 10–19. [Google Scholar] [CrossRef] [PubMed]

- Yazdani, M.; Ebrahimi-Nik, M.; Heidari, A.; Abbaspour-Fard, M. Improvement of biogas production from slaughterhouse wastewater using biosynthesized iron nanoparticles from water treatment sludge. Renew. Energy 2019, 135, 496–501. [Google Scholar] [CrossRef]

- Windpassinger, S.; Friedt, W.; Frauen, M.; Snowdon, R.; Wittko, B. Designing adapted sorghum silage types with an enhanced energy density for biogas generation in temperate Europe. Biomass Bioenergy 2015, 81, 496–504. [Google Scholar] [CrossRef]

- Wannasek, L.; Ortner, M.; Amon, B.; Amon, T. Sorghum, a sustainable feedstock for biogas production? Impact of climate, variety, and harvesting time on maturity and biomass yield. Biomass Bioenergy 2017, 106, 137–145. [Google Scholar] [CrossRef]

- Herrmann, C.; Idler, C.; Heiermann, M. Improving aerobic stability and biogas production of maize silage using silage additives. Bioresour. Technol. 2015, 197, 393–403. [Google Scholar] [CrossRef]

- Vassalle, L.; Díez-Montero, R.; Machado, A.; Moreira, C.; Ferrer, F.; Mota, C.; Passos, F. Upflow anaerobic sludge blanket in microalgae-based sewage treatment: Co-digestion for improving biogas production. Bioresour. Technol. 2020, 300, 122677. [Google Scholar] [CrossRef]

- Yu, D.; Meng, X.; Liu, J.; Dian, L.; Sui, Q.; Zhang, J.; Zhong, H.; Wei, Y. Formation and characteristics of a ternary pH buffer system for in-situ biogas upgrading in a two-phase anaerobic membrane bioreactor treating starch wastewater. Bioresour. Technol. 2018, 269, 57–66. [Google Scholar] [CrossRef]

- Liu, C.F.; Yuan, X.Z.; Zeng, G.M.; Li, W.W.; Li, J. Prediction of methane yield at optimum pH for anaerobic digestion of organic fraction of municipal solid waste. Bioresour. Technol. 2008, 99, 882–888. [Google Scholar] [CrossRef]

| Substrate | Total Solid | Volatile Solid | pH |

|---|---|---|---|

| % | % T.S. | - | |

| Sewage sludge | 0.9 ± 0.1 | 76.28 ± 0.1 | 6.62 ± 0.1 |

| Sorghum silage | 34.6 ± 0.1 | 96.65 ± 0.1 | 3.81 ± 0.1 |

| Pomace | 90.7 ± 0.2 | 97.74 ± 0.1 | 5.50 ± 0.1 |

| Juice | 14.6 ± 0.2 | 92.49 ± 0.1 | 5.24 ± 0.2 |

| Inoculum | 3.4 ± 0.1 | 70.33 ± 0.2 | 7.84 ± 0.2 |

| Substrates | Total Solid in Batch | Substrates from Sorghum | Sewage Sludge | Inoculum |

|---|---|---|---|---|

| % | g | |||

| Sorghum silage | 5 | 26 | 74 | 300 |

| 7 | 50 | 50 | 300 | |

| Pomace | 5 | 10 | 90 | 300 |

| 7 | 19 | 81 | 300 | |

| Juice | 5 | 65 | 35 | 300 |

| 7 | 140 | 45 | 215 | |

| Sewage sludge | 3 | - | 70 | 330 |

| Inoculum | 3.4 | - | - | 400 |

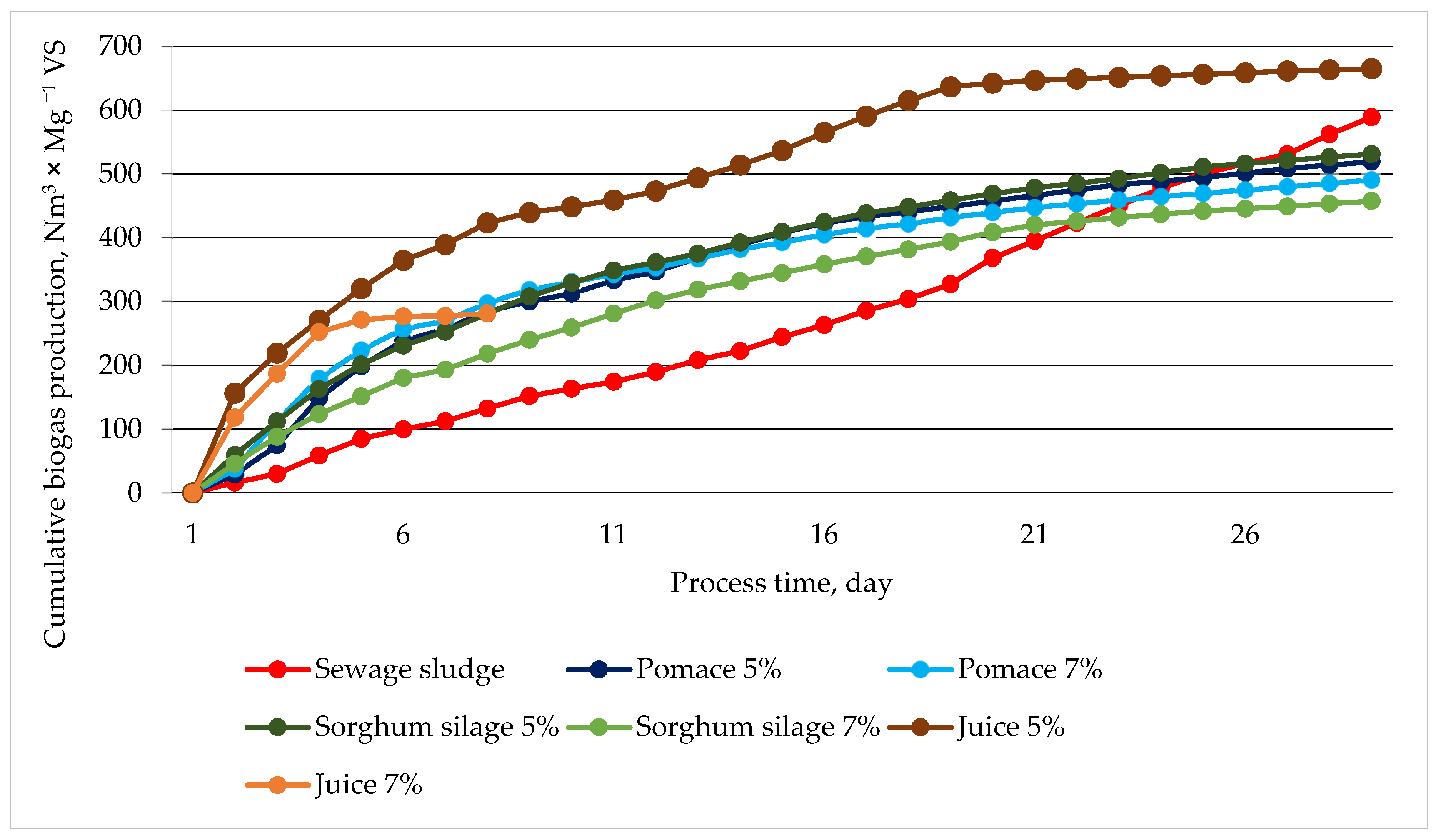

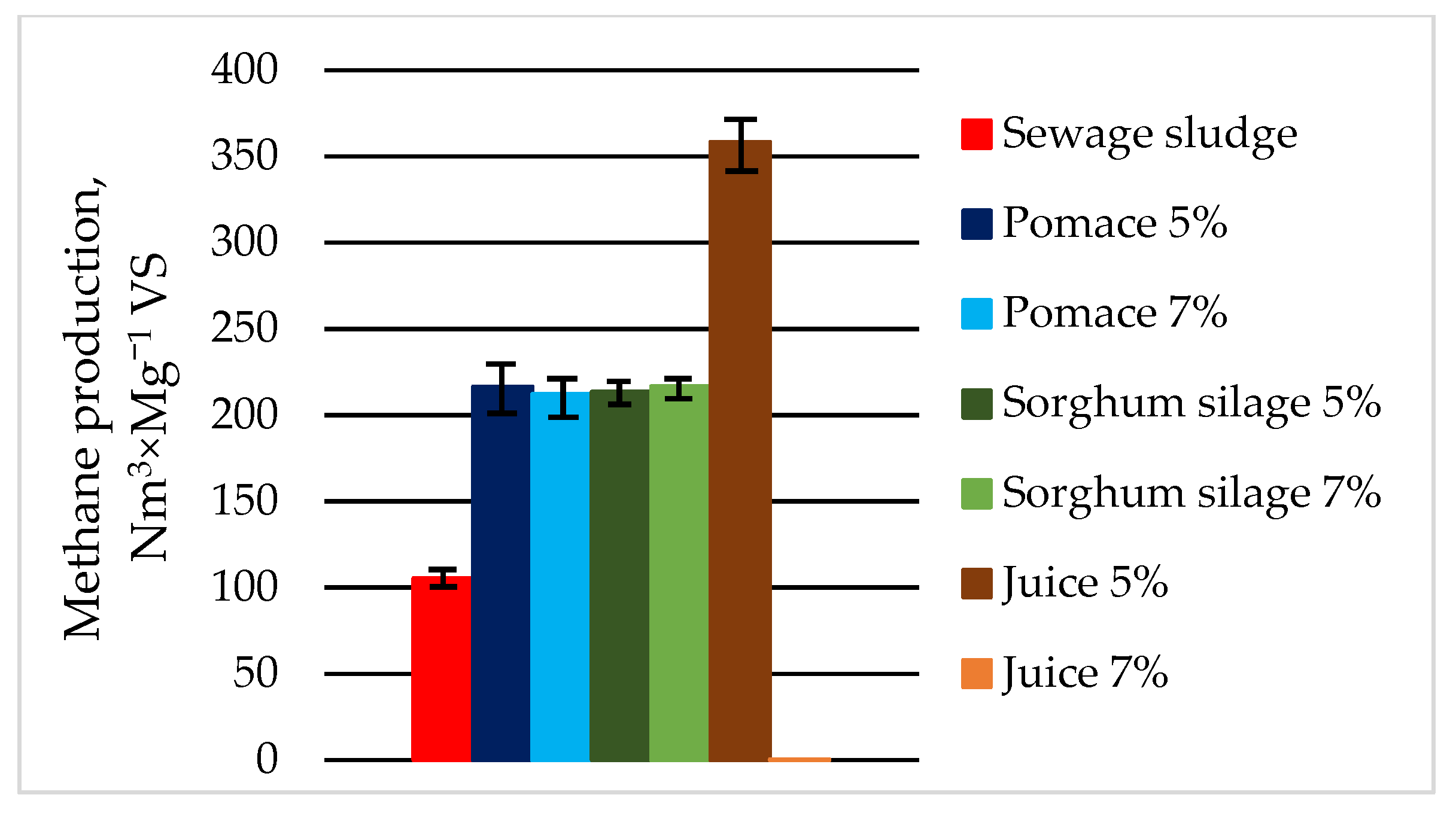

| Substrates | Total Solid in Batch | Biogas Yield | Biogas Yield | Methane Yield | Methane Yield |

|---|---|---|---|---|---|

| % | Nm3∙Mg−1 VS | Nm3∙Mg−1 FM | % | Nm3∙Mg−1 VS | |

| Sorghum silage | 5 | 531.0 ± 62.6 | 42.0 ± 7.01 | 40.2 ± 2,89 | 213.4 ± 8,42 |

| 7 | 457.4 ± 51.3 | 70.0 ± 11.11 | 47.4 ± 1.47 | 216.7 ± 10.4 | |

| Pomace | 5 | 519.1 ± 62.8 | 36.6 ± 6.27 | 41.7 ± 3.74 | 216.4 ± 21.4 |

| 7 | 485.5 ± 30.7 | 72.4 ± 4.38 | 43.3 ± 2.65 | 212.4 ± 15.4 | |

| Juice | 5 | 664.8 ± 7.3 | 56.5 ± 0.87 | 53.9 ± 2.33 | 358.3 ± 21.6 |

| 7 | 281.5 ± 5.5 | 11.8 ± 0.12 | 0.0 ± 0.0 | 0.0 ± 0.0 | |

| Sewage sludge | 3 | 588.8 ± 19.5 | 3.99 ± 0.16 | 17.9 ± 1.12 | 105.4 ± 5.9 |

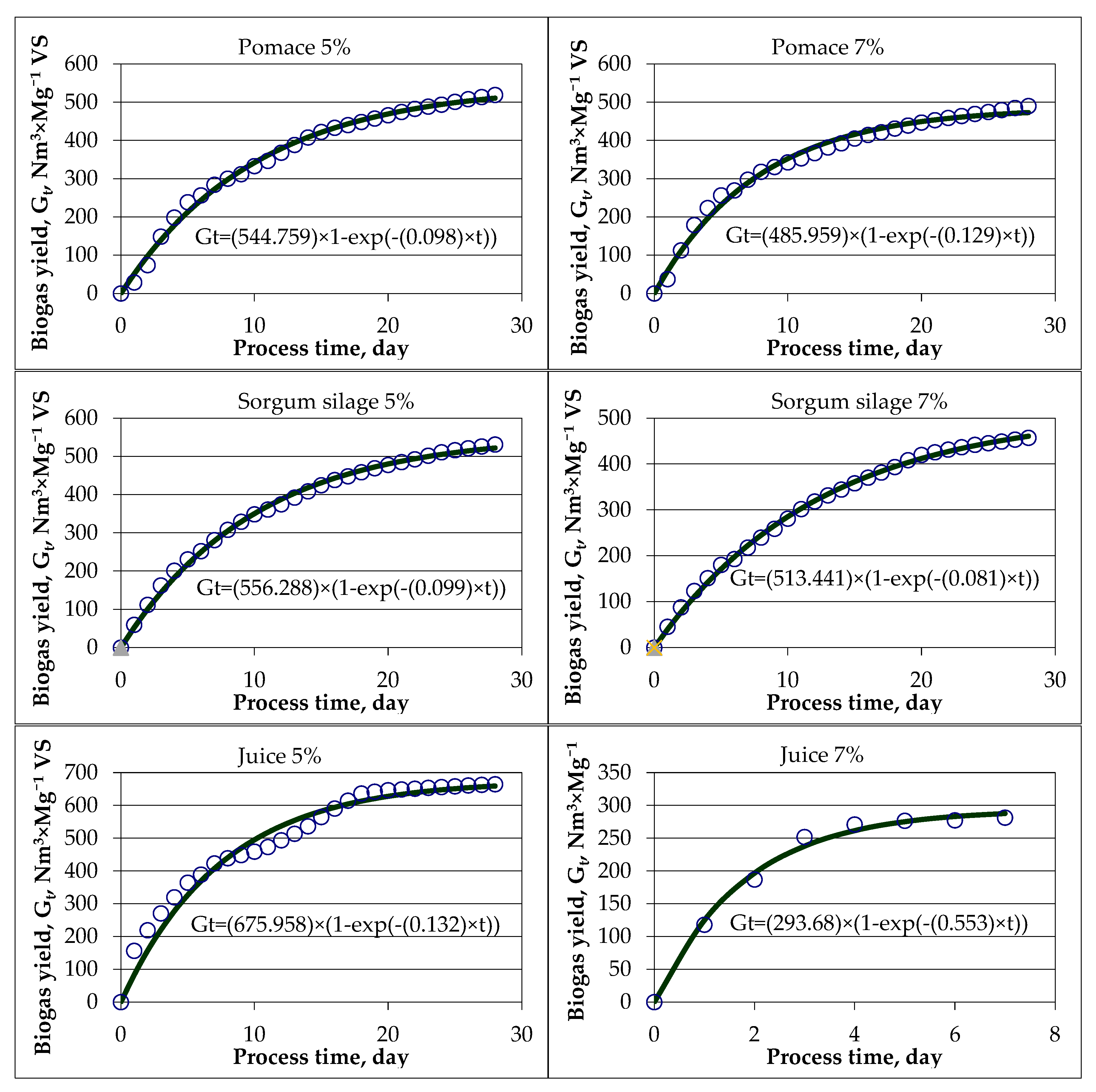

| Substrates | The Efficiency of Biogas Gt, Nm3∙Mg−1 VS | Rate Constant k, 1∙Day−1 | Degradation Half-Lives T1/2, Day | Coefficient of Determination R2 | Root Mean Squared Error, RMSE | Duration of Process t, Day |

|---|---|---|---|---|---|---|

| Sorghum silage 5% | 556.3 | 0.099 | 3.001 | 0.997 | 8.216 | 23 |

| Sorghum silage 7% | 513.4 | 0.081 | 3.205 | 0.998 | 5.354 | 23 |

| Pomace 5% | 544.7 | 0.098 | 3.006 | 0.995 | 10.615 | 23 |

| Pomace 7% | 485.9 | 0.129 | 2.739 | 0.991 | 12.641 | 23 |

| Juice 5% | 675.9 | 0.132 | 2.718 | 0.969 | 30.225 | 23 |

| Juice 7% | 293.6 | 0.553 | 1.284 | 0.993 | 7.875 | 8 |

| Sewage sludge | 3,919,626 | 0.0005 | 12.890 | 0.985 | 21.302 | 23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prask, H.; Fugol, M.; Dyjakon, A.; Głąb, L.; Sowiński, J.; Whitaker, A. The Impact of Sewage Sludge-Sweet Sorghum Blends on the Biogas Production for Energy Purposes. Energies 2023, 16, 2105. https://doi.org/10.3390/en16052105

Prask H, Fugol M, Dyjakon A, Głąb L, Sowiński J, Whitaker A. The Impact of Sewage Sludge-Sweet Sorghum Blends on the Biogas Production for Energy Purposes. Energies. 2023; 16(5):2105. https://doi.org/10.3390/en16052105

Chicago/Turabian StylePrask, Hubert, Małgorzata Fugol, Arkadiusz Dyjakon, Liliana Głąb, Józef Sowiński, and Alena Whitaker. 2023. "The Impact of Sewage Sludge-Sweet Sorghum Blends on the Biogas Production for Energy Purposes" Energies 16, no. 5: 2105. https://doi.org/10.3390/en16052105

APA StylePrask, H., Fugol, M., Dyjakon, A., Głąb, L., Sowiński, J., & Whitaker, A. (2023). The Impact of Sewage Sludge-Sweet Sorghum Blends on the Biogas Production for Energy Purposes. Energies, 16(5), 2105. https://doi.org/10.3390/en16052105