Applied Complex Diagnostics and Monitoring of Special Power Transformers

Abstract

:1. Introduction

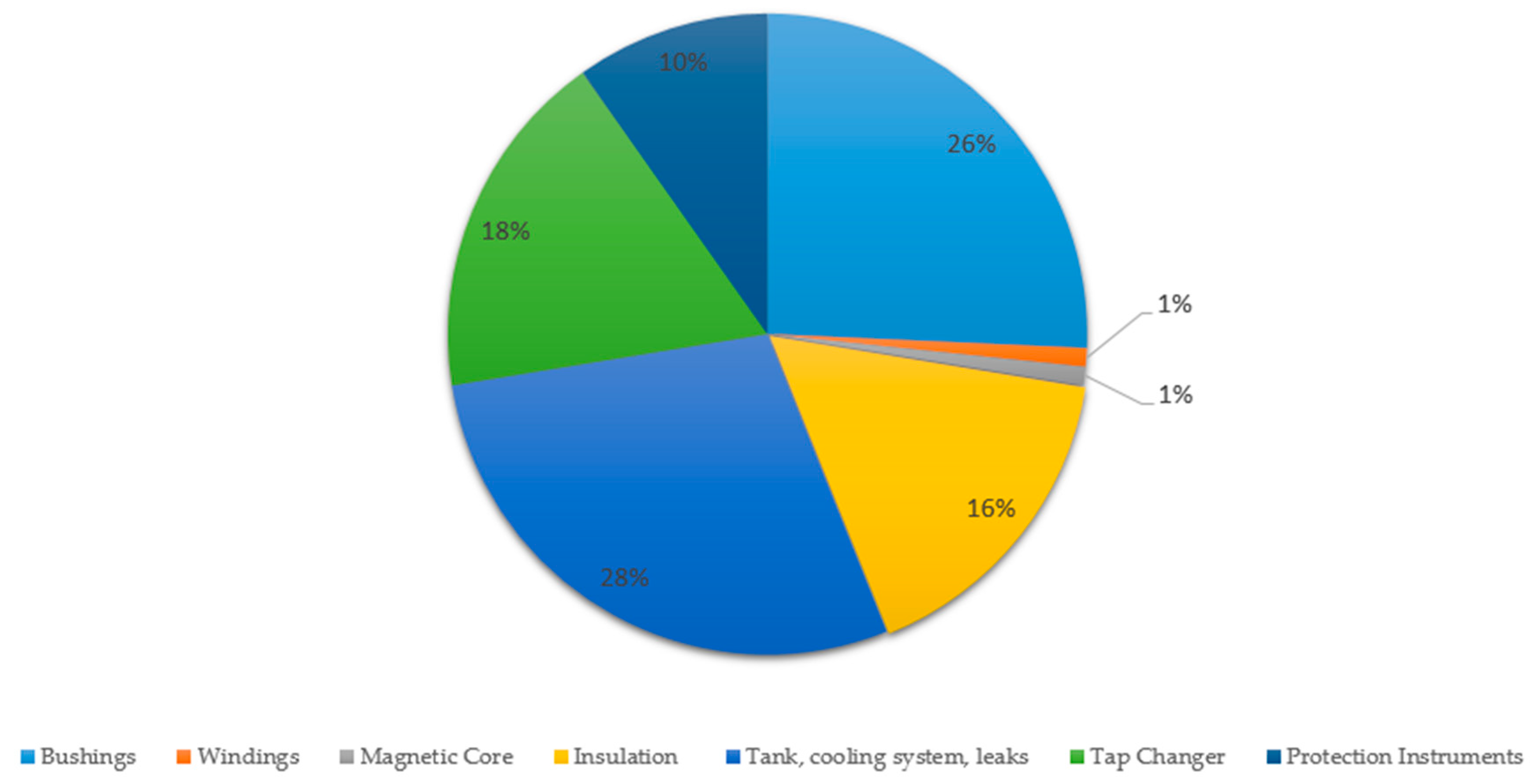

2. Methods Used to Investigate Transformers

- Generalization: all information which is received via different tests and algorithms is generalized and discussed to receive more detailed information about the current state of the transformer. Most of the tests usually result in data which are detailed for specific subsystems of the transformer [16,40,42,43];

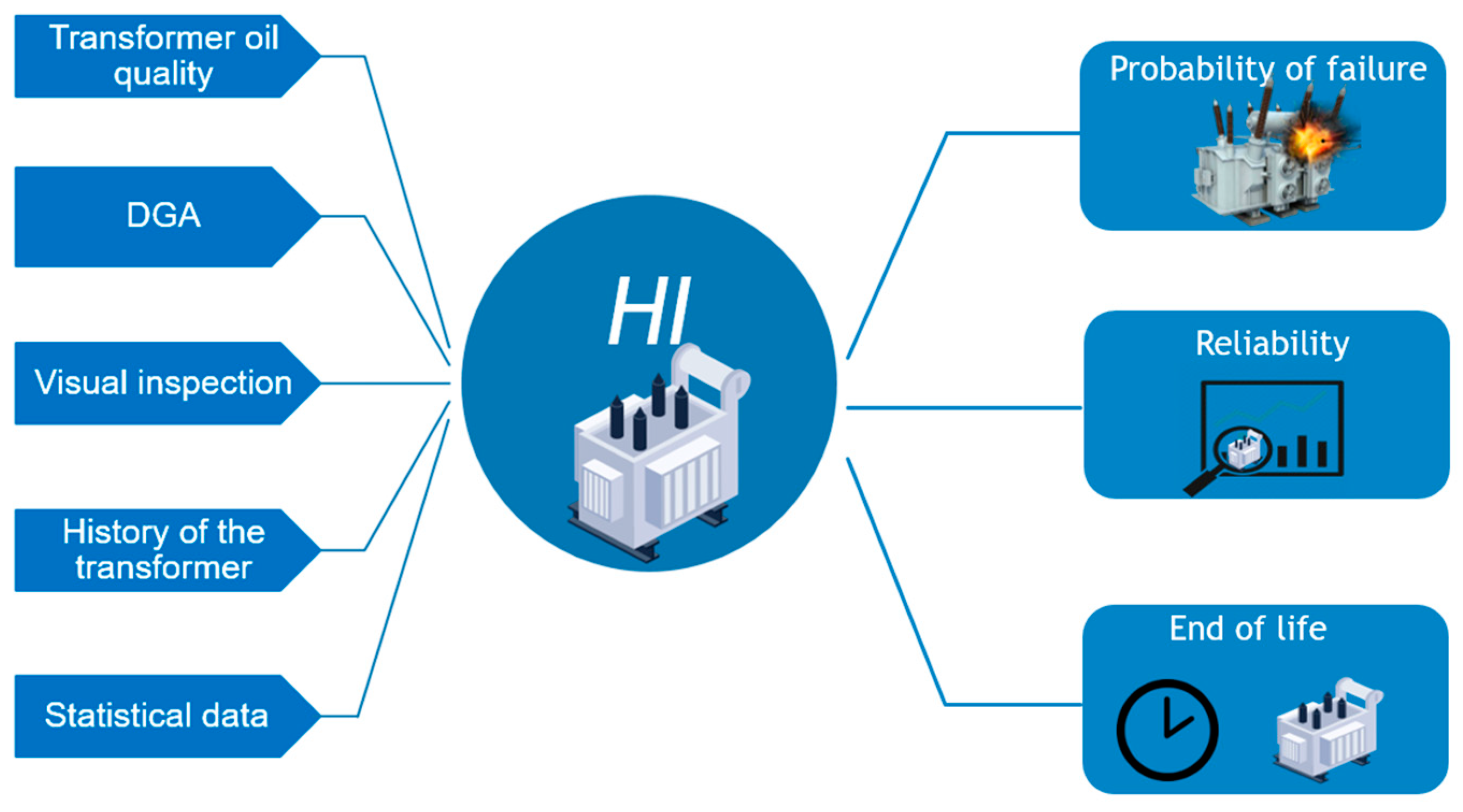

- Conclusions, forecasts and recommendations: based on results achieved from the applied diagnostic tests and methods, conclusions are drawn, and forecasts are made for probability of failure, EOL of the transformers and reliability. Recommendations are given to prioritize repair for the most degenerated transformers or to scrap them if end of life is reached [10,17,44]. In Figure 1 is shown a block scheme of the five stages used during the technical diagnostics.

2.1. Diagnostic Measuments Conducted on the Transformer Oil

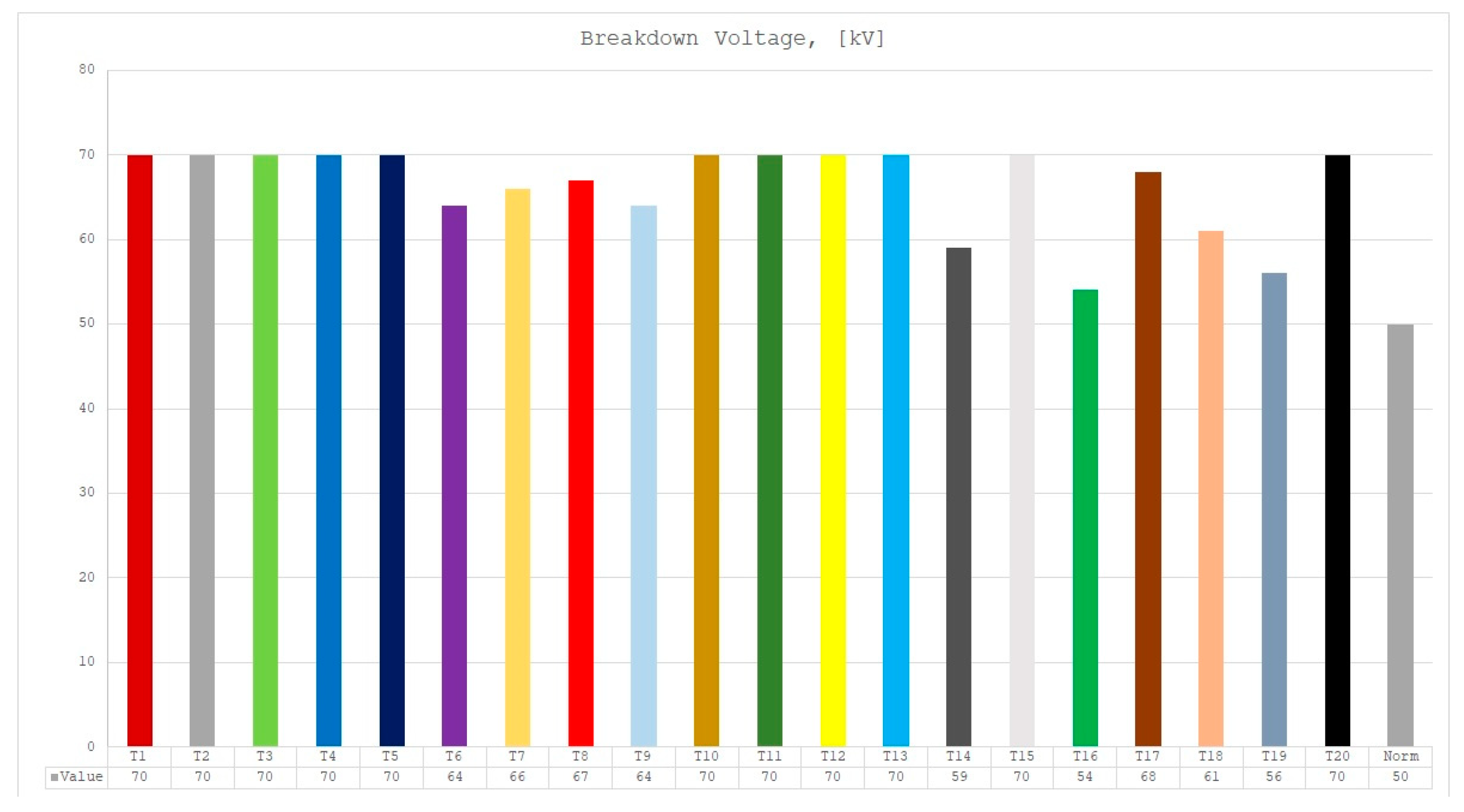

- Measurement of breakdown voltage of the transformer oil according to IEC 60,156 Insulating Liquids: determination of the breakdown voltage at power frequency-test method [30];

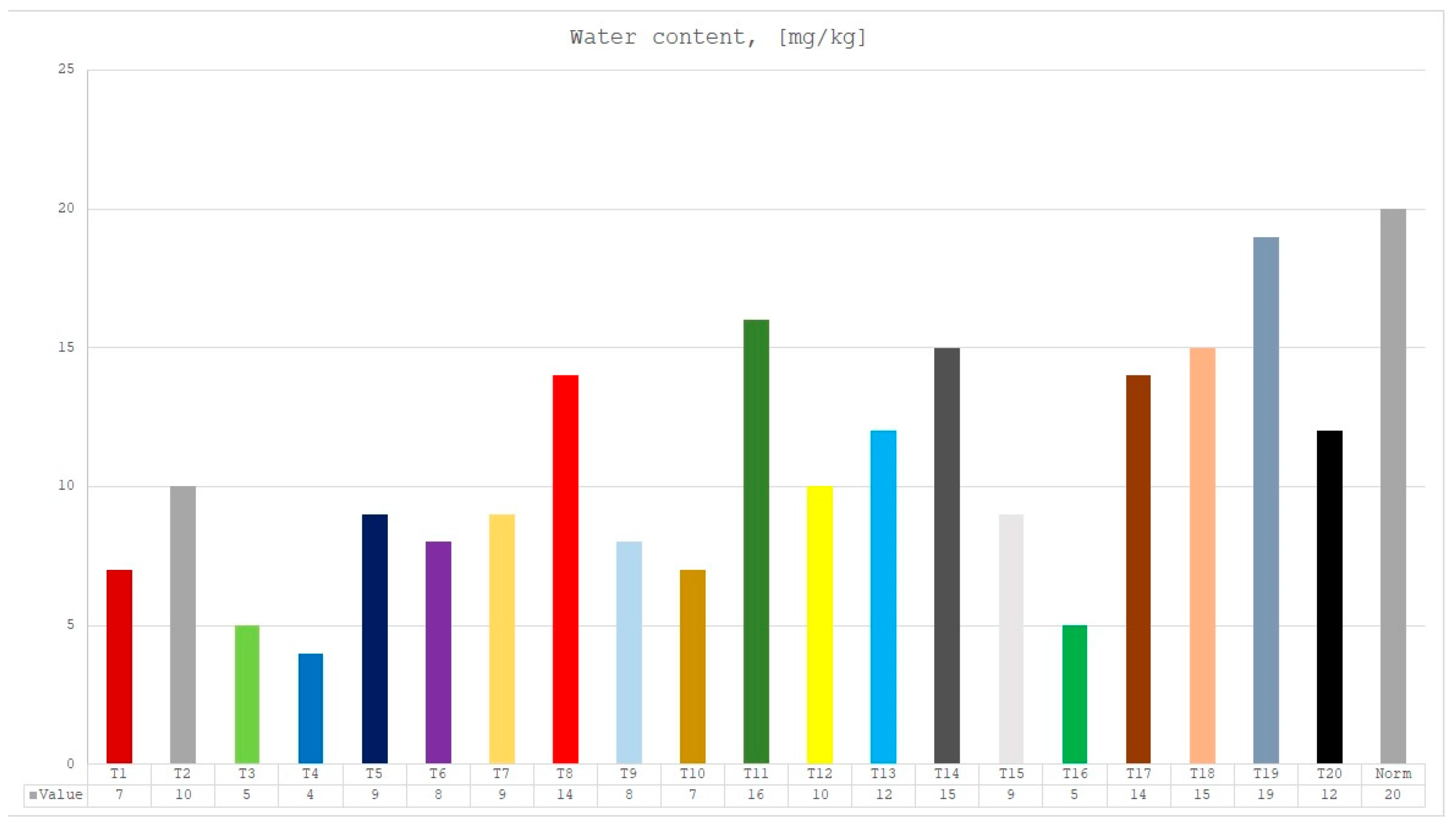

- Measurement of water content in the transformer oil according to IEC 60,814 Oil-impregnated paper and pressboard: determination of water by automatic coulometric Karl Fischer titration [29];

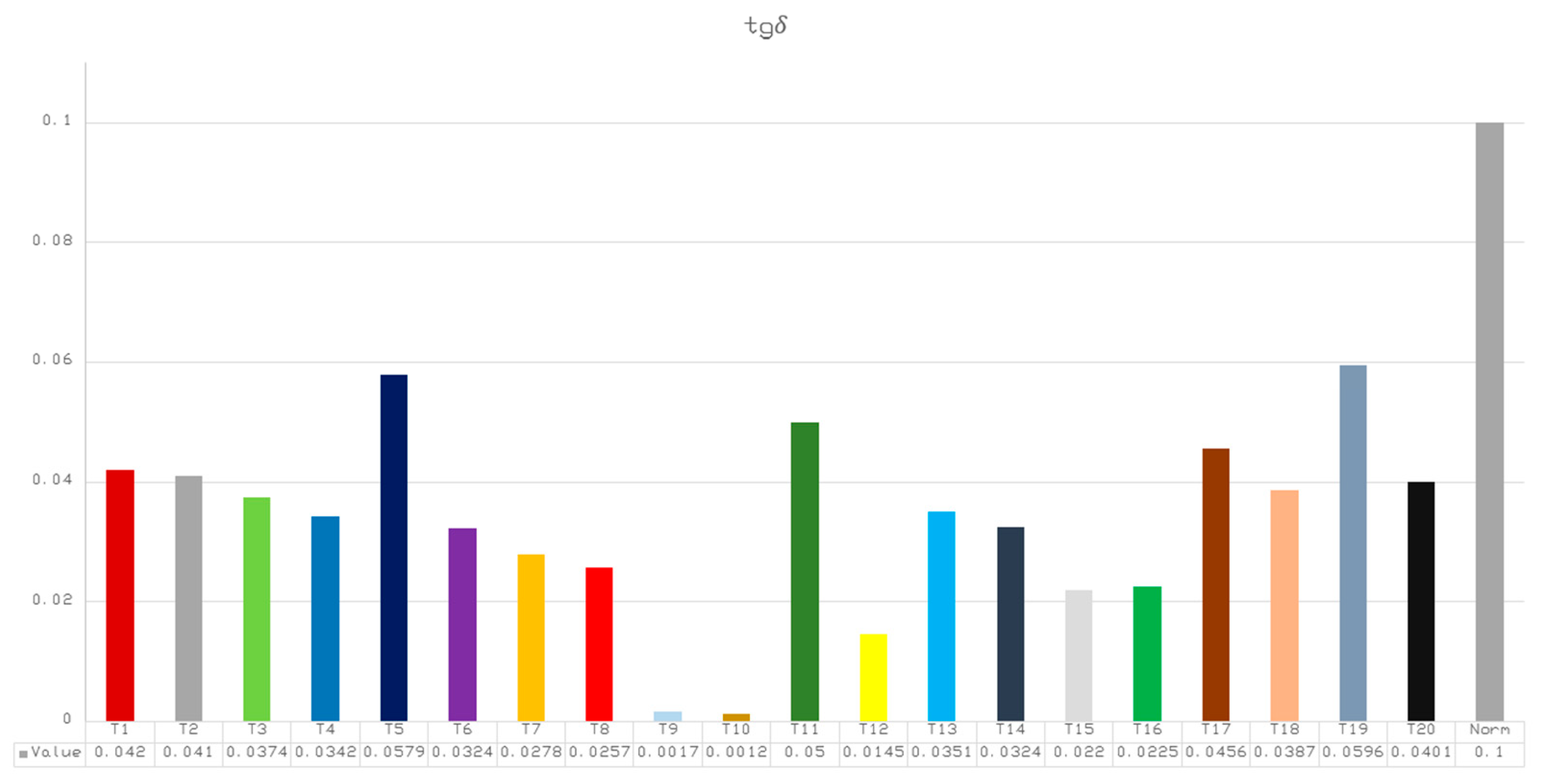

- Measurement of dissipation factor of the transformer oil tan δ according to IEC 60,247 Insulating Liquids: measurement of relative permittivity, dielectric dissipation factor (tan δ) and d.c. resistivity [31];

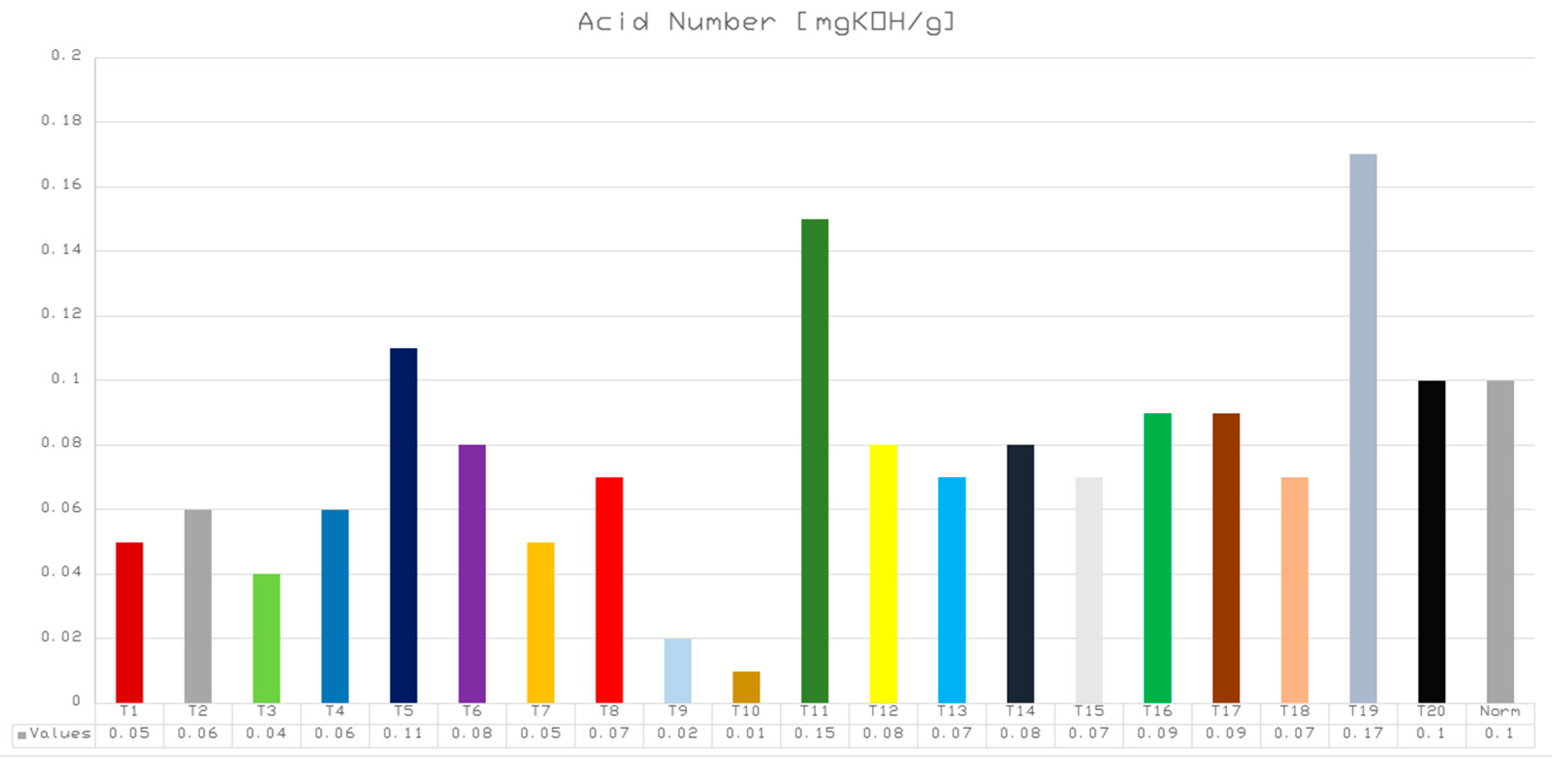

- Measurement of acid number of the transformer oil according to IEC 62021-1 Insulating liquids—determination of acidity—part 1: automatic potentiometric titration [33];

- Measurement of corrosive sulfur of transformer oil according to ASTM D1275-15 Standard test method for corrosive sulfur in electrical insulating liquids;

- Estimation of water content in insulating paper according to IEC 60,814 [29];

- Dissolved gas analyses of the transformer oil IEC 60,599 [32];

- Dissolved furans analyses of the transformer oil IEC 60,567 [32].

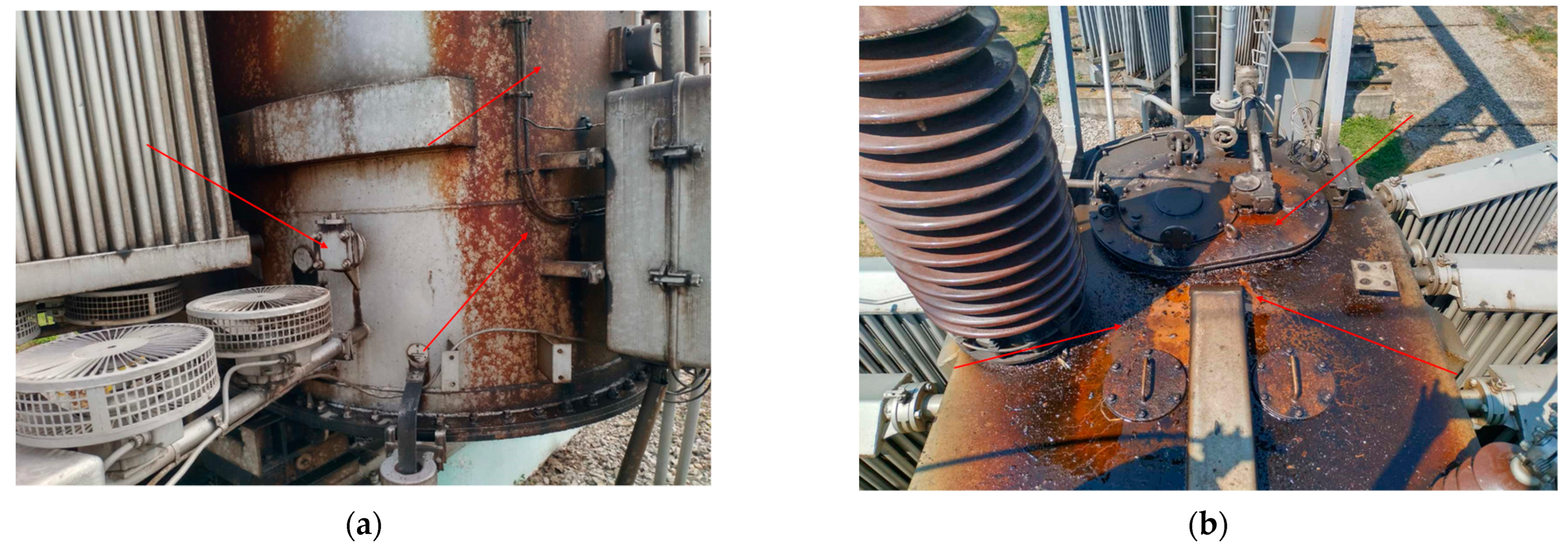

2.2. Visual Inspection Diagnostics Were Conducted on All Accessible Systems of the Transformers

- Cooling system;

- Bushings;

- Tank, conservator and valves;

- Protection instruments: breathers, Buchholz relays, temperature indicators, pressure relieve systems, magnetic oil levelers, gas relays.

2.3. Analysis of the Data Consisted of Several Methods for Assessment

- Chemical analysis of transformer oil was carried out to determine some of its parameters which are vital for the technical operation of the equipment these included the following:Electrical parameters: dielectric strength, specific resistance and dielectric dissipation factor (tan δ) [30,31].Each of these parameters has an impact on the quality and longevity of transformer oil, as well as on its insulating properties. As for the chemical parameters, excessive water content in transformer oil could lead to a reduced dielectric strength. The content of corrosive sulfur in transformer oil forms an acidic environment in the transformer oil, which leads to increased decomposition of paper insulation and the oil becoming more acidic. The acidity number is a very important parameter that characterizes the quality of transformer oil. It determines the degree of acidity of the transformer oil. The greater the number, the more acidic is the oil. This leads to increased decomposition of paper insulation and to better dissolution of water in oil so that the dielectric strength also decreases [27,28,30,31].Electrical parameters include the dielectric strength of the transformer oil, which indicates the maximum applied voltage which the oil will withstand as an insulator; specific resistance, which again reflects the insulating properties of transformer oil; and dielectric dissipation factor (tan δ), which reflects the quality of the transformer oil as an insulator and the level of losses when voltage is applied across it [27,28,30,31].

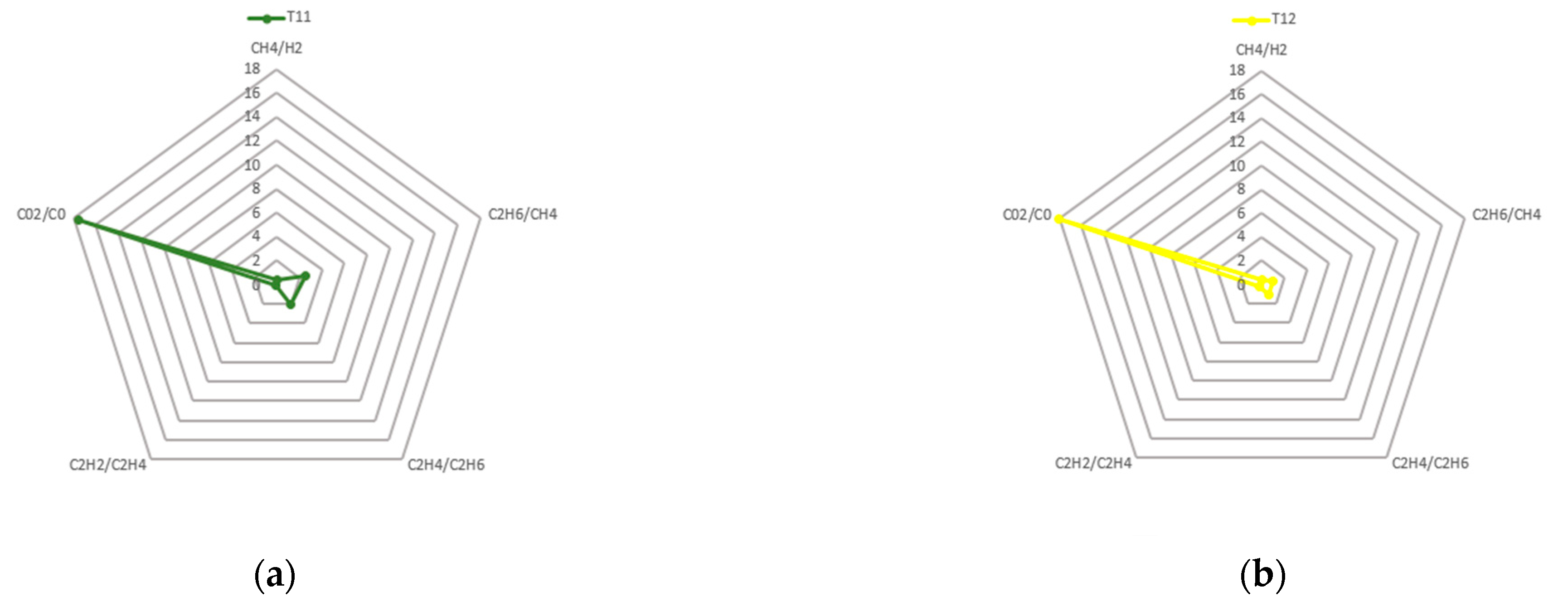

- During operation, power transformers generate decomposition gases which originate mainly from the organic insulation. The process of gas generation is due to thermal or electrical stresses, and decomposition of the transformer oil or the insulating paper. This could result from the normal exploitation of the transformer, or it could be caused by an emergency with the equipment. A certain amount of the generated gases dissolve in the transformer oil [22,26,27].Dissolved gas analysis (DGA) is a method used for analyzing the quantity of dissolved gases in transformer oil and afterward for making diagnostics of the transformer. This method is useful for detection of certain faults (thermal or electrical) and for monitoring the normal operation of transformers [32].There are various approaches for interpretation of the DGA. Generally, a combination of them is used to determine the source of gases. These methods include the identification of key gases (H2, CO2, CO, CH4, C2H4, C2H6 and C2H2) and their quantity in the oil. Increased content of more than one of these gases could be an indication for a problem. If so, the gas ratio should be determined. Then, a method for interpretating gas ratios proposed in IEC 60,599 could be used to determine the problem. Alternately, the Duval’s triangle also could be used as a method for interpretation of the results. In these methods, the levels of the determined gas ratios suggest a certain defect in the operation of the power transformer [27,32].Overall, the DGA has been used for many years, and it is a fairly accurate method for the diagnostics of transformers. It could also be employed for periodic tests, and a comparison between the results over time could be performed to follow the frequency of gas generation and determine the actual state of the transformer [32].

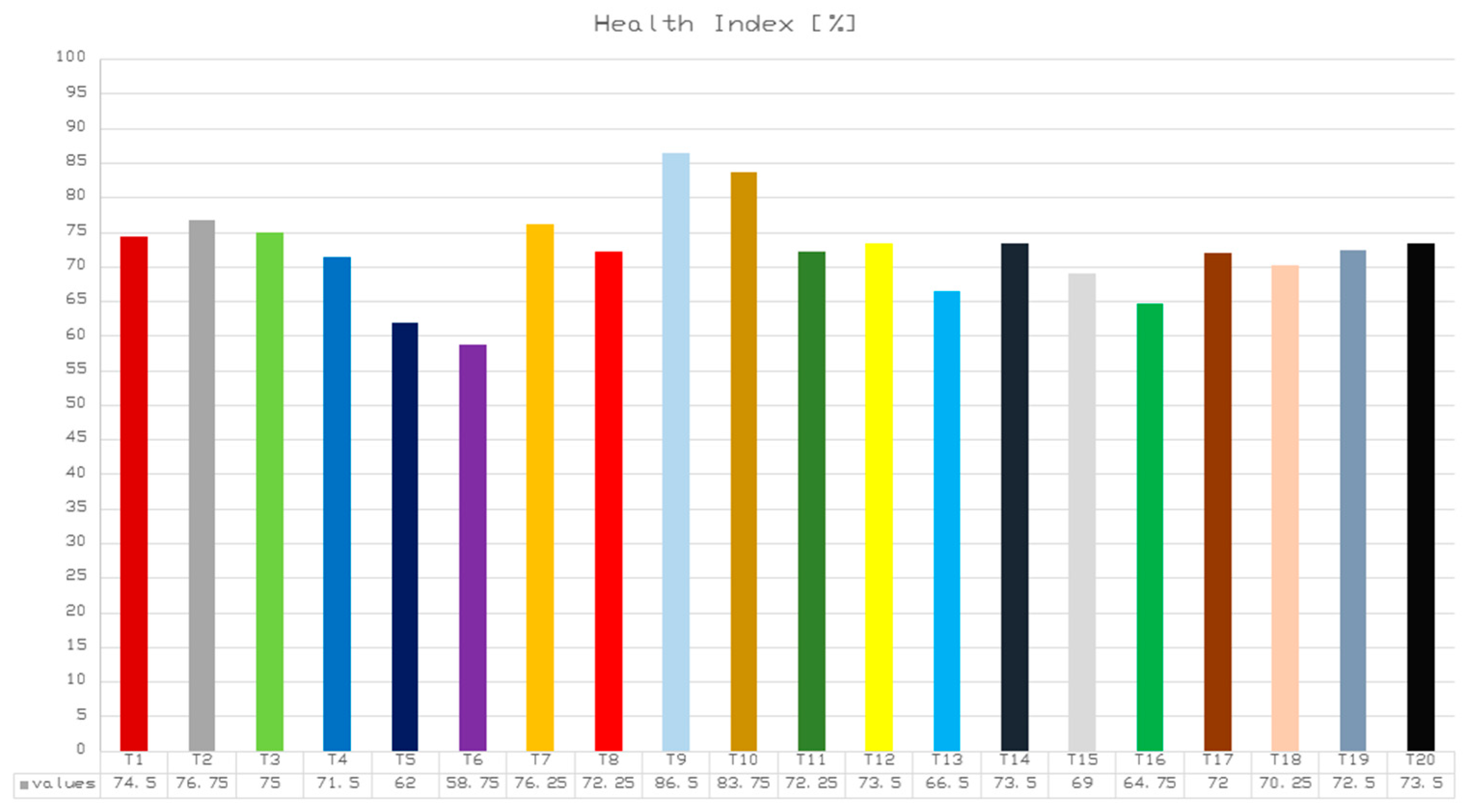

- This analysis involved calculations of the health indexes (HI) of transformers based on collected and measured data. To be able to obtain an overall picture of the condition of the transformer, measurements based on an approach with weighting coefficients is applied, through which is calculated a total HI factor [1,2]. In Figure 3 is shown calculation of HI components and results.

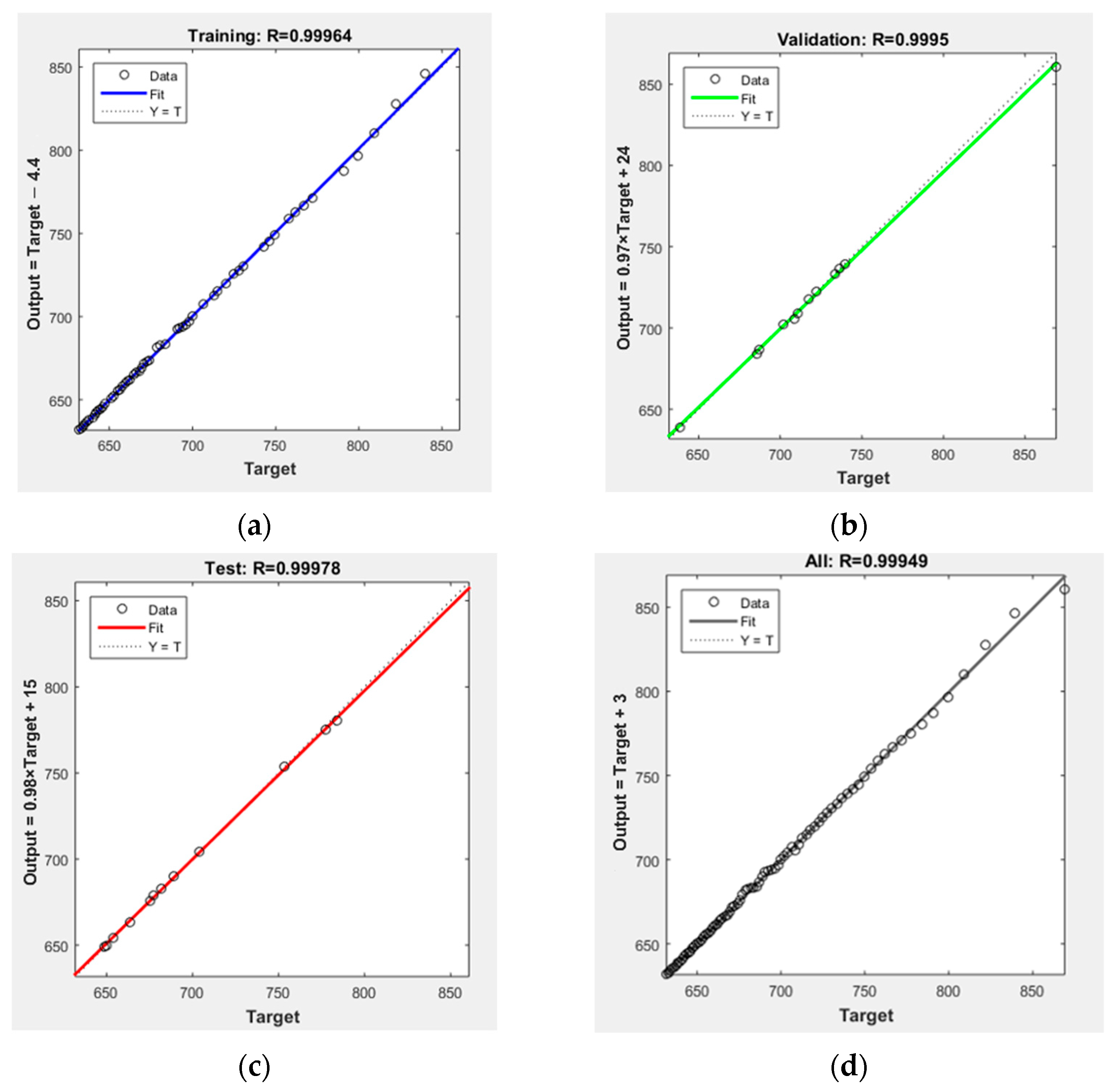

- Analysis of the remaining life of the power transformer was based on the degree of polymerization (DP) of insulation paper. The DP was calculated using indirect methods via values of furans 2-FAL in the oil. Correct estimation of DP to 2-FAL was carried out by deploying an artificial neural network (ANN) with feed-forward. The created ANN was trained with raw data of previous direct paper measurements of DP to 2-FAL. The ANN was fed data for 120 correlations between 2-FAL and DP. In Figure 5 is shown the topology of the created ANN, and in Figure 6 and Figure 7 are given some results of trained neurons [10,35,43].

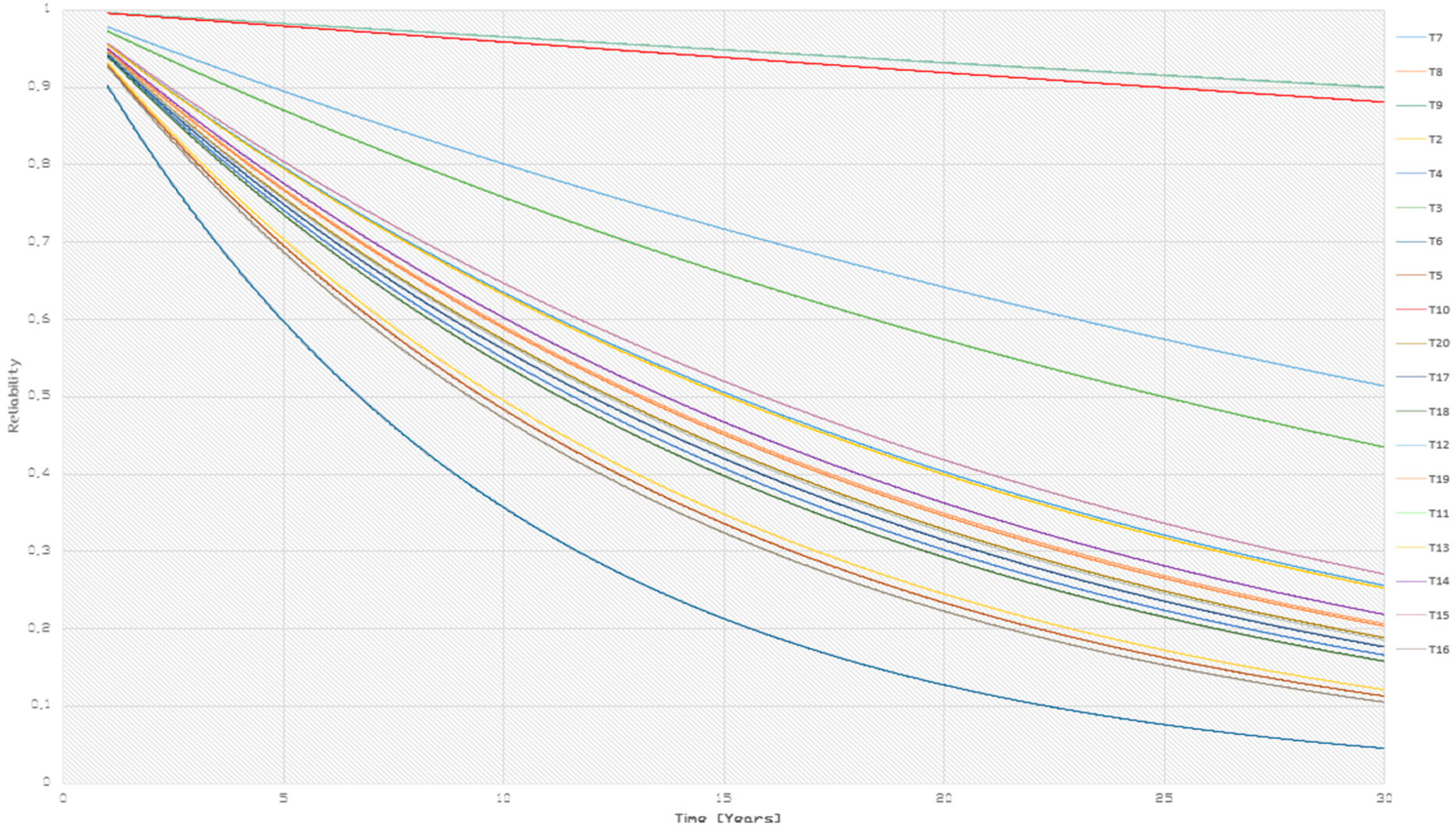

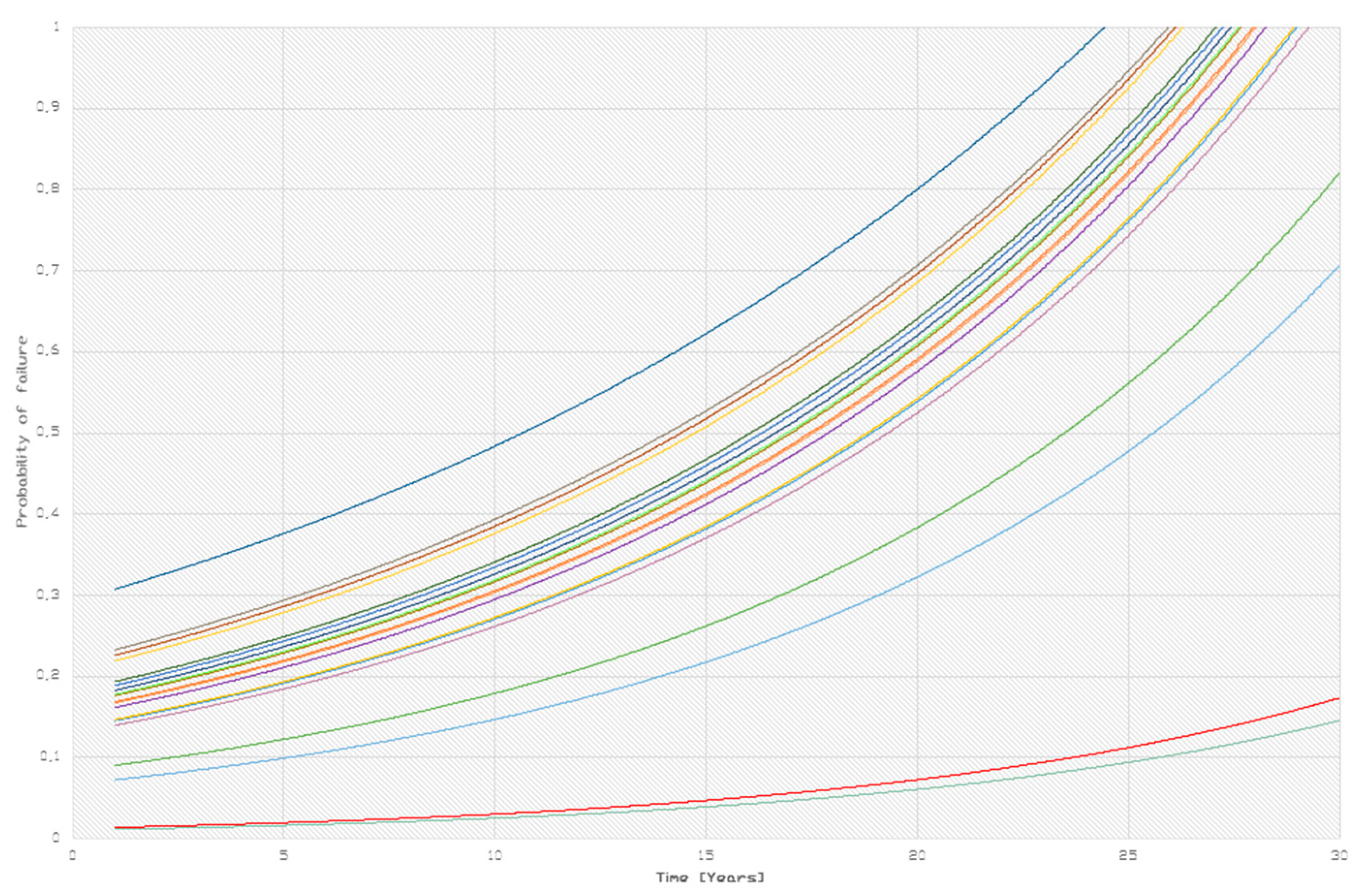

- Reliability calculations were carried out for transformers based on the calculated health index coefficient. The transformer’s reliability was defined as the ability of the unit to withstand nominal loads and stresses by maintaining its technical parameters over time. Transformer condition reliability can be calculated as follows [20,45]:where t is the time in years, and λ = f (HI).

3. Results

3.1. Transformer Oil Measurements and Test Data

3.1.1. Dissolved Gas Analysis (DGA) of the Transformer Oil

3.1.2. Chemical Analyses of the Transformer Oil

3.2. Data Collected through Visiual Inspection

3.2.1. Cooling System

3.2.2. Bushings

3.2.3. Tank, Conservator and Valves

3.2.4. Protection Instruments

3.3. Results Received through Applied Analysis on Collected Data

3.3.1. Dissolved Gas Analysis (DGA) of the Transformer Oil and Oils Tests

3.3.2. Calculated Health Indexes for Investigated Transformers

3.3.3. Calculated Degree of Polymerization

3.3.4. Calculated Reliability and Risk of Failure

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jahromi, A.; Piercy, R.; Cress, S.; Service, J.; Fan, W. An approach to power transformer asset management using health index. IEEE Electr. Insul. Mag. 2009, 25, 20–34. [Google Scholar] [CrossRef]

- Naderian, A.; Cress, S.; Piercy, R.; Wang, F.; Service, J. An approach to determine the health index of power transformers. In Proceedings of the Conference Record of the 2008 IEEE International Symposium on Electrical Insulation, Vancouver, BC, Canada, 8–11 June 2008. [Google Scholar]

- Badune, J.; Vitolina, S.; Maskalonok, V. Methods for Predicting Remaining Service Life of Power Transformers and Their Components. Power Electr. Eng. 2013, 31, 123–126. [Google Scholar]

- Hong, Y.; Meeker, W.Q.; McCalley, J.D. Prediction of remaining life of power transformers based on left truncated and right censored lifetime data. Ann. Appl. Stat. 2009, 3, 857–879. [Google Scholar] [CrossRef] [Green Version]

- Tan, C.; Wang, S.; Deng, H.; Han, G.; Du, G.; Song, W.; Zhang, X. The Health Index Prediction Model and Application of PCP in CBM Wells Based on Deep Learning. Geofluids 2021, 2021, 1–13. [Google Scholar] [CrossRef]

- Morais, N.F.O. Estimating the Remaining Lifetime of Power Transformers Using Paper Insulation Degradation. Master Thesis, Universidade do Porto, Porto, Portugal, 2018. Available online: https://hdl.handle.net/10216/115985 (accessed on 25 December 2022).

- Luopajärvi, J. Condition Monitoring of Power Transformer as Part of Power Plant Maintenance Process. Master Thesis, University of Vaasa, Vaasa, Finland, 2010. Available online: http://osuva.uwasa.fi/handle/10024/2886 (accessed on 25 December 2022).

- Quiñones, L.I.A.; Lozano-Moncada, C.A.; Montenegro, D.A.B. Machine learning for predictive maintenance scheduling of distribution transformers. J. Qual. Maint. Eng. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Tran, Q.T.; Davies, K.; Roose, L.; Wiriyakitikun, P.; Janjampop, J.; Sanseverino, E.R.; Zizzo, G. A Review of Health Assessment Techniques for Distribution Transformers in Smart Distribution Grids. Appl. Sci. 2020, 10, 8115. [Google Scholar] [CrossRef]

- Bektas, O.; Jones, J.A.; Sankararaman, S.; Roychoudhury, I.; Goebel, K. A neural network filtering approach for similarity-based remaining useful life estimation. Int. J. Adv. Manuf. Technol. 2018, 101, 87–103. [Google Scholar] [CrossRef] [Green Version]

- Dekker, K.J. Maintenance Optimization Through Remaining Useful Life Prediction A Case Study for Damen Shipyards. Master’s Thesis, Faculty of Industrial Engineering and Business Information Systems, University of Twente, Enschede, The Netherlands, 2020. [Google Scholar]

- Xu, C.; Wang, G.; Liu, X.; Guo, D.; Liu, T.-Y. Health Status Assessment and Failure Prediction for Hard Drives with Recurrent Neural Networks. IEEE Trans. Comput. 2016, 65, 3502–3508. [Google Scholar] [CrossRef]

- Yahaya, M.S.; Azis, N.; Ab Kadir, M.Z.A.; Jasni, J.; Hairi, M.H.; Talib, M.A. Estimation of Transformers Health Index Based on the Markov Chain. Energies 2017, 10, 1824. [Google Scholar] [CrossRef] [Green Version]

- Alqudsi, A.; El-Hag, A. Application of Machine Learning in Transformer Health Index Prediction. Energies 2019, 12, 2694. [Google Scholar] [CrossRef] [Green Version]

- Bohatyrewicz, P.; Mrozik, A. The Analysis of Power Transformer Population Working in Different Operating Conditions with the Use of Health Index. Energies 2021, 14, 5213. [Google Scholar] [CrossRef]

- Karlsson, S. A Review of Lifetime Assessment of Tranformers and the Use of Dissolved Gas Analysis; Elektroteknisk Teori & Konstruktion: Stockholm, Sweden, 2008. [Google Scholar]

- IEEE Std 62-1995; IEEE Guide for Diagnostic Field Testing of Electric Power Apparatus-Part 1: Oil Filled Power Transformers, Regulators, and Reactors. IEEE: Piscataway, NJ, USA, 1995.

- Guo, H.; Guo, L. Health index for power transformer condition assessment based on operation history and test data. Energy Rep. 2022, 8, 9038–9045. [Google Scholar] [CrossRef]

- Padmanaban, S.; Khalili, M.; Nasab, M.A.; Zand, M.; Shamim, A.G.; Khan, B. Determination of Power Transformers Health Index Using Parameters Affecting the Transformer’s Life. IETE J. Res. 2022, 1–22. [Google Scholar] [CrossRef]

- Nadai, N.; Melani, A.H.A.; Souza, G.F.M.; Nabeta, S.I. Equipment failure prediction based on neural network analysis incorporating maintainers inspection findings. In Proceedings of the 2017 Annual Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 23–26 January 2017; pp. 1–7. [Google Scholar] [CrossRef]

- Youssef, M.M.; Ibrahim, R.A.; Desouki, H.; Moustafa, M.M.Z. An Overview on Condition Monitoring & Health Assessment Techniques for Distribution Transformers. In Proceedings of the 2022 6th International Conference on Green Energy and Applications (ICGEA), Singapore, 4–6 March 2022; pp. 187–192. [Google Scholar] [CrossRef]

- lal Rajora, G.; Sanz-Bobi, M.A.; Domingo, C.M. Application of Machine Learning Methods for Asset Management on Power Distribution Networks. Emerg. Sci. J. 2022, 6, 905–920. [Google Scholar] [CrossRef]

- Sharma, N.K.; Bhalla, D.; Manisha; Kaur,, K. Smart Techniques for Fault Diagnosis in Power Transformer. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1228. [Google Scholar] [CrossRef]

- Bhushan, U.P.; Jarial, R.K.; Jadoun, V.K.; Agarwal, A. On Condition Monitoring Aspects of in-Service Power Transformers Using Computational Techniques. In Advances in Electromechanical Technologies; Springer: Singapore, 2021; pp. 343–355. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.; Zhang, F.; Wan, J.; Kou, L.; Ke, W. Review on Evolution of Intelligent Algorithms for Transformer Condition Assessment. Front. Energy Res. 2022, 10, 904109. [Google Scholar] [CrossRef]

- IEC 60076-1; Power transformers–Part 1: General. International Electrotechnical Commission: Geneva, Switzerland, 2011.

- IEC 60422:2013; Mineral Insulating Oils in Electrical Equipment–Supervision and Maintenance Guidance. International Electrotechnical Commission: Geneva, Switzerland, 2013.

- IEC 60296:2020; Fluids for Electrotechnical Applications—Mineral Insulating Oils for Electrical Equipment. International Electrotechnical Commission: Geneva, Switzerland, 2020.

- IEC 60814:1997; Insulating liquids—Oil-impregnated paper and pressboard—Determination of water by automatic coulometric Karl Fischer titration. International Electrotechnical Commission: Geneva, Switzerland, 1997.

- IEC 60156:2018; Insulating Liquids—Determination of the Breakdown Voltage at Power Frequency—Test Method. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- IEC 60247:2004; Insulating Liquids-Measurement of Relative Permittivity, Dielectric Dissipation Factor (tan d) and d.c. Resistivity. International Electrotechnical Commission: Geneva, Switzerland, 2004.

- IEC 60599:2022; Mineral Oil-Filled Electrical Equipment In Service—Guidance on the Interpretation of Dissolved and Free Gases Analysis. International Electrotechnical Commission: Geneva, Switzerland, 2022.

- EN 62021-1:2003; Insulating Liquids—Determination of Acidity—Part 1: Automatic Potentiometric Titration. International Electrotechnical Commission: Geneva, Switzerland, 2003.

- Badawi, M.; Ibrahim, S.A.; Mansour, D.-E.A.; El-Faraskoury, A.A.; Ward, S.A.; Mahmoud, K.; Lehtonen, M.; Darwish, M.M.F. Reliable Estimation for Health Index of Transformer Oil Based on Novel Combined Predictive Maintenance Techniques. IEEE Access 2022, 10, 25954–25972. [Google Scholar] [CrossRef]

- Thango, B.A.; Bokoro, P.N. Prediction of the Degree of Polymerization in Transformer Cellulose Insulation Using the Feedforward Backpropagation Artificial Neural Network. Energies 2022, 15, 4209. [Google Scholar] [CrossRef]

- Ma, H.; Yang, P.; Wang, F.; Wang, X.; Yang, D.; Feng, B. Short-Term Heavy Overload Forecasting of Public Transformers Based on Combined LSTM-XGBoost Model. Energies 2023, 16, 1507. [Google Scholar] [CrossRef]

- Putchala, S.R.; Kotha, R.; Guda, V.; Ramadevi, Y. Transformer Data Analysis for Predictive Maintenance. In Proceedings of the Second International Conference on Advances in Computer Engineering and Communication Systems; Springer: Singapore, 2022. [Google Scholar]

- Barkas, D.A.; Kaminaris, S.D.; Kalkanis, K.K.; Ioannidis, G.C.; Psomopoulos, C.S. Condition Assessment of Power Transformers through DGA Measurements Evaluation Using Adaptive Algorithms and Deep Learning. Energies 2022, 16, 54. [Google Scholar] [CrossRef]

- Ralchev, M.; Mateev, V.; Ivanov, G.; Marinova, I. Remote Monitoring of On-Load Tap Changer Switching Cycle Based on Acoustic Sensing. In Proceedings of the 2021 13th Electrical Engineering Faculty Conference (BulEF), Varna, Bulgaria, 8–11 September 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Salim, N.A.; Jasni, J.; Mohamad, H.; Yasin, Z.M. Transformer health index prediction using feedforward neural network according to scoring and ranking method. Int. J. Adv. Technol. Eng. Explor. 2021, 8, 292–303. [Google Scholar] [CrossRef]

- Peimankar, A. Intelligent Condition Assessment of Power Transformers; University of Canterbury: Christchurch, New Zealand, 2017. [Google Scholar]

- Voronov, S. Machine Learning Models for Predictive Maintenance. Ph.D. Thesis, Linköping University Electronic, Linköping, Sweden, 2020. [Google Scholar] [CrossRef]

- Roland, U.; Eseosa, O. Artificial neural network approach to distribution transformers maintenance. Int. J. Sci. Res. Eng. Technol. 2015, 1, 62–70. [Google Scholar]

- Taha, I.B.M.; Ibrahim, S.; Mansour, D.-E.A. Power Transformer Fault Diagnosis Based on DGA Using a Convolutional Neural Network with Noise in Measurements. IEEE Access 2021, 9, 111162–111170. [Google Scholar] [CrossRef]

- Ibrahim, K.; Sharkawy, R.; Temraz, H.; Salama, M. Reliability calculations based on an enhanced transformer life expectancy model. Ain Shams Eng. J. 2021, 13, 101661. [Google Scholar] [CrossRef]

| Index | Serial Number | Rated Power and Rated Voltage | Year of Manufacturing |

|---|---|---|---|

| T1 | 109553 | 10.5 MVA 110 kV/27.5 kV | 1984 |

| T2 | 109153 | 10.5 MVA 110 kV/27.5 kV | 1981 |

| T3 | 111927 | 10.5 MVA 110 kV/27.5 kV | 1987 |

| T4 | 109152 | 10.5 MVA 110 kV/27.5 kV | 1984 |

| T5 | 108628 | 10.5 MVA 110 kV/27.5 kV | 1988 |

| T6 | 106647 | 10.5 MVA 110 kV/27.5 kV | 1982 |

| T7 | 103642 | 8.33 MVA 110 kV/27.5 kV | 1980 |

| T8 | 103643 | 8.33 MVA 110 kV/27.5 kV | 1980 |

| T9 | 112752 | 10.33 MVA 110 kV/27.5 kV | 2003 |

| T10 | 112753 | 10.33 MVA 110 kV/27.5 kV | 2003 |

| T11 | 85234 | 8.33 MVA 110 kV/27.5 kV | 1973 |

| T12 | 94209 | 8.33 MVA 110 kV/27.5 kV | 1991 |

| T13 | 109554 | 10.5 MVA 110 kV/27.5 kV | 1984 |

| T14 | 109555 | 10.5 MVA 110 kV/27.5 kV | 1984 |

| T15 | 110932 | 10.5 MVA 110 kV/27.5 kV | 1988 |

| T16 | 110981 | 10.5 MVA 110 kV/27.5 kV | 1985 |

| T17 | 108269 | 10.5 MVA 110 kV/27.5 kV | 1983 |

| T18 | 108270 | 10.5 MVA 110 kV/27.5 kV | 1983 |

| T19 | 95833 | 10.5 MVA 110 kV/27.5 kV | 1980 |

| T20 | 105090 | 10.5 MVA 110 kV/27.5 kV | 1981 |

| No. | Criteria | S | Grades | HIW |

|---|---|---|---|---|

| 1 | DGA | 16 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| 2 | Load History | 5 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| 3 | Temperature and hot spots | 3 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| 4 | Oil Quality | 16 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| 5 | Furans | 8 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| 6 | Water content in insulating paper | 4 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| 7 | Bushing Condition | 4 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| 8 | Tank Corrosion | 3 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| 9 | Cooling System Condition | 4 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| 10 | Gaskets Condition | 2 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| 11 | Protection Instruments Condition | 5 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| 12 | Oil Leaks | 3 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| 13 | Oil Level | 1 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| 14 | Overall Condition of Tap Changer | 26 | A, B, C, D, E | 4, 3, 2, 1, 0 |

| Index | Hydrogen H2 | Ethylene C2H4 | Acetylene C2H2 | Ethane C2H6 | Methane CH4 | Carbon Monoxide CO | Carbon Dioxide CO2 |

|---|---|---|---|---|---|---|---|

| T1 | 5 | 16 | 0.5 | 8 | 2 | 53 | 723 |

| T2 | 5 | 11 | 0.5 | 17 | 2 | 87 | 762 |

| T3 | 5 | 6 | 5.5 | 2 | 2 | 69 | 638 |

| T4 | 5 | 15 | 8 | 3 | 2 | 82 | 702 |

| T5 | 9 | 63 | 115.5 | 2 | 13 | 102 | 944 |

| T6 | 5 | 35 | 58.6 | 9 | 6 | 74 | 794 |

| T7 | 5 | 19 | 3 | 3 | 2 | 69 | 767 |

| T8 | 5 | 21 | 2 | 7 | 2 | 57 | 820 |

| T9 | 5 | 7 | 0.5 | 2 | 2 | 64 | 936 |

| T10 | 5 | 4 | 0.5 | 2 | 2 | 63 | 960 |

| T11 | 5 | 10 | 0.5 | 5 | 2 | 50 | 874 |

| T12 | 5 | 2 | 0.5 | 2 | 2 | 29 | 522 |

| T13 | 5 | 17 | 10.1 | 7 | 2 | 39 | 899 |

| T14 | 5 | 15 | 8 | 2 | 2 | 40 | 899 |

| T15 | 5 | 16 | 11.5 | 2 | 4 | 92 | 802 |

| T16 | 5 | 27 | 18.7 | 11 | 8 | 89 | 771 |

| T17 | 5 | 28 | 2 | 6 | 2 | 57 | 797 |

| T18 | 5 | 19 | 5 | 2 | 2 | 49 | 773 |

| T19 | 5 | 9 | 8 | 8 | 2 | 74 | 788 |

| T20 | 5 | 21 | 2 | 10 | 4 | 27 | 857 |

| Observed Defect | Number Transformers Observed with the Defect | Transformers without Noted Defect |

|---|---|---|

| Corrosion on coolers | 17 | T6, T7 and T17 |

| Corrosion on fans | 5 | T1 to T3, T5 to T11, T13 to T15 and T19 to T20 |

| Oil leakages from coolers | 18 | T9 and T10 |

| Oil leakages from valves | 20 | - |

| Missing coolers | 5 | T1, T2, T4 to T10, T12 to T15 and T19 to T20 |

| Missing fans | 9 | T4 to T12 and T15, T16 |

| Observed Defect | Number of Transformers Observed with the Defect | Transformers without Noted Defect |

|---|---|---|

| Oil leakage LV bushing | 14 | T7 to T10 and T15, T16 |

| Oil leakage HV bushings | 17 | T10, T15 and T16 |

| Broken porcelain LV bushing | 3 | T1 to T9 and T12 to T19 |

| Broken porcelain HV bushing | 2 | T1 to T13 and T15 to T18 |

| Polluted LV bushing | 17 | T7 to T9 |

| Polluted HV bushings | 20 | - |

| Observed Defect | Number of Transformers with Observed Defect | Transformers without Noted Defect |

|---|---|---|

| Medium to high corrosion on tank | 18 | T9 and T10 |

| Oil leaks from tank | 19 | T10 |

| Medium to high corrosion on conservator | 18 | T9 and T10 |

| Oil leaks from conservator | 18 | T9 and T10 |

| Medium to high corrosion on valves | 19 | T9 |

| Oil leaks from valves | 19 | T10 |

| Oil leaks from tap changer | 19 | T10 |

| Observed Defect | Number of Transformers with Observed Defect | Transformers without Noted Defect |

|---|---|---|

| Missing magnetic oil level indicator | 14 | T3, T4, T9, T10 and T15, T16 |

| Faulty magnetic oil level indicator | 2 | T1 to T10 and T13 to T20 |

| Missing oil temperature indicator | 2 | T1 to T13, T15 and T17 to T20 |

| Faulty oil temperature indicator | 7 | T2, T3, T7, T9 to T14, T16 to T18, T20 |

| Breather with wet silica | 12 | T3, T4, T12, T13, T15, T17, T19 and T20 |

| Index | DGA Results | Oil Tests Results |

|---|---|---|

| T1 | No fault detected | Normal |

| T2 | No fault detected | Normal |

| T3 | No fault detected | Normal |

| T4 | No fault detected | Normal |

| T5 | Fault was detected with low-intensity partial discharges and overheating with temperature below T < 300 °C | High acid number |

| T6 | Fault was detected with low-intensity partial discharges and overheating with temperature below T < 300 °C | Normal |

| T7 | No fault detected | Normal |

| T8 | No fault detected | Normal |

| T9 | No fault detected | Normal |

| T10 | No fault detected | Normal |

| T11 | No fault detected | Normal |

| T12 | No fault detected | Normal |

| T13 | No fault detected | Normal |

| T14 | No fault detected | Normal |

| T15 | No fault detected. High quantities of acetylene, C2H2, caution is needed. | High acid number |

| T16 | No fault detected. High quantities of acetylene, C2H2, caution is needed. | Normal |

| T17 | No fault detected | Normal |

| T18 | No fault detected | Normal |

| T19 | No fault detected | High acid number |

| T20 | No fault detected | High acid number |

| Health Index [%] | Condition | Expected Years of Service | Number of Transformers |

|---|---|---|---|

| 85–100 | Excellent | >15 | 1 |

| 70–85 | Good | >10 | 14 |

| 50–70 | Fair | <10 | 5 |

| 30–50 | Poor | <3 | 0 |

| 0–30 | Very Poor | End of life | 0 |

| DP Units | Condition | Number of Transformers |

|---|---|---|

| 600–800 | Normal Aging Rate | 20 |

| 360–600 | Accelerated Aging Rate | 0 |

| 300–360 | Excessive Aging Rate (Danger Zone) | 0 |

| 200–300 | High Risk of Failure | 0 |

| <200 | End of life | 0 |

| Action | Transformers | Criteria | |||

|---|---|---|---|---|---|

| DGA | HI | DP | R | ||

| Repair | T5 | Poor | Fair | Excellent | Poor |

| T6 | Poor | Fair | Excellent | Poor | |

| Close monitoring and further diagnostics | T15 | Fair | Fair | Excellent | Fair |

| T16 | Fair | Fair | Excellent | Fair | |

| Maintenance | T1 | Excellent | Good | Excellent | Good |

| T2 | Excellent | Good | Excellent | Good | |

| T3 | Excellent | Good | Excellent | Good | |

| T4 | Excellent | Good | Excellent | Good | |

| T7 | Excellent | Good | Excellent | Good | |

| T8 | Excellent | Good | Excellent | Good | |

| T9 | Excellent | Excellent | Excellent | Good | |

| T10 | Excellent | Good | Excellent | Good | |

| T11 | Excellent | Good | Excellent | Good | |

| T12 | Excellent | Good | Excellent | Good | |

| T13 | Excellent | Fair | Excellent | Good | |

| T14 | Excellent | Good | Excellent | Good | |

| T17 | Excellent | Good | Excellent | Good | |

| T18 | Excellent | Good | Excellent | Good | |

| T19 | Excellent | Good | Excellent | Good | |

| T20 | Excellent | Good | Excellent | Good | |

| Method Used | Number of Transformers | |||

|---|---|---|---|---|

| Excellent | Fair | Good | Poor | |

| Dissolved gas analysis | 16 | 2 | 0 | 2 |

| Health Index | 1 | 5 | 14 | 0 |

| Degree of Polymerization | 20 | 0 | 0 | 0 |

| Risk of failure | 0 | 2 | 16 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ivanov, G.; Spasova, A.; Mateev, V.; Marinova, I. Applied Complex Diagnostics and Monitoring of Special Power Transformers. Energies 2023, 16, 2142. https://doi.org/10.3390/en16052142

Ivanov G, Spasova A, Mateev V, Marinova I. Applied Complex Diagnostics and Monitoring of Special Power Transformers. Energies. 2023; 16(5):2142. https://doi.org/10.3390/en16052142

Chicago/Turabian StyleIvanov, Georgi, Anelia Spasova, Valentin Mateev, and Iliana Marinova. 2023. "Applied Complex Diagnostics and Monitoring of Special Power Transformers" Energies 16, no. 5: 2142. https://doi.org/10.3390/en16052142

APA StyleIvanov, G., Spasova, A., Mateev, V., & Marinova, I. (2023). Applied Complex Diagnostics and Monitoring of Special Power Transformers. Energies, 16(5), 2142. https://doi.org/10.3390/en16052142