Sensitivity Analysis of the Complex Dynamics of an Expansion Process in Low-Pressure Compressed Air for an Electrical Energy Storage System

Abstract

1. Introduction

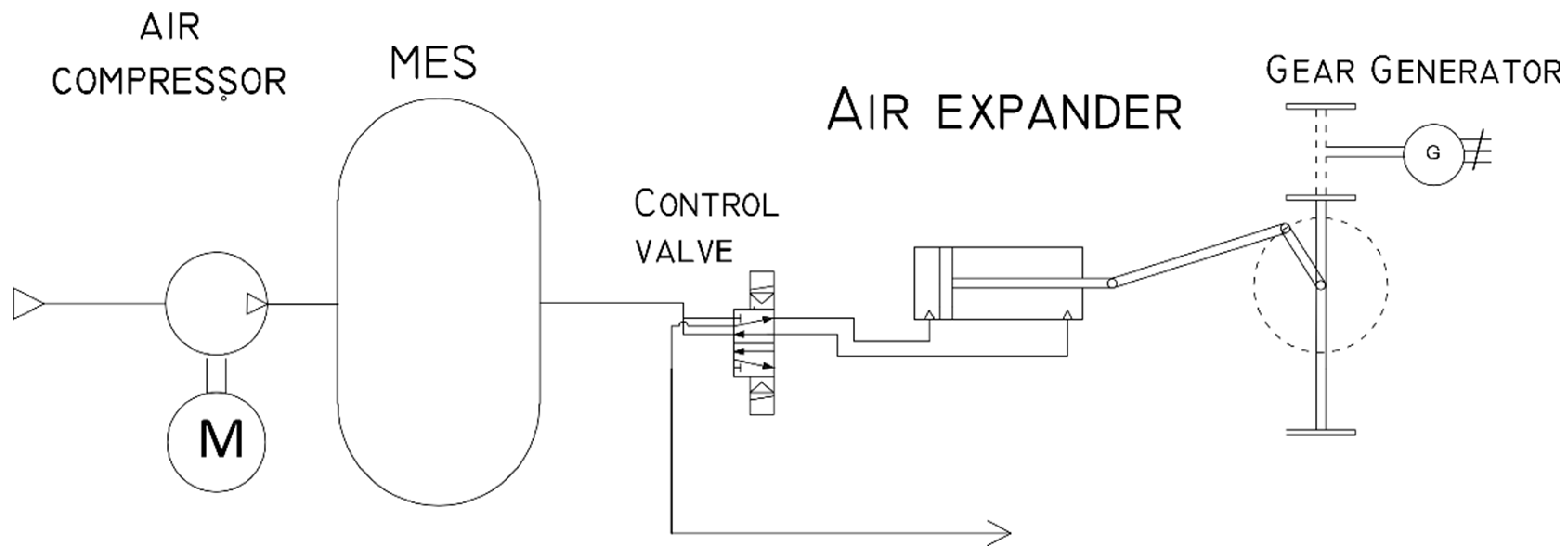

2. Materials and Methods

2.1. Mathematical Model

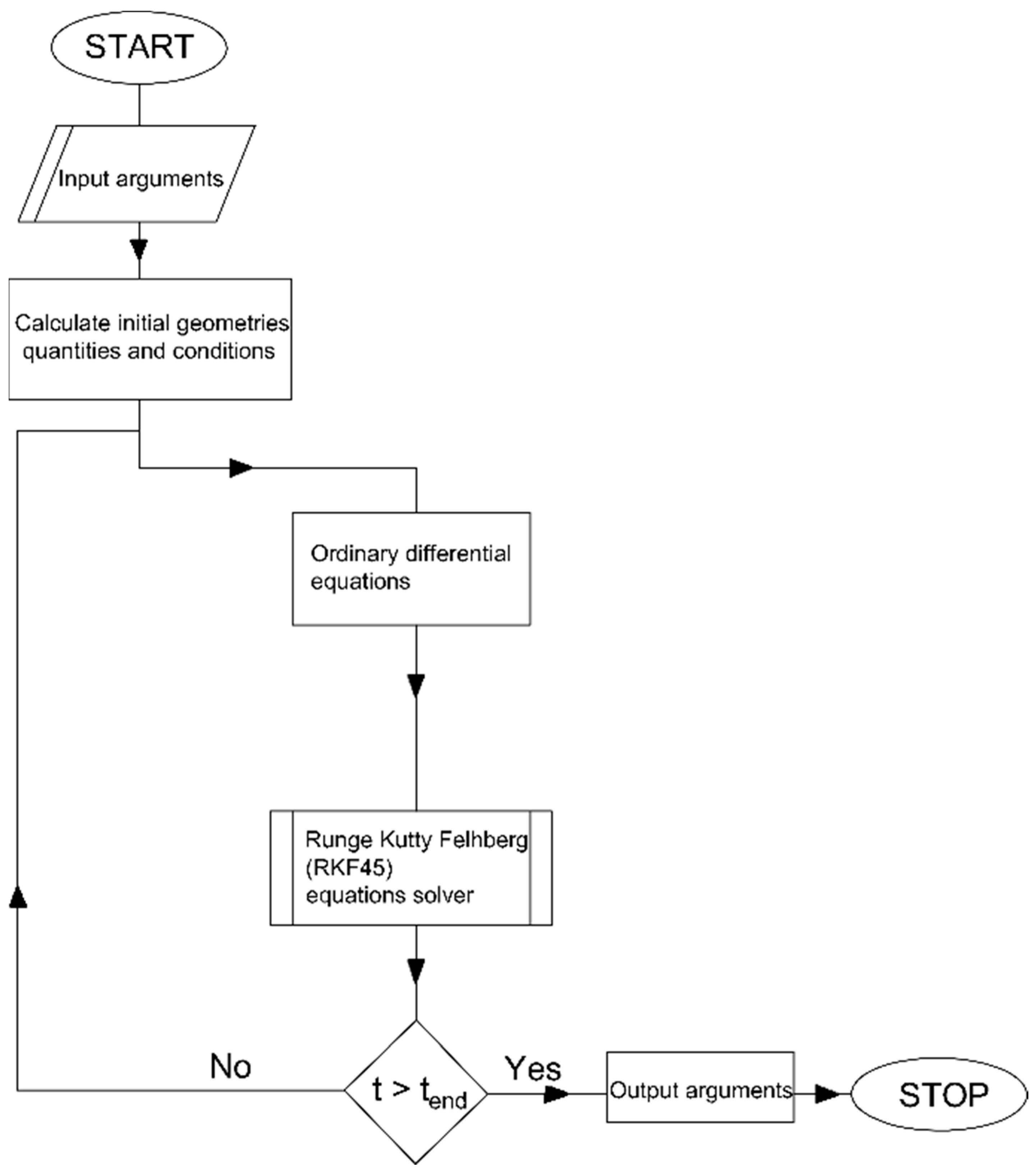

2.2. Solution Procedure

3. Results

3.1. Research Motivation

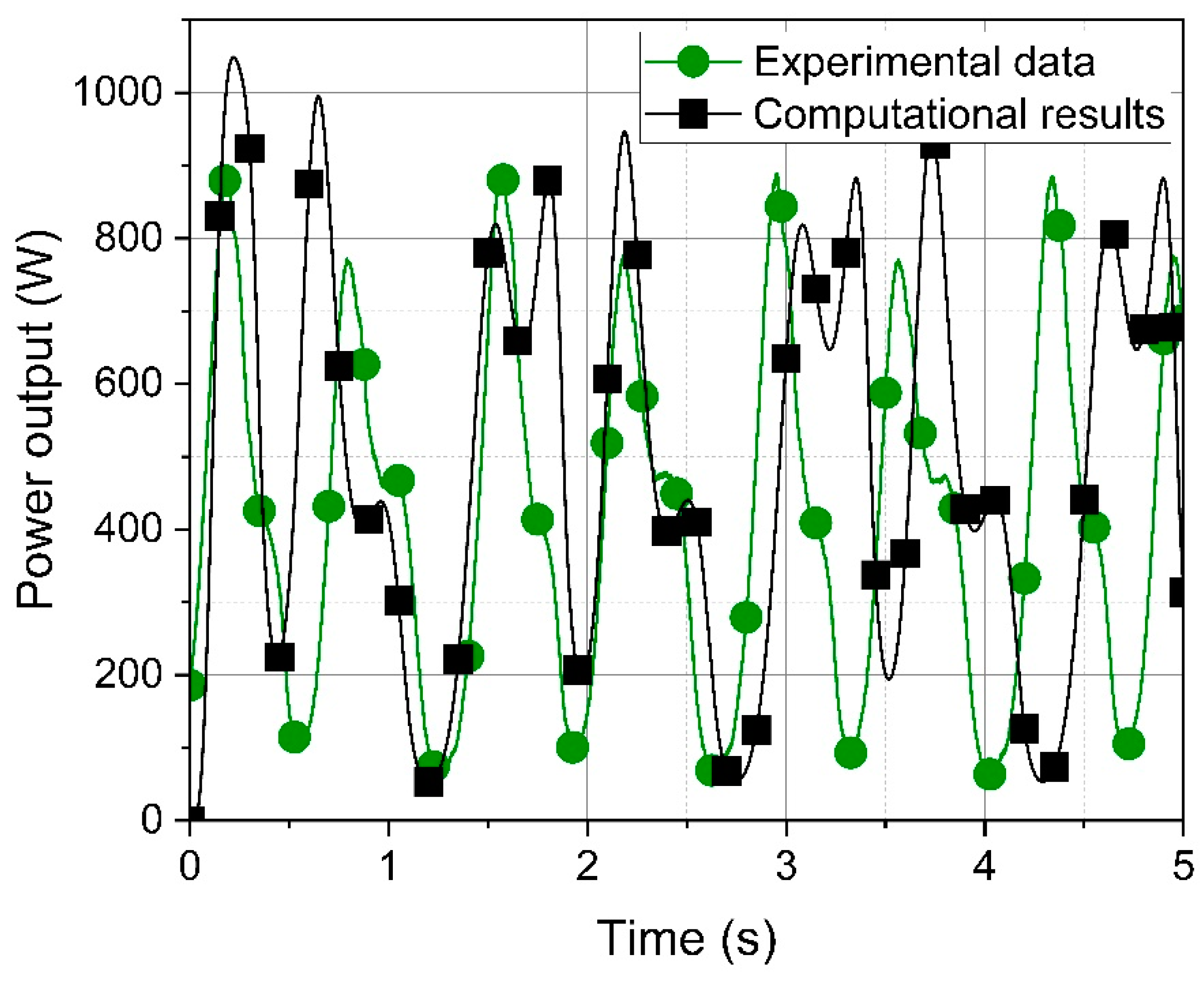

3.2. Validation

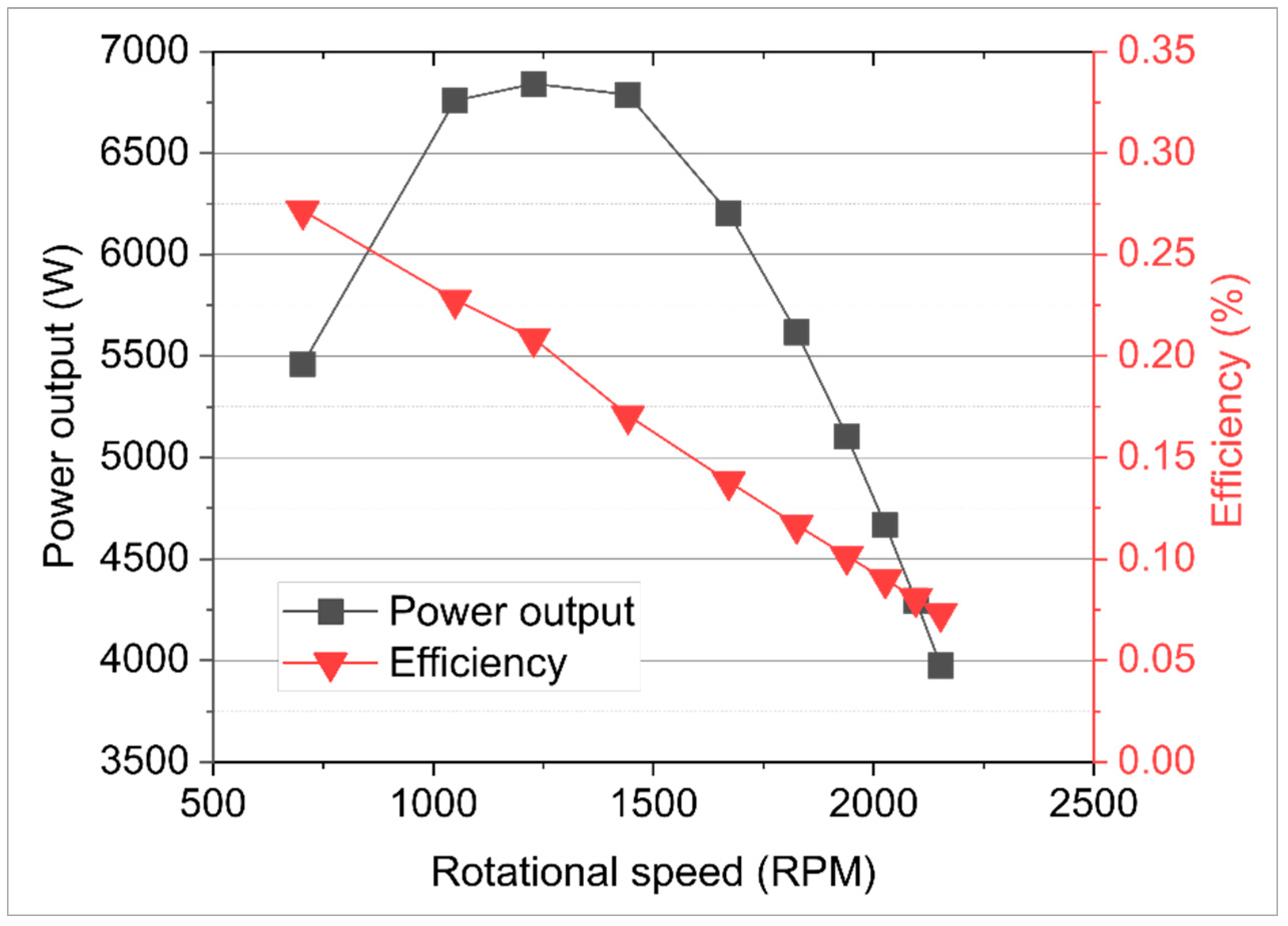

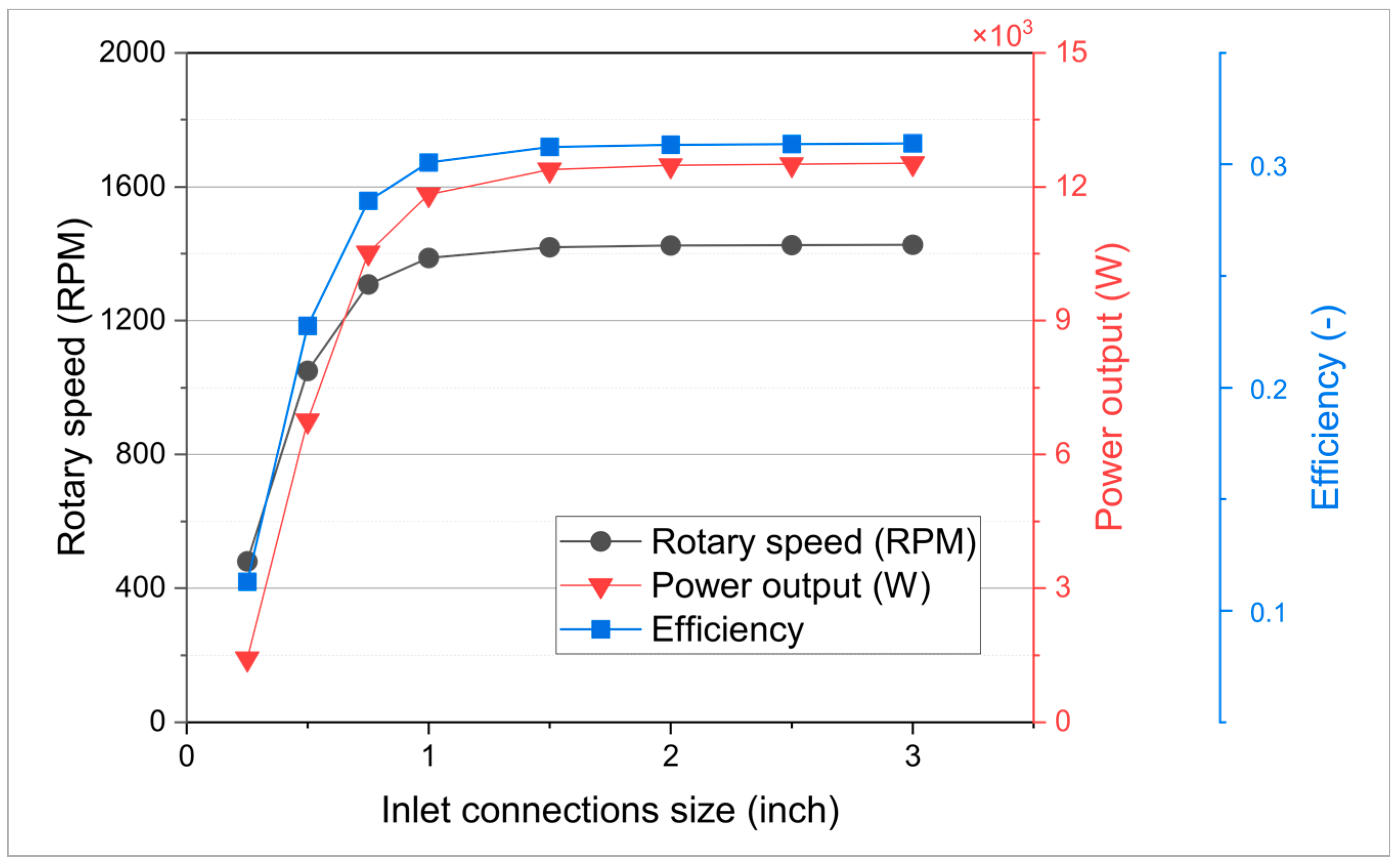

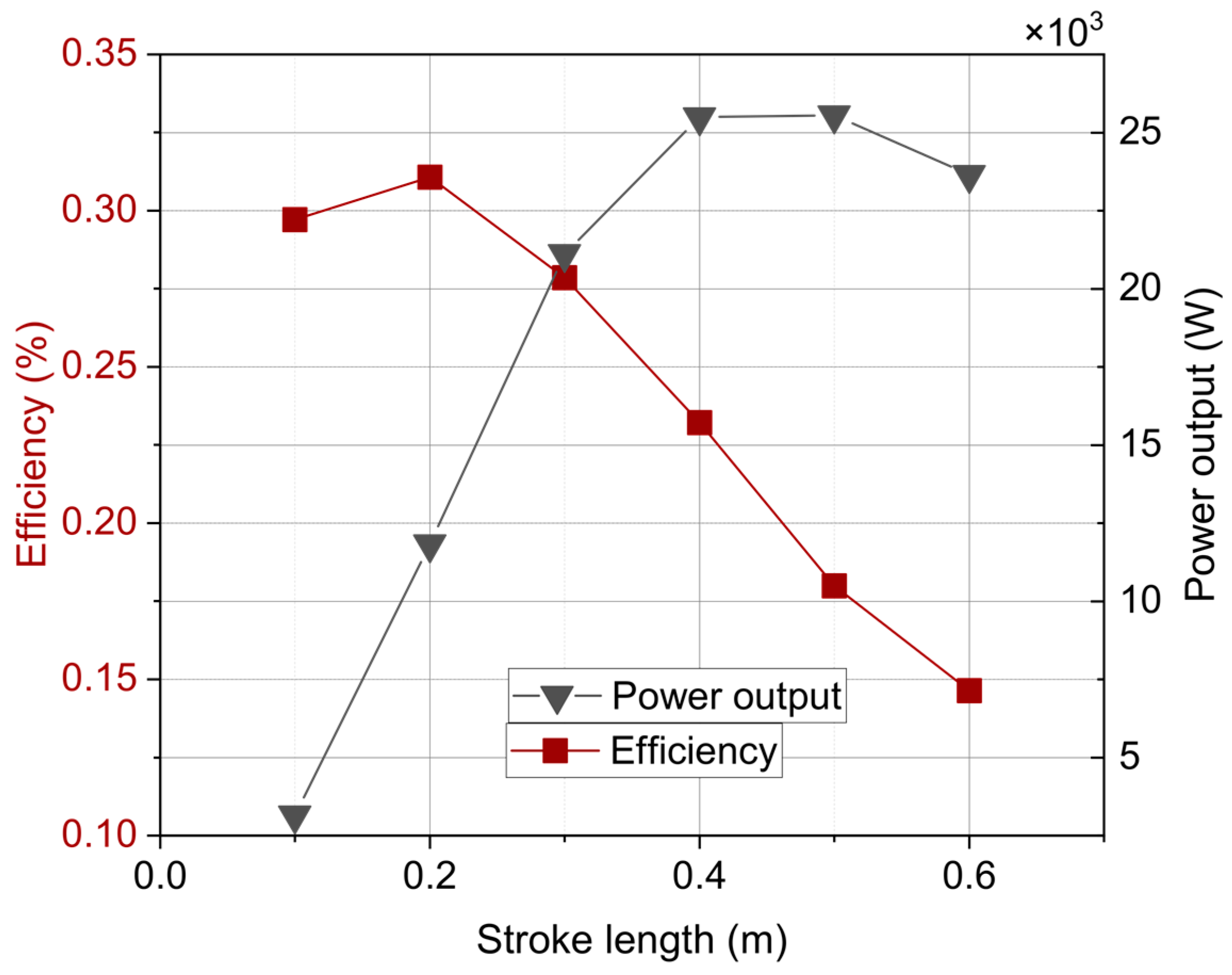

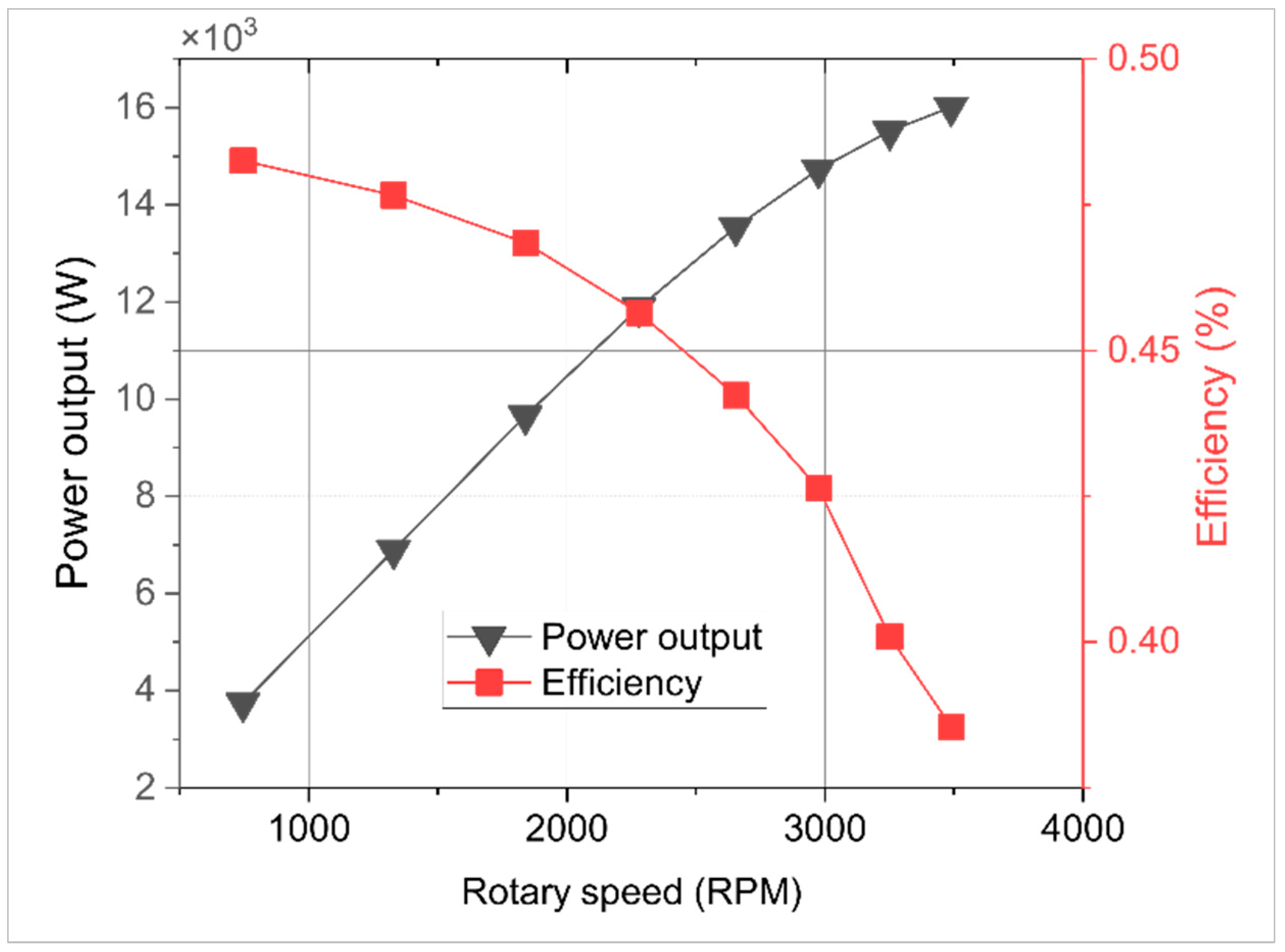

3.3. Computer Simulations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bollinger, B. Demonstration of Isothermal Compressed Air Energy Storage to Support Renewable Energy Production; SustainX Smart Grid Program, Technical Raport; OSTI: Pittsburgh, PA, USA; Morgantown, WV, USA, 2015. [Google Scholar] [CrossRef]

- Chen, H.; Cong, T.N.; Yang, W.; Tan, C.; Li, Y.; Ding, Y. Progress in Electrical Energy Storage System: A Critical Review. Prog. Nat. Sci. 2009, 19, 291–312. [Google Scholar] [CrossRef]

- Mitali, J.; Dhinakaran, S.; Mohamad, A.A. Energy Storage Systems: A Review. Energy Storage Sav. 2022, 1, 166–216. [Google Scholar] [CrossRef]

- Maia, T.A.C.; Barros, J.E.M.; Cardoso Filho, B.J.; Porto, M.P. Experimental Performance of a Low Cost Micro-CAES Generation System. Appl. Energy 2016, 182, 358–364. [Google Scholar] [CrossRef]

- Tallini, A.; Vallati, A.; Cedola, L. Applications of Micro-CAES Systems: Energy and Economic Analysis. Energy Procedia 2015, 82, 797–804. [Google Scholar] [CrossRef]

- He, W.; Luo, X.; Evans, D.; Busby, J.; Garvey, S.; Parkes, D.; Wang, J. Exergy Storage of Compressed Air in Cavern and Cavern Volume Estimation of the Large-Scale Compressed Air Energy Storage System. Appl. Energy 2017, 208, 745–757. [Google Scholar] [CrossRef]

- Shengwei, M.; Wang, J.; Fang, T.; Laijun, C.; Xiaodai, X.; Qiang, L.U.; Yuan, Z.; Zhou, X. Science China Design and Engineering Implementation of Non-Supplementary Fired Compressed Air Energy Storage System: TICC-500. Sci. China Tech. Sci. 2015, 58, 600–611. [Google Scholar] [CrossRef]

- Technology—Hydrostor. Available online: https://www.hydrostor.ca/technology/ (accessed on 19 November 2022).

- Camargos, T.P.L.; Pottie, D.L.F.; Ferreira, R.A.M.; Maia, T.A.C.; Porto, M.P. Experimental Study of a PH-CAES System: Proof of Concept. Energy 2018, 165, 630–638. [Google Scholar] [CrossRef]

- Barbour, E.R.; Pottie, D.L.; Eames, P. Why Is Adiabatic Compressed Air Energy Storage yet to Become a Viable Energy Storage Option? iScience 2021, 24, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Mazloum, Y.; Sayah, H.; Nemer, M. Exergy Analysis and Exergoeconomic Optimization of a Constant-Pressure Adiabatic Compressed Air Energy Storage System. J. Energy Storage 2017, 14, 192–202. [Google Scholar] [CrossRef]

- Tong, Z.; Wang, H.; Xiong, W.; Ting, D.S.; Carriveau, R.; Wang, Z. Accumulated and Transient Exergy Analyses of Pneumatic Systems with Isochoric and Isobaric Compressed Air Storage Tanks. Energy Storage 2021, 3, 1–10. [Google Scholar] [CrossRef]

- Mazloum, Y.; Sayah, H.; Nemer, M. Dynamic Modeling and Simulation of an Isobaric Adiabatic Compressed Air Energy Storage (IA-CAES) System. J. Energy Storage 2017, 11, 178–190. [Google Scholar] [CrossRef]

- Wang, H.; Tong, Z.; Dong, X.; Xiong, W.; Ting, D.S.K.; Carriveau, R.; Wang, Z. Design and Energy Saving Analysis of a Novel Isobaric Compressed Air Storage Device in Pneumatic Systems. J. Energy Storage 2021, 38, 102614. [Google Scholar] [CrossRef]

- Budt, M.; Wolf, D.; Span, R.; Yan, J. A Review on Compressed Air Energy Storage: Basic Principles, Past Milestones and Recent Developments. Appl. Energy 2016, 170, 250–268. [Google Scholar] [CrossRef]

- Qing, S.; Wang, Y.; Wen, X.; Zhong, J.; Gou, X.; Tang, S. Optimal Working-Parameter Analysis of an Ejector Integrated into the Energy-Release Stage of a Thermal-Storage Compressed Air Energy Storage System under Constant-Pressure Operation: A Case Study. Energy Convers Manag. 2021, 247, 114715. [Google Scholar] [CrossRef]

- He, W.; Wang, J. Optimal Selection of Air Expansion Machine in Compressed Air Energy Storage: A Review. Renew. Sustain. Energy Rev. 2018, 87, 77–95. [Google Scholar] [CrossRef]

- Leszczyński, J.S.; Gryboś, D. Compensation for the Complexity and Over-Scaling in Industrial Pneumatic Systems by the Accumulation and Reuse of Exhaust Air. Appl. Energy 2019, 239, 1130–1141. [Google Scholar] [CrossRef]

- Cai, M.; Kagawa, T.; Kawashima, K. Energy Conversion Mechanics and Power Evaluation of Compressible Fluid in Pneumatic Actuator Systems. In Proceedings of the 37th Intersociety Energy Conversion Engineering Conference (IECEC) 2002, Washington, DC, USA, 29–31 July 2002; pp. 471–474. [Google Scholar]

- Mohd Nor, M.A.; Suwa, Y. Evaluation of the Accuracy of Trajectory Time Integration Used for Lagrangian Particle Tracking. Earozoru Kenkyu 2022, 37, 127–135. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Cylinder Stroke | 0.2 | m |

| Cylinder diameter | 0.1 | m |

| Crank length | 0.1 | m |

| Crank arm length | 0.42 | m |

| Supply pressure | 7 | bar |

| Inlet ports size | 0.5 | inch |

| Temperature of stored air | 293 | K |

| From 1 to 9 | Ohm | |

| 0.13 | Ohm | |

| 6 | - | |

| 0.26 | mH | |

| 0.08 | Wb |

| Expander | Efficiency [%] |

|---|---|

| One Cylinder engine | 19 |

| Three-cylinders engine | 32 |

| Three-cylinder engine with air injection system | 48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leszczyński, J.; Markowski, J.; Gryboś, D.; Suwa, Y. Sensitivity Analysis of the Complex Dynamics of an Expansion Process in Low-Pressure Compressed Air for an Electrical Energy Storage System. Energies 2023, 16, 2310. https://doi.org/10.3390/en16052310

Leszczyński J, Markowski J, Gryboś D, Suwa Y. Sensitivity Analysis of the Complex Dynamics of an Expansion Process in Low-Pressure Compressed Air for an Electrical Energy Storage System. Energies. 2023; 16(5):2310. https://doi.org/10.3390/en16052310

Chicago/Turabian StyleLeszczyński, Jacek, Jan Markowski, Dominik Gryboś, and Yoshihide Suwa. 2023. "Sensitivity Analysis of the Complex Dynamics of an Expansion Process in Low-Pressure Compressed Air for an Electrical Energy Storage System" Energies 16, no. 5: 2310. https://doi.org/10.3390/en16052310

APA StyleLeszczyński, J., Markowski, J., Gryboś, D., & Suwa, Y. (2023). Sensitivity Analysis of the Complex Dynamics of an Expansion Process in Low-Pressure Compressed Air for an Electrical Energy Storage System. Energies, 16(5), 2310. https://doi.org/10.3390/en16052310