Optimization of CO2 Huff-n-Puff in Unconventional Reservoirs with a Focus on Pore Confinement Effects, Fluid Types, and Completion Parameters

Abstract

:1. Introduction

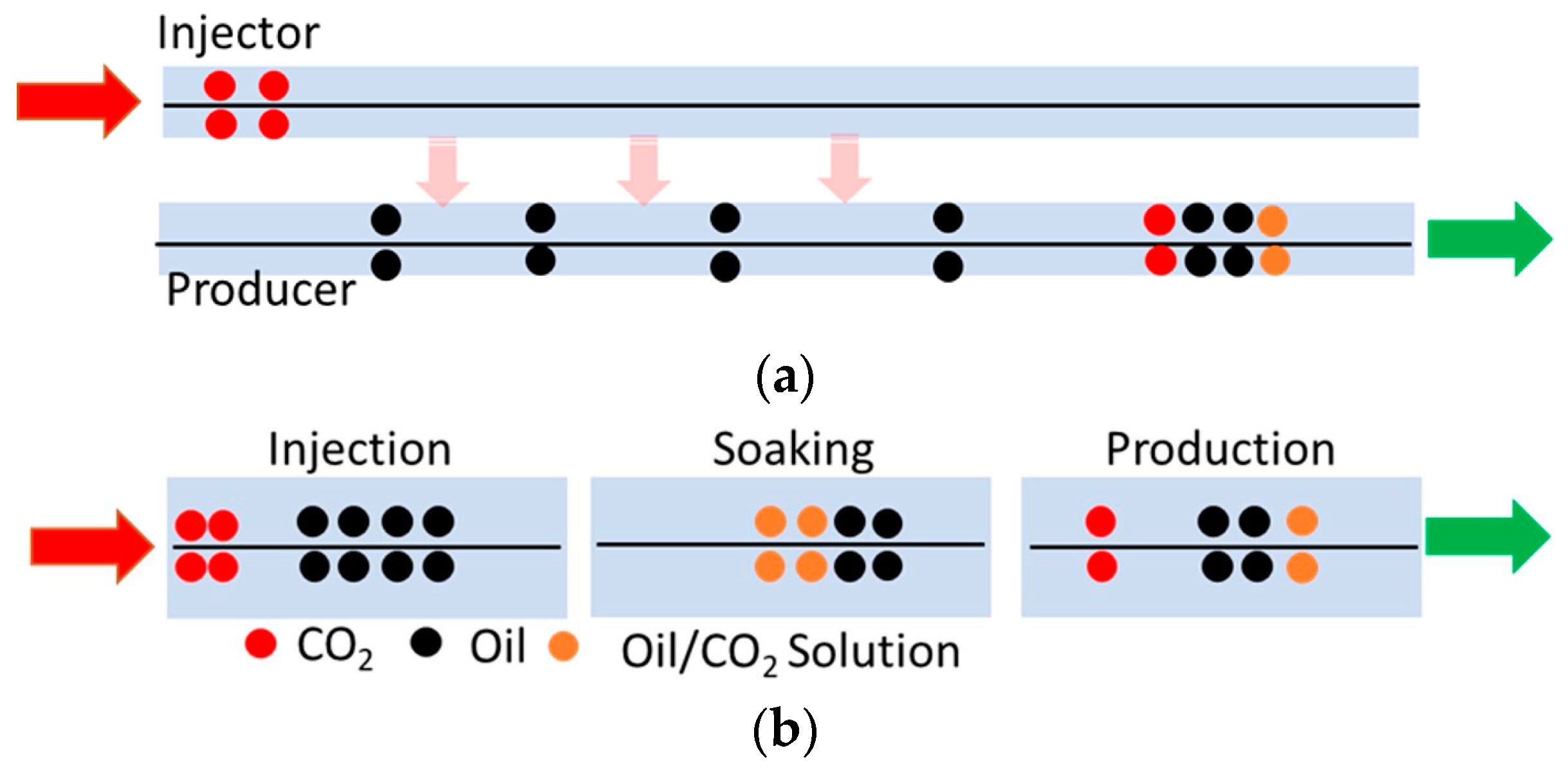

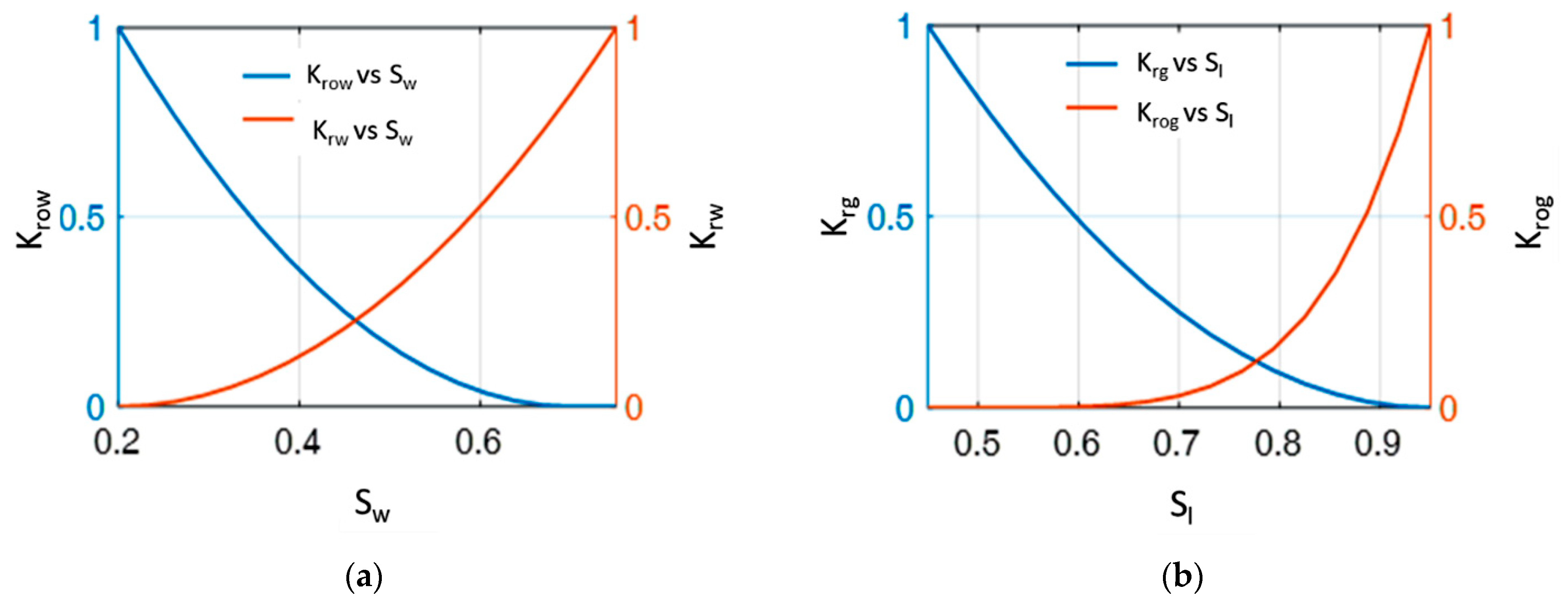

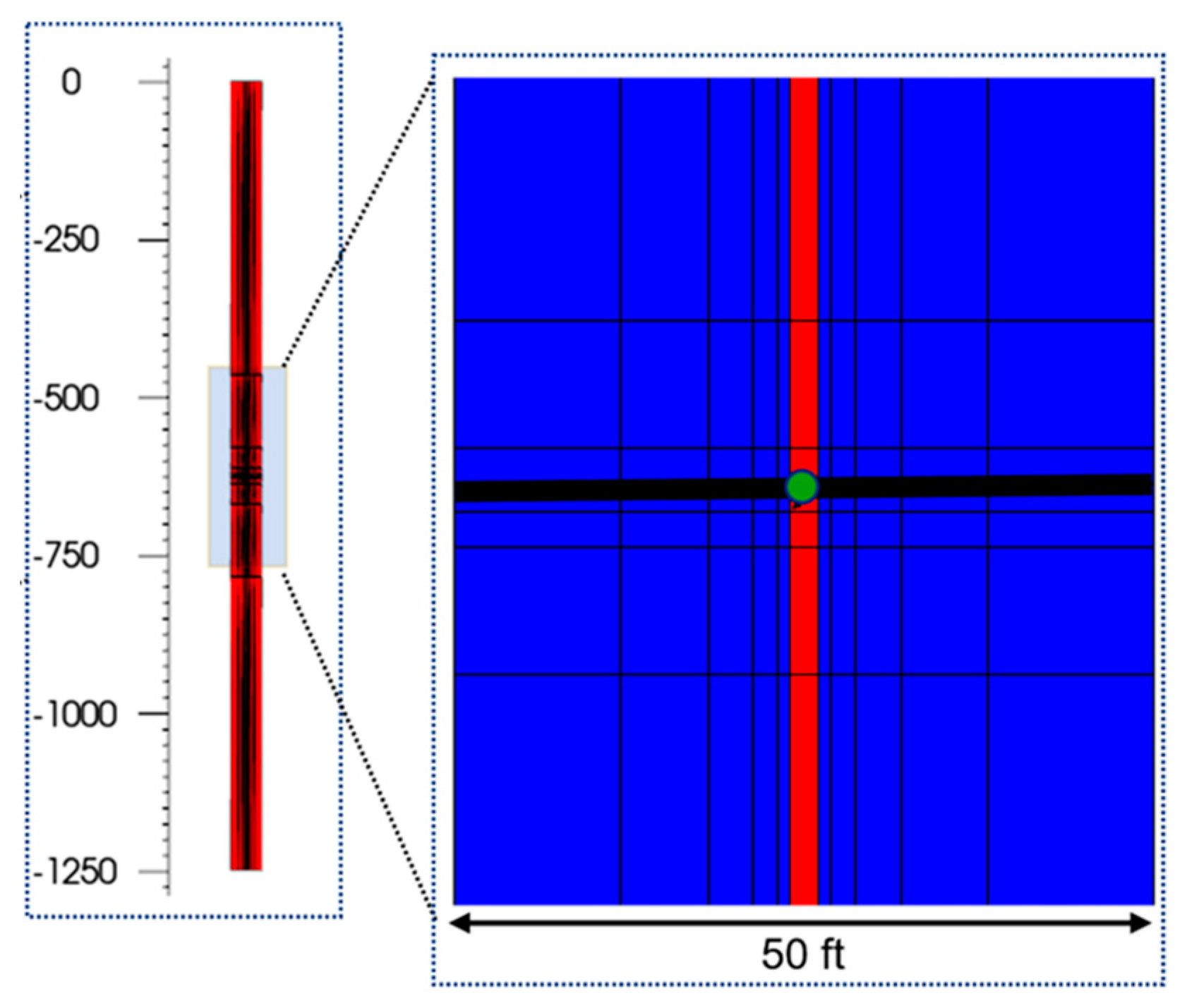

2. Base Case Model

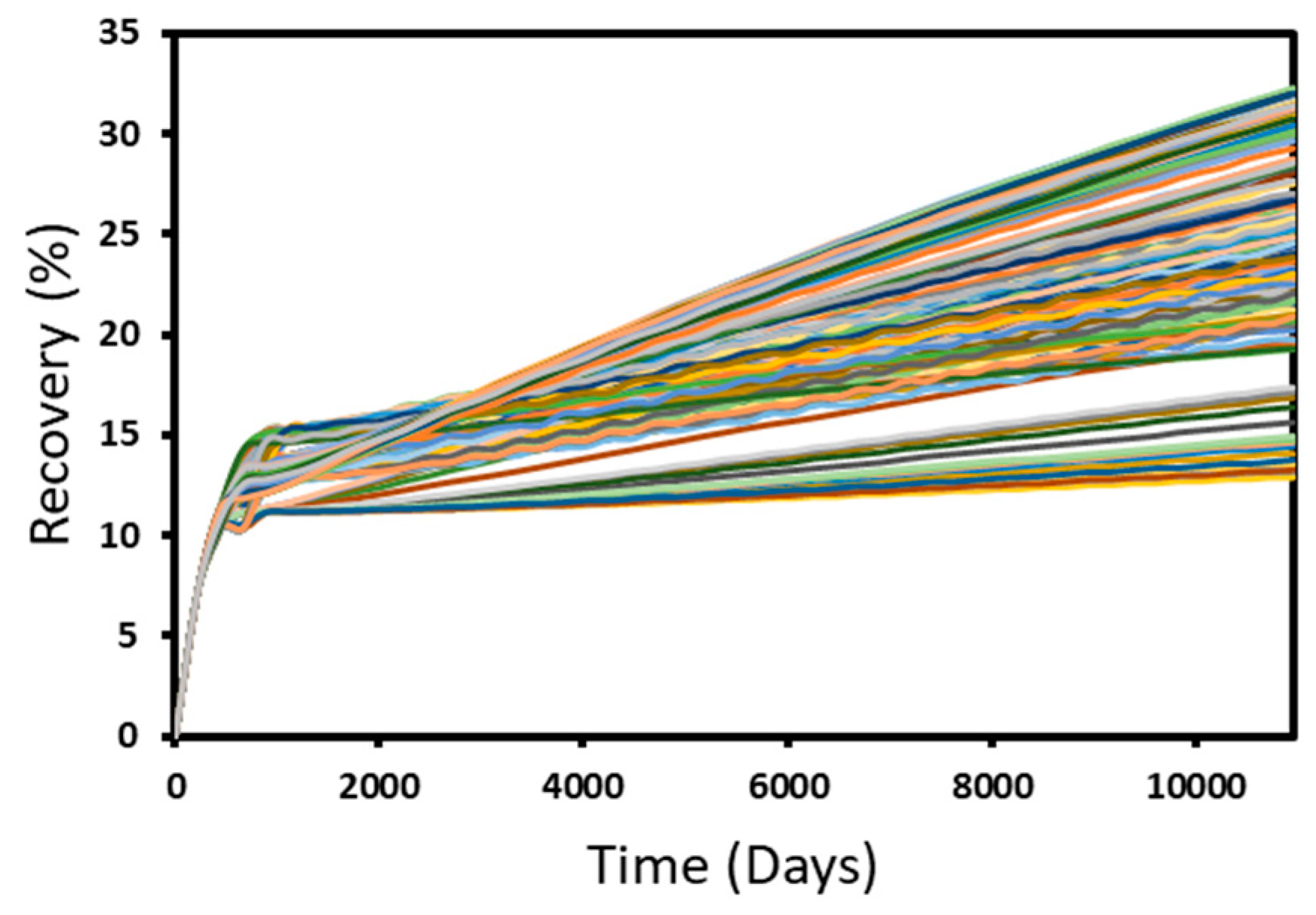

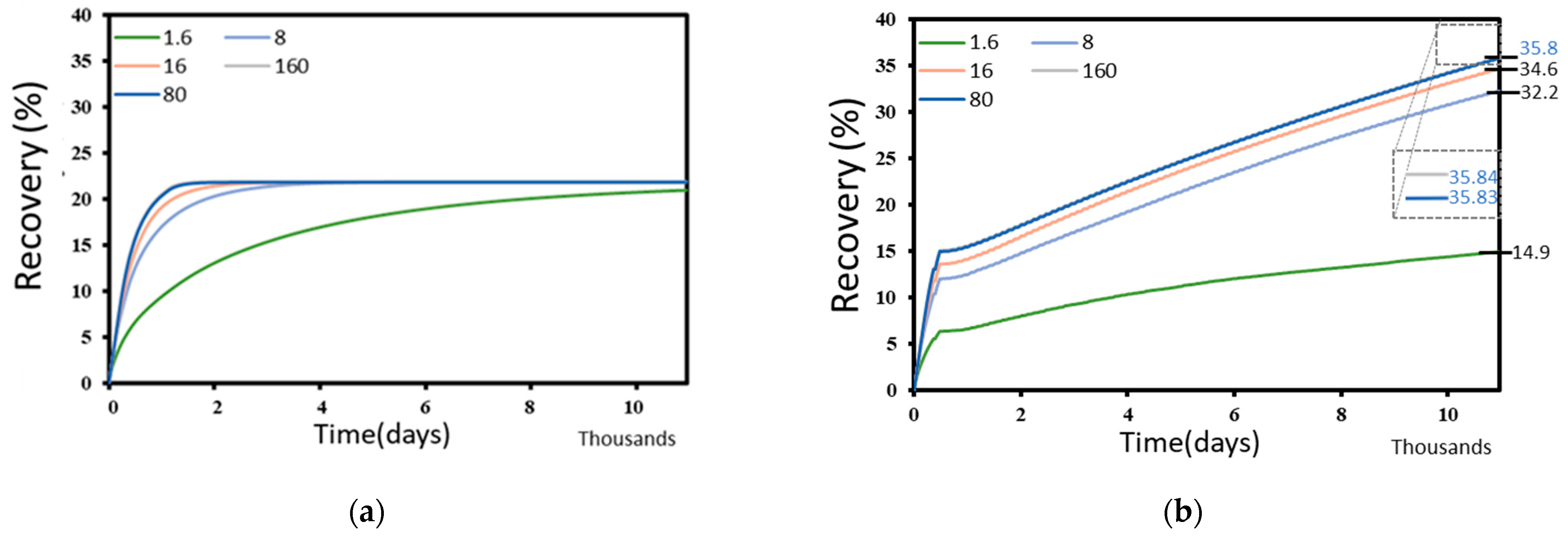

3. Optimization of the HnP Process

4. Effect of Different Parameters in the HnP Process

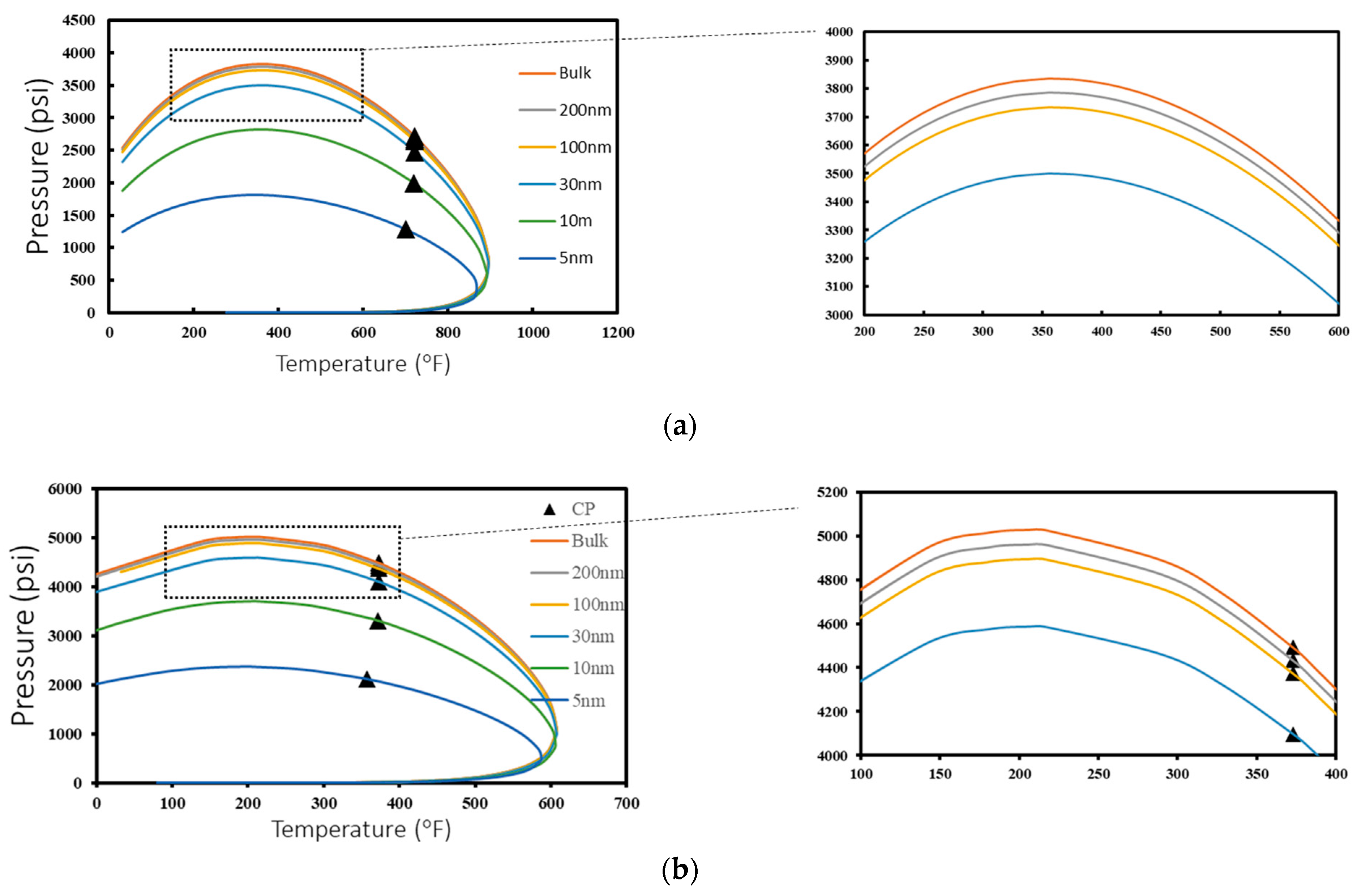

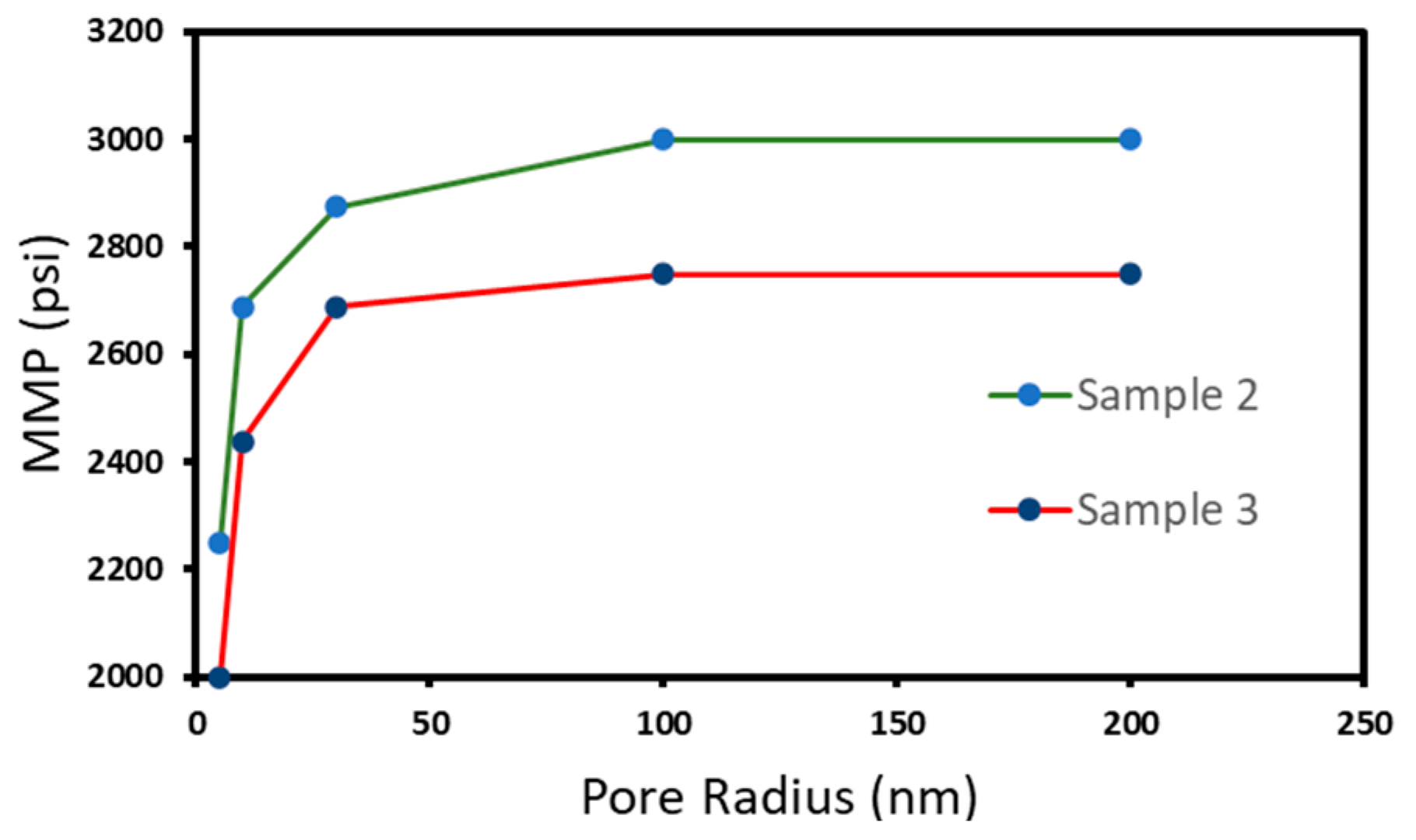

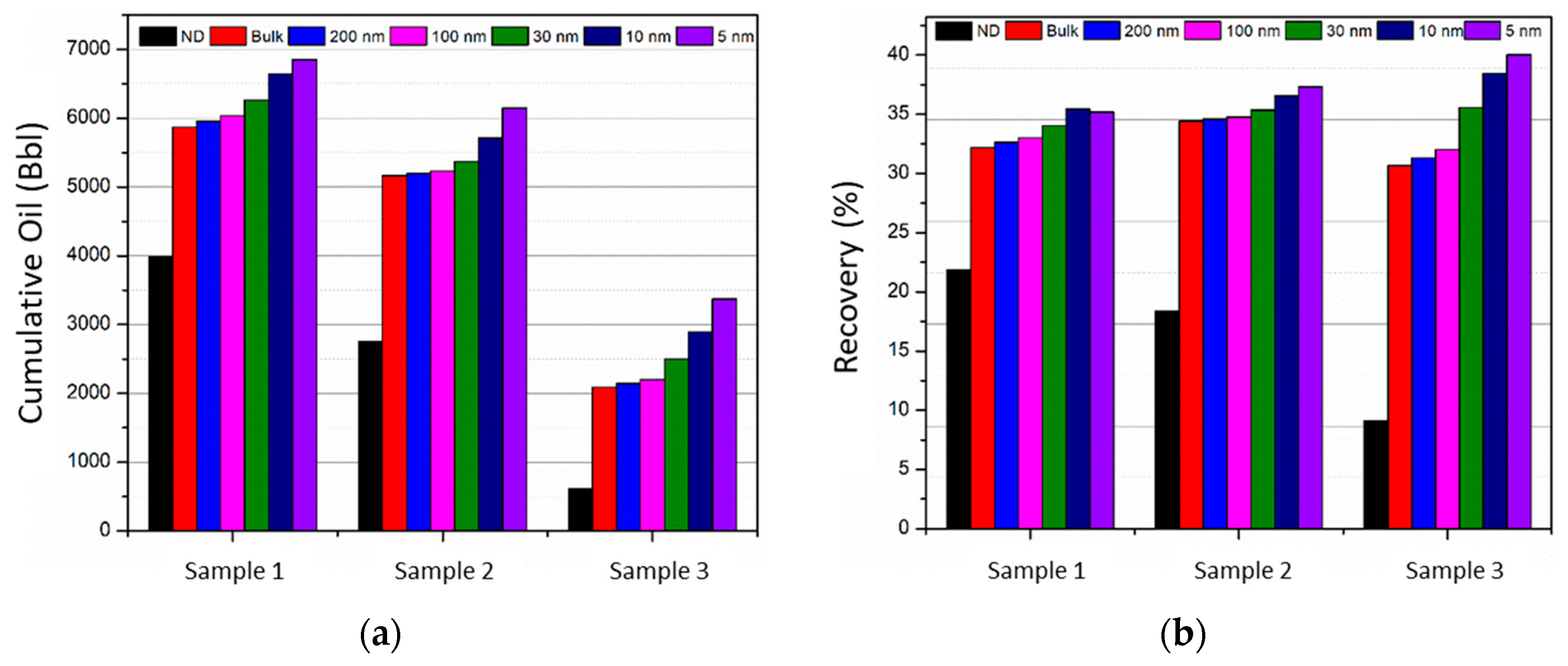

4.1. Effect of Pore Confinement

4.2. Effect of Fluid Composition

4.3. Effect of Injection Solvent

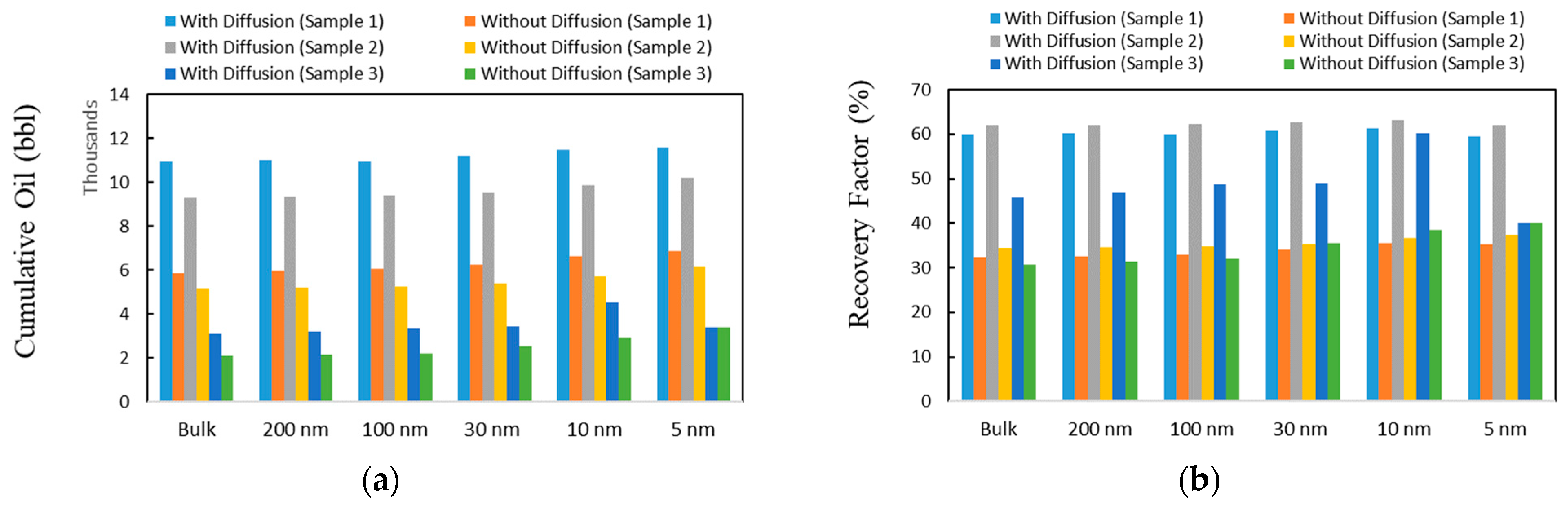

4.4. Effect of Diffusivity

4.5. Effect of Fracture Conductivity

5. CO2 Storage during HnP

6. Discussion

7. Conclusions

- (1)

- As the well loses productive time during the injection and soaking period, the recovery factor may be lower than natural depletion if the injection, soaking, and production period are not optimized. For example, compared to 21.9% recovery for natural depletion, a non-optimal HnP cycle had only 18% recovery, which is counterproductive to the desired goal of improving recovery (Figure 5).

- (2)

- The optimized CO2 HnP process resulted in 32.03% recovery over 30 years, significantly higher than 21.9% from natural depletion (Figure 8).

- (3)

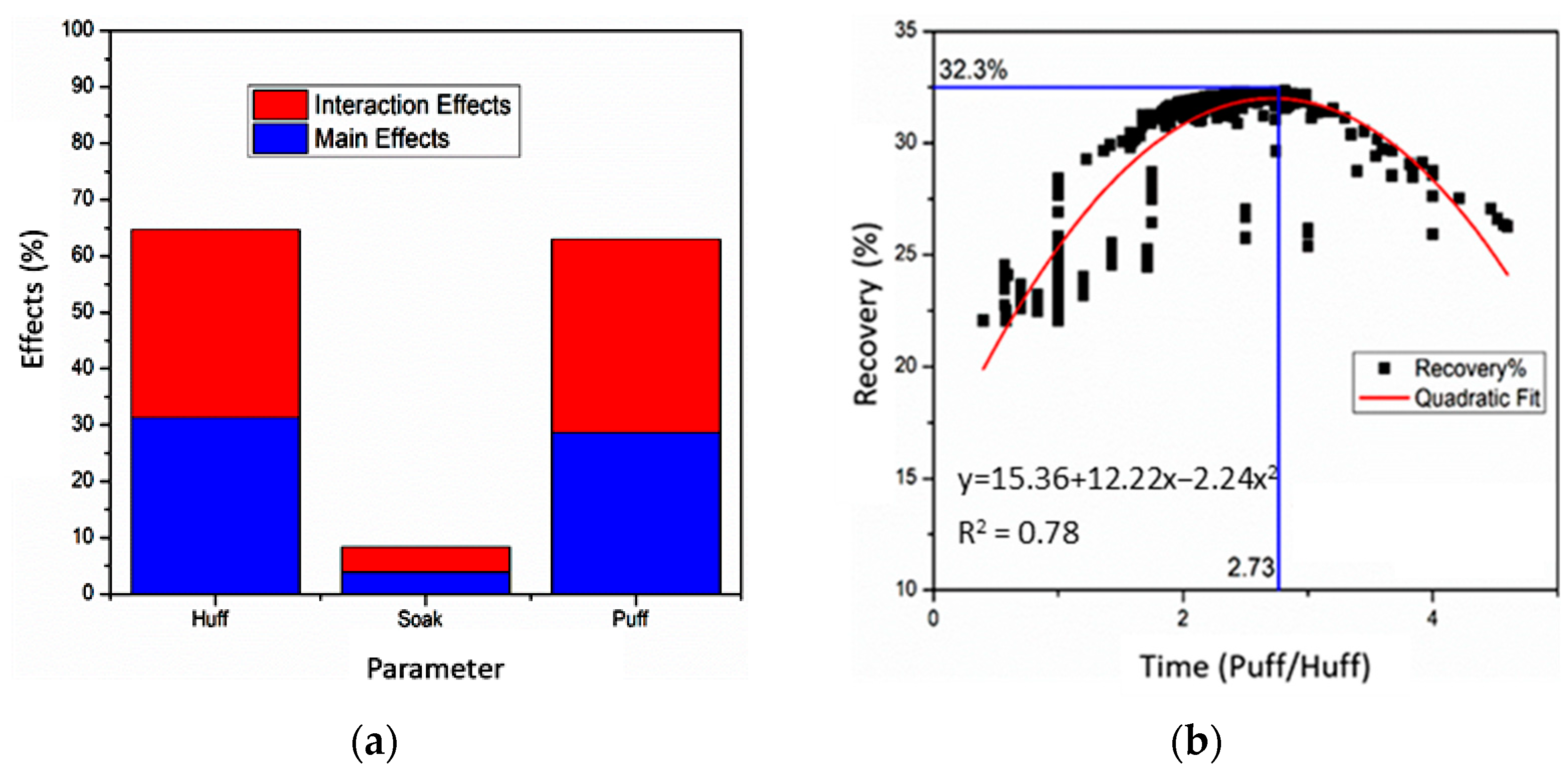

- The injection and production time are the two most important parameters to optimize a CO2 HnP process. However, the soaking period had the least impact on the overall recovery. The ratio of around 2.7 for puff (production) and huff (injection) with a soaking period of fewer than 2.7 days resulted in the most optimal recovery for the base case fluid and reservoir conditions (Figure 9).

- (4)

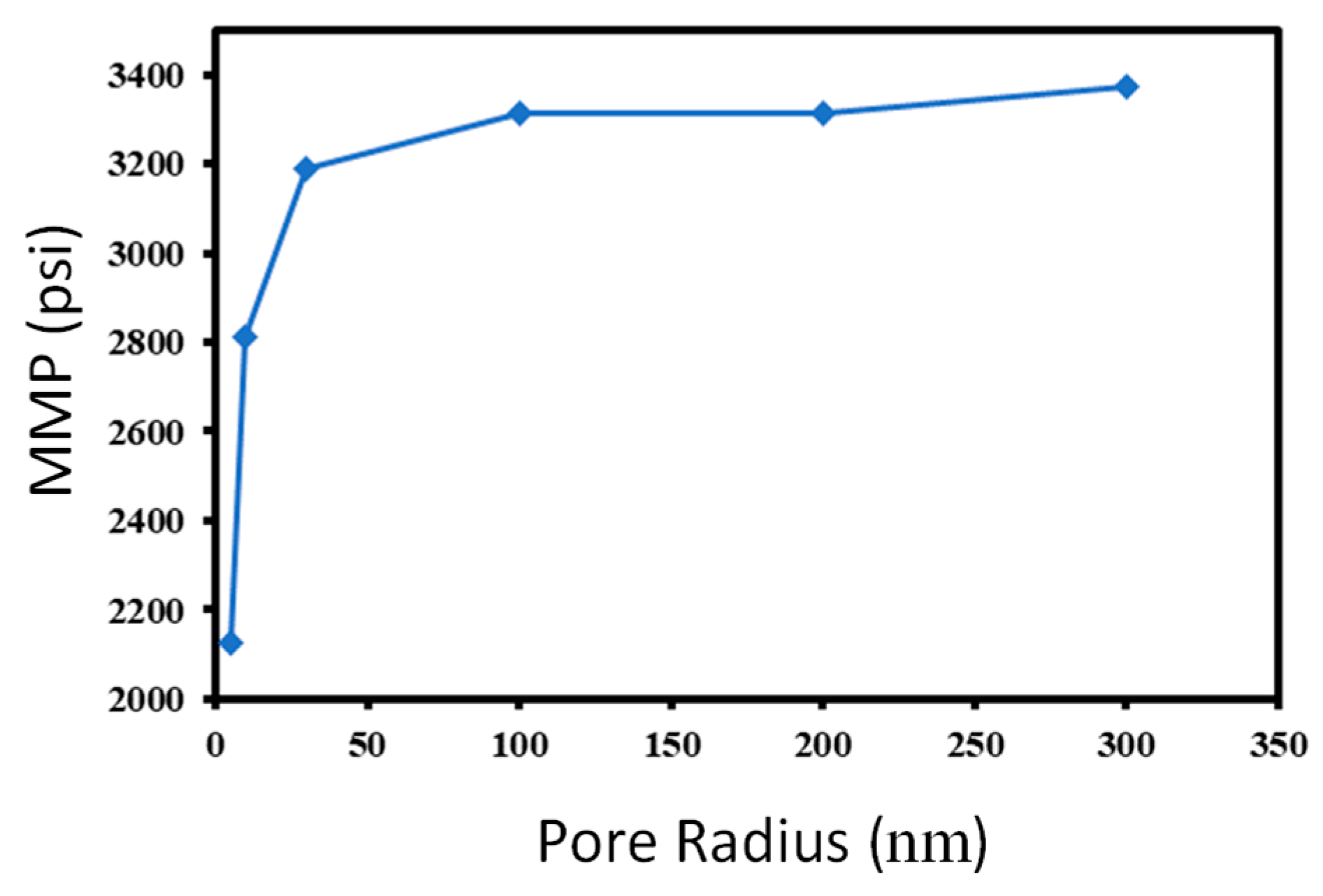

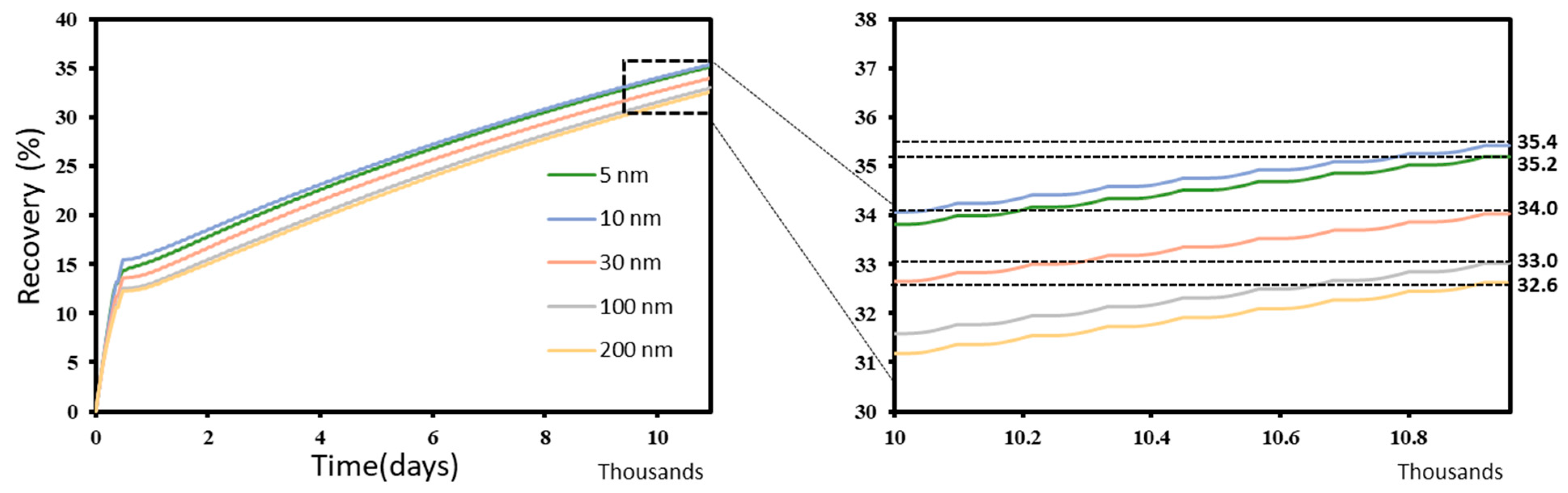

- The confinement effect of nanopores enhances recovery compared to cases with bulk-phase PVT properties. Significant pore confinement (pore sizes ≤ 10 nm) results in around 3.4% additional recovery compared to the case without pore confinement. Hence, reservoir simulators need to include probable pore-size distribution to account for any uncertainty due to the change in PVT properties (Figure 12).

- (5)

- CO2 EOR results in significantly improved recovery for a reservoir with a significant fraction of light hydrocarbons, with an over 300% increase in recovery compared to around 50% increase in recovery for a sample with a significant fraction of heavy hydrocarbons (C7+) (Figure 15).

- (6)

- CO2 showed higher effectiveness as an injection solvent than N2 during the HnP process, as CO2 HnP had a higher recovery % than N2 for all the fluid samples at different pore confinement considered in this study (Figure 16).

- (7)

- Including diffusion resulted in a 40–60% recovery compared to a 30 to 40% recovery when no diffusion was considered. However, it was noteworthy that a lack of accurate diffusivity data can cause inaccuracy in prediction and must be accounted for in calculations (Figure 17).

- (8)

- The increase in dimensionless fracture conductivity (FCD) can significantly improve the recovery from the CO2 HnP process (Figure 18). However, if the FCD is suboptimal due to fracture deterioration, the recovery can be lower than what is observed from natural depletion.

- (9)

- Although higher oil recovery is the primary optimization factor considered in this study, the considerable amount of CO2 stored (970 to 1067 ton CO2 per fracture) shows that CO2 HnP could be an effective strategy for managing anthropogenic CO2. Therefore, selecting both CO2 storage and oil recovery as optimization parameters, and prioritizing CO2 storage over oil production could be used if carbon sequestration is the main goal of the project.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BHP | Bottomhole Pressure |

| EOR | Enhanced Oil Recovery |

| GOR | Gas–Oil Ratio |

| HnP | Huff-n-Puff |

| LGR | Logarithmically Refined Grids |

| MMP | Minimum Miscibility Pressure |

| ND | Natural Depletion |

| NPV | Net Present Value |

| PVT | Pressure, Volume, and Temperature |

| VIT | Vanishing Interfacial Tension |

References

- Raimi, D.; Campbell, E.; Newell, R.G.; Prest, B.; Villanueva, S.; Wingenroth, J. Global Energy Outlook 2022: Turning Points and Tension in the Energy Transition; Resources for the Future: Washington, DC, USA, 2022. [Google Scholar]

- Zheng, Z.; Di, Y.; Wu, Y.S. Nanopore confinement effect on the phase behavior of CO2/Hydrocarbons in tight oil reservoirs considering capillary pressure, fluid-wall interaction, and molecule adsorption. Geofluids 2021, 2021, 2435930. [Google Scholar] [CrossRef]

- Jha, H.S.; Lee, W.J. Problems With Application of Material Balance Time to Transient Flow Data in Diagnostic Plots. In Proceedings of the 5th Unconventional Resources Technology Conference, London, UK, 15–18 October 2017; American Association of Petroleum Geologists: Tulsa, OK, USA, 2017. [Google Scholar]

- Shabib-Asl, A.; Plaksina, T.; Moradi, B. Evaluation of nanopore confinement during CO2 huff and puff process in liquid-rich shale formations. Comput. Geosci. 2020, 24, 1163–1178. [Google Scholar] [CrossRef]

- Hawthorne, S.B.; Gorecki, C.D.; Sorensen, J.A.; Steadman, E.N.; Harju, J.A.; Melzer, S. Hydrocarbon mobilization mechanisms from upper, middle, and lower Bakken reservoir rocks exposed to CO2. In Proceedings of the SPE Unconventional Resources Conference Canada 2013, Calgary, AB, Canada, 5–7 November 2013; Volume 2, pp. 920–928. [Google Scholar] [CrossRef]

- Gamadi, T.D.; Sheng, J.J.; Soliman, M.Y.; Menouar, H.; Watson, M.C.; Emadibaladehi, H. An experimental study of cyclic CO2 injection to improve shale oil recovery. SPE-DOE Improv. Oil Recover. Symp. Proc. 2014, 3, 1554–1562. [Google Scholar] [CrossRef]

- Yu, W.; Lashgari, H.R.; Wu, K.; Sepehrnoori, K. CO2 injection for enhanced oil recovery in Bakken tight oil reservoirs. Fuel 2015, 159, 354–363. [Google Scholar] [CrossRef]

- Birol, F.; Cozzi, L.; Bromhead, A.; Gould, T.; Baroni, M. World Energy Outlook 2014; IEA: Paris, French, 2014; p. 726. [Google Scholar]

- Langston, M.V.; Hoadley, S.F.; Young, D.N. Definitive Co2 Flooding Response in the Sacroc Unit. In Proceedings of the SPE Enhanced Oil Recovery Symposium, Tulsa, Oklahoma, 16–21 April 1988; pp. 27–34. [Google Scholar] [CrossRef]

- Carbon Capture and Sequestration Technologies @ MIT. Century Plant Fact Sheet: Commercial EOR Using Anthropogenic Carbon Dioxide. 2019. Available online: https://sequestration.mit.edu/tools/projects/century_plant.html (accessed on 10 December 2022).

- Mohammad, R.S.; Zhang, S.; Haq, E.; Zhao, X.; Lu, S. Carbon Dioxide Minimum Miscibility Pressure with Nanopore Confinement in Tight Oil Reservoirs. In Proceedings of the IOP Conference Series: Earth and Environmental Science 2018, Banda Aceh, Indonesia, 26–27 September 2018. [Google Scholar] [CrossRef]

- Song, C.; Yang, D. Experimental and numerical evaluation of CO2 huff-n-puff processes in Bakken formation. Fuel 2017, 190, 145–162. [Google Scholar] [CrossRef]

- Alharthy, N.; Teklu, T.; Kazemi, H.; Graves, R.; Hawthorne, S.; Braunberger, J.; Kurtoglu, B. Enhanced oil recovery in liquid-rich shale reservoirs: Laboratory to field. Proc.-SPE Annu. Tech. Conf. Exhib. 2015, 2015, 4450–4478. [Google Scholar] [CrossRef]

- Kanfar, M.S.; Clarkson, C.R. Factors affecting huff-n-puff efficiency in hydraulically-fractured tight reservoirs. In Proceedings of the SPE Unconventional Resources Conference, Calgary, AB, Canada, 15–16 February 2017; pp. 636–652. [Google Scholar] [CrossRef]

- Chen, C.; Balhoff, M.; Mohanty, K.K. Effect of reservoir heterogeneity on primary recovery and CO2 huff “n” puff recovery in shale-oil reservoirs. SPE Reserv. Eval. Eng. 2014, 17, 404–413. [Google Scholar] [CrossRef]

- Enab, K.; Emami-Meybodi, H. Effects of diffusion, adsorption, and hysteresis on huff-n-puff performance in ultratight reservoirs with different fluid types and injection gases. Energies 2021, 14, 7379. [Google Scholar] [CrossRef]

- Min, B.; Mamoudou, S.; Dang, S.; Tinni, A.; Sondergeld, C.; Rai, C. Comprehensive experimental study of huff-n-puff enhanced oil recovey in eagle ford: Key parameters and recovery mechanism. In Proceedings of the SPE Improved Oil Recovery Conference, Virtual, 31 August–4 September 2020. [Google Scholar] [CrossRef]

- Khanal, A.; Khoshghadam, M.; Jha, H.S.; Lee, W.J. Understanding the effect of nanopores on flow behavior and production performance of liquid-rich shale reservoirs. In Proceedings of the 9th Unconventional Resources Technology Conference, Houston, TX, USA, 26–28 July 2021; American Association of Petroleum Geologists: Tulsa, OK, USA, 2021. [Google Scholar]

- Alharthy, N.S.; Teklu, T.W.; Nguyen, T.N.; Kazemi, H.; Graves, R.M. Nanopore compositional modeling in unconventional shale reservoirs. SPE Reserv. Eval. Eng. 2016, 19, 415–428. [Google Scholar] [CrossRef]

- Li, L.; Sheng, J.J.; Su, Y.; Zhan, S. Further Investigation of Effects of Injection Pressure and Imbibition Water on CO2 Huff-n-Puff Performance in Liquid-Rich Shale Reservoirs. Energy Fuels 2018, 32, 5789–5798. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, W.; Sepehrnoori, K.; Di, Y. Investigation of nanopore confinement on fluid flow in tight reservoirs. J. Pet. Sci. Eng. 2017, 150, 265–271. [Google Scholar] [CrossRef]

- Shoaib, S.; Hoffman, B.T. CO2 Flooding the Elm Coulee Field. In Proceedings of the SPE Rocky Mountain Petroleum Technology Conference, Denver, CO, USA, 14–16 April 2009. [Google Scholar]

- Khanal, A.; Weijermars, R. Visualization of drained rock volume (DRV) in hydraulically fractured reservoirs with and without natural fractures using complex analysis methods (CAMs). Pet. Sci. 2019, 16, 550–577. [Google Scholar] [CrossRef] [Green Version]

- Boling, K.S.; Dworkin, S.I. Origin of organic matter in the Eagle Ford Formation. Interpretation 2015, 3, SH27–SH39. [Google Scholar] [CrossRef]

- Khanal, A.; Weijermars, R. Pressure depletion and drained rock volume near hydraulically fractured parent and child wells. J. Pet. Sci. Eng. 2019, 172, 607–626. [Google Scholar] [CrossRef]

- Khanal, A.; Khoshghadam, M.; Lee, W.J.; Nikolaou, M. New forecasting method for liquid rich shale gas condensate reservoirs with data driven approach using principal component analysis. J. Nat. Gas Sci. Eng. 2017, 38, 621–637. [Google Scholar] [CrossRef]

- Khoshghadam, M.; Khanal, A.; Lee, W.J. Numerical study of production mechanisms and gas-oil ratio behavior of liquid-rich shale oil reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015; Volume 2015. [Google Scholar]

- Khanal, A.; Khoshghadam, M.; Makinde, I.; Lee, W.J. Modeling production decline in liquid rich shale (LRS) gas condensate reservoirs. In Proceedings of the Society of Petroleum Engineers—SPE/CSUR Unconventional Resources Conference, Calgary, AB, Canada, 20–22 October 2015. [Google Scholar]

- Khanal, A.; Khoshghadam, M.; Lee, W.J. Effect of well spacing on productivity of Liquid Rich Shale (LRS) reservoirs with multiphase flow: A simulation study. In Proceedings of the Society of Petroleum Engineers—SPE Liquids-Rich Basins Conference—North America, Midland, TX, USA, 2–3 September 2015. [Google Scholar]

- Li, L.; Su, Y.; Sheng, J.J.; Hao, Y.; Wang, W.; Lv, Y.; Zhao, Q.; Wang, H. Experimental and Numerical Study on CO2 Sweep Volume during CO2 Huff-n-Puff Enhanced Oil Recovery Process in Shale Oil Reservoirs. Energy Fuels 2019, 33, 4017–4032. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, K.S. Investigation of asphaltene-derived formation damage and nano-confinement on the performance of CO2 huff-n-puff in shale oil reservoirs. J. Pet. Sci. Eng. 2019, 182, 106304. [Google Scholar] [CrossRef]

- Carlsen, M.L.; Mydland, S.; Dahouk, M.M.; Whitson, C.H.; Yusra, I.; Thuesen, M.; Ambrose, R.; Nohavitza, J. Compositional Tracking of a Huff-n-Puff Project in the Eagle Ford: A Second Take. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Virtual, 20–22 July 2020. [Google Scholar] [CrossRef]

- Kurtoglu, B. Integrated Reservoir Characterization and Modeling in Support of Enhanced Oil Recovery for Bakken; Colorado School of Mines: Golden, CO, USA, 2013. [Google Scholar]

- Wang, X.; Luo, P.; Er, V.; Huang, S. Assessment of CO2 flooding potential for bakken formation, Saskatchewan. In Proceedings of the Canadian Unconventional Resources and International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010; Volume 3, pp. 2003–2016. [Google Scholar] [CrossRef]

- Teklu, T.W.; Ghedan, S.G.; Graves, R.M.; Yin, X. Minimum miscibility pressure determination: Modified multiple mixing cell method. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia 2012, Muscat, Oman, 16–18 April 2012; Volume 2, pp. 707–719. [Google Scholar] [CrossRef]

- Salahshoor, S.; Fahes, M.; Teodoriu, C. A review on the effect of confinement on phase behavior in tight formations. J. Nat. Gas Sci. Eng. 2018, 51, 89–103. [Google Scholar] [CrossRef]

- Dong, X.; Liu, H.; Hou, J.; Wu, K.; Chen, Z. Phase Equilibria of Confined Fluids in Nanopores of Tight and Shale Rocks Considering the Effect of Capillary Pressure and Adsorption Film. Ind. Eng. Chem. Res. 2016, 55, 798–811. [Google Scholar] [CrossRef]

- Jin, L.; Ma, Y.; Jamili, A. Investigating the effect of pore proximity on phase behavior and fluid properties in shale formations. In Proceedings of the SPE Annual Technical Conference and Exhibition 2013, New Orleans, LA, USA, 30 September–2 October 2013; Volume 2, pp. 1422–1437. [Google Scholar] [CrossRef]

- Wu, D.; Chen, S. A modified Peng-Robinson equation of state. Chem. Eng. Commun. 1997, 156, 215–225. [Google Scholar] [CrossRef]

- Yang, G.; Li, X. Modified Peng-Robinson equation of state for CO2/hydrocarbon systems within nanopores. J. Nat. Gas Sci. Eng. 2020, 84, 103700. [Google Scholar] [CrossRef]

- Lake, L.W. Enhanced Oil Recovery, 1st ed.; Prentice Hall: Hoboken, NJ, USA, 1996; ISBN 0132816016. [Google Scholar]

- Junin, R.; Milad, M.; Sidek, A.; Imqam, A.; Tarhuni, M. Huff-n-puff technology for enhanced oil recovery in shale/tight oil reservoirs: Progress, gaps, and perspectives. Energy Fuels 2021, 35, 17279–17333. [Google Scholar] [CrossRef]

- Li, L.; Su, Y.; Hao, Y.; Zhan, S.; Lv, Y.; Zhao, Q.; Wang, H. A comparative study of CO2 and N2 huff-n-puff EOR performance in shale oil production. J. Pet. Sci. Eng. 2019, 181, 106174. [Google Scholar] [CrossRef]

- Wan, T.; Mu, Z. The use of numerical simulation to investigate the enhanced Eagle Ford shale gas condensate well recovery using cyclic CO2 injection method with nano-pore effect. Fuel 2018, 233, 123–132. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Y.; Yu, X.; Wang, C.; Yao, B.; Wang, S.; Winterfeld, P.H.; Wang, X.; Yang, Z.; Wang, Y.; et al. Advances in improved/enhanced oil recovery technologies for tight and shale reservoirs. Fuel 2017, 210, 425–445. [Google Scholar] [CrossRef]

- Mukherjee, S.; Dang, S.T.; Rai, C.S.; Sondergeld, C.H. Measurement of oil-gas diffusivity at reservoir conditions for huff-n-puff EOR in shales. In Proceedings of the SPE Improved Oil Recovery Conference 2020, Virtual, 31 August–4 September 2020. [Google Scholar] [CrossRef]

- Sun, R.; Yu, W.; Xu, F.; Pu, H.; Miao, J. Compositional simulation of CO2 Huff-n-Puff process in Middle Bakken tight oil reservoirs with hydraulic fractures. Fuel 2019, 236, 1446–1457. [Google Scholar] [CrossRef]

- Yu, W.; Zhang, Y.; Varavei, A.; Sepehrnoori, K.; Zhang, T.; Wu, K.; Miao, J. Compositional simulation of CO2 huff’n’ puff in eagle ford tight oil reservoirs with CO2 molecular diffusion, nanopore confinement, and complex natural fractures. SPE Reserv. Eval. Eng. 2019, 22, 492–508. [Google Scholar] [CrossRef]

- Yu, W.; Lashgari, H.R.; Sepehrnoori, K. Simulation study of CO2 huff-n-puff process in Bakken tight oil reservoirs. In Proceedings of the SPE Western North American and Rocky Mountain Joint Meeting 2014, Denver, CO, USA, 17–18 April 2014; Volume 2, pp. 881–896. [Google Scholar]

- Alzahabi, A.; Kamel, A.; Harouaka, A.; Trindade, A.A. A Model for Estimating Optimal Spacing of the Wolfcamp in the Delaware Basin. In Proceedings of the 8th Unconventional Resources Technology Conference, Virtual, 20–22 July 2020; American Association of Petroleum Geologists: Tulsa, OK, USA, 2020. [Google Scholar]

- Alzahabi, A.; Trindade, A.A.; Kamel, A.; Harouaka, A. Optimizing initial oil production of horizontal Wolfcamp wells utilizing data analytics. J. Pet. Explor. Prod. Technol. 2020, 10, 2357–2371. [Google Scholar] [CrossRef]

- Alzahabi, A.; Alexandre Trindade, A.A.; Kamel, A.A.; Harouaka, A.; Baustian, W.; Campbell, C. Optimal Drawdown for Woodford and Mayes in the Anadarko Basin Using Data Analytics. SPE Prod. Oper. 2021, 36, 572–582. [Google Scholar] [CrossRef]

- Ma, Y.Z.; Holditch, S. Unconventional Oil and Gas Resources Handbook; Gulf Professional Publishing: Houston, TX, USA, 2015; ISBN 9780128022382. [Google Scholar]

- Belyadi, H.; Fathi, E.; Belyadi, F. Hydraulic Fracturing in Unconventional Reservoirs; Gulf Professional Publishing: Houston, TX, USA, 2019; ISBN 9780128498712. [Google Scholar]

- Cinco-Ley, H.; Samaniego, F. Transient Pressure Analysis for Fractured Wells. JPT J. Pet. Technol. 1981, 33, 1749–1766. [Google Scholar] [CrossRef]

- Shahriar, M.F.; Khanal, A. The current techno-economic, environmental, policy status and perspectives of sustainable aviation fuel (SAF). Fuel 2022, 325, 124905. [Google Scholar] [CrossRef]

- Zhou, X.; Li, X.; Shen, D.; Shi, L.; Zhang, Z.; Sun, X.; Jiang, Q. CO2 huff-n-puff process to enhance heavy oil recovery and CO2 storage: An integration study. Energy 2022, 239, 122003. [Google Scholar] [CrossRef]

- Khanal, A.; Shahriar, M.F. Physics-Based Proxy Modeling of CO2 Sequestration in Deep Saline Aquifers. Energies 2022, 15, 4350. [Google Scholar] [CrossRef]

- Seinfeld, J.H.; Pandis, S.N. Atmospheric Chemistry and Physics; John Wiley & Sons: New York, NY, USA, 2006; Volume 5, ISBN 0195093623. [Google Scholar]

- Jin, L.; Hawthorne, S.; Sorensen, J.; Pekot, L.; Kurz, B.; Smith, S.; Heebink, L.; Herdegen, V.; Bosshart, N.; Torres, J.; et al. Advancing CO2 enhanced oil recovery and storage in unconventional oil play—Experimental studies on Bakken shales. Appl. Energy 2017, 208, 171–183. [Google Scholar] [CrossRef]

- Li, X.; Elsworth, D. Geomechanics of CO2 enhanced shale gas recovery. J. Nat. Gas Sci. Eng. 2014, 26, 1607–1619. [Google Scholar] [CrossRef]

- Aljamaan, H.; Holmes, R.; Vishal, V.; Haghpanah, R.; Wilcox, J.; Kovscek, A.R. CO2 Storage and Flow Capacity Measurements on Idealized Shales from Dynamic Breakthrough Experiments. Energy Fuels 2017, 31, 1193–1207. [Google Scholar] [CrossRef]

- Liu, F.; Ellett, K.; Xiao, Y.; Rupp, J.A. Assessing the feasibility of CO2 storage in the New Albany Shale (Devonian-Mississippian) with potential enhanced gas recovery using reservoir simulation. Int. J. Greenh. Gas Control 2013, 17, 111–126. [Google Scholar] [CrossRef]

- Teklu, T.W.; Alharthy, N.; Kazemi, H.; Yin, X.; Graves, R.M.; AlSumaiti, A.M. Phase Behavior and Minimum Miscibility Pressure in Nanopores. SPE Reserv. Eval. Eng. 2014, 17, 396–403. [Google Scholar] [CrossRef]

- Pitakbunkate, T.; Balbuena, P.B.; Moridis, G.J.; Blasingame, T.A. Effect of confinement on pressure/volume/temperature properties of hydrocarbons in shale reservoirs. SPE J. 2016, 21, 621–634. [Google Scholar] [CrossRef]

| Parameters | Values | Units |

|---|---|---|

| Well Length | 6550 | ft |

| Initial Reservoir Pressure | 4891 | psia |

| Reservoir Temperature | 220 | °F |

| Total Compressibility | 3 × 10−6 | psi−1 |

| Permeability | 600 | nD |

| Fracture Half-length | 625 | ft |

| Number of Fractures | 131 | |

| Fracture Spacing | 50 | ft |

| Fracture Stages | 22 | |

| Fracture Width | 0.01 | ft |

| Fracture Permeability | 300 | mD |

| Fracture Height | 60 | ft |

| Fluid Properties | Table 2 | |

| Net Pay | 60 | Ft |

| Porosity | 4.5% | |

| Initial Oil Saturation | 0.85 |

| Component | Mole. Frac | Pc (atm) | Tc (K) | Acentric Factor | Mol. Wt | Vc (L/mol) | S.G | Parachor |

|---|---|---|---|---|---|---|---|---|

| CH4 | 38.52 | 45.4 | 190.6 | 0.008 | 16.0 | 0.099 | 0.3 | 77 |

| C2H6 | 4.93 | 48.2 | 305.4 | 0.098 | 30.1 | 0.148 | 0.356 | 108 |

| C3H8 | 2.75 | 41.9 | 369.8 | 0.152 | 44.1 | 0.203 | 0.507 | 150.3 |

| IC4 | 0.63 | 36 | 408.1 | 0.176 | 58.1 | 0.263 | 0.563 | 181.5 |

| NC4 | 1.09 | 37.5 | 425.2 | 0.193 | 58.1 | 0.255 | 0.584 | 189.9 |

| IC5 | 0.50 | 33.4 | 460.4 | 0.227 | 72.2 | 0.306 | 0.625 | 225 |

| NC5 | 0.53 | 33.3 | 469.6 | 0.251 | 72.2 | 0.304 | 0.631 | 231.5 |

| FC6 | 0.75 | 32.46 | 507.5 | 0.275 | 86 | 0.344 | 0.69 | 250.1 |

| C07–C11 | 26.98 | 28.71 | 545.1 | 0.307 | 103.9 | 0.409 | 0.711 | 300.6 |

| C12–C16 | 7.33 | 18.19 | 684.7 | 0.553 | 192.7 | 0.740 | 0.788 | 529.3 |

| C17–C23 | 6.56 | 13.94 | 767.3 | 0.733 | 274.7 | 1.014 | 0.832 | 709.9 |

| C24–C29 | 3.43 | 11.15 | 838.2 | 0.941 | 367.0 | 1.291 | 0.867 | 877.7 |

| C30 | 0.44 | 10.05 | 872.5 | 1.036 | 419.2 | 1.434 | 0.884 | 956.0 |

| C31+ | 5.56 | 7.41 | 981 | 1.288 | 612.2 | 1.882 | 0.933 | 1141.5 |

| (a) | |||

| Sample 2 | Sample 3 | ||

| Component | Mole Frac. | Component | Mole Frac. |

| CH4 | 49.9 | CH4 | 67.44 |

| C2H6 | 6.4 | C2H6 | 8.27 |

| C3H8 | 3.6 | C3H8 | 4.63 |

| IC4 | 0.8 | IC4 | 1.07 |

| NC4 | 1.4 | NC4 | 1.82 |

| IC5 | 0.6 | IC5 | 0.83 |

| NC5 | 0.7 | NC5 | 0.89 |

| FC6 | 1.0 | FC6 | 1.27 |

| C7+ | 35.5 | C7+ | 13.79 |

| (b) | |||

| Properties | Sample 2 | Sample 3 | |

| Sat. Pressure (psi) | 3265 | 4754 | |

| GOR, scf/STB | 1000 | 4000 | |

| ° API | 40 | 44.5 | |

| C7+ Mol. Wt. | 195 | 164 | |

| C7+ Mol% | 34.88 | 13.78 | |

| Std. Gravity C7+ | 0.81 | 0.79 | |

| Sample 1 | Sample 2 | Sample 3 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pore Size (nm) | Pc (bar) | Tc (°F) | Pc (bar) | Tc (°F) | Pc (bar) | Tc (°F) | ||||||

| 3 | 230 | 88.0 | 751 | −13.4 | 326 | 88.0 | 618 | −14.3 | 540 | 88.0 | 300 | −19.6 |

| 5 | 901 | 52.8 | 842 | −2.89 | 1281 | 52.8 | 699 | −3.09 | 2121 | 52.8 | 357 | −4.21 |

| 10 | 1405 | 26.4 | 867 | 0.00 | 1996 | 26.4 | 719 | −0.38 | 3306 | 26.4 | 371 | −0.51 |

| 30 | 1741 | 8.8 | 867 | 0.00 | 2473 | 8.8 | 721 | −0.01 | 4097 | 8.8 | 373 | −0.02 |

| 100 | 1858 | 2.6 | 867 | 0.00 | 2640 | 2.6 | 721 | 0.00 | 4373 | 2.6 | 373 | 0.00 |

| 200 | 1883 | 1.3 | 867 | 0.00 | 2676 | 1.3 | 721 | 0.00 | 4432 | 1.3 | 373 | 0.00 |

| Bulk * | 1908 | 0.0 | 867 | 0.00 | 2712 | 0.0 | 721 | 0.00 | 4492 | 0.0 | 373 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khanal, A.; Shahriar, M.F. Optimization of CO2 Huff-n-Puff in Unconventional Reservoirs with a Focus on Pore Confinement Effects, Fluid Types, and Completion Parameters. Energies 2023, 16, 2311. https://doi.org/10.3390/en16052311

Khanal A, Shahriar MF. Optimization of CO2 Huff-n-Puff in Unconventional Reservoirs with a Focus on Pore Confinement Effects, Fluid Types, and Completion Parameters. Energies. 2023; 16(5):2311. https://doi.org/10.3390/en16052311

Chicago/Turabian StyleKhanal, Aaditya, and Md Fahim Shahriar. 2023. "Optimization of CO2 Huff-n-Puff in Unconventional Reservoirs with a Focus on Pore Confinement Effects, Fluid Types, and Completion Parameters" Energies 16, no. 5: 2311. https://doi.org/10.3390/en16052311