A Scoping Review of Options for Increasing Biogas Production from Sewage Sludge: Challenges and Opportunities for Enhancing Energy Self-Sufficiency in Wastewater Treatment Plants

Abstract

:1. Introduction

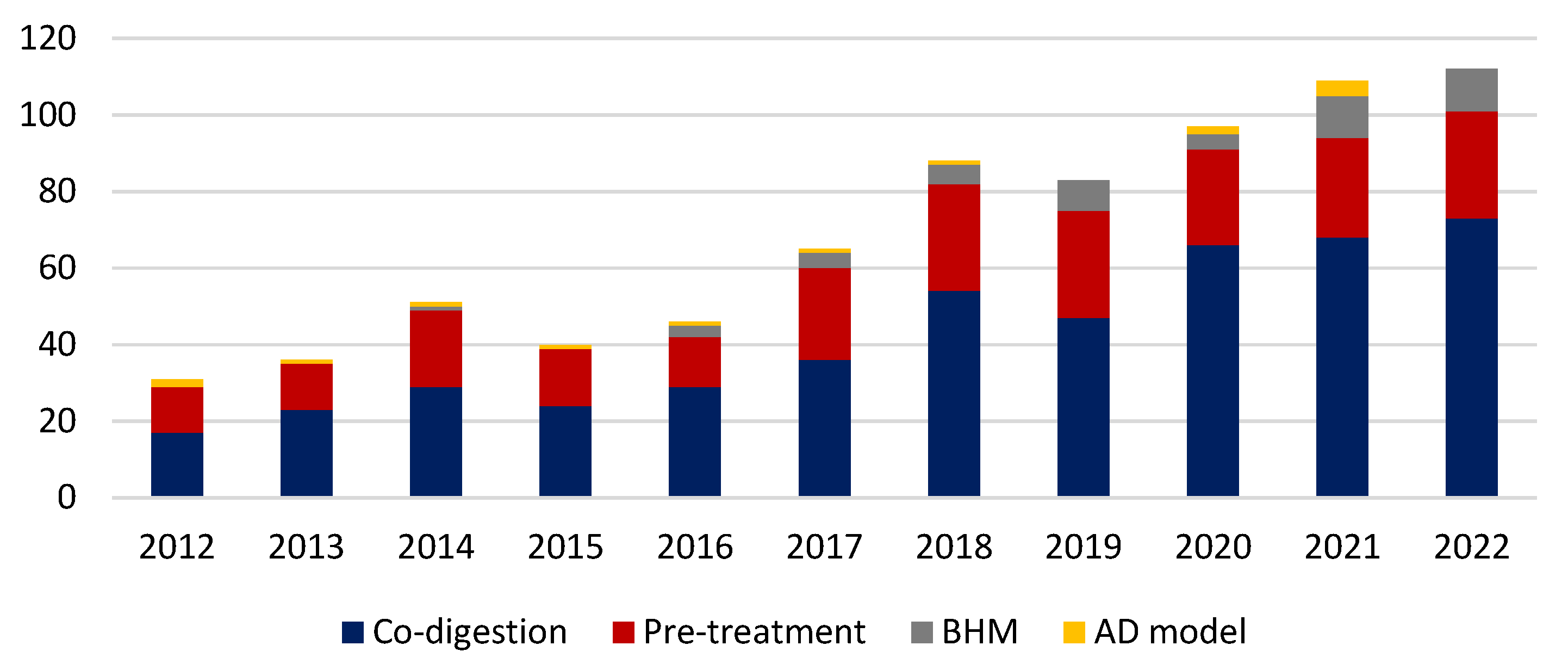

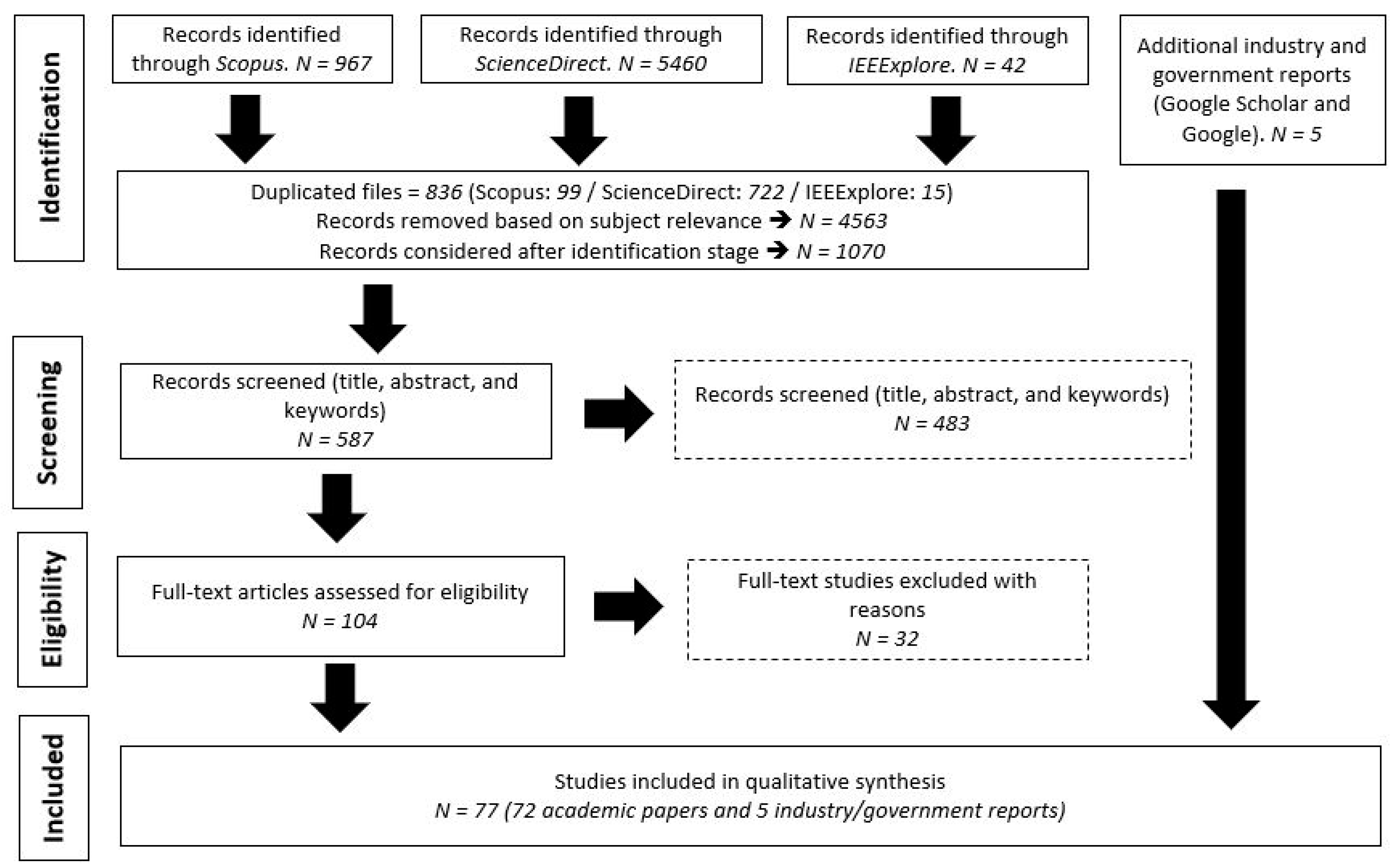

2. Methodology

- Search strings: co-digestion OR pre-treatment OR biological hydrogen methanation AND sewage sludge. Maximising OR optim* OR increas* OR improv* AND anaerobic digestion OR biogas production OR generation AND sewage sludge. Biogas production AND Municipal OR sewage wastewater treatment plants OR WWTP

- Year published: From 2012 to 2022

- Language type: English

- Peer-to-peer articles, government reports, and industry reports;

- Only documents written in the English language;

- Reports and articles published as journal articles, conference proceedings, symposiums, and technical documentation;

- Published between 2012 and 2022;

- Works with a focus on improving the biodegradability of sewage sludge and alternatives to improve biogas production in WWTPs.

3. Biogas in WWTPs

3.1. Biogas Production

- Hydrolysis: Insoluble compounds (e.g., carbohydrates, fats, and proteins) are broken down by bacteria into soluble elements (monosaccharides, amino acids, and long-chain fatty acids) by enzyme catalysis in hydrolytic bacteria. The main objective of this process is to simplify large molecules [5].

- Acidogenesis: Also called fermentation, in this process, the substrate resulting from hydrolysis is converted into sugar, hydrogen, and intermediate compounds, such as volatile fatty acids (i.e., acetic, propionic, and butyric acids), by a large number of fermentative bacteria. Alcohols, ammonia, and hydrogen sulphide are also produced [5,25].

- Acetogenesis: Compounds produced in the acidogenesis (volatile fatty acids and alcohols) step are transformed into acetate by reducing carbon dioxide or organic acids. Most of the carbon dioxide and hydrogen are produced at this stage [25].

- (a)

- Feedstock parameters

- Total solids (TS): TS refers to the quantity of residues that remain after the feedstock’s dehydration. TS combines the suspended and dissolved solids, and it is expressed as a percentage (%). TS concentration is not always a reliable indicator of organic content in the substrate [25]. In a typical WWTP with primary and secondary treatment, primary sludge consists of about 50% of the total sludge solids [29].

- Volatile solids (VS): Refers to the quantity of organic solids in wastewater and is an important parameter to evaluate the performance of a WWTP [29,31]. The concentration of VS in the influent wastewater is conventionally assumed to be the same as that in the sludge. The VS of the raw sludge can range from 70% to 75%, and the VS of the digested sludge varies from 45% to 50%. Anaerobic digestion can reduce VS by 40–60% [31,32].

- Volatile suspended solids (VSS): Associated with the quantity of volatile matter present in the solid part of the wastewater [25].

- Chemical oxygen demand (COD): It is the quantity of dissolved oxygen present in the wastewater that breaks down the organic materials. The COD of the influent wastewater usually ranges between 0.3 and 1 g/L, and after treatment, the COD in the effluent can be as low as 0.02 g/L. Monitoring COD is useful for measuring the efficiency of the treatment process and ensuring compliance with regulations for effluent disposal [5,25,29].

- Biological oxygen demand (BOD): The amount of dissolved oxygen required by bacteria and microorganisms to degrade organic matter under anaerobic conditions. In a WWTP, BOD can be related to biodegradability, and sewage sludge is characterized for its low anaerobic biodegradability [33]. The average BOD for municipal wastewater can range from 200–300 mg/L [34].

- Carbon/nitrogen ratio (C/N): Carbon is responsible for providing energy for microbial activity, whereas nitrogen is the primary microbial cell element. If it is high, the anaerobic digestion has difficulty starting the process, whereas if it is low, nitrogen is converted into ammonia, which can decrease the digestion efficiency. Sewage sludge has a low C/N ratio (lower than 10:1); therefore, the addition of a carbon-rich feedstock can increase it (the optimal range is between 20:1 and 30:1 for anaerobic digestion performance) [33,35].

- (b)

- Design and operational parameters

- pH: The pH for acidogenic bacteria is less sensitive and can range from 4.5 to 8, whereas the optimal value for methanogens is between 6.5 and 7.5. The optimal pH for methane production ranges between 6.8 and 7.2. If the pH is higher or lower than these values, it should be neutralized before feeding into the reactors [25,29,37].

- Temperature: Affects the organic material’s properties and influences the growth of bacteria. In anaerobic digestion, the two main operational temperatures are mesophilic (30~38 °C) and thermophilic (50~57 °C). In the acidogenesis stage, the optimal temperature range is 25~35 °C, and in methanogens, it is 32~42 °C [29]. Most WWTPs are designed to operate under mesophilic conditions since it is easier to control, more adaptable to environmental changes, more stable, and cheaper to operate [25,39].

- Retention time: Solid retention time (SRT) and hydraulic retention time (HRT) are the average times that bacteria and feedstock stay in the anaerobic reactor before they are withdrawn, respectively. Usually, in WWTPs, both are considered the same [40]. The HRT depends on the sludge flow and biodegradability, and most plants operate within a 20-day timeframe. Higher HRT decreases the WWTP’s treatment capacity, increases operating costs, and requires a higher digester capacity. Shorter HRT reduces digestion efficiency, including poor sludge stabilisation, lower biogas yields, and higher volumes of biosolids [41].

- Organic load rate (OLR): Quantifies the mass of carbon in the digester feedstock in a specific period. It is affected by the feedstock flow, temperature, HRT, digestor type, and volume. Higher OLR can increase biogas production; however, excessive OLR may cause inhibition and decrease anaerobic digestion performance [42,43].

- Digestion volume: In WWTPs, the digester size is directly associated with the sewage sludge flow, OLR, and pre-treatment processes used in the plant [25].

- Digester mixing: The main objective of mixing is to uniformly blend the feedstock to ensure uniform microbial contact and avoid the formation of scum or a bottom layer on the digestor to improve the anaerobic digestion performance. Mixing in WWTPs can be done by impellers, pumps, or gas recirculation [44].

- Digestion stages: Anaerobic digestion can occur in one or two stages. In a two-stage reaction, hydrolysis and acidogenesis are separated from acetogenesis and methanogenesis to optimise performance. Benefits achieved from that include higher VS reduction, loading rates, biogas production, process stability, reduction of pathogens, and a smaller reactor volume [29]. The major drawback is the higher sensitivity and operating costs [45].

- Digester type: There are a wide variety of anaerobic reactors, each one performing the same function in a slightly different manner. Examples of digesters include the continuous stirred-tank reactor (CSTR), the anaerobic baffled reactor (ABR), the up-flow anaerobic sludge blanket (UASB), the expanded granular sludge bed (EGSB), the anaerobic fluidized bed reactor (AFBR), and the up-flow blanket filter (UBF) [5,13,25].

- (c)

- Inhibition

3.2. Optimising Biogas Generation in WWTPs

- (a)

- Anaerobic digestion optimisation

- (b)

- Co-digestion

- (c)

- Pre-treatment techniques

| Ref. | Feedstock | Reactor Vol. (L) | T (°C) | Mixing | Mixing Ratio | HRT (d) | OLR (g VS/L. d) | VS Removal (%) | CH4 Production (L/kg VS) | CH4 Concentration (%) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mono | Co-Digestion | Mono | Co-Digestion | |||||||||

| [64] | SS and SW | 1 | 37 | n.i. | SHW:WMS w/w & 4% TS 20% | 20 | 1 | 51.2 | SS:434.8 SW: n.i. | 171.1 | SS: 67.2 | 70.5 |

| w/w & 4% TS 40% | 20 | 1.5 | 53.3 | 736.4 | 71.4 | |||||||

| w/w & 4% TS 60% | 18 | 2 | 64.6 | 674.8 | 71.5 | |||||||

| w/w & 7% TS 20% | 11 | 2.5 | 63.1 | 647.7 | 75.6 | |||||||

| w/w & 7% TS 40% | 11 | 2.3 | 58.6 | 674.4 | 74.9 | |||||||

| w/w & 7% TS 60% | 11 | 2.8 | 72.4 | 674.1 | 78.3 | |||||||

| [65] | SS and FW | 0.5 | 35 | Yes (300 rpm) | FW:SS 30:70 | 30 | 1.77 | 60.58 | SS: 288 FW: 537 | 462 | SS: 68.6 FW: 64.3 | 64.9 |

| 20 | 2.70 | 58.16 | 408 | 65.4 | ||||||||

| 25 | 2.42 | 63.60 | 449 | 65.7 | ||||||||

| [66] | SS and SW | 4.5 | 37 | Yes (160 rpm) | SW: 2.5% | 22.5 | 2.13 | 57 | SS: 234 SW: 719 | 396 | n.i. | n.i. |

| 5% | 2.68 | 64 | 619 | |||||||||

| 7.5% | 3.55 | 61~65 | 585~644 | |||||||||

| 10% | 4.54 | n.i. | 551 | |||||||||

| [67] | WAS and GTS | 200 (type A) 3.4 (type B) | 36 | Yes | GTS: 10% | 30 | 1.8 | 43 | WAS: 255 GTS: 871 | 180 | WAS: 63 GTS: 80 | 66 |

| 17% | 24 | 2.0 | 36 | 333 | 69 | |||||||

| 19% | 25 | 1.7 | 42 | 324 | 67 | |||||||

| 28% | 26 | 1.6 | 42 | 292 | 67 | |||||||

| 42% | 25 | 1.4 | 39 | 398 | 67 | |||||||

| 60% | 24 | 1.2 | 44 | 546 | 69 | |||||||

| 80% | 24 | 1.0 | 33 | 454 | 69 | |||||||

| 90% | 25 | 0.8 | 17 | 158 | 63 | |||||||

| [68] | SS and ABP (mix of DTC, DW, DS, and GTS) | 4 | 35 | Yes (300 rpm) | SS:ABP R1 = 7:1 v/v | 14 | 3.3 | 61 | SS: 300 DTC: 400 DW: 230 DS: 340 GTS: 900 | 380 | n.i. | 65 |

| 20 | 2.4 | 400 | 63 | |||||||||

| 25 | 1.8 | 340 | 56 | |||||||||

| R2 = 7:1 v/v | 14 | 3.7 | 60 | 400 | 64 | |||||||

| 20 | 2.8 | 430 | 65 | |||||||||

| 25 | 2.1 | 370 | 59 | |||||||||

| R3 = 3:1 v/v | 14 | 4.0 | 65 | 390 | 67 | |||||||

| 20 | 2.9 | 410 | 65 | |||||||||

| 25 | 2.2 | 340 | 62 | |||||||||

| [69] | SS and FW | 6 | 35 | Yes (60 rpm) | SS:FW R2 = 2.4:1 | 8 | 15 | 39.7 | SS: 157~237 FW: 377~465 | 215 | SS: 63~65 FW: 50~54 | 56 |

| 12 | 10.1 | 43.1 | 239 | 58 | ||||||||

| 16 | 7.5 | 45 | 261 | 60 | ||||||||

| 20 | 6.3 | 45.5 | 258 | 59 | ||||||||

| 30 | 4.6 | 51 | 303 | 61 | ||||||||

| R3 = 0.9:1 | 8 | 17.8 | 52.2 | 288 | 56 | |||||||

| 12 | 11.5 | 55 | 306 | 57 | ||||||||

| 16 | 8.5 | 56 | 303 | 56 | ||||||||

| 20 | 7.2 | 58.1 | 332 | 58 | ||||||||

| 30 | 5.1 | 62.2 | 350 | 57 | ||||||||

| R4 = 0.4:1 | 8 | 18.5 | 59.2 | 304 | 53 | |||||||

| 12 | 12.5 | 65.4 | 352 | 54 | ||||||||

| 16 | 10.3 | 64.9 | 355 | 55 | ||||||||

| 20 | 8.4 | 67 | 380 | 56 | ||||||||

| 30 | 6.4 | 70 | 400 | 56 | ||||||||

| [70] | SS and FW | 5 | 35 | Yes | FW:SSbc 1:1 | 20 | 0.5~7 | 86.2 | SSbc: 507.5 SSac: 385.9 FW: 625.4 | 404.8 | SSbc: 58.6 SSac: 55.9 FW: 58.8 | 60.4 |

| 1.5:1 | 85.2 | 485 | 60.4 | |||||||||

| 2:1 | 87.7 | 470 | 53 | |||||||||

| 1:1.5 | 82,8 | 490.6 | 60.3 | |||||||||

| 1:2 | 84,8 | 492.1 | 59.8 | |||||||||

| FW:SSac 1:1 | 84 | 453.7 | 58.4 | |||||||||

| 1.5:1 | 87.1 | 410 | 53 | |||||||||

| 2:1 | 86.3 | 384.6 | 58.6 | |||||||||

| 1:1.5 | 86.2 | 417.5 | 57.5 | |||||||||

| 1:2 | 85.3 | 471.1 | 58.9 | |||||||||

| [71] | SS, FOG and MSW | 30 | 38 | Yes | oil 0.5% | 34. | 0.91 | n.i. | SS: 325.4 FOG: 682.3 MSW: 748.3 | 428.23 | SS: 76.3 FOG: 73 MSW: 77.1 | 65.1 |

| 20 | 0.91 | 422.90 | 66.4 | |||||||||

| 23 | 0.74 | 231.13 | 66 | |||||||||

| 18 | 1.21 | 363.23 | 60.7 | |||||||||

| 1–2% | 23 | 0.64 | 225.80 | 62.1 | ||||||||

| 28 | 0.98 | 265.37 | 61.8 | |||||||||

| 14 | 1.51 | 432.75 | 62.6 | |||||||||

| 10 | 0.97 | 398 | 60.8 | |||||||||

| [72] | SS, GTS and MSW | 2 × 6 | 37 | Yes (180 rpm) | 5~30% | 20 | S1 *: 1.15~1.35 | S1: 50 | SS: 300 GTS: n.i. MSW: n.i. | S2: 456 S3: 547 | S1: 66 | S1: 66 |

| S2: 1.44~1.8 | S2: 56.4 | S2: 66 | ||||||||||

| S3: 2.5 | S3: 64.7 | S3: 69 | ||||||||||

| [73] | SS and FW | 100 | 35 | Yes | n.i. | 11~14 | 1.46~2.1 | SS + MSW: 35~43 | SS: 84 FW: 335 | 90~430 | n.i. | n.i. |

| [74] | SS and CM | 2.5 | 35 | n.i. | SS:CM 4:1 | 63 | n.i. | 49.91 | SS: 319 CM: 251 | 270 | n.i. | n.i. |

| 3:2 | 52.77 | 301 | ||||||||||

| 2:3 | 54.8 | 328 | ||||||||||

| 1:4 | 53.73 | 323 | ||||||||||

- Biological: The main objective of biological treatment is to reduce and remove the organic matter and nutrients (i.e., nitrogen and phosphorous) from the wastewater to follow the effluent disposal requirement and regulatory limits [5]. Some of the most common techniques are aerobic digestion, dual-stage digestion, temperature phase, and enzyme addition [46,75]. Dual digestion aims to physically separate the hydrolysis and methanogenesis stages. The addition of enzymes improves the sludge’s stabilisation and biodegradability and promotes better sludge dewaterability and methane generation. Aerobic digestion uses an aeration process to stabilise and reduce the organic matter in the wastewater, and it is typically used in an activated sludge treatment process in WWTP [63].

- Chemical: Chemical methods hydrolyse the organic compounds in sludge by using different reagents. The most common techniques include alkaline and acid hydrolysis, ozonation, and oxidation processes [63]. Alkaline treatment is the most common chemical method used due to its efficiency in adjusting the pH, improving hydrolysis rates, and solubilising organic compounds. Acid hydrolysis and oxidation focused on the enhancement of hydrolysis performance and biogas production, whereas ozonation enhanced biodegradability, hydrolyse potential, and sludge mass reduction [15,76].

- Mechanical: Aims to increase the contact surface area of the particles, making them easily available for the microorganisms to digest [63]. These methods include ultrasound, ultrasonic, microwave, high-pressure homogenizer, and pulse methods; among them, microwave and ultrasound are the most studied and applied in sewage sludge [15]. Usually, they require moderate electricity consumption, and the efficiency of anaerobic digestion of sewage sludge is very low when not combined with other methods [46].

- Thermal: Breakdown of organic matter by exposing it from a low temperature (~70 °C) to a high temperature (150–200 °C) and pressure (600–2500 kPa). The aim of high temperatures is to disrupt the particle structure and solubilise the compounds. These methods have been used to increase the sewage sludge’s biodegradability and enhance biogas production and biosolids dewaterability. Thermal hydrolysis is the most widely used pre-treatment in WWTPs [33,46]. Commercial thermal hydrolysis systems are available on the market. Some demonstrate the capacity to increase biogas production by up to 150% after applying 180 °C for a 30-min treatment. Thermal pre-treatment can also operate with increases in OLR, and it lowers HRT [15,39,76].

- (d)

- Biological hydrogen methanation (BHM)

| Ref. | Method | Substrate | Treatment Details | Anaerobic Digestion | Outcomes |

|---|---|---|---|---|---|

| [79] | Thermal pre-treatment | Mixed sludge (pH 6.9 and 19.3 g VS/L). | Thermal process of 75–225 °C for 15 to 105 min. | Batch and continuous mode. | The optimal treatment was found to be applying 180 °C for 76 min to improve methane production by 40% (from 194.5 to 272.9 mL CH4/g COD). |

| [80] | Thermal pre-treatment | Digested sludge (117.8 g VS/kg and 222.5 g TS/kg) and mixed sludge (19.3 g VS/kg and 27.6 g TS/kg). | Thermal process of 180–200 °C during 30 min. | Mesophilic, batch mode, and 25 days. | Methane yield can improve by up to 50% when compared with raw sludge. The sludge’s biodegradability increased from 35% to 62% after thermal pre-treatment. |

| [81] | Thermal pre-treatment | Primary sludge (29 g TS/L) and digested sludge (29 g TS/L). | Thermal process of 150 °C for 30 min at 500 kPa. Thickening ratio of 1.33 | Mesophilic (35 °C) and 20 days. | Thermal pre-treatment and recuperative thickening could improve biogas generation by 15% and sludge biodegradability by 17–50%. |

| [82] | Thermal pre-treatment | Primary, WAS, and digested sludge from 5 different WWTPs. | Thermal treatment was applied at 80 °C for 5 h with an initial pH of 10. | Mesophilic (37 °C), batch mode, and 20 days. | COD solubilization and VS reduction increased by 20% and 44%, respectively. Methane was produced at a higher rate, but the overall yield was not significantly improved. |

| [83] | Thermal pre-treatment | WAS (23.5 g TSS/L, 17.9 g VSS/L, and 22.9 g TCOD/L). | Combination of the thermal process at 70 °C with ammonia (135.4 mg NH3-N/L). | Mesophilic (35 °C), batch mode, and 37 days. | Methane potential improved by 25% for ammonia treatment, 18% for thermal treatment, and 16.5% for the combined ammonia-thermal treatment. Hydrolysis rates increased by 52%, 25%, and 30% for ammonia, thermal, and combined ammonia-thermal, respectively. |

| [84] | Microwave | Mix of primary sludge and WAS. | Microwave pre-treatment at 2450 MHz, ambient pressure, and mechanical stirring at 55 rpm. | Mesophilic (35 °C), batch mode, and 25–30 days. | Methane yield increased by 20% (from 215 to 258 mL/g VS) and VS removal improved by 31% (from 35.3% to 46.8%) for a 1-stage reactor configuration with HRT of 37 days. Methane yield increased from 258 to 288 mL/g VS (11.6% higher than 1-stage reactor) with 26 days of HRT for a two-stage reactor configuration. |

| [85] | Microwave | Mixed sludge (70% of primary and 30% of secondary). | Microwave pre-treatment at 80 W for 5–15 min. | Mesophilic (29 °C), batch mode, and 11 days. | Biogas production and biodegradability rate increased to 11.9% and 38.5%, respectively, compared with the untreated sludge. |

| [86] | Microwave | Mixed sludge (21.9 g TS/L and 17.6 g VS/L). | Microwave pre-treatment at 20 MJ/ kg TS and 700 J/s. | Mesophilic (35 °C), continuous mode, and 22–35 days. | Methane production and biodegradability increased by 20% (155 to 186 mL/g VS) and 34.6% (from 52% to 70%), respectively, when compared with the untreated sludge. |

| [87] | Microwave | Mixed sludge. | Pre-treatment using 400 and 700 W and ranging the energy applied from 0 to 30 kJ/g TS. | Mesophilic (35 °C), batch mode, and up to 90 days. | Methane yield and methane production rate increased by 17% and 43%, respectively. Optimal values for the TS and microwave powers were 20 kJ/g TS and 700 W. OLR increased by 39%. |

| [88] | Microwave | Primary sludge (37.7 g TS/L and 27.1 g VS/L) and WAS (25.6 g TS/L and 21.8 g VS/L) are mixed in a ratio of 30:70 PS–WAS. | Pre-treatment using 975 kJ/L was performed. | Mesophilic (34 °C), batch mode, and HRT up to 25 days. | Methane yield improved by 29%, 41%, 45%, and 43% for an HRT of 5, 10, 20, and 25 days, respectively. VS removal increased by 33.3%, 43.7%, 14%, and 34.3% for an HRT of 5, 10, 20, and 25 days, respectively. |

| [89] | Microwave with sodium citrate (SC) | Raw sludge (48.5 g TS/kg, 33.3 g VS/kg). | Microwave at 850 W, varying between 3 and 30 s, and energy input of 10 to 40 MJ/kg TS. | Mesophilic (37 °C), batch mode, and 30 days. | Methane production improved by 148%. Energy applied was 269.4 kWh for the optimal pre-treatment configuration. Method not economically attractive. |

| [90] | Ultrasound | Thickened mixed sludge (40/60% of primary–secondary sludges). | Ultrasound operating at 26 kHz and thermal hydrolysis (55 °C). | Mesophilic, batch mode up to 35 days. | Tests were performed for 0.5, 15,500, and 30.5 MJ/kg TS and retention times of 3, 8, and 13 h. Methane yield increased by 50% and maximum rate of methane production was 30~80% higher. |

| [91] | Ultrasound and microwave | Thickened sludge (43.6 g TS/kg and 30.8 g VS/kg). | Ultrasound and microwave were used for treating sludge. The specific energy used in both treatments was 96 kJ/kg sludge. | Mesophilic (37 °C), semi-continuous mode, and up to 67 days. | Biogas increased by 20% and 27% for the microwave and ultrasonic, respectively. Treatments were found not to be economically feasible. |

| [92] | Ultrasonic | WAS (2.58% TS). | Ultrasound at a specific energy of different ranges of values (i.e., 5, 10, 15, 20, 25, 30, and 35 MJ/kg TS) was applied to the sludge. | Mesophilic, batch mode, and 30 days. | Biogas production increased by 8.6%, 22.9%, and 31.4%, by applying 15, 25, and 35 MJ/kg TS, respectively, compared with untreated sludge. |

| [93] | Ultrasonic | Mixed sludge (8% TS and 30/70% of primary-WAS). | Applied ultrasonic (225, 450, and 675 kJ/kg TS) and alkaline (lime ranging from 0.02 to 0.08 g/g TS) pre-treatment methods to sludge. | Mesophilic (37.5 °C), batch mode, and 30 days. | Methane yield enhanced by 60%, 51%, and 73% for the ultrasound treatment of 225, 450, and 675 kJ/kg TS with lime at 0.04 g/g TS when compared with raw sludge. |

| [94] | Ultrasonic | Mixed sludge (132 g TS/kg and 88 g VS/kg). | Ultrasonic conditions: power generator of 150 W, pressure of 1 atm, 25 °C and operation time up to 60 min. | Mesophilic (35 °C), batch mode, and 10 days HRT. | Methane yield increased from 88 to 172 mL /g VS (up to 95%). Biodegradability reached 81% in VS. |

| [95] | Ultrasonic | WAS (23.75 g DS/kg). | Ultrasound conditions: 25 kHz frequency was applied with power up to 1 kW. | Mesophilic (37 °C), batch mode, and 21 days HRT. | Methane production increased by 20%. |

| [96] | Ultrasonic and ultrasonic-ozone | Thickened WAS (15.15 g TS/L and 12.9 g VS/L). | Ultrasonic conditions: 20 kHz frequency and specific energy of 9 kJ/g TS. The ozone amount used was 12 mg O3/g TS. | Mesophilic (37 °C), semi-continuous mode, and 10–20 days HRT. | Biogas production increased by 20.7% and 35.9% for 10 days HRT, and by 7.7% and 25.6% for 20 days HRT for ultrasonic and ultrasonic–ozone, respectively. VS removal improved by 7.6% and 18.3% for 10 days HRT, and by 9.7% and 21.4% for 20 days HRT for ultrasonic and ultrasonic–ozone, respectively. |

| [97] | Microwave, ultrasonic and thermal hydrolysis | Mixed sludge (135 g TS/kg and 92 g VS/kg). | Thermal conditions: 120 °C, 2 atm for 15 min. Ultrasonic conditions: 25 °C, 1 atm, 150 W for 45 min. Microwave conditions: Power range of 100–900 W for 1.4 min. | Mesophilic (35 °C) and batch mode. | Methane production improved by 95%, 29%, and 20% by using sonication, thermal, and microwave, respectively. Sludge solubility increased by 19.2% and 83.4% using thermal and microwave methods, respectively. Ultrasonic, thermal, and microwave required 136, 36, and 20,145 kJ/g TS of specific energy, respectively. |

| [98] | Ozonation and ultrasound | Mix of primary sludge and TWAS (ratio 1:1 DS) with 16.7 g TS/L and 13 g VS/L. | Sequential treatment of ultrasonic (9 kJ/g TS) and ozone (0.036 g O3/g TS). | Mesophilic (35 °C), batch mode, and 30 days HRT. | Biogas production increased by 11% and 15.4% for ultrasonic and ultrasonic-ozone, respectively. Sludge biodegradability improved by 35% with the combined treatment. |

| [99] | Thermal and ultrasonic | Mixture of primary sludge and TWAS (ratio 1:1 DS) with average values of 15.4 g TS/L and 12 g VS/L. | Sludge was treated with ultrasonic at 5 MJ/kg TS and thermal treatment operating at 65 °C. | Mesophilic (35 °C) and batch mode. | Biogas production increased by 20% with the combined treatment. |

| [100] | Thermal pre-treatment | Sludge (33.56 g TS/L and 25.9 g VS/L). | Thermal pre-treatment of 120 °C for 0.5 h at 2 bar. Ultrasonic at 20 kHz and 50 W. | Mesophilic (35 °C) and batch mode. | Methane production increased by 51.27% and 33.61% for thermal and ultrasonic, respectively. Sludge biodegradability increased from 38.1% (raw sludge) to 46.1%, 45,16%, 44%, 45,3%, and 46% for 0.5, 1, 2, 3, and 4 h of thermal treatment. |

4. Challenges and Opportunities

4.1. Challenges of Implementing Co-Digestion and Pre-Treatment Methods

- Digester overloading: The addition of new feedstocks (i.e., FOG and FW) can lead to high OLR, longer HRT, foaming issues, and process interferences. In addition, it may increase biosolids (the solid portion of digested sludge) yields and the accumulation of solids in the bottom of the digester [20,61,119].

- Digestion inhibition: Digestion of high-strength organic matter can produce inhibitory products during the anaerobic digestion process, including ammonia, organic acids, and heavy metals, which can decrease process efficiency, especially affecting the methanogenic bacteria. In addition, the use of co-digestion can promote sludge flotation, digester foaming, pipe and pump blocking, and system clogging [61,119].

- System upgrading: Some upgrade/update may be needed to store the new substrate and increase biogas production and biosolids amounts. Examples of installations include storage tanks (for biogas and feedstock) and systems (i.e., pumps, pipelines, mixers, biogas upgrade equipment, increased power system capacity, or enlarged reactor volume). Therefore, it may require extra expenditure with investment and operating costs [33,62,119].

4.2. Economic Feasibility of Co-Digestion and Pre-Treatment Methods

4.3. Snapshot of the Biogas Production in WWTPs Worldwide

4.4. Biogas Opportunities in WWTPs

4.5. Incentives and Subsidies

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Energy neutrality versus carbon footprint minimization in municipal wastewater treatment plants. Bioresour. Technol. 2020, 300, 122647. [Google Scholar] [CrossRef] [PubMed]

- BECA. Opportunities for Renewable Energy in the Australian Water Sector; ARENA: Canberra, Australia, 2015. Available online: https://arena.gov.au/assets/2016/01/Opportunities-for-renewable-energy-in-the-Australian-water-sector.pdf (accessed on 13 September 2022).

- Topare, N.S.; Attar, S.; Manfe, M.M. Sewage/wastewater treatment technologies: A review. Sci. Rev. Chem. Commun. 2011, 1, 18–24. [Google Scholar]

- Andreoli, C.V.; Von Sperling, M.; Fernandes, F. Sludge Treatment and Disposal; IWA Publishing: London, UK, 2007. [Google Scholar]

- Riffat, R.; Husnain, T. Fundamentals of Wastewater Treatment and Engineering; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Nguyen, H.T.; Safder, U.; Nguyen, X.N.; Yoo, C. Multi-objective decision-making and optimal sizing of a hybrid renewable energy system to meet the dynamic energy demands of a wastewater treatment plant. Energy 2020, 191, 116570. [Google Scholar] [CrossRef]

- Lima, D.; Li, L.; Zhang, J. Minimizing electricity costs using biogas generated from food waste. In Proceedings of the 2021 31st Australasian Universities Power Engineering Conference (AUPEC), Perth, Australia, 26–30 September 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–6. [Google Scholar]

- Cao, Y.; Wei, J.; Li, C.; Zhou, B.; Huang, L.; Feng, G.; Yang, H. Optimal operating control strategy for biogas generation under electricity spot market. J. Eng. 2019, 2019, 5183–5186. [Google Scholar] [CrossRef]

- Hochloff, P.; Braun, M. Optimizing biogas plants with excess power unit and storage capacity in electricity and control reserve markets. Biomass Bioenergy 2014, 65, 125–135. [Google Scholar] [CrossRef]

- Gu, Y.; Li, Y.; Li, X.; Luo, P.; Wang, H.; Wang, X.; Wu, J.; Li, F. Energy self-sufficient wastewater treatment plants: Feasibilities and challenges. Energy Procedia 2017, 105, 3741–3751. [Google Scholar] [CrossRef]

- NSW Government. Energy Efficiency Opportunities in Wastewater Treatment Facilities; Publication 25 June 2019. 2019. Available online: https://www.environment.nsw.gov.au/resources/business/wastewater-treatment-facilities-energy-efficiency-opportunities-190114.pdf (accessed on 10 February 2022).

- Daw, J.; Hallett, K.; DeWolfe, J.; Venner, I. Energy Efficiency Strategies for Municipal Wastewater Treatment Facilities; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2012. [Google Scholar]

- Rocha-Meneses, L.; Zannerni, R.; Inayat, A.; Abdallah, M.; Shanableh, A.; Ghenai, C.; Kamil, M.; Kikas, T. Current progress in anaerobic digestion reactors and parameters optimization. Biomass Convers. Biorefinery 2022, 1–24. [Google Scholar] [CrossRef]

- Junior, I.V.; de Almeida, R.; Cammarota, M.C. A review of sludge pretreatment methods and co-digestion to boost biogas production and energy self-sufficiency in wastewater treatment plants. J. Water Process Eng. 2021, 40, 101857. [Google Scholar] [CrossRef]

- Neumann, P.; Pesante, S.; Venegas, M.; Vidal, G. Developments in pre-treatment methods to improve anaerobic digestion of sewage sludge. Rev. Environ. Sci. Bio/Technol. 2016, 15, 173–211. [Google Scholar] [CrossRef]

- Mitraka, G.-C.; Kontogiannopoulos, K.N.; Batsioula, M.; Banias, G.F.; Zouboulis, A.I.; Kougias, P.G. A Comprehensive Review on Pretreatment Methods for Enhanced Biogas Production from Sewage Sludge. Energies 2022, 15, 6536. [Google Scholar] [CrossRef]

- Rusmanis, D.; O’Shea, R.; Wall, D.M.; Murphy, J.D. Biological hydrogen methanation systems–an overview of design and efficiency. Bioengineered 2019, 10, 604–634. [Google Scholar] [CrossRef]

- Elalami, D.; Carrere, H.; Monlau, F.; Abdelouahdi, K.; Oukarroum, A.; Barakat, A. Pretreatment and co-digestion of wastewater sludge for biogas production: Recent research advances and trends. Renew. Sustain. Energy Rev. 2019, 114, 109287. [Google Scholar] [CrossRef]

- Tabatabaei, M.; Aghbashlo, M.; Valijanian, E.; Panahi, H.K.S.; Nizami, A.-S.; Ghanavati, H.; Sulaiman, A.; Mirmohamadsadeghi, S.; Karimi, K. A comprehensive review on recent biological innovations to improve biogas production, part 1: Upstream strategies. Renew. Energy 2020, 146, 1204–1220. [Google Scholar] [CrossRef]

- Nguyen, L.N.; Kumar, J.; Vu, M.T.; Mohammed, J.A.; Pathak, N.; Commault, A.S.; Sutherland, D.; Zdarta, J.; Tyagi, V.K.; Nghiem, L.D. Biomethane production from anaerobic co-digestion at wastewater treatment plants: A critical review on development and innovations in biogas upgrading techniques. Sci. Total Environ. 2021, 765, 142753. [Google Scholar] [CrossRef]

- Chrispim, M.C.; Scholz, M.; Nolasco, M.A. Biogas recovery for sustainable cities: A critical review of enhancement techniques and key local conditions for implementation. Sustain. Cities Soc. 2021, 72, 103033. [Google Scholar] [CrossRef]

- Liu, M.; Wei, Y.; Leng, X. Improving biogas production using additives in anaerobic digestion: A review. J. Clean. Prod. 2021, 297, 126666. [Google Scholar] [CrossRef]

- Poblete, I.B.S.; Araujo, O.d.Q.F.; de Medeiros, J.L. Sewage-Water Treatment and Sewage-Sludge Management with Power Production as Bioenergy with Carbon Capture System: A Review. Processes 2022, 10, 788. [Google Scholar] [CrossRef]

- Selçuk, A.A. A guide for systematic reviews: PRISMA. Turk. Arch. Otorhinolaryngol. 2019, 57, 57. [Google Scholar] [CrossRef]

- Deng, L.; Liu, Y.; Wang, W. Biogas Technology; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Poh, P.; Gouwanda, D.; Mohan, Y.; Gopalai, A.; Tan, H. Optimization of wastewater anaerobic digestion using mechanistic and meta-heuristic methods: Current limitations and future opportunities. Water Conserv. Sci. Eng. 2016, 1, 1–20. [Google Scholar] [CrossRef]

- Schnaars, K. What every operator should know about anaerobic digestion. Water Environ. Technol. 2012, 24, 82–83. [Google Scholar]

- Pandey, A.; Bhaskar, T.; Stöcker, M.; Sukumaran, R. Recent Advances in Thermochemical Conversion of Biomass; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Turovskiy, I.S.; Mathai, P. Wastewater Sludge Processing; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Kong, Z.; Wu, J.; Rong, C.; Wang, T.; Li, L.; Luo, Z.; Ji, J.; Hanaoka, T.; Sakemi, S.; Ito, M. Sludge yield and degradation of suspended solids by a large pilot-scale anaerobic membrane bioreactor for the treatment of real municipal wastewater at 25 °C. Sci. Total Environ. 2021, 759, 143526. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.; Zhao, Y.; Li, X.; Damgaard, A.; Christensen, T.H. Review of inventory data for the biological treatment of sewage sludge. Waste Manag. 2023, 156, 66–74. [Google Scholar] [CrossRef] [PubMed]

- Wisconsin, D. Advanced Anaerobic Digestion Study Guide; Wisconsin Department of Natural Resources: Madison, WI, USA, 1992. Available online: https://dnr.wi.gov/regulations/opcert/documents/wwsganaerobdigintro.pdf (accessed on 23 September 2013).

- Shen, Y.; Linville, J.L.; Urgun-Demirtas, M.; Mintz, M.M.; Snyder, S.W. An overview of biogas production and utilization at full-scale wastewater treatment plants (WWTPs) in the United States: Challenges and opportunities towards energy-neutral WWTPs. Renew. Sustain. Energy Rev. 2015, 50, 346–362. [Google Scholar] [CrossRef]

- Karapanagioti, H. Water Management, Treatment and Environmental Impact; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Periyasamy, S.; Temesgen, T.; Karthik, V.; Isabel, J.B.; Kavitha, S.; Banu, J.R.; Sivashanmugam, P. Wastewater to biogas recovery. In Clean Energy and Resource Recovery; Elsevier: Amsterdam, The Netherlands, 2022; pp. 301–314. [Google Scholar]

- Schellenberg, T.; Subramanian, V.; Ganeshan, G.; Tompkins, D.; Pradeep, R. Wastewater discharge standards in the evolving context of urban sustainability–The case of India. Front. Environ. Sci. 2020, 8, 30. [Google Scholar] [CrossRef]

- Wei, X.; Kusiak, A. Optimization of biogas production process in a wastewater treatment plant. In Proceedings of the IIE Annual Conference, Orlando, FL, USA, 19–23 May 2012; Citeseer: Princeton, NJ, USA, 2012; p. 1. [Google Scholar]

- Li, H.; Li, C.; Liu, W.; Zou, S. Optimized alkaline pretreatment of sludge before anaerobic digestion. Bioresour. Technol. 2012, 123, 189–194. [Google Scholar] [CrossRef]

- Appels, L.; Baeyens, J.; Degrève, J.; Dewil, R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Moo-Young, M. Comprehensive Biotechnology; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Arhoun, B.; Villen-Guzman, M.; El Mail, R.; Gomez-Lahoz, C. Anaerobic codigestion with fruit and vegetable wastes: An opportunity to enhance the sustainability and circular economy of the WWTP digesters. In Clean Energy and Resources Recovery; Elsevier: Amsterdam, The Netherlands, 2021; pp. 103–132. [Google Scholar]

- Grangeiro, L.C.; de Almeida, S.G.C.; de Mello, B.S.; Fuess, L.T.; Sarti, A.; Dussán, K.J. New trends in biogas production and utilization. In Sustainable Bioenergy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 199–223. [Google Scholar]

- Gautam, R.; Nayak, J.K.; Daverey, A.; Ghosh, U.K. Emerging sustainable opportunities for waste to bioenergy: An overview. In Waste-To-Energy Approaches Towards Zero Waste; Elsevier: Amsterdam, The Netherlands, 2022; pp. 1–55. [Google Scholar]

- López-Jiménez, P.A.; Escudero-González, J.; Martínez, T.M.; Montanana, V.F.; Gualtieri, C. Application of CFD methods to an anaerobic digester: The case of Ontinyent WWTP, Valencia, Spain. J. Water Process Eng. 2015, 7, 131–140. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (EPA). Biosolids Technology Fact Sheet; Environmental Protection Agency, Office of Water: Washington, DC, USA, 2006.

- Cano, R.; Pérez-Elvira, S.; Fdz-Polanco, F. Energy feasibility study of sludge pretreatments: A review. Appl. Energy 2015, 149, 176–185. [Google Scholar] [CrossRef]

- Akbaş, H.; Bilgen, B.; Turhan, A.M. An integrated prediction and optimization model of biogas production system at a wastewater treatment facility. Bioresour. Technol. 2015, 196, 566–576. [Google Scholar] [CrossRef]

- Batstone, D.J.; Keller, J.; Angelidaki, I.; Kalyuzhnyi, S.V.; Pavlostathis, S.G.; Rozzi, A.; Sanders, W.T.M.; Siegrist, H.A.; Vavilin, V.A. The IWA Anaerobic digestion model No 1 (ADM1). Water Sci. Technol. J. Int. Assoc. Water Pollut. Res. 2002, 45, 65–73. [Google Scholar] [CrossRef]

- Henze, M.; Gujer, W.; Mino, T.; Van Loosedrecht, M. Activated Sludge Models ASM1, ASM2, ASM2d and ASM3; IWA Publishing: London, UK, 2006. [Google Scholar]

- Sari, T.; Benyahia, B. The operating diagram for a two-step anaerobic digestion model. Nonlinear Dyn. 2021, 105, 2711–2737. [Google Scholar] [CrossRef]

- Fakharudin, A.S.; Sulaiman, M.N.; Salihon, J.; Zainol, N. Implementing artificial neural networks and genetic algorithms to solve modeling and optimisation of biogas production. 2013. Available online: https://soc.uum.edu.my/icoci/2023/icoci2013/PDF/PID88.pdf (accessed on 7 October 2022).

- Enitan, A.M.; Adeyemo, J.; Swalaha, F.M.; Kumari, S.; Bux, F. Optimization of biogas generation using anaerobic digestion models and computational intelligence approaches. Rev. Chem. Eng. 2017, 33, 309–335. [Google Scholar] [CrossRef]

- Athanasoulia, E.; Melidis, P.; Aivasidis, A. Optimization of biogas production from waste activated sludge through serial digestion. Renew. Energy 2012, 47, 147–151. [Google Scholar] [CrossRef]

- Zhao, J.; Hou, T.; Wang, Q.; Zhang, Z.; Lei, Z.; Shimizu, K.; Guo, W.; Ngo, H.H. Application of biogas recirculation in anaerobic granular sludge system for multifunctional sewage sludge management with high efficacy energy recovery. Appl. Energy 2021, 298, 117212. [Google Scholar] [CrossRef]

- Zhao, J.; Hou, T.; Lei, Z.; Shimizu, K.; Zhang, Z. Performance and stability of biogas recirculation-driven anaerobic digestion system coupling with alkali addition strategy for sewage sludge treatment. Sci. Total Environ. 2021, 783, 146966. [Google Scholar] [CrossRef]

- Karki, R.; Chuenchart, W.; Surendra, K.; Shrestha, S.; Raskin, L.; Sung, S.; Hashimoto, A.; Khanal, S.K. Anaerobic co-digestion: Current status and perspectives. Bioresour. Technol. 2021, 330, 125001. [Google Scholar] [CrossRef]

- Sobczak, A.; Chomać-Pierzecka, E.; Kokiel, A.; Różycka, M.; Stasiak, J.; Soboń, D. Economic Conditions of Using Biodegradable Waste for Biogas Production, Using the Example of Poland and Germany. Energies 2022, 15, 5239. [Google Scholar] [CrossRef]

- Hagos, K.; Zong, J.; Li, D.; Liu, C.; Lu, X. Anaerobic co-digestion process for biogas production: Progress, challenges and perspectives. Renew. Sustain. Energy Rev. 2017, 76, 1485–1496. [Google Scholar] [CrossRef]

- García-Cascallana, J.; Carrillo-Peña, D.; Morán, A.; Smith, R.; Gómez, X. Energy Balance of Turbocharged Engines Operating in a WWTP with Thermal Hydrolysis. Co-Digestion Provides the Full Plant Energy Demand. Appl. Sci. 2021, 11, 11103. [Google Scholar] [CrossRef]

- Macintosh, C.; Astals, S.; Sembera, C.; Ertl, A.; Drewes, J.; Jensen, P.; Koch, K. Successful strategies for increasing energy self-sufficiency at Grüneck wastewater treatment plant in Germany by food waste co-digestion and improved aeration. Appl. Energy 2019, 242, 797–808. [Google Scholar] [CrossRef]

- Long, J.H.; Aziz, T.N.; Francis, L., III; Ducoste, J.J. Anaerobic co-digestion of fat, oil, and grease (FOG): A review of gas production and process limitations. Process Saf. Environ. Prot. 2012, 90, 231–245. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (EPA). User’s Manual: Co-Digestion Economic Analysis Tool. 2016. Available online: https://www.epa.gov/sites/default/files/2017-09/documents/co-eat_users_manual_fin_sept_2017.pdf (accessed on 10 October 2022).

- Salehiyoun, A.R.; Di Maria, F.; Sharifi, M.; Norouzi, O.; Zilouei, H.; Aghbashlo, M. Anaerobic co-digestion of sewage sludge and slaughterhouse waste in existing wastewater digesters. Renew. Energy 2020, 145, 2503–2509. [Google Scholar] [CrossRef]

- Borowski, S.; Boniecki, P.; Kubacki, P.; Czyżowska, A. Food waste co-digestion with slaughterhouse waste and sewage sludge: Digestate conditioning and supernatant quality. Waste Manag. 2018, 74, 158–167. [Google Scholar] [CrossRef] [PubMed]

- Pitk, P.; Kaparaju, P.; Palatsi, J.; Affes, R.; Vilu, R. Co-digestion of sewage sludge and sterilized solid slaughterhouse waste: Methane production efficiency and process limitations. Bioresour. Technol. 2013, 134, 227–232. [Google Scholar] [CrossRef] [PubMed]

- Girault, R.; Bridoux, G.; Nauleau, F.; Poullain, C.; Buffet, J.; Peu, P.; Sadowski, A.; Béline, F. Anaerobic co-digestion of waste activated sludge and greasy sludge from flotation process: Batch versus CSTR experiments to investigate optimal design. Bioresour. Technol. 2012, 105, 1–8. [Google Scholar] [CrossRef]

- Luste, S.; Luostarinen, S. Anaerobic co-digestion of meat-processing by-products and sewage sludge–Effect of hygienization and organic loading rate. Bioresour. Technol. 2010, 101, 2657–2664. [Google Scholar] [CrossRef]

- Dai, X.; Duan, N.; Dong, B.; Dai, L. High-solids anaerobic co-digestion of sewage sludge and food waste in comparison with mono digestions: Stability and performance. Waste Manag. 2013, 33, 308–316. [Google Scholar] [CrossRef]

- Prabhu, M.S.; Mutnuri, S. Anaerobic co-digestion of sewage sludge and food waste. Waste Manag. Res. 2016, 34, 307–315. [Google Scholar] [CrossRef]

- Pastor, L.; Ruiz, L.; Pascual, A.; Ruiz, B. Co-digestion of used oils and urban landfill leachates with sewage sludge and the effect on the biogas production. Appl. Energy 2013, 107, 438–445. [Google Scholar] [CrossRef]

- Grosser, A.; Neczaj, E.; Singh, B.; Almås, Å.; Brattebø, H.; Kacprzak, M. Anaerobic digestion of sewage sludge with grease trap sludge and municipal solid waste as co-substrates. Environ. Res. 2017, 155, 249–260. [Google Scholar] [CrossRef]

- Di Maria, F.; Sordi, A.; Cirulli, G.; Micale, C. Amount of energy recoverable from an existing sludge digester with the co-digestion with fruit and vegetable waste at reduced retention time. Appl. Energy 2015, 150, 9–14. [Google Scholar] [CrossRef]

- Li, J.; Jha, A.K.; He, J.; Ban, Q.; Chang, S.; Wang, P. Assessment of the effects of dry anaerobic co-digestion of cow dung with waste water sludge on biogas yield and biodegradability. Int. J. Phys. Sci. 2011, 6, 3679–3688. [Google Scholar]

- Bachmann, N.; la Cour Jansen, J.; Bochmann, G.; Montpart, N. Sustainable Biogas Production in Municipal Wastewater Treatment Plants; IEA Bioenergy: Massongex, Switzerland, 2015. [Google Scholar]

- Carrère, H.; Dumas, C.; Battimelli, A.; Batstone, D.J.; Delgenes, J.P.; Steyer, J.-P.; Ferrer, I. Pretreatment methods to improve sludge anaerobic degradability: A review. J. Hazard. Mater. 2010, 183, 1–15. [Google Scholar] [CrossRef]

- Ariunbaatar, J.; Panico, A.; Esposito, G.; Pirozzi, F.; Lens, P.N. Pretreatment methods to enhance anaerobic digestion of organic solid waste. Appl. Energy 2014, 123, 143–156. [Google Scholar] [CrossRef]

- Materazzi, M.; Foscolo, P.U. The role of waste and renewable gas to decarbonize the energy sector. In Substitute Natural Gas from Waste; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–19. [Google Scholar]

- Lecker, B.; Illi, L.; Lemmer, A.; Oechsner, H. Biological hydrogen methanation—A review. Bioresour. Technol. 2017, 245, 1220–1228. [Google Scholar] [CrossRef]

- Choi, J.-M.; Han, S.-K.; Lee, C.-Y. Enhancement of methane production in anaerobic digestion of sewage sludge by thermal hydrolysis pretreatment. Bioresour. Technol. 2018, 259, 207–213. [Google Scholar] [CrossRef]

- Ortega-Martinez, E.; Sapkaite, I.; Fdz-Polanco, F.; Donoso-Bravo, A. From pre-treatment toward inter-treatment. Getting some clues from sewage sludge biomethanation. Bioresour. Technol. 2016, 212, 227–235. [Google Scholar] [CrossRef]

- Yang, S.; McDonald, J.; Hai, F.I.; Price, W.E.; Khan, S.J.; Nghiem, L.D. Effects of thermal pre-treatment and recuperative thickening on the fate of trace organic contaminants during anaerobic digestion of sewage sludge. Int. Biodeterior. Biodegrad. 2017, 124, 146–154. [Google Scholar] [CrossRef]

- Nazari, L.; Yuan, Z.; Santoro, D.; Sarathy, S.; Ho, D.; Batstone, D.; Xu, C.C.; Ray, M.B. Low-temperature thermal pre-treatment of municipal wastewater sludge: Process optimization and effects on solubilization and anaerobic degradation. Water Res. 2017, 113, 111–123. [Google Scholar] [CrossRef]

- Liu, X.; Xu, Q.; Wang, D.; Zhao, J.; Wu, Y.; Liu, Y.; Ni, B.-J.; Wang, Q.; Zeng, G.; Li, X. Improved methane production from waste activated sludge by combining free ammonia with heat pretreatment: Performance, mechanisms and applications. Bioresour. Technol. 2018, 268, 230–236. [Google Scholar] [CrossRef]

- Liu, J.; Yang, M.; Zhang, J.; Zheng, J.; Xu, H.; Wang, Y.; Wei, Y. A comprehensive insight into the effects of microwave-H2O2 pretreatment on concentrated sewage sludge anaerobic digestion based on semi-continuous operation. Bioresour. Technol. 2018, 256, 118–127. [Google Scholar] [CrossRef] [PubMed]

- David, H.; Palanisamy, K.; Normanbhay, S. Pre-treatment of sewage sludge to enhance biogas production to generate green energy for reduction of carbon footprint in sewage treatment plant (STP). In Proceedings of the 2014 International Conference and Utility Exhibition on Green Energy for Sustainable Development (ICUE), Pattaya, Thailand, 19–21 March 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 1–5. [Google Scholar]

- Gil, A.; Siles, J.; Martín, M.; Chica, A.; Estévez-Pastor, F.; Toro-Baptista, E. Effect of microwave pretreatment on semi-continuous anaerobic digestion of sewage sludge. Renew. Energy 2018, 115, 917–925. [Google Scholar] [CrossRef]

- Serrano, A.; Siles, J.; Martín, M.; Chica, A.; Estévez-Pastor, F.; Toro-Baptista, E. Improvement of anaerobic digestion of sewage sludge through microwave pre-treatment. J. Environ. Manag. 2016, 177, 231–239. [Google Scholar] [CrossRef] [PubMed]

- Martínez, E.; Gil, M.; Rosas, J.; Moreno, R.; Mateos, R.; Morán, A.; Gómez, X. Application of thermal analysis for evaluating the digestion of microwave pre-treated sewage sludge. J. Therm. Anal. Calorim. 2017, 127, 1209–1219. [Google Scholar] [CrossRef]

- Peng, L.; Appels, L.; Su, H. Combining microwave irradiation with sodium citrate addition improves the pre-treatment on anaerobic digestion of excess sewage sludge. J. Environ. Manag. 2018, 213, 271–278. [Google Scholar] [CrossRef]

- Neumann, P.; González, Z.; Vidal, G. Sequential ultrasound and low-temperature thermal pretreatment: Process optimization and influence on sewage sludge solubilization, enzyme activity and anaerobic digestion. Bioresour. Technol. 2017, 234, 178–187. [Google Scholar] [CrossRef]

- Houtmeyers, S.; Degrève, J.; Willems, K.; Dewil, R.; Appels, L. Comparing the influence of low power ultrasonic and microwave pre-treatments on the solubilisation and semi-continuous anaerobic digestion of waste activated sludge. Bioresour. Technol. 2014, 171, 44–49. [Google Scholar] [CrossRef]

- Lizama, A.C.; Figueiras, C.C.; Herrera, R.R.; Pedreguera, A.Z.; Espinoza, J.E.R. Effects of ultrasonic pretreatment on the solubilization and kinetic study of biogas production from anaerobic digestion of waste activated sludge. Int. Biodeterior. Biodegrad. 2017, 123, 1–9. [Google Scholar] [CrossRef]

- Zhang, B.; Ji, M.; Wang, F.; Li, R.; Zhang, K.; Yin, X.; Li, Q. Damage of EPS and cell structures and improvement of high-solid anaerobic digestion of sewage sludge by combined (Ca(OH)2+ multiple-transducer ultrasonic) pretreatment. RSC Adv. 2017, 7, 22706–22714. [Google Scholar] [CrossRef]

- Martín, M.Á.; González, I.; Serrano, A.; Siles, J.Á. Evaluation of the improvement of sonication pre-treatment in the anaerobic digestion of sewage sludge. J. Environ. Manag. 2015, 147, 330–337. [Google Scholar] [CrossRef]

- Appels, L.; Houtmeyers, S.; Van Mechelen, F.; Degrève, J.; Van Impe, J.; Dewil, R. Effects of ultrasonic pre-treatment on sludge characteristics and anaerobic digestion. Water Sci. Technol. 2012, 66, 2284–2290. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Trzcinski, A.P.; Lin, L.L.; Ng, W.J. Impact of ozone assisted ultrasonication pre-treatment on anaerobic digestibility of sewage sludge. J. Environ. Sci. 2015, 33, 29–38. [Google Scholar] [CrossRef]

- Serrano, A.; Siles, J.Á.; Gutiérrez, M.d.C.; Martín, M.d.l.Á. Comparison of Pre-treatment Technologies to Improve Sewage Sludge Biomethanization. Appl. Biochem. Biotechnol. 2021, 193, 777–790. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Wang, C.; Trzcinski, A.P.; Lin, L.; Ng, W.J. Interpreting the synergistic effect in combined ultrasonication–ozonation sewage sludge pre-treatment. Chemosphere 2015, 140, 63–71. [Google Scholar] [CrossRef]

- Trzcinski, A.P.; Tian, X.; Wang, C.; Lin, L.L.; Ng, W.J. Combined ultrasonication and thermal pre-treatment of sewage sludge for increasing methane production. J. Environ. Sci. Health Part A 2015, 50, 213–223. [Google Scholar] [CrossRef] [PubMed]

- Mirmasoumi, S.; Ebrahimi, S.; Saray, R.K. Enhancement of biogas production from sewage sludge in a wastewater treatment plant: Evaluation of pretreatment techniques and co-digestion under mesophilic and thermophilic conditions. Energy 2018, 157, 707–717. [Google Scholar] [CrossRef]

- Hidalgo, D.; Martín-Marroquín, J. Power-to-methane, coupling CO2 capture with fuel production: An overview. Renew. Sustain. Energy Rev. 2020, 132, 110057. [Google Scholar] [CrossRef]

- Voelklein, M.; Rusmanis, D.; Murphy, J. Biological methanation: Strategies for in-situ and ex-situ upgrading in anaerobic digestion. Appl. Energy 2019, 235, 1061–1071. [Google Scholar] [CrossRef]

- Wu, B.; Lin, R.; Kang, X.; Deng, C.; Dobson, A.D.; Murphy, J.D. Improved robustness of ex-situ biological methanation for electro-fuel production through the addition of graphene. Renew. Sustain. Energy Rev. 2021, 152, 111690. [Google Scholar] [CrossRef]

- Thema, M.; Bauer, F.; Sterner, M. Power-to-Gas: Electrolysis and methanation status review. Renew. Sustain. Energy Rev. 2019, 112, 775–787. [Google Scholar] [CrossRef]

- Gustafsson, M.; Ammenberg, J.; Murphy, J.D. IEA Bioenergy Task 37—A Perspective on the State of the Biogas Industry from Selected Member Countries. 2022. Available online: https://www.ieabioenergy.com/wp-content/uploads/2022/03/IEA_T37_CountryReportSummary_2021.pdf (accessed on 18 October 2022).

- Inova, H.Z. Inauguration of Switzerland’s First Industrial Power to Gas Plant. 2022. Available online: https://www.hz-inova.com/wp-content/uploads/2022/05/Inauguration-of-Switzerlands-first-industrial-Power-to-Gas-plant.pdf (accessed on 12 October 2022).

- Seifert, A.; Rittmann, S.; Herwig, C. Analysis of process related factors to increase volumetric productivity and quality of biomethane with Methanothermobacter marburgensis. Appl. Energy 2014, 132, 155–162. [Google Scholar] [CrossRef]

- Luo, G.; Angelidaki, I. Integrated biogas upgrading and hydrogen utilization in an anaerobic reactor containing enriched hydrogenotrophic methanogenic culture. Biotechnol. Bioeng. 2012, 109, 2729–2736. [Google Scholar] [CrossRef] [PubMed]

- Martin, M.R.; Fornero, J.J.; Stark, R.; Mets, L.; Angenent, L.T. A single-culture bioprocess of Methanothermobacter thermautotrophicus to upgrade digester biogas by CO2-to-CH4 conversion with H2. Archaea 2013, 2013, 157529. [Google Scholar] [CrossRef] [PubMed]

- Luo, G.; Angelidaki, I. Co-digestion of manure and whey for in situ biogas upgrading by the addition of H2: Process performance and microbial insights. Appl. Microbiol. Biotechnol. 2013, 97, 1373–1381. [Google Scholar] [CrossRef]

- Illi, L.; Lecker, B.; Lemmer, A.; Müller, J.; Oechsner, H. Biological methanation of injected hydrogen in a two-stage anaerobic digestion process. Bioresour. Technol. 2021, 333, 125126. [Google Scholar] [CrossRef]

- Burkhardt, M.; Koschack, T.; Busch, G. Biocatalytic methanation of hydrogen and carbon dioxide in an anaerobic three-phase system. Bioresour. Technol. 2015, 178, 330–333. [Google Scholar] [CrossRef]

- Alfaro, N.; Fdz-Polanco, M.; Fdz-Polanco, F.; Díaz, I. Evaluation of process performance, energy consumption and microbiota characterization in a ceramic membrane bioreactor for ex-situ biomethanation of H2 and CO2. Bioresour. Technol. 2018, 258, 142–150. [Google Scholar] [CrossRef]

- Díaz, I.; Pérez, C.; Alfaro, N.; Fdz-Polanco, F. A feasibility study on the bioconversion of CO2 and H2 to biomethane by gas sparging through polymeric membranes. Bioresour. Technol. 2015, 185, 246–253. [Google Scholar] [CrossRef]

- Bassani, I.; Kougias, P.G.; Angelidaki, I. In-situ biogas upgrading in thermophilic granular UASB reactor: Key factors affecting the hydrogen mass transfer rate. Bioresour. Technol. 2016, 221, 485–491. [Google Scholar] [CrossRef]

- Savvas, S.; Donnelly, J.; Patterson, T.; Chong, Z.S.; Esteves, S.R. Biological methanation of CO2 in a novel biofilm plug-flow reactor: A high rate and low parasitic energy process. Appl. Energy 2017, 202, 238–247. [Google Scholar] [CrossRef]

- Alitalo, A.; Niskanen, M.; Aura, E. Biocatalytic methanation of hydrogen and carbon dioxide in a fixed bed bioreactor. Bioresour. Technol. 2015, 196, 600–605. [Google Scholar] [CrossRef] [PubMed]

- Kozak, M.; Köroğlu, E.O.; Cirik, K.; Zaimoğlu, Z. Evaluation of ex-situ hydrogen biomethanation at mesophilic and thermophilic temperatures. Int. J. Hydrogen Energy 2022, 47, 15434–15441. [Google Scholar] [CrossRef]

- Schafer, P.; Muller, C.; Willis, J. Improving the performance and economics of co-digestion and energy production. In Proceedings of the WEFTEC 2013, Chicago, IL, USA, 5–9 October 2013; Water Environment Federation: Alexandria, VA, USA, 2013. [Google Scholar]

- Blank, A.; Hoffmann, E. Upgrading of a co-digestion plant by implementation of a hydrolysis stage. Waste Manag. Res. 2011, 29, 1145–1152. [Google Scholar] [CrossRef] [PubMed]

- Shaddel, S.; Bakhtiary-Davijany, H.; Kabbe, C.; Dadgar, F.; Østerhus, S.W. Sustainable sewage sludge management: From current practices to emerging nutrient recovery technologies. Sustainability 2019, 11, 3435. [Google Scholar] [CrossRef]

- Lyng, K.-A.; Skovsgaard, L.; Jacobsen, H.K.; Hanssen, O.J. The implications of economic instruments on biogas value chains: A case study comparison between Norway and Denmark. Environ. Dev. Sustain. 2020, 22, 7125–7152. [Google Scholar] [CrossRef]

- Gustafsson, M.; Ammenberg, J.; Murphy, J.D. IEA Bioenergy Task 37–Country Reports Summaries 2019. 2020. Available online: https://task37.ieabioenergy.com/country-reports/ (accessed on 17 October 2022).

- Carlu, E.; Truong, T.; Kundevsk, M. Biogas opportunities for Australia; ENEA Consulting: Paris, France, 2019. [Google Scholar]

- Wehner, M.; Lichtmannegger, T.; Robra, S.; Lopes, A.d.C.P.; Ebner, C.; Bockreis, A. The economic efficiency of the co-digestion at WWTPs: A full-scale study. Waste Manag. 2021, 133, 110–118. [Google Scholar] [CrossRef]

- Jellali, S.; Charabi, Y.; Usman, M.; Al-Badi, A.; Jeguirim, M. Investigations on biogas recovery from anaerobic digestion of raw sludge and its mixture with agri-food wastes: Application to the largest industrial estate in Oman. Sustainability 2021, 13, 3698. [Google Scholar] [CrossRef]

- Jones, C.A.; Coker, C.; Kirk, K.; Reynolds, L. Food Waste Co-Digestion at Water Resource Recovery Facilities: Business Case Analysis. 2019. Available online: https://www.waterrf.org/system/files/resource/2019-12/DRPT-4792.pdf (accessed on 13 October 2022).

- García-Cascallana, J.; Barrios, X.G.; Martinez, E.J. Thermal Hydrolysis of Sewage Sludge: A Case Study of a WWTP in Burgos, Spain. Appl. Sci. 2021, 11, 964. [Google Scholar] [CrossRef]

- Rus, E.; Mills, N.; Shana, A.; Perrault, A.; Fountain, P.; Thorpe, R.; Ouki, S.; Nilsen, P. The intermediate thermal hydrolysis process: Results from pilot testing and techno-economic assessment. Water Pract. Technol. 2017, 12, 406–422. [Google Scholar] [CrossRef]

- Azizi, S.M.M.; Dastyar, W.; Meshref, M.N.; Maal-Bared, R.; Dhar, B.R. Low-temperature thermal hydrolysis for anaerobic digestion facility in wastewater treatment plant with primary sludge fermentation. Chem. Eng. J. 2021, 426, 130485. [Google Scholar]

- Papadias, D.D.; Ahmed, S.; Kumar, R. Fuel quality issues with biogas energy–An economic analysis for a stationary fuel cell system. Energy 2012, 44, 257–277. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Wellinger, A.; Murphy, J.P.; Baxter, D. The Biogas Handbook: Science, Production and Applications; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- U.S. Department of Energy. Reciprocating Engines; Combined Heat and Power Technology Fact Sheet Series; U.S. Department of Energy: Washington, DC, USA, 2016.

- Dincer, I.; Acar, C. Review and evaluation of hydrogen production methods for better sustainability. Int. J. Hydrog. Energy 2015, 40, 11094–11111. [Google Scholar] [CrossRef]

- Schneider, S.; Bajohr, S.; Graf, F.; Kolb, T. State of the art of hydrogen production via pyrolysis of natural gas. ChemBioEng Rev. 2020, 7, 150–158. [Google Scholar] [CrossRef]

- Venkatesh, G.; Elmi, R.A. Economic–environmental analysis of handling biogas from sewage sludge digesters in WWTPs (wastewater treatment plants) for energy recovery: Case study of Bekkelaget WWTP in Oslo (Norway). Energy 2013, 58, 220–235. [Google Scholar] [CrossRef]

- Mendiara, T.; Cabello, A.; Izquierdo, M.T.; Abad, A.; Mattisson, T.; Adánez, J. Effect of the Presence of Siloxanes in Biogas Chemical Looping Combustion. Energy Fuels 2021, 35, 14984–14994. [Google Scholar] [CrossRef]

- Khan, I.U.; Othman, M.H.D.; Hashim, H.; Matsuura, T.; Ismail, A.F.; Rezaei-DashtArzhandi, M.; Azeleeb, I.W. Biogas as a renewable energy fuel—A review of biogas upgrading, utilisation and storage. Energy Convers. Manag. 2017, 150, 277–294. [Google Scholar] [CrossRef]

- AEMO. Gas Quality Guidelines; AEMO (Australian Energy Market Operator): Melbourne, Australia, 2017; pp. 1–38. [Google Scholar]

- AS 4564-2011; Specification for General-purpose Natural Gas. Australian Government: Canberra, Australia, 2020.

- IEA. Member Country Reports. Available online: https://task37.ieabioenergy.com/country-reports.html (accessed on 12 September 2022).

- Sun, Q.; Li, H.; Yan, J.; Liu, L.; Yu, Z.; Yu, X. Selection of appropriate biogas upgrading technology-a review of biogas cleaning, upgrading and utilisation. Renew. Sustain. Energy Rev. 2015, 51, 521–532. [Google Scholar] [CrossRef]

- Baena-Moreno, F.M.; Rodríguez-Galán, M.; Vega, F.; Vilches, L.F.; Navarrete, B. Recent advances in biogas purifying technologies. Int. J. Green Energy 2019, 16, 401–412. [Google Scholar] [CrossRef]

- Adnan, A.I.; Ong, M.Y.; Nomanbhay, S.; Chew, K.W.; Show, P.L. Technologies for biogas upgrading to biomethane: A review. Bioengineering 2019, 6, 92. [Google Scholar] [CrossRef]

| Feedstock | CS | DM | FOG | FW | M | OFMSW | PS | RS | WAS | WS |

|---|---|---|---|---|---|---|---|---|---|---|

| Theoretical CH4 yield (L/kg TS) | 324 | 228 | 622 | 494 | 582 | 211~657 | 418 | 301 | 363 | 300 |

| Experimental CH4 yield (L/kg TS) | 241 | 51 | 580 | 510 | 420 | 170~557 | 213 | 281 | 186 | 245 |

| Ref. | Method | Environment | Reactor Type | P (atm) | pH | H2 inj. | CO2 inj. | Retention Time (h) | CH4 Production Rate | CH4 Concentration (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| [102] | Batch ex situ | Thermophilic | CSTR | 0 | 8.5 | 7.3 | 1.8 | 24 | 1.7 | 93 |

| 8.5 | 15.4 | 3.9 | 3.7 | 96 | ||||||

| Continuous ex situ | 8.1 | 14.7 | 3.7 | 2 | 2.9 | 78 | ||||

| 7.1 | 47.1 | 11.8 | 0.57 | 8.2 | 70 | |||||

| Batch in situ | 7.97 | 5 | - | 24 | 1.82 | 65 | ||||

| [107] | Ex situ with mixing (1500 rpm) | Thermophilic | CSTR | 0.74 | 6.85 | 331.2 | 86.4 | 0.09 | 75.3 | 65 |

| 4.93 | 576 | 144 | 0.054 | 137.1 | 80 | |||||

| [108] | In situ with mixing (500 rpm) | Thermophilic | CSTR | 1.48 | 7.8 | 2.9 | - | 8 | 0.9 | 93.5 |

| 5.9 | 4 | 1.5 | 95.4 | |||||||

| 11.3 | 2 | 2.6 | 90 | |||||||

| 11.6 | 2 | 2.7 | 94.2 | |||||||

| 22.8 | 1 | 5.3 | 90.8 | |||||||

| [109] | Ex situ with mixing (700 rpm) | Thermophilic | CSTR | 0 | 6.85 | 345 | 86 | 0.076 | 47.9 | 22 |

| 46 | 11.5 | 0.76 | 10 | 85 | ||||||

| 0.2 | 230.4 | 57.6 | 0.117 | 46.9 | 42 | |||||

| 100 | 28 | 0.13 | 16 | 74 | ||||||

| 7.35 | 960 | 240 | 0.022 | 65.6 | 7 | |||||

| [110] | In situ with mixing (150 to 300 rpm) | Thermophilic | CSTR | 0 | 7.75 | 3.17 | 0.86 | 14.4 | 1.4 | 53 |

| [111] | In situ and liquid recirculation (0.58 m3/h) | Mesophilic | AF | 1 | 7.91 | 71.3 | 36.5 | 28 | 9.42 | 63 |

| 143.5 | 36.5 | 18 | 7.12 | 57 | ||||||

| [112] | Continuous ex situ | Mesophilic | TB | 0 | 7.3 | 4.8 | 1.15 | 4 | 1.2 | 98~100 |

| 6 | 1.4 | 1.5 | 98 | |||||||

| [113] | Ex situ | Thermophilic | M | 0 | 7.4 | 9.9 | 2.4 | 3.1 | 2.4 | 79 |

| [114] | Ex situ | Thermophilic | HFM | 0 | 7.2 | 10 | 2.6 | 2.8 | 2 | 84 |

| 20 | 5.2 | 1.37 | 3.8 | 75 | ||||||

| 45.2 | 11.2 | 0.64 | 9.5 | 65 | ||||||

| [115] | In situ with mixing (155 rpm) | Thermophilic | UASB | 0 | 7.9 | 7.92 | 2 | 3.29 | 1.8 | 81 |

| 7.9 | 3.18 | 1.8 | 66 | |||||||

| 8.2 | 2.83 | 1.5 | 52 | |||||||

| [116] | Ex situ | Mesophilic | BPF | 0 | - | 83.2 | 20.8 | 0.37 | 20 | 97 |

| 120 | 30 | 0.27 | 30 | 90 | ||||||

| 114.4 | 28.6 | 0.27 | 27 | 75 | ||||||

| [117] | Ex situ | Thermophilic | FB | 0 | 6.8–6.9 | 19.8 | 5 | 144 | 4 | 46 |

| 11 | 2.7 | 1.7 | 26 | |||||||

| 7 | 1.7 | 1.7 | 87 | |||||||

| [118] | Ex situ | Mesophilic Thermophilic | B | 0 | 7–7.5 | 0.36 | 0.09 | 24 | 0.19 | 79 81 |

| Country | Number of Biogas Plants | Generation Potential (GWh/Year) | Year | ||

|---|---|---|---|---|---|

| WWTPs | Total * | WWTPs | Total * | ||

| Australia | 52 | 242 | 381 | 1587 | 2020 |

| Brazil | 57 ** | 638 | 8590 ** | 11,700 | 2021 |

| Canada | 31 | 150 | na *** | na *** | 2019 |

| Denmark | 51 | 172 | 308 | 3723 | 2018 |

| Finland | 16 | 96 | 221 | 877 | 2020 |

| France | 88 | 687 | 442 | 3527 | 2017 |

| Germany | 1271 | 10,551 | 4000 | 54,100 | 2020 |

| Ireland | 15 | 59 | na *** | 752 | 2019 |

| Republic of Korea | 36 | 119 | 630 | 2815 | 2017 |

| Netherlands | 80 | 262 | 640 | 3465 | 2018 |

| Norway | 27 | 162 | 305 | 782 | 2019 |

| Sweden | 134 | 282 | 721 | 2161 | 2020 |

| Switzerland | 271 | 434 | 638 | 1519 | 2019 |

| UK | 163 | 994 | 1280 | 8317 | 2018 |

| FC | GT | ICE | Micro GT | |

|---|---|---|---|---|

| Size | Small | Large | Small/Medium | Small |

| Capacity (kW) | 300–1500 | 3500–15,000 | 110–3000 | 30–300 |

| Electrical/Thermal/ Overall Efficiency (%) | 40–45/30–40/ 75–80 | 40–45/30–40/ 75–80 | 30–40/40–50/ 70–80 | 40–45/30–40/ 75–80 |

| CH4 minimum level (%) | 85 | 30 | 60 | 40 |

| Emissions NOx | Extremely low | Low | Medium/High | Very low |

| Capital costs (GBP/kW) | 3000~4000 | 400~1100 | 900~1500 | 600~1200 |

| O&M costs (GBP/kWh) | 0.003~0.01 | 0.01~0.02 | 0.005~0.01 | 0.008~0.015 |

| Country | Electricity | Heat | CHP | Biomethane | Flare | Others | Year |

|---|---|---|---|---|---|---|---|

| Australia * | 33.3 | 26.2 | 21.4 | - | 19 | - | 2020 |

| Brazil | 73 | 8.2 | - | 18.4 | - | 0.4 | 2021 |

| Canada | 50 | 10 | 25 | 5 | - | 10 | 2019 |

| Denmark | 17 | 29 | - | 54 | <1 | - | 2018 |

| Finland | 21 | 32 | - | 13 | 17 | 17 | 2020 |

| France | 47 | 43 | - | 10 | - | - | 2017 |

| Germany | 62.7 | 35.6 | - | 1.7 | - | - | 2020 |

| Republic of Korea | 39.5 | 23.7 | - | 4.2 | 11.3 | 21.3 | 2017 |

| Netherlands | 32.4 | 65 | - | 2.6 | - | - | 2018 |

| Norway | 5 | 25 | - | 51 | 14 | 5 | 2019 |

| Sweden | 2 | 19 | - | 65 | 11 | 3 | 2020 |

| Switzerland | 25 | 23 | - | 26 | 13 | 13 | 2018 |

| UK | 66.70 | 0.05 | - | 33.25 | - | - | 2018 |

| Method | Energy Required (kWh/m3) | CH4 Recovery rate (%) | Capital Cost (GBP/kWh) | Op. Cost (GBP/kWh) | Number of Plants * | Benefits | Drawbacks |

|---|---|---|---|---|---|---|---|

| CA | 0.06–0.17 | 99.9 | 264–438 | 1.15–1.92 | 104 | • Provide the highest biomethane purity • No need for pressurized biogas • No need for treatment | • Prior treatment is needed • Heat, water, and chemical is required • Higher energy consumption • Problems with corrosion and precipitation |

| CS | 0.18–0.25 | 98–99.9 | 394–960 | 4.80–7.10 | 9 | • No water and chemicals required • High biomethane purity | • Biogas treatment is required • Not mature technology • High investment and O&M • Prior treatment is needed |

| PSA | 0.16–0.35 | 90–98.5 | 255–831 | 0.92–6.50 | 81 | • Low energy consumption • Compact technology • No water and chemicals required • Widely used in small-scale sites | • Lower biomethane purity compared with others • Prior treatment is needed • High energy consumption and strict process control |

| WS | 0.20–0.30 | 98–99.5 | 357–731 | 0.47–0.94 | 175 | • Low energy consumption • Simple, flexible, and low O&M costs • Remove and • Most used type | • Dried process is needed • More strict process control • Chemicals may be required • High water demand is needed |

| OPS | 0.23–0.33 | 96–99 | 510–969 | 0.92–1.05 | 19 | • Remove , and other compounds • High biomethane purity | • High investment and O&M • Higher energy consumption • Heat and chemicals may be required |

| MS | 0.18–0.35 | 85–99 | 205–367 | 0.79–5.50 | 148 | • Simple, flexible, and low O&M costs • Compact and reliable technology • No chemicals, water, or heat required | • Require multiple stages • High investment costs (membranes) • Not mature technology • Can be inefficient • Not recommended for biogas composed of many impurities |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lima, D.; Appleby, G.; Li, L. A Scoping Review of Options for Increasing Biogas Production from Sewage Sludge: Challenges and Opportunities for Enhancing Energy Self-Sufficiency in Wastewater Treatment Plants. Energies 2023, 16, 2369. https://doi.org/10.3390/en16052369

Lima D, Appleby G, Li L. A Scoping Review of Options for Increasing Biogas Production from Sewage Sludge: Challenges and Opportunities for Enhancing Energy Self-Sufficiency in Wastewater Treatment Plants. Energies. 2023; 16(5):2369. https://doi.org/10.3390/en16052369

Chicago/Turabian StyleLima, Derick, Gregory Appleby, and Li Li. 2023. "A Scoping Review of Options for Increasing Biogas Production from Sewage Sludge: Challenges and Opportunities for Enhancing Energy Self-Sufficiency in Wastewater Treatment Plants" Energies 16, no. 5: 2369. https://doi.org/10.3390/en16052369

APA StyleLima, D., Appleby, G., & Li, L. (2023). A Scoping Review of Options for Increasing Biogas Production from Sewage Sludge: Challenges and Opportunities for Enhancing Energy Self-Sufficiency in Wastewater Treatment Plants. Energies, 16(5), 2369. https://doi.org/10.3390/en16052369