3.1. General Introduction

The use of HEVs in the military has a number of direct and indirect reasons. Direct vehicular applications use electrically controlled rods, or they have a vehicular electrical system, which supplies the power to a military base to create a microgrid. When considering HEVs for military use, especially the high cost of fuel is one of the biggest problems. Fuel can cost a lot more to transport to the field over long distances and through risky routes. Transporting fuel to the battlefield can cost anywhere from $1 per gallon in a typical civilian setting to $400 per gallon, and the price could even rise to $1000 per gallon if an airlift is required. An average, reasonable price to ship fuel to the site is typically around $100 per gallon. In the end, we can safely assume that fuel prices in military settings will be several hundred dollars per gallon. Therefore, even a modest reduction in fuel consumption can result in significant savings totaling billions of dollars annually. The following are some of the indirect benefits of HEVs: When the military is active in a combat, some infrastructures which are used may need utility-level voltages at electricity. If multiple HEVs are perfectly affiliated and intersected, utility-level voltages can be generated to power various stationary equipment. With a reliable utility power source, a microgrid of several HEVs can actually be formed. Naturally, appropriate control electronics will be required to properly connect multiple HEVs to generate electricity. Utilizing vehicles for power generation in this way can be very beneficial because it can cut down on the need for auxiliary power units and save money and weight associated with acquiring and transporting them to the field. The HEV will benefit from the redundancy in the event of the failure of one of the motors, for example, if it uses a SHEV architecture and has wheel hub motors for each wheel or the propulsion will be operated by one motor per each axle. This makes it easier to transfer the vehicle to a safe zone and operate it in a fully degradable mode with reduced performance. As a result, it is evident that using HEVs for military purposes has numerous advantages. According to studies on commercial vehicles, the ICE vehicle is the lightest one, while the PHEV is slightly heavier. However, it was discovered that the series hybrid vehicle weighed significantly more. This analysis may be operated for military vehicles even if it is used on a commercial vehicle. When ICE vehicle is taken into consideration as the standard vehicle, then other architectures can be compared in the following ways. Evidently, the power pack in the SHEV must be the same size as the ICE is necessary to match the performance. The worst-case scenario should be presented after studies of various drive cycles have been conducted. The battery or other form of storage, as well as whether or not they are able to supply the required maximum power, are critical considerations in this process. The generator will only need to be the same size as the maximum power requirement if the battery is always completely floating, and when the motor and the battery are parallel, the power from the ICE and generator is easily fed in this layout. However, SHEVs’ ICEs and generators could certainly be smaller because the purpose of battery and the power source is to deal with sudden peaks and higher demands. In many cases, PHEV have an independent generator from the main propulsion motor in some other architectures. The control strategy greatly influences the need for this generator. Depending on the power required to perform the propulsion and the state of charge of the battery (SOC), additional charging may be required. This generator comes into play in situations like these. Taking into consideration the battery or any other storage device is an essential component in the design of the SHEV and PHEV. Most military vehicles use diesel engines. These vehicles will always benefit from advancements in the technology of diesel engines. However, hybridization can always be used to get better fuel economy besides its other advantages, no matter what technology is used in diesel engines. The next question that needs to be answered is whether the architecture of military vehicles should be series, parallel, or complex for the purpose of hybridization. The best way to respond to this question is to ask oneself what comes first: Weight, fuel economy, size, or dependability? If fuel economy is paramount, a PHEV should be preferred. A PHEV will be superior to a SHEV if size and lightness are important because of the need to transport the vehicle in an aircraft, for example. Usually, the SHEV is slightly heavier than the PHEV, which may also have an effect on fuel economy in a small way. On the other hand, if the vehicle’s performance, or power output, is of the utmost importance, the SHEV architecture might be a good choice. Additionally, thanks to its faster motor control ability when compared to an ICE engine, it is inevitable that it will be in more demand because it offers a lighter transmission. As ICE and motor provide excessive propulsion, a PHEV may better address reliability concerns in general. In a military vehicle, reliability is an important issue to be considered. The PHEV, on the other hand, introduces complexity into its mechanical coupling and is more difficult to control. Before a definitive conclusion can be reached regarding this issue of reliability, it is necessary to conduct an in-depth study of these devices’ failure modes. Maintenance is another issue that comes with military vehicle system reliability. For a number of reasons, it occurs that maintaining a SHEV may be done easily. Controlling it is simpler. In contrast to a PHEV, its mechanical linkage is also very straightforward. In the event of failure, hub motors which are used during the propulsion are possible to change. The advantages and disadvantages of parallel and SHEVs are outlined above. However, a PHEV probably provides better service for overall reliability and, more specifically, survival requirements. Having said that, the application and drive cycle may significantly influence the decision. Thanks to its drive cycle, A PHEV probably has more advantages for military or noncombat vehicles that travel longer ranges, such as logistic or support vehicles. In order to arrive at the best possible choice, reliability, fuel economy, and performance should be conducted, besides other possible requirements.

3.3. A Shev Tracked Vehicle Example

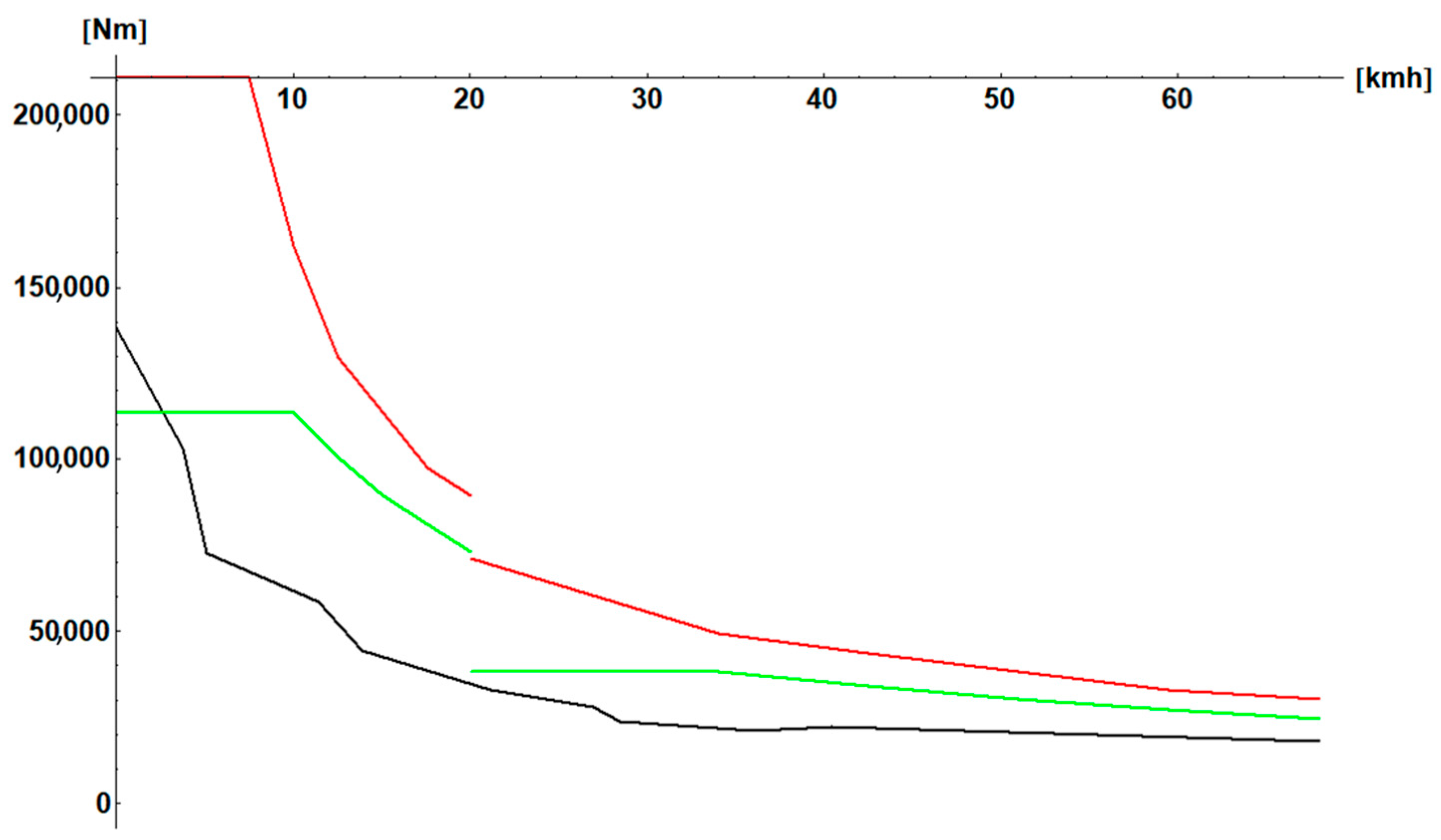

There are a few key requirements that must be met for armored tracked vehicles that are mostly used for military purposes. Their off-road mobility is one of these requirements. Distinctive obstacles and abrupt slopes characterize the deformable irregular surfaces of off-road terrain. It is generally acknowledged that the mechanical properties of the terrain dominate the complex interaction between tracked vehicles and soft terrain. Furthermore, depending on the applied road wheel normal load and driving torque, some soils may exhibit excessive sinkage and slippage. One of the most important aspects of studies on off-road vehicles is the mechanics of how track and soil interact. Sinkage, multi-pass sinkage, and slip sinkage are just a few of the many effects that occur when deformable soil and a pneumatic tire interact. Thrust, motion resistance, sinkage, slip, driving torque, and sprocket angular speed typically define vehicle performance. How to accurately predict these parameters is a major concern for all off-road vehicle researchers and designers. The problem, in this case, is to understand whether maximum instantaneous motor torque can be used for off-road MBT use. In normal conditions, the MBT will use maximum torque on starting for a few seconds, afterwards, the armored vehicle tends to float on the tracks, and the required torque is reduced. Looking at

Figure 3 and

Figure 4, this is exactly what the traditional torque and power curves are designed for. The problem arises when the armored vehicle stick-slips into the soft terrain. It starts with large torque, then accelerates with reduced friction, and then decelerates to stop again because the friction value increases. A friction increase requires a torque increase. This problem is also present in traditional transmissions where the torque converter abuse will exceed the maximum allowed lubricant temperature in the automatic transmission. The tractive force required to move a vehicle is known as tractive effort (

Te). The

Te over Weight (

Te/Wt) is used to specify some of the mobility requirements, such as gradeability and steering. The torque at the sprocket is the product of the

Te and the sprocket radius. A tracked vehicle traveling at 25 km/h while turning on a 15 radius places stresses on its tracks comparable to climbing a 40% grade. The

Te/Wt for pivot steer and 60% grade is approximately the same. This necessitates that the cooling system of the vehicle be constructed in such a way that the drivetrain components can endure loads of 0.7

Te/Wt on a continuous basis without exceeding their thermal limits. When pulling out of deep, frozen mud, for example, the maximum transient

Te/Wt requirement for the vehicle as a whole may reach more than 1.2. This is necessary in some extremely challenging operating conditions. In traditional transmission with regenerative steering, the most important

Te/Wt ratio is 0.9 per side, with a 1.0

Te/Wt difference between the two sides. The reason for the last requirement was that the vehicle’s weight would only be supported by one track under certain rare operating conditions. When a single track is in a ditch or completely ensnared in frozen mud or ice, these conditions occur. When one track is in a ditch to the point where significant earth movement is required, this is another scenario. Therefore, the maximum allowed torque and power load should satisfy Condition (7).

In other words, the maximum continuous torque required by the vehicle Tmax_required should never exceed the maximum continuous torque allowed by the electric motors Tcontinuous. At the same time, the electric motors should satisfy the same requirement for the power maximum allowed power Pcontinuous. The single-track requirement is an exception that may be satisfied by using the full maximum instantaneous torque briefly.

Figure 8 shows an automatic transmission for an MBT with a weight of over 50 t. As it will be shown, the engine should output about 2000 HP to fully exploit the electric motor performances. The motors chosen are automotive-derived axial flux motors that now have the best torque-to-weight capacity. The engine chosen is the off-the-shelf Caterpillar “Cat C32 ACERT Marine Propulsion Engine (1900 HP @ 2300 rpm)”. It is possible that using it without the TIER III limitations, it will output more than 2000 HP. The use of marine engines in MBTs is not new. However, modifications are needed due to the higher cooling temperatures and the different duty cycle. In this case, the engine always works at the maximum speed. Therefore, the low torque requirement is no longer valid. The sprockets and final drives are not to scale. The power pack of

Figure 8 lacks a proper air filter, the motor controllers, the generator controllers, and the cooling system with the large fans. A complete design of the power pack is beyond the scope of this paper.

Figure 9a,b shows the size of this incomplete power pack.

The calculation of the right SHEV transmission starts from the torque requirement of

Figure 4. The maximum torque at “0 speed” can be obtained only for a few seconds due to the overheating of the torque multiplier/converter. Therefore, in this condition, the black curve of

Figure 7 will be used. It is possible to satisfy the torque requirements of

Figure 4 by using several electric motors on the same sprocket shaft. The sprocket shaft is usually driven by the final reduction gears that, in our case, have a maximum reduction ratio of

ratiofinal_drive = 19.5. If the electric motors run at maximum speed (3500 rpm), the vehicle will run at a maximum of about 20 kmh (7).

Crfsprocket is the primitive circumference of the track-sprocket [m].

This speed would be unacceptable for modern MBTs, therefore, the final reduction gear should implement two speeds up to the maximum on-road velocity of 68 km/h. In this case, the II speed has a reduction ratio of about 6.58. A clutch system or a Selespeed clutchless gearbox will implement this feature. The number of motors for each sprocket can be calculated with Equation (9). T

max_sprocket is the maximum torque from the traditional power pack for the two sprockets. T

motor is the maximum torque output of the electric motor for “minutes”.

In case of emergency, the T

max seconds-red line in

Figure 7 can be used. In this case, the minimum number of electric motors for each sprocket is calculated in Equation (10).

Therefore, the six electric motors coupled to the single sprocket will be grouped in three motors with two rotors each. In this way, in case of failure of a single motor, the vehicle can limp home. In case the vehicle’s weight would only be supported by one track under certain rare operating conditions, Equation (11) should be satisfied.

where

ηTR is the recirculation efficiency of a traditional MBT steering system. Therefore, in an emergency, with only one track operational, the vehicle will operate in the same way as a traditional ICE MBT.

Figure 10 shows the torque of the SHEV compared to the torque of a traditional ICE-powered MBT.

The blue curve of torque at sprocket (

Figure 10) is always above the black curve of a traditional ICE-powered MBT. This is not true for the continuous curve of torque at sprocket (green) of

Figure 10. This is due to the fact the starting torque can be held only for a few seconds, both in the ICE-powered MBT and in the SHEV MBT. Another very important condition is given by the shift from the lower speed to the higher speed of the final drives. Certain continuity of torque should be kept avoiding shocks on the gearboxes, tracks, and motors.

Figure 11 also shows that even in the worst conditions: Vehicle running and shifting at full torque (green line), the instantaneous torque (red line) will provide a smooth shifting at about 20 km/h.

The curves of

Figure 10 and

Figure 11 demonstrate that the MBT can operate with the SHEV transmission and motors. These motors will take the energy from the ICE generator. This unit will run independently, just keeping the microgrid electrical parameters within tolerances. Therefore, the amount of power installed is a choice of the designer, who can choose to fully exploit the torque capacity of the electric motors or to cut the maximum torque with a smaller and lighter ICE generator. The power requirements are shown in

Figure 12 for continuous (green) and transient operations (red). A minimum power of 1500 HP is required to have a smooth gearshift at full throttle. The SHEV tank will outperform the traditional one in both off-road (below 20 km/h) and on-road conditions. The torque available is higher in most conditions, and gear shifting is nearly absent with smoother operations and less track and transmission fatigue.

3.4. Shev Reliability

Concerns about the dependability of HEVs have grown significantly because of recent statistical data from the automotive market. This paper will look at the architecture of a vehicle with a standard diesel IC engine, followed by parallel SHEVs. Initially, some assumed reliability numbers are used to introduce, and then the reliabilities of elements and total subsystem are analyzed. Naturally, it is important to acknowledge that consistent and supported results of these kinds of systems are required with some tests, such as experimental tests, modeling and simulation of the design. In our case, most of these data are taken from the automotive market. It is necessary to keep the basic or proven values of these kinds of subsystems. For the purposes of this discussion, when we talk about reliability, the probability that a component, subsystem, or system is functional which performs in a specific time period. In this period, there are no other changes in this system or a maintenance issue. As a result, reliability is linked to probability and time. Additionally, we define availability by considering a hypothetical system with a reliability of one. It will be referred to as “fully” available. Using the straightforward approach outlined below, system reliability regarding each subsystem of a SHEV can be examined. Take into consideration the various items shown in the first column of the table and assume that the reliability of each of those items is as shown in

Table 4 [

19].

Keep in mind that numerous constituent subsystems and components are used to construct each of the aforementioned items. However, a single cumulative reliability number can be used for each of the aforementioned items. Instead of delving into the motor’s individual components, one example is that an overall reliability of 0.99974 can be used. If the ICE power unit has a reliability rating of, say, 0.99974, there is a three in 10,000 chance that it will break down in 1000 h. It is true that as a system ages, reliability decreases. However, for the purposes of this discussion, it will be assumed constant. In the system described above, the only redundant system is the motor assembly on each sprocket, which survives a single motor failure. Two motors in parallel and one motor in serial arrangement, therefore, compose the system. Equation (12) shows that the three-motor system has approximately the same reliability as the single motor.

The overall SHEV reliability is calculated in Equation (13).

Therefore, the power pack has seven probabilities of failure in 4500 h. This figure is unacceptable for an MBT, therefore, the TBO should be reduced. During the Vietnam War, the M113 power pack was replaced every 300 h. In our case, we would have had 0.5 failures in 300 h. By using two ICEs instead of one, the reliability would be 0.99959 or four failures in 4500 h. However, the diagnostic probability should be considered. The SHEV has an OBD system for every component. This software runs with the real-time controllers of the various subsystems. The early diagnosis probability is the probability of diagnosing a failure in time to repair the failing part before the failure occurs. These values are summarized in

Table 5.

The probability of an early failure diagnosis DR is four in 4500 h (14). The SHEV is still not reliable enough for a TBO of 4500 h. Everything changes if two ICE subsystems are used in the SHEV, with one failure probability over 4500 h. This figure is acceptable. Therefore, it is convenient to use two ICE subsystems instead of one. The two subsystems may output half the power. In this case, a single ICE failure will reduce the MBT performance but not its safety.