Biodesulfurization Processes for the Removal of Sulfur from Diesel Oil: A Perspective Report

Abstract

:1. Introduction

1.1. Effects of Sulfur

1.1.1. Effects on Human and Animal Health

1.1.2. Effects on Environment and Infrastructure

1.1.3. Effects on the Economy

1.2. Sulfur Content Regulations

2. Information and Emerging Trends of Diesel Oil and Its Production

3. Existing Technologies for Desulfurization of Diesel Oil

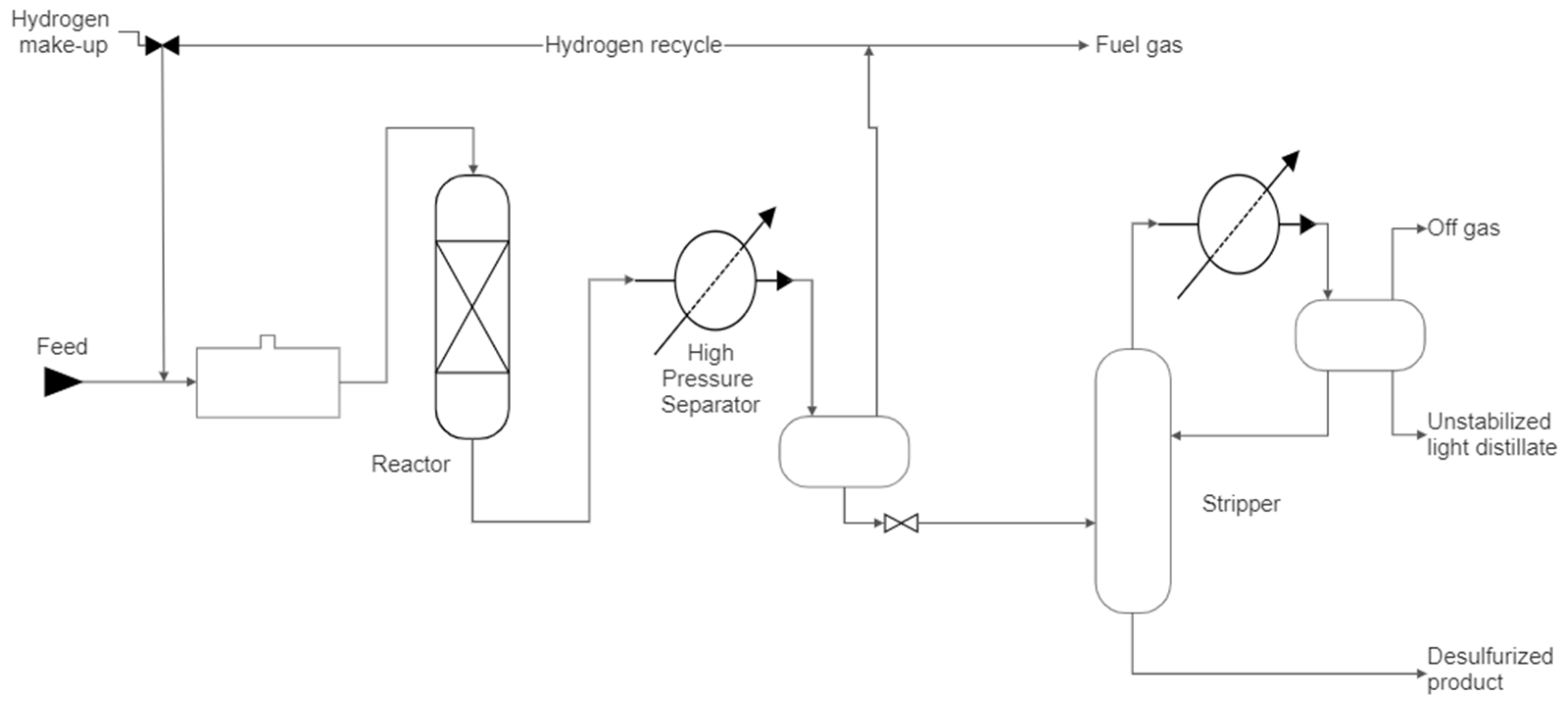

3.1. Hydrodesulfurization (HDS)

3.2. Adsorptive Desulfurization (ADS)

3.3. Oxidative Desulfurization (ODS)

3.4. Desulfurization of Diesel Fuel Using Ionic Liquids (ILs)

3.5. Biodesulfurization

4. Recent Studies on BDS

5. Industrial View on Biodesulfurization

6. Conclusions and Future Perspective

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Javadli, R.; de Klerk, A. Desulfurization of heavy oil. Appl. Petrochem. Res. 2012, 1, 3–19. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Zang, M.; Li, L.; Chen, J.; Liu, Q.; Feng, X.; Sun, S.; Zang, C.; Zhao, C. Efficient Biodesulfurization of Diesel Oil by Gordonia Sp. SC-10 with Highly Hydrophobic Cell Surfaces. Biochem. Eng. J. 2021, 174, 108094. [Google Scholar] [CrossRef]

- Kalita, M.; Sangannavar, P.A.; Chutia, M.; Jha, D.K.; Sathyanarayana, K.; Kumar, J.S.; Subrahmanyam, G. Microbial Biodesulfurization: A Sustainable Technology for Refining Fossil Fuels; Elsevier Inc.: Amsterdam, The Netherlands, 2022; ISBN 9780323905909. [Google Scholar]

- Sadare, O.O.; Obazu, F.; Daramola, M.O. Biodesulfurization of Petroleum Distillates—Current Status, Opportunities and Future Challenges. Environments 2017, 4, 85. [Google Scholar] [CrossRef] [Green Version]

- Guobin, S.; Huaiying, Z.; Jianmin, X.; Guo, C.; Wangliang, L.; Huizhou, L. Biodesulfurization of Hydrodesulfurized Diesel Oil with Pseudomonas Delafieldii R-8 from High Density Culture. Biochem. Eng. J. 2006, 27, 305–309. [Google Scholar] [CrossRef]

- Xie, Y.; Posada, F.; Minjare, R. Diesel Sulfur Content impactson Euro VI Soot-Free Vehicles: Considerations for Emerging. Front. Environ. Sci. Eng. 2020, 10. Available online: https://theicct.org/publications/diesel-sulfur-content-soot-free-emerging-markets (accessed on 3 March 2023).

- Stratas Advisors. 11 Countries Move Up in Top 100 Ranking on Diesel Sulfur Limits; Stratas Advisors: Houston, TX, USA, 2018; p. 3. [Google Scholar]

- Dembaremba, T.O.; Majodina, S.; Walmsley, R.S.; Ogunlaja, A.S.; Tshentu, Z.R. Perspectives on Strategies for Improving Ultra-Deep Desulfurization of Liquid Fuels through Hydrotreatment: Catalyst Improvement and Feedstock Pre-Treatment. Front. Chem. 2022, 10, 807225. [Google Scholar] [CrossRef] [PubMed]

- Britannica. Diesel Fuel. Br. Ed. Encycl. 2023. Available online: https://www.britannica.com/technology/diesel-fuel (accessed on 17 February 2023).

- Yu, B.; Xu, P.; Shi, Q.; Ma, C. Deep Desulpurization of Diesel Oil and Crude Oils by a Newly Isolated Rhodococcus Erythropolis Strain. Appl. Environ. Microbiol. 2006, 72, 54–58. [Google Scholar] [CrossRef] [Green Version]

- Awadh, M.; Mahmoud, H.; Abed, R.M.M.; El Nayal, A.M.; Abotalib, N.; Ismail, W. Diesel-Born Organosulfur Compounds Stimulate Community Re-Structuring in a Diesel-Biodesulfurizing Consortium. Biotechnol. Rep. 2020, 28, e00572. [Google Scholar] [CrossRef]

- Zhao, H.; Ge, Y.; Wang, X.; Tan, J.; Wang, A.; You, K. Effects of Fuel Sulfur Content and Diesel Oxidation Catalyst on PM Emitted from Light-Duty Diesel Engine. Energy Fuels 2010, 24, 985–991. [Google Scholar] [CrossRef]

- Lee, H.; Kang, S.; Jin, Y.; Jung, D.; Park, K.; Li, K.; Lee, J. Systematic Investigation of the Extractive Desulfurization of Fuel Using Deep Eutectic Solvents from Multifarious Aspects. Fuel 2020, 264, 116848. [Google Scholar] [CrossRef]

- Optenhostert, T.; Puthenkalam, S.; Stegmann, N.; Steffen, M.; Schmidt, W. Catalytic Hydrodesulfurization of Gaseous Fuels with Autogenously Formed Hydrogen. Chem. Ing. Tech. 2021, 93, 1028–1032. [Google Scholar] [CrossRef]

- Abid, M.F.; Ahmed, S.M.; AbuHamid, W.H.; Ali, S.M. Study on Novel Scheme for Hydrodesulfurization of Middle Distillates Using Different Types of Catalyst. J. King Saud Univ. Eng. Sci. 2019, 31, 144–151. [Google Scholar] [CrossRef]

- Ganiyu, S.A.; Lateef, S.A. Review of Adsorptive Desulfurization Process: Overview of the Non-Carbonaceous Materials, Mechanism and Synthesis Strategies. Fuel 2021, 294, 120273. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Wu, P.; Feng, C.; Xue, G. Catalytic Oxidative/Extractive Desulfurization of Model Oil Using Transition Metal Substituted Phosphomolybdates-Based Ionic Liquids. Catalysts 2018, 8, 639. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.; Jiang, Z.; Li, J.; Zhang, Y.; Lin, F.; Liu, Y.; Li, C. Catalytic Oxidation of Thiophene and Its Derivatives via Dual Activation for Ultra-Deep Desulfurization of Fuels. J. Catal. 2012, 287, 5–12. [Google Scholar] [CrossRef]

- Rajendran, A.; Cui, T.Y.; Fan, H.X.; Yang, Z.F.; Feng, J.; Li, W.Y. A Comprehensive Review on Oxidative Desulfurization Catalysts Targeting Clean Energy and Environment. J. Mater. Chem. A 2020, 8, 2246–2285. [Google Scholar] [CrossRef]

- Choi, A.E.S.; Roces, S.; Dugos, N.; Wan, M.W. Adsorption of Benzothiophene Sulfone over Clay Mineral Adsorbents in the Frame of Oxidative Desulfurization. Fuel 2017, 205, 153–160. [Google Scholar] [CrossRef]

- Martínez, I.; Mohamed, M.E.S.; García, J.L.; Díaz, E. Enhancing Biodesulfurization by Engineering a Synthetic Dibenzothiophene Mineralization Pathway. Front. Microbiol. 2022, 13, 987084. [Google Scholar] [CrossRef]

- Mohebali, G.; Ball, A.S. Biodesulfurization of Diesel Fuels—Past, Present and Future Perspectives. Int. Biodeterior. Biodegrad. 2016, 110, 163–180. [Google Scholar] [CrossRef]

- Bradford, A.; Briggs, B. Acid Rain: Causes, Effects and Solutions. Live Science. 16 March 2022. Available online: https://www.livescience.com/63065-acid-rain.html (accessed on 17 February 2023).

- Mahima, K. Science behind Smog and Ominous Implications. Down to Earth. 2 April 2018. Available online: https://www.downtoearth.org.in/blog/air/science-behind-smog-and-its-ominous-implications-60080 (accessed on 17 February 2023).

- Ashok, B.; Kumar, A.N.; Jacob, A.; Vignesh, R. Emission Formation in IC Engines; Elsevier Inc.: Amsterdam, The Netherlands, 2021; ISBN 9780128239551. [Google Scholar]

- Wu, X.; Gao, M.; Guo, S.; Maqbool, R. Environmental and Economic Effects of Sulfur Dioxide Emissions Trading Pilot Scheme in China: A Quasi-Experiment. Energy Environ. 2019, 30, 1255–1274. [Google Scholar] [CrossRef]

- Martin, S.A.; Gallaher, M.P.; O’Conor, A.C. Economic Impact of Standard Reference Materials for Sulfur in Fossil Fuels; Institute of Portland Metropolitan Studies: Portland, OR, USA, 2000. [Google Scholar]

- Ackland, J.; White, J.; Waibel, R.T.; Londerville, S.B. Fuels. In The Coen & Hamworthy Combustion Handbook; CRC: Boca Raton, FL, USA, 2013; pp. 71–94. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration (EIA). Diesel Fuel Explained. 2021. Available online: https://www.eia.gov/energyexplained/diesel-fuel/ (accessed on 17 February 2023).

- Chianelli, R.R.; Berhault, G.; Raybaud, P.; Kasztelan, S.; Hafner, J.; Toulhoatf, H. Periodic Trends in Hydrodesulfurization: In Support of the Sabatier Principle. Appl. Catal. A Gen. 2002, 227, 83–96. [Google Scholar] [CrossRef]

- Bacha, J.; Freel, J.; Gibbs, A.; Gibbs, L.; Hemighaus, G.; Hoekman, K.; Horn, J.; Ingham, M.; Jossens, L.; Kohler, D.; et al. Diesel Fuels Technical Review; Chevron Corporation: San Ramon, CA, USA, 2007; pp. 1–116. [Google Scholar]

- U.S. Energy Information Administration (EIA). Short-Term Energy Outlook; U.S. Energy Information Administration (EIA): Washington, DC, USA, 2023.

- Choi, A.E.S.; Roces, S.A.; Dugos, N.P.; Wan, M.-W.W. Parametric Screening Analysis for the Oxidative Desulfurization of Diesel Oil. Chem. Eng. Trans. 2021, 88, 91–96. [Google Scholar] [CrossRef]

- Sönnichsen, N. Daily Global Crude Oil Demand 2006–2026. Statistica. 7 March 2023. Available online: https://www.statista.com/statistics/271823/daily-global-crude-oil-demand-since-2006/ (accessed on 7 March 2023).

- Piemonte, V. Desulfurization from Gas Oil: Sulfur Removal of Gas Oil to 10 ppm. J. Clean Energy Technol. 2013, 1, 2–7. [Google Scholar]

- Yang, Y.; Kadam, V.D.; You, J. Thiophenes and Their Benzo Derivatives: Reactivity, 4th ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; ISBN 9780128186565. [Google Scholar]

- Saha, B.; Vedachalam, S.; Dalai, A.K. Review on Recent Advances in Adsorptive Desulfurization. Fuel Process. Technol. 2021, 214, 106685. [Google Scholar] [CrossRef]

- Omar, R.A.; Verma, N. Review of Adsorptive Desulfurization of Liquid Fuels and Regeneration Attempts. Ind. Eng. Chem. Res. 2022, 61, 8595–8606. [Google Scholar] [CrossRef]

- Farshi, A.; Shiralizadeh, P. Sulfur Reduction of Heavy Fuel Oil by Oxidative Desulfurization (ODS) Method. Pet. Coal 2015, 57, 295–302. [Google Scholar]

- Capecchi, E.; Piccinino, D.; Bizzarri, B.M.; Botta, L.; Crucianelli, M.; Saladino, R. Oxidative Bio-Desulfurization by Nanostructured Peroxidase Mediator System. Catalysts 2020, 10, 313. [Google Scholar] [CrossRef]

- Mohammadi, P. Ionic Liquids for Desulfurization. In Ionic Liquid-Based Technologies for Environmental Sustainability; Elsevier: Amsterdam, The Netherlands, 2022; pp. 61–74. ISBN 9780128245453. [Google Scholar] [CrossRef]

- Hosseini, A.; Khoshsima, A.; Sabzi, M.; Rostam, A. Toward Application of Ionic Liquids to Desulfurization of Fuels: A Review. Energy Fuels 2022, 36, 4119–4152. [Google Scholar] [CrossRef]

- Francisco, M.; Arce, A.; Soto, A. Ionic Liquids on Desulfurization of Fuel Oils. Fluid Phase Equilib. 2010, 294, 39–48. [Google Scholar] [CrossRef]

- Desai, K.; Dharaskar, S.; Khalid, M.; Gedam, V. Effectiveness of Ionic Liquids in Extractive–Oxidative Desulfurization of Liquid Fuels: A Review. Chem. Pap. 2022, 76, 1989–2028. [Google Scholar] [CrossRef]

- Bhutto, A.W.; Abro, R.; Gao, S.; Abbas, T.; Chen, X.; Yu, G. Oxidative Desulfurization of Fuel Oils Using Ionic Liquids: A Review. J. Taiwan Inst. Chem. Eng. 2016, 62, 84–97. [Google Scholar] [CrossRef]

- Crucianelli, M.; Bizzarri, B.M.; Saladino, R. SBA-15 Anchored Metal Containing Catalysts in the Oxidative Desulfurization Process. Catalysts 2019, 9, 984. [Google Scholar] [CrossRef] [Green Version]

- Feng, S.; Yang, H.; Zhan, X.; Wang, W. Enhancement of Dibenzothiophene Biodesulfurization by Weakening the Feedback Inhibition Effects Based on a Systematic Understanding of the Biodesulfurization Mechanism by Gordonia Sp. through the Potential “4S” Pathway. RSC Adv. 2016, 6, 82872–82881. [Google Scholar] [CrossRef]

- Maghsoudi, S.; Vossoughi, M.; Kheirolomoom, A.; Tanaka, E.; Katoh, S. Biodesulfurization of Hydrocarbons and Diesel Fuels by Rhodococcus sp. Strain P32C1. Biochem. Eng. J. 2001, 8, 151–156. [Google Scholar] [CrossRef]

- Chang, J.; Kim, Y.J.; Lee, B.H.; Kho, K.-S.; Rye, H.W.; Chang, Y.K.; Chang, H.N. Production of a Desulfurization Biocatalyst by Two-Stage Fermentation and Its Application for the Treatment of Model and Diesel Oils. Biotechnol. Progr. 2001, 17, 876–880. [Google Scholar] [CrossRef]

- Mingfang, L.; Jianmin, X.; Zhongxuan, G.; Huizhou, I.; Jiayong, C. Microbial Desulfurization of Dithiophene and 4,6-Dimethyldibenzothiphene in Dodecane and Straight-Run Diesel Oil. Korean J. Chem. Eng. 2003, 20, 2169–2183. [Google Scholar] [CrossRef]

- Darzins, A.; Mrachko, G.T. Sphingomonas Biodesulfurization Catalyst. U.S. Patent 6133016, 17 October 2000. [Google Scholar]

- Srinivasaraghavan, K.; Sarma, P.M.; Lal, B. Comparative Analysis of Phenotypic and Genotypic Characteristics of Two Desulfurizing Bacterial Strains, Mycobacterium Phlei SM-120 and Mycobacterium Phlei GTIS10. Lett. Appl. Microbiol. 2006, 42, 483–489. [Google Scholar] [CrossRef]

- Abo-State, M.A.; El-Gendy, N.S.; El-Temtamy, S.A.; Mahdi, H.M.; Nassar, H.N. Modification of Basal Salts Medium for Enhancing Dibenzothiophene Biodesulfurization by Brevibacillus invocatus C19 and Rhodococcus erythropolis IGTS8. World Appl. Sci. J. 2014, 30, 133–140. [Google Scholar]

- Kirimura, K.; Furuya, T.; Nishii, Y.; Ishii, Y.; Kino, K.; Usami, S. Biodesulfurization of Dibenzothiophene and Its Derivatives through the Selective Cleavage of Carbon-Sulfur Bonds by Moderately Thermophillic Baterium Bacillus subtilis WU-S2B. J. Biosci. Bioeng. 2001, 91, 262–266. [Google Scholar] [CrossRef] [PubMed]

- Kodama, K.; Umechara, K.; Shimizu, K.; Nakatani, S.; Minoda, Y.; Yamada, K. Identification of Microbial Products from Dithiophene and Its Proposed Oxidation Pathway. Agric. Biol. Chem. 1973, 37, 45–50. [Google Scholar] [CrossRef]

- Wang, L.; Ji, G.; Huang, S. Contribution of the Kodama and 4S Pathways to the Dibenzothiophene Biodegradation in Different Coastal Wetlands under Different C/N Ratios. J. Environ. Sci. 2019, 76, 217–226. [Google Scholar] [CrossRef] [PubMed]

- Hou, Y.; Kong, K.; Yang, J.; Zhang, J.; Shi, D.; Xin, W. Biodesulfurization of Benzothiphene by Immobilized Cells of Pseudomonas Stutzeri UP-1. Fuel 2005, 84, 1975–1979. [Google Scholar] [CrossRef]

- Abin-Fuentes, A.; Mohamed, M.E.S.; Wang, D.I.C.; Prather, K.L.J. Exploring the Mechanism of Biocatalyst Inhibition in Microbial Desulfurization. Appl. Environ. Microbiol. 2013, 79, 7807–7817. [Google Scholar] [CrossRef] [Green Version]

- Papizadeh, M.; Roayaei Ardakani, M.; Motamedi, H. Growth-Phase Dependent Biodesulfurization of Dibenzothiophene by Enterobacter sp. Strain NISOC-03. Pollution 2017, 3, 101–111. [Google Scholar] [CrossRef]

- Alves, L.; Melo, M.; Mendonça, D.; Simões, F.; Matos, J.; Tenreiro, R.; Gírio, F.M. Sequencing, Cloning and Expression of the Dsz Genes Required for Dibenzothiophene Sulfone Desulfurization from Gordonia alkanivorans Strain 1B. Enzyme Microb. Technol. 2007, 40, 1598–1603. [Google Scholar] [CrossRef]

- Caro, A.; Boltes, K.; Letón, P.; García-Calvo, E. Dibenzothiophene Biodesulfurization in Resting Cell Conditions by Aerobic Bacteria. Biochem. Eng. J. 2007, 35, 191–197. [Google Scholar] [CrossRef]

- Gün, G.; Yürüm, Y.; Dinler Doʇanay, G. Revisiting the Biodesulfurization Capability of Hyperthermophilic Archaeon Sulfolobus solfataricus P2 Revealed DBT Consumption by the Organism in an Oil/Water Two-Phase Liquid System at High Temperatures. Turk. J. Chem. 2015, 39, 255–266. [Google Scholar] [CrossRef] [Green Version]

- Bhanjadeo, M.M.; Rath, K.; Gupta, D.; Pradhan, N.; Biswal, S.K.; Mishra, B.K.; Subudhi, U. Differential Desulfurization of Dibenzothiophene by Newly Identified MTCC Strains: Influence of Operon Array. PLoS ONE 2018, 13, e0192536. [Google Scholar] [CrossRef]

- Davoodi-Dehaghani, F.; Vosoughi, M.; Ziaee, A.A. Biodesulfurization of Dibenzothiophene by a Newly Isolated Rhodococcus Erythropolis Strain. Bioresour. Technol. 2010, 101, 1102–1105. [Google Scholar] [CrossRef]

- Aribike, D.S.; Susu, A.A.; Nwachukwu, S.C.U.; Kareem, S.A. Microbial Desulfurization of Diesel by Desulfobacterium Aniline. Acad. Arena 2009, 1, 11–14. [Google Scholar]

- Zhang, Q.; Tong, M.Y.; Li, Y.S.; Gao, H.J.; Fang, X.C. Extensive Desulfurization of Diesel by Rhodococcus erythropolis. Bioethanol. Lett. 2007, 29, 123–127. [Google Scholar] [CrossRef] [PubMed]

- Gunam, I.B.W.; Yaku, Y.; Hirano, M.; Yamamura, K.; Tomita, F.; Sone, T.; Asano, K. Biodesulfurization of Alkylated Forms of Dibenzothiophene and Benzothiophene by Sphingomonas Subartica 17b. J. Biosci. Bioeng. 2006, 101, 322–327. [Google Scholar] [CrossRef] [Green Version]

- Boshagh, F.; Mokhtarani, B.; Mortaheb, H.R. Effect of Electrokinetics on Biodesulfurization of the Model Oil by Rhodococcus Erythropolis PTCC1767 and Bacillus Subtilis DSMZ 3256. J. Hazard. Mater. 2014, 280, 781–787. [Google Scholar] [CrossRef]

- Bordoloi, N.K.; Sudhir, R.K.; Chaudhuri, M.K.; Mukherjee, A.K. Deep-Desulfurization of Dibenzothiphene and Its Derivatives Present in Diesel Oil by a Newly Isolated Bacterium Achromobacter sp. to Reduce the Environmental Pollution from Fuel Combustion. Fuel Process. Technol. 2014, 119, 236–244. [Google Scholar] [CrossRef]

- Yang, J.; Yongqi, H.; Dishun, Z.; Shaozhao, W.; Lau, P.C.K.; Marison, I.W. Two-Layer Continous-Process Design for the Biodesulfurization of Diesel Oils under Bacterial Growth Conditions. Biochem. Eng. J. 2007, 37, 212–218. [Google Scholar] [CrossRef]

- Nassar, H.N.; Ali, H.R.; El-Gendy, N.S. Waste Prosperity: Mandarin (Citrus Reticulata) Peels Inspired SPION for Enhancing Diesel Oil Biodesulfurization Efficiency by Rhodococcus Erythropolis HN2. Fuel 2021, 294, 120534. [Google Scholar] [CrossRef]

- Chen, S.; Zhao, C.; Liu, Q.; Zhang, X.; Sun, S.; Zang, M. Biodesulfurization of Diesel Oil in Oil–Water Two Phase Reaction System by Gordonia sp. SC-10. Biotechnol. Lett. 2019, 41, 547–554. [Google Scholar] [CrossRef] [PubMed]

- Pokethitiyooka, P.; Tangaromsuk, J.; Kruatrachue, M.; Kalambaheti, C.; Borole, A.P. Biological Removal of Organic Sulphur by Bacterial Strains Isolated in Thailand. Sci. Asia 2008, 34, 361–366. [Google Scholar] [CrossRef]

- Agarwal, M.; Dikshit, P.K.; Bhasarkar, J.B.; Borah, A.J.; Moholkar, V.S. Physical Insight into Ultrasound-Assisted Biodesulfurization Using Free and Immobilized Cells of Rhodococcus Rhodochrous MTCC 3552. Chem. Eng. J. 2016, 295, 254–267. [Google Scholar] [CrossRef]

- Martínez, I.; Mohamed, M.E.S.; Rozas, D.; García, J.L.; Díaz, E. Engineering Synthetic Bacterial Consortia for Enhanced Desulfurization and Revalorization of Oil Sulfur Compounds. Metab. Eng. 2016, 35, 46–54. [Google Scholar] [CrossRef] [PubMed]

- Alves, L.; Paixão, S.M. Enhancement of Dibenzothiophene Desulfurization by Gordonia alkanivorans Strain 1B Using Sugar Beet Molasses as Alternative Carbon Source. Appl. Biochem. Biotechnol. 2014, 172, 3297–3305. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dai, Y.; Shao, R.; Qi, G.; Ding, B.-B. Enhanced Dibenzothiophene Biodesulfurization by Immobilized Cells of Brevibacterium Lutescens in N-Octane–Water Biphasic System. Appl. Biochem. Biotechnol. 2014, 174, 2236–2244. [Google Scholar] [CrossRef]

- Agarwal, P.; Sharma, D.K. Comparative Studies on the Bio-Desulfurization of Crude Oil with Other Desulfurization Techniques and Deep Desulfurization through Integrated Processes. Energy Fuels 2010, 24, 518–524. [Google Scholar] [CrossRef]

| Microbial Strain | Optimum Conditions | References | |||

|---|---|---|---|---|---|

| Sulfur Conc (ppm) | Temperature (°C) | Final Sulfur Conc (ppm) | % Efficiency of Bacteria | ||

| Erithrobacter spp. NISOC-03 | 3000 | 30 | 1080 | 64 | [59] |

| Gordonia alkanivorans 1B | 37 | 37 | 8.5 | 77 | [60] |

| Rhodococcus erythropolis IGTS8 | 10 | 30 | 2 | 80 | [61] |

| Sulfulubus solfataricus P2 | 55.28 | 78 | 6.36 | 88.5 | [62] |

| Rhodococcus erythropolis MTCC3552 | 92.13 | 50 | 1.01 | 98.9 | [63] |

| Arthrobacter sulfureus MTCC3332 | 92.13 | 50 | 0.68 | 99.26 | [63] |

| Gordonia rubrotica MTCC 289 | 92.13 | 50 | 0.55 | 99.4 | [63] |

| Rhodococcus erythropolis MTCC3951 | 92.13 | 50 | 0.37 | 99.6 | [63] |

| Rhodococcus erythropolis SHT87 | 552.78 | 30 | 0 | 100 | [64] |

| Desulfubacterium anilini | - | 30 | - | 82 | [65] |

| Rhodococcus erythropolis FSD-2 | 198 | 30 | 11.88 | 94 | [66] |

| Spingomonas subarctica T7b | 280 | 27 | 114.8 | 59 | [67] |

| Rhodococcus erythropolis XP | 259 | 30 | 14.25 | 94.5 | [10] |

| Pseudomonas delafieldii R-8 | 591 | 30 | 313.05 | 47.03 | [5] |

| Gordonia sp. SC-10 | 167.7 | 30 | 19.62 | 88.3 | [2] |

| Bacillus subtilis DSMZ 3256 | 1842 | 30 | 1270.98 | 31 | [68] |

| Rhodococcus erythropolis PTCC1767 | 1842 | 30 | 1178.88 | 36 | [68] |

| Bacterium achromobacter sp. | 92.13 | 37 | 6.54 | 92.9 | [69] |

| Rhodococcus globerulus DAQ3 | 16,100 | 30 | 14,183.46 | 11.90 | [70] |

| Rhodococcus erythropolis HN2 | 630 | 30 | 25.2 | 96 | [53] |

| Rhodococcus erythropolis HN2 | 690 | 60 | 27.6 | 96 | [71] |

| Combination of Alphaproteobacteria, Gammaproteobacteria and Actinobacteria | 100 | 30 | 25 | 75 | [11] |

| Gordonia sp. Sc-10 | 10.2 194.7 3035.3 | 30 30 30 | 5 30.4 1792.8 | 50.98 84.39 40.93 | [72] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mamuad, R.Y.; Choi, A.E.S. Biodesulfurization Processes for the Removal of Sulfur from Diesel Oil: A Perspective Report. Energies 2023, 16, 2738. https://doi.org/10.3390/en16062738

Mamuad RY, Choi AES. Biodesulfurization Processes for the Removal of Sulfur from Diesel Oil: A Perspective Report. Energies. 2023; 16(6):2738. https://doi.org/10.3390/en16062738

Chicago/Turabian StyleMamuad, Roselle Y., and Angelo Earvin Sy Choi. 2023. "Biodesulfurization Processes for the Removal of Sulfur from Diesel Oil: A Perspective Report" Energies 16, no. 6: 2738. https://doi.org/10.3390/en16062738

APA StyleMamuad, R. Y., & Choi, A. E. S. (2023). Biodesulfurization Processes for the Removal of Sulfur from Diesel Oil: A Perspective Report. Energies, 16(6), 2738. https://doi.org/10.3390/en16062738