Influence of Yttria-Stabilized Zirconium Oxide Thermal Swing Coating on the Flame-Wall Interaction in Spark Ignition Engines

Abstract

:1. Introduction

2. Materials and Methods

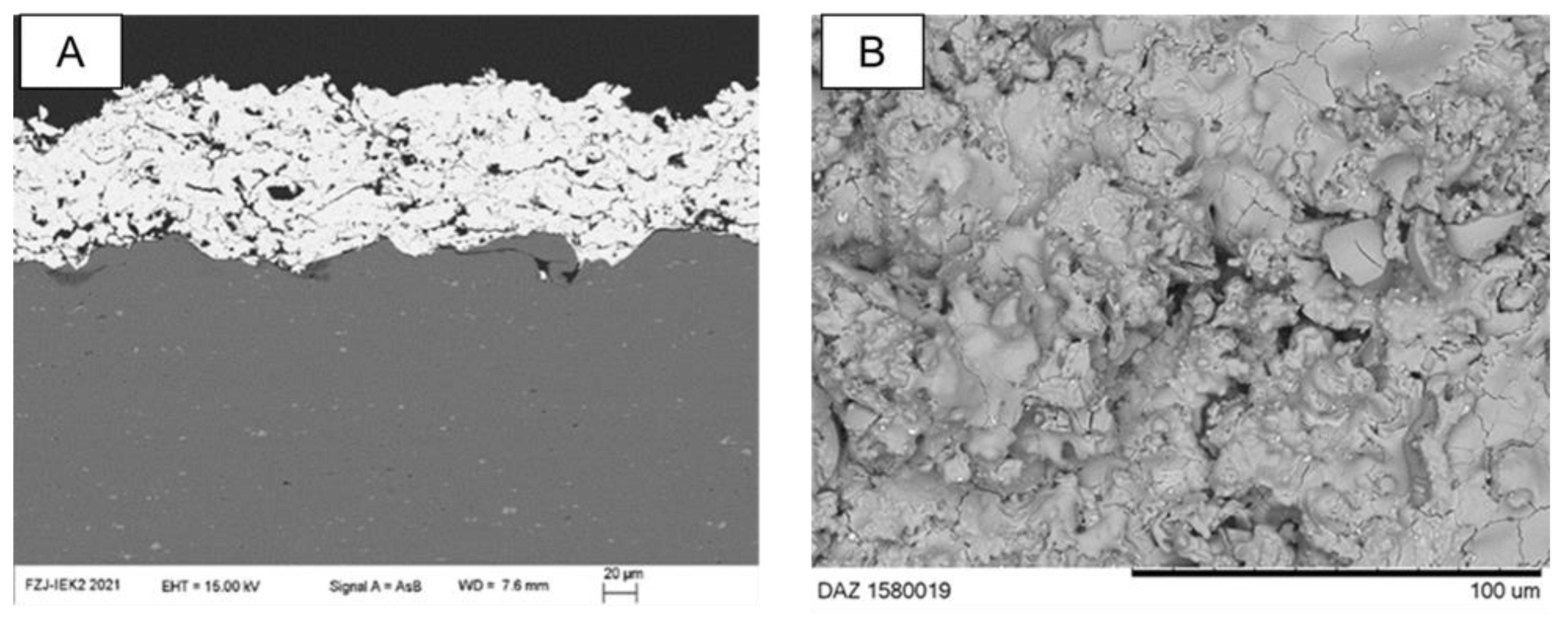

2.1. Coating Spraying

- An arc was ignited between an anode and a tungsten cathode by applying a voltage between the cathode and the anode.

- The gas flow between the electrodes (Ar, He mixtures) was ionized, producing a high-velocity high-temperature plasma jet.

- The powder feedstock was introduced into the plasma flame with a carrier gas. After being heated and accelerated by the plasma flame, the particles impacted on the substrate forming the coating.

2.2. In-Situ DRIFTS

2.3. Constant Volume Combustion Chamber

2.4. Fast Gas Sampling Methodology

2.4.1. Fast Gas Sampling Valve

2.4.2. Single-Cylinder Engine

2.4.3. Gas Analyzers

3. Results

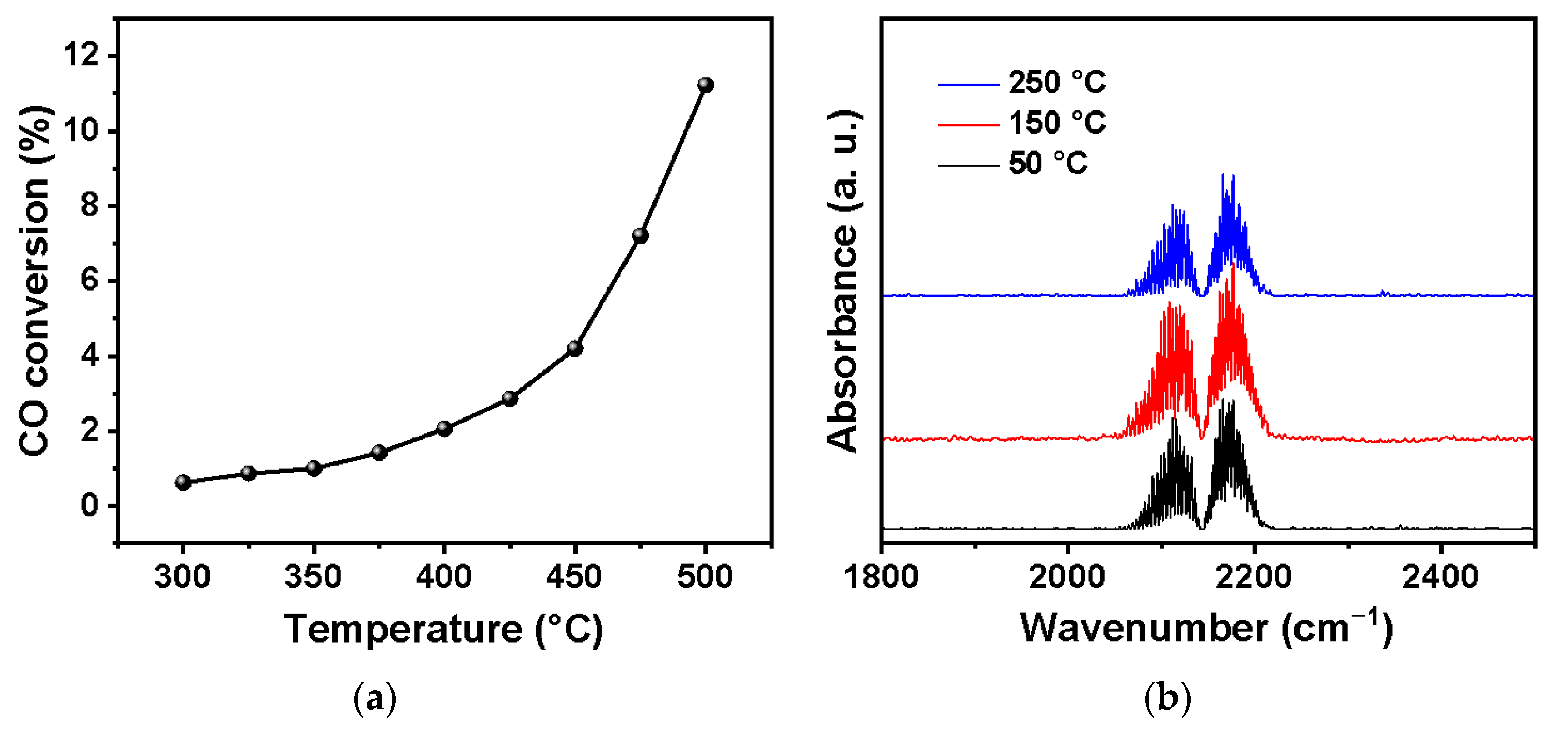

3.1. Catalytic Activity

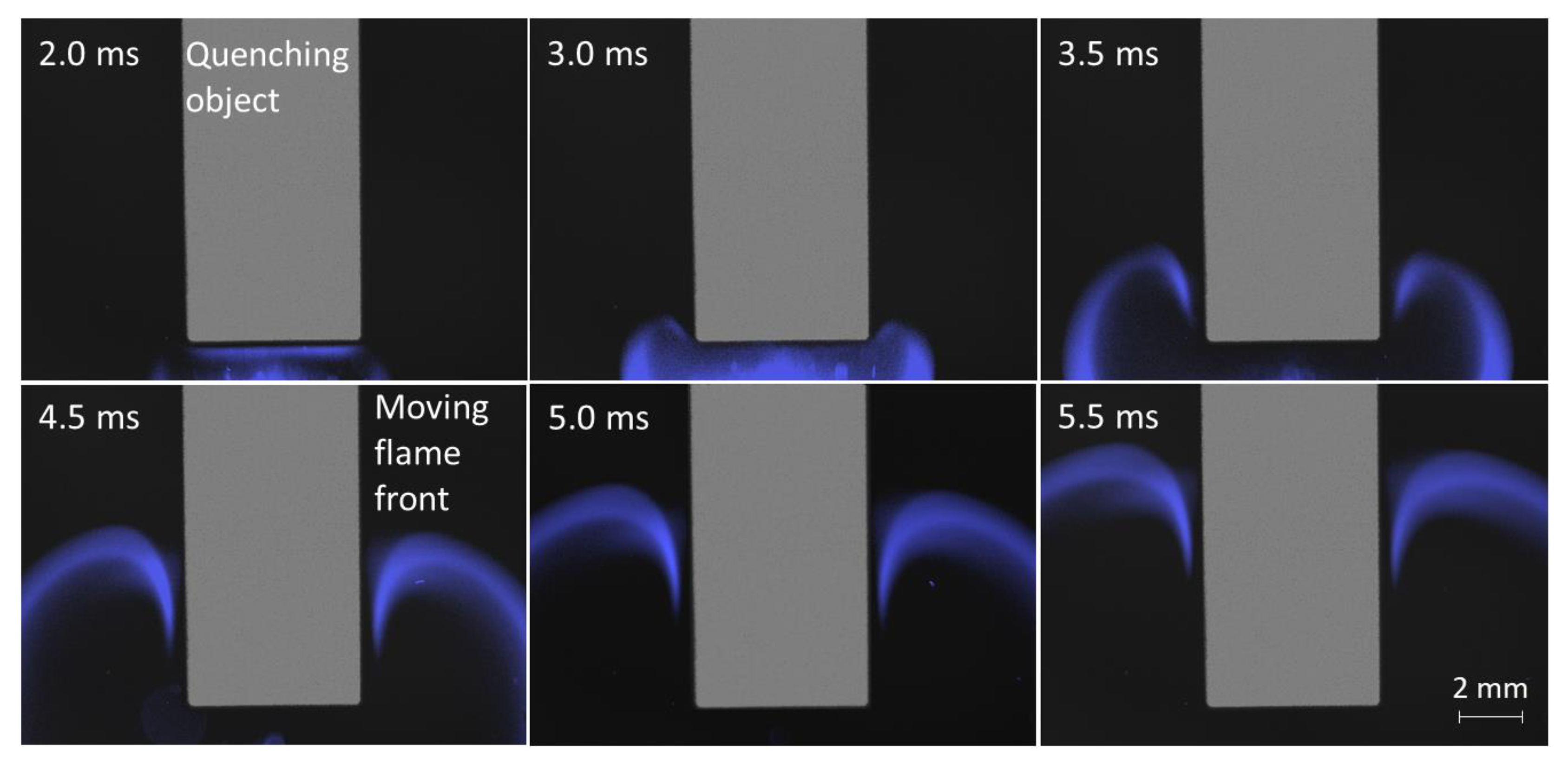

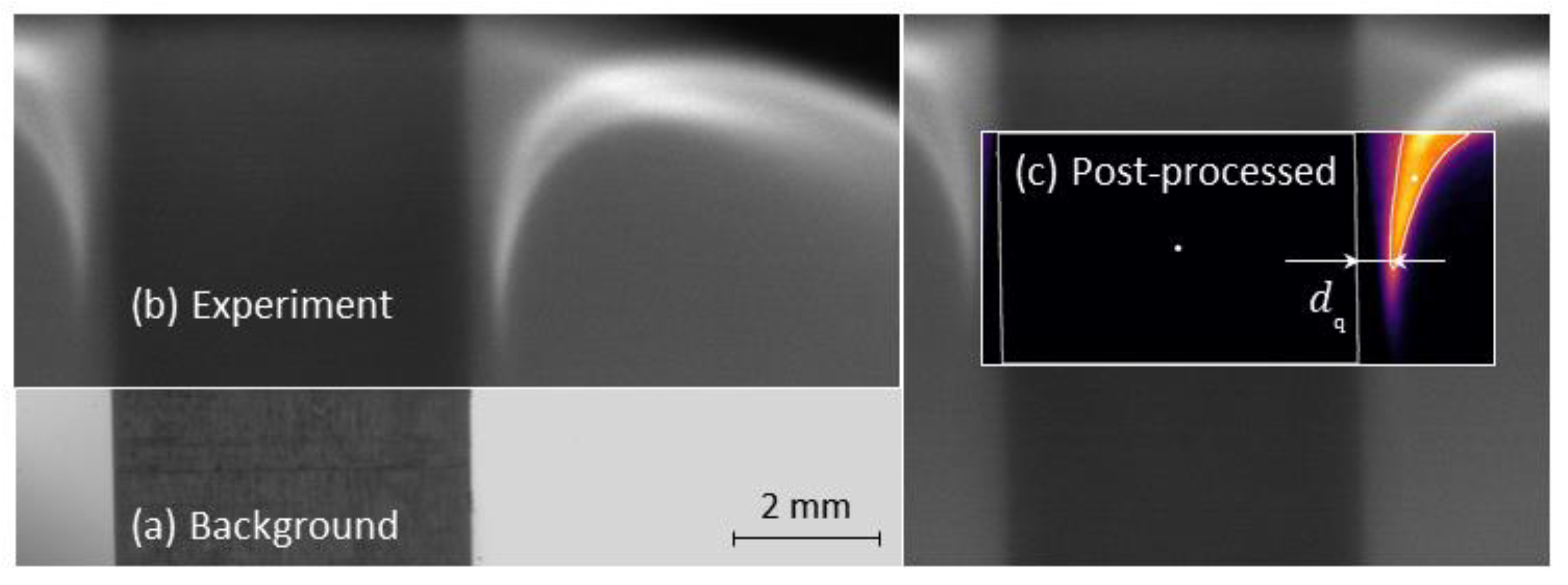

3.2. Flame Quenching

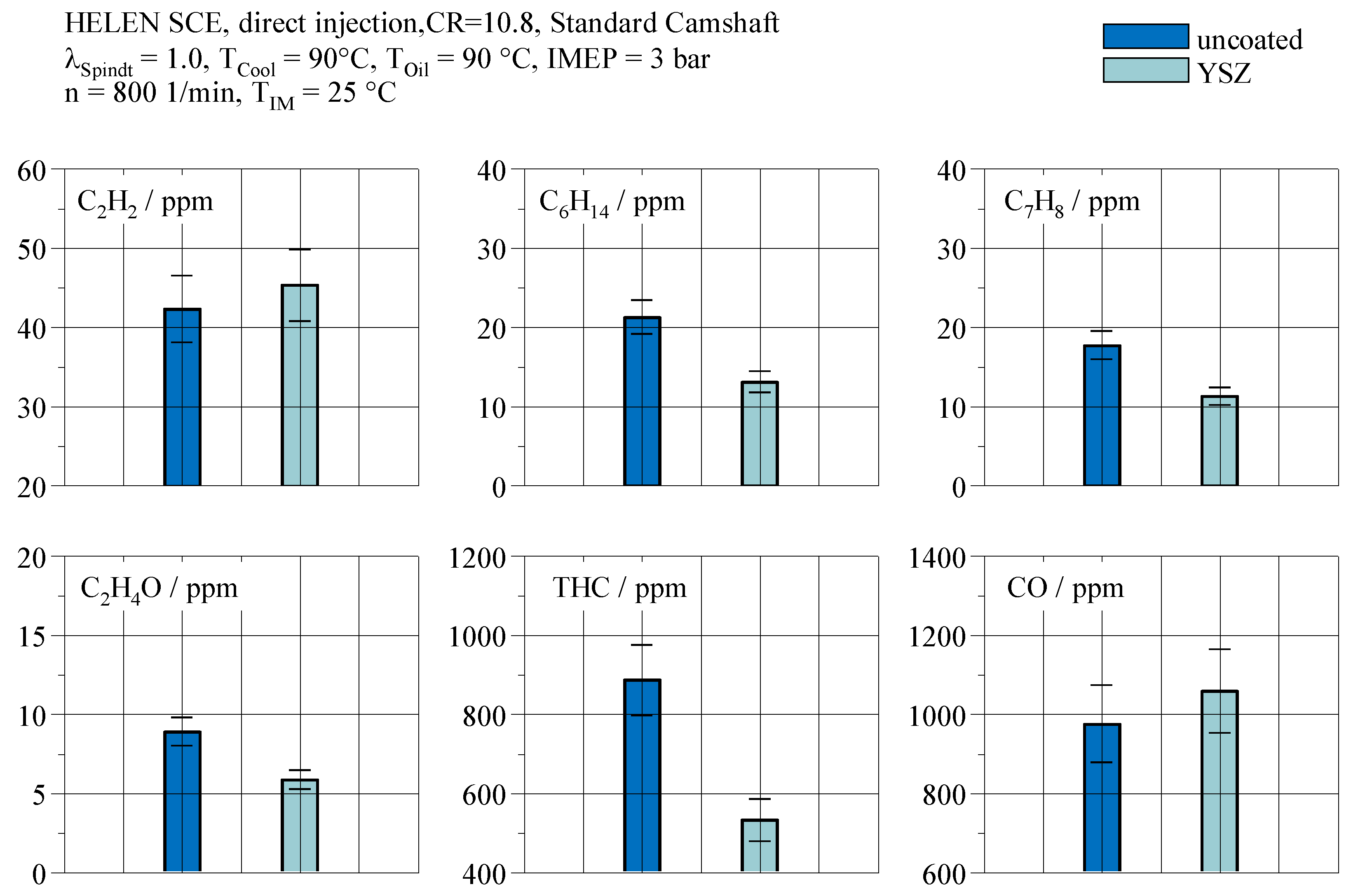

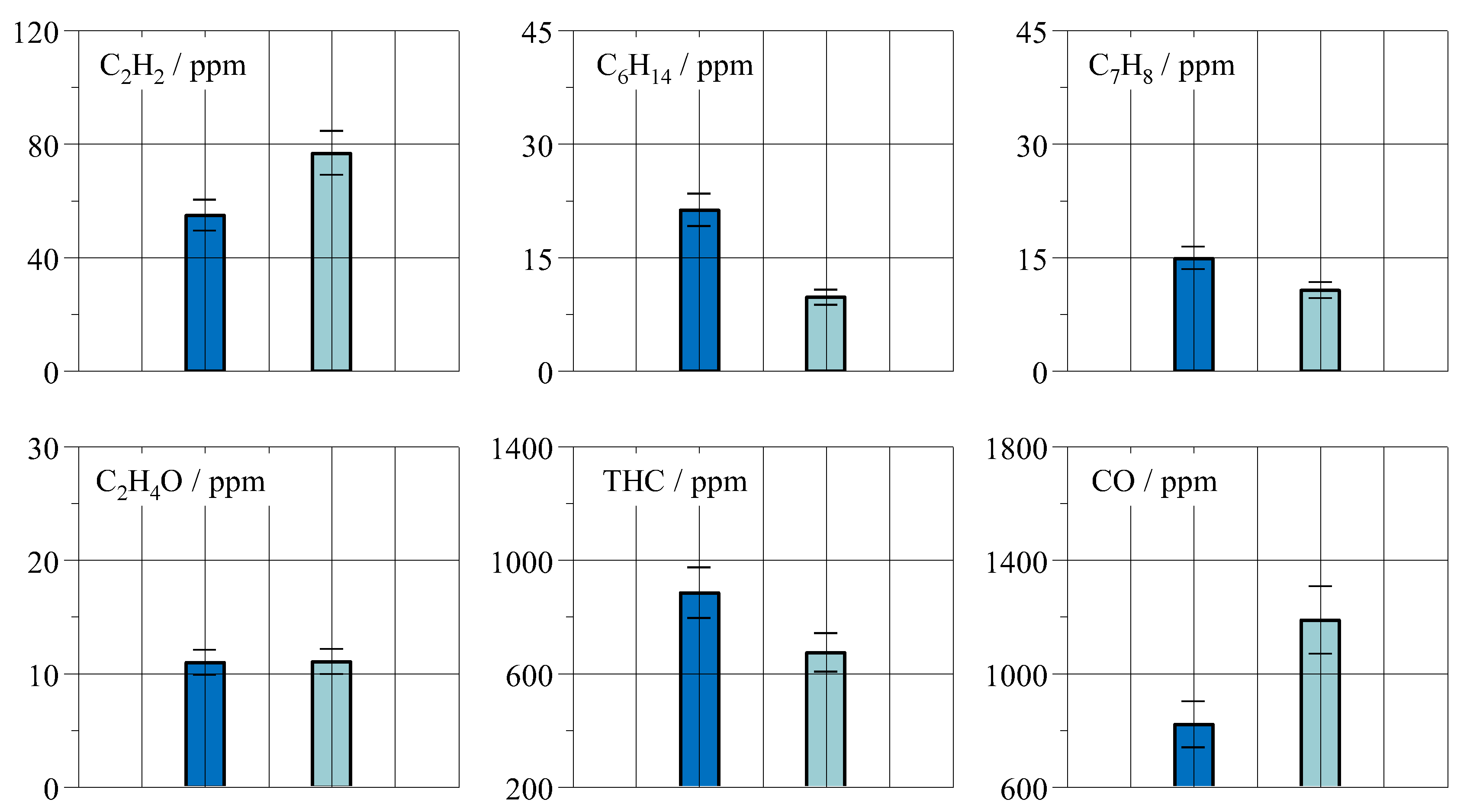

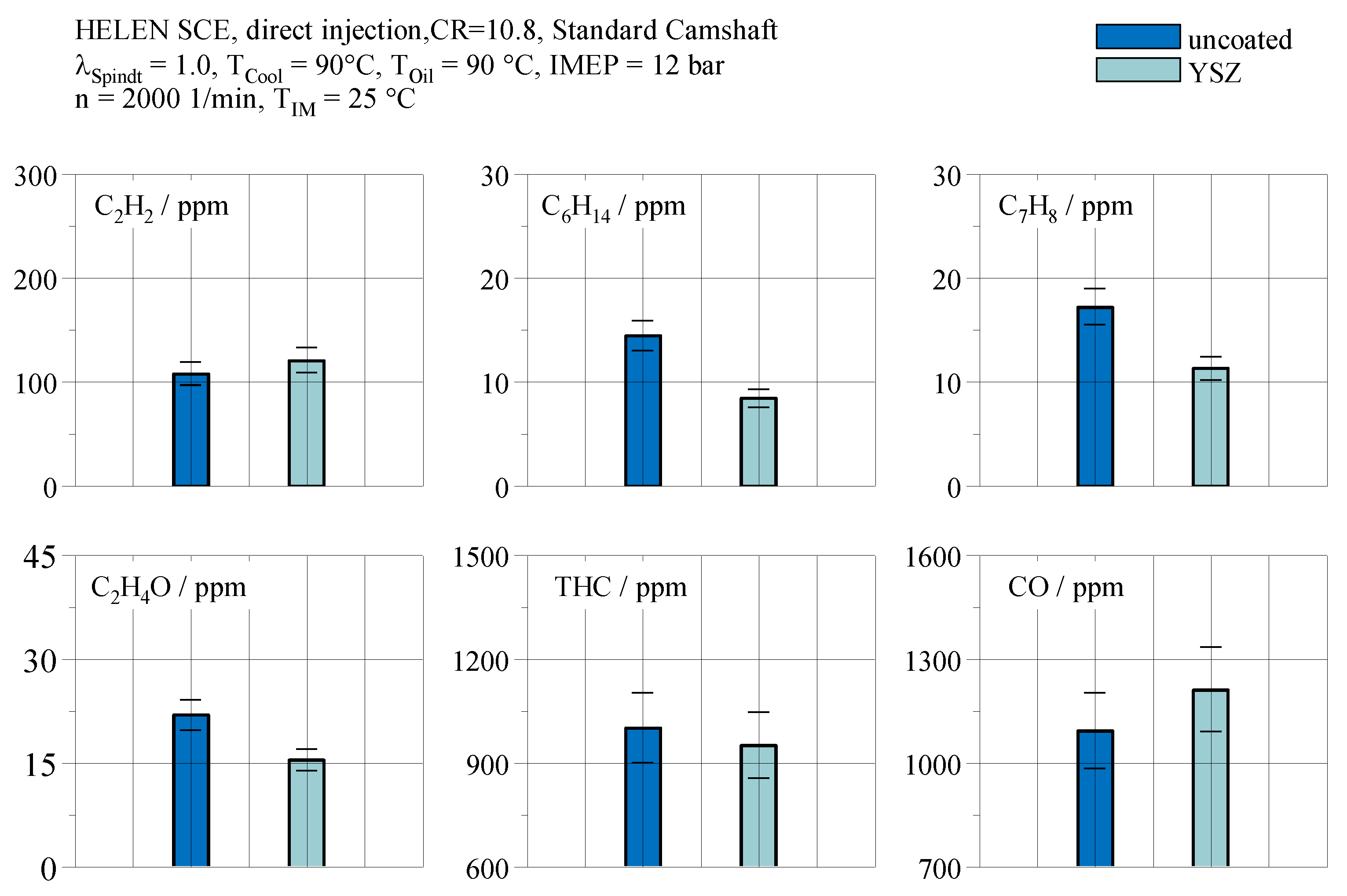

3.3. Near-Wall Gas Composition

4. Conclusions

- YSZ shows no significant catalytic activity, and, accordingly, the observed effects regarding the gas composition are deemed to result from the flame quenching at the wall.

- Flame quenching distance is reduced when applying a YSZ layer by 10.0% at ambient conditions and 5.6% at 200 °C in the CVCC measurements.

- Near-wall gas composition shows significantly lower total hydrocarbon emissions if the YSZ coating is applied near idle engine operation, which seems to be related to the lower quenching distance when the YSZ layer is applied.

- Increased engine speed and load still showed reduced total hydrocarbon emissions, but of significant lower amount due to the higher in-cylinder temperatures and pressures at these operating conditions.

- Saturated hydrocarbons such as C6H14 become reduced, which aligns with the lower quenching distance.

- Hydrocarbons such as C2H2 and C2H4O are partially increased or decreased, indicating a partial oxidation of these species in the unburned zones due to the higher wall and accordingly gas temperatures, but changes are within measurement uncertainty.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Samaras, Z.C.; Kontses, A.; Dimaratos, A.; Kontses, D.; Balazs, A.; Hausberger, S.; Ntziachristos, L.; Andersson, J.; Ligterink, N.; Aakko-Saksa, P.; et al. A European Regulatory Perspective towards a Euro 7 Proposal; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2022. [Google Scholar]

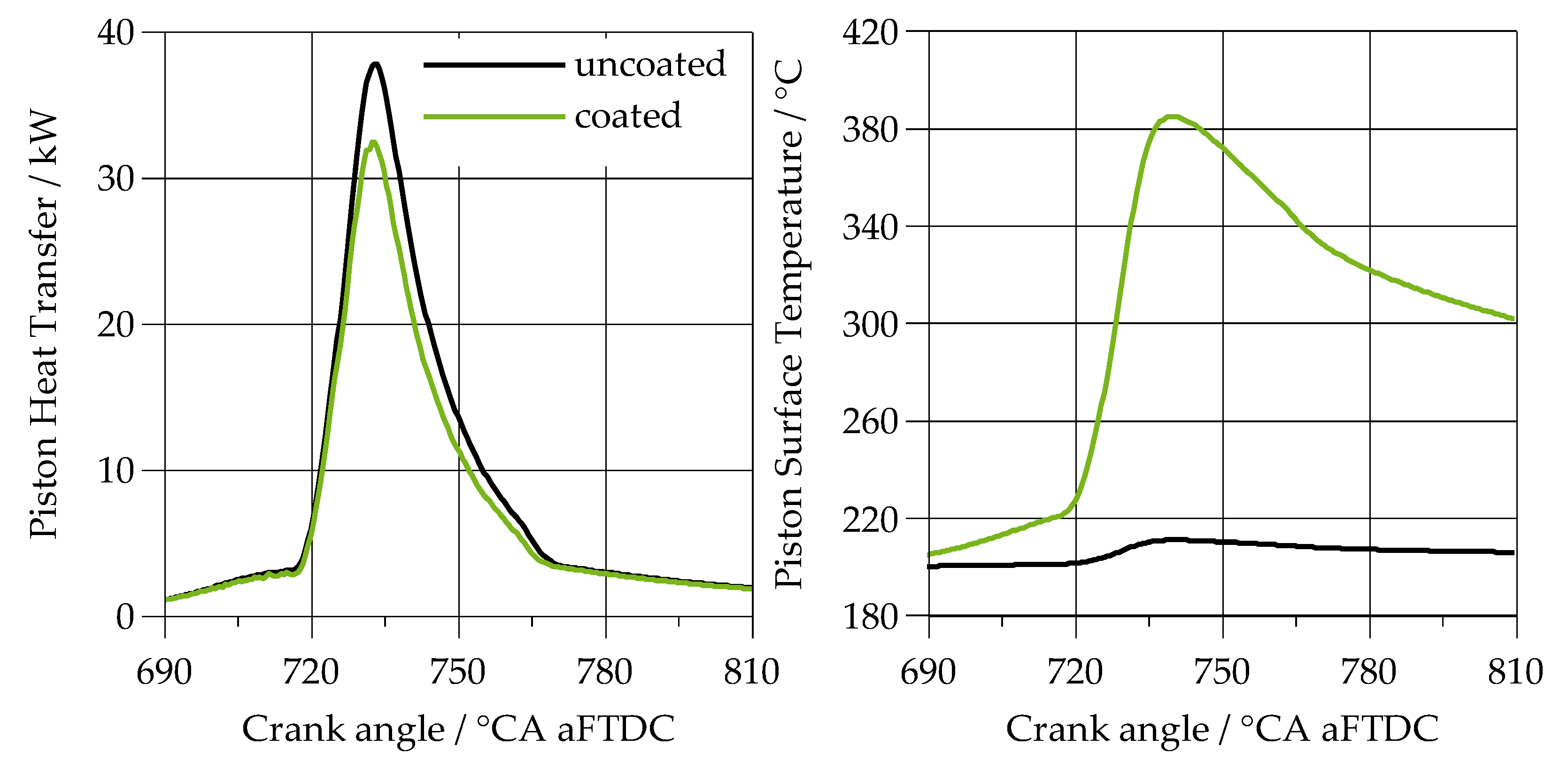

- Achenbach, J.; Fischer, M.; Lehrheuer, B.; Guenther, M.; Pischinger, S. Influence of thermal piston insulation on the indicated efficiency of SI-engines. In Proceedings of the COMODIA2022: 10th International Conference on Modeling and Diagnostics for Advanced Engine Systems, Sapporo, Japan, 5–8 July 2022. [Google Scholar]

- Hasse, C.; Bollig, M.; Peters, N.; Dwyer, H. Quenching of laminar iso-octane flames at cold walls. Combust. Flame 2000, 122, 117–129. [Google Scholar] [CrossRef]

- Memme, S.; Wallace, J.S. The Influence of Thermal Barrier Coating Surface Roughness on Spark-Ignition Engine Performance and Emissions. In Proceedings of the ASME 2012 Internal Combustion Engine Division Fall Technical Conference, Vancouver, BC, Canada, 23–26 September 2012; pp. 893–905. [Google Scholar]

- Büyükkaya, E.; Engin, T.; Cerit, M. Effects of thermal barrier coating on gas emissions and performance of a LHR engine with different injection timings and valve adjustments. Energy Convers. Manag. 2006, 47, 1298–1310. [Google Scholar] [CrossRef]

- Andrie, M.; Kokjohn, S.; Paliwal, S.; Kamo, L.S.; Kamo, A.; Procknow, D. Low Heat Capacitance Thermal Barrier Coatings for Internal Combustion Engines; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Chan, S.H.; Khor, K. The Effect of Thermal Barrier Coated Piston Crown on Engine Characteristics. J. Mater. Eng. Perform. 2000, 9, 103–109. [Google Scholar] [CrossRef]

- de Goes, W.U.; Markocsan, N.; Gupta, M.; Vaßen, R.; Matsushita, T.; Illkova, K. Thermal barrier coatings with novel architectures for diesel engine applications. Surf. Coat. Technol. 2020, 396, 125950. [Google Scholar] [CrossRef]

- Uchida, N. A review of thermal barrier coatings for improvement in thermal efficiency of both gasoline and diesel reciprocating engines. Int. J. Engine Res. 2020, 23, 3–19. [Google Scholar] [CrossRef]

- Babu, A.; Koutsakis, G.; Kokjohn, S.; Andrie, M. Experimental and Analytical Study of Temperature Swing Piston Coatings in a Medium-Duty Diesel Engine. SAE Int. J. Adv. Curr. Pract. Mobil. 2022, 5, 235–248. [Google Scholar]

- Uczak de Goes, W.; Markocsan, N.; Gupta, M. Thermal Swing Evaluation of Thermal Spray Coatings for Internal Combustion Engines. Coatings 2022, 12, 830. [Google Scholar] [CrossRef]

- Dhomne, S.; Mahalle, A.M. Thermal barrier coating materials for SI engine. J. Mater. Res. Technol. 2019, 8, 1532–1537. [Google Scholar] [CrossRef]

- Vaßen, R.; Mack, D.E.; Tandler, M.; Sohn, Y.J.; Sebold, D.; Guillon, O. Unique performance of thermal barrier coatings made of yttria-stabilized zirconia at extreme temperatures (>1500 °C). J. Am. Ceram. Soc. 2020, 104, 463–471. [Google Scholar] [CrossRef]

- Chen, L.B. Yttria-Stabilized Zirconia Thermal Barrier Coatings—A Review. Surf. Rev. Lett. 2006, 13, 535–544. [Google Scholar] [CrossRef]

- Bobzin, K.; Lugscheider, E.; Bagcivan, N. Thermal cycling behavior of Yttria Stabilized Zirconia and Lanthanum Zirconate as graded and bilayer EB-PVD thermal barrier coatings. High Temp. Mater. Process. Int. Q. High-Technol. Plasma Process. 2006, 10, 103–116. [Google Scholar] [CrossRef]

- Planques, P.; Vidal, V.; Lours, P.; Proton, V.; Crabos, F.; Huez, J.; Viguier, B. Mechanical properties of yttria-stabilised-zirconia for thermal barrier coating systems: Effects of testing procedure and thermal aging. In Proceedings of the 2017 IEEE 20th International Conference on Intelligent Transportation Systems (ITSC), Dusseldorf, Germany, 7–9 June 2017; pp. 302–307. [Google Scholar]

- Häber, T.; Suntz, R. Effect of different wall materials and thermal-barrier coatings on the flame-wall interaction of laminar premixed methane and propane flames. Int. J. Heat Fluid Flow 2018, 69, 95–105. [Google Scholar] [CrossRef]

- Sivakumar, G.; Kumar, S.S. Investigation on effect of Yttria Stabilized Zirconia coated piston crown on performance and emission characteristics of a diesel engine. Alex. Eng. J. 2014, 53, 787–794. [Google Scholar] [CrossRef] [Green Version]

- Powell, T.; O’Donnell, R.; Hoffman, M.; Filipi, Z. Impact of a Yttria-Stabilized Zirconia Thermal Barrier Coating on HCCI Engine Combustion, Emissions, and Efficiency. J. Eng. Gas Turbines Power 2017, 139, 111504. [Google Scholar] [CrossRef] [Green Version]

- Powell, T.; O’Donnell, R.; Hoffman, M.; Filipi, Z.; Jordan, E.H.; Kumar, R.; Killingsworth, N.J. Experimental investigation of the relationship between thermal barrier coating structured porosity and homogeneous charge compression ignition engine combustion. Int. J. Engine Res. 2021, 22, 88–108. [Google Scholar] [CrossRef]

- Lorenzo-Bañuelos, M.; Díaz, A.; Rodríguez, D.; Cuesta, I.; Fernández, A.; Alegre, J. Influence of Atmospheric Plasma Spray Parameters (APS) on the Mechanical Properties of Ni-Al Coatings on Aluminum Alloy Substrate. Metals 2021, 11, 612. [Google Scholar] [CrossRef]

- Vaßen, R.; Jarligo, M.O.; Steinke, T.; Mack, D.E.; Stöver, D. Overview on advanced thermal barrier coatings. Surf. Coat. Technol. 2010, 205, 938–942. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Jia, Z.; Lyu, F.; Liang, S.-X.; Lu, J. A review of catalytic performance of metallic glasses in wastewater treatment: Recent progress and prospects. Prog. Mater. Sci. 2019, 105, 100576. [Google Scholar] [CrossRef]

- Rizzotto, V.; Chen, D.; Tabak, B.M.; Yang, J.Y.; Ye, D.; Simon, U.; Chen, P. Spectroscopic identification and catalytic relevance of NH4+ intermediates in selective NOx reduction over Cu-SSZ-13 zeolites. Chemosphere 2020, 250, 126272. [Google Scholar] [CrossRef]

- Wu, X.; Fischer, M.; Nolte, A.; Lenßen, P.; Wang, B.; Ohlerth, T.; Wöll, D.; Heufer, K.A.; Pischinger, S.; Simon, U. Perovskite Catalyst for In-Cylinder Coating to Reduce Raw Pollutant Emissions of Internal Combustion Engines. ACS Omega 2022, 7, 5340–5349. [Google Scholar] [CrossRef]

- Bellenoue, M.; Kageyama, T.; Labuda, S.; Sotton, J. Direct measurement of laminar flame quenching distance in a closed vessel. Exp. Therm. Fluid Sci. 2003, 27, 323–331. [Google Scholar] [CrossRef]

- Boust, B.; Sotton, J.; Labuda, S.; Bellenoue, M. A thermal formulation for single-wall quenching of transient laminar flames. Combust. Flame 2007, 149, 286–294. [Google Scholar] [CrossRef]

- Bradski, G.; Kaehler, A. OpenCV. Dr. Dobbs J. Softw. Tools 2000, 3. [Google Scholar]

- Fischer, M.; Lehrheuer, B.; Pischinger, S. Evaluation of the near-wall gas composition in SI-engines using fast gas sampling. Int. J. Engine Res. 2023, 14680874221149603. [Google Scholar] [CrossRef]

- Yücel, N.; Karaaslan, S.; Ender, H.; Dinler, N. High Speed Gas Sampling System for Engine Cylinder Emission Analyses. JOCET 2013, 1, 144–147. [Google Scholar] [CrossRef] [Green Version]

- Talibi, M.; Hellier, P.; Balachandran, R.; Ladommatos, N. Development of a Fast-Acting, Time-Resolved Gas Sampling System for Combustion and Fuels Analysis. SAE Int. J. Engines 2016, 9, 1102–1116. [Google Scholar] [CrossRef]

- Dell, R.M.; Moseley, P.T.; Rand, D.A. Chapter 4—Development of Road Vehicles with Internal-Combustion Engines. In Towards Sustainable Road Transport; Dell, R.M., Moseley, P.T., Rand, D.A.J., Eds.; Academic Press: Boston, MA, USA, 2014; pp. 109–156. [Google Scholar]

- Wouters, C.; Burkardt, P.; Fischer, M.; Blomberg, M.; Pischinger, S. Effects of stroke on spark-ignition combustion with gasoline and methanol. Int. J. Engine Res. 2021, 23, 804–815. [Google Scholar] [CrossRef]

- De Hoffmann, E.; Stroobant, V. Mass Spectrometry: Principles and Applications; Wiley: Chichester, UK; Hoboken, NJ, USA, 2007. [Google Scholar]

- Akashi, K.; Inoue, K.; Adachi, M.; Ishida, K.; Villinger, J.; Federer, W.; Dornauer, A. Utilization of a Soft Ionization Mass Spectrometer for Ultra High Sensitivity and Fast Response Emission Measurements. SAE J. Fuels Lubr. 1998, 107, 13–23. [Google Scholar]

- Villinger, J.; Federer, W.; Dornauer, A.; Weissnicht, A.; Hönig, M.; Mayr, T. Dynamic Monitoring of Differentiated Hydrocarbons in Direct Engine Exhaust: A Versatile Tool in Engine Development. SAE Int. J. Engines 1996, 105, 172–179. [Google Scholar]

- Poinsot, T.J.; Haworth, D.C.; Bruneaux, G. Direct Simulation and Modeling of Flame-Wall Interaction for Pre-mixed Turbulent Combustion. Combust. Flame 1993, 95, 118–132. [Google Scholar] [CrossRef]

- Smith, G.P.; Golden, D.M.; Frenklach, M.; Moriarty, N.W.; Eiteneer, B.; Goldenberg, M.; Bowman, C.T.; Hanson, R.K.; Song, S.; Gardiner, W.C.; et al. Gri3.0. 2021. Available online: http://www.me.berkeley.edu/gri_mech/ (accessed on 23 March 2021).

- Goodwin, D.G.; Moffat, H.K.; Speth, R.L. Cantera: An Object-Oriented Software Toolkit for Chemical Kinetics, Thermodynamics, and Transport Processes, version 2.2. 1; Cantera Developers: Warrenville, IL, USA, 2021. [Google Scholar]

- Heywood, J.B. Internal combustion engine fundamentals. Edição Estados Unidos 1988, 25, 1117–1128. [Google Scholar]

- Glarborg, P.; Bentzen, L.L.B. Chemical Effects of a High CO2 Concentration in Oxy-Fuel Combustion of Methane. Energy Fuels 2007, 22, 291–296. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Current [A] | 350 |

| Spraying distance [mm] | 187 |

| Plasma gas composition | 46 SLPM Ar 4 SLPM He |

| Robot speed (mm/s) | 1000 |

| Spraying cycles | 280 |

| Cooling gas (bar) | 4 |

| Stroke [mm] | 113.2 |

| Bore [mm] | 75 |

| Swept volume [cm3] | 500 |

| Pressure intake manifold [bar] | Max. 3.5 |

| Stroke-to-bore ratio [-] | 1.5 |

| Injection pressure [bar] | 200 |

| Compression ratio [-] | 10.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fischer, M.; Nolte, A.; Wu, X.; Zhou, D.; Pischinger, S.; Heufer, K.A.; Simon, U.; Vaßen, R. Influence of Yttria-Stabilized Zirconium Oxide Thermal Swing Coating on the Flame-Wall Interaction in Spark Ignition Engines. Energies 2023, 16, 2872. https://doi.org/10.3390/en16062872

Fischer M, Nolte A, Wu X, Zhou D, Pischinger S, Heufer KA, Simon U, Vaßen R. Influence of Yttria-Stabilized Zirconium Oxide Thermal Swing Coating on the Flame-Wall Interaction in Spark Ignition Engines. Energies. 2023; 16(6):2872. https://doi.org/10.3390/en16062872

Chicago/Turabian StyleFischer, Marcus, Adrian Nolte, Xiaochao Wu, Dapeng Zhou, Stefan Pischinger, Karl Alexander Heufer, Ulrich Simon, and Robert Vaßen. 2023. "Influence of Yttria-Stabilized Zirconium Oxide Thermal Swing Coating on the Flame-Wall Interaction in Spark Ignition Engines" Energies 16, no. 6: 2872. https://doi.org/10.3390/en16062872