Influence of Pre-Chamber Volume, Orifice Diameter and Orifice Number on Performance of Pre-Chamber SI Engine—An Experimental and Numerical Study

Abstract

1. Introduction

2. Methodology

2.1. Experimental Study

2.2. Numerical Study

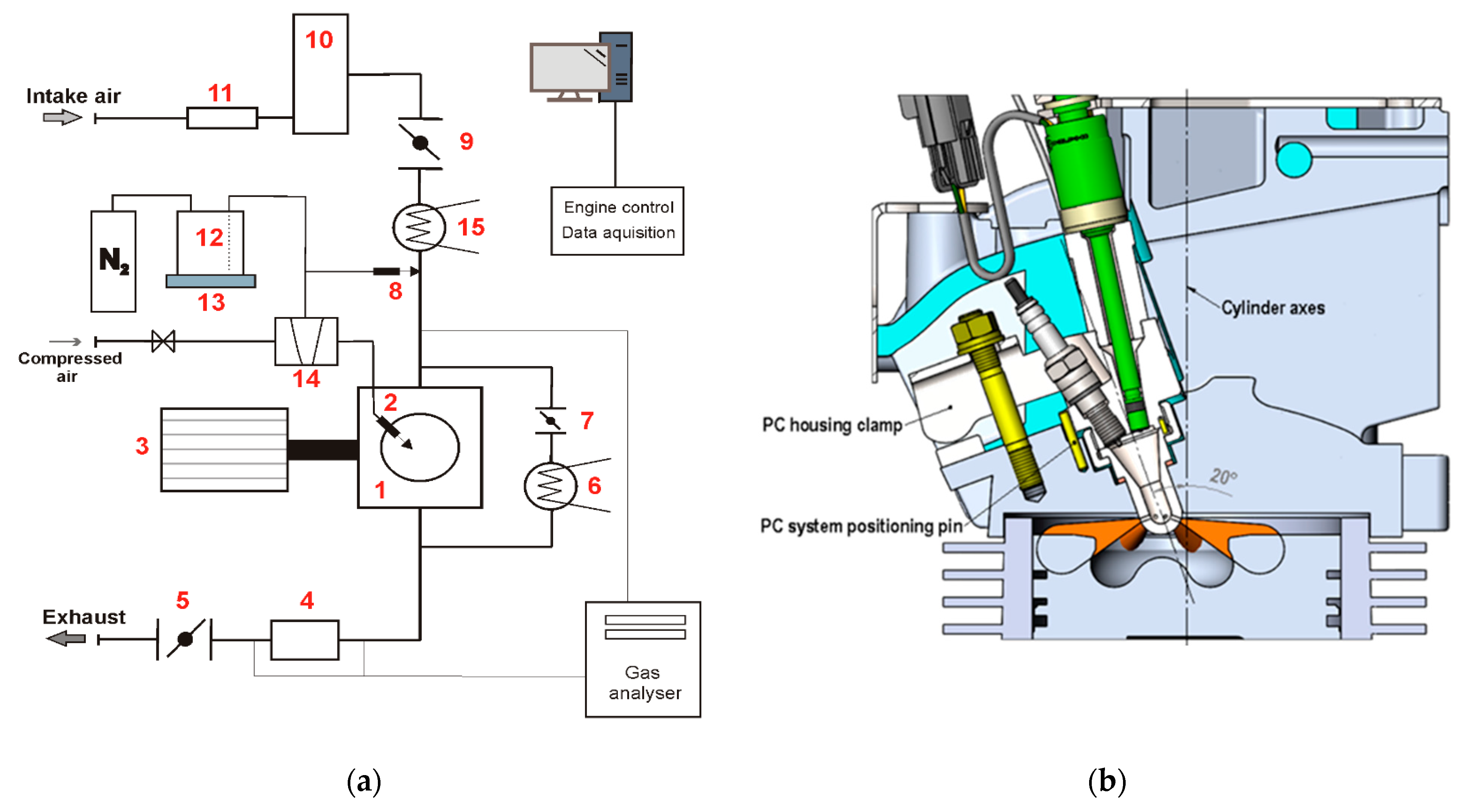

3. Experimental Setup

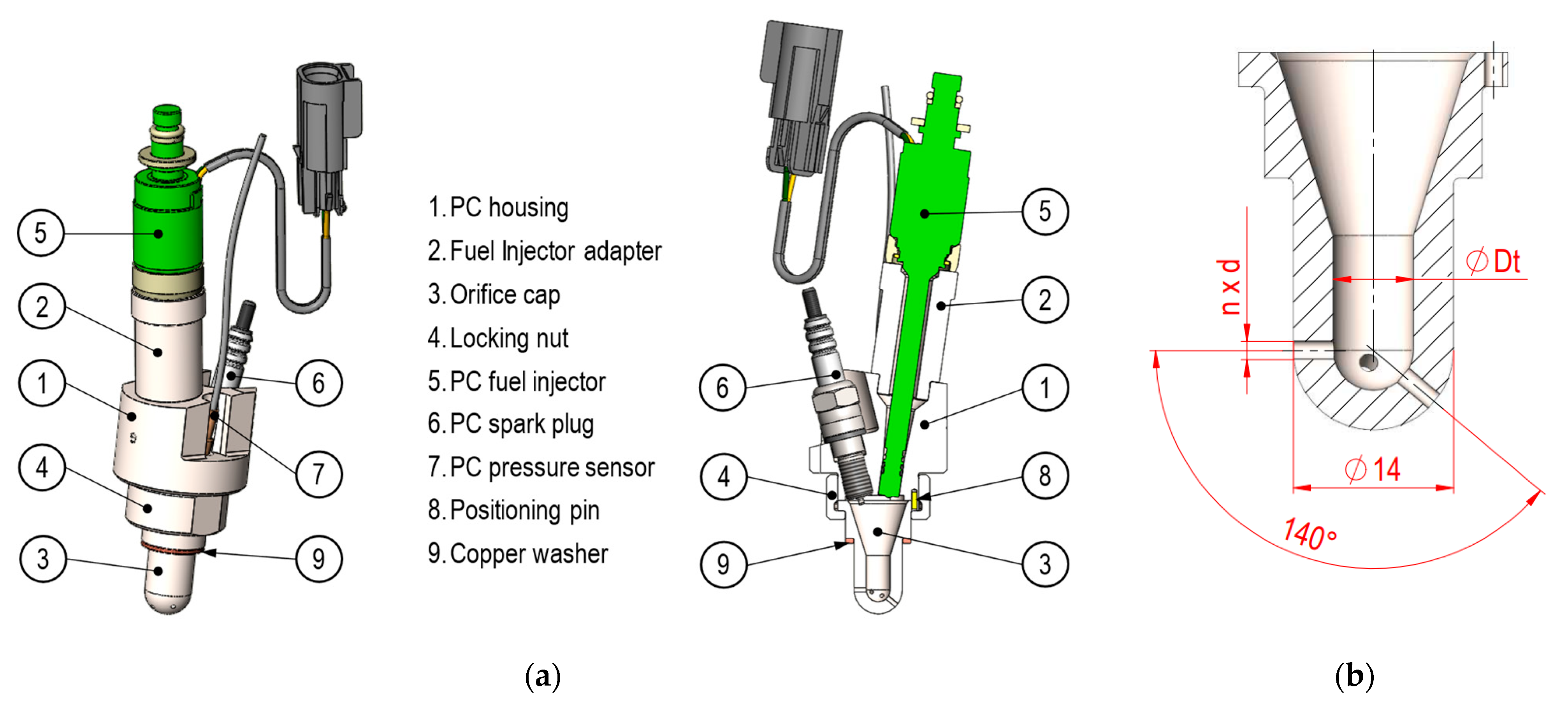

Pre-Chamber Ignition System Design

4. Numerical Model of the Experimental Engine

5. Results and Discussions

5.1. Experimental Results

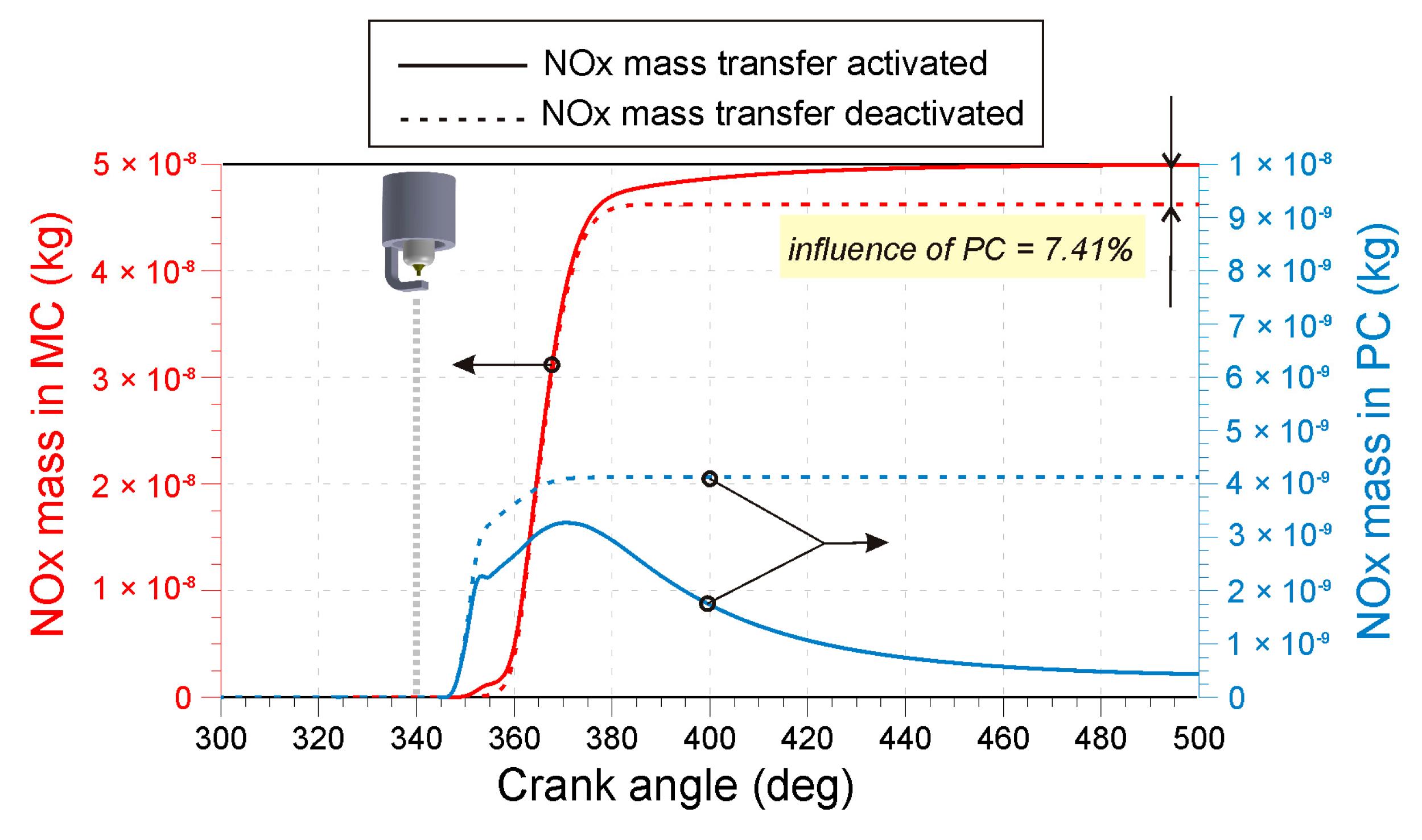

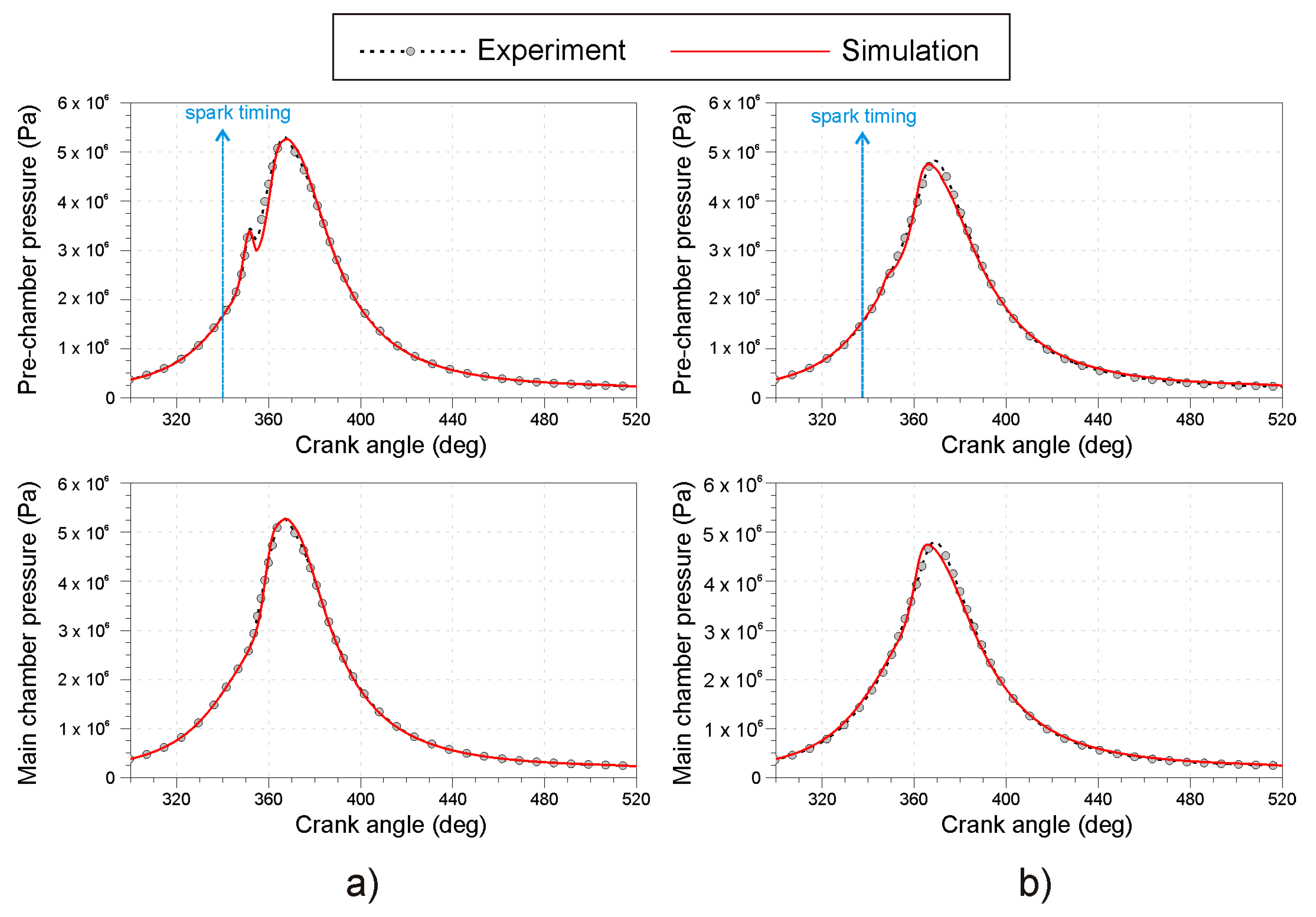

5.2. Numerical Results

6. Conclusions

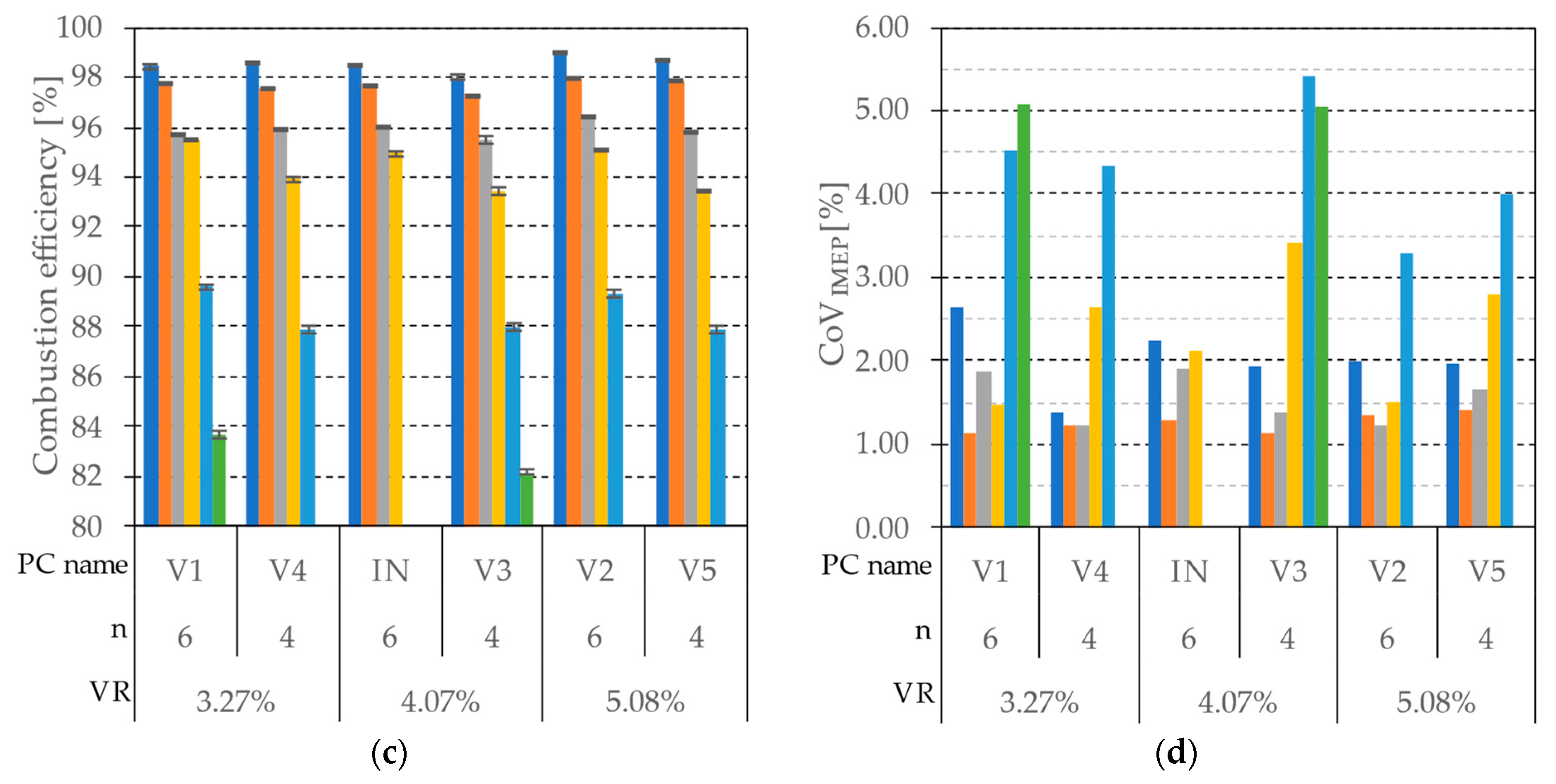

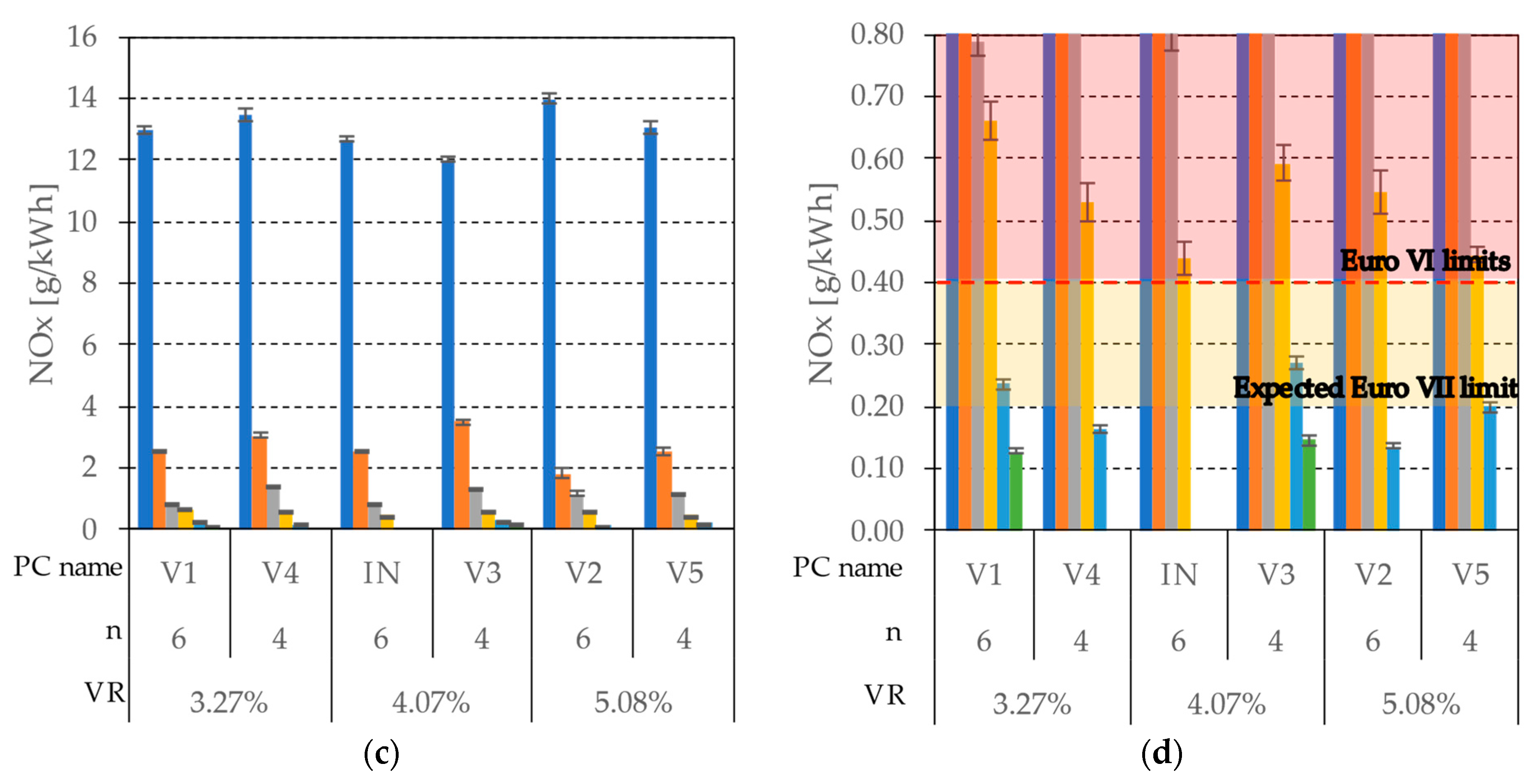

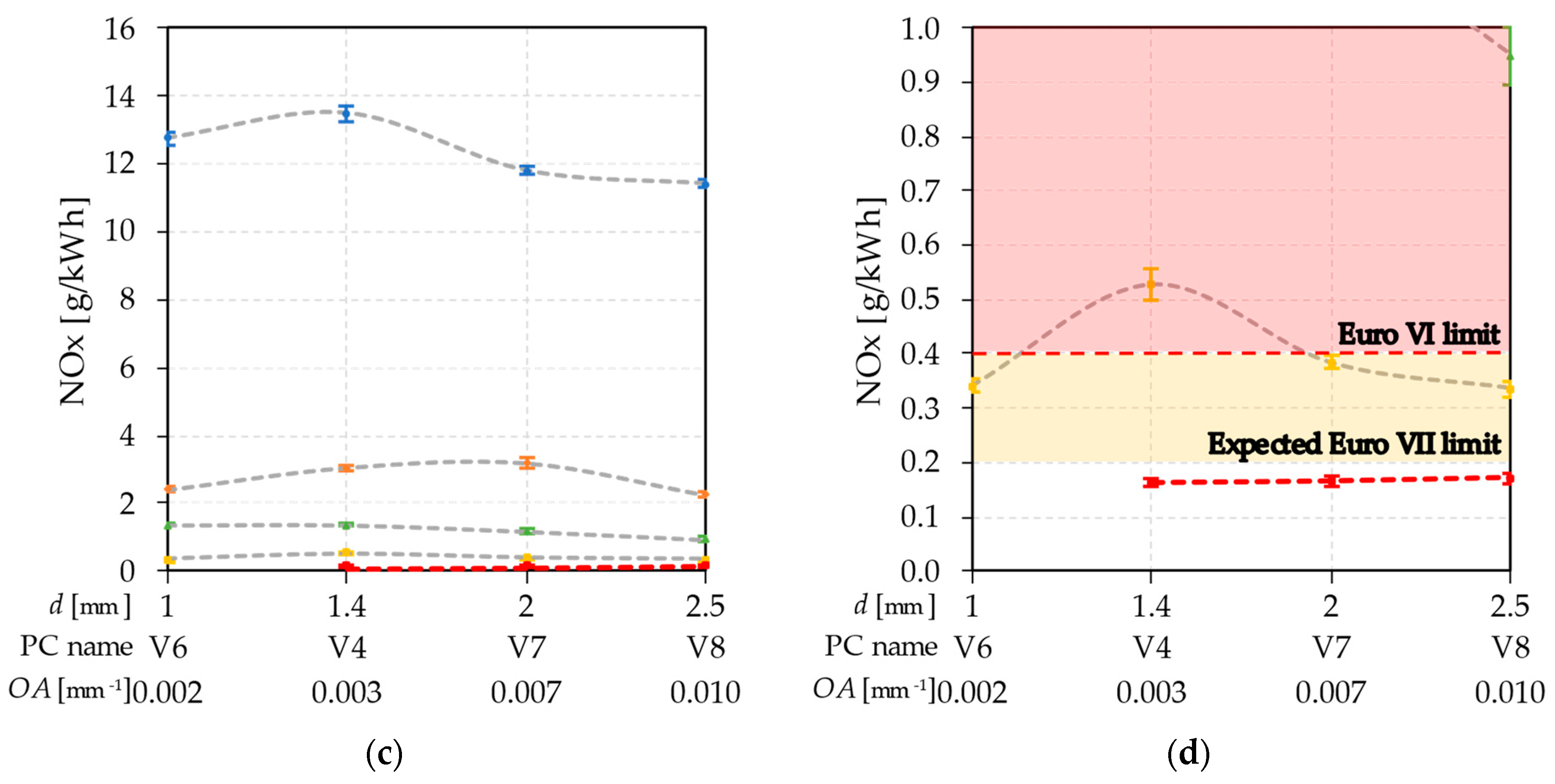

- The indicated efficiency data showed that a larger orifice area (OA) or larger orifice diameter at constant pre-chamber volume and orifice number is more favorable regarding indicated efficiency. Although the larger number of orifices mostly yielded higher indicated and combustion efficiencies which were more pronounced at higher excess air ratios and larger pre-chamber volumes, the overall best performance was obtained with the smallest pre-chamber with four orifices and the largest orifice area, which was most likely the result of the lowest wall heat losses directly affected by the jet protrusion velocity. The highest obtained indicated efficiency was equal to 39%, at an excess air ratio 1.6;

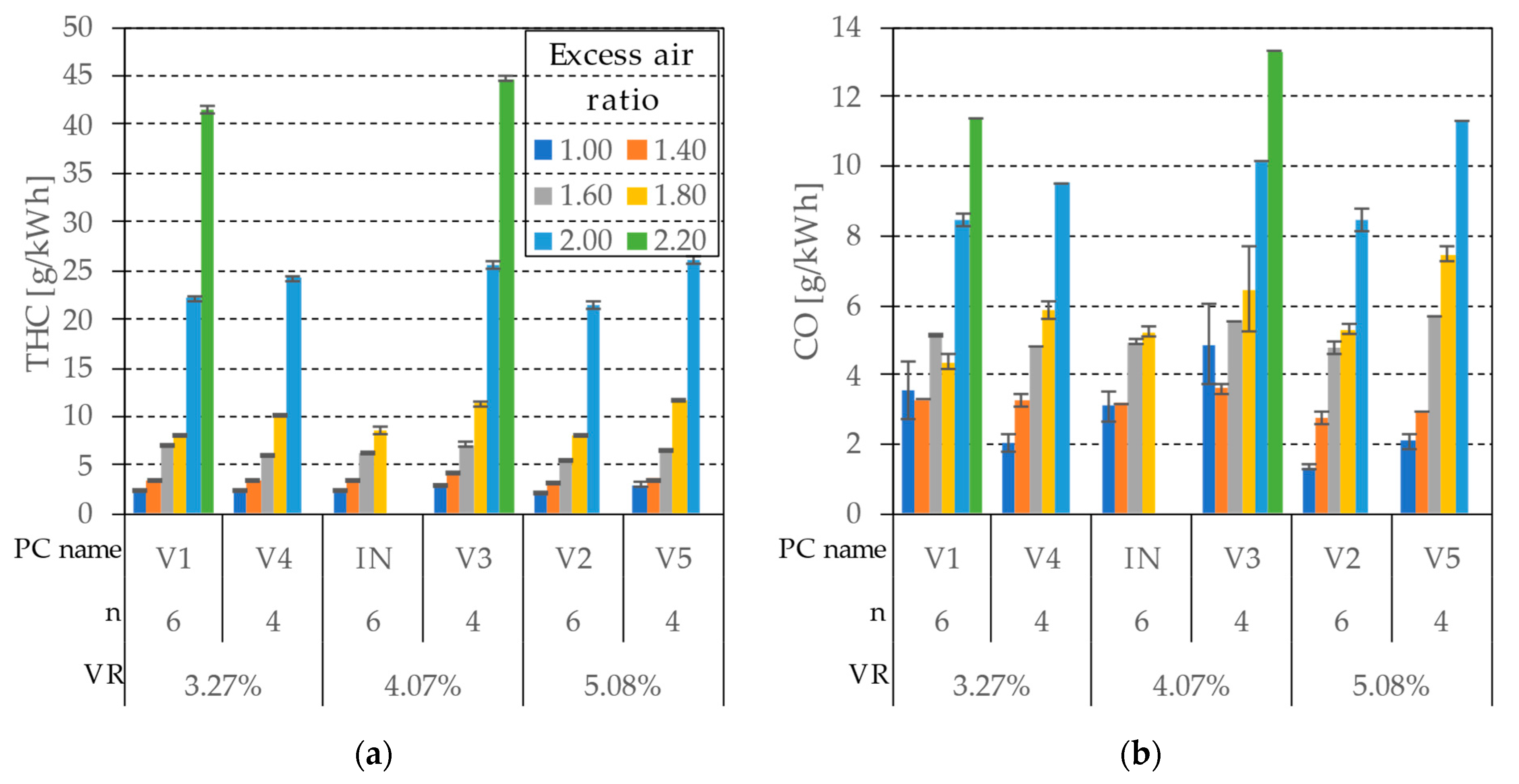

- The THC emission values showed a trend where PC types with a larger number of orifices emitted lower emissions THC emissions, which corresponds with PC types that yielded higher indicated efficiencies. Similar trends can be observed in case of CO emissions. On the other hand, the NOx emissions do not show a clear trend regarding volume ratio and orifice number influence. The orifice area ratio (OA) suggested by the literature yielded the overall lowest emission values. In the case of NOx emissions, the opposite trend was observed, with emission values decreasing with the increase in OA values;

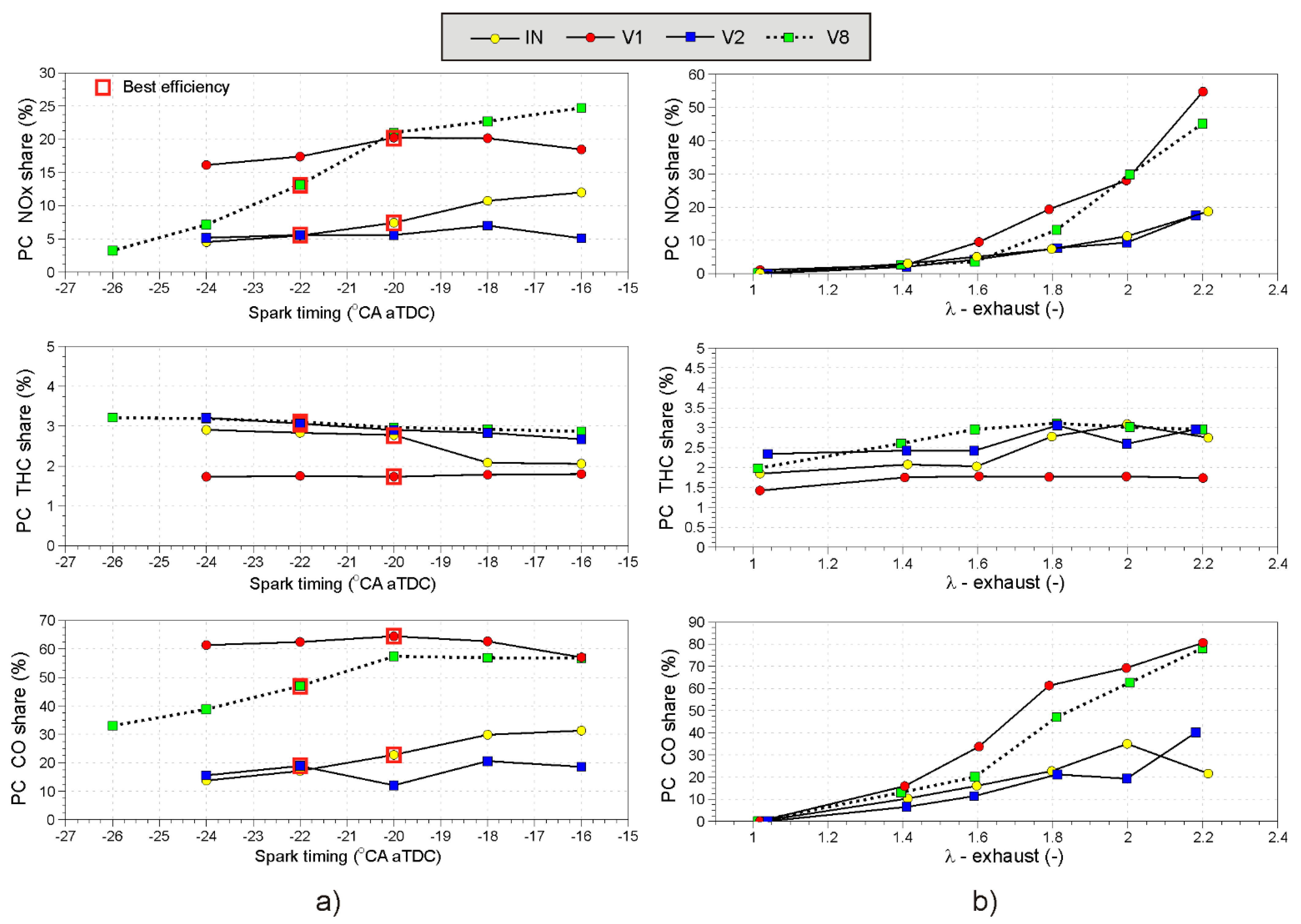

- The numerical analysis of the pre-chamber emission shares showed that when PC volume was lower, PC emission shares of NOX and CO became larger. The influence of orifice number and size had a minor effect on the pre-chamber emissions shares. The maximum PC emission shares of 54.8% and 80.6% were achieved at a lean limit (λ = 2.2) for NOX and CO, respectively. THC emission share, on the other hand, was not affected in a significant manner either by the pre-chamber geometry or by the operating conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Attard, W.P.; Fraser, N.; Parsons, P.; Toulson, E. A Turbulent Jet Ignition pre-chamber combustion system for large fuel economy improvements in a modern vehicle powertrain. SAE Int. J. Engines 2010, 3, 20–37. [Google Scholar] [CrossRef]

- Bunce, M.; Blaxill, H. Sub-200 g/kWh BSFC on a Light Duty Gasoline Engine; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2016; Volume 2016. [Google Scholar] [CrossRef]

- Stadler, A.; Wessoly, M.; Blochum, S.; Härtl, M.; Wachtmeister, G. Gasoline Fueled Pre-Chamber Ignition System for a Light-Duty Passenger Car Engine with Extended Lean Limit. SAE Int. J. Engines 2019, 12, 323–339. [Google Scholar] [CrossRef]

- Müller, C.; Morcinkowski, B.; Schernus, C.; Habermann, K.; Uhlmann, T. Development of a Pre-chamber for Spark Ignition Engines in Vehicle Applications. In Proceedings of the Ignition Systems for Gasoline Engines: 4th International Conference, Berlin, Germany, 6–7 December 2018; pp. 261–274. [Google Scholar]

- Schumacher, M.; Russwurm, T.; Wensing, M. Pre-chamber Ignition System for Homogeneous Lean Combustion Processes with Active Fuelling by Volatile Fuel Components. In Proceedings of the Ignition Systems for Gasoline Engines: 4th International Conference, Berlin, Germany, 6–7 December 2018; pp. 292–310. [Google Scholar]

- Baumgartner, L.S.; Karmann, S.; Backes, F.; Stadler, A.; Wachtmeister, G. Experimental Investigation of Orifice Design Effects on a Methane Fuelled Prechamber Gas Engine for Automotive Applications; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Shah, A.; Tunestal, P.; Johansson, B. Effect of Pre-Chamber Volume and Nozzle Diameter on Pre-Chamber Ignition in Heavy Duty Natural Gas Engines; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2015; Volume 2015. [Google Scholar] [CrossRef]

- Gussak, L.A.; Turkish, M.C.; Siegla, D.C. High Chemical Activity of Incomplete Combustion Products and a Method of Prechamber Torch Ignition for Avalanche Activation of Combustion in Internal Combustion Engines. SAE Trans. 1975, 84, 2421–2445. [Google Scholar] [CrossRef]

- Gussak, L.A.; Karpov, V.P.; Tikhonov, Y.V. The Application of Lag-Process in Prechamber Engines. SAE Trans. 1979, 88, 790527–790858. [Google Scholar] [CrossRef]

- Gussak, L.A. The Role of Chemical Activity and Turbulence Intensity in Prechamber-Torch Organization of Combustion of a Stationary Flow of a Fuel-Air Mixture; SAE International: Warrendale, PA, USA, 1983. [Google Scholar] [CrossRef]

- Yusuf, A.A.; Inambao, F.L.; Farooq, A.A. Impact of n-butanol-gasoline-hydrogen blends on combustion reactivity, performance and tailpipe emissions using TGDI engine parameters variation. Sustain. Energy Technol. Assess. 2020, 40, 100773. [Google Scholar] [CrossRef]

- Hlaing, P.; Marquez, M.E.; Burgos, P.; Cenker, E.; Houidi, M.B.; Johansson, B. Analysis of Fuel Properties on Combustion Characteristics in a Narrow-Throat Pre-Chamber Engine. SAE Int. J. Adv. Curr. Prac. Mobil. 2021, 3, 3020–3043. [Google Scholar] [CrossRef]

- Aljabri, H.; Silva, M.; Houidi, M.B.; Liu, X.; Allehaibi, M.; Almatrafi, F.; AlRamadan, A.S.; Mohan, B.; Cenker, E.; Im, H.G. Comparative Study of Spark-Ignited and Pre-Chamber Hydrogen-Fueled Engine: A Computational Approach. Energies 2022, 15, 8951. [Google Scholar] [CrossRef]

- Sandoval, M.H.B.; Alvarez, C.E.C.; Roso, V.R.; Santos, N.D.S.A.; Valle, R.M. The influence of volume variation in a homogeneous prechamber ignition system in combustion characteristics and exhaust emissions. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 72. [Google Scholar] [CrossRef]

- Onofrio, G.; Napolitano, P.; Tunestål, P.; Beatrice, C. Combustion sensitivity to the nozzle hole size in an active pre-chamber ultra-lean heavy-duty natural gas engine. Energy 2021, 235, 121298. [Google Scholar] [CrossRef]

- Pan, J.; He, Y.; Li, T.; Wei, H.; Wang, L.; Shu, G. Effect of temperature conditions on flame evolutions of turbulent jet ignition. Energies 2021, 14, 2226. [Google Scholar] [CrossRef]

- Gingrich, J.W.; Olsen, D.B.; Puzinauskas, P.; Willson, B.D. Precombustion chamber NOx emission contribution to an industrial natural gas engine. Int. J. Engine Res. 2006, 7, 41–49. [Google Scholar] [CrossRef]

- Accurso, F.; Piano, A.; Millo, F.; Caputo, G.; Cimarello, A.; Cafari, A. Numerical Simulation of a Prechamber-Ignited Lean-Burn Gas Engine by means of Predictive Combustion Models. SAE Int. J. Engines 2022, 16. [Google Scholar] [CrossRef]

- Dilber, V.; Sjerić, M.; Tomić, R.; Krajnović, J.; Ugrinić, S.; Kozarac, D. Optimization of Pre-Chamber Geometry and Operating Parameters in a Turbulent Jet Ignition Engine. Energies 2022, 15, 4758. [Google Scholar] [CrossRef]

- Ugrinić, S.; Dilber, V.; Sjeric, M.; Kozarac, D.; Krajnovic, J.; Tomic, R. Experimental Study of Pre-Chamber Geometry Influence on Performance and Emissions in a Gasoline Spark Ignited Engine; SAE International: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Kozarac, D.; Tomic, R.; Taritas, I.; Chen, J.-Y.; Dibble, R.W. A Model for Prediction of Knock in the Cycle Simulation by Detail Characterization of Fuel and Temperature Stratification. SAE Int. J. Engines 2015, 8, 1520–1534. [Google Scholar] [CrossRef]

- Fischer, M.; Günther, M.; Röpke, K.; Lindemann, M.; Placzek, R. Klopferkennung im Ottomotor. MTZ—Mot. Z. 2003, 64, 186–195. [Google Scholar] [CrossRef]

- Krajnovic, J.; Dilber, V.; Sjeric, M.; Tomic, R.; Vucetic, A.; Kozarac, D. Development of Numerical Framework for Research of the Pre-Chamber SI Combustion; SAE International: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Sjerić, M.; Krajnović, J.; Vučetić, A.; Kozarac, D. Influence of Swirl Flow on Combustion and Emissions in Spark-Ignition Experimental Engine. J. Energy Eng. 2021, 147, 04021014. [Google Scholar] [CrossRef]

- Mulholland, E.; Miller, J.; Bernard, Y.; Lee, K.; Rodríguez, F. The role of NOx emission reductions in Euro 7/VII vehicle emission standards to reduce adverse health impacts in the EU27 through 2050. Transp. Eng. 2022, 9, 100133. [Google Scholar] [CrossRef]

| Name | Orifice Number n [-] | Volume [mm3] | Volume Ratio VR [%] | Orifice Diameter d [mm] | Throat Diameter Dt [mm] | Orifice Area to Volume Ratio OA [mm−1] | Area to Volume Ratio [mm−1] |

|---|---|---|---|---|---|---|---|

| IN | 6 | 2400 | 4.07 | 1.30 | 7 | 0.003 | 0.016 |

| V1 | 6 | 1911 | 3.27 | 1.15 | 5 | 0.003 | 0.010 |

| V2 | 6 | 3027 | 5.08 | 1.40 | 9 | 0.003 | 0.021 |

| V3 | 4 | 2400 | 4.07 | 1.60 | 7 | 0.003 | 0.016 |

| V4 | 4 | 1911 | 3.27 | 1.40 | 5 | 0.003 | 0.010 |

| V5 | 4 | 3027 | 5.08 | 1.80 | 9 | 0.003 | 0.021 |

| V6 | 4 | 1911 | 3.27 | 1.00 | 5 | 0.002 | 0.010 |

| V7 | 4 | 1911 | 3.27 | 2.00 | 5 | 0.007 | 0.010 |

| V8 | 4 | 1911 | 3.27 | 2.50 | 5 | 0.010 | 0.010 |

| Parameter | Settings |

|---|---|

| Engine speed | 1600 rpm |

| Pre-chamber fuel injection duration | 0.3 ms |

| Pre-chamber fuel injection timing | 120 °CA bTDC |

| Port fuel injection timing | 190 °CA aTDC |

| Excess air ratio λ | 1.0, 1.4, 1.6, 1.8, 2.0, 2.2 |

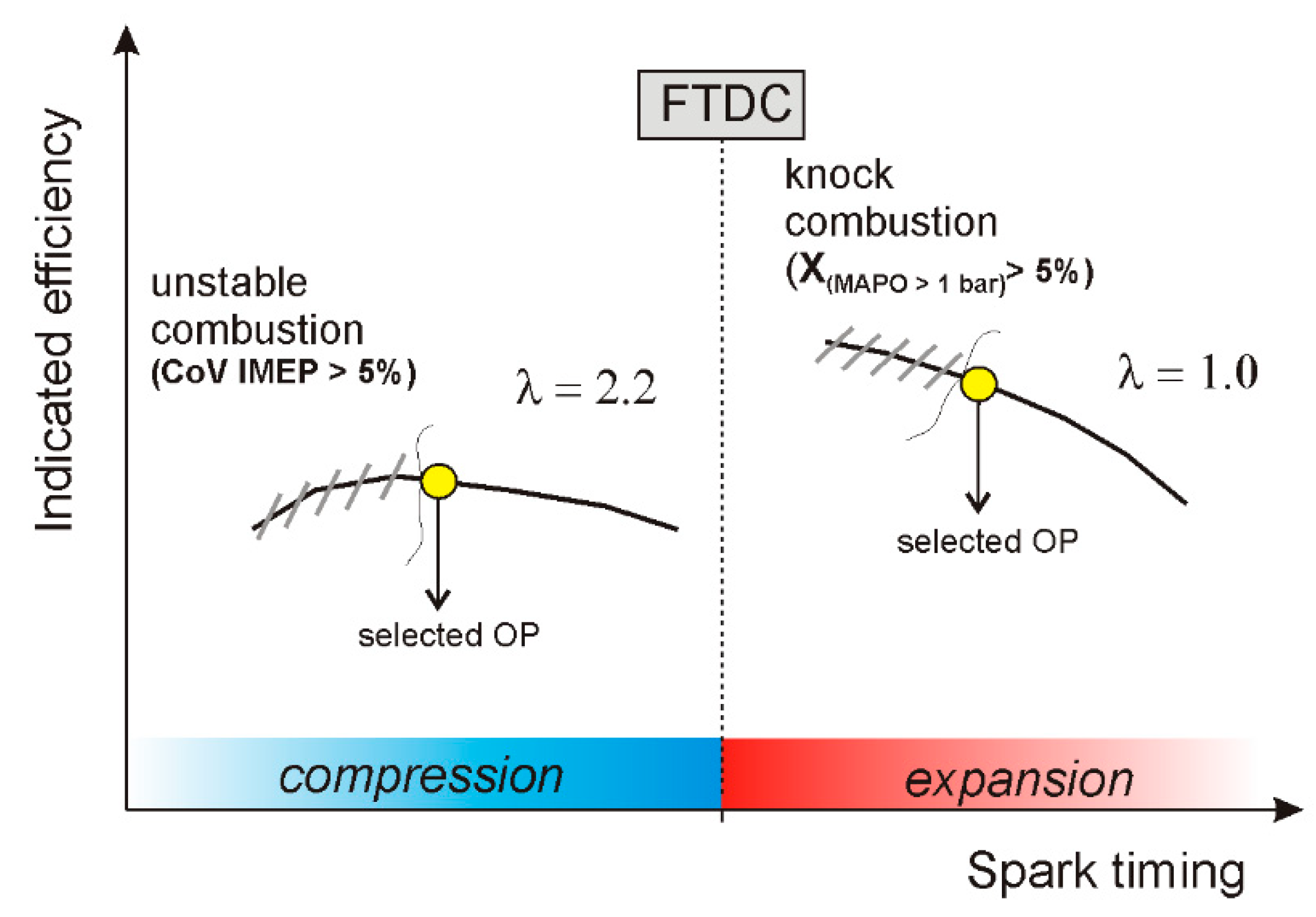

| Spark timing | Sweep limited by combustion stability and knock limit |

| Intake pressure | ambient (WOT) |

| Intake temperature | 33 °C |

| Fuel properties (commercial gasoline) | lower heating value 42.63 MJ/kg; RON 95.4; density 741.7 kg/m3 at 15 °C |

| Parameter | Value |

|---|---|

| Displacement | 667 cm3 |

| Stroke | 85 mm |

| Bore | 100 mm |

| Connecting Rod length | 127 mm |

| Compression ratio | 12.8 (without the pre-chamber) |

| Number of Valves | 2 |

| Inlet Valve Opens/Closes | 36 °CA BTDC/60 °CA ABDC |

| Exhaust Valve Opens/Closes | 54 °CA BBDC/21 °CA ATDC |

| Gas | Analyzer | Range | Accuracy |

|---|---|---|---|

| NOX | ECM NOX 5210t | NOX: 0–5000 ppm | ±5 ppm (0–200 ppm) ±20 ppm (200–1000 ppm) ±2% (>1000 ppm) |

| λ: 0.4–25 | ±0.008 (at λ = 1) ±0.016 (0.8 < λ < 1.2) | ||

| O2: 0–25% | ±0.4 (0 % < O2 < 2%) | ||

| THC | Environnement Graphite 52M | 0–10,000 ppm | <1% of measured value at range 15–100% of full scale (FS) |

| CO | Environnement MIR 2M | 10–50,000 ppm | Zero drift: <1% FS/24 h Span drift: <1% FS/24 h |

| CO2 | Environnement MIR 2M | 100–250,000 ppm | Linearity: <1% for range 20–100% FS |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomić, R.; Sjerić, M.; Krajnović, J.; Ugrinić, S. Influence of Pre-Chamber Volume, Orifice Diameter and Orifice Number on Performance of Pre-Chamber SI Engine—An Experimental and Numerical Study. Energies 2023, 16, 2884. https://doi.org/10.3390/en16062884

Tomić R, Sjerić M, Krajnović J, Ugrinić S. Influence of Pre-Chamber Volume, Orifice Diameter and Orifice Number on Performance of Pre-Chamber SI Engine—An Experimental and Numerical Study. Energies. 2023; 16(6):2884. https://doi.org/10.3390/en16062884

Chicago/Turabian StyleTomić, Rudolf, Momir Sjerić, Josip Krajnović, and Sara Ugrinić. 2023. "Influence of Pre-Chamber Volume, Orifice Diameter and Orifice Number on Performance of Pre-Chamber SI Engine—An Experimental and Numerical Study" Energies 16, no. 6: 2884. https://doi.org/10.3390/en16062884

APA StyleTomić, R., Sjerić, M., Krajnović, J., & Ugrinić, S. (2023). Influence of Pre-Chamber Volume, Orifice Diameter and Orifice Number on Performance of Pre-Chamber SI Engine—An Experimental and Numerical Study. Energies, 16(6), 2884. https://doi.org/10.3390/en16062884