Integrated Energy Microgrid Economic Dispatch Optimization Model Based on Information-Gap Decision Theory

Abstract

:1. Introduction

2. Integrated Energy Microgrid System Architecture

2.1. Combined-Operation Mode of CHP Units with P2G and CCS

2.1.1. Characterization of the Combined-Operation Mode of CHP Units with CCS and P2G Technologies

2.1.2. Calculation of Carbon Emission of CHP Unit Combined-Operation Mode with CCS and P2G Technology

2.1.3. The Operating Cost of CHP Unit Combined-Operation Mode with CCS and P2G Technology

- (1)

- P2G unit-operating costs

- (2)

- CCS unit operating costs

- (3)

- CO2 storage costs

- (4)

- Combined-operating costs of CHP units with P2G and CCS technologies are taken into account

2.1.4. Combined-Operation Constraints of CHP Units Taking into Account P2G and CCS Technologies

- (1)

- Climbing constraint of CHP units with P2G and CCS technologies

- (2)

- CCS carbon-capture operational constraints

2.2. Demand-Response Model

2.2.1. Analysis of the Principle of Time-Sharing Tariffs

2.2.2. Demand-Response Cost Model

3. Deterministic Integrated Energy Microgrid Optimal Economic Dispatch Model

3.1. Integrated Energy Microgrid Operating Costs

- (1)

- CHP unit operating cost

- (2)

- External interaction costs

- (3)

- Energy storage system operating costs

- (4)

- Carbon quota and carbon trading costs

- (5)

- Demand-response cost

- (6)

- Gas boiler operating costs

3.2. Constraints

- (1)

- Electrical power balance

- (2)

- Thermal power balance

- (3)

- G.B. unit operating constraints

- (4)

- Electricity sales constraints

- (5)

- Gas purchase constraints

- (6)

- Gas power balance constraint

4. Interval Uncertainty and IGDT Optimization Model

4.1. Interval Uncertainty Model

4.2. IGDT Optimization Model

4.2.1. Risk Avoidance Strategy

4.2.2. IGDT Opportunity Optimization Model for Risk Appetite

4.3. Optimization Model Solving

4.3.1. IGDT Model-Solving Method

4.3.2. IGDT Model Solving Steps

5. Example Analysis

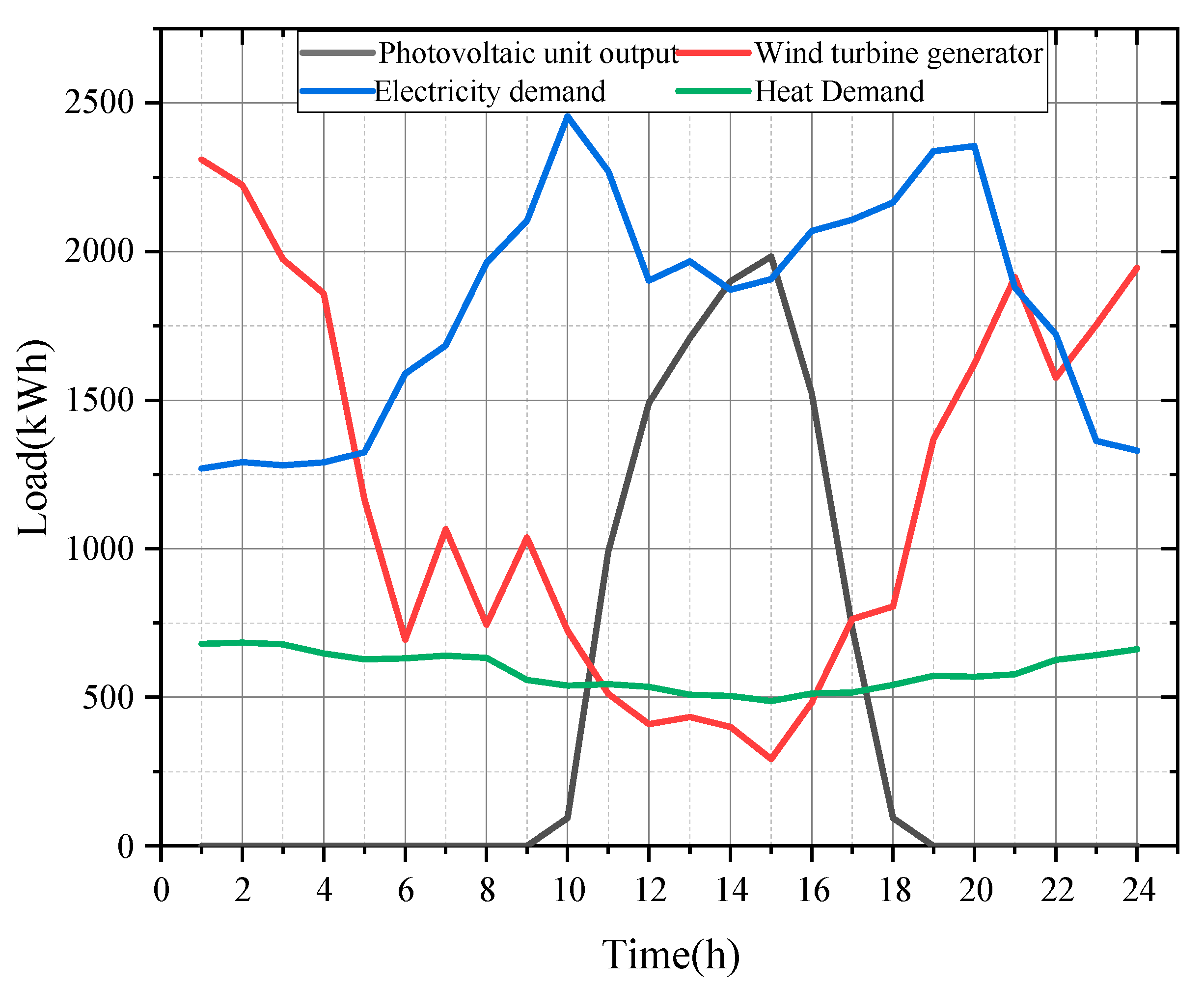

5.1. Simulation Data and Experimental Platform

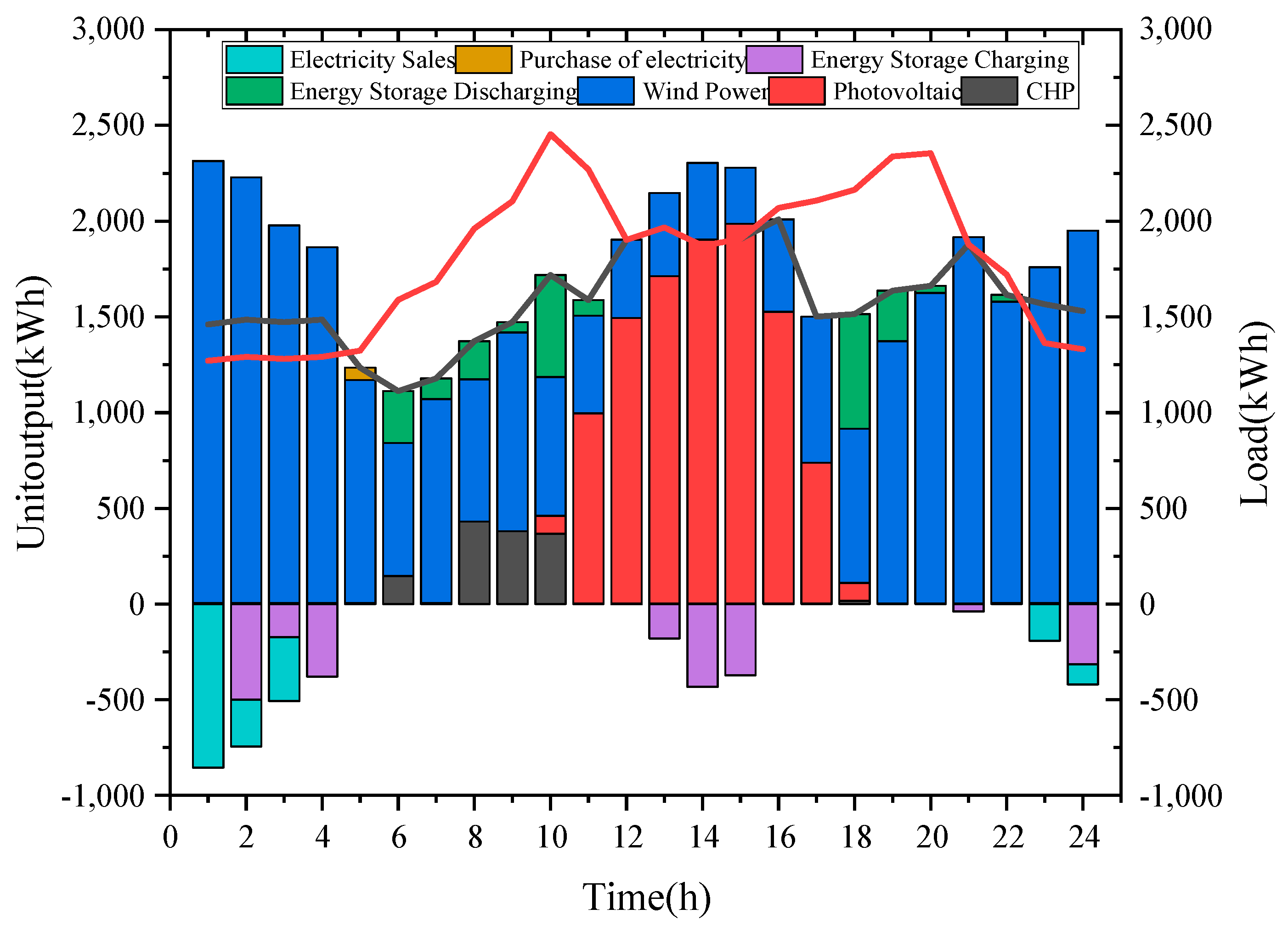

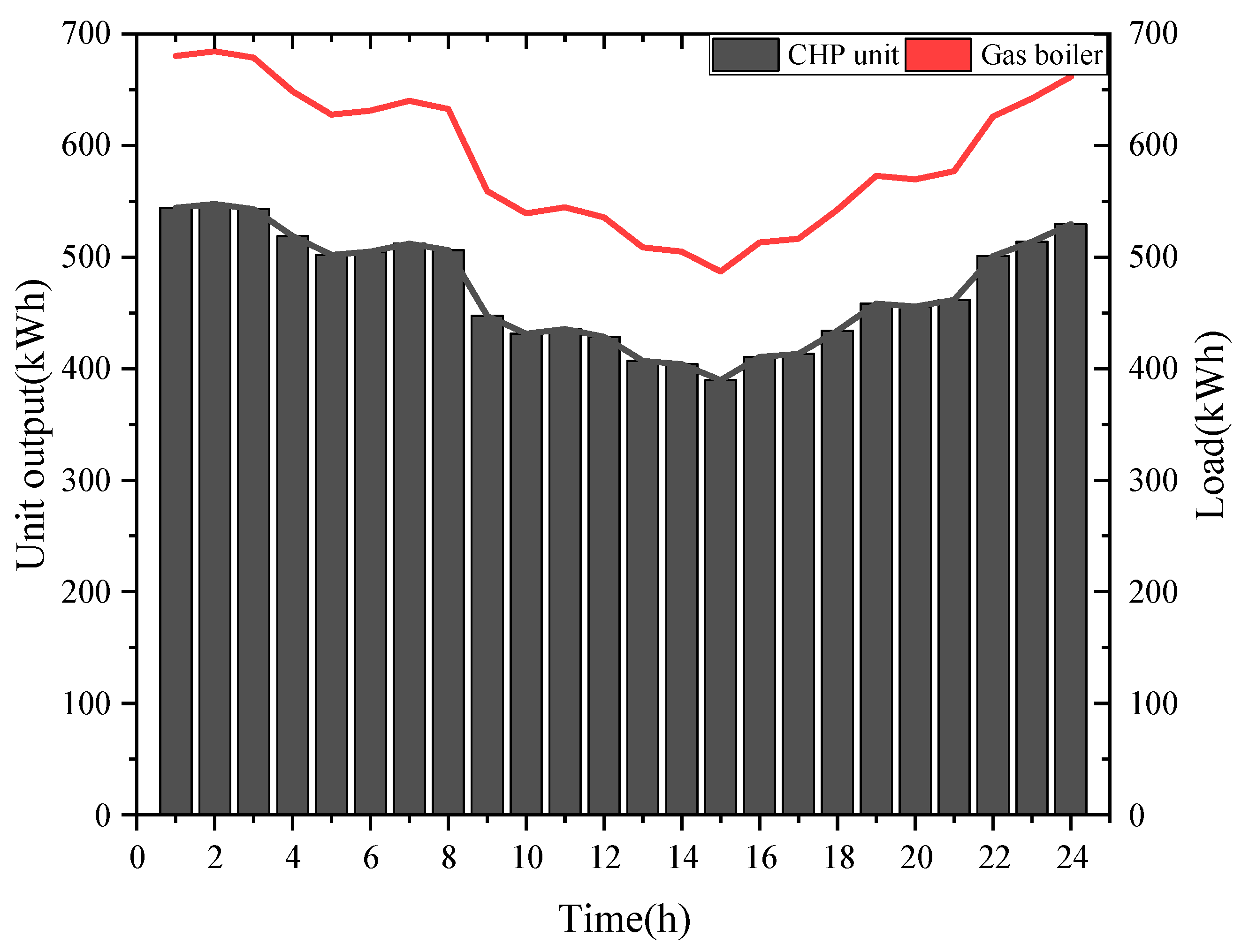

5.2. Scheduling Operation of Integrated Energy Microgrid System under Deterministic Conditions

- Example 1: Integrated energy microgrid without P2G and CCS and carbon trading costs.

- Example 2: Integrated energy microgrid without P2G and CCS but considering carbon trading costs.

- Example 3: Integrated energy microgrid considering P2G and CCS but not carbon trading costs.

- Example 4: Integrated energy microgrid considering P2G and CCS with carbon trading costs.

5.2.1. Comparison of Different Scheduling Results

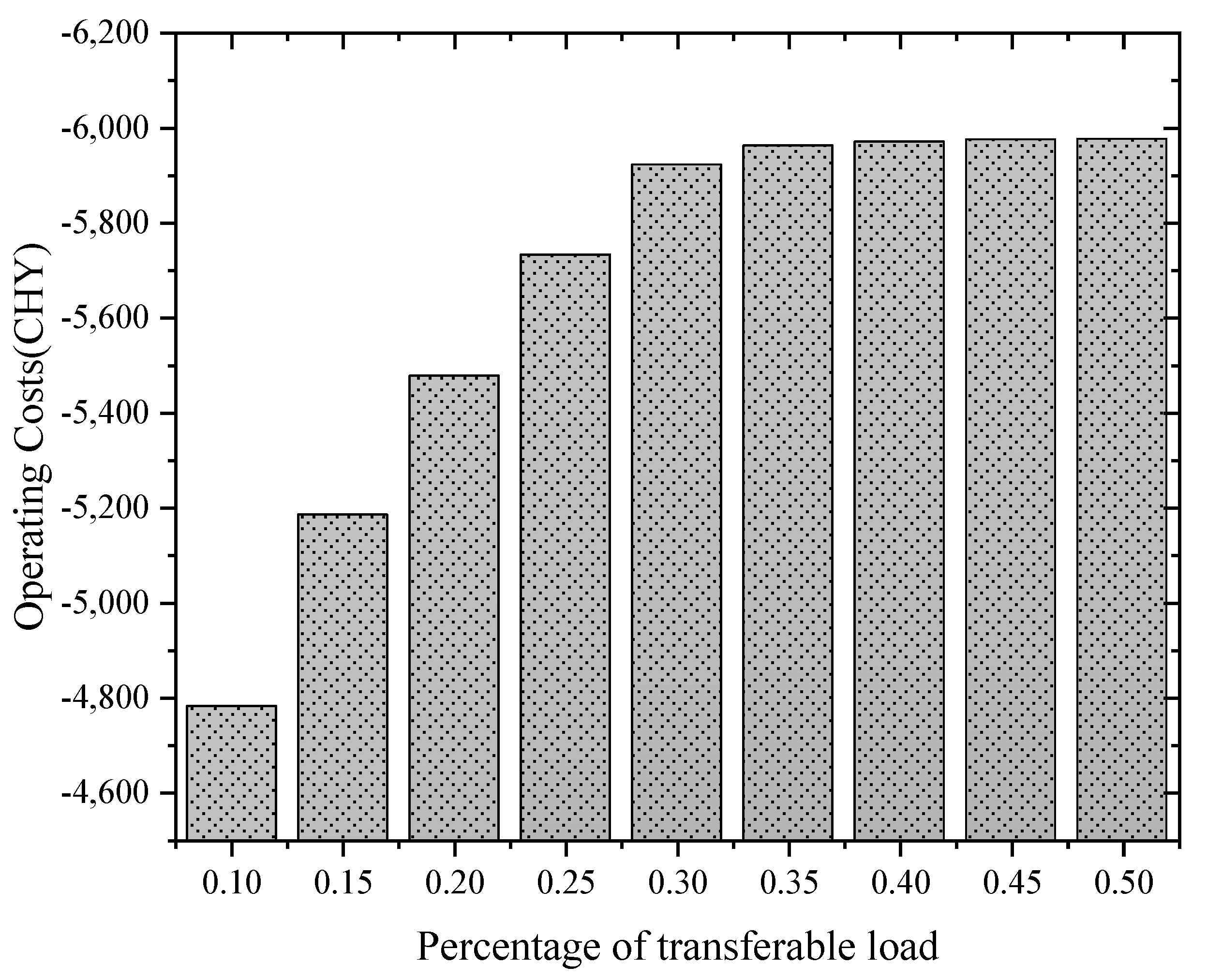

5.2.2. Integrated Energy Microgrid Scheduling Model under C Demand Response

5.3. Analysis of IGDT Optimization Results

5.3.1. Comparative Analysis of Traditional IGDT Scheduling Results under Seven Uncertain Scenarios

5.3.2. IGDT Scheduling Model Optimization Results Analysis

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, B.; Sun, L.; Qin, L. Optimization of China’s provincial carbon emission transfer structure under the dual constraints of economic development and emission reduction goals. Environ. Sci. Pollut. Res. Int. 2022, 29, 50335–50351. [Google Scholar] [CrossRef]

- Amigues, J.-P.; Kama, A.A.L.; Moreaux, M. Equilibrium transitions from non-renewable energy to renewable energy under capacity constraints. J. Econ. Dyn. Control 2015, 55, 89–112. [Google Scholar] [CrossRef] [Green Version]

- Shang, Y.; Han, D.; Gozgor, G.; Mahalik, M.K.; Sahoo, B.K. The impact of climate policy uncertainty on renewable and non-renewable energy demand in the United States. Renew. Energy 2022, 197, 654–667. [Google Scholar] [CrossRef]

- Peng, T.; Deng, H. Research on the sustainable development process of low-carbon pilot cities: The case study of Guiyang, a low-carbon pilot city in south-west China. Environ. Dev. Sustain. 2020, 23, 2382–2403. [Google Scholar] [CrossRef]

- Pang, Q.; Dong, X.; Zhang, L.; Chiu, Y.-h. Drivers and key pathways of the household energy consumption in the Yangtze River economic belt. Energy 2023, 262, 125404. [Google Scholar] [CrossRef]

- Jiang, Y.; Hu, Y.; Asante, D.; Mintah Ampaw, E.; Asante, B. The Effects of Executives’ low-carbon cognition on corporate low-carbon performance: A study of managerial discretion in China. J. Clean. Prod. 2022, 357, 132015. [Google Scholar] [CrossRef]

- Endreny, T.; Avignone-Rossa, C.; Nastro, R.A. Generating electricity with urban green infrastructure microbial fuel cells. J. Clean. Prod. 2020, 263, 121337. [Google Scholar] [CrossRef]

- Mualim, A.; Huda, H.; Altway, A.; Sutikno, J.P.; Handogo, R. Evaluation of multiple time carbon capture and storage network with capital-carbon trade-off. J. Clean. Prod. 2021, 291, 125710. [Google Scholar] [CrossRef]

- Bi, T.; Zhu, M.; Liu, H. A Powerful Tool for Power System Monitoring: Distributed Dynamic State Estimation Based on a Full-View Synchronized Measurement System. IEEE Power Energy Mag. 2023, 21, 26–35. [Google Scholar] [CrossRef]

- Neuenkamp, L.; Lewis, R.J.; Koorem, K.; Zobel, K.; Zobel, M.; Botta-Dukát, Z. Changes in dispersal and light capturing traits explain post-abandonment community change in semi-natural grasslands. J. Veg. Sci. 2016, 27, 1222–1232. [Google Scholar] [CrossRef]

- Liu, H.; Li, J.; Ge, S. Research on hierarchical control and optimization learning method of multi-energy microgrid considering the multi-agent game. IET Smart Grid 2020, 3, 479–489. [Google Scholar] [CrossRef]

- Zakeri, B.; Syri, S. Electrical energy storage systems: A comparative life cycle cost analysis. Renew. Sustain. Energy Rev. 2015, 42, 569–596. [Google Scholar] [CrossRef]

- Wang, H.; Zuo, Z.; Wang, Y.; Yang, H.; Hu, C. Estimator-Based Turning Control for Unmanned Ground Vehicles: An Anti-Peak Extended State Observer Approach. IEEE Trans. Veh. Technol. 2022, 71, 12489–12498. [Google Scholar] [CrossRef]

- Wang, X.; Han, L.; Wang, C.; Yu, H.; Yu, X. A time-scale adaptive dispatching strategy considering the matching of time characteristics and dispatching periods of the integrated energy system. Energy 2023, 267, 126584. [Google Scholar] [CrossRef]

- Liu, Z.; Xiao, Z.; Wu, Y.; Hou, H.; Xu, T.; Zhang, Q.; Xie, C. Integrated Optimal Dispatching Strategy Considering Power Generation and Consumption Interaction. IEEE Access 2021, 9, 1338–1349. [Google Scholar] [CrossRef]

- Yang, T.; Zhao, L.; Li, W.; Zomaya, A.Y. Dynamic energy dispatch strategy for an integrated energy system based on improved deep reinforcement learning. Energy 2021, 235, 121377. [Google Scholar] [CrossRef]

- Zhao, J.; Wen, F.; Xue, S. Stochastic economic dispatch with uncertainty in electric vehicle and wind power output. Power Syst. Autom. 2010, 34, 22–29. [Google Scholar]

- Dong, C.; Zhao, J.; Wen, F. From Smart Grid to Energy Internet: Basic Concepts and Research Framework. Power Syst. Autom. 2014, 38, 1–11. [Google Scholar]

- Shahidehpour, M.; Yong, F.; Wiedman, T. Impact of Natural Gas Infrastructure on Electric Power Systems. Proc. IEEE 2005, 93, 1042–1056. [Google Scholar] [CrossRef]

- Gahleitner, G. Hydrogen from renewable electricity: An international review of power-to-gas pilot plants for stationary applications. Int. J. Hydrog. Energy 2013, 38, 2039–2061. [Google Scholar] [CrossRef]

- Liu, W.; Wen, S.; Xue, S. Cost characteristics and operating economy analysis of electricity to gas technology. Power Syst. Autom. 2016, 40, 1–11. [Google Scholar] [CrossRef]

- Kim, B.; Um, T.T.; Suh, C.; Park, F.C. Tangent bundle RRT: A randomized algorithm for constrained motion planning. Robotica 2014, 34, 202–225. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Liu, S.; Chai, Y. Robust counterparts and robust, efficient solutions in vector optimization under uncertainty. Oper. Res. Lett. 2015, 43, 293–298. [Google Scholar] [CrossRef]

- Peng, C.; Zhang, J.; Chen, L. Coordinated and optimal scheduling of microgrid source-load-storage for calculating and differentiating demand response. Power Autom. Equip. 2020, 40. [Google Scholar] [CrossRef]

- Liu, D.; Li, Q.; Yuan, X. Optimal scheduling model for microgrid energy considering stochasticity. Power Syst. Prot. Control 2014, 42, 61–65. [Google Scholar]

- Ding, H.; Gao, F.; Liu, K. Robust optimization-based economic dispatch model for industrial microgrids with wind power. Power Syst. Autom. 2015, 39, 160–167. [Google Scholar]

- He, Y.; Lyu, Y.; Che, Y. Operational optimization of combined cooling, heat and power system based on information gap decision theory method considering probability distribution. Sustain. Energy Technol. Assess. 2022, 51, 101977. [Google Scholar] [CrossRef]

- Dai, X.; Wang, Y.; Yang, S.; Zhang, K. IGDT-based economic dispatch considering the uncertainty of wind and demand response. IET Renew. Power Gener. 2018, 13, 856–866. [Google Scholar] [CrossRef]

- Najafi-Ghalelou, A.; Nojavan, S.; Zare, K. Robust thermal and electrical management of smart home using information gap decision theory. Appl. Therm. Eng. 2018, 132, 221–232. [Google Scholar] [CrossRef]

- Ma, H.; Liu, Y. Coordinated scheduling decision of wind power climbing events based on IGDT robust model. Chin. J. Electr. Eng. 2016, 36, 4580–4589. [Google Scholar]

- Tang, L.; Liu, J.; Yang, Y.; Zhou, L. Power purchase and sales strategies of power sales companies under multiple retail contract models based on information gap decision theory. Grid Technol. 2019, 43. [Google Scholar] [CrossRef]

- Lu, J.; Li, G.; Wu, Z.; Cheng, C. IGDT-based medium-term operational risk measurement method under multi-market of ladder hydropower. Chin. J. Electr. Eng. 2021, 41. [Google Scholar] [CrossRef]

| Parameter | Numerical Value | Parameter | Numerical Value |

|---|---|---|---|

| (kWh) | 800 | (kW) | 0 |

| 0.95 | (kW) | 600 | |

| 0.96 | (kW) | 0 | |

| (kWh) | 500 | (kW) | 2000 |

| (kWh) | 1800 | 0.55 | |

| (kW) | 0 | (kg/kWh) | 1.02 |

| (kW) | 300 | (kW) | 0 |

| (kW) | 500 | (kW) | 500 |

| (kW) | 2000 | 0.9 | |

| 0.15 | (kg/kWh) | 0.424 | |

| 0.25 | (CHY/kg) | 0.75 | |

| 0.82 | (CHY/kWh) | 0.01 | |

| (kg/kWh) | 0.93 | (CHY/m3) | 2.9 |

| (kg/kWh) | 0.0015 | (CHY/kW) | 0.022 |

| 28.79 | (CHY/kg) | 0.064 |

| Time | Electricity Purchase Tariff (CHY/kWh) | Electricity Sales Tariff (CHY/kWh) |

|---|---|---|

| Valley hours (23:00–05:00) | 0.25 | 0.2 |

| Weekday periods (06:00–08:00, 12:00–18:00, 21:00–22:00) | 0.62 | 0.2 |

| Valley hours (23:00–05:00) | 0.92 | 0.2 |

| Example | System Operating Cost/CNY | Wind-Power Consumption | Photovoltaic-Power Consumption | Carbon Emission/kg |

|---|---|---|---|---|

| Example 1 | 11,156.38 | 86.55% | 100% | 8461.44 |

| Example 2 | 1076.28 | 100% | 100% | 8419.84 |

| Example 3 | 11,062.12 | 89.745% | 100% | 7875.57 |

| Example 4 | 231.42 | 100% | 100% | 3755.63 |

| Uncertainty of Wind-Power Output | Photovoltaic-Output Uncertainty | Electric-Load Forecast Uncertainty | Uncertainty in Thermal-Load Forecasting | |

|---|---|---|---|---|

| Case 1 | ◯ | × | × | × |

| Case 2 | × | ◯ | × | × |

| Case 3 | × | × | ◯ | × |

| Case 4 | × | × | × | ◯ |

| Case 5 | ◯ | ◯ | × | × |

| Case 6 | ◯ | ◯ | ◯ | × |

| Case 7 | ◯ | ◯ | ◯ | ◯ |

| 0.25 | 0.25 | 0.25 | 0.25 | 0.0140 | 0.0061 |

| 0.5 | 0.2 | 0.2 | 0.1 | 0.0121 | 0.0051 |

| 0.2 | 0.5 | 0.2 | 0.1 | 0.0148 | 0.0067 |

| 0.2 | 0.2 | 0.5 | 0.1 | 0.0125 | 0.0059 |

| 0.1 | 0.2 | 0.2 | 0.5 | 0.0179 | 0.0071 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, X.; Chen, Y.; Wang, R.; Luo, J.; Wang, J.; Cao, D. Integrated Energy Microgrid Economic Dispatch Optimization Model Based on Information-Gap Decision Theory. Energies 2023, 16, 3314. https://doi.org/10.3390/en16083314

Fan X, Chen Y, Wang R, Luo J, Wang J, Cao D. Integrated Energy Microgrid Economic Dispatch Optimization Model Based on Information-Gap Decision Theory. Energies. 2023; 16(8):3314. https://doi.org/10.3390/en16083314

Chicago/Turabian StyleFan, Xiaowei, Yongtao Chen, Ruimiao Wang, Jiaxin Luo, Jingang Wang, and Decheng Cao. 2023. "Integrated Energy Microgrid Economic Dispatch Optimization Model Based on Information-Gap Decision Theory" Energies 16, no. 8: 3314. https://doi.org/10.3390/en16083314