Effect of KLT-40S Fuel Assembly Design on Burnup Characteristics

Abstract

:1. Introduction

2. Materials and Methods

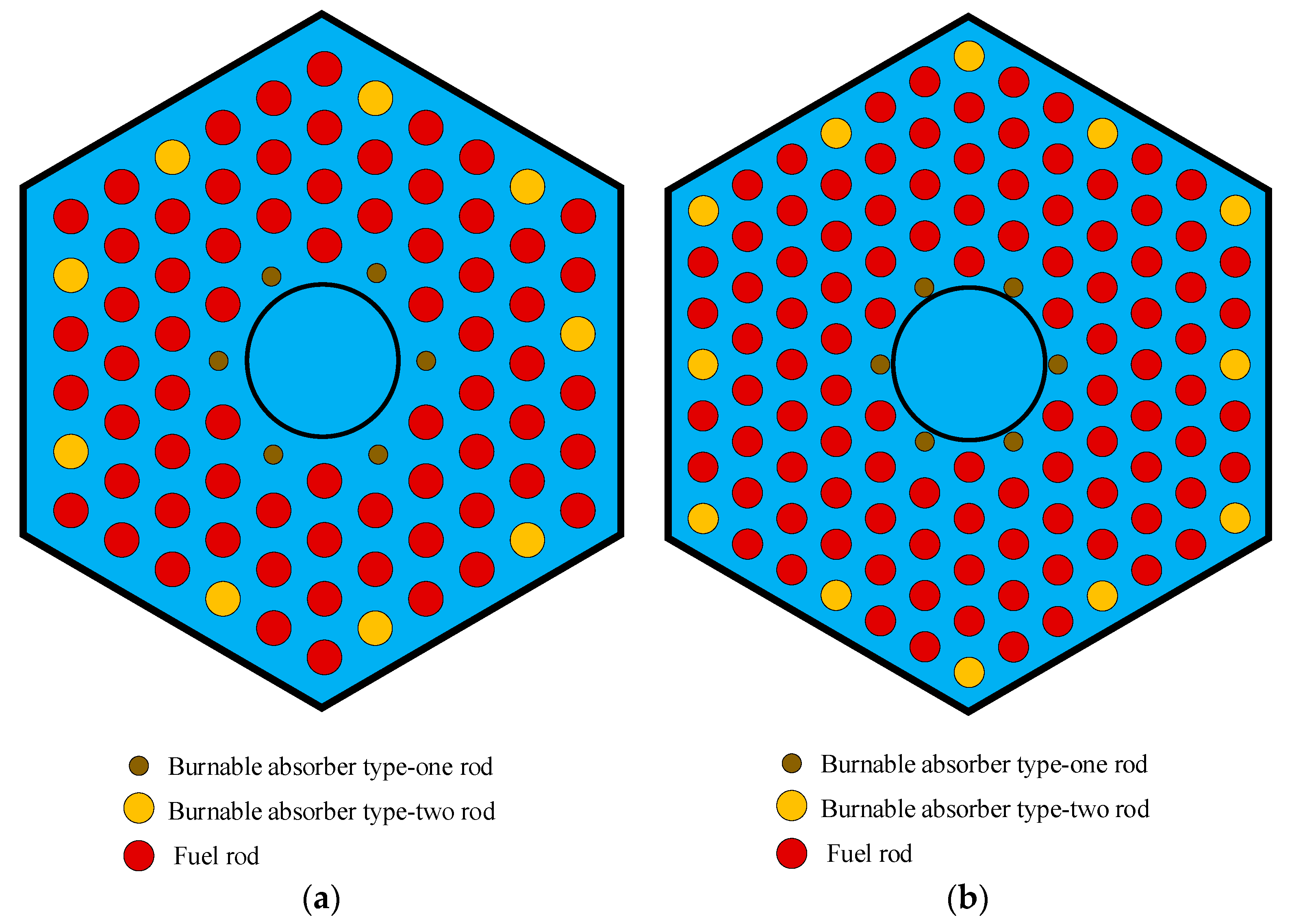

2.1. KLT-40S Fuel Assembly Designs

2.2. Power-Flattening Design

2.3. Calculation Procedure: OpenMC

3. Results and Discussion

3.1. Effect of Fuel Assembly Design on Burnup

3.2. Effect of Fuel Rod Diameter on Burnup

3.3. Power-Flattening Design

4. Conclusions and Discussion

- (1)

- The initial infinite multiplication factors, kinf, of the four-ring and five-ring fuel assembly designs are the same. However, compared with the four-ring fuel assembly, the five-ring fuel assembly has a 16.67% higher initial fuel loading, a significant lifetime improvement of 21.31%, and a 2% increase in the 235U utilization rate. Therefore, the KLT-40S five-ring fuel assembly has better burnup characteristics than the four-ring fuel assembly. This is the reason why most of the computational studies are conducted using the KLT-40S five-ring fuel assembly as the computational model.

- (2)

- At a fuel rod diameter of 0.52 cm for the five-ring fuel assembly, the water–uranium ratio is optimal and the initial infinite multiplication factor kinf reaches a maximum value of 1.717. With an increase in the fuel rod diameter, the fuel assembly lifetime increases, and the burnup depth increases and then decreases. At a fuel rod diameter of 0.62 cm, the burnup depth and 235U utilization rate of the five-ring fuel assembly reach their maximum values (optimal burnup lattice). Russia uses fuel rods with a diameter of 0.62 cm in the KLT-40S reactor, which proves that the country not only aims to extend the fuel assembly lifetime, but also to enhance fuel utilization. This provides some design concepts for the development of small modular reactors.

- (3)

- The use of a power-flattening design can effectively reduce the local power peaking factor. The lower the fuel enrichment of the innermost ring, the better the power-flattening effect and the smaller the local power peaking factor. Because the fuel enrichment used in the KLT-40S does not exceed 19.75%, the 15.84% + 19.75% power-flattening design is the best arrangement for fuel enrichment. Under the 15.84% + 19.75% power-flattening design, the local power peaking factor decreases from 1.19 to 1.09 at the beginning of the lifetime; it is less than 1.11, and remains at approximately 1.10 throughout the lifetime. This provides some guidance for the design of power-flattening for small modular reactors.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; Fan, J. Technology readiness assessment of small modular reactor (SMR) designs. Prog. Nucl. Energy 2014, 70, 20–28. [Google Scholar] [CrossRef]

- Locatelli, G.; Bingham, C.; Mancini, M. Small modular reactors: A comprehensive overview of their economics and strategic aspects. Prog. Nucl. Energy 2014, 73, 75–85. [Google Scholar] [CrossRef]

- Asif, M.; Muneer, T. Energy supply, its demand and security issues for developed and emerging economies. Renew. Sustain. Energy Rev. 2007, 11, 1388–1413. [Google Scholar] [CrossRef]

- Subki, H. Advances in Small Modular Reactor Technology Developments; INIS-XA—20M3048; International Atomic Energy Agency (IAEA): Vienna, Austria, 2020. [Google Scholar]

- Ingersoll, D.T.; Carelli, M.D. Handbook of Small Modular Nuclear Reactors; Woodhead Publishing: Cambridge, UK, 2020. [Google Scholar]

- Di Maio, F.; Bani, L.; Zio, E. The Contribution of Small Modular Reactors to the Resilience of Power Supply. J. Nucl. Eng. 2022, 3, 152–162. [Google Scholar] [CrossRef]

- Ghazaie, S.; Sadeghi, K.; Sokolova, E.; Fedorovich, E.; Shirani, A. Comparative Analysis of Hybrid Desalination Technologies Powered by SMR. Energies 2020, 13, 5006. [Google Scholar] [CrossRef]

- Reistad, O.; Ølgaard, P.L. Russian Nuclear Power Plants for Marine Applications; NKS-138; Nordic Nuclear Safety Research: Roskilde, Denmark, 2006. [Google Scholar]

- Polunichev, V.I. Prospects for the Utilization of Small Nuclear Plants for Civil Ships, Floating Heat and Power Stations and Power Seawater Desalination Complexes; IAEA-TECDOC-1184; International Atomic Energy Agency: Vienna, Austria, 2000. [Google Scholar]

- Lee, K.-H.; Kim, M.-G.; Lee, J.I.; Lee, P.-S. Recent Advances in Ocean Nuclear Power Plants. Energies 2015, 8, 11470–11492. [Google Scholar] [CrossRef] [Green Version]

- International Atomic Energy Agency. Available online: https://aris.iaea.org/PDF/KLT-40S.pdf (accessed on 1 April 2023).

- Fajri, D.F.; Agung, A.; Harto, A.W. The Study of Floating Nuclear Power Plant Reactor Core Neutronic Parameters Using Scale 6.1 Code. Int. J. Adv. Sci. Eng. Inf. Technol. 2020, 10, 1774–1783. [Google Scholar] [CrossRef]

- Baybakov, D.; Godovykh, A.; Martynov, I.; Nesterov, V. The dependence of the nuclide composition of the fuel core loading on multiplying and breeding properties of the KLT-40S nuclear facility. Nucl. Energy Technol. 2016, 2, 183–190. [Google Scholar] [CrossRef] [Green Version]

- Beliavskii, S.V.; Nesterov, V.N.; Laas, R.A.; Godovikh, A.V.; Bulakh, O.I. Effect of fuel nuclide composition on the fuel lifetime of reactor KLT-40S. Nucl. Eng. Des. 2020, 360, 110524. [Google Scholar] [CrossRef]

- Baatar, T.; Glazkov, O.V. Increasing burn-up of KLT-40S fuel by introduction of neptunium. J. Physics Conf. Ser. 2020, 1689, 012061. [Google Scholar] [CrossRef]

- Tiang, Z.H.; Xiao, S. Long-term reactivity control of accident tolerant fuel loaded marine small modular reactor using particle-type burnable poisons. Ann. Nucl. Energy 2021, 156, 108177. [Google Scholar] [CrossRef]

- Diakov, A.C.; Dmitriev, A.M.; Kang, J.; Shuvayev, A.M.; von Hippel, F.N. Feasibility of Converting Russian Icebreaker Reactors from HEU to LEU Fuel. Sci. Glob. Secur. 2006, 14, 33–48. [Google Scholar] [CrossRef]

- Oettingen, M.; Kim, J. Detection of Numerical Power Shift Anomalies in Burnup Modeling of a PWR Reactor. Sustainability 2023, 15, 3373. [Google Scholar] [CrossRef]

- Romano, P.K.; Horelik, N.E.; Herman, B.R.; Nelson, A.G.; Forget, B.; Smith, K. OpenMC: A state-of-the-art Monte Carlo code for research and development. Ann. Nucl. Energy 2015, 82, 90–97. [Google Scholar] [CrossRef] [Green Version]

- Zverev, D.L.; Pakhomov, A.N.; Polunichev, V.I.; Veshnyakov, K.B.; Kabin, S.V. RITM-200: New-generation reactor for a new nuclear icebreaker. Sov. At. Energy 2013, 113, 404–409. [Google Scholar] [CrossRef]

- Savitsky, D.E.; Kuzmin, A.V. The calculation of the campaign of reactor RITM-200. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1019, 012057. [Google Scholar] [CrossRef]

- Naumov, V.; Gusak, S.; Naumov, A. Small nuclear power plants for power supply in arctic regions: Assessment of spent nuclear fuel radioactivity. Nucl. Energy Technol. 2018, 4, 119–125. [Google Scholar] [CrossRef]

- Tramm, J.R.; Siegel, A.R.; Islam, T.; Schulz, M. XSBench-the development and verification of a performance abstraction for Monte Carlo reactor analysis. In Proceedings of the Role of Reactor Physics toward a Sustainable Future (PHYSOR), Kyoto, Japan, 28 September–3 October 2014. [Google Scholar]

- Romano, P.K.; Forget, B. The Open MC Monte Carlo particle transport code. Ann. Nucl. Energy 2013, 51, 274–281. [Google Scholar] [CrossRef] [Green Version]

- Stacey, W.M. Nuclear Reactor Physics; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

| Parameter | Value |

|---|---|

| Average fuel power density/(kw/kgU) | 117.8 |

| Width across flats of fuel assembly/cm | 10 |

| Thickness of fuel assembly/cm | 0.1 |

| Diameter of inner cylindrical shroud/cm | 2.6 |

| Thickness of inner cylindrical shroud/cm | 0.05 |

| Cladding material | Zr + 1% Nb |

| Fuel materials | Uranium dioxide in aluminum–silicon matrix |

| UO2 volume fraction | 0.436 |

| Average 235U enrichment/% | 18.6 |

| Element | Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| Mass fraction/% | 10.0 | 0.15 | 0.03 | 0.1 | 0.4 | 0.07 | 0.15 | 89.1 |

| Parameter | Four-Ring Fuel Assembly | Five-Ring Fuel Assembly |

|---|---|---|

| Number of fuel rods | 69 | 102 |

| Diameter of fuel rod/cm | 0.62 | 0.68 |

| Number of burnable type I absorber rods | 6 | 6 |

| Diameter of burnable type I absorber rods/cm | 0.476 | 0.46 |

| Number of burnable type II absorber rods | 9 | 12 |

| Diameter of burnable type II absorber rods/cm | 0.68 | 0.62 |

| Fuel rod lattice pitch/cm | 0.995 | 0.835 |

| Temperature of fuel/°C | 427 | 427 |

| Temperature of clad/°C | 377 | 377 |

| Design | Uranium Enrichment in Innermost and Outermost Rings | Uranium Enrichment in Inner Rings |

|---|---|---|

| Model 1 | 18.6% | 18.6% |

| Model 2 | 15.7% | 19.808% |

| Model 3 | 15.84% | 19.75% |

| Model 4 | 17.4% | 19.1% |

| Fuel Assembly Design | kinf (BOL) | Lifetime/EFPD | 235U Utilization Rate |

|---|---|---|---|

| Four-ring fuel assembly | 1.686 | 1220 | 84.57% |

| Five-ring fuel assembly | 1.681 | 1480 | 86.7% |

| Fuel Rod Diameter/cm | kinf (BOL) | Lifetime/EFPD | Maximum Burnup Depth/(GW·d/tU) | 235U Utilization Rate | 238U Utilization Rate |

|---|---|---|---|---|---|

| 0.42 | 1.68823 | 513 | 128.727 | 82.07% | 2.176% |

| 0.52 | 1.71715 | 935 | 140.161 | 86.28% | 3.2913% |

| 0.62 | 1.68175 | 1480 | 145.861 | 86.41% | 4.709% |

| 0.72 | 1.60252 | 2000 | 140.731 | 81.16% | 6.227% |

| 0.82 | 1.49916 | 2288 | 115.492 | 73.57% | 7.694% |

| Design | Fuel Enrichment | kinf (BOL) | Lifetime/EFPD | Local Power Peaking Factor |

|---|---|---|---|---|

| Model 1 | 18.6% | 1.68175 | 1480 | 1.193 |

| Model 2 | 15.7% + 19.8% | 1.67852 | 1449 | 1.093 |

| Model 3 | 15.8% + 19.75% | 1.67709 | 1452 | 1.091 |

| Model 4 | 17.4% + 19.1% | 1.67787 | 1466 | 1.141 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Xie, J.; Deng, N.; Chen, P.; Wu, Z.; Yu, T. Effect of KLT-40S Fuel Assembly Design on Burnup Characteristics. Energies 2023, 16, 3364. https://doi.org/10.3390/en16083364

Zhou Z, Xie J, Deng N, Chen P, Wu Z, Yu T. Effect of KLT-40S Fuel Assembly Design on Burnup Characteristics. Energies. 2023; 16(8):3364. https://doi.org/10.3390/en16083364

Chicago/Turabian StyleZhou, Zedong, Jinsen Xie, Nianbiao Deng, Pengyu Chen, Zhiqiang Wu, and Tao Yu. 2023. "Effect of KLT-40S Fuel Assembly Design on Burnup Characteristics" Energies 16, no. 8: 3364. https://doi.org/10.3390/en16083364