Integrating Prospective Scenarios in Life Cycle Engineering: Case Study of Lightweight Structures

Abstract

:1. Introduction

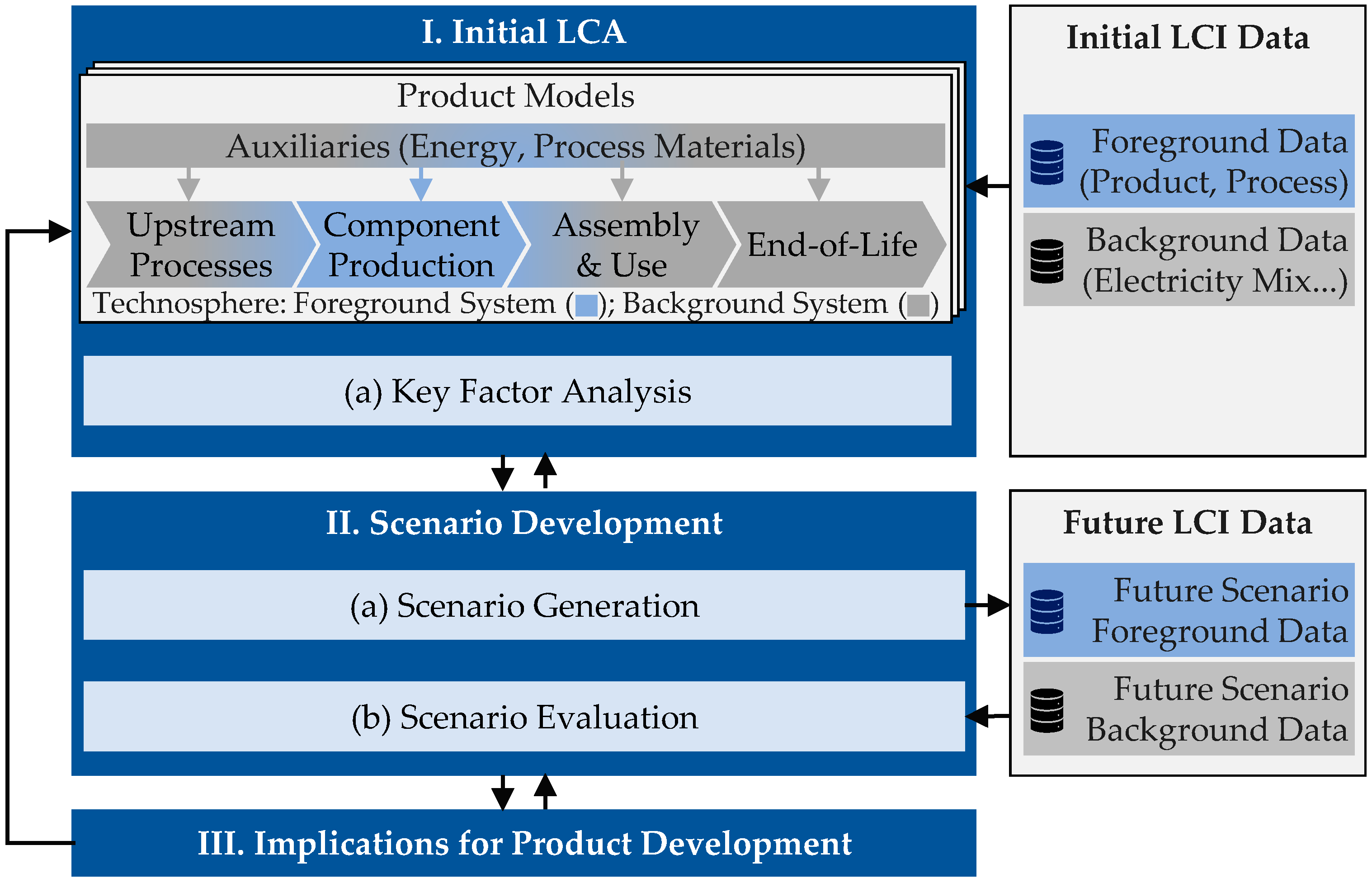

2. Materials and Methods

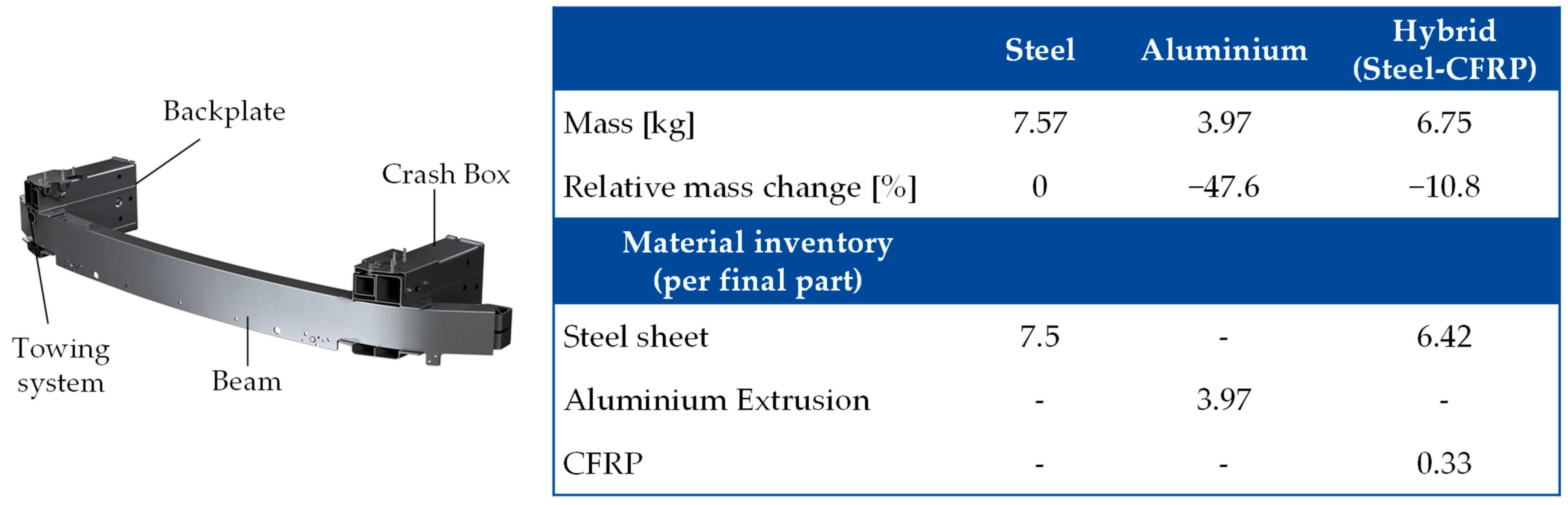

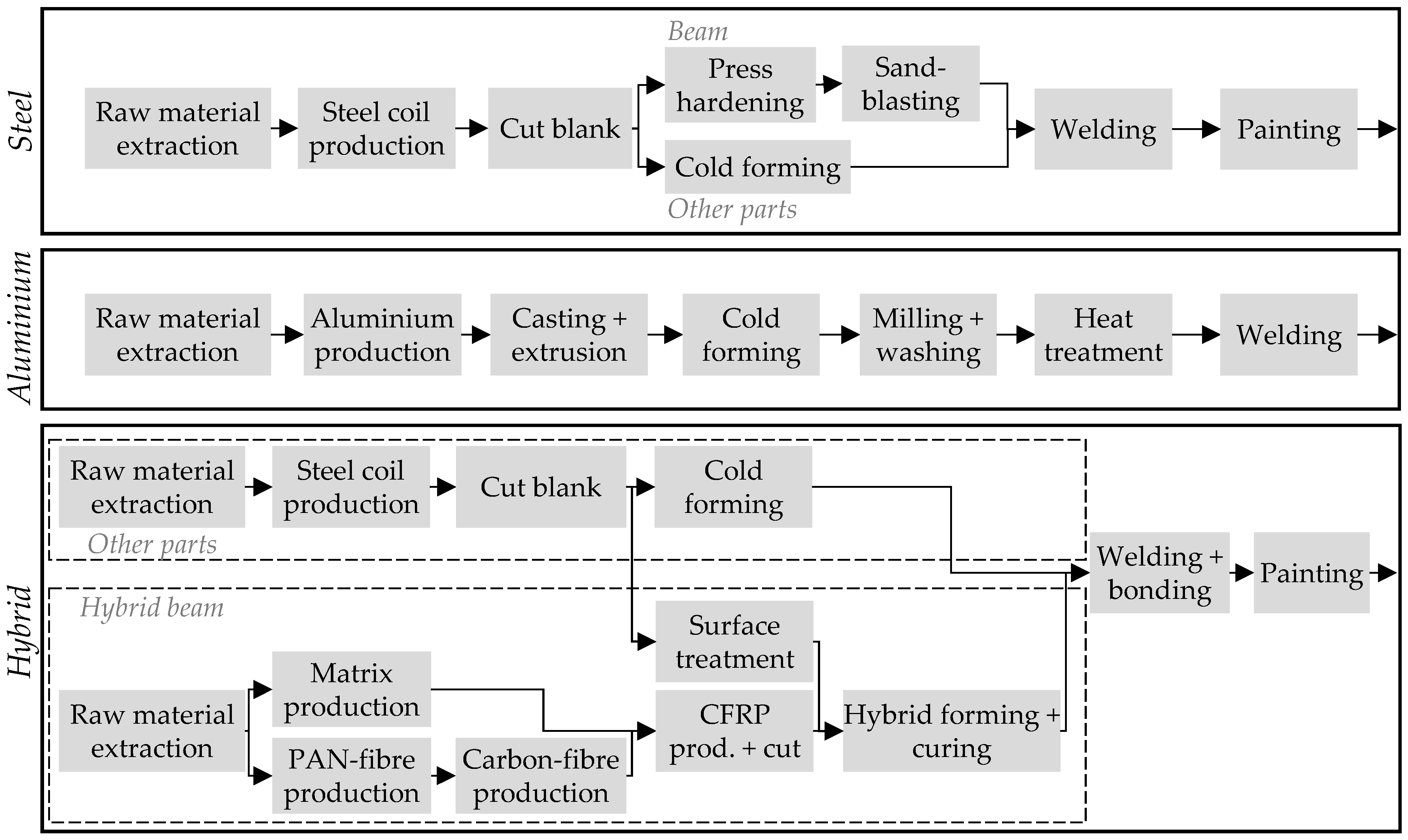

3. Case Study

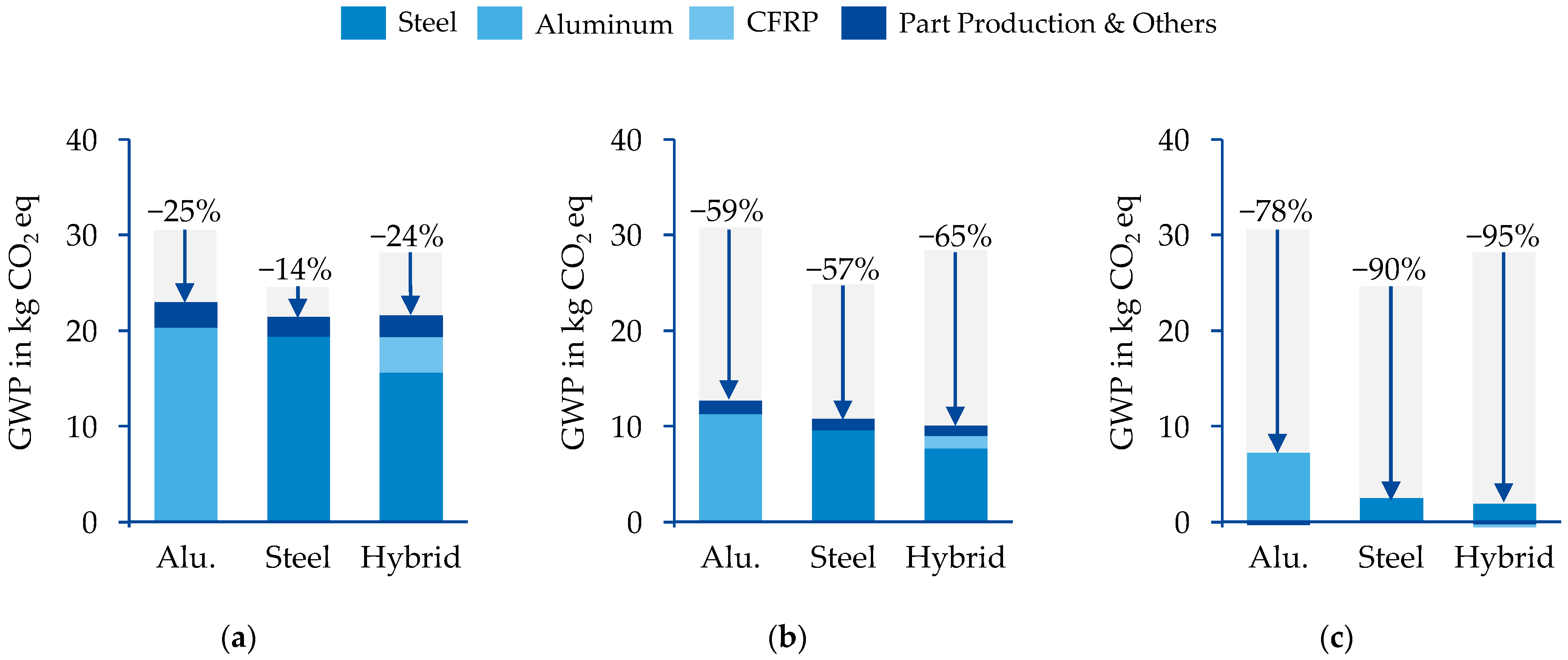

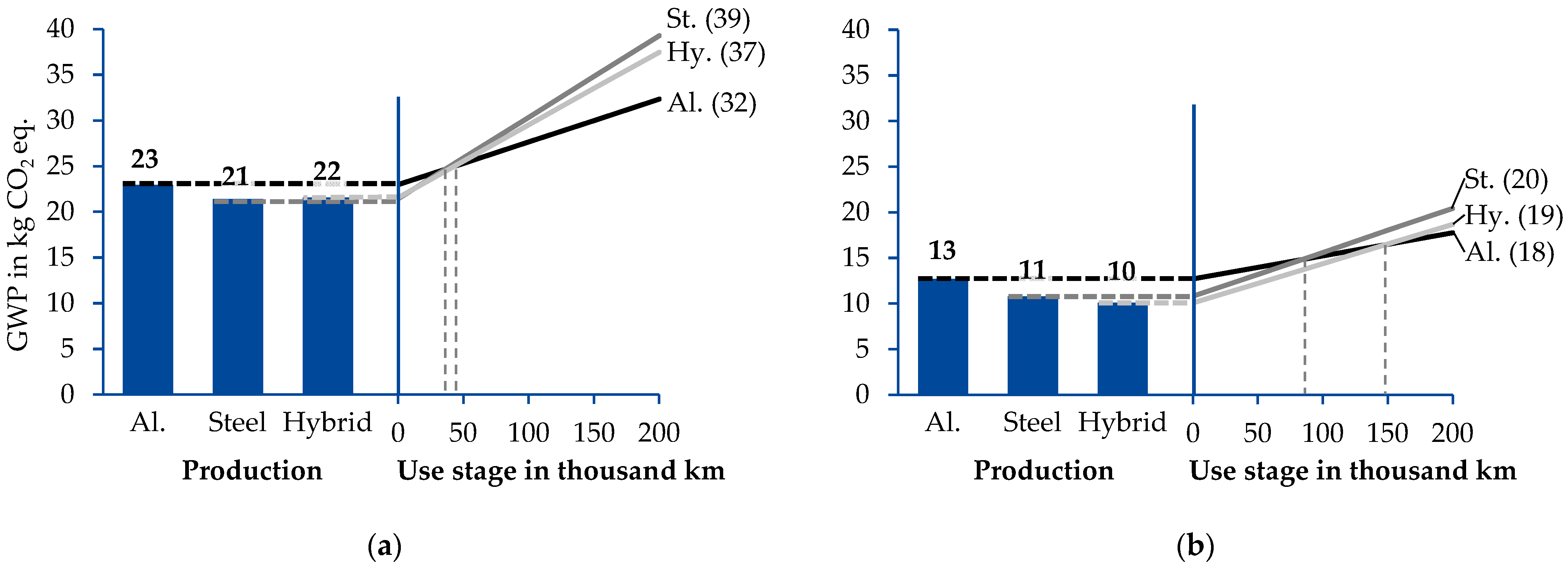

4. Results

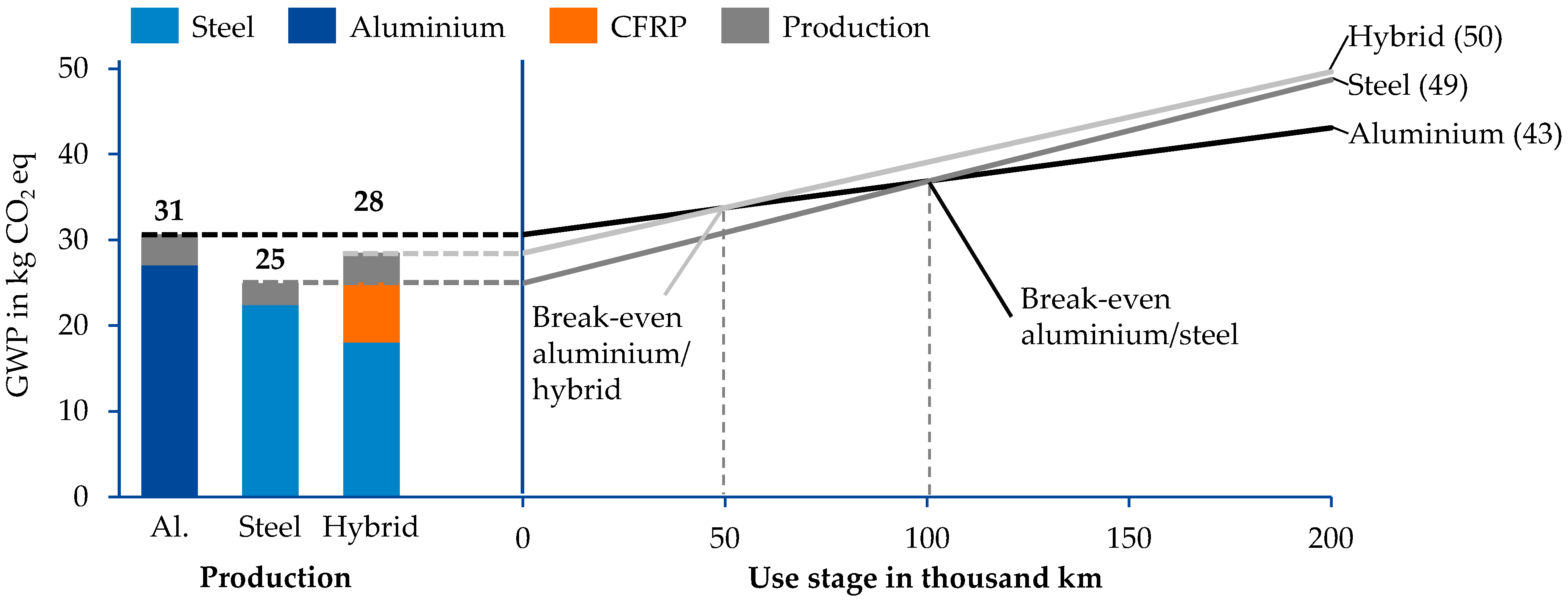

4.1. Initial LCA (I)

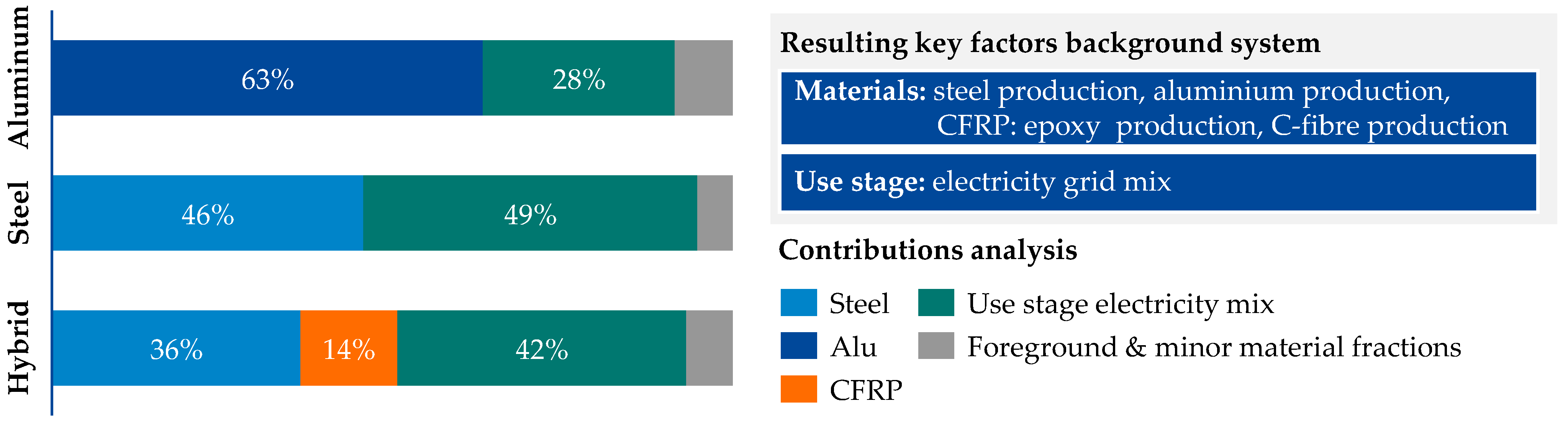

Key Factor Analysis (I-a)

4.2. Scenario Development (II)

4.2.1. Scenario Generation (II-a)

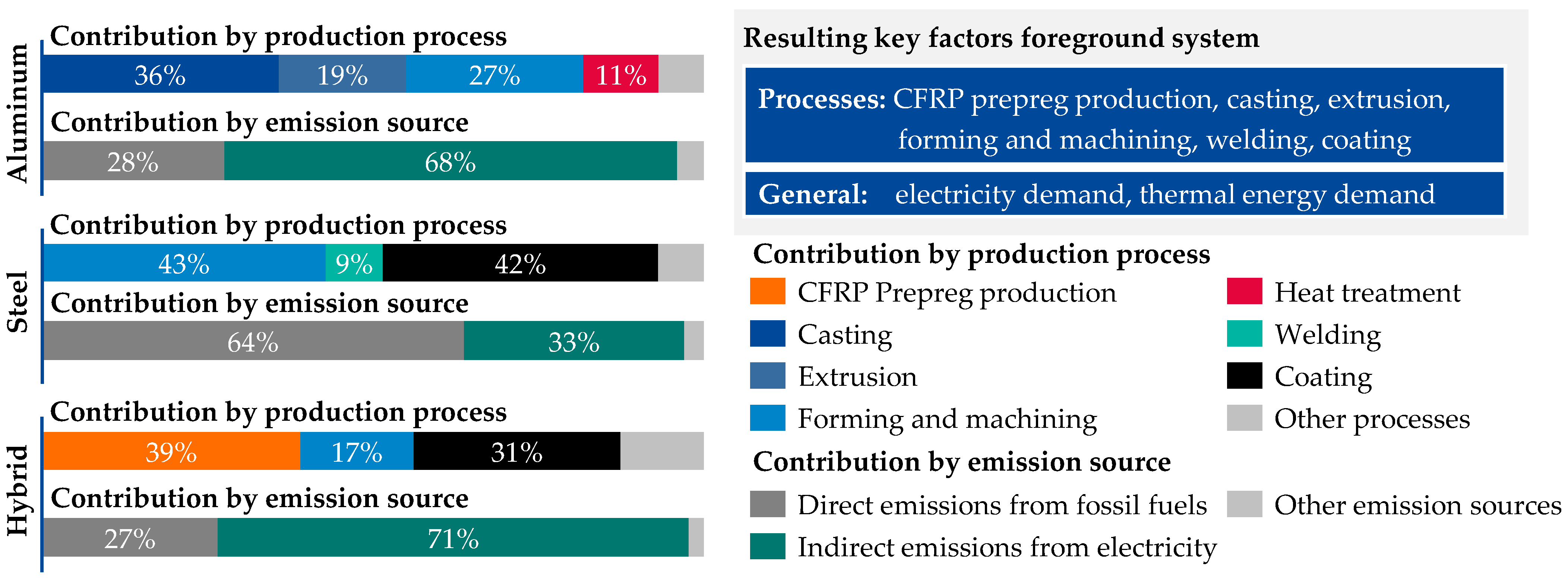

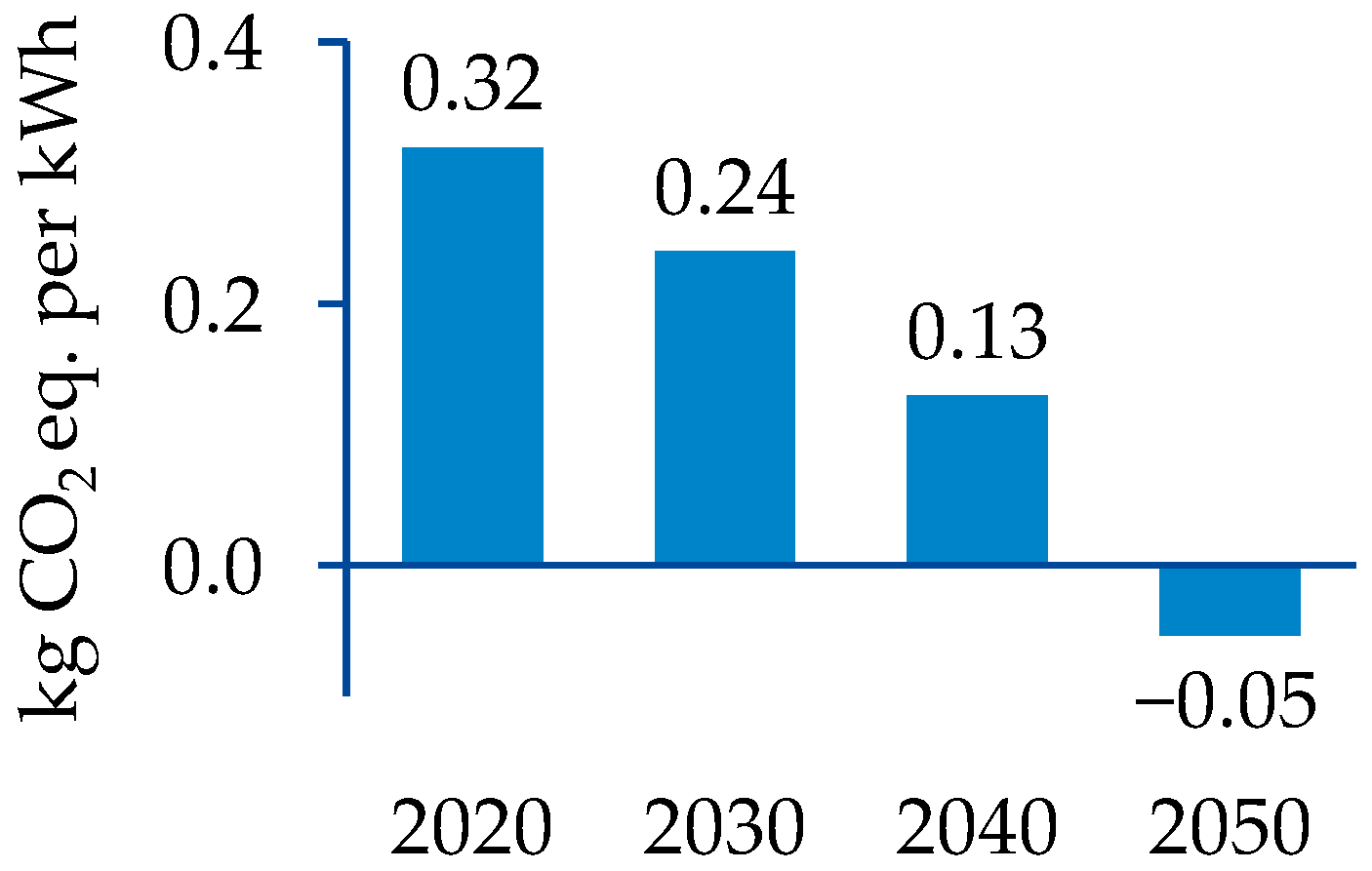

4.2.2. Scenario Evaluation (II-b)

4.3. Implications for Product Development (III)

5. Conclusions and Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Key Factor | Assumptions |

| Hot-forming process |

|

| Coating (cathodic dip coating) |

|

| Aluminium Casting and Extrusion |

|

| Other processes: Welding, Surface Treatment, Forming and Machining |

|

| Hybrid forming and curing process |

|

| Prepreg production and cutting |

|

| Material efficiency in Production processes |

|

| Key Factor | Assumptions |

| Electricity generation |

|

| Steel production |

|

| Primary aluminium production |

|

| Epoxy matrix production |

|

| PAN precursor production |

|

| Carbon fibre production |

|

References

- Regulation (EU) 2021/1119 of the European Parliament and of the Council of 30 June 2021 Establishing the Framework for Achieving Climate Neutrality and Amending Regulations (EC) No 401/2009 and (EU) 2018/1999 (‘European Climate Law’): (EU) 2021/1119. 2021. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32021R1119 (accessed on 5 March 2023).

- European Environmental Agency. EEA Greenhouse Gases: Sectoral Shares in EU-27 in 2020. Available online: https://www.eea.europa.eu/data-and-maps/data/data-viewers/greenhouse-gases-viewer (accessed on 9 August 2022).

- Reimer, L.; Kaluza, A.; Cerdas, F.; Meschke, J.; Vietor, T.; Herrmann, C. Design of Eco-Efficient Body Parts for Electric Vehicles Considering Life Cycle Environmental Information. Sustainability 2020, 12, 5838. [Google Scholar] [CrossRef]

- Koffler, C.; Rohde-Brandenburger, K. On the calculation of fuel savings through lightweight design in automotive life cycle assessments. Int. J. Life Cycle Assess. 2010, 15, 128–135. [Google Scholar] [CrossRef]

- Egede, P. Environmental Assessment of Lightweight Electric Vehicles, 1st ed.; Springer International Publishing: Cham, Switzerland, 2017; ISBN 9783319402772. [Google Scholar]

- Delogu, M.; Del Pero, F.; Pierini, M. Lightweight Design Solutions in the Automotive Field: Environmental Modelling Based on Fuel Reduction Value Applied to Diesel Turbocharged Vehicles. Sustainability 2016, 8, 1167. [Google Scholar] [CrossRef] [Green Version]

- Del Pero, F.; Berzi, L.; Antonacci, A.; Delogu, M. Automotive Lightweight Design: Simulation Modeling of Mass-Related Consumption for Electric Vehicles. Machines 2020, 8, 51. [Google Scholar] [CrossRef]

- Luk, J.M.; Kim, H.C.; de Kleine, R.; Wallington, T.J.; MacLean, H.L. Review of the Fuel Saving, Life Cycle GHG Emission, and Ownership Cost Impacts of Lightweighting Vehicles with Different Powertrains. Environ. Sci. Technol. 2017, 51, 8215–8228. [Google Scholar] [CrossRef] [PubMed]

- Muttana, S.B.; Sardar, A. Lightweighting of Battery Electric Cars: An Impact Analysis Using Indian Driving Cycle. In SAE Technical Paper Series, Proceedings of the 8th SAEINDIA International Mobility Conference & Exposition and Commercial Vehicle Engineering Congress 2013 (SIMCOMVEC), Chennai, India, 4 December 2013; SAE: Warrendale, PA, USA, 2013. [Google Scholar]

- Wang, J.; Li, Y.; Hu, G.; Yang, M. Lightweight Research in Engineering: A Review. Appl. Sci. 2019, 9, 5322. [Google Scholar] [CrossRef] [Green Version]

- Herrmann, C.; Dewulf, W.; Hauschild, M.; Kaluza, A.; Kara, S.; Skerlos, S. Life cycle engineering of lightweight structures. CIRP Ann. 2018, 67, 651–672. [Google Scholar] [CrossRef]

- Haraldsson, J.; Johansson, M.T. Effects on primary energy use, greenhouse gas emissions and related costs from improving energy end-use efficiency in the electrolysis in primary aluminium production. Energy Effic. 2020, 13, 1299–1314. [Google Scholar] [CrossRef]

- Nunez, P.; Jones, S. Cradle to gate: Life cycle impact of primary aluminium production. Int. J. Life Cycle Assess. 2016, 21, 1594–1604. [Google Scholar] [CrossRef] [Green Version]

- Hohmann, A. Ökobilanzielle Untersuchung von Herstellungsverfahren für CFK-Strukturen zur Identifikation von Optimierungspotentialen: Systematische Methodik zur Abschätzung der Umweltwirkungen von Fertigungsprozessketten. Ph.D. Dissertation, Technische Universität München, München, German, 2019. [Google Scholar]

- Arnold, U.; de Palmenaer, A.; Brück, T.; Kuse, K. Energy-Efficient Carbon Fiber Production with Concentrated Solar Power: Process Design and Techno-economic Analysis. Ind. Eng. Chem. Res. 2018, 57, 7934–7945. [Google Scholar] [CrossRef]

- Dér, A.; Dilger, N.; Kaluza, A.; Creighton, C.; Kara, S.; Varley, R.; Herrmann, C.; Thiede, S. Modelling and analysis of the energy intensity in polyacrylonitrile (PAN) precursor and carbon fibre manufacturing. J. Clean. Prod. 2021, 303, 127105. [Google Scholar] [CrossRef]

- Hill, C.; Norton, A. LCA Database of Environmental Impacts to Inform Material Selection Process, DACOMAT. 2018. Available online: https://www.sintef.no/globalassets/project/dacomat/dacomat-deliverable-6.1.pdf (accessed on 5 March 2023).

- Deng, Y. Life Cycle Assessment of Biobased Fibre-Reinforced Polymer Composites. Ph. D. Dissertation, KU Leuven, Leuven, Belgium, 2014. [Google Scholar]

- Jacob-Lopes, E. Sustainability Metrics and Indicators of Environmental Impact: Industrial and Agricultural Life Cycle Assessment; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Standardization Organization: Geneva, Switzerland, 2006.

- Hauschild, M.Z.; Herrmann, C.; Kara, S. An Integrated Framework for Life Cycle Engineering. Procedia CIRP 2017, 61, 2–9. [Google Scholar] [CrossRef] [Green Version]

- Reimer, L.; Jois, P.K.; Henkelmann, H.; Meschke, J.; Vietor, T.; Herrmann, C. Systematic Design of Body Concepts Regarding Mini-Mal Environmental Impacts in an Early Concept Phase. In Technologies for Economic and Functional Lightweight Design; Dröder, K., Vietor, T., Eds.; Springer Vieweg: Berlin/Heidelberg, Germany, 2021; pp. 97–109. ISBN 978-3-662-62924-6. [Google Scholar]

- Kaluza, A.; Kleemann, S.; Fröhlich, T.; Herrmann, C.; Vietor, T. Concurrent Design & Life Cycle Engineering in Automotive Lightweight Component Development. Procedia CIRP 2017, 66, 16–21. [Google Scholar] [CrossRef]

- Hirz, M.; Nguyen, T.T. Life-Cycle CO2-Equivalent Emissions of Cars Driven by Conventional and Electric Propulsion Systems. World Electr. Veh. J. 2022, 13, 61. [Google Scholar] [CrossRef]

- Koffler, C. Life cycle assessment of automotive lightweighting through polymers under US boundary conditions. Int. J. Life Cycle Assess. 2014, 19, 538–545. [Google Scholar] [CrossRef]

- Witik, R.A.; Payet, J.; Michaud, V.; Ludwig, C.; Månson, J.-A.E. Assessing the life cycle costs and environmental performance of lightweight materials in automobile applications. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1694–1709. [Google Scholar] [CrossRef]

- Del Pero, F.; Delogu, M.; Kerschbaum, M. Design of a Lightweight Rear Crash Management System in a Sustainable Perspective. Sustainability 2020, 12, 5243. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Turner, T.; Wong, K.H.; Pickering, S.J. Environmental Aspects of Use of Recycled Carbon Fiber Composites in Automotive Applications. Environ. Sci. Technol. 2017, 51, 12727–12736. [Google Scholar] [CrossRef]

- Raugei, M.; Morrey, D.; Hutchinson, A.; Winfield, P. A coherent life cycle assessment of a range of lightweighting strategies for compact vehicles. J. Clean. Prod. 2015, 108, 1168–1176. [Google Scholar] [CrossRef] [Green Version]

- Mayyas, A.T.; Qattawi, A.; Mayyas, A.R.; Omar, M.A. Life cycle assessment-based selection for a sustainable lightweight body-in-white design. Energy 2012, 39, 412–425. [Google Scholar] [CrossRef]

- Shanmugam, K.; Gadhamshetty, V.; Yadav, P.; Athanassiadis, D.; Tysklind, M.; Upadhyayula, V.K. Advanced High-Strength Steel and Carbon Fiber Reinforced Polymer Composite Body in White for Passenger Cars: Environmental Performance and Sustainable Return on Investment under Different Propulsion Modes. ACS Sustain. Chem. Eng. 2019, 7, 4951–4963. [Google Scholar] [CrossRef]

- Arvidsson, R.; Tillman, A.-M.; Sandén, B.A.; Janssen, M.; Nordelöf, A.; Kushnir, D.; Molander, S. Environmental Assessment of Emerging Technologies: Recommendations for Prospective LCA. J. Ind. Ecol. 2018, 22, 1286–1294. [Google Scholar] [CrossRef] [Green Version]

- Weber, J. Automotive Development Processes; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 978-3-642-01252-5. [Google Scholar]

- Pfeifer, F.; Dietrich, A.; Marten, T.; Tröster, T.; Nacke, B. Investigation on Inductive Heating of Sheet Metal for an Industrial Hot Stamping Process. In Hot Sheet Metal Forming of High-Performance Steel, Proceedings of the CHS2: 7th International Conference, Luleå, Sweden, 2–5 June 2019; Oldenburg, M., Hardell, J., Casellas, D., Eds.; Verlag Wissenschaftliche Scripten: Auerbach/Vogtland, Germany, 2019; pp. 585–593. ISBN 9783957351043. [Google Scholar]

- Zeichner, A. Entwicklung einer Ofenrollenbeschichtung für das Presshärten. Ph.D. Dissertation, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, Germany, 2013. [Google Scholar]

- Stehfest, E.; van Vuuren, D.; Kram, T.; Bouwman, L.; Alkemade, R.; Bakkenes, M.; Biemans, H.; Bouwman, A.; den Elzen, M.; Janse, J.; et al. Integrated Assessment of Global Environmentl Change with IMAGE 3.0; PBL Netherlands Environmental Assessment Agency: The Hauge, The Netherlands, 2014. [Google Scholar]

- International Energy Agency. Iron and Steel Technology Roadmap; OECD: Paris, France, 2020; ISBN 9789264441149. [Google Scholar]

- Bataille, C.; Stiebert, S.; Li, F.G.N. Global Facility Level Net-Zero Steel Pathways: Technical Report on the First Scenarios of the Net-Zero Steel Project. 2021. Available online: http://netzerosteel.org/wp-content/uploads/pdf/net_zero_steel_report.pdf (accessed on 18 September 2022).

- European Aluminium. Vision 2050: European Aluminium’s Contribution to EU’s Mid-Century Low-Carbon Roadmap; European Aluminium: Woluwe-Saint-Pierre, Belgium, 2018. [Google Scholar]

- International Aluminium Institute. 1.5 Degrees Scenario: A Model to Drive Emissions Reduction; International Aluminium Institute: London, UK, 2021. [Google Scholar]

- Hermansson, F.; Heimersson, S.; Janssen, M.; Svanström, M. Can carbon fiber composites have a lower environmental impact than fiberglass? Resour. Conserv. Recycl. 2022, 181, 106234. [Google Scholar] [CrossRef]

- Arnold, U.; Brück, T.; de Palmenaer, A.; Kuse, K. Carbon Capture and Sustainable Utilization by Algal Polyacrylonitrile Fiber Production: Process Design, Techno-Economic Analysis, and Climate Related Aspects. Ind. Eng. Chem. Res. 2018, 57, 7922–7933. [Google Scholar] [CrossRef]

- Hohmann, A.; Frank, J. Environmental friendly fiber reinforced plastics (FRP) for high performance applications: Assessment of the global warming potential (GWP) and related levers. In Proceedings of the Composites and Sustainability by Composites United, Virtual, Switzerland, November 2021. [Google Scholar]

- Dér, A.; Kaluza, A.; Reimer, L.; Herrmann, C.; Thiede, S. Integration of Energy Oriented Manufacturing Simulation into the Life Cycle Evaluation of Lightweight Body Parts. Int. J. Precis. Eng. Manuf.-Green Technol. 2022, 9, 899–918. [Google Scholar] [CrossRef]

- Pei, M.; Petäjäniemi, M.; Regnell, A.; Wijk, O. Toward a Fossil Free Future with HYBRIT: Development of Iron and Steelmaking Technology in Sweden and Finland. Metals 2020, 10, 972. [Google Scholar] [CrossRef]

- Buyle, M.; Audenaert, A.; Billen, P.; Boonen, K.; van Passel, S. The Future of Ex-Ante LCA? Lessons Learned and Practical Recommendations. Sustainability 2019, 11, 5456. [Google Scholar] [CrossRef] [Green Version]

- Mendoza Beltran, A.; Cox, B.; Mutel, C.; Vuuren, D.P.; Font Vivanco, D.; Deetman, S.; Edelenbosch, O.Y.; Guinée, J.; Tukker, A. When the Background Matters: Using Scenarios from Integrated Assessment Models in Prospective Life Cycle Assessment. J. Ind. Ecol. 2020, 24, 64–79. [Google Scholar] [CrossRef] [Green Version]

- Pesonen, H.-L.; Ekvall, T.; Fleischer, G.; Huppes, G.; Jahn, C.; Klos, Z.S.; Rebitzer, G.; Sonnemann, G.W.; Tintinelli, A.; Weidema, B.P.; et al. Framework for scenario development in LCA. Int. J. LCA 2000, 5, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Fukushima, Y.; Hirao, M. A structured framework and language for scenario-based Life Cycle assessment. Int. J. Life Cycle Assess. 2002, 7, 317–329. [Google Scholar] [CrossRef]

- Thonemann, N.; Schulte, A.; Maga, D. How to Conduct Prospective Life Cycle Assessment for Emerging Technologies? A Systematic Review and Methodological Guidance. Sustainability 2020, 12, 1192. [Google Scholar] [CrossRef] [Green Version]

- Morimoto, S.; Cheng, Y.; Mizukoshi, N.; Tahara, K. Methodological Study of Evaluating Future Lightweight Vehicle Scenarios and CO2 Reduction Based on Life Cycle Assessment. Sustainability 2020, 12, 5713. [Google Scholar] [CrossRef]

- Koroma, M.S.; Brown, N.; Cardellini, G.; Messagie, M. Prospective Environmental Impacts of Passenger Cars under Different Energy and Steel Production Scenarios. Energies 2020, 13, 6236. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Kupfer, T.; Baitz, M.; Colodel, C.M.; Kokborg, M.; Schöll, S.; Rudolf, M.; Bos, U.; Bosch, F.; Gonzalez, M.; Schuller, O.; et al. GaBi Databases and Modelling Principles 2020. 2020. Available online: https://sphera.com/wp-content/uploads/2020/04/Modeling-Principles-GaBi-Databases-2021.pdf (accessed on 5 March 2023).

- Camberg, A.A.; Tröster, T. Optimization-based material design of tailored stacked hybrids for further improvement in lightweight car body structures. In Proceedings of the 3rd International Conference on Building Innovations, Bremen, Germany, 18–19 April 2018. [Google Scholar]

- BENTELER International AG. Structures—BENTELER International AG. Available online: https://www.benteler.com/en/products/automotive-products/structures/ (accessed on 30 September 2022).

- Heggemann, T.; Homberg, W.; Sapli, H. Combined Curing and Forming of Fiber Metal Laminates. Procedia Manuf. 2020, 47, 36–42. [Google Scholar] [CrossRef]

- Eberle, R.; Franze, H.A. Modelling the Use Phase of Passenger Cars in LCI; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 1998. [Google Scholar]

- WorldAutoSteel. UCSB Automotive Energy & GHG Model; WorldAutoSteel: Middletown, OH, USA, 2017. [Google Scholar]

- World Steel Association. Life Cycle Inventory (LCI) Study: 2020 Data Release; World Steel Association: Brussels, Belgium, 2020. [Google Scholar]

- European Aluminium. Environmental Profile Report: Life-Cycle Inventory Data for Aluminium Production and Transformation Process in Europe; European Aluminium: Woluwe-Saint-Pierre, Belgium, 2018. [Google Scholar]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Turner, T.A.; Pickering, S.J. Energy and environmental assessment and reuse of fluidised bed recycled carbon fibres. Compos. Part A Appl. Sci. Manuf. 2017, 100, 206–214. [Google Scholar] [CrossRef]

- Bachmann, J.; Hidalgo, C.; Bricout, S. Environmental analysis of innovative sustainable composites with potential use in aviation sector—A life cycle assessment review. Sci. China Technol. Sci. 2017, 60, 1301–1317. [Google Scholar] [CrossRef] [Green Version]

- Stiller, H. Material Intensity of Advanced Composite Materials: Results of a Study for the Verbundwerkstofflabor Bremen e.V.; Wuppertal Papers No. 90. 1999. Available online: https://epub.wupperinst.org/frontdoor/deliver/index/docId/926/file/WP90.pdf (accessed on 14 September 2022).

- Suzuki, T.; Takahashi, J. Prediction of energy intensity of carbon fiber reinforced plastics for mass-produced passenger cars. In Proceedings of the 9th Japan International SAMPE Symposium, Tokyo, Japan, 29 November–2 December 2005. [Google Scholar]

- Witik, R.A.; Gaille, F.; Teuscher, R.; Ringwald, H.; Michaud, V.; Månson, J.-A.E. Economic and environmental assessment of alternative production methods for composite aircraft components. J. Clean. Prod. 2012, 29–30, 91–102. [Google Scholar] [CrossRef]

- Nothdurft, N. Integrierte Umweltkostenrechnung von Faserverbundfertigungsprozessen am Beispiel einer CFK-Flügelrippe. Ph.D. Dissertation, Technische Universität Braunschweig, Braunschweig, Germany, 2016. [Google Scholar]

- Bianco, I.; Panepinto, D.; Blengini, G.A.; Onofrio, M.; Zanetti, M. Inventory and life cycle assessment of an Italian automotive painting process. Clean Technol. Environ. Policy 2020, 22, 247–258. [Google Scholar] [CrossRef]

- Sacchi, R.; Terlouw, T.; Siala, K.; Dirnaichner, A.; Bauer, C.; Cox, B.; Mutel, C.; Daioglou, V.; Luderer, G. PRospective EnvironMental Impact AsSEssment (premise): A streamlined approach to producing databases for prospective life cycle assessment using integrated assessment models. Renew. Sustain. Energy Rev. 2022, 160, 112311. [Google Scholar] [CrossRef]

- ArcelorMittal. Climate Action Report 2. 2021. Available online: https://corporate-media.arcelormittal.com/media/ob3lpdom/car_2.pdf (accessed on 18 September 2022).

- Wang, P.; Ryberg, M.; Yang, Y.; Feng, K.; Kara, S.; Hauschild, M.; Chen, W.-Q. Efficiency stagnation in global steel production urges joint supply- and demand-side mitigation efforts. Nat. Commun. 2021, 12, 2066. [Google Scholar] [CrossRef]

- Hohmann, A. Nachhaltige Verbundwerkstoffe für Hochleistungsanwendungen. In Proceedings of the Technologietag Leichtbau—Global Lightweight Summit, Stuttgart, Germany, November 2021. [Google Scholar]

- Peng, T.; Ren, L.; Du, E.; Ou, X.; Yan, X. Life Cycle Energy Consumption and Greenhouse Gas Emissions Analysis of Primary and Recycled Aluminum in China. Processes 2022, 10, 2299. [Google Scholar] [CrossRef]

- International Aluminium Institute. Greenhouse Gas Emissions—Primary Aluminium—International Aluminium Institute. Available online: https://international-aluminium.org/statistics/greenhouse-gas-emissions-intensity-primary-aluminium/ (accessed on 18 September 2022).

- ELYSIS. Start of Construction of Commercial-Scale Inert Anode Cells. Available online: https://elysis.com/en/start-of-construction-of-commercial-scale-inert-anode-cells (accessed on 18 September 2022).

- Moretti, C.; Junginger, M.; Shen, L. Environmental life cycle assessment of polypropylene made from used cooking oil. Resour. Conserv. Recycl. 2020, 157, 104750. [Google Scholar] [CrossRef]

- Renó, M.L.G.; Lora, E.E.S.; Palacio, J.C.E.; Venturini, O.J.; Buchgeister, J.; Almazan, O. A LCA (life cycle assessment) of the methanol production from sugarcane bagasse. Energy 2011, 36, 3716–3726. [Google Scholar] [CrossRef]

- Dürr Aktiengesellschaft. Sustainability in the Paint Shop. Available online: https://www.durr.com/en/company/sustainability/sustainability-in-the-paint-shop (accessed on 18 September 2022).

- Schmitt, R.J. Melting of Aluminum by Electricity: A Review of Operating Practice and Discussion of Cost Factors for Melting Aluminum; CR-108641; Electric Power Research Institute: Palo Alto, CA, USA, March 1991; Available online: https://www.epri.com/research/products/CR-1086411991 (accessed on 5 March 2023).

- Hexcel Corporation. HexPly M77 Fast Curing Epoxy Resin Matrix for Prepregs: Product Data Sheet. 2022. Available online: https://www.hexcel.com/user_area/content_media/raw/HexPly_M77_EpoxyResin_DataSheet.pdf (accessed on 5 March 2023).

- Hermansson, F.; Janssen, M.; Svanström, M. Prospective study of lignin-based and recycled carbon fibers in composites through meta-analysis of life cycle assessments. J. Clean. Prod. 2019, 223, 946–956. [Google Scholar] [CrossRef]

- Pfeifer, F.; Knorr, L.; Schlosser, F.; Tröster, T.; Marten, T. Ecological and Economical Feasibility of Inductive Heating for Sustainable Press Hardening Processes. In Proceedings of the 17th Conference on Sustainable Development of Energy, Water and Environment Systems, Paphos, Cyprus, 6–10 November 2022. [Google Scholar]

- Kaluza, A.; Kleemann, S.; Broch, F.; Herrmann, C.; Vietor, T. Analyzing Decision-making in Automotive Design towards Life Cycle Engineering for Hybrid Lightweight Components. Procedia CIRP 2016, 50, 825–830. [Google Scholar] [CrossRef] [Green Version]

- Tröster, T.; Camberg, A.A.; Wingenbach, N.; Hielscher, C.; Grenz, J. A New Numerical Method for Potential Analysis and Design of Hybrid Components from Full Vehicle Simulations: Implementation and Component Design. In Technologies for Economic and Functional Lightweight Design; Dröder, K., Vietor, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2021; pp. 353–365. ISBN 978-3-662-62923-9. [Google Scholar]

- Grienitz, V.; Schmidt, A.-M. Weiterentwicklung der Konsistenzanalyse auf Basis evolutinärer Strategien für die Entwicklung von Markt-und Umfeldszenarien. In Vorausschau und Technologieplanung, 5. Symposium für Vorausschau und Technologieplanung; Gausemeier, J., Ed.; Heinz Nixdorf Institut: Paderborn, Germany; Berlin-Brandenburgischen Akademie der Wissenschaften: Berlin, Germany, 2009. [Google Scholar]

- International Aluminium Institute. Global Cycle—International Aluminium Institute. Available online: https://alucycle.international-aluminium.org/public-access/public-global-cycle/ (accessed on 22 January 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ostermann, M.; Grenz, J.; Triebus, M.; Cerdas, F.; Marten, T.; Tröster, T.; Herrmann, C. Integrating Prospective Scenarios in Life Cycle Engineering: Case Study of Lightweight Structures. Energies 2023, 16, 3371. https://doi.org/10.3390/en16083371

Ostermann M, Grenz J, Triebus M, Cerdas F, Marten T, Tröster T, Herrmann C. Integrating Prospective Scenarios in Life Cycle Engineering: Case Study of Lightweight Structures. Energies. 2023; 16(8):3371. https://doi.org/10.3390/en16083371

Chicago/Turabian StyleOstermann, Moritz, Julian Grenz, Marcel Triebus, Felipe Cerdas, Thorsten Marten, Thomas Tröster, and Christoph Herrmann. 2023. "Integrating Prospective Scenarios in Life Cycle Engineering: Case Study of Lightweight Structures" Energies 16, no. 8: 3371. https://doi.org/10.3390/en16083371

APA StyleOstermann, M., Grenz, J., Triebus, M., Cerdas, F., Marten, T., Tröster, T., & Herrmann, C. (2023). Integrating Prospective Scenarios in Life Cycle Engineering: Case Study of Lightweight Structures. Energies, 16(8), 3371. https://doi.org/10.3390/en16083371