Sustainability of Biorefineries: Challenges and Perspectives

Abstract

:1. Introduction

2. Biorefineries: Concept, Design, and Assessment

2.1. Biorefinery Concept

| Authors | Biorefinery Concept | Refs. |

|---|---|---|

| International Energy Agency—Task 42 | Sustainable processing of biomass into a spectrum of marketable products and energy | [24] |

| US Department of Energy (DOE) | A biorefinery is an overall concept of a spectrum of valuable products based on the petrochemical refinery | [25] |

| National Renewable Energy Laboratory | A biorefinery is a facility that integrates biomass conversion processes and equipment to produce fuels, power, and chemicals from biomass. The biorefinery concept is analogous to today’s petroleum refineries, which produce multiple fuels and products from petroleum. Industrial biorefineries have been identified as the most promising route to the creation of a new domestic biobased industry | [7] |

| Huang, H.J.; Ramaswamy, S.; Tschirner, U.W.; Ramarao, B. V | A biorefinery is a set of processes that use bio-based resources such as agriculture or forest biomass to produce energy and a wide variety of chemicals and bio-based materials, similar to modern petroleum refineries. | [26] |

| Moncada, Aristizábal, and Cardona | A biorefinery is a complex system where biomass is integrally processed or fractionated to obtain more than one product, including bioenergy, biofuels, chemicals, and high value-added compounds that only can be extracted from bio-based sources after an accurate design | [1] |

| Ganti S. Murthy | A biorefinery is defined as a facility/cluster of facilities for processing biobased feedstocks into valuable products addressing the needs of diverse markets for fuels, feed, plastics, and other commodity chemicals in a sustainable manner. | [25] |

2.2. Biorefineries Design

2.2.1. Optimization Approach

2.2.2. Knowledge-Based Approach/Conceptual Design

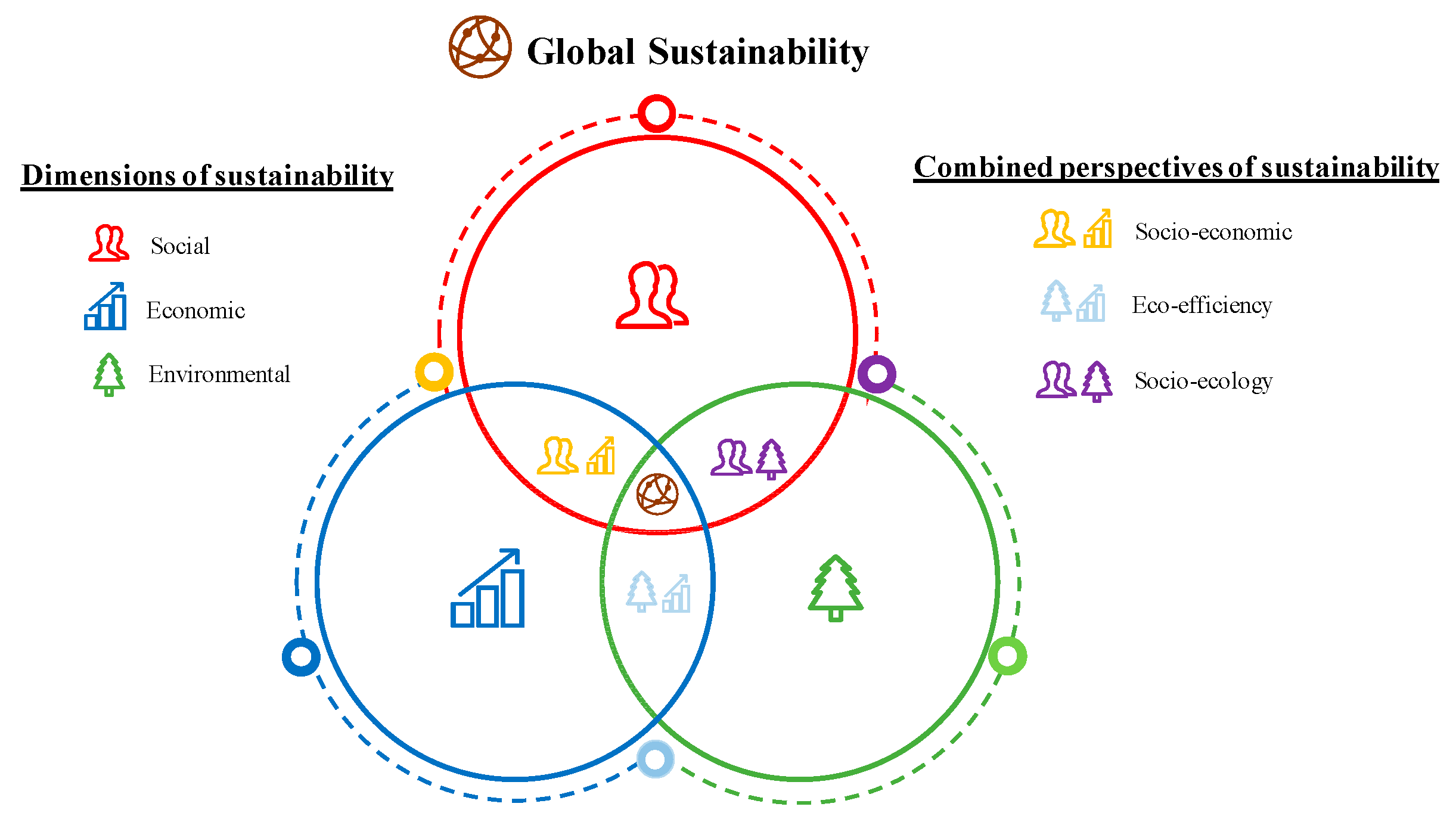

3. Sustainability Assessment of Biorefineries

4. Trends for Improving Biorefinery Sustainability

4.1. Waste Streams Valorization

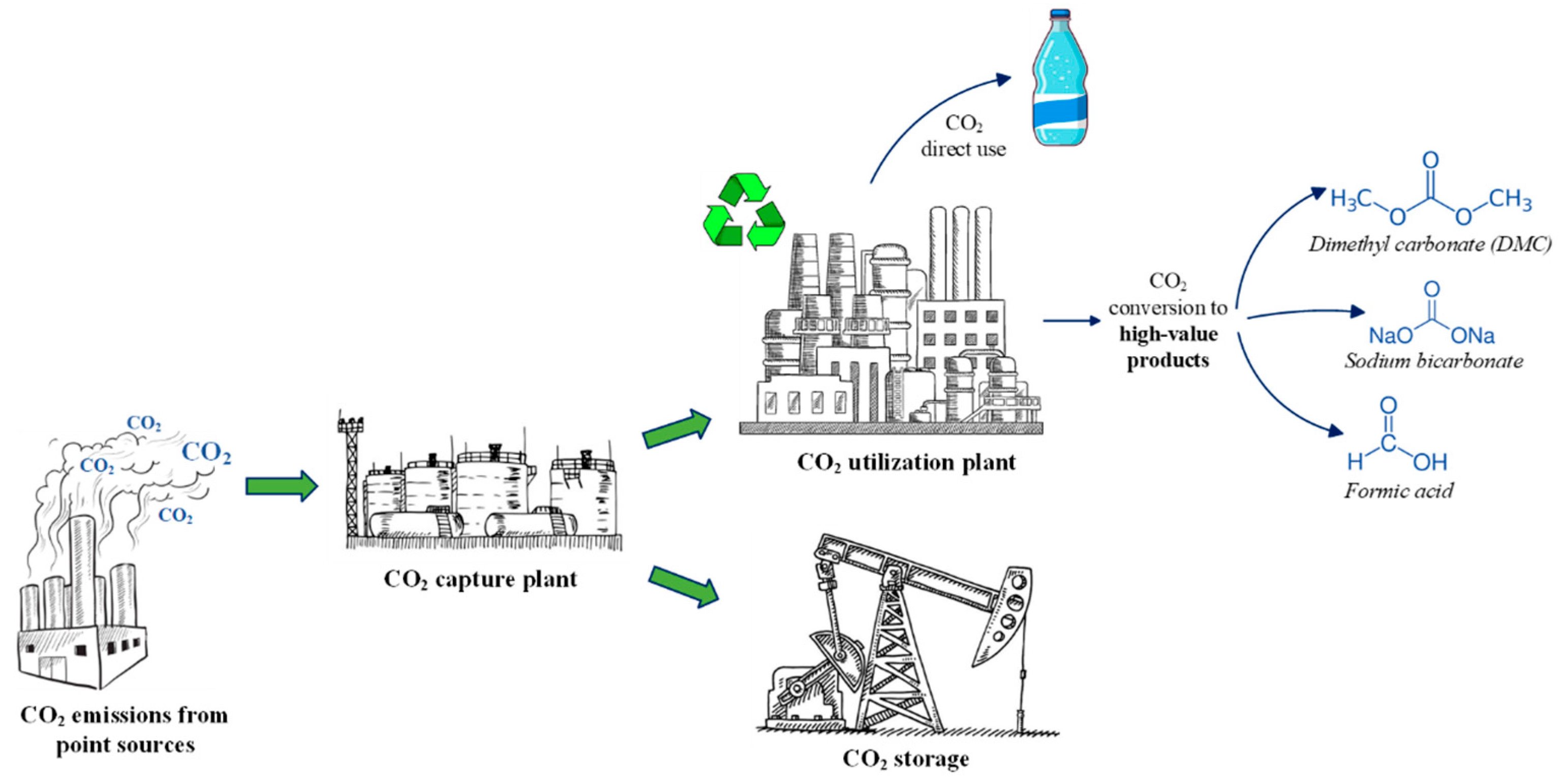

4.1.1. Carbon Dioxide Storage and Upgrading

4.1.2. Stillage Upgrading

4.2. Multifeedstocks Biorefineries

4.3. New Ways for Biomass Upgrading

4.3.1. Bioactive Compounds

4.3.2. Proteins

4.3.3. Lignin

4.3.4. Catalysis Involving

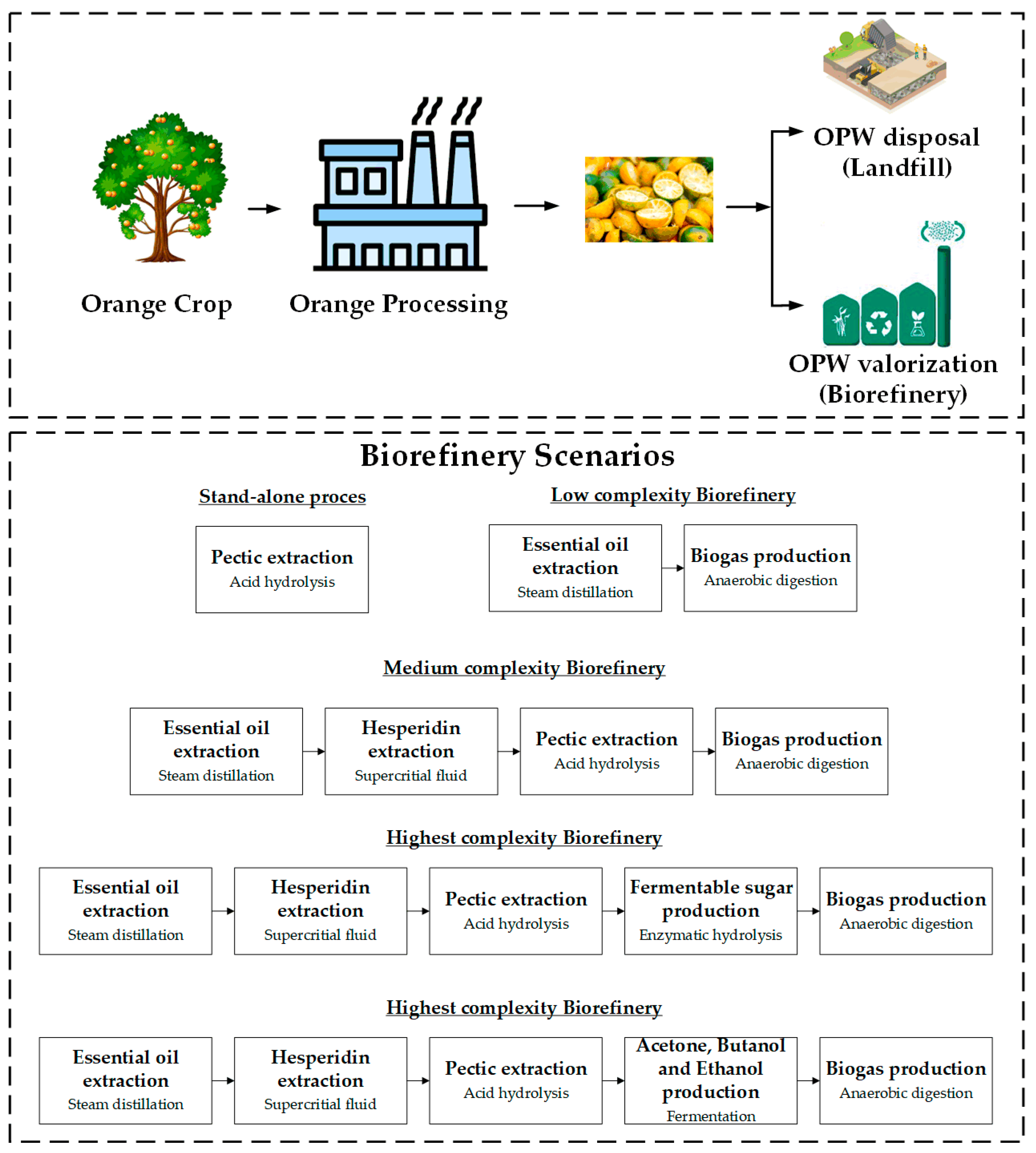

5. Potential Implications of Biorefineries: The Orange Peel Waste Case

- (i)

- Stand-alone process: pectin production by acid hydrolysis.

- (ii)

- Low complexity biorefinery: extraction of essential oil by steam distillation and biogas by anaerobic digestion.

- (iii)

- Medium complexity biorefinery: extraction of essential oil, extraction of bioactive compounds (i.e., hesperidin) with supercritical fluids, pectin extraction and biogas production.

- (iv)

- Highest complexity biorefinery: extraction of essential oil, extraction of bioactive compounds, pectin extraction, production of fermentable sugars from the enzymatic hydrolysis of cellulose and biogas production.

- (v)

- Highest complexity biorefinery: extraction of essential oil, extraction of bioactive compounds, pectin extraction, acetone butanol and ethanol production from the fermentation of fermentable sugars and biogas production.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moncada, J.; Aristizábal, V.; Cardona, C.A. Design Strategies for Sustainable Biorefineries. Biochem. Eng. J. 2016, 116, 122–134. [Google Scholar] [CrossRef]

- Ortiz-Sanchez, M.; Inocencio-García, P.-J.; Alzate-Ramírez, A.F.; Alzate, C.A.C. Potential and Restrictions of Food-Waste Valorization through Fermentation Processes. Fermentation 2023, 9, 274. [Google Scholar] [CrossRef]

- Jones, R.E.; Speight, R.E.; Blinco, J.L.; O’Hara, I.M. Biorefining within Food Loss and Waste Frameworks: A Review. Renew. Sustain. Energy Rev. 2022, 154, 111781. [Google Scholar] [CrossRef]

- Dahmen, N.; Lewandowski, I.; Zibek, S.; Weidtmann, A. Integrated Lignocellulosic Value Chains in a Growing Bioeconomy: Status Quo and Perspectives. GCB Bioenergy 2019, 11, 107–117. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; Laghezza, M.; Fiore, S.; Berruti, F.; Moustakas, K.; Cardona Alzate, C.A. Review of the Impact of Socio-Economic Conditions on the Development and Implementation of Biorefineries. Fuel 2022, 328, 125169. [Google Scholar] [CrossRef]

- Singh, N.; Singhania, R.R.; Nigam, P.S.; Dong, C.D.; Patel, A.K.; Puri, M. Global Status of Lignocellulosic Biorefinery: Challenges and Perspectives. Bioresour. Technol. 2022, 344, 126415. [Google Scholar] [CrossRef] [PubMed]

- Palmeros Parada, M.; Osseweijer, P.; Posada Duque, J.A. Sustainable Biorefineries, an Analysis of Practices for Incorporating Sustainability in Biorefinery Design. Ind. Crops Prod. 2017, 106, 105–123. [Google Scholar] [CrossRef]

- Bautista, S.; Narvaez, P.; Camargo, M.; Chery, O.; Morel, L. Biodiesel-TBL+: A New Hierarchical Sustainability Assessment Framework of PC&I for Biodiesel Production—Part I. Ecol. Indic. 2016, 60, 84–107. [Google Scholar] [CrossRef]

- Asadikia, A.; Rajabifard, A.; Kalantari, M. Systematic Prioritisation of SDGs: Machine Learning Approach. World Dev. 2021, 140, 105269. [Google Scholar] [CrossRef]

- Udemba, E.N.; Tosun, M. Energy Transition and Diversification: A Pathway to Achieve Sustainable Development Goals (SDGs) in Brazil. Energy 2022, 239, 122199. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; Cardona, C.A. Biorefineries as the Base for Accomplishing the Sustainable Development Goals (SDGs) and the Transition to Bioeconomy: Technical Aspect, Challenges and Perspectives. Bioresour. Technol. 2021, 340, 125626. [Google Scholar] [CrossRef]

- Heimann, T. Bioeconomy and SDGs: Does the Bioeconomy Support the Achievement of the SDGs? Earth’s Future 2019, 7, 43–57. [Google Scholar] [CrossRef]

- Hemansi; Saini, J.K. Enhanced Cellulosic Ethanol Production via Fed-Batch Simultaneous Saccharification and Fermentation of Sequential Dilute Acid-Alkali Pretreated Sugarcane Bagasse. Bioresour. Technol. 2023, 372, 128671. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Chen, G.; Qin, H.; Cheng, H.; Chen, L.; Qi, Z. Systematic Screening of Bifunctional Ionic Liquid for Intensifying Esterification of Methyl Heptanoate in the Reactive Extraction Process. Chem. Eng. Sci. 2021, 246, 116888. [Google Scholar] [CrossRef]

- Krishna, A.; Wayne, K.; Show, P.; Siti, H.; Munawaroh, H.; Chang, J. Liquid Triphasic Systems as Sustainable Downstream Processing of Chlorella sp. Biorefinery for Potential Biofuels and Feed Production. Bioresour. Technol. 2021, 333, 125075. [Google Scholar] [CrossRef]

- Dziugan, P.; Romanowska-Duda, Z.; Piotrowski, K.; Cieciura-Wloch, W.; Antolak, H.; Smigielski, K.; Witonska, I.; Domański, J.; Binczarski, M. Improving Biorefinery Sustainability and Profitability by Cultivating Aquatic Plants on Ozonized Distillery Effluents. BioResources 2021, 18, 20. [Google Scholar] [CrossRef]

- Pham, T.; Dong, X.; Vu, L.; Trang, K.; Le, T.; Ly, M.; Trinh, D.; Thi, N.; Phuong, D.; Shiong, K.; et al. Isolation of Indole-3-Acetic Acid-Producing Azospirillum Brasilense from Vietnamese Wet Rice: Co-Immobilization of Isolate and Microalgae as a Sustainable Biorefinery. J. Biotechnol. 2022, 349, 12–20. [Google Scholar] [CrossRef]

- Vučurović, V.M.; Razmovski, R.N. Sugar Beet Pulp as Support for Saccharomyces Cerivisiae Immobilization in Bioethanol Production. Ind. Crops Prod. 2012, 39, 128–134. [Google Scholar] [CrossRef]

- Padi, R.K.; Chimphango, A. Feasibility of Commercial Waste Biorefineries for Cassava Starch Industries: Techno-Economic Assessment. Bioresour. Technol. 2020, 297, 122461. [Google Scholar] [CrossRef]

- Fonseca, G.C.; Costa, C.B.B.; Cruz, A.J.G. Economic Analysis of a Second-Generation Ethanol and Electricity Biorefinery Using Superstructural Optimization. Energy 2020, 204, 117988. [Google Scholar] [CrossRef]

- Bhoi, P.R.; Ouedraogo, A.S.; Soloiu, V.; Quirino, R. Recent Advances on Catalysts for Improving Hydrocarbon Compounds in Bio-Oil of Biomass Catalytic Pyrolysis. Renew. Sustain. Energy Rev. 2020, 121, 109676. [Google Scholar] [CrossRef]

- Cardona-Alzate, C.A.; Serna-Loaiza, S.; Ortiz-Sanchez, M. Sustainable Biorefineries: What Was Learned from the Design, Analysis and Implementation. J. Sustain. Dev. Energy, Water Environ. Syst. 2020, 8, 88–117. [Google Scholar] [CrossRef]

- Barron, A.; Chrisandina, N.; López-Molina, A.; Sengupta, D.; Shi, C.; El-Halwagi, M.M. Assessment of Modular Biorefineries with Economic, Environmental, and Safety Considerations. In Biofuels and Biorefining; Gutiérrez-Antonio, C., Gómez-Castro, F.I., Eds.; Elsevier B.V.: Moscow, Rusia, 2022; pp. 293–303. ISBN 978-0-12-824117-2. [Google Scholar]

- Cherubini, F.; Wellisch, M.; Willke, T.; Jungmeier, G.; Skiadas, I.; Van Ree, R.; de Jong, E. Toward a Common Classifi Cation Approach for Biorefi Nery Systems. Biofuels Bioprod. Biorefining 2009, 3, 534–546. [Google Scholar] [CrossRef]

- U.S. Department of Energy (DOE). Biomass Cofiring: A Renewable Alternative for Utilities; U.S. Department of Energy (DOE): Washington, DC, USA, 2000.

- Huang, H.J.; Ramaswamy, S.; Tschirner, U.W.; Ramarao, B.V. A Review of Separation Technologies in Current and Future Biorefineries. Sep. Purif. Technol. 2008, 62, 1–21. [Google Scholar] [CrossRef]

- Murthy, G. Systems Analysis Frameworks for Biorefineries. In Biofuels: Alternative Feedstocks and Conversion Processes for the Production of Liquid and Gaseous Biofuels; Pandey, A., Larroche, C., Ricke, S., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 77–92. ISBN 978-0-12-816856-1. [Google Scholar]

- Cardona-Alzate, C.A.; Moncada Botero, J.; Aristizábal-Marulanda, V. Biorefineries: Design and Analysis; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: London, UK, 2019; ISBN 9781315114088. [Google Scholar]

- Meramo-Hurtado, S.I.; González-Delgado, Á.D. Biorefinery Synthesis and Design Using Sustainability Parameters and Hierarchical/3D Multi-Objective Optimization. J. Clean. Prod. 2019, 240, 118134. [Google Scholar] [CrossRef]

- Pyrgakis, K.A.; Kokossis, A.C. A Total Site Synthesis Approach for the Selection, Integration and Planning of Multiple-Feedstock Biorefineries. Comput. Chem. Eng. 2019, 122, 326–355. [Google Scholar] [CrossRef]

- Ahmadi, A.; Esmaeili, A.; Golzary, A. Software Tools for Microalgae Biorefineries: Cultivation, Separation, Conversion Process Integration, Modeling, and Optimization. Algal Res. 2022, 61, 102597. [Google Scholar] [CrossRef]

- Pongpat, P.; Mahmood, A.; Ghani, H.; Silalertruksa, T.; Gheewala, S. Optimization of Food-Fuel- Fibre in Biorefinery Based on Environmental and Economic Assessment: The Case of Sugarcane Utilization in Thailand. Sustain. Prod. Consum. 2023, 37, 398–411. [Google Scholar] [CrossRef]

- Dickson, R.; Liu, J.J. A Strategy for Advanced Biofuel Production and Emission Utilization from Macroalgal Biore Fi Nery Using Superstructure Optimization. Energy 2021, 221, 119883. [Google Scholar] [CrossRef]

- Douglas, J.M. Conceptual Design of Chemical Processes; McGraw Hill: New York, NY, USA, 1988. [Google Scholar]

- Ortiz-Sanchez, M.; Solarte-Toro, J.C.; Cardona Alzate, C.A. A Comprehensive Approach for Biorefineries Design Based on Experimental Data, Conceptual and Optimization Methodologies: The Orange Peel Waste Case. Bioresour. Technol. 2021, 325, 124682. [Google Scholar] [CrossRef]

- Zhang, H.; Cabañeros, P.; Claire, L.; Alan, H.; Ambye, M.; Claus, J.; Sune, F.; Thomsen, T. The Multi-Feedstock Biorefinery—Assessing the Compatibility of Alternative Feedstocks in a 2G Wheat Straw Biorefinery Process. Glob. Chang. Biol. Bioenergy 2018, 10, 946–959. [Google Scholar] [CrossRef]

- Piedrahita-Rodríguez, S.; Solarte-Toro, J.C.; Piñeres, P.P.; Ortiz-Sánchez, M.; Pérez-Cordero, A.; Cardona-Alzate, C.A. Analysis of a Biorefinery with Multiple Raw Materials in the Context of Post-Conflict Zones in Colombia: Plantain and Avocado Integration in the Montes de María Region. Biomass Convers. Biorefin. 2022, 12, 4531–4548. [Google Scholar] [CrossRef]

- Moncada, J.; Tamayo, J.A.; Cardona, C.A. Integrating First, Second, and Third Generation Biorefineries: Incorporating Microalgae into the Sugarcane Biorefinery. Chem. Eng. Sci. 2014, 118, 126–140. [Google Scholar] [CrossRef]

- Kumar, B.; Verma, P. Biomass-Based Biorefineries: An Important Architype towards a Circular Economy. Fuel 2021, 288, 119622. [Google Scholar] [CrossRef]

- Serna-Loaiza, S.; Carmona-Garcia, E.; Cardona, C.A. Potential Raw Materials for Biorefineries to Ensure Food Security: The Cocoyam Case. Ind. Crops Prod. 2018, 126, 92–102. [Google Scholar] [CrossRef]

- Kapanji, K.K.; Haigh, K.F.; Görgens, J.F. Techno-Economics of Lignocellulose Biorefineries at South African Sugar Mills Using the Biofine Process to Co-Produce Levulinic Acid, Furfural and Electricity along with Gamma Valeractone. Biomass Bioenergy 2021, 146, 106008. [Google Scholar] [CrossRef]

- Ginni, G.; Kavitha, S.; Yukesh Kannah, R.; Bhatia, S.K.; Adish Kumar, S.; Rajkumar, M.; Kumar, G.; Pugazhendhi, A.; Chi, N.T.L.; Rajesh Banu, J. Valorization of Agricultural Residues: Different Biorefinery Routes. J. Environ. Chem. Eng. 2021, 9, 105435. [Google Scholar] [CrossRef]

- Parisi, C. Distribution of the Bio-Based Industry in the EU Database and Visualisation; Publications Office of the European Union: Luxenburg, 2020.

- Gírio, F.; Marques, S.; Pinto, F.; Oliveira, A.C.; Costa, P.; Reis, A.; Moura, P. Biorefineries in the World. In Biorefineries; Springer International Publishing: Berlin, Germany, 2017; Volume 57, pp. 227–281. ISBN 9783319482880. [Google Scholar]

- Bio-Based Industries Consortium. Biorefineries in Europe 2017; Bio-Based Industries Consortium: Brussel, Belgium, 2017. [Google Scholar]

- Bataille, C.; Åhman, M.; Neuhoff, K.; Nilsson, L.J.; Fischedick, M.; Lechtenb, S. A Review of Technology and Policy Deep Decarbonization Pathway Options for Making Energy-Intensive Industry Production Consistent with the Paris Agreement. J. Clean. 2018, 187, 960–973. [Google Scholar] [CrossRef]

- Lerman, L.V.; Benitez, G.B.; Gerstlberger, W.; Rodrigues, V.P.; Frank, A.G. Sustainable Conditions for the Development of Renewable Energy Systems: A Triple Bottom Line Perspective. Sustain. Cities Soc. 2021, 75, 103362. [Google Scholar] [CrossRef]

- Bautista, S.; Enjolras, M.; Narvaez, P.; Camargo, M.; Morel, L. Biodiesel-Triple Bottom Line (TBL): A New Hierarchical Sustainability Assessment Framework of Principles Criteria & Indicators (PC&I) for Biodiesel Production. Part II-Validation. Ecol. Indic. 2016, 69, 803–817. [Google Scholar] [CrossRef]

- Sabatini, F. Culture as Fourth Pillar of Sustainable Development: Perspectives for Integration, Paradigms of Action. Eur. J. Sustain. Dev. 2019, 8, 31. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; Ortiz-Sánchez, M.; Cardona Alzate, C.A. Sustainability Analysis of Biorefineries Based on Country Socio-Economic and Environmental Context: A Step-by-Step Way for the Integral Analysis of Biomass Upgrading Processes. Renew. Energy 2023, 206, 1147–1157. [Google Scholar] [CrossRef]

- Del Borghi, A.; Strazza, C.; Magrassi, F.; Taramasso, A.C.; Gallo, M. Life Cycle Assessment for Eco-Design of Product–Package Systems in the Food Industry—The Case of Legumes. Sustain. Prod. Consum. 2018, 13, 24–36. [Google Scholar] [CrossRef]

- Syed, S.; Tollamadugu, N.V.K.V.P. Role of Plant Growth-Promoting Microorganisms as a Tool for Environmental Sustainability. In Recent Developments in Applied Microbiology and Biochemistry; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 209–222. ISBN 9780128163283. [Google Scholar]

- ICONTEC Norma Técnica Colombia NTC-ISO14040. Gestión Ambiental. Análisis de Ciclo de Vida. Princ. Y Marco De Refencia 2007, 2, 1–24. [Google Scholar]

- Joglekar, S.N.; Pathak, P.D.; Mandavgane, S.A.; Kulkarni, B.D. Process of Fruit Peel Waste Biorefinery: A Case Study of Citrus Waste Biorefinery, Its Environmental Impacts and Recommendations. Environ. Sci. Pollut. Res. 2019, 26, 34713–34722. [Google Scholar] [CrossRef] [PubMed]

- Solarte-Toro, J.C.; Ortiz-Sanchez, M.; Cardona Alzate, C.A. Environmental Life Cycle Assessment (E-LCA) and Social Impact Assessment (SIA) of Small-Scale Biorefineries Implemented in Rural Zones: The Avocado (Persea Americana Var. Americana) Case in Colombia. Environ. Sci. Pollut. Res. 2022, 30, 8790–8808. [Google Scholar] [CrossRef]

- Saldarriaga, G.; Acosta-Alba, I.; Sfez, P.; Ullóa, W.; Buriticá, A. Análisis de La Cadena de Valor Del Café En Ecuador. 2021. Available online: https://europa.eu/capacity4dev/file/123813/download?token=II98A1qa (accessed on 30 March 2023).

- Solarte-Toro, J.C.; Rueda-duran, C.A.; Ortiz-sanchez, M.; Cardona, C. A Comprehensive Review on the Economic Assessment of Biorefineries: The First Step towards Sustainable Biomass Conversion. Bioresour. Technol. Rep. 2021, 15, 100776. [Google Scholar] [CrossRef]

- Nieder-Heitmann, M.; Haigh, K.F.; Gorgens, J.F. Life Cycle Assessment and Multi-Criteria Analysis of Sugarcane Biorefinery Scenarios: Finding a Sustainable Solution for the South African Sugar Industry. J. Clean. Prod. 2019, 239, 118039. [Google Scholar] [CrossRef]

- Rueda-Duran, C.; Ortiz-Sánchez, M.; Cardona, C.A. Detailed Economic Assessment of Polylactic Acid Production by Using Glucose Platform: Sugarcane Bagasse, Coffee Cut Stems, and Plantain Peels as Possible Raw Materials. Biomass Convers. Biorefinery 2022, 12, 4419–4434. [Google Scholar] [CrossRef]

- UNEP. Guidelines for Social Life Cycle Assessment of Products; Benoît Norris, C., Traverso, M., Neugebauer, S., Ekener, E., Schaubroeck, T., Russo Garrido, S., Berger, M., Valdivia, S., Lehmann, A., Finkbeiner, M., et al., Eds.; UNEP: Nairobi, Kenya, 2020; ISBN 9789280730210. [Google Scholar]

- Eisfeldt, F.; Ciroth, A. PSILCA—A Product Social Impact Life Cycle Assessment Database; GreenDelta: Berlin, Germany, 2018. [Google Scholar]

- Valente, A.; Iribarren, D.; Dufour, J. Life Cycle Sustainability Assessment of Hydrogen from Biomass Gasification: A Comparison with Conventional Hydrogen. Int. J. Hydrogen Energy 2019, 44, 21193–21203. [Google Scholar] [CrossRef]

- Aristizábal-Marulanda, V.; Solarte-Toro, J.C.; Cardona Alzate, C.A. Economic and Social Assessment of Biorefineries: The Case of Coffee Cut-Stems (CCS) in Colombia. Bioresour. Technol. Rep. 2020, 9, 100397. [Google Scholar] [CrossRef]

- Matthews, N.E.; Stamford, L.; Shapira, P. Aligning Sustainability Assessment with Responsible Research and Innovation: Towards a Framework for Constructive Sustainability Assessment. Sustain. Prod. Consum. 2019, 20, 58–73. [Google Scholar] [CrossRef]

- Horlings, L.G. The Inner Dimension of Sustainability: Personal and Cultural Values. Curr. Opin. Environ. Sustain. 2015, 14, 163–169. [Google Scholar] [CrossRef]

- Schmidt Rivera, X.C.; Gallego-schmid, A.; Najdanovic-visak, V.; Azapagic, A. Life Cycle Environmental Sustainability of Valorisation Routes for Spent Coffee Grounds: From Waste to Resources. Resour. Conserv. Recycl. 2020, 157, 104751. [Google Scholar] [CrossRef]

- Sanchez, A.; Magaña, G.; Sanchez, S. Bi-Dimensional Sustainability Analysis of a Multi-Feed Biorefinery Design for Biofuels Co-Production from Lignocellulosic Residues and Agro-Industrial Wastes. Chem. Eng. Res. Des. 2022, 7, 195–217. [Google Scholar] [CrossRef]

- Timonen, K.; Sinkko, T.; Luostarinen, S.; Tampio, E.; Joensuu, K. LCA of Anaerobic Digestion: Emission Allocation for Energy and Digestate. J. Clean. Prod. 2019, 235, 1567–1579. [Google Scholar] [CrossRef]

- Li, G.; Wang, S.; Zhao, J.; Qi, H.; Ma, Z.; Cui, P.; Zhu, Z.; Gao, J.; Wang, Y. Life Cycle Assessment and Techno-Economic Analysis of Biomass-to- Hydrogen Production with Methane Tri-Reforming. Energy 2020, 199, 117488. [Google Scholar] [CrossRef]

- Mikhail, J.; Gallego-schmid, A.; Azapagic, A. Environmental Sustainability of Small-Scale Biomass Power Technologies for Agricultural Communities in Developing Countries. Renew. Energy 2019, 141, 493–506. [Google Scholar] [CrossRef]

- Mart, M.; Quinteiro, P.; Cl, A. Comparative Social Life Cycle Assessment of Two Biomass-to-Electricity Systems. Int. J. Environ. Res. Public Health 2021, 18, 4918. [Google Scholar] [CrossRef]

- Appiah-nkansah, N.B.; Li, J.; Rooney, W.; Wang, D. A Review of Sweet Sorghum as a Viable Renewable Bioenergy Crop and Its Techno-Economic Analysis. Renew. Energy 2019, 143, 1121–1132. [Google Scholar] [CrossRef]

- Thengane, S.K.; Burek, J.; Kung, K.S.; Ghoniem, A.F.; Sanchez, D.L. Life Cycle Assessment of Rice Husk Torrefaction and Prospects for Decentralized Facilities at Rice Mills. J. Clean. Prod. 2020, 275, 123177. [Google Scholar] [CrossRef]

- Bora, R.; Lei, M.; Tester, J.W.; Lehmann, J.; You, F. Life Cycle Assessment and Techno-Economic Analysis of Thermochemical Conversion Technologies Applied to Poultry Litter with Energy and Nutrient Recovery. ACS Sustain. Chem. Eng. 2020, 8, 8436–8447. [Google Scholar] [CrossRef]

- Ahmadi, L.; Kannangara, M.; Bensebaa, F. Cost-Effectiveness of Small Scale Biomass Supply Chain and Bioenergy Production Systems in Carbon Credit Markets: A Life Cycle Perspective. Sustain. Energy Technol. Assess. 2020, 37, 100627. [Google Scholar] [CrossRef]

- García, C.A.; Peña, Á.; Betancourt, R.; Cardona, C.A. Energetic and Environmental Assessment of Thermochemical and Biochemical Ways for Producing Energy from Agricultural Solid Residues: Coffee Cut-Stems Case. J. Environ. Manag. 2017, 216, 160–168. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Malik, A.; Wang, Y.; Chang, Y.; Lenzen, M.; Zhou, D.; Pang, M.; Huang, Q. The Social, Economic, and Environmental Implications of Biomass Ethanol Production in China: A Multi-Regional Input-Output-Based Hybrid LCA Model. J. Clean. Prod. 2020, 249, 119326. [Google Scholar] [CrossRef]

- Tito, E.; Zoppi, G.; Pipitone, G.; Miliotti, E.; Di Fraia, A.; Rizzo, A.M.; Pirone, R.; Chiaramonti, D.; Bensaid, S. Conceptual Design and Techno-Economic Assessment of Coupled Hydrothermal Liquefaction and Aqueous Phase Reforming of Lignocellulosic Residues. J. Environ. Chem. Eng. 2023, 11, 109076. [Google Scholar] [CrossRef]

- Zoppi, G.; Tito, E.; Bianco, I.; Pipitone, G.; Pirone, R.; Bensaid, S. Life Cycle Assessment of the Biofuel Production from Lignocellulosic Biomass in a Hydrothermal Liquefaction—Aqueous Phase Reforming Integrated Biorefinery. Renew. Energy 2023, 206, 375–385. [Google Scholar] [CrossRef]

- Kiehbadroudinezhad, M.; Merabet, A.; Hosseinzadeh-Bandbafha, H. A Life Cycle Assessment Perspective on Biodiesel Production from Fish Wastes for Green Microgrids in a Circular Bioeconomy. Bioresour. Technol. Rep. 2023, 21, 101303. [Google Scholar] [CrossRef]

- Kiehbadroudinezhad, M.; Hosseinzadeh-Bandbafha, H.; Varjani, S.; Wang, Y.; Peng, W.; Pan, J.; Aghbashlo, M.; Tabatabaei, M. Marine Shell-Based Biorefinery: A Sustainable Solution for Aquaculture Waste Valorization. Renew. Energy 2023, 206, 623–634. [Google Scholar] [CrossRef]

- Luis, P. Use of Monoethanolamine ( MEA ) for CO2 Capture in a Global Scenario: Consequences and Alternatives. Desalinitation 2016, 380, 93–99. [Google Scholar] [CrossRef]

- Kongpanna, P.; Pavarajarn, V.; Gani, R.; Assabumrungrat, S. Techno-Economic Evaluation of Different CO2-Based Processes for Dimethyl Carbonate Production. Chem. Eng. Res. Des. 2014, 93, 496–510. [Google Scholar] [CrossRef]

- Van-Dal, É.S.; Bouallou, C. Design and Simulation of a Methanol Production Plant from CO2 Hydrogenation. J. Clean. Prod. 2013, 57, 38–45. [Google Scholar] [CrossRef]

- Pietzcker, R.C.; Osorio, S.; Rodrigues, R. Tightening EU ETS Targets in Line with the European Green Deal: Impacts on the Decarbonization of the EU Power Sector. Appl. Energy 2021, 293, 116914. [Google Scholar] [CrossRef]

- Antolini, D.; Shivananda, S.; Patuzzi, F.; Grigiante, M.; Baratieri, M. Experimental Investigations of Air-CO2 Biomass Gasification in Reversed Downdraft Gasifier. Fuel 2019, 253, 1473–1481. [Google Scholar] [CrossRef]

- Ong, M.Y.; Nomanbhay, S.; Kusumo, F.; Show, P.L. Application of Microwave Plasma Technology to Convert Carbon Dioxide (CO2) into High Value Products: A Review. J. Clean. Prod. 2022, 336, 130447. [Google Scholar] [CrossRef]

- Li, B.; Zhang, N.; Smith, R. Simulation and Analysis of CO2 Capture Process with Aqueous Monoethanolamine Solution Q. Appl. Energy 2016, 161, 707–717. [Google Scholar] [CrossRef]

- Xie, B.T.; Liu, Z.Y.; Tian, L.; Li, F.L.; Chen, X.H. Physiological Response of Clostridium Ljungdahlii DSM 13528 of Ethanol Production under Different Fermentation Conditions. Bioresour. Technol. 2015, 177, 302–307. [Google Scholar] [CrossRef]

- Jack, J.; Lo, J.; Maness, P.C.; Ren, Z.J. Directing Clostridium Ljungdahlii Fermentation Products via Hydrogen to Carbon Monoxide Ratio in Syngas. Biomass Bioenergy 2019, 124, 95–101. [Google Scholar] [CrossRef]

- Zielinska, M.; Bułkowska, K.; Mikucka, W. Valorization of Distillery Stillage for Bioenergy Production: A Review. Energies 2021, 14, 7235. [Google Scholar] [CrossRef]

- Gebreeyessus, G.D.; Mekonnen, A.; Alemayehu, E. A Review on Progresses and Performances in Distillery Stillage Management. J. Clean. Prod. 2019, 232, 295–307. [Google Scholar] [CrossRef]

- Mikucka, W.; Zielinska, M. Individual Phenolic Acids in Distillery Stillage Inhibit Its Biomethanization. Energies 2022, 15, 5377. [Google Scholar] [CrossRef]

- Rajagopal, R.; Massé, D.I.; Singh, G. Bioresource Technology A Critical Review on Inhibition of Anaerobic Digestion Process by Excess Ammonia. Bioresour. Technol. 2013, 143, 632–641. [Google Scholar] [CrossRef] [PubMed]

- Sillero, L.; Solera, R. ScienceDirect Anaerobic Co-Digestion of Sewage Sludge, Wine Vinasse and Poultry Manure for Bio-Hydrogen Production. Int. J. Hydrogen Energy 2021, 47, 3667–3678. [Google Scholar] [CrossRef]

- Apollo, S.; Aoyi, O. Performance and Kinetics of a Fluidized Bed Anaerobic Reactor Treating Distillery Effluent. Phys. Sci. Rev. 2022. [Google Scholar] [CrossRef]

- Siles, J.A.; Martín, A.; Martín, M.A. Integrated Ozonation and Biomethanization Treatments of Vinasse Derived from Ethanol Manufacturing. J. Hazard. Mater. 2011, 188, 247–253. [Google Scholar] [CrossRef] [PubMed]

- Hernandez, J.E.; Edyvean, R.G.J. Inhibition of Biogas Production and Biodegradability by Substituted Phenolic Compounds in Anaerobic Sludge. J. Hazard. Mater. 2008, 160, 20–28. [Google Scholar] [CrossRef]

- Mikulski, D.; Grzegorz, K. Microwave-Assisted Dilute Acid Pretreatment in Bioethanol Production from Wheat and Rye Stillages. Biomass Bioenergy 2020, 136, 105528. [Google Scholar] [CrossRef]

- Mikulski, D.; Kłosowski, G. Efficiency of Dilute Sulfuric Acid Pretreatment of Distillery Stillage in the Production of Cellulosic Ethanol. Bioresour. Technol. 2018, 268, 424–433. [Google Scholar] [CrossRef]

- Prado, C.D.; Mandrujano, G.P.L.; Souza, J.P.; Sgobbi, F.B.; Novaes, H.R.; Silva, J.P.M.O.; Alves, M.H.R.; Eliodório, K.P.; Cunha, G.C.G.; Giudici, R.; et al. Physiological Characterization of a New Thermotolerant Yeast Strain Isolated during Brazilian Ethanol Production, and Its Application in High—Temperature Fermentation. Biotechnol. Biofuels 2020, 13, 178. [Google Scholar] [CrossRef]

- Arimi, M.M.; Knodel, J.; Kiprop, A.; Namango, S.S. Strategies for Improvement of Biohydrogen Production from Organic-Rich Wastewater: A Review. Biomass Bioenergy 2015, 75, 101–118. [Google Scholar] [CrossRef]

- Mishra, P.; Roy, S.; Das, D. Comparative Evaluation of the Hydrogen Production by Mixed Consortium, Synthetic Co-Culture and Pure Culture Using Distillery Effluent. Bioresour. Technol. 2015, 198, 593–602. [Google Scholar] [CrossRef] [PubMed]

- Murthy, G.S. Systems Analysis Frameworks for Biorefineries, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2019; ISBN 9780128168561. [Google Scholar]

- Starkey, J. High Soy Prices Idling Biodiesel Plants. 2008. Available online: https://www.worldpress.org/Americas/3146.cfm (accessed on 30 March 2023).

- OECD. Meeting Policy Challenges for a Sustainable Bioeconomy; OECD Publishing: Paris, France, 2018; ISBN 9789264292345. [Google Scholar]

- Piedrahita-Rodríguez, S.; Cardona Urrea, S.; Escobar García, D.A.; Ortiz-Sánchez, M.; Solarte-Toro, J.C.; Cardona Alzate, C.A. Life Cycle Assessment and Potential Geolocation of a Multi-Feedstock Biorefinery: Integration of the Avocado and Plantain Value Chains in Rural Zones. Bioresour. Technol. Rep. 2023, 21, 101318. [Google Scholar] [CrossRef]

- Cotta, R.F.; Martins, R.A.; Pereira, M.M.; da Silva Rocha, K.A.; Kozhevnikova, E.F.; Kozhevnikov, I.V.; Gusevskaya, E.V. Heteropoly Acid Catalysis for the Isomerization of Biomass-Derived Limonene Oxide and Kinetic Separation of the Trans-Isomer in Green Solvents. Appl. Catal. Gen. 2019, 584, 117173. [Google Scholar] [CrossRef]

- De Carvalho, C.C.C.R.; Da Fonseca, M.M.R. Biotransformation of Terpenes. Biotechnol. Adv. 2006, 24, 134–142. [Google Scholar] [CrossRef] [PubMed]

- van der Werf, M.J.; de Bont, J.A.M.; Leak, D.J. Opportunities in Microbial Biotransformation of Monoterpenes. In Biotechnology of Aroma Compounds; Springer: Berlin/Heidelberg, Germany, 1997; pp. 147–177. [Google Scholar]

- Sultana, N.; Saify, Z.S. Enzymatic Biotransformation of Terpenes as Bioactive Agents. J. Enzyme Inhib. Med. Chem. 2013, 28, 1113–1128. [Google Scholar] [CrossRef]

- De Carvalho, C.C.R.; Van Keulen, F.; Da Fonseca, M.M.R. Production and Recovery of Limonene-1,2-Diol and Simultaneous Resolution of a Diastereomeric Mixture of Limonene-1,2-Epoxide with Whole Cells of Rhodococcus Erythropolis DCL14. Biocatal. Biotransformation 2000, 18, 223–235. [Google Scholar] [CrossRef]

- Poveda-Giraldo, J.A.; Solarte-Toro, J.C.; Cardona, C.A. The Potential Use of Lignin as a Platform Product in Biorefineries: A Review. Renew. Sustain. Energy Rev. 2021, 138, 110688. [Google Scholar] [CrossRef]

- Sar, T.; Larsson, K.; Fristedt, R.; Undeland, I.; Taherzadeh, M.J. Demo-Scale Production of Protein-Rich Fungal Biomass from Potato Protein Liquor for Use as Innovative Food and Feed Products. Food Biosci. 2022, 47, 101637. [Google Scholar] [CrossRef]

- Dragone, G.; Kerssemakers, A.A.J.; Driessen, J.L.S.P.; Yamakawa, C.K.; Brumano, L.P.; Mussatto, S.I. Innovation and Strategic Orientations for the Development of Advanced Biorefineries. Bioresour. Technol. 2020, 302, 122847. [Google Scholar] [CrossRef]

- De Schouwer, F.; Claes, L.; Vandekerkhove, A.; Verduyckt, J.; De Vos, D.E. Protein-Rich Biomass Waste as a Resource for Future Bio-Refineries: State of the Art, Challenges and Opportunities. ChemSusChem 2019, 12, 1272–1303. [Google Scholar] [CrossRef]

- Carvajal, J.C.; Gómez, Á.; Cardona, C.A. Comparison of Lignin Extraction Processes: Economic and Environmental Assessment. Bioresour. Technol. 2016, 214, 468–476. [Google Scholar] [CrossRef]

- Sharma, V.; Tsai, M.L.; Nargotra, P.; Chen, C.W.; Sun, P.P.; Singhania, R.R.; Patel, A.K.; Dong, C. Di Journey of Lignin from a Roadblock to Bridge for Lignocellulose Biorefineries: A Comprehensive Review. Sci. Total Environ. 2023, 861, 160560. [Google Scholar] [CrossRef] [PubMed]

- Sheldon, R.A. Green Chemistry, Catalysis and Valorization of Waste Biomass. J. Mol. Catal. Chem. 2016, 422, 3–12. [Google Scholar] [CrossRef]

- Cardona Alzate, C.A.; Solarte-Toro, J.C.; Peña, Á.G. Fermentation, Thermochemical and Catalytic Processes in the Transformation of Biomass through Efficient Biorefineries. Catal. Today 2018, 302, 61–72. [Google Scholar] [CrossRef]

- Zhou, C.-H.; Xia, X.; Lin, C.-X.; Tong, D.-S.; Beltramini, J. Catalytic Conversion of Lignocellulosic Biomass to Fine Chemicals and Fuels. Chem. Soc. Rev. 2011, 40, 5588–5617. [Google Scholar] [CrossRef] [PubMed]

- Namioka, T.; Okudaira, K.; Yukumoto, M.; Ninomiya, Y.; Ito, H. Low-Temperature Trace Light-Tar Reforming in Biomass Syngas by Atmospheric Hydrogenation and Hydrogenolysis. Fuel Process. Technol. 2018, 181, 304–310. [Google Scholar] [CrossRef]

- Nishu; Liu, R.; Rahman, M.M.; Sarker, M.; Chai, M.; Li, C.; Cai, J. A Review on the Catalytic Pyrolysis of Biomass for the Bio-Oil Production with ZSM-5: Focus on Structure. Fuel Process. Technol. 2020, 199, 106301. [Google Scholar] [CrossRef]

- Deng, F.; Amarasekara, A.S. Industrial Crops & Products Catalytic Upgrading of Biomass Derived Furans. Ind. Crop. Prod. 2021, 159, 113055. [Google Scholar] [CrossRef]

- Yan, P.; Wang, H.; Liao, Y.; Wang, C. Zeolite Catalysts for the Valorization of Biomass into Platform Compounds and Biochemicals/Biofuels: A Review. Renew. Sustain. Energy Rev. 2023, 178, 113219. [Google Scholar] [CrossRef]

- Ortiz, D.L.; Batuecas, E.; Orrego, C.E.; Rodríguez, L.J.; Camelin, E.; Fino, D. Sustainable Management of Peel Waste in the Small-Scale Orange Juice Industries: A Colombian Case Study. J. Clean. Prod. 2020, 265, 121587. [Google Scholar] [CrossRef]

| Raw Material | Products | Process | Simulation Tool | Approach | Sustainability Dimensions | Refs. | ||

|---|---|---|---|---|---|---|---|---|

| Economic | Environmental | Social | ||||||

| Biomass | Biohydrogen | Biomass gasification | Aspen Plus | LSCA = LCA + LCC + SLCA | (Value per kg H2) LCoH: 3.59 €2017 | (Values per kg H2) GWP: 0.18 kg CO2 eq. AP: 1.45 × 10−2 kg SO2 eq. | (Values in mrh/kg H2) GWG: 0.594 HE: 0.128 | [62] |

| Spent coffee grounds (SCGs) | Biodiesel | Transesterification process of the extracted oil | GaBi 8.7 software | Dimensional analysis | N.R. | (Values per 1 t of SCGs) * Climate change: −0.04 × 100 kg CO2 eq. FE: 5.51 × 0.01 kg P eq. PED: 1.26 × 10 GJ PM: 0.97 kg PM2.5 eq. HTc: 0.50 × 10 kg 1,4-DB eq. | N.R. | [66] |

| Lignocellulosic residues and cheese whey and tequila vinasses | Bioethanol | Bioethanol production in a pretreatment- saccharification-fermentation train | SuperPro Designer v8.5 (SPD 8.5) | Dimensional analysis | Y: 3.07 MJout/kgpolysacharides PC: 1.40 × 10−1 USD/MJout | (Values per MJout) Emitted GHG: 4.26 × 102 g CO2 eq. Water consumption: 16.00 × 10−1 LFreshWater | N.R. | [67] |

| Pig slurry | Heat and electricity | Anaerobic digestion | N.R. | LCA | N.R. | CC: 6.0 g CO2 eq./MJ | N.R. | [68] |

| Corn straw | Hydrogen | Hydrogen production with methane tri-reforming | Aspen Plus v8.8 | Dimensional analysis and LCA | TCI: 171 million USD PC: 582,216 USD PBP: 4.72 year | (Values per 1004.5 kg H2) EC: 117,674 MJ Emitted GHG: 5409.9 kg CO2 eq. | N.R. | [69] |

| Rice and coconut residues | Electricity | Biomass gasification | N.R. | LCA | N.R. | (Values per 1 kWh of electricity produced) * GWP: −13.15 × 10 g CO2 eq. PM: −290.20 × 10−1 CFC-11 eq. HTP: 72.90 × 10 g 1.4-DB eq. | N.R. | [70] |

| Eucalyptus logging residues | Electricity | Biomass combustion | N.R. | LCSA = SLCA | N.R. | N.R. | (Values in mrh/1 kWh electricity) CL: 2.59 × 10−3 GWG: 1.17 × 10−2 HE: 4.22 × 10−2 FFL: 1.58 × 10−4 WSLF: 3.21 × 10−2 | [71] |

| Sweet sorghum | Bioethanol | Bioethanol production in a pretreatment- saccharification-fermentation train | N.R. | Dimensional analysis | PC: 735.76 USD/ha Total expense: 407.19 USD/ha | N.R. | N.R. | [72] |

| Avocado seeds and peels | Syngas | Anaerobic digestion | Aspen Plus v.9.0 | LSCA = LCA + LCC + SLCA | PBP: 6.24 year TR: 0.81 | (Values per syngas) CF: 8.99 kg CO2 eq. WF: 6.66 m3 | M/L: 0.72 Max M/L: 0.95 | [11] |

| Coffee cut stems | Bioethanol, electricity, and steam | Bioethanol production in a pretreatment- saccharification-fermentation train | Aspen Plus v9.0 | LCA | N.R. | CC: 0.0784 kg CO2/MJethanol | N.R. | [63] |

| Rice husk | Torrefied rice husk pellets (TRH) | Partially oxidative torrefaction of biomass | N.R. | LCA | ACC: 2.32 million USD AOP: 3.14 million USD | (Values per TRH) Annual GHG emissions: 604 ton CO2 eq. | N.R. | [73] |

| Wet poultry litter (WPL) | Biofuel and biochar | Gasification | N.R. | LCA | POC: 155 USD/ton CHP: 68 USD/ton | (Values per 1000 kg WPL) * HH: −6.10 × 10−5 pts EQ: −5.02 × 10−6 pts CC: 8.61 × 10−5 pts | N.R. | [74] |

| Waste cooking oil | Biodiesel | Transesterification process of the extracted oil | N.R. | LCA | N.R. | (Values per 1 ton produced biodiesel/day) GWP: 2.72 × 10 kg CO2 eq. HTP: 2.07 kg 1,4-DB eq. FWAE: 2.86 × 10−1 kg 1,4-DB eq. TE: 1.75 × 10−2 kg 1,4-DB eq. | N.R. | [59] |

| Forestry residues | Heat and electricity | Biomass gasification | N.R. | TEA and LCA | Electricity cost: 0.469 USD/kWh | Emitted GHG: 91 g CO2/kWh | N.R. | [75] |

| Coffee cut stems | Heat and hydrogen | Biomass gasification | Aspen Plus v9.0 | LSCA = LCA + LCC + SLCA | Total cost: 15.97 million USD. | CC: 0.320 kg CO2 eq. HTP: 0.019 kg 1,4-DB eq. PMF: 4.89 × 10−4 kg PM10 eq. ALO: 0.022 kg oil eq. | 56 h/week 48 h/week | [76] |

| Paddy straw | Bioethanol | Bioethanol production in a pretreatment- saccharification-fermentation train | N.R. | LCSA = SLCA | N.R. | N.R. | Employment: 1.94 FTE/106 yuan Wage: 1.78 yuan/yuan | [77] |

| Corn stover and Lignin-rich stream | Biofuel | Hydrothermal liquefaction (HTL) + aqueous phase reforming (APR) | Microsoft Excel | TEA and LCA | MSP: 1.23 €/kg (LRS) 1.27 €/kg (CS) | GWP: 56.1 and 58.4 g CO2 eq/MJ biofuel of Corn Stover and Lignin | N.R. | [78,79] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Solarte-Toro, J.C.; Cardona Alzate, C.A. Sustainability of Biorefineries: Challenges and Perspectives. Energies 2023, 16, 3786. https://doi.org/10.3390/en16093786

Solarte-Toro JC, Cardona Alzate CA. Sustainability of Biorefineries: Challenges and Perspectives. Energies. 2023; 16(9):3786. https://doi.org/10.3390/en16093786

Chicago/Turabian StyleSolarte-Toro, Juan Camilo, and Carlos Ariel Cardona Alzate. 2023. "Sustainability of Biorefineries: Challenges and Perspectives" Energies 16, no. 9: 3786. https://doi.org/10.3390/en16093786

APA StyleSolarte-Toro, J. C., & Cardona Alzate, C. A. (2023). Sustainability of Biorefineries: Challenges and Perspectives. Energies, 16(9), 3786. https://doi.org/10.3390/en16093786