The Micro-Occurrence Mechanisms of Tight Oil: Fluid–Rock Interactions at Microscale Pores, Nanoscale Pores, and Mineral Surfaces

Abstract

:1. Introduction

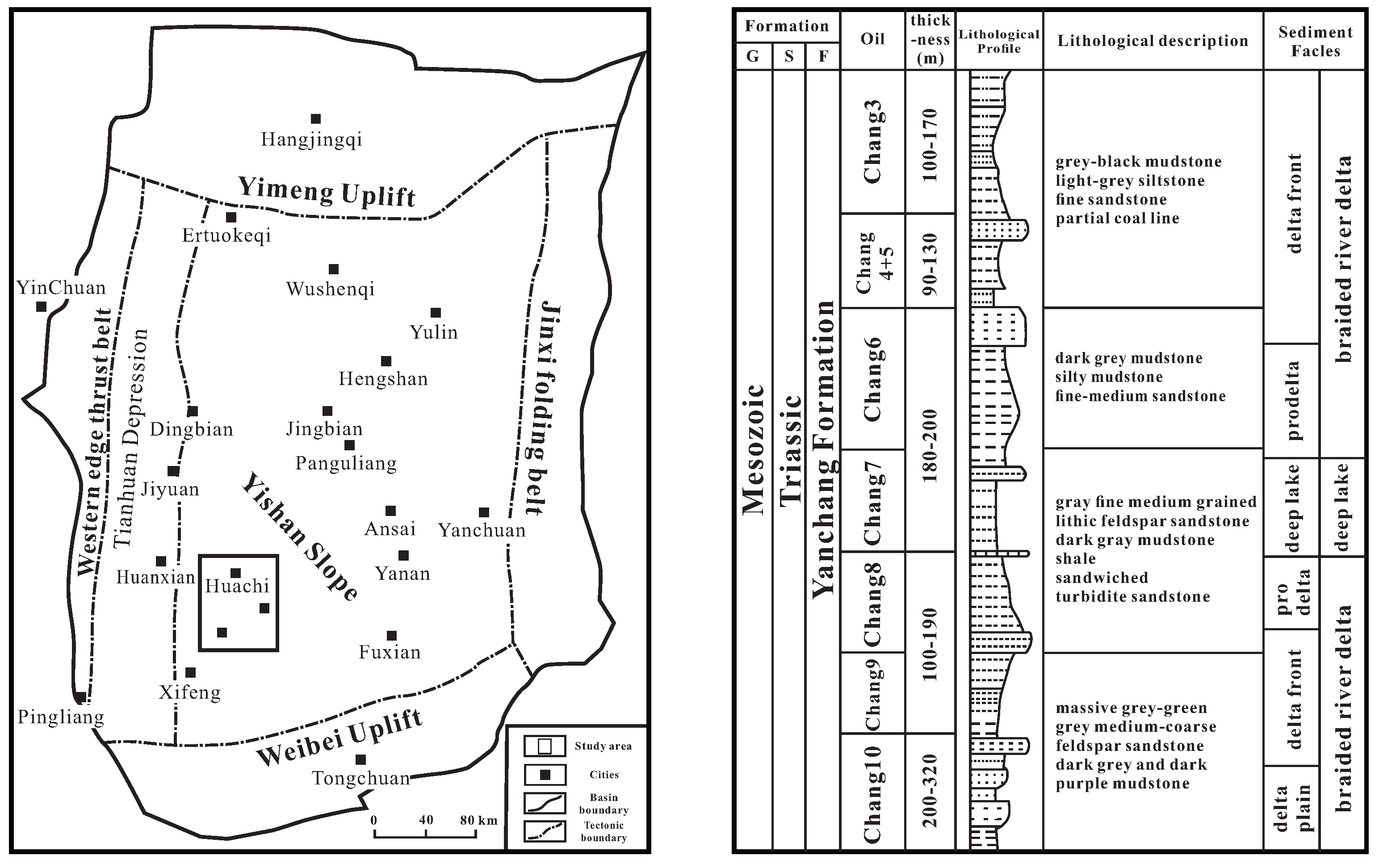

2. Geological Settings

3. Materials and Methods

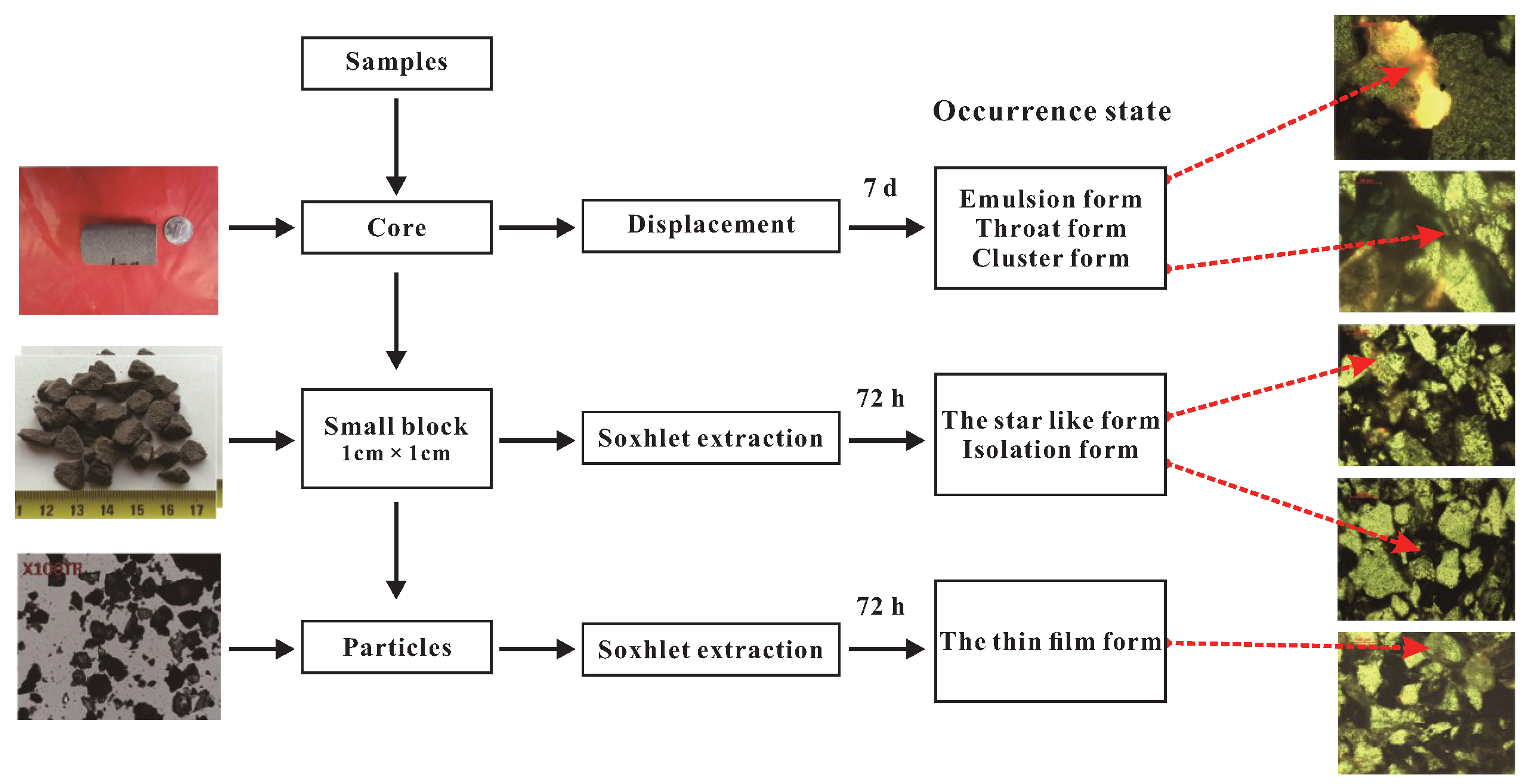

3.1. FTS and ESEM Observation

3.2. Extraction of Tight Oil from Sandstones

3.3. Separation of Fractional Compositions

3.4. GC/MS Analysis

3.5. FTIR Analysis

4. Results and Discussion

4.1. The Occurrence State of Tight Oil

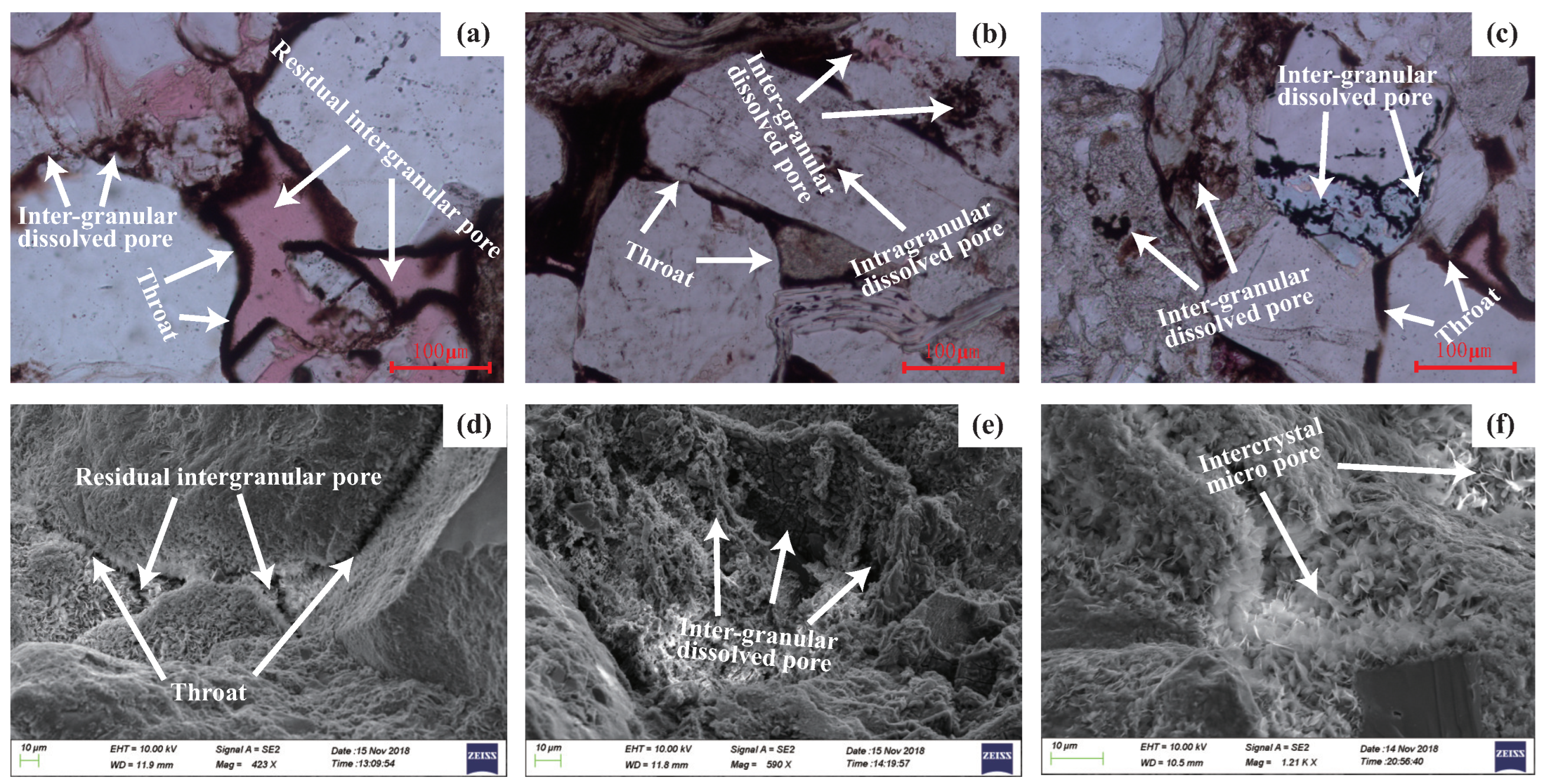

4.1.1. Distribution of Pores and Throats

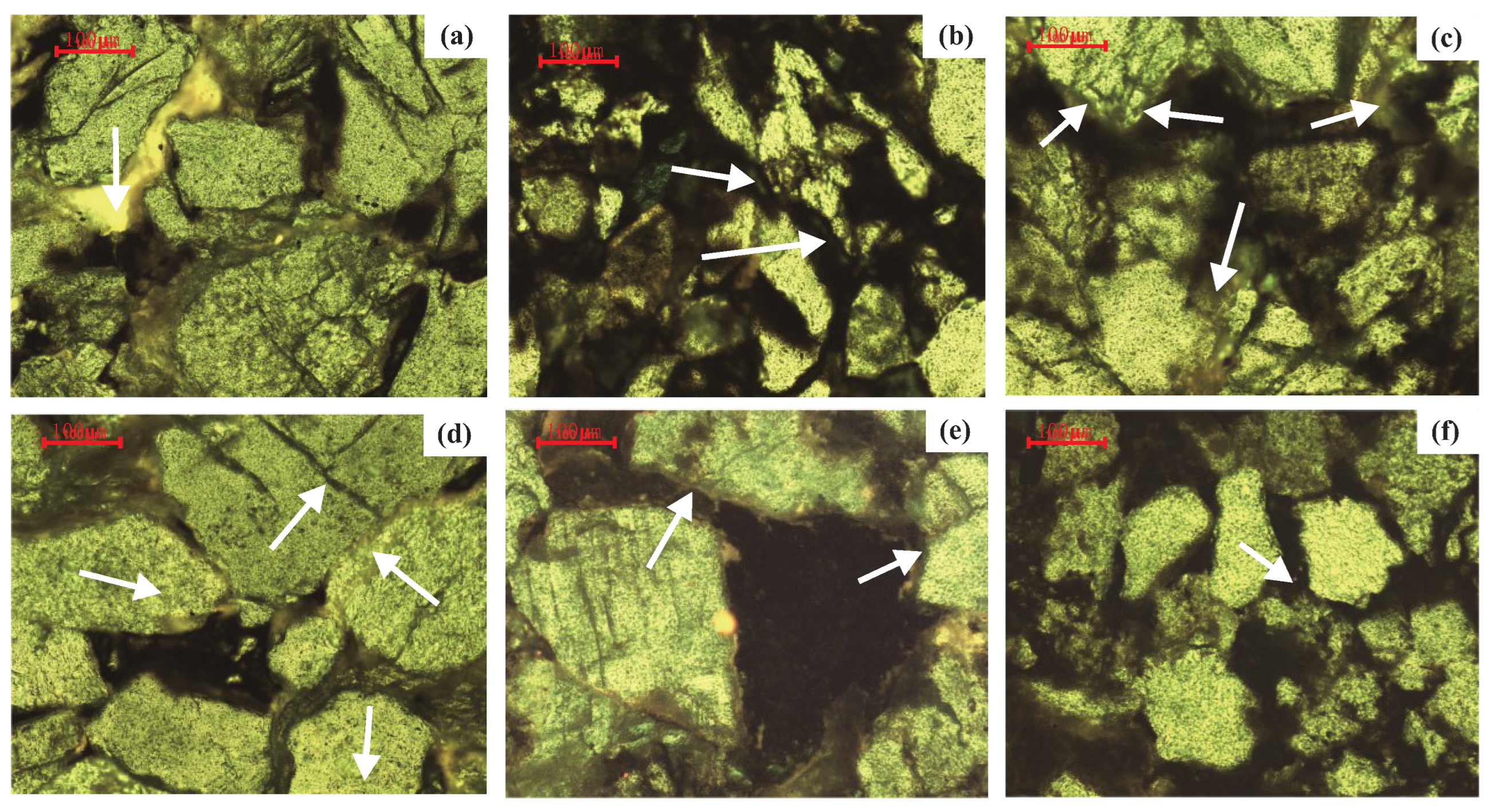

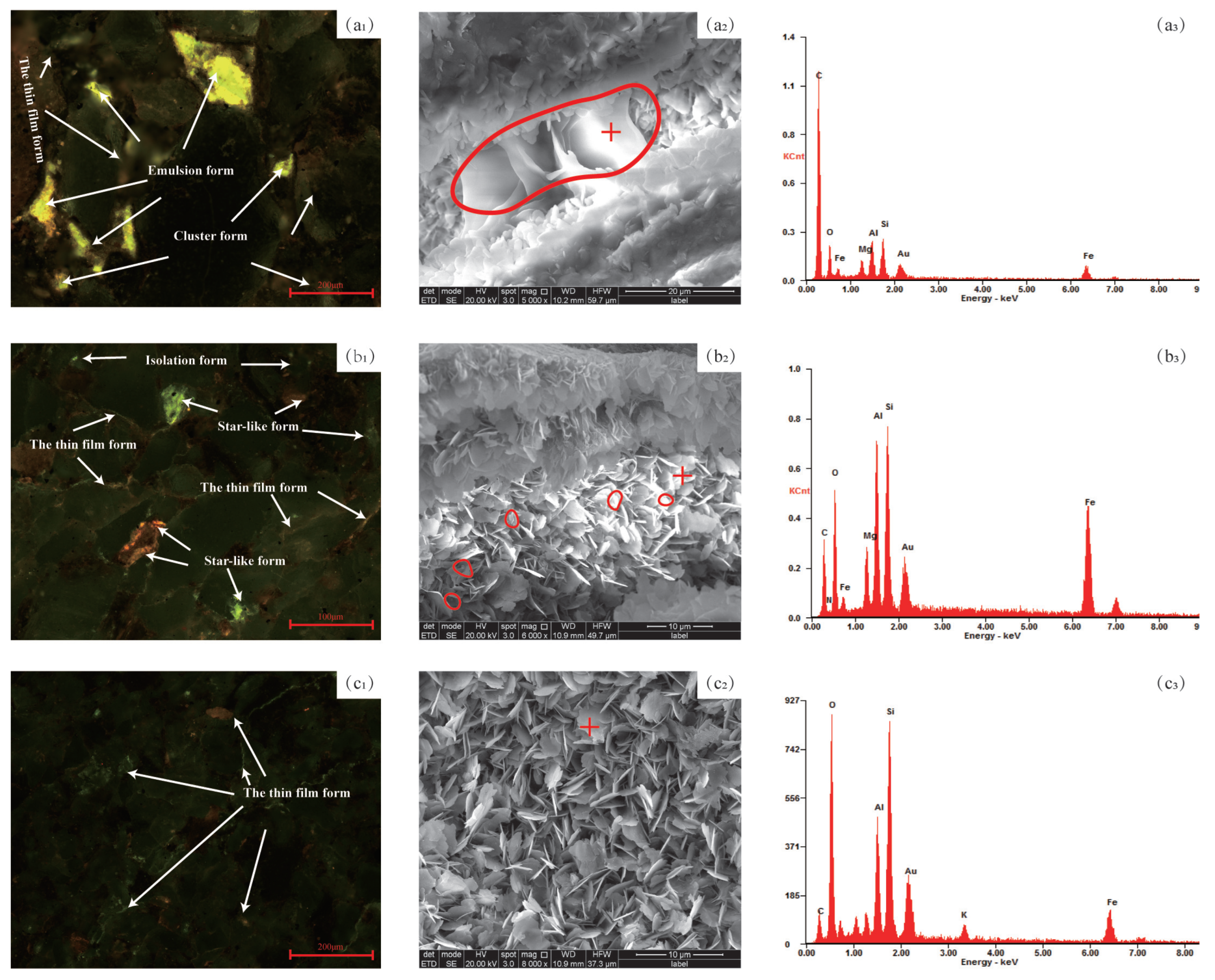

4.1.2. Micro-Occurrence State of Tight Oil

4.2. The Influencing Factors of Tight Oil Content in Sandstones

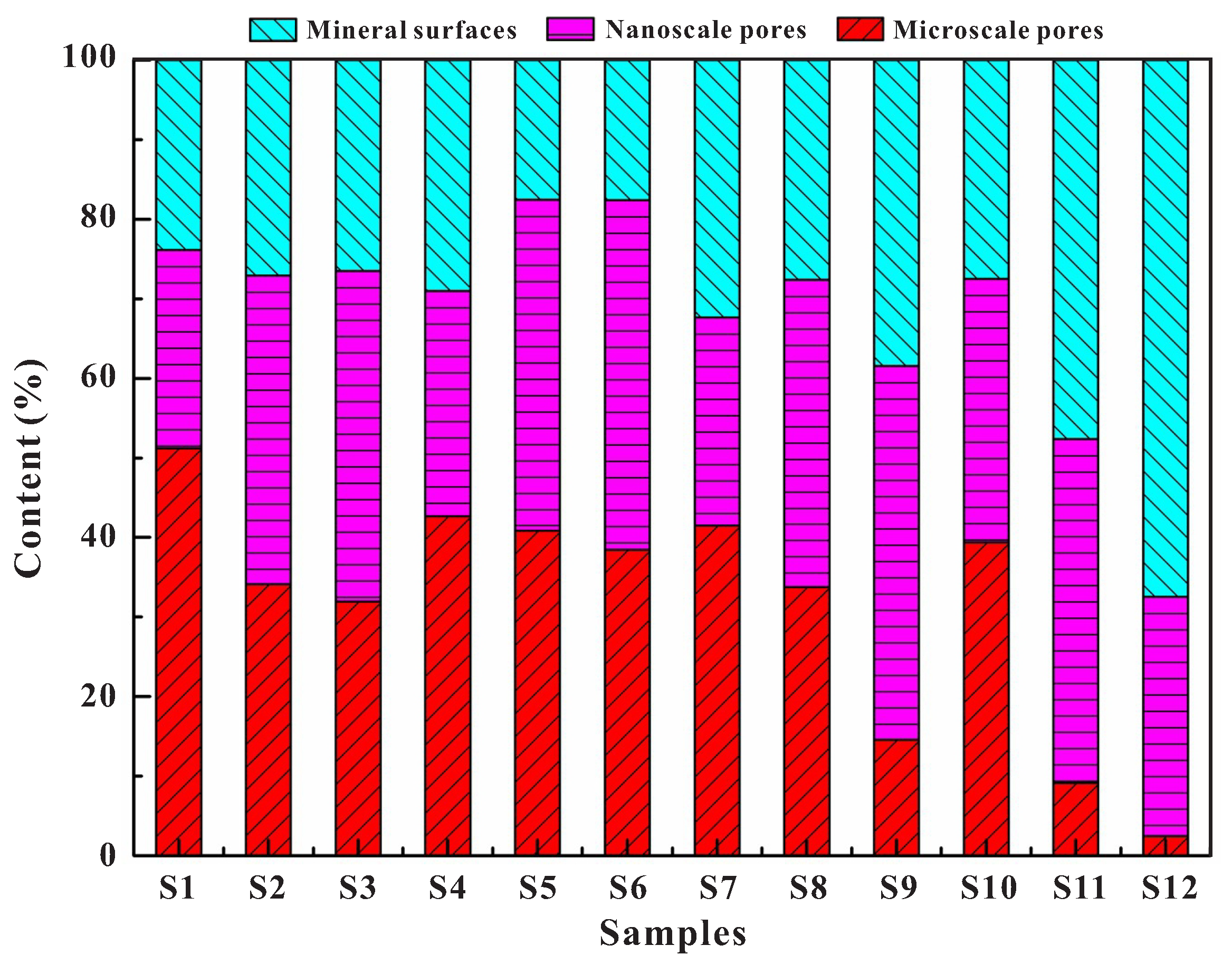

4.2.1. The Content of Tight Oil Storage in Sandstones

4.2.2. The Influencing Factors of Tight Oil Occurrence

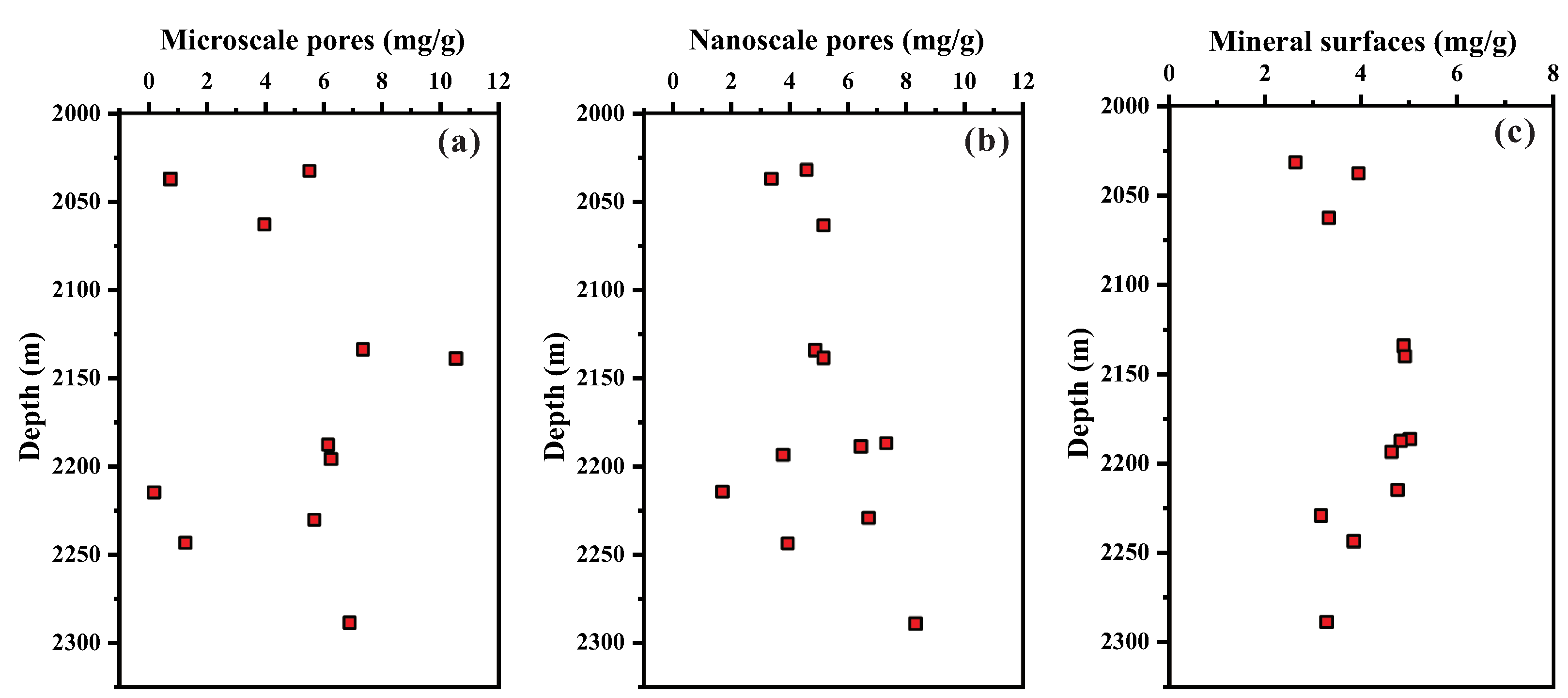

- 1. Burial depth of tight oil: Figure 9 illustrates the relationship between burial depth and the content of tight oil existing in microscale pores, nanoscale pores, and on mineral surfaces. The content of tight oil in microscale pores showed no correlation with burial depth. This phenomenon may be attributed to the tight sandstone reservoirs experiencing complex diagenesis, which led to high reservoir heterogeneity. The detailed calculation process can be found in the Table S1 of the Supplementary Material.As the burial depth increased, the content of tight oil in the nanoscale pores demonstrated a moderate increase. This phenomenon may be attributed to the following reasons: (1) With increasing burial depth, the compaction effect is intensified, leading to a higher densification degree of the reservoir, more developed nanoscale pores, and a greater capacity for storage [5]. (2) As the burial depth and geothermal gradient increase, the viscosity of tight oil decreases, the content of saturated hydrocarbons increases, and more tight oil can enter nanoscale pores under formation pressure [11,41]. Conversely, as the burial depth increased, the content of tight oil on the mineral surface initially increased between 2000 and 2100 m, but decreased with community succession from 2100 to 2300 m. The underlying reason for this is that as the burial depth increases, tight oil viscosity decreases, and the interaction between tight oil and minerals is reduced, resulting in a decrease in the tight oil present on mineral surfaces.

- 2. Quality factor: The occurrence of tight oil in the reservoir was inevitably influenced by the reservoir’s spatial distribution and pore–throat connectivity. The reservoir quality factor () is a critical parameter that determines the reservoir properties, and a Q factor close to 1 indicates superior reservoir properties [15]. As shown in Figure 10a,b, the content of tight oil stored in the microscale and nanoscale pores exhibited a positive relationship with the Q factor, with correlation coefficients of 0.500 and 0.431, respectively. This suggested that the tight oil deposition in sandstones was governed by reservoir properties. The better the original physical properties of the reservoir, the greater the pore–throat connectivity, and the more favorable the conditions for tight oil storage in the reservoir space [47]. In contrast, no significant correlation was observed between the amount of tight oil present on the mineral surface and the reservoir quality factor (Figure 10c). This phenomenon indicated that the storage mechanism of tight oil on mineral surfaces differed from that of pores. Consequently, it was essential to examine the relationship between tight oil content and mineral composition and then clarify the reasons for the differences in tight oil accumulation in sandstones.

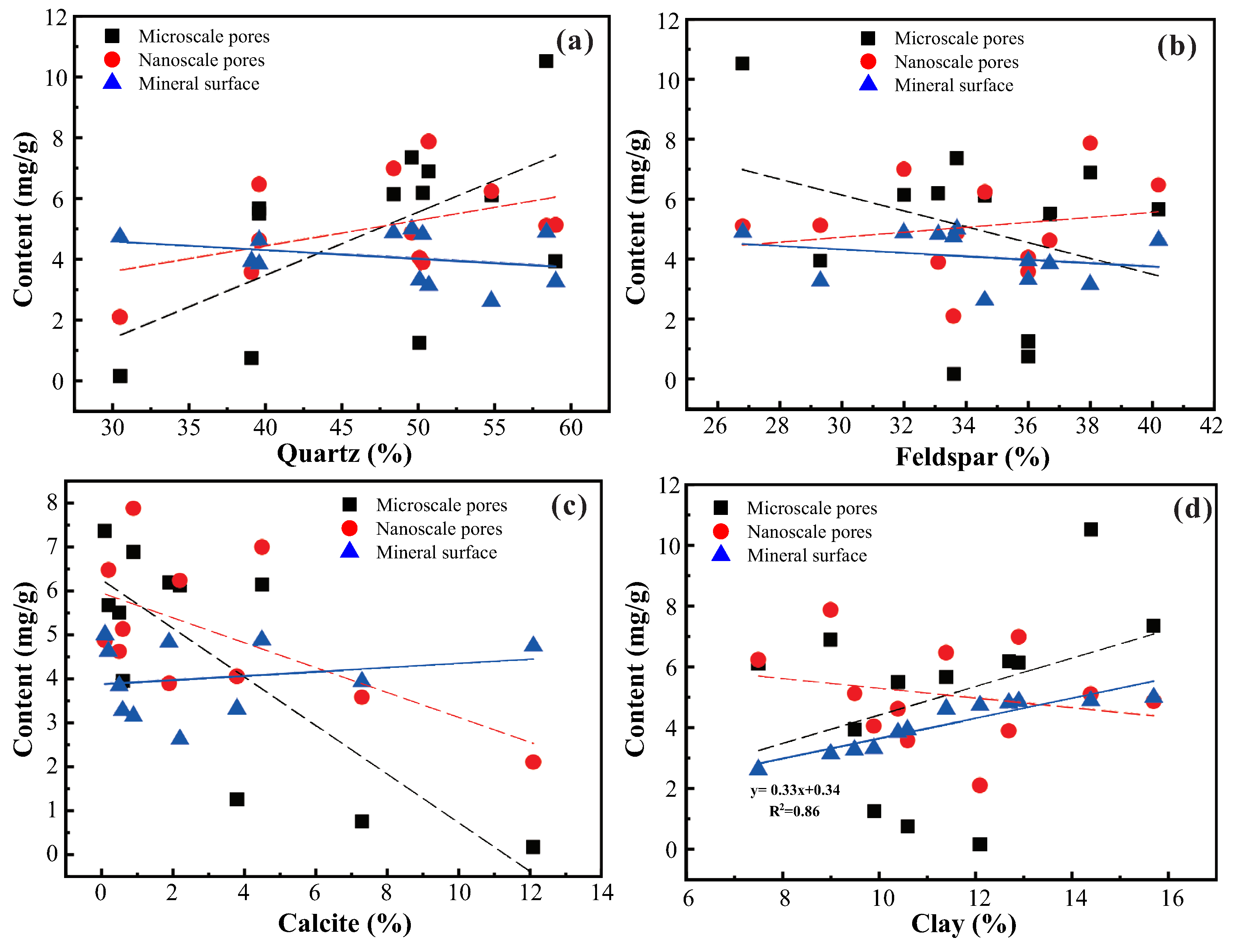

- 3. Mineral composition: Minerals serve as the foundation for various reservoir spaces, and intricate oil–rock interactions are crucial to the formation of tight oil in sandstones [31,39,48,49,50]. Through the examination and analysis of core samples and thin sections (TSs), it was determined that the Chang 8 Member of the Yanchang Formation in the Ordos Basin predominantly consisted of black/dark gray fine/medium debris/feldspar and fine feldspar/debris sandstones. The results are presented in Table 1.The relationship between the content of tight oil in sandstones and different minerals is illustrated in Figure 11. The higher the quartz and clay contents, the greater the amount of tight oil stored in microscale pores. Conversely, higher feldspar and calcite contents result in less tight oil being stored in microscale pores. This phenomenon is related to the preservation mechanisms of different minerals in microscale pores within the reservoir during diagenesis. Quartz is an essential framework mineral in tight sandstone reservoirs, exhibiting strong resistance to compaction. This characteristic is conducive to the preservation of residual microscale pores during compaction. As the quartz content increases, so does the corresponding amount of tight oil stored in the microscale pores (Figure 11a). Calcite, which is primarily distributed in residual intergranular pores as microcrystals, is the main factor causing pore and throat reduction in tight sandstones, particularly in microscale pores [51]. Thus, as the calcite content increases, microscale pores significantly decrease, along with the corresponding amount of tight oil (Figure 11c). The development of clay minerals, especially chlorite, can enhance a reservoir’s resistance to compaction, thus promoting the preservation of residual intergranular pores. The higher the clay mineral content, the more favorable the conditions for the distribution of tight oil in microscale pores (Figure 11d).Furthermore, the content of tight oil stored in nanoscale pores exhibited a specific positive correlation with the quartz and feldspar content, while a negative correlation existed with calcite and clay content. This outcome may be associated with the pore–throat connectivity and the development of nanoscale pores in reservoirs. On the one hand, as the quartz content increases, the resistance of a reservoir to compaction becomes stronger, and the enhanced pore–throat connectivity is beneficial for crude oil to be charged into nanoscale pores. On the other hand, a higher feldspar content indicates that more dissolved pores are developed in the feldspar grains, which is conducive to the corresponding tight oil existing in nanoscale pores (Figure 11b). In contrast, as the content of calcite and clay increased, the tight oil stored in nanoscale pores noticeably decreased. This observation was related to the fact that calcite and clay occupied a significant amount of pore space in the reservoir and weakened the fluidity of tight oil, making it challenging for tight oil to enter the nanoscale pores [29].The content of tight oil present on the mineral surface exhibited a strong positive correlation with clay minerals () but a weak relationship with minerals such as quartz, feldspar, and calcite. These results demonstrate that the primary factor influencing the occurrence of tight oil on mineral surfaces was clay minerals. Due to their large specific surface area and inherent mineral properties, clay minerals possess excellent adsorption capabilities for tight oil [52]. Consequently, clay minerals play a crucial role in determining the distribution of tight oil present on mineral surfaces [30,39].Based on this analysis, it can be concluded that the influence of authigenic minerals on the occurrence of tight oil in reservoir spaces manifested through multiple effects, which can be described as follows: (1) Authigenic minerals—particularly clay minerals—increase the specific surface area of pores and throats, which facilitates the adsorption of tight oil onto mineral surfaces, thereby forming a substantial amount of tight oil in the thin film form; (2) the growth of authigenic minerals generates numerous intercrystalline pores within clay minerals, providing storage space for the enrichment of tight oil in isolated forms within nanoscale pores; (3) the growth of authigenic minerals, such as calcite, significantly alters the reservoir’s pore structure and the seepage patterns of tight oil within the pores, resulting in a heterogeneous distribution of tight oil in the reservoir.

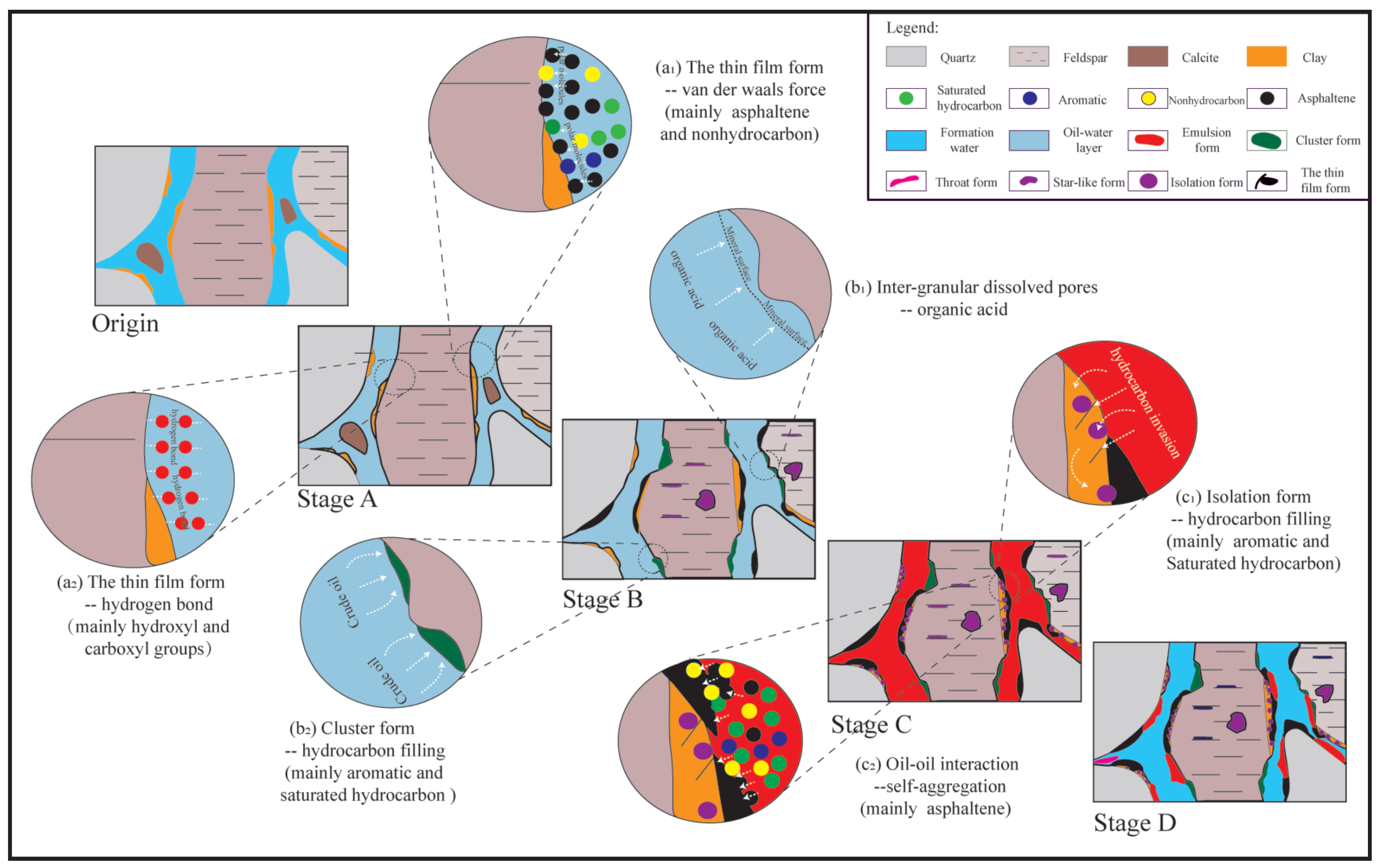

4.3. The Micro-Occurrence Process of Tight Oil

4.3.1. The Oil Components

4.3.2. The Carbon Composition

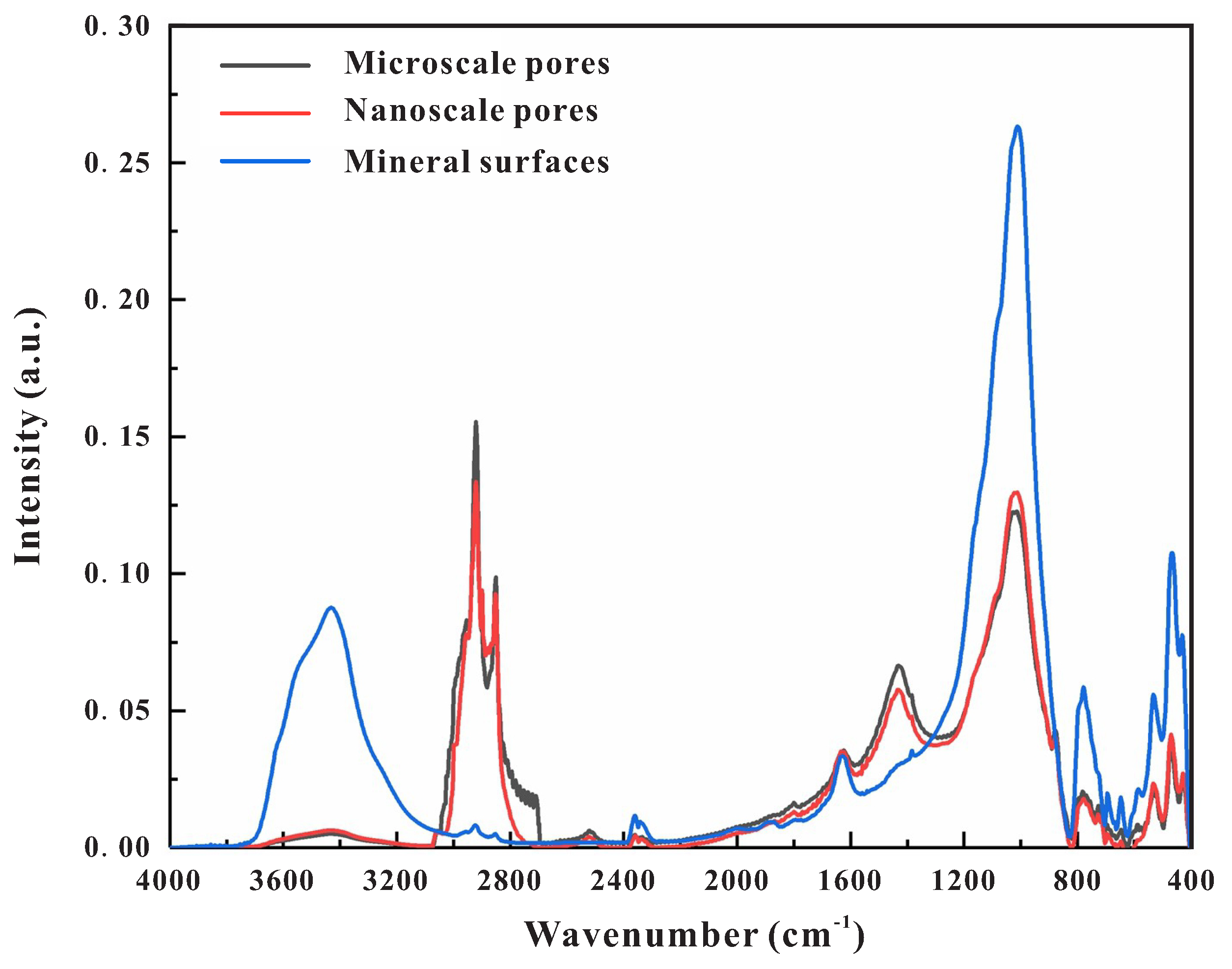

4.3.3. The Functional Groups

4.4. The Micro-Occurrence Mechanism of Tight Oil

5. Conclusions

- Based on the variations in micromorphology and the location of tight oil, the micro-occurrence states of tight oil weren classified into six types: the emulsion form, cluster form, throat form, star-like form, isolation form, and thin film form. The emulsion form, cluster form, and throat form were primarily developed in microscale pores, while the star-like form and isolation form were predominantly developed in nanoscale pores. The thin film form mainly existed on mineral surfaces.

- Tight oil found in microscale pores, nanoscale pores, and mineral surfaces was extracted step by step through tight oil extraction, accounting for 35.46%, 35.74%, and 28.79% of the total content, respectively. Microscale and nanoscale pores served as the primary storage spaces for tight oil; however, tight oil present on mineral surfaces also constituted a significant potential resource.

- A micro-occurrence pattern of tight oil in sandstones was established for the residual tight oil observed in each type of pore. The content of anti-compaction minerals, original reservoir properties, and the content of light components primarily controlled the occurrence of tight oil stored in microscale and nanoscale pores. Conversely, the amount of tight oil present on mineral surfaces was chiefly influenced by clay minerals and heavy components.

- Oil–rock interaction is a crucial factor contributing to component differentiation during the micro-occurrence process of tight oil. The adsorption of heavy components by minerals results in the remaining crude oil components being concentrated in microscale and nanoscale pores, which are characterized by higher saturated and aromatic hydrocarbon content and increased fluidity. The intrusion of formation water in later stages establishes the current micro-occurrence characteristics of tight oil. Consequently, the micro-occurrence process of tight oil in the reservoir is fundamentally a product of the combined effects of oil–rock interactions and the disruption and reformation caused by the presence of formation water.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, Z.; Liu, L.; Liu, B.; Wang, T.; Zhang, Z.; Wu, K.; Feng, C.; Dou, W.; Wang, Y.; Shu, Y. Geochemical Characteristics of the Triassic Chang 7 Lacustrine Source Rocks, Ordos Basin, China: Implications for Paleoenvironment, Petroleum Potential and Tight Oil Occurrence. J. Asian Earth Sci. 2019, 178, 112–138. [Google Scholar] [CrossRef]

- Li, C.; Chen, G.; Li, X.; Zhou, Q.; Sun, Z. The Occurrence of Tight Oil in the Chang 8 Lacustrine Sandstone of the Huaqing Area, Ordos Basin, China: Insights into the Content of Adsorbed Oil and Its Controlling Factors. J. Nat. Gas Geosci. 2022, 7, 27–37. [Google Scholar] [CrossRef]

- Wu, S.; Zhu, R.; Yang, Z.; Mao, Z.; Cui, J.; Zhang, X. Distribution and Characteristics of Lacustrine Tight Oil Reservoirs in China. J. Asian Earth Sci. 2019, 178, 20–36. [Google Scholar] [CrossRef]

- Zheng, D.; Pang, X.; Zhou, L.; You, X.; Liu, X.; Guo, F.; Li, W. Critical Conditions of Tight Oil Charging and Determination of the Lower Limits of Petrophysical Properties for Effective Tight Reservoirs: A Case Study from the Fengcheng Formation in the Fengcheng Area, Junggar Basin. J. Pet. Sci. Eng. 2020, 190, 107135. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, X.; Qian, Z.; Chen, G.; Lyu, C.; Ma, X.; Li, C. The Occurrence of Adsorbed Tight Oil and Its Effect on Porosity and Permeability Reduction of Triassic Lacustrine Sandstone Reservoir. Geofluids 2022, 2022, 6923449. [Google Scholar] [CrossRef]

- Cui, J.; Li, S.; Mao, Z. Oil-Bearing Heterogeneity and Threshold of Tight Sandstone Reservoirs: A Case Study on Triassic Chang 7 Member, Ordos Basin. Mar. Pet. Geol. 2019, 104, 180–189. [Google Scholar] [CrossRef]

- Luan, B.; Zhang, B.; Wang, D.; Deng, C.; Wang, F. Quantitative Evaluation of Tight Oil Reservoirs in the Chang 8 Member of the Yanchang Formation in Southern Ordos Basin. Front. Earth Sci. 2022, 10, 1326. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Ran, Y.; Zhou, Z.; Cui, Y. Impact of Diagenesis on the Reservoir Quality of Tight Oil Sandstones: The Case of Upper Triassic Yanchang Formation Chang 7 Oil Layers in Ordos Basin, China. J. Pet. Sci. Eng. 2016, 145, 54–65. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Wang, Z.; Chen, J.; Pang, X.; Wang, S.; Zhou, Z.; He, Z.; Qin, Z.; Fan, X. A Review on Pore Structure Characterization in Tight Sandstones. Earth-Sci. Rev. 2018, 177, 436–457. [Google Scholar] [CrossRef]

- Li, Y.; Huang, Y.; Ma, H.; Chang, C.; Xie, W. Study on the Development Options of Tight Sandstone Oil Reservoirs and Their Influencing Factors. Front. Energy Res. 2022, 10, 1397. [Google Scholar] [CrossRef]

- Ma, Z.; Tan, J.; Zheng, L.; Ni, C.; Hu, R.; Ma, J. Simulation Experiment of Fluid-Feldspar Sandstone Interactions and Their Implications for Tight Oil and Gas Exploration of the Yanchang Formation, Ordos Basin, China. Mar. Pet. Geol. 2022, 142, 105737. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhang, D.; Li, X.; Qian, Z.; Chen, G.; Lyu, C.; Ma, X.; Li, C. Insight into the Desorption Behavior and Mechanism of Tight Oil with In-Situ Low-Temperature Thermal. J. Pet. Sci. Eng. 2022, 218, 111001. [Google Scholar] [CrossRef]

- Liu, K.; Wang, R.; Shi, W.; Travé, A.; Martín-Martín, J.D.; Baqués, V.; Qi, R.; Lin, J.; Ye, H. Diagenetic Controls on Reservoir Quality and Heterogeneity of the Triassic Chang 8 Tight Sandstones in the Binchang Area (Ordos Basin, China). Mar. Pet. Geol. 2022, 146, 105974. [Google Scholar] [CrossRef]

- Fu, L.; Zhu, X.; Gan, R.; Zhou, J.; Zheng, Y.; Jin, T. Research of Visualization of the Occurrence State of Fluids in the Extralow Permeability Reservoirs and Its Application. J. Yangtze Univ. (Nat. Sci. Ed.) 2017, 14, 35–39+117. [Google Scholar] [CrossRef]

- Gong, Y.; Liu, S.; Zhu, R.; Liu, K.; Tang, Z.; Jiang, L. Micro-Occurrence of Cretaceous Tight Oil in Southern Songliao Basin, NE China. Pet. Explor. Dev. 2015, 42, 323–328. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, S.; Zhang, F.; Liu, Y.; Ganu, H.; Li, J.; Shao, L.; Yang, S.; She, Y. Quantitative Research on Tight Oil Microscopic State of Chang 7 Member of Triassic Yanchang Formation in Ordos Basin, NW China. Pet. Explor. Dev. 2015, 42, 827–832. [Google Scholar] [CrossRef]

- Li, P.; Sun, W.; Wu, B.; Gao, Y.; Du, K. Occurrence Characteristics and Influential Factors of Movable Fluids in Pores with Different Structures of Chang 63 Reservoir, Huaqing Oilfield, Ordos Basin, China. Mar. Pet. Geol. 2018, 97, 480–492. [Google Scholar] [CrossRef]

- Li, Z.; Wu, S.; Xia, D.; He, S.; Zhang, X. An Investigation into Pore Structure and Petrophysical Property in Tight Sandstones: A Case of the Yanchang Formation in the Southern Ordos Basin, China. Mar. Pet. Geol. 2018, 97, 390–406. [Google Scholar] [CrossRef]

- Taheri-Shakib, J.; Hosseini, S.A.; Kazemzadeh, E.; Keshavarz, V.; Rajabi-Kochi, M.; Naderi, H. Experimental and Mathematical Model Evaluation of Asphaltene Fractionation Based on Adsorption in Porous Media: Dolomite Reservoir Rock. Fuel 2019, 245, 570–585. [Google Scholar] [CrossRef]

- Wu, J.; Fan, Y.; Wu, F.; Li, C. Combining Large-Sized Model Flow Experiment and NMR Measurement to Investigate Drilling Induced Formation Damage in Sandstone Reservoir. J. Pet. Sci. Eng. 2019, 176, 85–96. [Google Scholar] [CrossRef]

- Wang, M.; Ma, R.; Li, J.; Lu, S.; Li, C.; Guo, Z.; Li, Z. Occurrence Mechanism of Lacustrine Shale Oil in the Paleogene Shahejie Formation of Jiyang Depression, Bohai Bay Basin, China. Pet. Explor. Dev. 2019, 46, 833–846. [Google Scholar] [CrossRef]

- Li, J.; Jiang, C.; Wang, M.; Xu, L.; Li, M.; Yu, C.; Wu, Y.; Lu, S. Determination of in Situ Hydrocarbon Contents in Shale Oil Plays. Part 1: Is Routine Rock–Eval Analysis Reliable for Quantifying the Hydrocarbon Contents of Preserved Shale Cores? Org. Geochem. 2022, 170, 104449. [Google Scholar] [CrossRef]

- Li, Q.; Chen, F.; Wu, S.; Zhang, L.; Wang, Y.; Xu, S. A Simple and Effective Evaluation Method for Lacustrine Shale Oil Based on Mass Balance Calculation of Rock-Eval Data. Appl. Geochem. 2022, 140, 105287. [Google Scholar] [CrossRef]

- Qian, M.; Jiang, Q.; Li, M.; Li, Z.; Liu, P.; Ma, Y.; Cao, T. Quantitative characterization of extractable organic matter in lacustrine shale with different occurrences. Pet. Geol. Exp. 2017, 39, 278–286. [Google Scholar] [CrossRef]

- Tian, Y.; Yan, C.; Jin, Z. Characterization of Methane Excess and Absolute Adsorption in Various Clay Nanopores from Molecular Simulation. Sci. Rep. 2017, 7, 12040. [Google Scholar] [CrossRef]

- Li, J.; Lu, S.; Xie, L.; Zhang, J.; Xue, H.; Zhang, P.; Tian, S. Modeling of Hydrocarbon Adsorption on Continental Oil Shale: A Case Study on n-Alkane. Fuel 2017, 206, 603–613. [Google Scholar] [CrossRef]

- Luo, Y.; Xiao, H.; Liu, X.; Zheng, T. Occurrence Characteristics and Influential Factors of Movable Oil in Nano-Pores by Molecular Dynamics Simulation. Colloids Surf. A Physicochem. Eng. Asp. 2022, 655, 130320. [Google Scholar] [CrossRef]

- Marcano, M.C.; Kim, S.; Becker, U. Surface Interaction of Crude Oil, Maltenes, and Asphaltenes with Calcite: An Atomic Force Microscopy Perspective of Incipient Wettability Change. Appl. Geochem. 2020, 113, 104501. [Google Scholar] [CrossRef]

- Zhang, Z.; Xi, K.; Xin, H.; Yang, C.; Zhao, H.; Wang, Y.; Dan, W.; Luo, B. Origin of Calcite Cements in Tight Sandstone Reservoirs of Chang 8 Member of the Yanchang Formation in Zhijing-Ansai Area, Ordos Basin, China. Energies 2022, 15, 9544. [Google Scholar] [CrossRef]

- Xie, L.; You, Q.; Wang, E.; Li, T.; Song, Y. Quantitative Characterization of Pore Size and Structural Features in Ultra-Low Permeability Reservoirs Based on X-Ray Computed Tomography. J. Pet. Sci. Eng. 2022, 208, 109733. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, C.; Chen, G.; Lyu, C.; Qu, X.; Ma, X.; Li, C.; Lei, Q.; Xie, Q. The Formation Mechanism of Authigenic Chlorite in Tight Sandstone and Its Effect on Tight Oil Adsorption during Hydrocarbon Filling. Oil Gas Sci. Technol.-Rev. D’IFP Energies Nouv. 2021, 76, 39. [Google Scholar] [CrossRef]

- Taheri-Shakib, J.; Keshavarz, V.; Kazemzadeh, E.; Hosseini, S.A.; Rajabi-Kochi, M.; Salimidelshad, Y.; Naderi, H.; Bakhtiari, H.A. Experimental and Mathematical Model Evaluation of Asphaltene Fractionation Based on Adsorption in Porous Media: Part 1. Calcite Reservoir Rock. J. Pet. Sci. Eng. 2019, 177, 24–40. [Google Scholar] [CrossRef]

- Zhang, Y.; Zeng, J.; Dai, Z.; Viswanathan, H.; Xiao, T.; Ma, Y.; Feng, X. Experimental Investigation on Oil Migration and Accumulation in Tight Sandstones. J. Pet. Sci. Eng. 2018, 160, 267–275. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X.; Shi, J.; Guo, W.; Kang, L.; Yu, R.; Sun, Y.; Wang, Z.; Pan, M. A Reservoir Quality Evaluation Approach for Tight Sandstone Reservoirs Based on the Gray Correlation Algorithm: A Case Study of the Chang 6 Layer in the W Area of the as Oilfield, Ordos Basin. Energy Explor. Exploit. 2021, 39, 1027–1056. [Google Scholar] [CrossRef]

- Konan, N.F.D.S.; Li, M.; Shi, S.; Liu, X.; Tang, Y.; Kojo, A.; Toyin, A. Simple Column Chromatography Separation Procedure for Polycyclic Aromatic Hydrocarbons: Controlling Factor(s). Arab. J. Geosci. 2022, 15, 1350. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, L.; Su, L.; Wu, Y.; Sun, R.; Wu, C.; Song, D.; Tuo, J. The Chemical Kinetics of the Semi-Open Hydrous Pyrolysis System: Time Series Analysis of Lithostatic Pressure and Fluid Pressure. Int. J. Coal Geol. 2020, 220, 103418. [Google Scholar] [CrossRef]

- Ma, W.; Hou, L.; Luo, X.; Tao, S.; Guan, P.; Liu, J.; Lin, S. Role of Bitumen and NSOs during the Decomposition Process of a Lacustrine Type-II Kerogen in Semi-Open Pyrolysis System. Fuel 2020, 259, 116211. [Google Scholar] [CrossRef]

- Hou, L.; Luo, X.; Zhao, Z.; Zhang, L. Identification of Oil Produced from Shale and Tight Reservoirs in the Permian Lucaogou Shale Sequence, Jimsar Sag, Junggar Basin, NW China. ACS Omega 2021, 6, 2127–2142. [Google Scholar] [CrossRef]

- Zhou, Q.; Lv, C.; Li, C.; Chen, G.; Ma, X.; Li, C. Formation Mechanism of Authigenic Chlorite in Tight Sandstone and Its Influence on Tight Oil Adsorption, Triassic Ordos Basin, China. Energy Explor. Exploit. 2020, 38, 2667–2694. [Google Scholar] [CrossRef]

- Gong, Y.; Liu, K. Pore Throat Size Distribution and Oiliness of Tight Sands-A Case Study of the Southern Songliao Basin, China. J. Pet. Sci. Eng. 2020, 184, 106508. [Google Scholar] [CrossRef]

- Wood, J.M.; Cesar, J.; Ardakani, O.H.; Rudra, A.; Sanei, H. Geochemical Evidence for the Internal Migration of Gas Condensate in a Major Unconventional Tight Petroleum System. Sci. Rep. 2022, 12, 7931. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Lu, S.; Li, J.; Chang, X.; Lin, Z.; Chen, G.; Li, J.; Liu, J.; Tian, S. Evaluating Microdistribution of Adsorbed and Free Oil in a Lacustrine Shale Using Nuclear Magnetic Resonance: A Theoretical and Experimental Study. J. Pet. Sci. Eng. 2022, 212, 110208. [Google Scholar] [CrossRef]

- Cho, H.; Kar, T.; Firoozabadi, A. Effect of Interface Elasticity on Improved Oil Recovery in a Carbonate Rock from Low Salinity and Ultra-Low Concentration Demulsifier. Fuel 2020, 270, 117504. [Google Scholar] [CrossRef]

- Zhou, Y.; Wu, X.; Zhong, X.; Reagen, S.; Zhang, S.; Sun, W.; Pu, H.; Zhao, J. Polymer Nanoparticles Based Nano-Fluid for Enhanced Oil Recovery at Harsh Formation Conditions. Fuel 2020, 267, 117251. [Google Scholar] [CrossRef]

- Vahdanikia, N.; Divandari, H.; Hemmati-Sarapardeh, A.; Nait Amar, M.; Schaffie, M.; Ranjbar, M. Integrating New Emerging Technologies for Enhanced Oil Recovery: Ultrasonic, Microorganism, and Emulsion. J. Pet. Sci. Eng. 2020, 192, 107229. [Google Scholar] [CrossRef]

- Afekare, D.; Gupta, I.; Rao, D. Nanoscale Investigation of Silicon Dioxide Nanofluids and Implications for Enhanced Oil Recovery—An Atomic Force Microscope Study. J. Pet. Sci. Eng. 2020, 191, 107165. [Google Scholar] [CrossRef]

- Wang, J.; Wu, S.; Li, Q.; Zhang, J.; Guo, Q. Characterization of the Pore-Throat Size of Tight Oil Reservoirs and Its Control on Reservoir Physical Properties: A Case Study of the Triassic Tight Sandstone of the Sediment Gravity Flow in the Ordos Basin, China. J. Pet. Sci. Eng. 2020, 186, 106701. [Google Scholar] [CrossRef]

- Khishvand, M.; Oraki Kohshour, I.; Alizadeh, A.H.; Piri, M.; Prasad, S. A Multi-Scale Experimental Study of Crude Oil-Brine-Rock Interactions and Wettability Alteration during Low-Salinity Waterflooding. Fuel 2019, 250, 117–131. [Google Scholar] [CrossRef]

- Saxena, N.; Goswami, A.; Dhodapkar, P.; Nihalani, M.; Mandal, A. Bio-Based Surfactant for Enhanced Oil Recovery: Interfacial Properties, Emulsification and Rock-Fluid Interactions. J. Pet. Sci. Eng. 2019, 176, 299–311. [Google Scholar] [CrossRef]

- Takeya, M.; Ubaidah, A.; Shimokawara, M.; Okano, H.; Nawa, T.; Elakneswaran, Y. Crude Oil/Brine/Rock Interface in Low Salinity Waterflooding: Experiments, Triple-Layer Surface Complexation Model, and DLVO Theory. J. Pet. Sci. Eng. 2020, 188, 106913. [Google Scholar] [CrossRef]

- Zhao, S.; Fu, Q.; Fu, J.; Liu, X.; Li, S.; Zhang, G.; Teng, J. Effect of Authigenic Clay Minerals and Carbonate Cements on Quality of Tight Sandstone Reservoirs: Insight from Triassic Tight Sandstones in the Huaqing Area, Ordos Basin, Northern China. J. Asian Earth Sci. 2022, 229, 105099. [Google Scholar] [CrossRef]

- Zheng, R.; Pan, J.; Cai, G.; Liang, J.; Liu, D.; Song, Q.; Yao, Q. Effects of Clay Minerals on the Low-Temperature Oxidation of Heavy Oil. Fuel 2019, 254, 115597. [Google Scholar] [CrossRef]

- Bai, Y.; Sui, H.; Liu, X.; He, L.; Li, X.; Thormann, E. Effects of the N, O, and S Heteroatoms on the Adsorption and Desorption of Asphaltenes on Silica Surface: A Molecular Dynamics Simulation. Fuel 2019, 240, 252–261. [Google Scholar] [CrossRef]

- Cai, J.; Lu, L.; Ding, F.; Fan, F. Significance of Interaction Between Soluble Organic Matter and Clay Minerals in Muddy Source Rocks. J. Tongji Univ. Sci. 2009, 37, 1679–1684. [Google Scholar] [CrossRef]

- Hemmati-Sarapardeh, A.; Dabir, B.; Ahmadi, M.; Mohammadi, A.H.; Husein, M.M. Toward Mechanistic Understanding of Asphaltene Aggregation Behavior in Toluene: The Roles of Asphaltene Structure, Aging Time, Temperature, and Ultrasonic Radiation. J. Mol. Liq. 2018, 264, 410–424. [Google Scholar] [CrossRef]

- Craddock, P.R.; Le Doan, T.V.; Bake, K.; Polyakov, M.; Charsky, A.M.; Pomerantz, A.E. Evolution of Kerogen and Bitumen during Thermal Maturation via Semi-Open Pyrolysis Investigated by Infrared Spectroscopy. Energy Fuels 2015, 29, 2197–2210. [Google Scholar] [CrossRef]

- Chen, Q.; Yang, H.J.; Liu, H.; Liu, Y.; Zhao, D.F. Spatially Resolved Micron-Scale Wrinkle Structures at Asphaltene Films Induced by Mild Thermal Treatment and Its Impact on Emulsion Stability. Pet. Sci. 2022, 19, 3107–3115. [Google Scholar] [CrossRef]

- Yang, Z.; Zou, C.; Hou, L.; Wu, S.; Lin, S.; Luo, X.; Zhang, L.; Zhao, Z.; Cui, J.; Pan, S. Division of Fine-Grained Rocks and Selection of “Sweet Sections” in the Oldest Continental Shale in China: Taking the Coexisting Combination of Tight and Shale Oil in the Permian Junggar Basin. Mar. Pet. Geol. 2019, 109, 339–348. [Google Scholar] [CrossRef]

- Wang, C.; Li, T.; Gao, H.; Zhao, J.; Li, H.A. Effect of Asphaltene Precipitation on CO2-Flooding Performance in Low-Permeability Sandstones: A Nuclear Magnetic Resonance Study. RSC Adv. 2017, 7, 38367–38376. [Google Scholar] [CrossRef]

- Boczkaj, G.; Makoś, P.; Przyjazny, A. Application of Dispersive Liquid–Liquid Microextraction and Gas Chromatography with Mass Spectrometry for the Determination of Oxygenated Volatile Organic Compounds in Effluents from the Production of Petroleum Bitumen. J. Sep. Sci. 2016, 39, 2604–2615. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, L.; Lu, X.; Shi, C.; Tang, T.; Wang, X.; Huang, Q.; Zeng, H. Adsorption Kinetics of Asphaltenes at Oil/Water Interface: Effects of Concentration and Temperature. Fuel 2018, 212, 387–394. [Google Scholar] [CrossRef]

| Sample | Depth (m) | Porosity (%) | Permeability (×10−3 μm2) | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 2138.10 | 15.00 | 1.250 | 58.4 | 26.8 | - | 14.4 | 3.15 | 1.44 | 9.81 |

| S2 | 2185.60 | 12.99 | 0.754 | 48.4 | 32.0 | 4.5 | 12.9 | 1.97 | 1.65 | 9.29 |

| S3 | 2062.20 | 10.46 | 0.741 | 59.0 | 29.3 | 0.6 | 9.5 | 2.14 | 0.74 | 6.63 |

| S4 | 2133.45 | 14.09 | 0.725 | 49.6 | 33.7 | 0.1 | 15.7 | 4.88 | 1.57 | 9.25 |

| S5 | 2187.45 | 11.68 | 0.568 | 54.8 | 34.6 | 2.2 | 7.5 | 0.15 | 0.63 | 6.73 |

| S6 | 2288.00 | 13.00 | 0.542 | 50.7 | 38.0 | 0.9 | 9.0 | 2.39 | 0.77 | 5.84 |

| S7 | 2192.60 | 11.08 | 0.521 | 50.3 | 33.1 | 1.9 | 12.7 | 2.92 | 2.03 | 7.75 |

| S8 | 2228.33 | 12.15 | 0.431 | 39.6 | 40.2 | 0.2 | 11.4 | 1.48 | 1.14 | 8.78 |

| S9 | 2242.40 | 10.20 | 0.406 | 50.1 | 36.0 | 3.8 | 9.9 | 2.49 | 0.99 | 6.43 |

| S10 | 2031.65 | 12.53 | 0.316 | 39.6 | 36.7 | 0.5 | 10.4 | 3.54 | 0.94 | 5.93 |

| S11 | 2036.85 | 7.88 | 0.120 | 39.1 | 36.0 | 7.3 | 10.6 | 3.60 | 1.17 | 5.83 |

| S12 | 2213.35 | 6.33 | 0.037 | 30.5 | 33.6 | 12.1 | 12.1 | 2.90 | 2.30 | 6.90 |

| Microscale Pores | Nanoscale Pores | Mineral Surfaces | |

|---|---|---|---|

| RN−H or RO−H index | 0.81 | 1.13 | 14.86 |

| Aliphatic branching index | 0.84 | 0.84 | 1.15 |

| Aromatic index | 0.46 | 0.58 | 0.35 |

| Aliphatic index | 0.17 | 0.16 | 0.13 |

| Long-chain index | 0.11 | 0.1 | 0.55 |

| Microscale Pores | Nanoscale Pores | Mineral Surfaces | |||

|---|---|---|---|---|---|

| Wavelength (cm−1) | Intensity (%) | Wavelength (cm−1) | Intensity (%) | Wavelength (cm−1) | Intensity (%) |

| 713 | 1.5 | 695 | 0.51 | 695 | 1.99 |

| 726 | 1.53 | 728 | 1.2 | 728 | 2.75 |

| 769 | 1.92 | 765 | 1.58 | 780 | 5.87 |

| 781 | 2.06 | 780 | 1.79 | ||

| 827 | 0.58 | 878 | 4.04 | ||

| 878 | 4.29 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Han, M.; Zhou, Q.; Ye, T.; Zhou, Y.; Chang, J.; Lin, X. The Micro-Occurrence Mechanisms of Tight Oil: Fluid–Rock Interactions at Microscale Pores, Nanoscale Pores, and Mineral Surfaces. Energies 2023, 16, 3917. https://doi.org/10.3390/en16093917

Zhang D, Han M, Zhou Q, Ye T, Zhou Y, Chang J, Lin X. The Micro-Occurrence Mechanisms of Tight Oil: Fluid–Rock Interactions at Microscale Pores, Nanoscale Pores, and Mineral Surfaces. Energies. 2023; 16(9):3917. https://doi.org/10.3390/en16093917

Chicago/Turabian StyleZhang, Dongwei, Meng Han, Qianshan Zhou, Tianrui Ye, Yujie Zhou, Ji Chang, and Xiaohui Lin. 2023. "The Micro-Occurrence Mechanisms of Tight Oil: Fluid–Rock Interactions at Microscale Pores, Nanoscale Pores, and Mineral Surfaces" Energies 16, no. 9: 3917. https://doi.org/10.3390/en16093917