Oxygen Carrier Circulation Rate for Novel Cold Flow Chemical Looping Reactors

Abstract

:1. Introduction

2. Materials and Methods

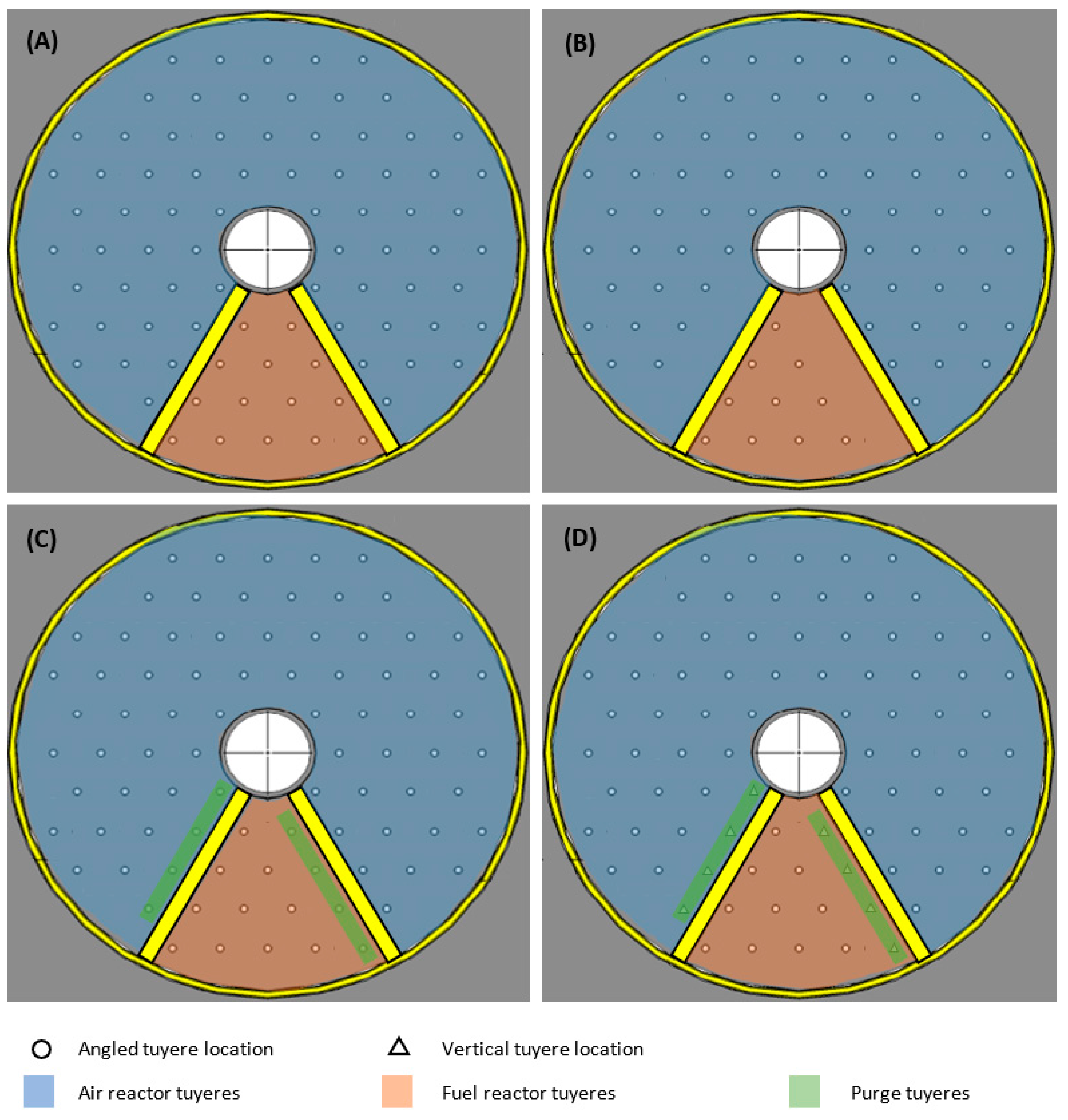

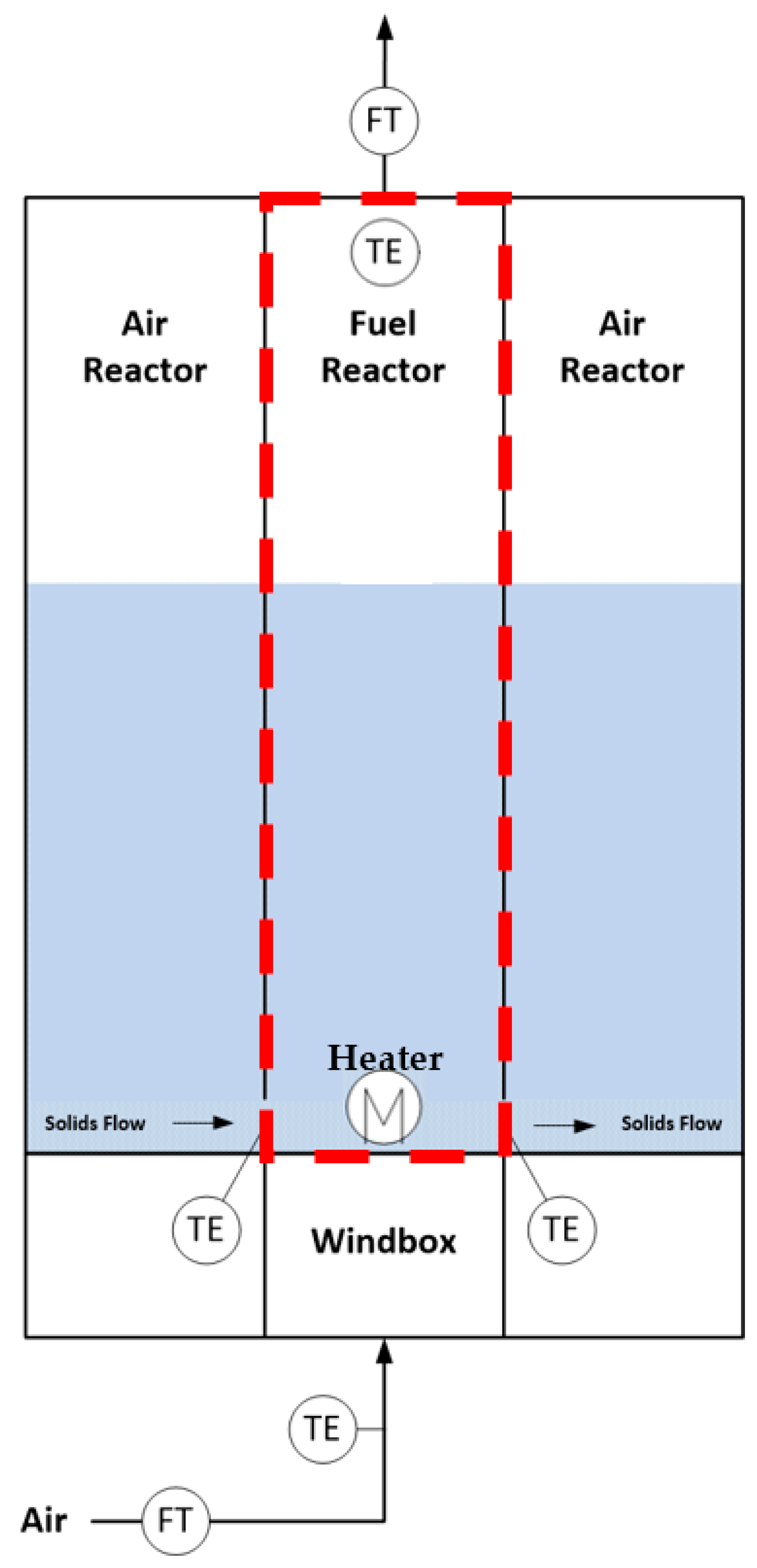

2.1. Experimental Setup of the PFIR Column

2.2. Solid Circulation Rate Measurement Methodology

3. Results and Discussion

3.1. Static Bed Height

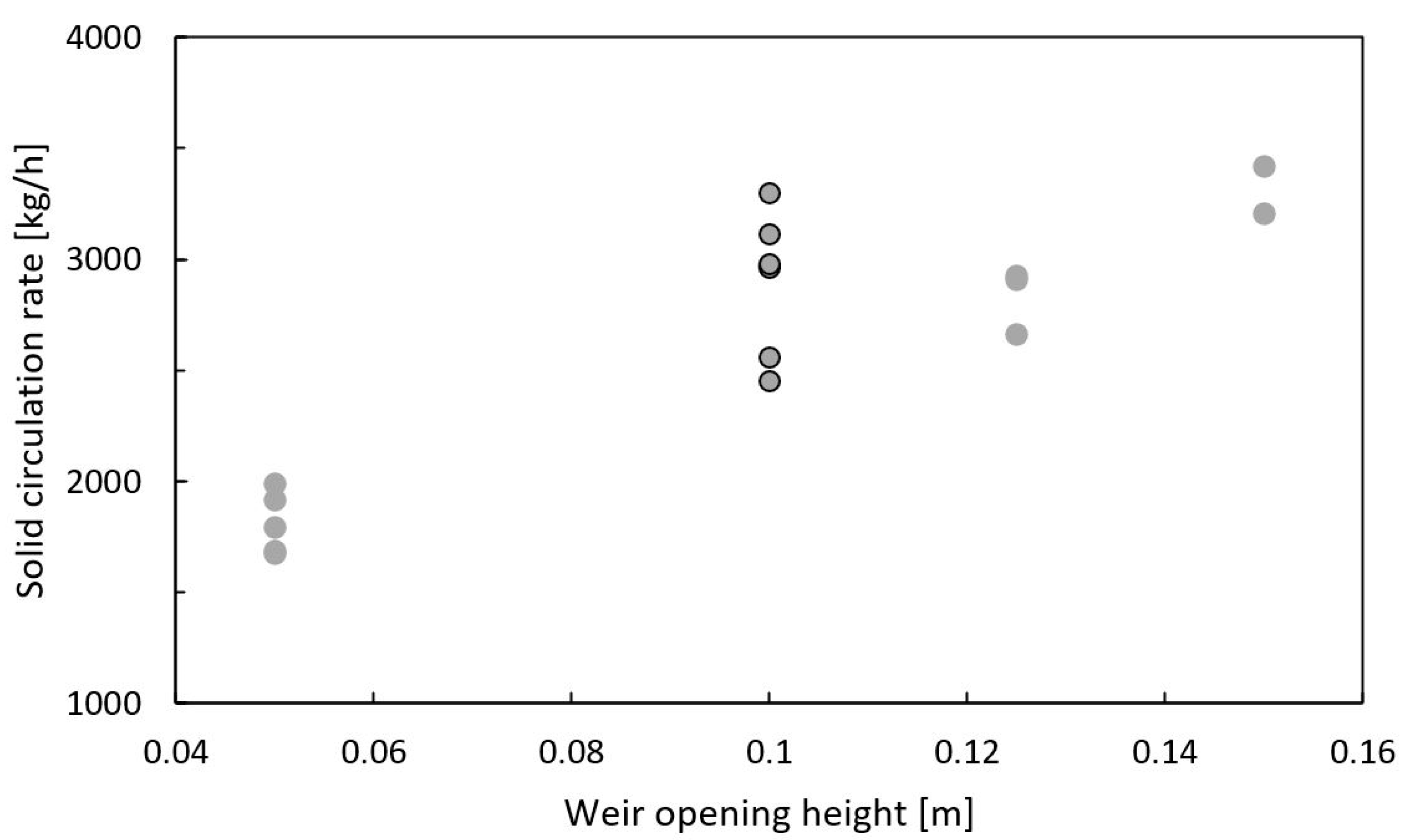

3.2. Weir Opening Height

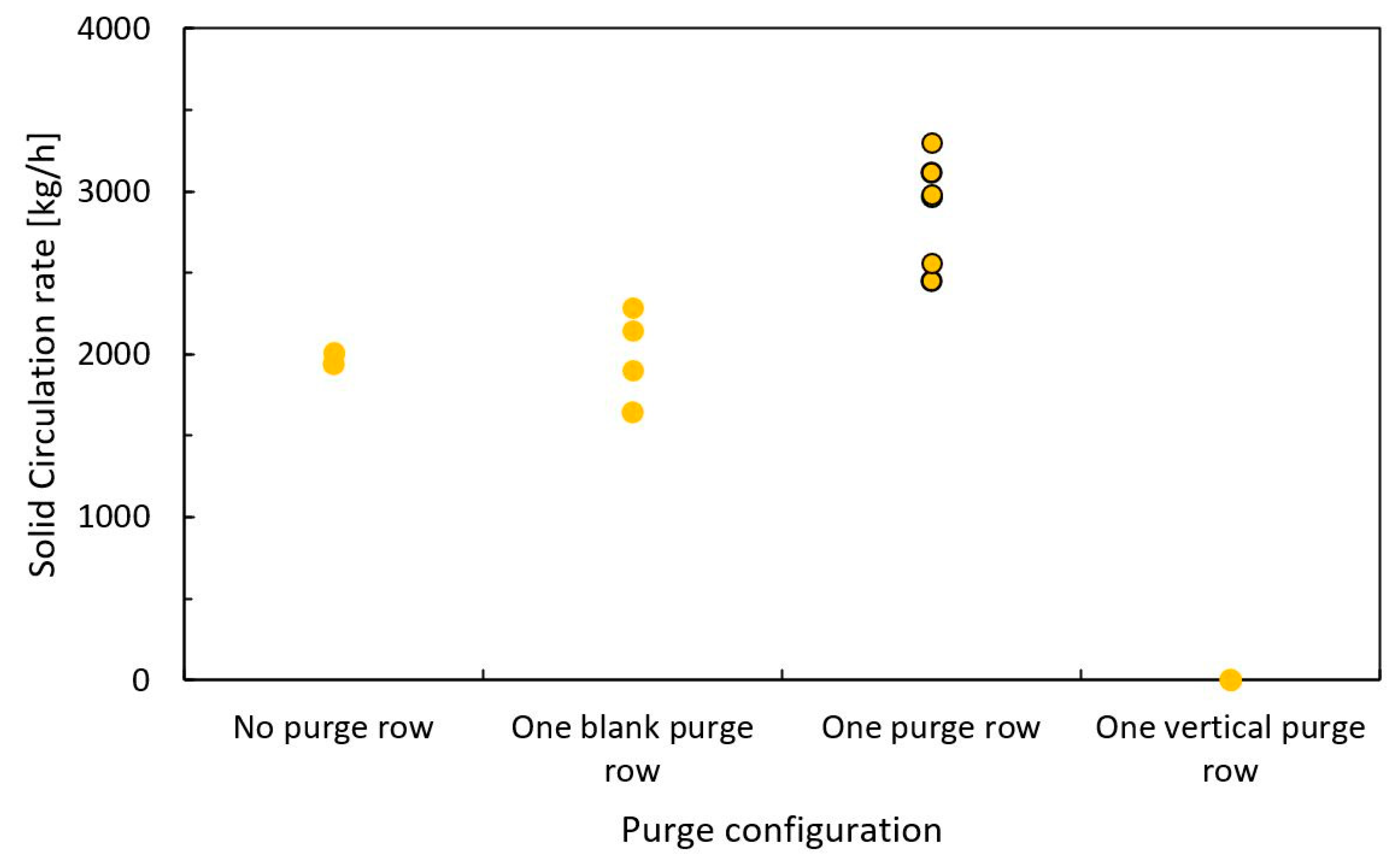

3.3. Purge Configuration

3.4. Fluidization Ratio/Jet Velocity

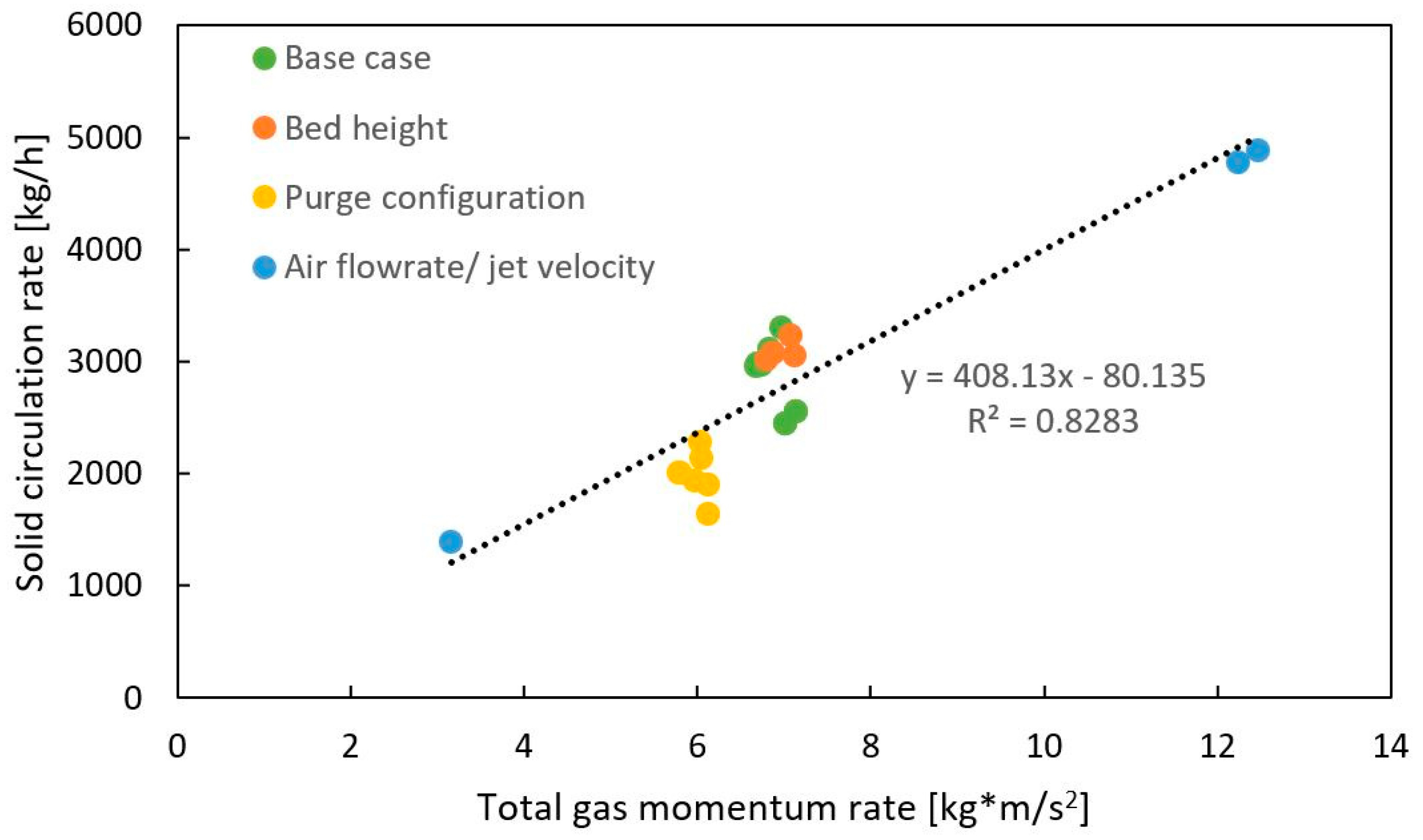

3.5. Relationship between Solid Circulation Rate and Total Gas Momentum

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Environment and Climate Change Canada Greenhouse Gas Reporting Program (GHGRP)—Facility Greenhouse Gas (GHG) Data. 2018. Available online: https://open.canada.ca/data/en/dataset/a8ba14b7-7f23-462a-bdbb-83b0ef629823 (accessed on 19 April 2023).

- Panja, P.; McPherson, B.; Deo, M. Techno-Economic Analysis of Amine-Based CO2 Capture Technology: Hunter Plant Case Study. Carbon Capture Sci. Technol. 2022, 3, 100041–100049. [Google Scholar] [CrossRef]

- Symonds, R.T.; Hughes, R.W.; De Las Obras Loscertales, M. Oxy-Pressurized Fluidized Bed Combustion: Configuration and Options Analysis. Appl. Energy 2020, 262, 114531. [Google Scholar] [CrossRef]

- Zhao, J.; Ma, L.; Zayed, M.E.; Elsheikh, A.H.; Li, W.; Yan, Q.; Wang, J. Industrial Reheating Furnaces: A Review of Energy Efficiency Assessments, Waste Heat Recovery Potentials, Heating Process Characteristics and Perspectives for Steel Industry. Process Saf. Environ. Prot. 2021, 147, 1209–1228. [Google Scholar] [CrossRef]

- Yun, S.; Lee, J.; Cho, H.; Kim, J. Oxy-Fuel Combustion-Based Blue Hydrogen Production with the Integration of Water Electrolysis. Energy Convers. Manag. 2023, 291, 117275. [Google Scholar] [CrossRef]

- Zanco, S.E.; Pérez-Calvo, J.-F.; Gasós, A.; Cordiano, B.; Becattini, V.; Mazzotti, M. Postcombustion CO2 Capture: A Comparative Techno-Economic Assessment of Three Technologies Using a Solvent, an Adsorbent, and a Membrane. ACS Eng. Au 2021, 1, 50–72. [Google Scholar] [CrossRef]

- Lyngfelt, A. Oxygen Carriers for Chemical-Looping Combustion. In Calcium and Chemical Looping Technology for Power Generation and Carbon Dioxide (CO2) Capture; Fennell, P., Anthony, B., Eds.; Elsevier: Sawston, UK, 2015; pp. 221–254. ISBN 978-0-85709-243-4. [Google Scholar]

- Daneshmand-Jahromi, S.; Sedghkerdar, M.H.; Mahinpey, N. A Review of Chemical Looping Combustion Technology: Fundamentals, and Development of Natural, Industrial Waste, and Synthetic Oxygen Carriers. Fuel 2023, 341, 127626. [Google Scholar] [CrossRef]

- Abuelgasim, S.; Wang, W.; Abdalazeez, A. A Brief Review for Chemical Looping Combustion as a Promising CO2 Capture Technology: Fundamentals and Progress. Sci. Total Environ. 2021, 764, 142892. [Google Scholar] [CrossRef] [PubMed]

- Pröll, T. Fundamentals of Chemical Looping Combustion and Introduction to CLC Reactor Design. In Calcium and Chemical Looping Technology for Power Generation and Carbon Dioxide (CO2) Capture; Fennell, P., Anthony, B., Eds.; Elsevier: Sawston, UK, 2015; pp. 197–219. ISBN 978-0-85709-243-4. [Google Scholar]

- Mission Innovation. Report of the Mission Innovation Carbon Capture, Utilization, and Storage Experts’ Workshop; Accelerating Breakthrough Innovation in Carbon Capture, Utilization, and Storage: Houston, TX, USA, 2017; pp. 1–291. [Google Scholar]

- Czakiert, T.; Krzywanski, J.; Zylka, A.; Nowak, W. Chemical Looping Combustion: A Brief Overview. Energies 2022, 15, 1563. [Google Scholar] [CrossRef]

- Di Giuliano, A.; Capone, S.; Anatone, M.; Gallucci, K. Chemical Looping Combustion and Gasification: A Review and a Focus on European Research Projects. Ind. Eng. Chem. Res. 2022, 61, 14403–14432. [Google Scholar] [CrossRef]

- Son, S.R.; Kim, S.D. Chemical-Looping Combustion with NiO and Fe2O3 in a Thermobalance and Circulating Fluidized Bed Reactor with Double Loops. Ind. Eng. Chem. Res. 2006, 45, 2689–2696. [Google Scholar] [CrossRef]

- Rydén, M.; Moldenhauer, P.; Mattisson, T.; Lyngfelt, A.; Younes, M.; Niass, T.; Fadhel, B.; Ballaguet, J.-P. Chemical-Looping Combustion with Liquid Fuels. Energy Procedia. 2013, 37, 654–661. [Google Scholar] [CrossRef]

- Moldenhauer, P.; Linderholm, C.; Rydén, M.; Lyngfelt, A. Avoiding CO2 Capture Effort and Cost for Negative CO2 Emissions Using Industrial Waste in Chemical-Looping Combustion/Gasification of Biomass. Mitig. Adapt. Strateg. Glob. Chang. 2020, 25, 1–24. [Google Scholar] [CrossRef]

- Chen, C.; Chen, C.-H.; Chang, M.-H.; Lee, H.-H.; Chang, Y.-C.; Wen, T.-W.; Shen, C.-H.; Wan, H.-P. A 30-kWth Moving-Bed Chemical Looping System for Hydrogen Production. Int. J. Greenh. Gas. Control 2020, 95, 102954–102960. [Google Scholar] [CrossRef]

- Zhang, Q.; Joshi, R.K.; Xu, D.; Tong, A.; Fan, L.-S. A Novel Moving Bed Chemical Looping Process with Integration of Combustor Heat Exchangers for Hydrogen Production: Process Simulation and Techno-Economic Analysis. Int. J. Hydrogen Energy 2024, 49, 823–839. [Google Scholar] [CrossRef]

- Noorman, S.; van Sint Annaland, M. Kuipers Packed Bed Reactor Technology for Chemical-Looping Combustion. Ind. Eng. Chem. Res. 2007, 46, 4212–4220. [Google Scholar] [CrossRef]

- Abanades, J.C.; Diego, M.E.; Fernández, J.R. A Novel Air Reactor Concept for Chemical Looping Combustion Systems Operated at High Pressure. Chem. Eng. J 2020, 390, 124507. [Google Scholar] [CrossRef]

- Diego, M.E.; Abanades, J.C. Experimental Investigation of a Diffusion-Controlled Chemical Looping Air Reactor for Energy Storage Applications. Chem. Eng. J. 2022, 428, 132083–132091. [Google Scholar] [CrossRef]

- Dahl, I.M.; Bakken, E.; Larring, Y.; Spjelkavik, A.I.; Håkonsen, S.F.; Blom, R. On the Development of Novel Reactor Concepts for Chemical Looping Combustion. Energy Procedia. 2009, 1, 1513–1519. [Google Scholar] [CrossRef]

- Håkonsen, S.F.; Blom, R. Chemical Looping Combustion in a Rotating Bed Reactor—Finding Optimal Process Conditions for Prototype Reactor. Environ. Sci. Technol. 2011, 45, 9619–9626. [Google Scholar] [CrossRef]

- Adham, K.; Harris, C.T.; Kokourine, A. Plug Flow Reactor with Internal Recirculation Fluidized Bed. 2017. CA 2951724 C, 8 May 2015. [Google Scholar]

- Alain, A.; Bond, N.; Champagne, S.; McIntyre, C.; Francey, S.; Macchi, A.; Hughes, R. Impact of Gas Distributor on Hydrodynamics in a Cold Flow Annular Dual Fluidized Bed for Pressurized Chemical Looping. In Proceedings of the Fluidized Bed Conversion Conference 2022, Gothenburg, Sweden, 8–11 May 2022; pp. 1–9. [Google Scholar]

- Riley, J.; Siriwardane, R.; Poston, J. Bench Scale Analysis of the Physical Attrition Properties for Copper-Ferri-Aluminate Oxygen Carriers during Chemical Looping Combustion. Powder Technol. 2020, 366, 891–905. [Google Scholar] [CrossRef]

- Reppenhagen, J.; Werther, J. Catalyst Attrition in Cyclones. Powder Technol. 2000, 113, 55–69. [Google Scholar] [CrossRef]

- Werther, J.; Reppenhagen, J. Catalyst Attrition in Fluidized-Bed Systems. AIChE J. 1999, 45, 2001–2010. [Google Scholar] [CrossRef]

- Kramp, M.; Thon, A.; Hartge, E.-U.; Heinrich, S.; Werther, J. The Role of Attrition and Solids Recovery in a Chemical Looping Combustion Process. Oil Gas Sci. Technol. 2011, 66, 277–290. [Google Scholar] [CrossRef]

- Grochowalski, J.; Widuch, A.; Sładek, S.; Melka, B.; Nowak, M.; Klimanek, A.; Andrzejczyk, M.; Klajny, M.; Czarnowska, L.; Hernik, B.; et al. Technique for Reducing Erosion in Large-Scale Circulating Fluidized Bed Units. Powder Technol. 2023, 426, 118651–118666. [Google Scholar] [CrossRef]

- Wang, Q.; Luo, Z.; Fang, M.; Ni, M.; Cen, K. Development of a New External Heat Exchanger for a Circulating Fluidized Bed Boiler. Chem. Eng. Process 2003, 42, 327–335. [Google Scholar] [CrossRef]

- Bai, R.; Zhou, T.; Zhang, M.; Zhu, S.; Yang, H. Time-Scaled Study on the Erosion in Circulating Fluidized Bed Based on CPFD Method. Powder Technol. 2023, 430, 118830–118839. [Google Scholar] [CrossRef]

- McIntyre, C. CPFD Modeling of a Novel Internally Circulating Bubbling Fluidized Bed for Chemical Looping Combustion; Université d’Ottawa/University of Ottawa: Ottawa, ON, Canada, 2021. [Google Scholar]

- Patil, D.J.; Van Sint Annaland, M.; Kuipers, J.A.M. Critical Comparison of Hydrodynamic Models for Gas–Solid Fluidized Beds—Part I: Bubbling Gas–Solid Fluidized Beds Operated with a Jet. Chem. Eng. Sci. 2005, 60, 57–72. [Google Scholar] [CrossRef]

- Adham, K.; Harris, C.; Kokourine, A. Modeling and Process Features of Plug Flow Reactor with Internal Recirculation for Biomass Pyrolysis. J. Chem. Eng. Process Technol. 2017, 08, 1000353–1000358. [Google Scholar] [CrossRef]

- South Florida Water Management District. Atlas of Flow Computations at District Hydraulic Structures in the South Florida Water Management District. Available online: https://www.sfwmd.gov/sites/default/files/documents/atlas_of_flow_computation_at_sfwmd_hydraulic_structures.pdf (accessed on 24 November 2023).

- Salatino, P.; Marzocchella, A.; Bareschino, P. Fluidization in Nature: Pyroclastic Flows. In Proceedings of the Presented at the Fluidization XVII Conference, Edinburgh, Scotland, 21–25 May 2023. [Google Scholar]

| Parameter | Value/Configuration | Base Case |

|---|---|---|

| Static bed height | 0.25 m, 0.35 m, 0.5 m | 0.5 m |

| Weir opening height | 0.05 m, 0.1 m, 0.125 m, 0.15 m | 0.1 m |

| Purge configuration | No purge row Blanked purge row One purge row One vertical purge row | One purge row |

| Fluidization ratio [jet velocity] | 2 U/Umf [43 m/s], 3 U/Umf [65 m/s], 4 U/Umf [86 m/s] | 3 U/Umf [65 m/s] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alain, A.E.; Bond, N.K.; Champagne, S.; Hughes, R.W.; Macchi, A. Oxygen Carrier Circulation Rate for Novel Cold Flow Chemical Looping Reactors. Energies 2024, 17, 198. https://doi.org/10.3390/en17010198

Alain AE, Bond NK, Champagne S, Hughes RW, Macchi A. Oxygen Carrier Circulation Rate for Novel Cold Flow Chemical Looping Reactors. Energies. 2024; 17(1):198. https://doi.org/10.3390/en17010198

Chicago/Turabian StyleAlain, Amanda E., Nicole K. Bond, Scott Champagne, Robin W. Hughes, and Arturo Macchi. 2024. "Oxygen Carrier Circulation Rate for Novel Cold Flow Chemical Looping Reactors" Energies 17, no. 1: 198. https://doi.org/10.3390/en17010198

APA StyleAlain, A. E., Bond, N. K., Champagne, S., Hughes, R. W., & Macchi, A. (2024). Oxygen Carrier Circulation Rate for Novel Cold Flow Chemical Looping Reactors. Energies, 17(1), 198. https://doi.org/10.3390/en17010198