A Comparative Investigation of the Emissions of a Heavy-Duty Diesel Engine under World Harmonized Transient Cycle and Road Spectrum Cycle

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Tested Engine and Vehicle

2.2. Experimental Instruments

2.3. Experimental Scenarios and Procedures

- The truck was driven between the point of departure (Taojia Twon of Chongqing City, China) and the destination position (Qingmuguan Twon of Chongqing City, China), which comprised a typical path for the truck’s application. The entire trip took ~3000 s, including about 20% urban roads, 25% suburb roads, and 55% motorways (required by GB 1769-2018 [10]). While EU standards require the inclusion of 30% urban driving, 25% rural driving, and 45% motorway driving for PEMS testing, we referred to the Chinese standard in these aspects because this vehicle type is used in China.

- The average speed required by the Chinese standard is 13–30 km/h, 45–70 km/h, and >70 km/h with respect to urban–rural driving, rural driving, and motorway driving, respectively. Our road test’s average speed was 27 km/h, 63 km/h, and 83 km/h for the above three phases, respectively. Of course, EU standards regulate higher average speeds for each driving phase, and again, we used the Chinese standard in this respect.

- At the beginning of the test, the atmospheric pressure was 97.2 kPa, relative humidity was 46.9%, and the temperature was 28 °C. All these parameters meet the requirements of both standards. Then, according to the standard, the vehicle was warmed up until the coolant temperature reached 70 °C and the test began.

- The standard required that the vehicle loading rate should be between 10 and 100% of the maximum cargo capacity. During road driving, the truck was loaded at 11.1% of the maximum cargo capacity.

3. Results and Discussion

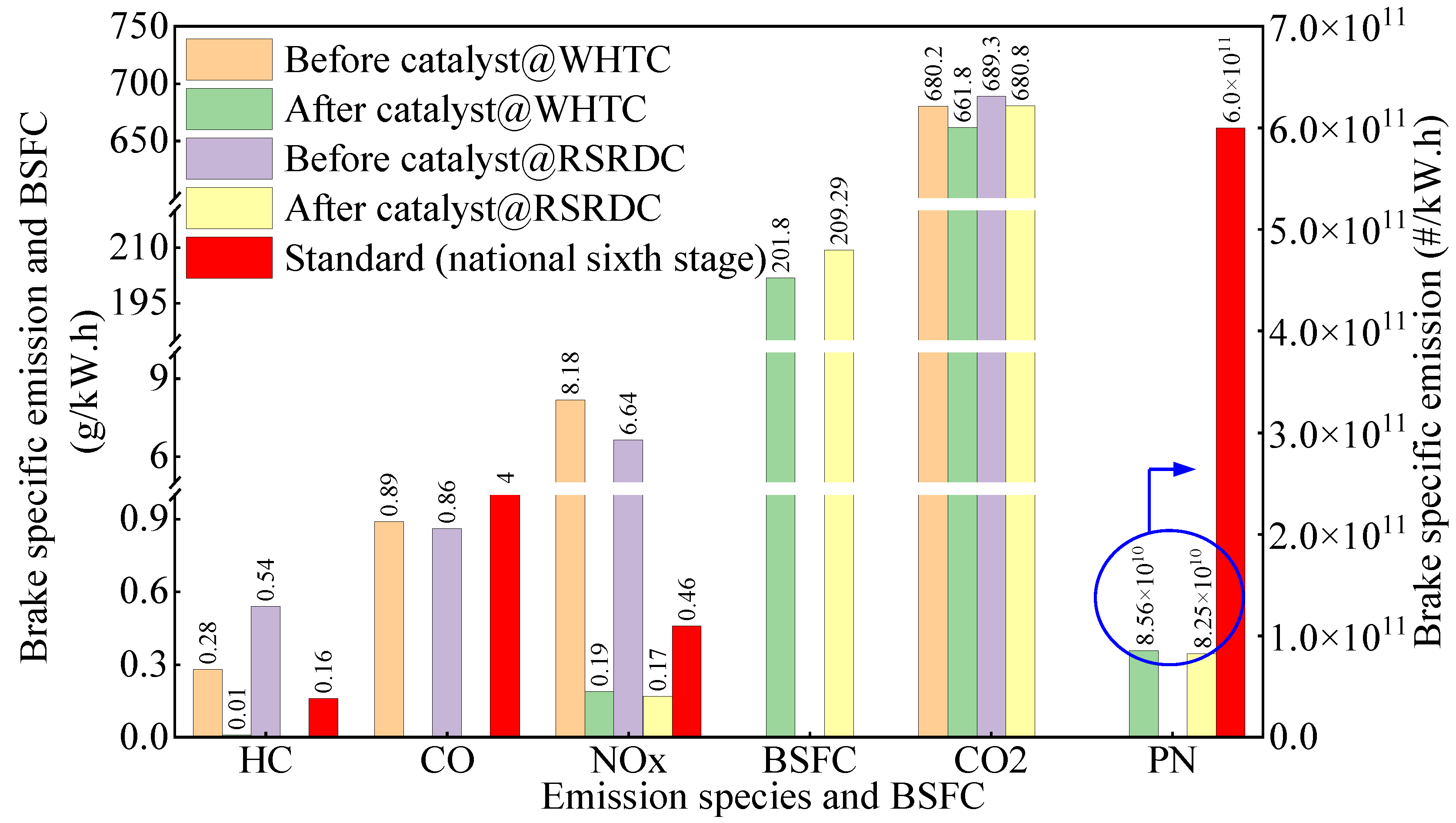

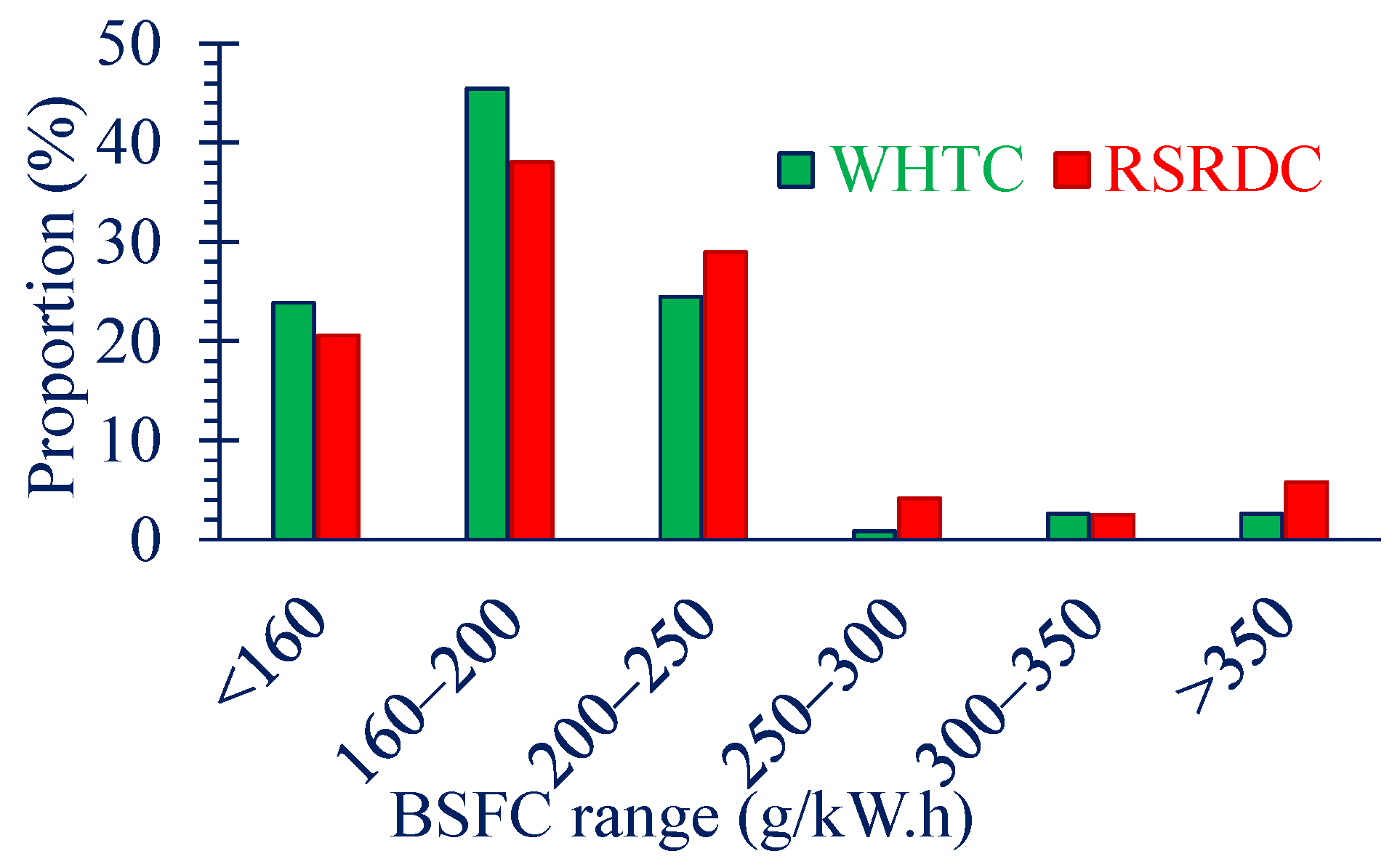

3.1. Fuel Consumption and Specific Emissions

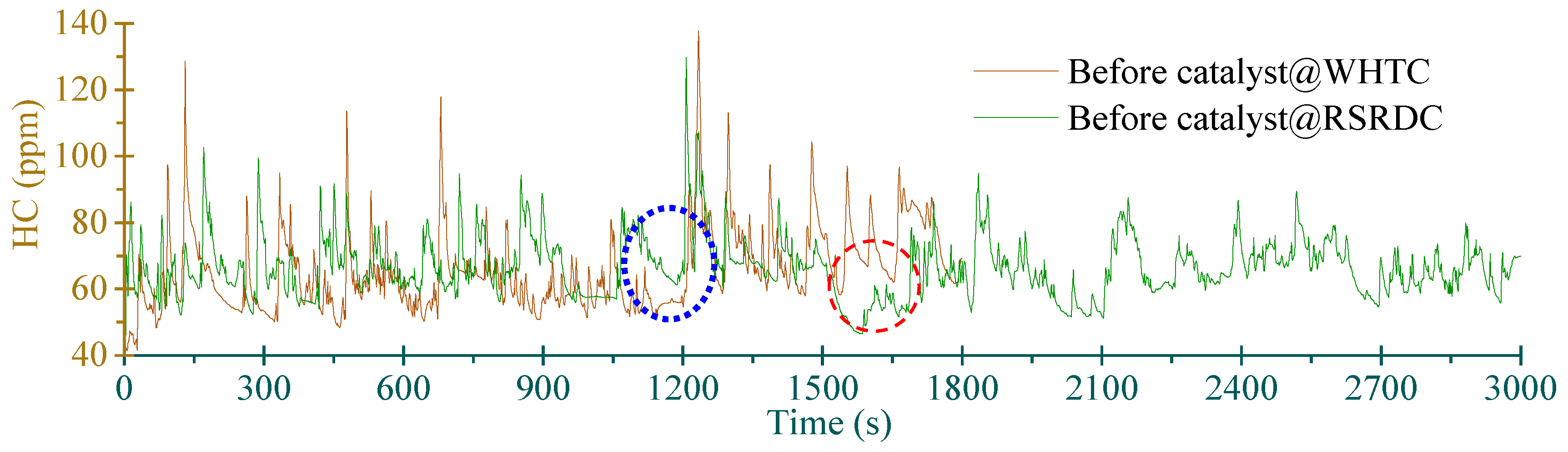

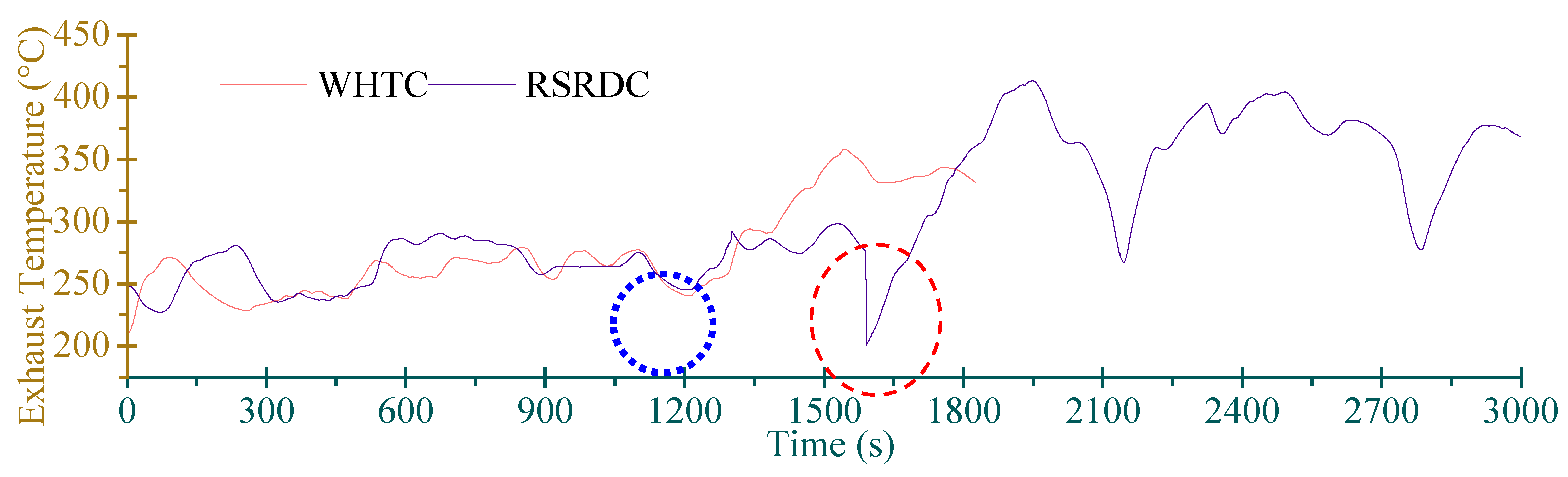

3.2. Transient Emissions: HC

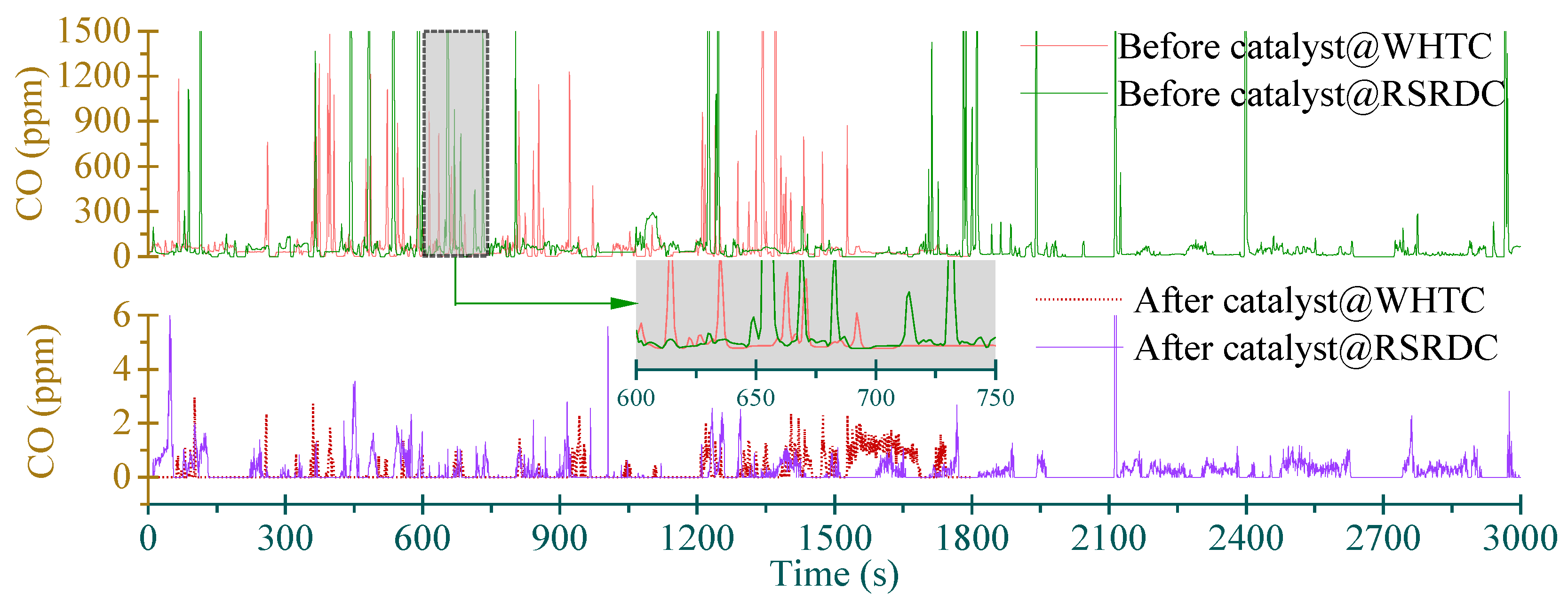

3.3. Transient Emissions: CO

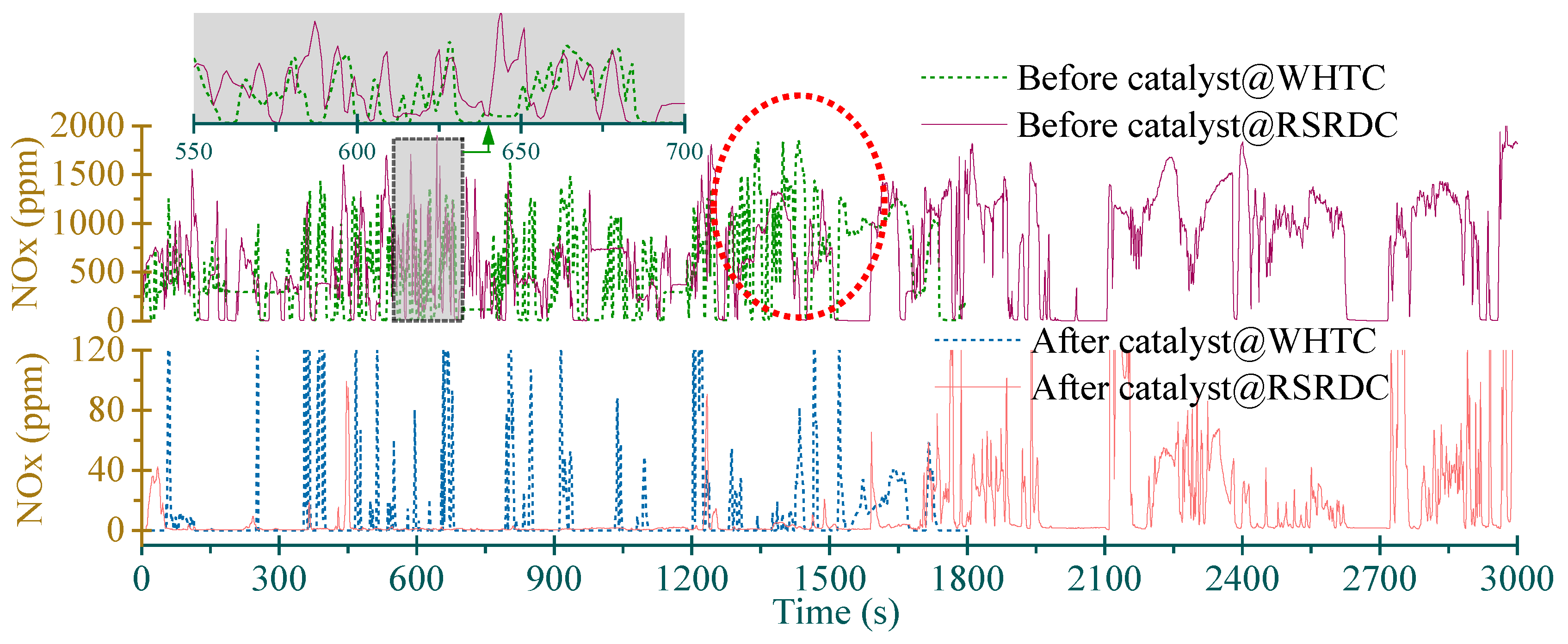

3.4. Transient Emissions: NOx

3.5. Transient Emissions: PN

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| WHTC | world harmonized transient cycle |

| RSRDC | road spectrum reversely deduced cycle |

| ICEs | internal combustion engines |

| CO | carbon monoxide |

| HC | hydrocarbon |

| THC | total hydrocarbon |

| NOx | oxynitride |

| PM | particulate matter |

| PN | particle number |

| EU | European Union |

| NEDC | new European driving cycle |

| WLTP | worldwide harmonized light-duty test procedure |

| DOC | diesel oxidation catalyst |

| WHVC | world harmonized vehicle cycle |

| VECTO | vehicle energy consumption calculation tool |

| DMDF | dual-mode dual-fuel |

| RCCI | reactivity-controlled compression ignition |

| CDC | conventional diesel combustion |

| LPG | liquefied petroleum gas |

| PEMS | portable emissions measurement system |

| OBM | on-board monitoring |

| DPF | diesel particulate filter |

| SCR | selective catalytic reduction |

| ASC | ammonia slip catalyst |

| EGR | exhaust gas recirculation |

| HDV | heavy-duty vehicle |

| GPS | global positioning system |

| OBD | on-board diagnostics |

| FID | flame ionization detector |

| NMHC | non-methane hydrocarbon |

| NMC-FID | flame ionization detector with non-methane cutter |

| NDIR | non-dispersive infrared |

| CLD | chemiluminescence detector |

| BSE | brake-specific emission |

| BSFC | brake-specific fuel consumption |

| EC | elemental carbon |

| PAHs | polycyclic aromatic hydrocarbons |

References

- Duan, X.; Feng, L.; Liu, H.; Jiang, P.; Chen, C.; Sun, Z. Experimental investigation on exhaust emissions of a heavy-duty vehicle powered by a methanol-fuelled spark ignition engine under world Harmonized Transient Cycle and actual on-road driving conditions. Energy 2023, 282, 128869. [Google Scholar] [CrossRef]

- Deng, B.; Chen, Z.; Sun, C.; Zhang, S.; Yu, W.; Huang, M.; Hou, K.; Ran, J.; Zhou, L.; Chen, C.; et al. Key design and layout factors influencing performance of three-way catalytic converters: Experimental and semidecoupled numerical study under real-life driving conditions. J. Clean. Prod. 2023, 425, 138993. [Google Scholar] [CrossRef]

- China Mobile Source Environmental Management Annual Report. Ministry of Ecology and Environment of the People’s Republic of China. 2022. Available online: https://www.mee.gov.cn/hjzl/sthjzk/ydyhjgl/202212/t20221207_1007111.shtml (accessed on 28 April 2023). (In Chinese)

- Wu, Y.; Zhang, S.; Hao, J.; Liu, H.; Wu, X.; Hu, J.; Walsh, M.P.; Wallington, T.J.; Zhang, K.M.; Stevanovic, S. On-road vehicle emissions and their control in China: A review and outlook. Sci. Total Environ. 2017, 574, 332–349. [Google Scholar] [CrossRef] [PubMed]

- Costagliola, M.A.; Costabile, M.; Prati, M.V. Impact of road grade on real driving emissions from two Euro 5 diesel vehicles. Appl. Energy 2018, 231, 586–593. [Google Scholar] [CrossRef]

- Gordon, T.D.; Presto, A.A.; Nguyen, N.T.; Robertson, W.H.; Na, K.; Sahay, K.N.; Zhang, M.; Maddox, C.; Rieger, P.; Chattopadhyay, S.; et al. Secondary organic aerosol production from diesel vehicle exhaust: Impact of aftertreatment, fuel chemistry and driving cycle. Atmos. Meas. Tech. 2014, 14, 4643–4659. [Google Scholar] [CrossRef]

- Giraldo, M.; Huertas, J.I. Real emissions, driving patterns and fuel consumption of in-use diesel buses operating at high altitude. Transp. Res. Part D 2019, 77, 21–36. [Google Scholar] [CrossRef]

- Shahariar, G.H.; Bodisco, T.A.; Zare, A.; Sajjad, M.; Jahirul, M.; Van, T.C.; Bartlett, H.; Ristovski, Z.; Brown, R.J. Impact of driving style and traffic condition on emissions and fuel consumption during real-world transient operation. Fuel 2022, 319, 123874. [Google Scholar] [CrossRef]

- Bodisco, T.; Zare, A. Practicalities and Driving Dynamics of a Real Driving Emissions (RDE) Euro 6 Regulation Homologation Test. Energies 2019, 12, 2306. [Google Scholar] [CrossRef]

- GB 17691-2018; Limits and Measurement Methods for Emissions from Diesel Fuelled Heavy-Duty Vehicles (CHINA VI). National Standard of The People’s Republic of China: Beijing, China, 2018. (In Chinese)

- Bai, S.; Han, J.; Liu, M.; Qin, S.; Wang, G.; Li, G. Experimental investigation of exhaust thermal management on NOx emissions of heavy-duty diesel engine under the world Harmonized transient cycle (WHTC). Appl. Therm. Eng. 2018, 142, 421–432. [Google Scholar] [CrossRef]

- Wu, D.; Deng, B.; Li, M.; Fu, J.; Hou, K. Improvements on performance and emissions of a heavy duty diesel engine by throttling degree optimization: A steady-state and transient experimental study. Chem. Eng. Process. Process. Intensif. 2020, 157, 108132. [Google Scholar] [CrossRef]

- Duan, L.-S.; Tan, P.-Q.; Liu, J.-T.; Liu, Y.; Chen, Y.-J.; Lou, D.-M.; Hu, Z.-Y. Emission characteristics of a diesel engine with an electrically heated catalyst under cold start conditions. J. Clean. Prod. 2022, 380, 134965. [Google Scholar] [CrossRef]

- Fontaras, G.; Grigoratos, T.; Savvidis, D.; Anagnostopoulos, K.; Luz, R.; Rexeis, M.; Hausberger, S. An experimental evaluation of the methodology proposed for the monitoring and certification of CO2 emissions from heavy-duty vehicles in Europe. Energy 2016, 102, 354–364. [Google Scholar] [CrossRef]

- García, A.; Monsalve-Serrano, J.; Roso, V.R.; Martins, M.E.S. Evaluating the emissions and performance of two dual-mode RCCI combustion strategies under the World Harmonized Vehicle Cycle (WHVC). Energy Convers. Manag. 2017, 149, 263–274. [Google Scholar] [CrossRef]

- Baek, S.; Kim, K.; Cho, J.; Myung, C.-L.; Park, S. Assessment of gaseous, particulate, and unregulated emissions from diesel compression ignition and LPG direct injection spark ignition minibus vehicles under the world harmonized vehicle cycle on a chassis dynamometer. Fuel 2021, 294, 120392. [Google Scholar] [CrossRef]

- Park, J.; Shin, M.; Lee, J.; Lee, J. Estimating the effectiveness of vehicle emission regulations for reducing NOx from light-duty vehicles in Korea using on-road measurements. Sci. Total Environ. 2021, 767, 144250. [Google Scholar] [CrossRef]

- O’Driscoll, R.; ApSimon, H.M.; Oxley, T.; Molden, N.; Stettler, M.E.; Thiyagarajah, A. A Portable Emissions Measurement System (PEMS) study of NOx and primary NO2 emissions from Euro 6 diesel passenger cars and comparison with COPERT emission factors. Atmos. Environ. 2016, 145, 81–91. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, P.; He, L.; Yang, Y.; Liu, B.; He, W.; Cheng, Y.; Liu, Y.; Liu, S.; Hu, Q.; et al. On-board monitoring (OBM) for heavy-duty vehicle emissions in China: Regulations, early-stage evaluation and policy recommendations. Sci. Total Environ. 2020, 731, 139045. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, L.; Yang, Z.; Zou, C.; Liu, X.; Zhang, K.; Mao, H. Characteristics of gaseous and particulate pollutants exhaust from logistics transportation vehicle on real-world conditions. Transp. Res. Part D 2016, 43, 40–48. [Google Scholar] [CrossRef]

- Yu, Q.; Yang, Y.; Xiong, X.; Sun, S.; Liu, Y.; Wang, Y. Assessing the impact of multi-dimensional driving behaviors on link-level emissions based on a Portable Emission Measurement System (PEMS). Atmos. Pollut. Res. 2021, 12, 414–424. [Google Scholar] [CrossRef]

- Yao, Z.; Wu, B.; Wu, Y.; Cao, X.; Jiang, X. Comparison of NOx emissions from China III and China IV in-use diesel trucks based on on-road measurements. Atmos. Environ. 2015, 123, 1–8. [Google Scholar] [CrossRef]

- Zhu, X.-H.; He, H.-D.; Lu, K.-F.; Peng, Z.-R.; Gao, H.O. Characterizing carbon emissions from China V and China VI gasoline vehicles based on portable emission measurement systems. J. Clean. Prod. 2022, 378, 134458. [Google Scholar] [CrossRef]

- Papadopoulos, G.; Ntziachristos, L.; Tziourtzioumis, C.; Keramydas, C.; Lo, T.-S.; Ng, K.-L.; Wong, H.-L.A.; Wong, C.K.-L. Real-world gaseous and particulate emissions from Euro IV to VI medium duty diesel trucks. Sci. Total Environ. 2020, 731, 139137. [Google Scholar] [CrossRef] [PubMed]

- Giechaskiel, B.; Schwelberger, M.; Delacroix, C.; Marchetti, M.; Feijen, M.; Prieger, K.; Andersson, S.; Karlsson, H.L. Experimental assessment of solid particle number Portable Emissions Measurement Systems (PEMS) for heavy-duty vehicles applications. J. Aerosol Sci. 2018, 123, 161–170. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Clairotte, M.; Valverde-Morales, V.; Bonnel, P.; Kregar, Z.; Franco, V.; Dilara, P. Framework for the assessment of PEMS (Portable Emissions Measurement Systems) uncertainty. Environ. Res. 2018, 166, 251–260. [Google Scholar] [CrossRef]

- Rodríguez, R.A.; Virguez, E.A.; Rodríguez, P.A.; Behrentz, E. Influence of driving patterns on vehicle emissions: A case study for Latin American cities. Transp. Res. Part D 2016, 43, 192–206. [Google Scholar] [CrossRef]

- Zhang, S.; Peng, D.; Li, Y.; Zu, L.; Fu, M.; Yin, H.; Ding, Y. Study on the real-world emissions of rural vehicles on different road types. Environ. Pollut. 2021, 273, 116453. [Google Scholar] [CrossRef] [PubMed]

- Lv, Z.F.; Zhang, Y.Z.; Ji, Z.; Deng, F.Y.; Shi, M.S.; Li, Q.W.; He, M.; Xiao, L.; Huang, Y.N.; Liu, H.; et al. A real-time NOx emission inventory from heavy-duty vehicles based on on-board diagnostics big data with acceptable quality in China. J. Clean. Prod. 2023, 422, 138592. [Google Scholar] [CrossRef]

- Malik, M.; Nandal, R. A framework on driving behavior and pattern using On-Board diagnostics (OBD-II) tool. Mater. Today: Proc. 2021, 80, 3762–3768. [Google Scholar] [CrossRef]

- EU: Heavy-Duty Truck and Bus Engines: OCE and ISC PEMS Testing. Available online: https://dieselnet.com/standards/eu/hd_isc.php (accessed on 1 December 2023).

- Zheng, X.; He, L.; He, X.; Zhang, S.; Cao, Y.; Hao, J.; Wu, Y. Real-Time Black Carbon Emissions from Light-Duty Passenger Vehicles Using a Portable Emissions Measurement System. Engineering 2022, 16, 73–81. [Google Scholar] [CrossRef]

- Mickūnaitis, V.; Pikūnas, A.; Mackoit, I. Reducing Fuel Consumption and CO2 Emission in Motor Cars. Transport 2007, 22, 160–163. [Google Scholar] [CrossRef]

- Shim, E.; Park, H.; Bae, C. Intake air strategy for low HC and CO emissions in dual-fuel (CNG-diesel) premixed charge com-pression ignition engine. Appl. Energy 2018, 225, 1068–1077. [Google Scholar] [CrossRef]

- Yildiz; Caliskan, H.; Mori, K. Effects of cordierite particulate filters on diesel engine exhaust emissions in terms of pollution prevention approaches for better environmental management. J. Environ. Manag. 2021, 293, 112873. [Google Scholar] [CrossRef] [PubMed]

- Iliyas; Zahedi-Niaki, H.M.; Eić, M. One-dimensional molecular sieves for hydrocarbon cold-start emission control: Influence of water and CO2. Appl. Catal. A Gen. 2010, 382, 213–219. [Google Scholar] [CrossRef]

- Iodice, P.; Senatore, A.; Langella, G.; Amoresano, A. Effect of ethanol–gasoline blends on CO and HC emissions in last generation SI engines within the cold-start transient: An experimental investigation. Appl. Energy 2016, 179, 182–190. [Google Scholar] [CrossRef]

- Kozina; Radica, G.; Nižetić, S. Analysis of methods towards reduction of harmful pollutants from diesel engines. J. Clean. Prod. 2020, 262, 121105. [Google Scholar] [CrossRef]

- Kang, S.B.; Hazlett, M.; Balakotaiah, V.; Kalamaras, C.; Epling, W. Effect of Pt:Pd ratio on CO and hydrocarbon oxidation. Appl. Catal. B Environ. 2018, 223, 67–75. [Google Scholar] [CrossRef]

- Schauer, J.J.; Kleeman, M.J.; Cass, G.R.; Simoneit, B.R.T. Measurement of Emissions from Air Pollution Sources. 2. C1 through C30 Organic Compounds from Medium Duty Diesel Trucks. Environ. Sci. Technol. 1999, 33, 1578–1587. [Google Scholar] [CrossRef]

- Lefort; Herreros, J.M.; Tsolakis, A. Reduction of Low Temperature Engine Pollutants by Understanding the Exhaust Species Interactions in a Diesel Oxidation Catalyst. Environ. Sci. Technol. 2014, 48, 2361–2367. [Google Scholar] [CrossRef]

- Westbrook, C.K.; Dryer, F.L. Chemical kinetic modeling of hydrocarbon combustion. Prog. Energy Combust. Sci. 1984, 10, 1–57. [Google Scholar] [CrossRef]

- Bougrine, S.; Richard, S.; Michel, J.-B.; Veynante, D. Simulation of CO and NO emissions in a SI engine using a 0D coherent flame model coupled with a tabulated chemistry approach. Appl. Energy 2014, 113, 1199–1215. [Google Scholar] [CrossRef]

- Chen, D.; Wang, T.; Yang, T.; Li, G.; Chen, Y.; Qiao, T. Effects of EGR combined with DOC on emission characteristics of a two-stage injected Fischer-Tropsch diesel/methanol dual-fuel engine. Fuel 2022, 329, 125451. [Google Scholar] [CrossRef]

- Hauff, K.; Tuttlies, U.; Eigenberger, G.; Nieken, U. A global description of DOC kinetics for catalysts with different platinum loadings and aging status. Appl. Catal. B Environ. 2010, 100, 10–18. [Google Scholar] [CrossRef]

- Simmance, K.; Thompsett, D.; Wang, W.; Thiebaut, B. Evaluation of perovskite catalysts prepared by flame spray pyrolysis for three-way catalyst activity under simulated gasoline exhaust feeds. Catal. Today 2019, 320, 40–50. [Google Scholar] [CrossRef]

- Zeng, F.; Hohn, K.L. Modeling of three-way catalytic converter performance with exhaust mixture from natural gas-fueled engines. Appl. Catal. B Environ. 2016, 182, 570–579. [Google Scholar] [CrossRef]

- Saravanan, S.; Nagarajan, G.; Anand, S.; Sampath, S. Correlation for thermal NOx formation in compression ignition (CI) engine fuelled with diesel and biodiesel. Energy 2012, 42, 401–410. [Google Scholar] [CrossRef]

- Dernotte, J.; Mounaim-Rousselle, C.; Halter, F.; Seers, P. Evaluation of Butanol–Gasoline Blends in a Port Fuel-injection, Spark-Ignition Engine. Oil Gas Sci. Technol. Rev. IFP 2010, 65, 345–351. [Google Scholar] [CrossRef]

- Feng, R.; Li, G.; Sun, Z.; Hu, X.; Deng, B.; Fu, J. Potential of emission reduction of a turbo-charged non-road diesel engine without aftertreatment under multiple operating scenarios. Energy 2023, 263, 125832. [Google Scholar] [CrossRef]

- Hu, S.; Deng, B.; Wu, D.; Hou, K. Energy flow behavior and emission reduction of a turbo-charging and EGR non-road diesel engine equipped with DOC and DPF under NRTC (non-road transient cycle). Fuel 2021, 305, 121571. [Google Scholar] [CrossRef]

- Khivantsev, K.; Kwak, J.-H.; Jaegers, N.R.; Koleva, I.Z.; Vayssilov, G.N.; Derewinski, M.A.; Wang, Y.; Aleksandrov, H.A.; Szanyi, J. Identification of the mechanism of NO reduction with ammonia (SCR) on zeolite catalysts. Chem. Sci. 2022, 13, 10383–10394. [Google Scholar] [CrossRef]

- Santos, H.; Costa, M. Evaluation of the conversion efficiency of ceramic and metallic three way catalytic converters. Energy Convers. Manag. 2008, 49, 291–300. [Google Scholar] [CrossRef]

- Jathar, S.H.; Sharma, N.; Galang, A.; Vanderheyden, C.; Takhar, M.; Chan, A.W.; Pierce, J.R.; Volckens, J. Measuring and modeling the primary organic aerosol volatility from a modern non-road diesel engine. Atmos. Environ. 2020, 223, 117221. [Google Scholar] [CrossRef]

- Huang, H.; Zhu, J.; Lv, D.; Wei, Y.; Zhu, Z.; Yu, B.; Chen, Y. Development of a reduced n-heptane-n-butylbenzene-polycyclic aromatic hydrocarbon (PAH) mechanism for engine combustion simulation and soot prediction. Energy 2018, 165, 90–105. [Google Scholar] [CrossRef]

- Liu, P.; Li, Z.; Roberts, W.L. The growth of PAHs and soot in the post-flame region. Proc. Combust. Inst. 2019, 37, 977–984. [Google Scholar] [CrossRef]

- Simonen, P.; Kalliokoski, J.; Karjalainen, P.; Rönkkö, T.; Timonen, H.; Saarikoski, S.; Aurela, M.; Bloss, M.; Triantafyllopoulos, G.; Kontses, A.; et al. Characterization of laboratory and real driving emissions of individual Euro 6 light-duty vehicles—Fresh particles and secondary aerosol formation. Environ. Pollut. 2019, 255, 113175. [Google Scholar] [CrossRef]

- Napolitano, P.; Di Maio, D.; Guido, C.; Borla, E.M.; Torbati, R. Experimental investigation on particulate filters for heavy-duty natural gas engines: Potentialities toward EURO VII regulation. J. Environ. Manag. 2023, 331, 117204. [Google Scholar] [CrossRef]

| Title | WHTC | PEMS |

|---|---|---|

| CO (mg/kW·h) | 4000 | 6000 |

| THC (mg/kW·h) | 160 | / |

| NOx (mg/kW·h) | 460 | 690 |

| PM (mg/kW·h) | 10 | / |

| PN (#/kW·h) | 6.0 × 1011 | 1.2 × 1012 |

| Item | Content |

|---|---|

| Engine type | Four-stroke and in-line six-cylinder, water-cooled |

| Aspiration mode | Turbo-charging with intercooling |

| Fuel supply mode | Electronic control high-pressure common rail, direct injection |

| Exhaust gas recirculation (EGR) mode | High-pressure EGR with water-cooler |

| Bore (mm) | 132 |

| Stroke (mm) | 157 |

| Compression ratio | 18.4 |

| Idle speed (rpm) | 600 ± 100 |

| Max speed (rpm) | 2100 |

| Rated power (kW/rpm) | 412/1800 |

| Max torque (N·m/rpm) | 2593/1000–1400 |

| Item | DOC |

|---|---|

| Size (diameter × length) | Φ304.8 mm × 127 mm |

| Cell density (cpsi) | 400 |

| Catalysts and ratios | Pt:Rh:Pd = 19:0:20 |

| Catalyst mass | 0.74 g/L |

| Coated material (support) | Al2O3 |

| Substrate material | Cordierite |

| Structure pattern | Honeycomb-shaped monolith |

| SCR (2 reactors connected in parallel) | |

| Size (diameter × length) | Φ304.8 mm × 177.8 (front)/88.9 (rear) mm |

| Cell density (cpsi) | 600 |

| Catalyst | Cu-zeolite |

| Substrate material | Cordierite |

| Structure pattern | Honeycomb-shaped monolith |

| ASC | |

| Size (diameter × length) | Φ304.8 mm × 63.5 mm |

| Cell density (cpsi) | 600 |

| Catalyst | Pt |

| Catalyst mass | 0.71 g/L |

| Coated material (support) | Al2O3 |

| Substrate material | Cordierite |

| Structure pattern | Honeycomb-shaped monolith |

| DPF | |

| Size (diameter × length) | Φ304.8 mm × 203.2 mm |

| Cell density (cpsi) | 300 |

| Catalysts and ratios | Pt:Rh:Pd = 4:0:1 |

| Catalyst mass | 0.071 g/L |

| Coated material (support) | Al2O3 |

| Substrate material | Cordierite |

| Structure pattern | Honeycomb-shaped with wall-flow channels |

| Instrument Name | Manufacturer/Type | Measurement Range | Accuracy |

|---|---|---|---|

| Gas sampling system | Horiba CVS-ONE (HORIBA, Ltd., Kyoto, Japan) | <30 m3/min | / |

| PM sampling system | Horiba DLS-7200E (HORIBA, Ltd., Kyoto, Japan) | 65–130 L/min | ±5.0% |

| Gas analyzer | Horiba MEXA-7200D (HORIBA, Ltd., Kyoto, Japan) | CO(L): 0–5000 ppm CO2: 0–6%vol HC: 0–2500 ppm NOx: 10–5000 ppm CH4: 0–2500 ppm | ±1.0% FS |

| Particle counter | Horiba MEXA-2000SPCS (HORIBA, Ltd., Kyoto, Japan) | 0–50,000 #/cm3 (after dilution) | Counting efficiency: 50 ± 12% (23 nm); ≥90% (41 nm) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, B.; Yu, W.; Zhou, L.; Sun, C. A Comparative Investigation of the Emissions of a Heavy-Duty Diesel Engine under World Harmonized Transient Cycle and Road Spectrum Cycle. Energies 2024, 17, 7. https://doi.org/10.3390/en17010007

Deng B, Yu W, Zhou L, Sun C. A Comparative Investigation of the Emissions of a Heavy-Duty Diesel Engine under World Harmonized Transient Cycle and Road Spectrum Cycle. Energies. 2024; 17(1):7. https://doi.org/10.3390/en17010007

Chicago/Turabian StyleDeng, Banglin, Weijiao Yu, Lili Zhou, and Chengqi Sun. 2024. "A Comparative Investigation of the Emissions of a Heavy-Duty Diesel Engine under World Harmonized Transient Cycle and Road Spectrum Cycle" Energies 17, no. 1: 7. https://doi.org/10.3390/en17010007