Biodiesel from Bark and Black Liquor—A Techno-Economic, Social, and Environmental Assessment

Abstract

:1. Introduction

2. Materials and Methods

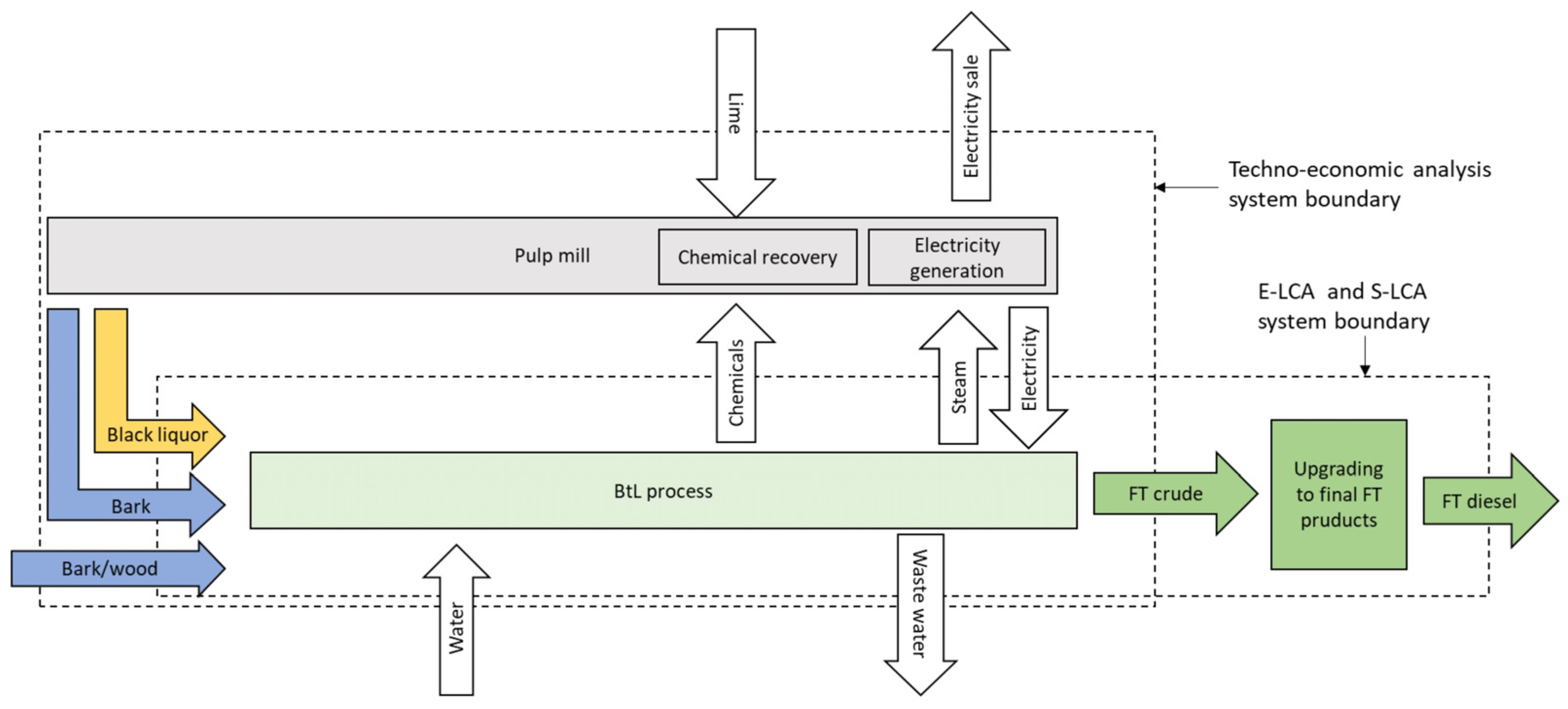

2.1. System Description and Modelling

2.1.1. Conversion of Black Liquor to Hydrogen

2.1.2. Conversion of Bark via Gasification

2.1.3. Fuel Synthesis and Upgrading

2.2. Scenario Development

2.3. System Bounderies

2.4. Environmental Sustainability Assessment

2.5. Techno-Economic Analysis

Sensitivity Analysis

2.6. Social Sustainability Assessment

3. Results

3.1. Techno-Economic Analysis

3.1.1. Sensitivity Analysis

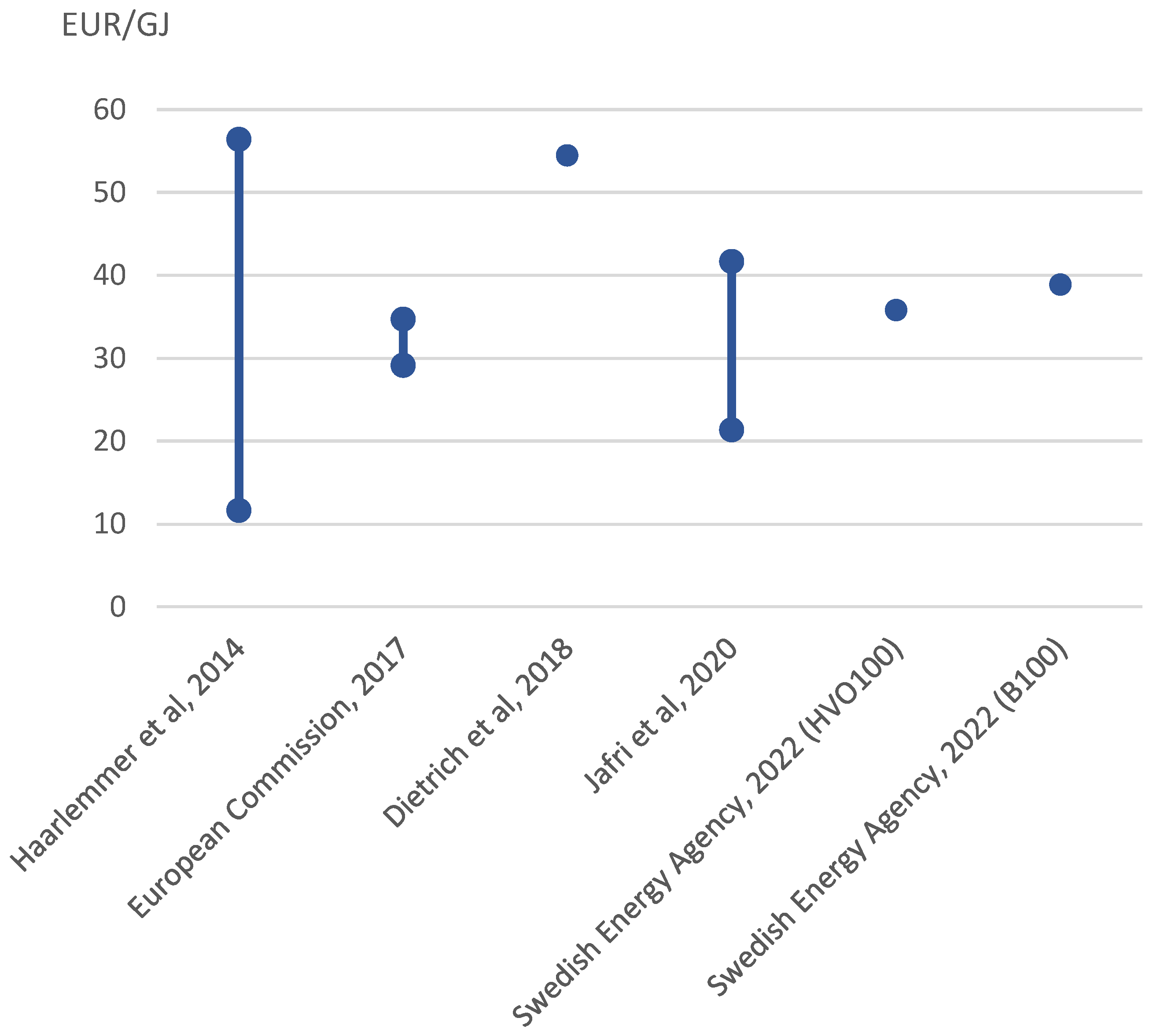

3.1.2. Cost Estimates from Literature

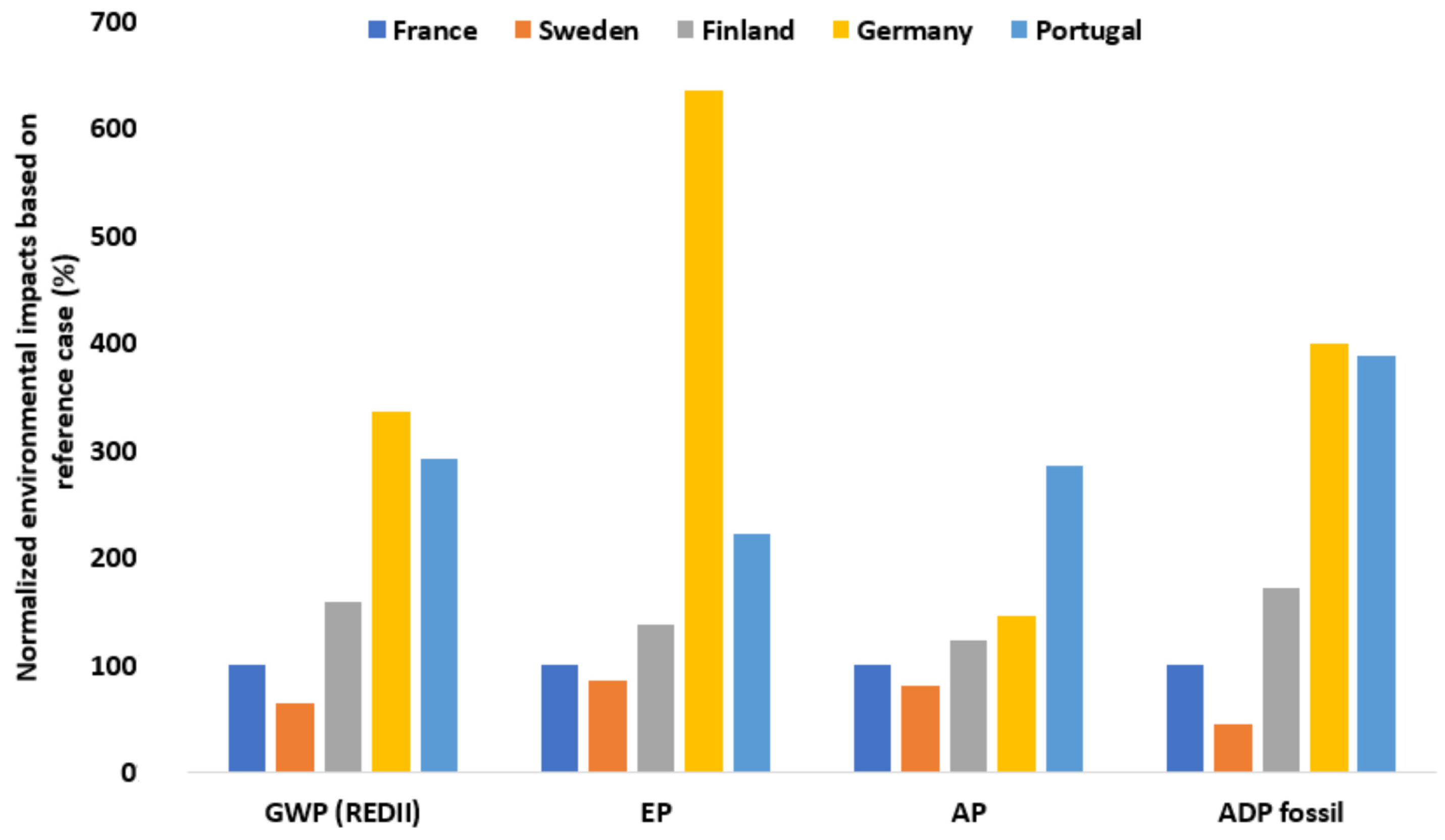

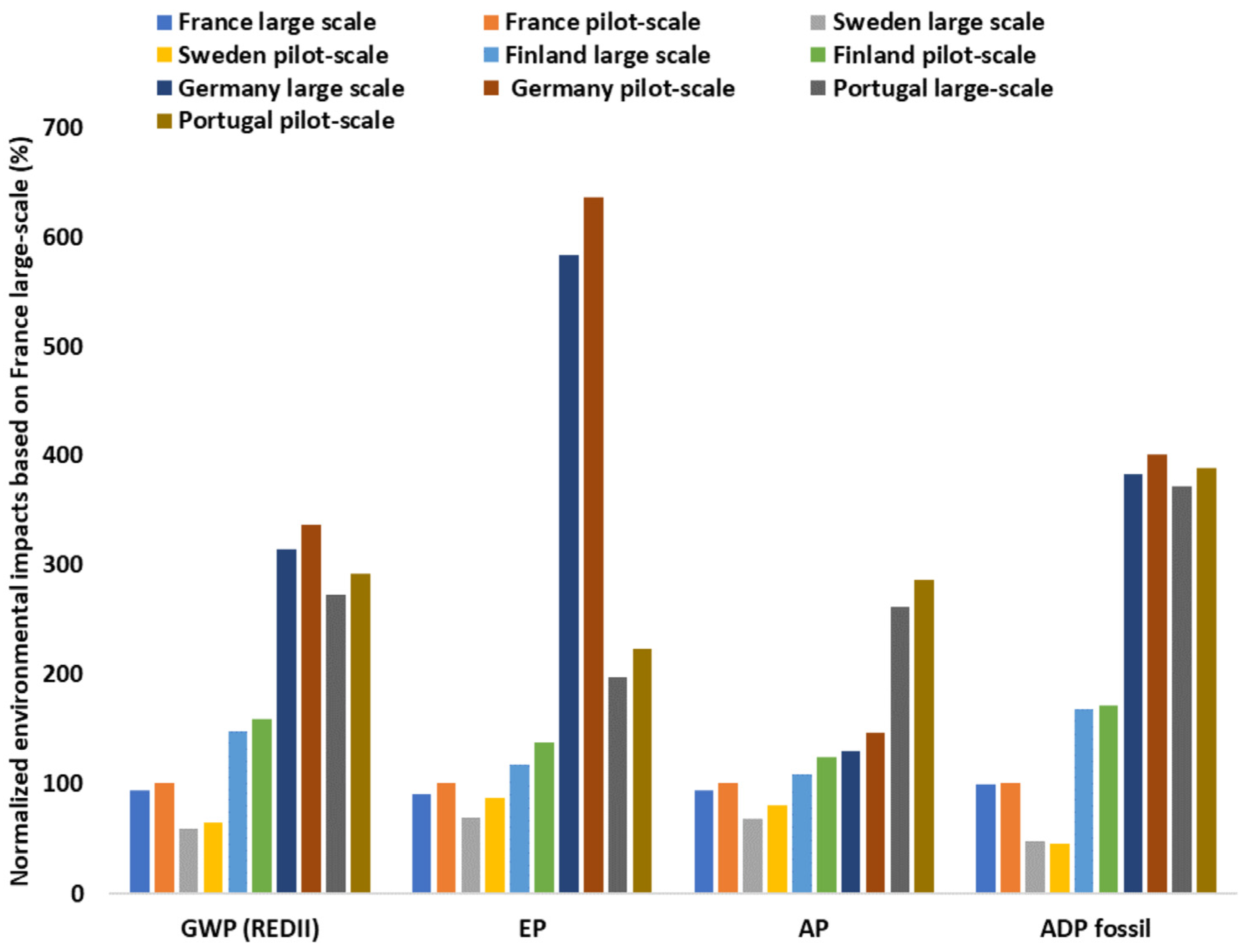

3.2. Environmental Assessment

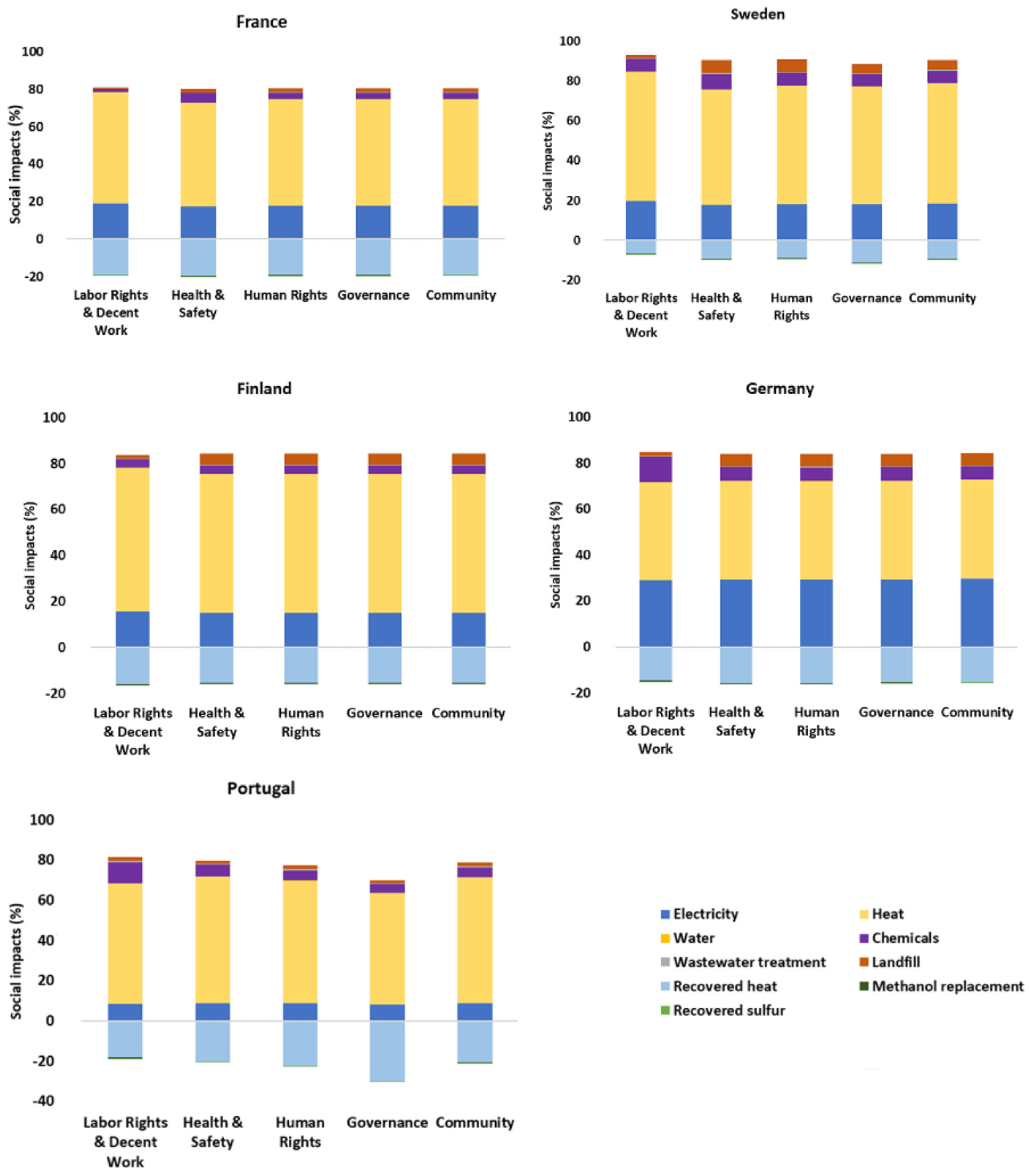

3.3. Social Sustainability Assessment

4. Discussion and Conclusions

4.1. Environmental Performance Is Promising but Varies

4.2. Production Cost Estimate Is Low but Uncertain

4.3. Conclusion and Future Perspectives

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AP | Acidification potential |

| BtL | Biomass-to-liquid |

| CAPEX | Capital expenditures |

| EF | Entrained flow |

| EP | Eutrophication potential |

| EU | European Union |

| FU | Functional unit |

| FT | Fischer–Tropsch |

| GHG | Greenhouse gas emissions |

| GWP | Global warming potential |

| LCA | Life cycle assessment |

| OPEX | Operational expenditures |

| REDII | Updated Renewable Energy |

| SCWG | Supercritical water gasification |

| SHDB | Social hotspots database |

| S-LCA | Social life cycle assessment |

| TEA | Techno-economic analysis |

| TRL | Technology Readiness Level |

References

- Safarian, S.; Unnthorsson, R.; Richter, C. Hydrogen production via biomass gasification: Simulation and performance analysis under different gasifying agents. Biofuels 2022, 13, 717–726. [Google Scholar] [CrossRef]

- Safarian, S. To what extent could biochar replace coal and coke in steel industries? Fuel 2023, 339, 127401. [Google Scholar] [CrossRef]

- EIA. Transportation Sector Energy Consumption. 2016. Available online: https://www.eia.gov/outlooks/ieo/pdf/transportation.pdf (accessed on 7 March 2023).

- EIA. Global Greenhouse Gas Emissions by the Transportation Sector. 2014. Available online: https://transportgeography.org/contents/chapter4/transportation-and-environment/greenhouse-gas-emissions-transportation/ (accessed on 7 March 2023).

- ICCT. Transport Could Burn up the EU’s Entire Carbon Budget. 2021. Available online: https://theicct.org/transport-could-burn-up-the-eus-entire-carbon-budget/ (accessed on 7 March 2023).

- Zandt, F. Diesel and Petrol Cars Losing Ground in the EU. 2021. Available online: https://www.statista.com/chart/26037/market-share-of-cars-registered-in-the-eu-by-fuel-type/ (accessed on 7 March 2023).

- ACEA. Average Age of the EU Vehicle Fleet, by Country. 2023. Available online: https://www.acea.auto/figure/average-age-of-eu-vehicle-fleet-by-country/ (accessed on 10 June 2023).

- ACEA. Electrification Trends Worldwide. 2023. Available online: https://www.acea.auto/news/electrification-trends-worldwide/ (accessed on 2 March 2023).

- European Environment Agency. Share of Energy from Renewable Sources Used in Transport in EUROPE. 2022. Available online: https://www.eea.europa.eu/data-and-maps/daviz/share-of-renewable-energy-10/#tab-chart_10 (accessed on 7 March 2023).

- European Commission. Renewable Energy Directive. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.328.01.0082.01.ENG&toc=OJ:L:2018:328:TOC (accessed on 4 February 2023).

- United States Department of Agriculture. Biofuel Mandates in the EU by Member State. 2022. Available online: https://apps.fas.usda.gov/newgainapi/api/Report/DownloadReportByFileName?fileName=Biofuel%20Mandates%20in%20the%20EU%20by%20Member%20State%20-%202022_Berlin_European%20Union_E42022-0044.pdf (accessed on 20 May 2023).

- ePure. Overview of Biofuels Policies and Markets across the EU-27 and the UK. 2020. Available online: https://www.epure.org/wp-content/uploads/2021/01/201104-DEF-REP-Overview-of-biofuels-policies-and-markets-across-the-EU-Nov.-2020.pdf (accessed on 20 May 2023).

- Murray, J.W. Limitations of oil production to the IPCC scenarios: The new realities of US and Global oil production. BioPhys. Econ. Resour. Qual. 2016, 1, 13. [Google Scholar] [CrossRef]

- Mo, W.; Xiong, Z.; Leong, H.; Gong, X.; Jiang, L.; Xu, J.; Su, S.; Hu, S.; Wang, Y.; Xiang, J. Processes simulation and environmental evaluation of biofuel production via Co-pyrolysis of tropical agricultural waste. Energy 2022, 242, 123016. [Google Scholar] [CrossRef]

- Ala’a, H.; Osman, A.I.; Jamil, F.; Mehta, N.; Al-Haj, L.; Coulon, F.; Al-Maawali, S.; Al Nabhani, A.; Kyaw, H.H.; Myint, M.T.Z.; et al. Integrating life cycle assessment and characterisation techniques: A case study of biodiesel production utilising waste Prunus Armeniaca seeds (PAS) and a novel catalyst. J. Environ. Manag. 2022, 304, 114319. [Google Scholar] [CrossRef]

- Gouran, A.; Aghel, B.; Nasirmanesh, F. Biodiesel production from waste cooking oil using wheat bran ash as a sustainable biomass. Fuel 2021, 295, 120542. [Google Scholar] [CrossRef]

- CEPI. Key Statistics 2021—European Pulp & Paper Industry. 2022. Available online: https://www.cepi.org/wp-content/uploads/2022/07/Key-Statistics-2021-Final.pdf (accessed on 18 April 2023).

- Food and Agriculture Organization of the United Nations. Forestry Production and Trade. 2023. Available online: https://unece.org/sites/default/files/2023-04/DP94-TF2022-web.pdf (accessed on 18 April 2023).

- European Commission. Grant Agreement Number 818011 Pulp and Fuel. 2018. Available online: https://cordis.europa.eu/project/id/818011 (accessed on 11 June 2023).

- Jha, S.; Nanda, S.; Acharya, B.; Dalai, A.K. A Review of Thermochemical Conversion of Waste Biomass to Biofuels. Energies 2022, 15, 6352. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Akram, A.; Ghobadian, B.; Rafiee, S.; Heijungs, R.; Tabatabaei, M. Environmental impact assessment of olive pomace oil biodiesel production and consumption: A comparative lifecycle assessment. Energy 2016, 106, 87–102. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Ghobadian, B.; Safa, M.; Heidari, M.D. Energy life-cycle assessment and CO2 emissions analysis of soybean-based biodiesel: A case study. J. Clean. Prod. 2014, 66, 233–241. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Tabatabaei, M.; Abdi, R.; Latifi, A.M.; Saberi, F.; Askari, M.; Zenouzi, A.; Ghorbani, M. Attributional and consequential environmental assessment of using waste cooking oil-and poultry fat-based biodiesel blends in urban buses: A real-world operation condition study. Biofuel Res. J. 2017, 4, 638. [Google Scholar] [CrossRef]

- Safarian, S.; Sattari, S.; Hamidzadeh, Z. Sustainability assessment of biodiesel supply chain from various biomasses and conversion technologies. BioPhys. Econ. Resour. Qual. 2018, 3, 6. [Google Scholar] [CrossRef]

- Rahimi, V.; Karimi, K.; Shafiei, M.; Naghavi, R.; Khoshnevisan, B.; Ghanavati, H.; Mohtasebi, S.S.; Rafiee, S.; Tabatabaei, M. Well-to-wheel life cycle assessment of Eruca Sativa-based biorefinery. Renew. Energy 2018, 117, 135–149. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafiee, S.; Tabatabaei, M.; Ghanavati, H.; Mohtasebi, S.S.; Rahimi, V.; Shafiei, M.; Angelidaki, I.; Karimi, K. Life cycle assessment of castor-based biorefinery: A well to wheel LCA. Int. J. Life Cycle Assess. 2018, 23, 1788–1805. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Nizami, A.S.; Kalogirou, S.A.; Gupta, V.K.; Park, Y.K.; Fallahi, A.; Sulaiman, A.; Ranjbari, M.; Rahnama, H.; Aghbashlo, M.; et al. Environmental life cycle assessment of biodiesel production from waste cooking oil: A systematic review. Renew. Sustain. Energy Rev. 2022, 161, 112411. [Google Scholar] [CrossRef]

- anak Erison, A.E.; Tan, Y.H.; Mubarak, N.M.; Kansedo, J.; Khalid, M.; Abdullah, M.O.; Ghasemi, M. Life cycle assessment of biodiesel production by using impregnated magnetic biochar derived from waste palm kernel shell. Environ. Res. 2022, 214, 114149. [Google Scholar] [CrossRef] [PubMed]

- Canabarro, N.I.; Silva-Ortiz, P.; Nogueira, L.A.H.; Cantarella, H.; Maciel-Filho, R.; Souza, G.M. Sustainability assessment of ethanol and biodiesel production in Argentina, Brazil, Colombia, and Guatemala. Renew. Sustain. Energy Rev. 2023, 171, 113019. [Google Scholar] [CrossRef]

- Ekener-Petersen, E.; Höglund, J.; Finnveden, G. Screening potential social impacts of fossil fuels and biofuels for vehicles. Energy Policy 2014, 73, 416–426. [Google Scholar] [CrossRef]

- Granacher, J.; Nguyen, T.V.; Castro-Amoedo, R.; McDonald, E.C.; Maréchal, F. Enhancing biomass utilization by combined pulp and fuel production. Front. Energy Res. 2022, 10, 979502. [Google Scholar] [CrossRef]

- Granacher, J.N.; Tuong-Van, S.M.; François, S. Energy Integration Model N1. In Pulp and Paper Industry Waste to Fuel; École Polytechnique Fédérale de Lausanne: Lausanne, Switzerland, 2021. [Google Scholar]

- Kannangara, M.; Bensebaa, F.; Vasudev, M. An adaptable life cycle greenhouse gas emissions assessment framework for electric, hybrid, fuel cell and conventional vehicles: Effect of electricity mix, mileage, battery capacity and battery chemistry in the context of Canada. J. Clean. Prod. 2021, 317, 128394. [Google Scholar] [CrossRef]

- Turton, R.; Bailie, R.C.; Whiting, W.B.; Shaeiwitz, J.A. Analysis, Synthesis, and Design of Chemical Processes; Pearson Education: London, UK, 2018. [Google Scholar]

- Maxwell, C. Cost Indices. 2023. Available online: https://www.toweringskills.com/financial-analysis/cost-indices/ (accessed on 8 October 2023).

- Haarlemmer, G.; Boissonnet, G.; Imbach, J.; Setier, P.A.; Peduzzi, E. Second generation BtL type biofuels—A production cost analysis. Energy Environ. Sci. 2012, 5, 8445–8456. [Google Scholar] [CrossRef]

- Lönnqvist, T.; Hansson, J.; Klintbom, P.; Furusjö, E.; Holmgren, K. Drop-in the Tank or a New Tank? 2021. Available online: https://f3centre.se/en/renewable-transportation-fuels-and-systems/ (accessed on 23 January 2023).

- Baltpool. Biomass and Heat Trade Statistics March of 2022. 2023. Available online: https://www.baltpool.eu/en/biomass-and-heat-trade-statistics-march-of-2022/ (accessed on 10 June 2023).

- Statista. 2022. Available online: https://www.statista.com/statistics/1267500/eu-monthly-wholesale-electricity-price-country/ (accessed on 11 June 2023).

- Peduzzi, E. Biomass to Liquids: Thermo-Economic Analysis and Multi-Objective Optimisation. Ph.D. Thesis, École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 2015. [Google Scholar]

- Benoît Norris, C.; Traverzo, M.; Neugebauer, S.; Ekener, E.; Schaubroeck, T.; Russo Garrido, S. Guidelines for Social Life Cycle Assessment of Products and Organizations 2020; United Nations Environment Programme: Nairobi, Kenya, 2020. [Google Scholar]

- Benoit Norris, C.; Bennema, M.; Norris, G. The Social Hotspots Database V4; NewEarth B: Lois Ln, ME, USA, 2019. [Google Scholar]

- Marting Vidaurre, N.A.; Jurišić, V.; Bieling, C.; Magenau, E.; Wagner, M.; Kiesel, A.; Lewandowski, I. Social assessment of miscanthus cultivation in Croatia: Assessing farmers’ preferences and willingness to cultivate the Crop. GCB Bioenergy 2023, 15, 916–931. [Google Scholar] [CrossRef]

- Goedkoop, M.J.; Indrane, D.; de Beer, I.M. Product Social Impact Assessment Handbook-2020; PRé Sustainability: Amersfoort, The Netherlands, 2020. [Google Scholar]

- Herrera Almanza, A.M.; Corona, B. Using social Life Cycle Assessment to analyze the contribution of products to the Sustainable Development Goals: A case study in the textile sector. Int. J. Life Cycle Assess. 2020, 25, 1833–1845. [Google Scholar] [CrossRef]

- Efraimsson, N.; Johnsson, S. Potential Social Impacts of a Possible Implementation of the Pulp & Fuel Concept for Producing Biofuels at a Pulp Mill. Bachelor’s Thesis, University of Borås, Borås, Sweden, 2022. Available online: http://urn.kb.se/resolve?urn=urn:nbn:se:hb:diva-27955 (accessed on 23 January 2023).

- Swanson, R.M.; Platon, A.; Satrio, J.A.; Brown, R.C. Techno-economic analysis of biomass-to-liquids production based on gasification. Fuel 2010, 89, S11–S19. [Google Scholar] [CrossRef]

- Gasafi, E.; Reinecke, M.Y.; Kruse, A.; Schebek, L. Economic analysis of sewage sludge gasification in supercritical water for hydrogen production. Biomass Bioenergy 2008, 32, 1085–1096. [Google Scholar] [CrossRef]

- Ulrich, G.D. A Guide to Chemical Engineering Process Design and Economics; Wiley: New York, NY, USA, 1984. [Google Scholar]

- Xu, J.; Zhang, X.; Cheng, J.J. Pretreatment of corn stover for sugar production with switchgrass-derived black liquor. Bioresour. Technol. 2012, 111, 255–260. [Google Scholar] [CrossRef] [PubMed]

- Stewart, M.; Arnold, K. Gas-Liquid and Liquid-Liquid Separators; Gulf Professional Publishing: Houston, TX, USA, 2008. [Google Scholar]

- Micheletti, A. Innovation at Top Industrie. In Proceedings of the General Assembly of the PulpAndFuel Project, Trondheim, Norway, 14 June 2022. [Google Scholar]

- Santa, R. Overview of innovations for the pulp and paper industry. In Proceedings of the General Assembly of the PulpAndFuel Project, Trondheim, Norway, 14 June 2022. [Google Scholar]

- Andersson, J.; Lundgren, J.; Marklund, M. Methanol production via pressurized entrained flow biomass gasification—Techno-economic comparison of integrated vs. stand-alone production. Biomass Bioenergy 2014, 64, 256–268. [Google Scholar] [CrossRef]

- Stigsson, C.C.; Furusjö, E.; Börjesson, P. Sunalfa, System Oriented Analysis of Processes for Renewable Fuels from Forest Raw Material. 2021. Available online: https://f3centre.se/app/uploads/FDOS-14-2021_P46969-1_SR-210517.pdf (accessed on 6 March 2023).

- Haarlemmer, G.; Boissonnet, G.; Peduzzi, E.; Setier, P.A. Investment and production costs of synthetic fuels—A literature survey. Energy Environ. Sci. 2014, 66, 667–676. [Google Scholar] [CrossRef]

- Eurostat. Gas Prices by Type of Users. 2022. Available online: https://ec.europa.eu/eurostat/databrowser/view/ten00118/default/table?lang=en (accessed on 10 June 2023).

- Boucher, J. Recent updates of the processes at Pulp Mill Fibre Excellence. In Proceedings of the General Assembly of the PulpAndFuel Project, Trondheim, Norway, 14 June 2022. [Google Scholar]

- Hedman, F.; Tjus, K.; Sellin, J.; Karlsson, J.; Särnbratt, M.; Kanders, L. PulpAndFuel D2.4 Effluent Management (Confidential Report); IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2023. [Google Scholar]

- Economics, M. Industrial Transformation 2050—Pathways to Net-Zero Emissions from EU Heavy Industry; University of Cambridge Institute for Sustainability Leadership (CISL): Cambridge, UK, 2019. [Google Scholar]

- Electricity supply, district heating and supply of natural gas 2020. In Final Statistics; Statistics Sweden: Solna, Sweden, 2021.

- European Commission. Building Up the Future Cost of Biofuel. 2018. Available online: https://op.europa.eu/en/publication-detail/-/publication/13e27082-67a2-11e8-ab9c-01aa75ed71a1 (accessed on 23 January 2023).

- Dietrich, R.U.; Albrecht, F.G.; Maier, S.; König, D.H.; Estelmann, S.; Adelung, S.; Bealu, Z.; Seitz, A. Cost calculations for three different approaches of biofuel production using biomass, electricity and CO2. Biomass Bioenergy 2018, 111, 165–173. [Google Scholar] [CrossRef]

- Afri, Y.; Wetterlund, E.; Mesfun, S.; Rådberg, H.; Mossberg, J.; Hulteberg, C.; Furusjö, E. Combining expansion in pulp capacity with production of sustainable biofuels—Techno-economic and greenhouse gas emissions assessment of drop-in fuels from black liquor part-streams. Appl. Energy 2020, 279, 115879. [Google Scholar] [CrossRef]

- Survailance Report Regarding Tax Exemption for Pure and High Blend-in Biofuels during 2021; Swedish Energy Agency: Eskilstuna, Sweden, 2022.

- Hansson, J.; Nojpanya, P.; Ahlström, J.; Furusjö, E.; Lundgren, J.; Gustavsson Binder, T. Costs for Reducing GHG Emissions from Road and Air Transport with Biofuels and Electrofuels; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2023. [Google Scholar]

- Hellsmark, H.; Hansen, T. A new dawn for (oil) incumbents within the bioeconomy? Trade-offs and lessons for policy. Energy Policy 2020, 145, 111763. [Google Scholar] [CrossRef]

| Sustainability Aspects Covered | |||

|---|---|---|---|

| References | Environmental | Economic | Social |

| [22,23,25,26,27,28,29] | X | ||

| [21] | X | X | |

| [24] | X | X | X |

| Property | Large-Scale | Pilot-Scale |

|---|---|---|

| Biomass energy content (bark and black liquor) [PJ/year] | 10.8 | |

| Bark [tonnes TS/year] | 490,000 | 8000 |

| Black liquor [tonnes TS/year] | 86,000 | 1200 |

| FT crude production [tonnes/year] | 143,000 | 1800 |

| Changed electricity export [MWh/year] | +189,000 | −14,000 |

| Component | Grass Roots Cost [M€] | Source | Alternative Grass Roots Cost [M€] | Source |

|---|---|---|---|---|

| Hydrothermal gasification (including hydrolysis, salt separator, SCWG) | 74.1 | [35,48] | 15–499 | [34,48,49,50,51,52] |

| Acid gas removal and Pressure Swing Adsorption | 3.9 | - | ||

| Drying and torrefaction | 17 | [53] | 17–21 | [34,40,49,53] |

| Entrained flow gasifier | 61.5 | [35,47] | 8–134 | [34,49,54,55] |

| Cold gas cleaning | 8.1 | [34,40,49] | - | |

| FT synthesis | 45.9 | [35,47] | 10–45.9 | [34,35,40,47,49] |

| Water Gas Shift | 12.9 | [34,40,49] | 12.9–17 | [34,40,49,53] |

| Cobalt catalyst | 25.5 | - | ||

| Upgrading | 5.6 | - | ||

| Water treatment | 15.1 | - | ||

| Total CAPEX | 269.6 |

| Revenues | [M€/year] | Assumptions and Sources |

| Electricity sales | 14.3 | 58 €/MWh: average sale price for France, 2019–2020 [39] |

| Fixed costs | [€/year] | Assumptions and sources |

| Depreciation and financial costs | 26.6 | 10% of CAPEX: Depreciation = 1/economic lifetime = 1/20 yrs = 5% Financial costs = interest rate 5% |

| Maintenance and labor costs | 13.5 | 5% of CAPEX [40] |

| Variable costs | [€/year] | Assumptions and sources |

| Natural gas | 0.32 | 7.5 €/GJ [57]: average price for France, 2018–2020. Medium-sized industries, without taxes. |

| Fresh water | 0.014 | 0.02 €/m3 [58] |

| Biomass feedstock | 50.1 | 5.6 €/GJ [36,37] |

| Water treatment | 4.5 | Based on cost estimates for treatment of actual wastewater streams from multiple processes in the BtL pathway used for experimental analysis [59] |

| Cooling | 0.63 | Mainly electricity [39] |

| Disposal | 0.48 | Mostly disposal of lime mud (calcium carbonate) |

| Crude Production Cost (€/GJ) | Assumptions |

|---|---|

| 8.1 | Biomass: 2.2 €/GJ; Electricity sales price: 58 €/MWh; investment cost: 269.6 M€ |

| 18.1 | Biomass: 9.2 €/GJ; Electricity sales price: 58 €/MWh; investment cost: 269.6 M€ |

| 9.4 | Investment cost: 121 M€; Biomass: 5.6 €/GJ; Electricity sales price: 58 €/MWh |

| 24.7 | Investment cost: 760 M€; Biomass: 5.6 €/GJ; Electricity sales price: 58 €/MWh |

| 11.7 | Electricity sales price: 87 €/MWh; Biomass: 5.6 €/GJ; investment cost: 269.6 M€ |

| 13.9 | Electricity sales price: 29 €/MWh; Biomass: 5.6 €/GJ; investment cost: 269.6 M€ |

| Impact Indicators | France | Sweden | Finland | Germany | Portugal |

|---|---|---|---|---|---|

| GWP (g CO2eq/MJ) | 22.6 | 16.1 | 39.5 | 83.3 | 72.7 |

| EP (g phosphate, PO4 eq/MJ) | 0.06 | 0.05 | 0.09 | 0.40 | 0.14 |

| AP (g SO2eq/MJ) | 0.19 | 0.15 | 0.23 | 0.28 | 0.54 |

| ADP fossil (g Sb/MJ) | 0.26 | 0.12 | 0.45 | 1.05 | 1.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hansson, J.; Klugman, S.; Lönnqvist, T.; Elginoz, N.; Granacher, J.; Hasselberg, P.; Hedman, F.; Efraimsson, N.; Johnsson, S.; Poulikidou, S.; et al. Biodiesel from Bark and Black Liquor—A Techno-Economic, Social, and Environmental Assessment. Energies 2024, 17, 99. https://doi.org/10.3390/en17010099

Hansson J, Klugman S, Lönnqvist T, Elginoz N, Granacher J, Hasselberg P, Hedman F, Efraimsson N, Johnsson S, Poulikidou S, et al. Biodiesel from Bark and Black Liquor—A Techno-Economic, Social, and Environmental Assessment. Energies. 2024; 17(1):99. https://doi.org/10.3390/en17010099

Chicago/Turabian StyleHansson, Julia, Sofia Klugman, Tomas Lönnqvist, Nilay Elginoz, Julia Granacher, Pavinee Hasselberg, Fredrik Hedman, Nora Efraimsson, Sofie Johnsson, Sofia Poulikidou, and et al. 2024. "Biodiesel from Bark and Black Liquor—A Techno-Economic, Social, and Environmental Assessment" Energies 17, no. 1: 99. https://doi.org/10.3390/en17010099

APA StyleHansson, J., Klugman, S., Lönnqvist, T., Elginoz, N., Granacher, J., Hasselberg, P., Hedman, F., Efraimsson, N., Johnsson, S., Poulikidou, S., Safarian, S., & Tjus, K. (2024). Biodiesel from Bark and Black Liquor—A Techno-Economic, Social, and Environmental Assessment. Energies, 17(1), 99. https://doi.org/10.3390/en17010099