Life Cycle Assessment of a Wood Biomass Gasification Plant and Implications for Syngas and Biochar Utilization

Abstract

:1. Introduction

1.1. Energy, Biomass, and Syngas

1.2. Biochar

1.3. Life Cycle Assessment

2. Materials and Methods

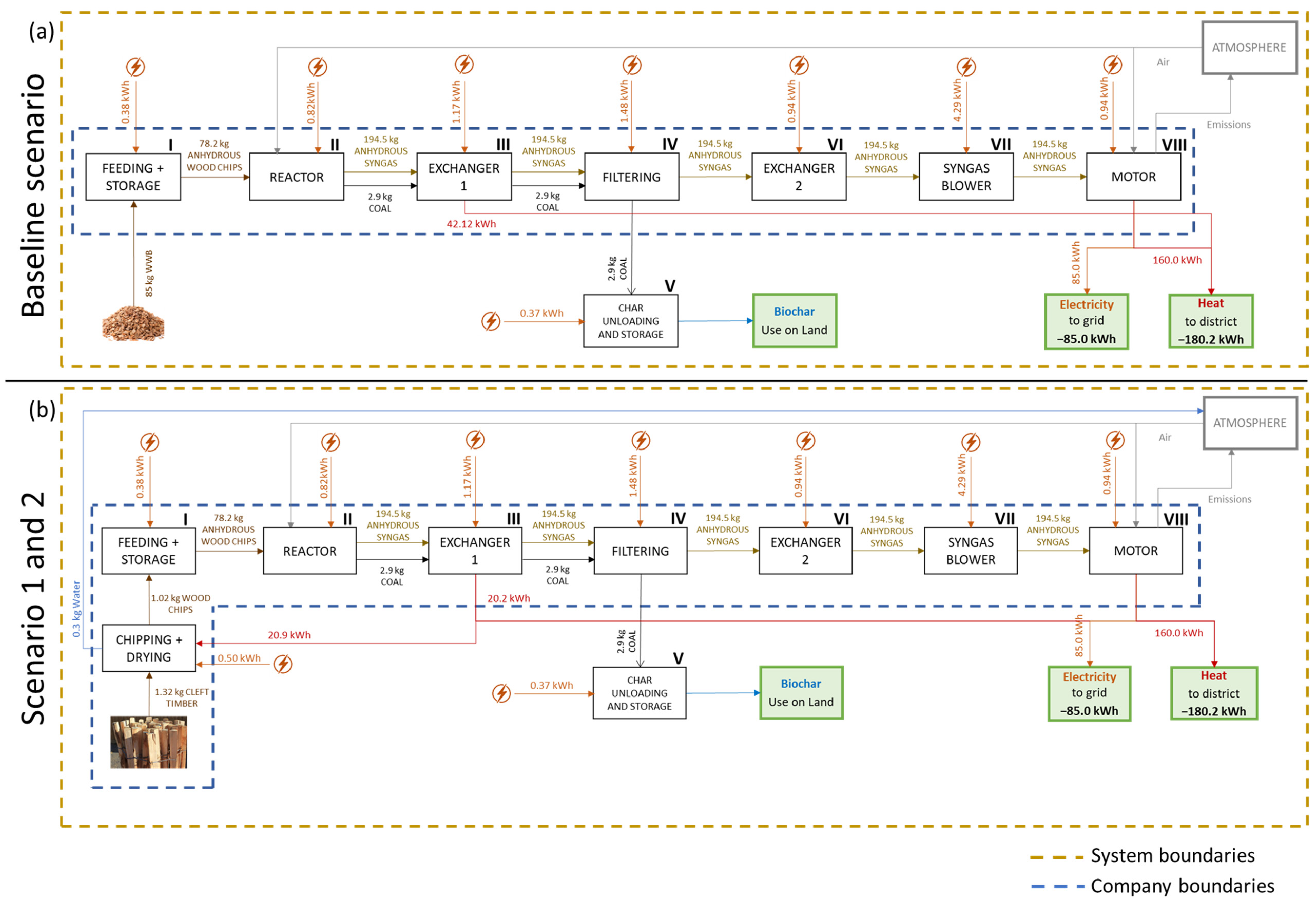

2.1. Goal and Scope Definition

2.2. Life Cycle Inventory (LCI)

2.2.1. General Assumptions

2.2.2. Baseline Scenario

- (I)

- Feeding + Storage

- (II)

- Reactor

- (III)

- Exchanger #1

- (IV)

- Filtering

- (V)

- Char unloading and storage

- (VI)

- Exchanger #2

- (VII)

- Syngas blower

- (VIII)

- Motor

2.2.3. Scenario 1

2.2.4. Scenario 2

2.3. Life Cycle Impact Assessment (LCIA)

2.4. Sensitivity and Uncertainty Analysis

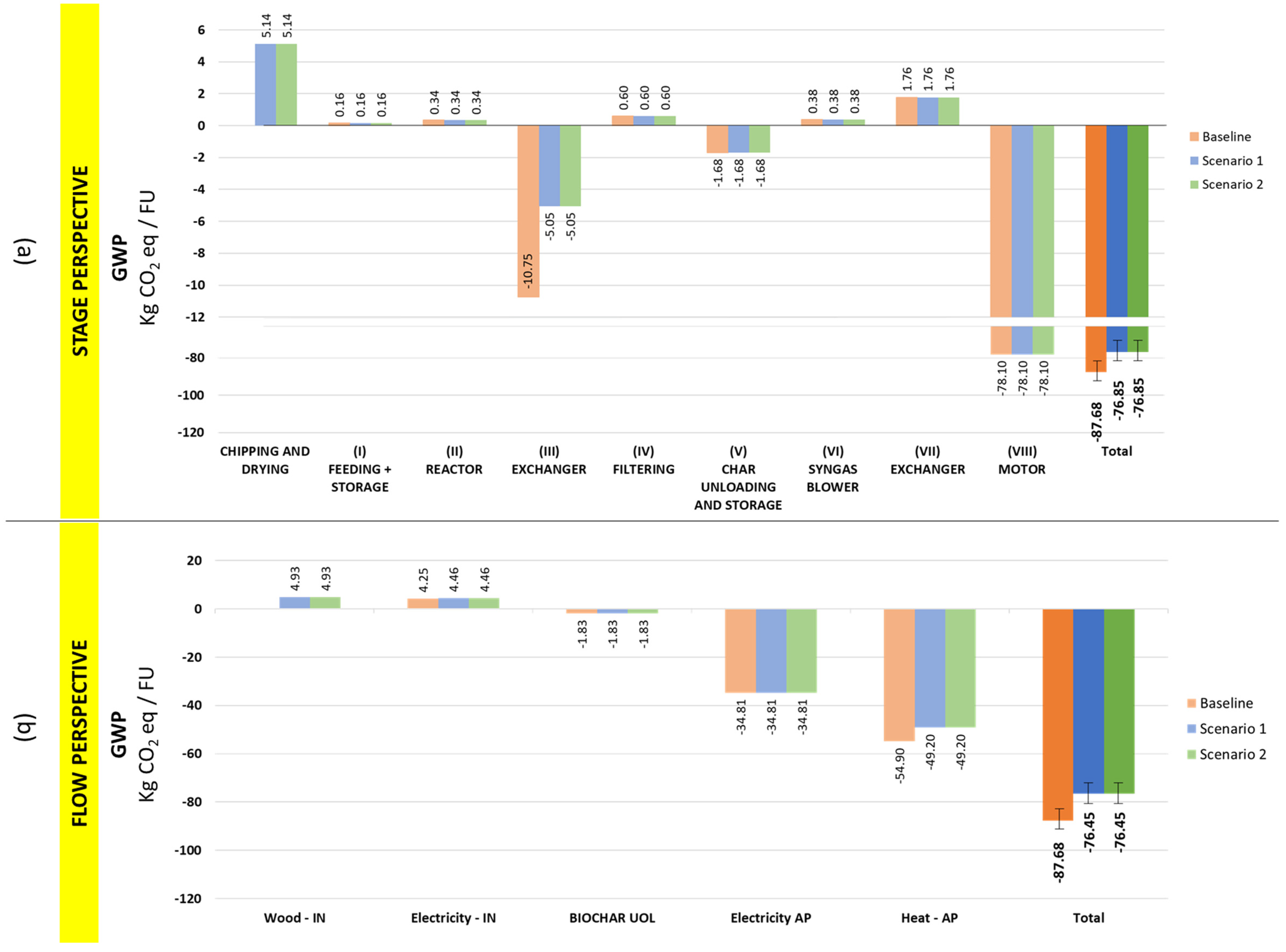

3. Results

3.1. Comparison between the Three Scenarios

3.2. Environmental Impacts Associated with Biochar UOL

3.3. Sensitivity Analysis on Transportation

3.4. Sensitivity Analysis on the Electricity Mix

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- van Ruijven, B.J.; De Cian, E.; Sue Wing, I. Amplification of Future Energy Demand Growth Due to Climate Change. Nat. Commun. 2019, 10, 2762. [Google Scholar] [CrossRef] [PubMed]

- Frilingou, N.; Xexakis, G.; Koasidis, K.; Nikas, A.; Campagnolo, L.; Delpiazzo, E.; Chiodi, A.; Gargiulo, M.; Mcwilliams, B.; Koutsellis, T.; et al. Navigating through an Energy Crisis: Challenges and Progress towards Electricity Decarbonisation, Reliability, and Affordability in Italy. Energy Res. Soc. Sci. 2023, 96, 102934. [Google Scholar] [CrossRef]

- Varun; Bhat, I.K.; Prakash, R. LCA of Renewable Energy for Electricity Generation Systems-A Review. Renew. Sustain. Energy Rev. 2009, 13, 1067–1073. [Google Scholar] [CrossRef]

- Reguyal, F.; Wang, K.; Sarmah, A.K. Electrification of New Zealand Transport: Environmental Impacts and Role of Renewable Energy. Sci. Total Environ. 2023, 894, 164936. [Google Scholar] [CrossRef] [PubMed]

- Osman, A.I.; Chen, L.; Yang, M.; Msigwa, G.; Farghali, M.; Fawzy, S.; Rooney, D.W.; Yap, P.S. Cost, Environmental Impact, and Resilience of Renewable Energy under a Changing Climate: A Review. Environ. Chem. Lett. 2023, 21, 741–764. [Google Scholar] [CrossRef]

- Arfelli, F.; Ciacci, L.; Vassura, I.; Passarini, F. Nexus Analysis and Life Cycle Assessment of Regional Water Supply Systems: A Case Study from Italy. Resour. Conserv. Recycl. 2022, 185, 106446. [Google Scholar] [CrossRef]

- Arfelli, F.; Cespi, D.; Ciacci, L.; Passarini, F. Application of Life Cycle Assessment to High-quality Soil Conditioner Production from Biowaste. Waste Manag. 2023, 172, 216–225. [Google Scholar] [CrossRef]

- Yana, S.; Nizar, M.; Irhamni; Mulyati, D. Biomass Waste as a Renewable Energy in Developing Bio-Based Economies in Indonesia: A Review. Renew. Sustain. Energy Rev. 2022, 160, 112268. [Google Scholar] [CrossRef]

- Abdulrahman, A.O.; Huisingh, D. The Role of Biomass as a Cleaner Energy Source in Egypt’s Energy Mix. J. Clean. Prod. 2018, 172, 3918–3930. [Google Scholar] [CrossRef]

- Ahmad, W.; Nisar, J.; Anwar, F.; Muhammad, F. Future Prospects of Biomass Waste as Renewable Source of Energy in Pakistan: A Mini Review. Bioresour. Technol. Rep. 2023, 24, 101658. [Google Scholar] [CrossRef]

- Cupertino, G.F.M.; da Silva, Á.M.; Pereira, A.K.S.; Delatorre, F.M.; Ucella-Filho, J.G.M.; de Souza, E.C.; Profeti, D.; Profeti, L.P.R.; Oliveira, M.P.; Saloni, D.; et al. Co-Pyrolysis of Biomass and Polyethylene Terephthalate (PET) as an Alternative for Energy Production from Waste Valorization. Fuel 2024, 362, 130761. [Google Scholar] [CrossRef]

- Tonini, D.; Astrup, T. LCA of Biomass-Based Energy Systems: A Case Study for Denmark. Appl. Energy 2012, 99, 234–246. [Google Scholar] [CrossRef]

- Peng, L.; Searchinger, T.D.; Zionts, J.; Waite, R. The Carbon Costs of Global Wood Harvests. Nature 2023, 620, 110–115. [Google Scholar] [CrossRef] [PubMed]

- Zbieć, M.; Franc-Dąbrowska, J.; Drejerska, N. Wood Waste Management in Europe through the Lens of the Circular Bioeconomy. Energies 2022, 15, 4352. [Google Scholar] [CrossRef]

- Chary, K.; Aubin, J.; Guindé, L.; Sierra, J.; Blazy, J.M. Cultivating Biomass Locally or Importing It? LCA of Biomass Provision Scenarios for Cleaner Electricity Production in a Small Tropical Island. Biomass Bioenergy 2018, 110, 1–12. [Google Scholar] [CrossRef]

- López-Bellido, L.; Wery, J.; López-Bellido, R.J. Energy Crops: Prospects in the Context of Sustainable Agriculture. Eur. J. Agron. 2014, 60, 1–12. [Google Scholar] [CrossRef]

- Steubing, B.; Zah, R.; Ludwig, C. Life Cycle Assessment of SNG from Wood for Heating, Electricity, and Transportation. Biomass Bioenergy 2011, 35, 2950–2960. [Google Scholar] [CrossRef]

- Chojnacki, J.; Najser, J.; Rokosz, K.; Peer, V.; Kielar, J.; Berner, B. Syngas Composition: Gasification Ofwood Pellet with Water Steam through a Reactor with Continuous Biomass Feed System. Energies 2020, 13, 4376. [Google Scholar] [CrossRef]

- Couto, N.; Rouboa, A.; Silva, V.; Monteiro, E.; Bouziane, K. Influence of the Biomass Gasification Processes on the Final Composition of Syngas. Energy Procedia 2013, 36, 596–606. [Google Scholar] [CrossRef]

- Uddin, M.N.; Techato, K.; Taweekun, J.; Rahman, M.M.; Rasul, M.G.; Mahlia, T.M.I.; Ashrafur, S.M. An Overview of Recent Developments in Biomass Pyrolysis Technologies. Energies 2018, 11, 3115. [Google Scholar] [CrossRef]

- Ferreira, S.; Monteiro, E.; Calado, L.; Silva, V.; Brito, P.; Vilarinho, C. Experimental and Modeling Analysis of Brewers’ Spent Grains Gasification in a Downdraft Reactor. Energies 2019, 12, 4413. [Google Scholar] [CrossRef]

- Bachmann, M.; Völker, S.; Kleinekorte, J.; Bardow, A. Syngas from What? Comparative Life-Cycle Assessment for Syngas Production from Biomass, CO2, and Steel Mill Off-Gases. ACS Sustain. Chem. Eng. 2023, 11, 5356–5366. [Google Scholar] [CrossRef]

- Tyagi, V.K.; Lo, S.-L. Chapter 10—Energy and Resource Recovery From Sludge: Full-Scale Experiences. In Environmental Materials and Waste; Prasad, M.N.V., Shih, K., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 221–244. ISBN 978-0-12-803837-6. [Google Scholar]

- Opia, A.C.; Hamid, M.K.B.A.; Syahrullail, S.; Rahim, A.B.A.; Johnson, C.A.N. Biomass as a Potential Source of Sustainable Fuel, Chemical and Tribological Materials—Overview. Mater. Today Proc. 2019, 39, 922–928. [Google Scholar] [CrossRef]

- Bartoletti, A.; Sangiorgi, A.; Mercadelli, E.; Melandri, C.; Gondolini, A.; García-González, S.; Ortiz-Membrado, L.; Morales, M.; Jimenez-Pique, E.; Sanson, A. 3D Microextrusion of Eco-Friendly Water Based Cer-Cer Composite Pastes for Hydrogen Separation. Open Ceram. 2023, 16, 100504. [Google Scholar] [CrossRef]

- Ardolino, F.; Arena, U. Biowaste-to-Biomethane: An LCA Study on Biogas and Syngas Roads. Waste Manag. 2019, 87, 441–453. [Google Scholar] [CrossRef] [PubMed]

- Kalinci, Y.; Hepbasli, A.; Dincer, I. Life Cycle Assessment of Hydrogen Production from Biomass Gasification Systems. Int. J. Hydrogen Energy 2012, 37, 14026–14039. [Google Scholar] [CrossRef]

- Yahyazadeh, A.; Nanda, S.; Dalai, A.K.; Zhang, L. Chapter 10—Conversion of Syngas to Olefins and Green Hydrocarbons through Fischer–Tropsch Catalysis. In Biomass to Bioenergy; Nanda, S., Dalai, A.K., Eds.; Woodhead Publishing: Cambridge, UK, 2024; pp. 237–276. ISBN 978-0-443-15377-8. [Google Scholar]

- Mahinpey, N.; Farooqui, A.; Abdalla, A.; Asghari, K. Chapter 12—Power Generation from Syngas. In Advances in Synthesis Gas: Methods, Technologies and Applications; Rahimpour, M.R., Makarem, M.A., Meshksar, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; Volume 3, pp. 289–319. ISBN 978-0-323-91878-7. [Google Scholar]

- Materazzi, M.; Chari, S.; Sebastiani, A.; Lettieri, P.; Paulillo, A. Waste-to-Energy and Waste-to-Hydrogen with CCS: Methodological Assessment of Pathways to Carbon-Negative Waste Treatment from an LCA Perspective. Waste Manag. 2024, 173, 184–199. [Google Scholar] [CrossRef]

- Novak, J.M.; Lima, I.; Xing, B.; Gaskin, J.W.; Steiner, C.; Das, K.C.; Ahmedna, M.; Rehrah, D.; Watts, D.W.; Busscher, W.J.; et al. Characterization of designer biochar produced at different temperatures and their effects on a loamy sand. Ann. Environ. Sci. 2009, 3, 195–206. [Google Scholar]

- Karhu, K.; Mattila, T.; Bergström, I.; Regina, K. Biochar Addition to Agricultural Soil Increased CH4 Uptake and Water Holding Capacity—Results from a Short-Term Pilot Field Study. Agric. Ecosyst. Environ. 2011, 140, 309–313. [Google Scholar] [CrossRef]

- Barrow, C.J. Biochar: Potential for Countering Land Degradation and for Improving Agriculture. Appl. Geogr. 2012, 34, 21–28. [Google Scholar] [CrossRef]

- Deem, L.M.; Crow, S.E. Biochar. In Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Schnell, R.W.; Vietor, D.M.; Provin, T.L.; Munster, C.L.; Capareda, S. Capacity of Biochar Application to Maintain Energy Crop Productivity: Soil Chemistry, Sorghum Growth, and Runoff Water Quality Effects. J. Environ. Qual. 2012, 41, 1044–1051. [Google Scholar] [CrossRef] [PubMed]

- Baronti, S.; Vaccari, F.P.; Miglietta, F.; Calzolari, C.; Lugato, E.; Orlandini, S.; Pini, R.; Zulian, C.; Genesio, L. Impact of Biochar Application on Plant Water Relations in Vitis vinifera (L.). Eur. J. Agron. 2014, 53, 38–44. [Google Scholar] [CrossRef]

- Oni, B.A.; Oziegbe, O.; Olawole, O.O. Significance of Biochar Application to the Environment and Economy. Ann. Agric. Sci. 2019, 64, 222–236. [Google Scholar] [CrossRef]

- Pesonen, J.; Kuokkanen, T.; Rautio, P.; Lassi, U. Bioavailability of Nutrients and Harmful Elements in Ash Fertilizers: Effect of Granulation. Biomass Bioenergy 2017, 100, 92–97. [Google Scholar] [CrossRef]

- Zardzewiały, M.; Bajcar, M.; Puchalski, C.; Gorzelany, J. The Possibility of Using Waste Biomass from Selected Plants Cultivated for Industrial Purposes to Produce a Renewable and Sustainable Source of Energy. Appl. Sci. 2023, 13, 3195. [Google Scholar] [CrossRef]

- Wu, Y.; Yan, Y.; Wang, Z.; Tan, Z.; Zhou, T. Biochar Application for the Remediation of Soil Contaminated with Potentially Toxic Elements: Current Situation and Challenges. J. Environ. Manag. 2024, 351, 119775. [Google Scholar] [CrossRef] [PubMed]

- Campion, L.; Bekchanova, M.; Malina, R.; Kuppens, T. The Costs and Benefits of Biochar Production and Use: A Systematic Review. J. Clean. Prod. 2023, 408, 137138. [Google Scholar] [CrossRef]

- Lehmann, J. Terra Preta Nova-Where to from Here? Springer: Dordrecht, The Netherlands, 2009. [Google Scholar]

- Ciacci, L.; Passarini, F. Life Cycle Assessment (Lca) of Environmental and Energy Systems. Energies 2020, 13, 5892. [Google Scholar] [CrossRef]

- Mantulet, G.; Bidaud, A.; Mima, S. The Role of Biomass Gasification and Methanisation in the Decarbonisation Strategies. Energy 2020, 193, 108–118. [Google Scholar] [CrossRef]

- Marzeddu, S.; Cappelli, A.; Ambrosio, A.; Décima, M.A.; Viotti, P.; Boni, M.R. A Life Cycle Assessment of an Energy-Biochar Chain Involving a Gasification Plant in Italy. Land 2021, 10, 1256. [Google Scholar] [CrossRef]

- Li, G.; Ma, S.; Liu, F.; Zhou, X.; Wang, K.; Zhang, Y. Life Cycle Water Footprint Assessment of Syngas Production from Biomass Chemical Looping Gasification. Bioresour. Technol. 2021, 342, 125940. [Google Scholar] [CrossRef]

- Koroneos, C.; Dompros, A.; Roumbas, G. Hydrogen Production via Biomass Gasification—A Life Cycle Assessment Approach. Chem. Eng. Process. Process Intensif. 2008, 47, 1261–1268. [Google Scholar] [CrossRef]

- Giuliano, A.; Catizzone, E.; Freda, C.; Cornacchia, G. Valorization of OFMSW Digestate-Derived Syngas toward Methanol, Hydrogen, or Electricity: Process Simulation and Carbon Footprint Calculation. Processes 2020, 8, 526. [Google Scholar] [CrossRef]

- Carvalho, J.; Nascimento, L.; Soares, M.; Valério, N.; Ribeiro, A.; Faria, L.; Silva, A.; Pacheco, N.; Araújo, J.; Vilarinho, C. Life Cycle Assessment (LCA) of Biochar Production from a Circular Economy Perspective. Processes 2022, 10, 2684. [Google Scholar] [CrossRef]

- Roberts, K.G.; Gloy, B.A.; Joseph, S.; Scott, N.R.; Lehmann, J. Life Cycle Assessment of Biochar Systems: Estimating the Energetic, Economic, and Climate Change Potential. Environ. Sci. Technol. 2010, 44, 827–833. [Google Scholar] [CrossRef] [PubMed]

- Azzi, E.S.; Karltun, E.; Sundberg, C. Life Cycle Assessment of Urban Uses of Biochar and Case Study in Uppsala, Sweden. Biochar 2022, 4, 18. [Google Scholar] [CrossRef]

- Hussin, F.; Hazani, N.N.; Khalil, M.; Aroua, M.K. Environmental Life Cycle Assessment of Biomass Conversion Using Hydrothermal Technology: A Review. Fuel Process. Technol. 2023, 246, 107747. [Google Scholar] [CrossRef]

- Brás, I.; Silva, E.; Raimondo, R.; Saetta, R.; Mignano, V.; Fabbricino, M.; Ferreira, J. Valorisation of Forest and Agriculture Residual Biomass—The Application of Life Cycle Assessment to Analyse Composting, Mulching, and Energetic Valorisation Strategies. Sustainability 2024, 16, 630. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006; Volume 2003.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines/Amd 1:2017+Amd 2:2020. ISO: Geneva, Switzerland, 2006.

- PRé Consultants LCA Software. SimaPro 9.5, Eco-It, e-DEA e Triangle Tool. Available online: https://simapro.com/wp-content/uploads/2023/04/SimaPro950WhatIsNew.pdf (accessed on 20 February 2024).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. International Journal of Life Cycle Ass. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- IEA Electricity Generation by Source. Available online: https://www.iea.org/data-and-statistics/charts/electricity-generation-by-source-oecd-2000-2020 (accessed on 20 February 2024).

- Ware, A.; Power, N. Biogas from Cattle Slaughterhouse Waste: Energy Recovery towards an Energy Self-Sufficient Industry in Ireland. Renew. Energy 2016, 97, 541–549. [Google Scholar] [CrossRef]

- Arfelli, F.; Maria Pizzone, D.; Cespi, D.; Ciacci, L.; Ciriminna, R.; Salvatore Calabrò, P.; Pagliaro, M.; Mauriello, F.; Passarini, F. Prospective Life Cycle Assessment for the Full Valorization of Anchovy Fillet Leftovers: The LimoFish Process. Waste Manag. 2023, 168, 156–166. [Google Scholar] [CrossRef]

- Rodrigues, C.I.D.; Brito, L.M.; Nunes, L.J.R. Soil Carbon Sequestration in the Context of Climate Change Mitigation: A Review. Soil Syst. 2023, 7, 64. [Google Scholar] [CrossRef]

- Lindén, L.; Riikonen, A.; Setälä, H.; Yli-Pelkonen, V. Quantifying Carbon Stocks in Urban Parks under Cold Climate Conditions. Urban. Urban Green. 2020, 49, 126633. [Google Scholar] [CrossRef]

- Colantoni, A.; Longo, L.; Evic, N.; Gallucci, F.; Delfanti, L. Use of Hazelnut’s Pruning to Produce Biochar by Gasifier Small Scale Plant. Int. J. Renew. Energy Res. 2015, 5, 873–878. [Google Scholar]

- Hansen, V.; Müller-Stöver, D.; Ahrenfeldt, J.; Holm, J.K.; Henriksen, U.B.; Hauggaard-Nielsen, H. Gasification Biochar as a Valuable By-Product for Carbon Sequestration and Soil Amendment. Biomass Bioenergy 2015, 72, 300–308. [Google Scholar] [CrossRef]

- European Biochar Certificate Limit Composition of Biochar. Available online: https://www.european-biochar.org/en (accessed on 16 November 2023).

- Aguilar Quiroz, C.E.; Valverde Diaz, E.I.; Layza Escobar, E.G.; Urquiaga Rios, J.F.; Jáuregui Rosas, S.R. Leaching and Heat Treatment of Chrome Shavings: Stability of Chromium (III). Case Stud. Chem. Environ. Eng. 2023, 8, 100481. [Google Scholar] [CrossRef]

- Wang, Y.; Fang, X.; Deng, P.; Rong, Z.; Tang, X.; Cao, S. Study on Thermodynamic Model of Arsenic Removal from Oxidative Acid Leaching. J. Mater. Res. Technol. 2020, 9, 3208–3218. [Google Scholar] [CrossRef]

- Havlík, J.; Dlouhý, T. Indirect Dryers for Biomass Drying—Comparison of Experimental Characteristics for Drum and Rotary Configurations. ChemEngineering 2020, 4, 18. [Google Scholar] [CrossRef]

- LAIMET Laimet Chipper HS 21 A. Available online: https://www.laimet.com/en/chippers/hs-21-a/ (accessed on 16 November 2023).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Goedkoop, M.; Oele, M.; Leijting, J.; Ponsioen, T.; Meijer, E. Introduction to LCA with SimaPro. 2016. Available online: https://www.researchgate.net/publication/305444131_Introduction_to_LCA_with_SimaPro (accessed on 20 February 2024).

- Weidema, B.P.; Wesnæs, M.S. Data Quality Management for Life Cycle Inventories—An Example of Using Data Quality Indicators. J. Clean. Prod. 1996, 4, 167–174. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. Life Cycle Assessment; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Zang, G.; Zhang, J.; Jia, J.; Lora, E.S.; Ratner, A. Life Cycle Assessment of Power-Generation Systems Based on Biomass Integrated Gasification Combined Cycles. Renew. Energy 2020, 149, 336–346. [Google Scholar] [CrossRef]

- De Meyer, A.; Cattrysse, D.; Van Orshoven, J. Considering Biomass Growth and Regeneration in the Optimisation of Biomass Supply Chains. Renew. Energy 2016, 87, 990–1002. [Google Scholar] [CrossRef]

- Brtnicky, M.; Datta, R.; Holatko, J.; Bielska, L.; Gusiatin, Z.M.; Kucerik, J.; Hammerschmiedt, T.; Danish, S.; Radziemska, M.; Mravcova, L.; et al. A Critical Review of the Possible Adverse Effects of Biochar in the Soil Environment. Sci. Total Environ. 2021, 796, 148756. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Yang, S.H.; Jiang, Z.W.; Ding, J.; Sun, X. Biochar as a Tool to Reduce Environmental Impacts of Nitrogen Loss in Water-Saving Irrigation Paddy Field. J. Clean. Prod. 2021, 290, 125811. [Google Scholar] [CrossRef]

- Tonini, D.; Hamelin, L.; Astrup, T.F. Environmental Implications of the Use of Agro-Industrial Residues for Biorefineries: Application of a Deterministic Model for Indirect Land-Use Changes. GCB Bioenergy 2016, 8, 690–706. [Google Scholar] [CrossRef]

- Kujawska, J. Content of Heavy Metals in Various Biochar and Assessment Environmental Risk. J. Ecol. Eng. 2023, 24, 287–295. [Google Scholar] [CrossRef]

- Wang, Y.; Li, H.; Lin, S. Advances in the Study of Heavy Metal Adsorption from Water and Soil by Modified Biochar. Water 2022, 14, 3894. [Google Scholar] [CrossRef]

- Wang, J.X.; Xu, D.M.; Fu, R.B.; Chen, J.P. Bioavailability Assessment of Heavy Metals Using Various Multi-Element Extractants in an Indigenous Zinc Smelting Contaminated Site, Southwestern China. Int. J. Environ. Res. Public Health 2021, 18, 8560. [Google Scholar] [CrossRef]

- Zhu, Q.; Ji, J.; Tang, X.; Wang, C.; Sun, H. Bioavailability Assessment of Heavy Metals and Organic Pollutants in Water and Soil Using DGT: A Review. Appl. Sci. 2023, 13, 9760. [Google Scholar] [CrossRef]

- Olaniran, A.O.; Balgobind, A.; Pillay, B. Bioavailability of Heavy Metals in Soil: Impact on Microbial Biodegradation of Organic Compounds and Possible Improvement Strategies. Int. J. Mol. Sci. 2013, 14, 10197–10228. [Google Scholar] [CrossRef]

- Plum, L.M.; Rink, L.; Hajo, H. The Essential Toxin: Impact of Zinc on Human Health. Int. J. Environ. Res. Public Health 2010, 7, 1342–1365. [Google Scholar] [CrossRef] [PubMed]

| EBC Agro (g/tDM) | EBC AgroBio (g/tDM) | |

|---|---|---|

| Pb | 120 | 45 |

| Cd | 1.5 | 0.7 |

| Cu | 100 | 70 |

| Ni | 50 | 25 |

| Hg | 1 | 0.4 |

| Zn | 400 | 200 |

| Cr | 90 | 70 |

| As | 13 | 13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arfelli, F.; Tosi, C.; Ciacci, L.; Passarini, F. Life Cycle Assessment of a Wood Biomass Gasification Plant and Implications for Syngas and Biochar Utilization. Energies 2024, 17, 2599. https://doi.org/10.3390/en17112599

Arfelli F, Tosi C, Ciacci L, Passarini F. Life Cycle Assessment of a Wood Biomass Gasification Plant and Implications for Syngas and Biochar Utilization. Energies. 2024; 17(11):2599. https://doi.org/10.3390/en17112599

Chicago/Turabian StyleArfelli, Francesco, Cristian Tosi, Luca Ciacci, and Fabrizio Passarini. 2024. "Life Cycle Assessment of a Wood Biomass Gasification Plant and Implications for Syngas and Biochar Utilization" Energies 17, no. 11: 2599. https://doi.org/10.3390/en17112599