Assessing the Potential for Electrification of the Food Industry and Its Implications for Environmental Sustainability

Abstract

:1. Introduction

1.1. Assessment of the Environmental Impact of the Electrification of Industrial Heat

1.2. Sustainability Definition and Inclusion for Industrial Sectors’ Decarbonization

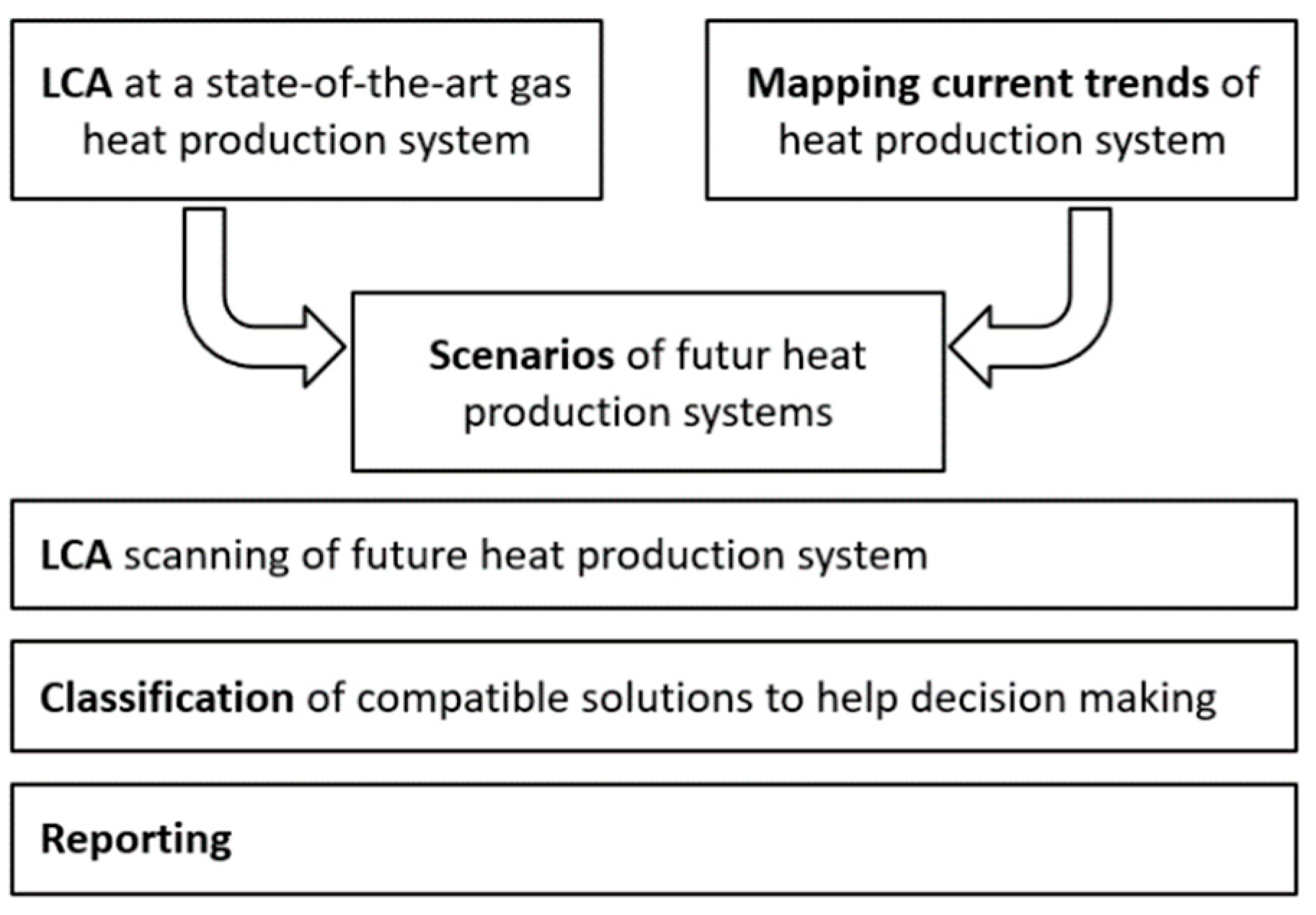

1.3. Present Work Objective and Novelties

- (a)

- The sustainability of the electrification is evaluated against “sustainable levels based on planet boundaries, resource consumption or human health; this is a clear step forward if compared to other available works, which mainly conduct evaluations using energy efficiency and/or LCA.

- (b)

- The combination of utilitarian and prioritarian methods is used to perform the downscaling at the industrial sector scale. Two utilitarian criterions are proposed, one based on the current GHG emissions level, and the other on economic value added. It is then proposed to couple the economic criterion with a “contribution” indicator developed in this work, which corrects the downscaling using a prioritarian principle (penalization of highly contributing sectors).

- (c)

- To illustrate the relevance of this original approach, the impacts of the electrification of the heat generation for the Danish and French food industry sectors are evaluated, so that two electrical mixes with different decarbonized production sources are considered.

2. Materials and Methods

2.1. Energy in an Environmental Assessment Framework

2.2. Energy an Environmental Assessment Framework

2.2.1. Energy Efficiency

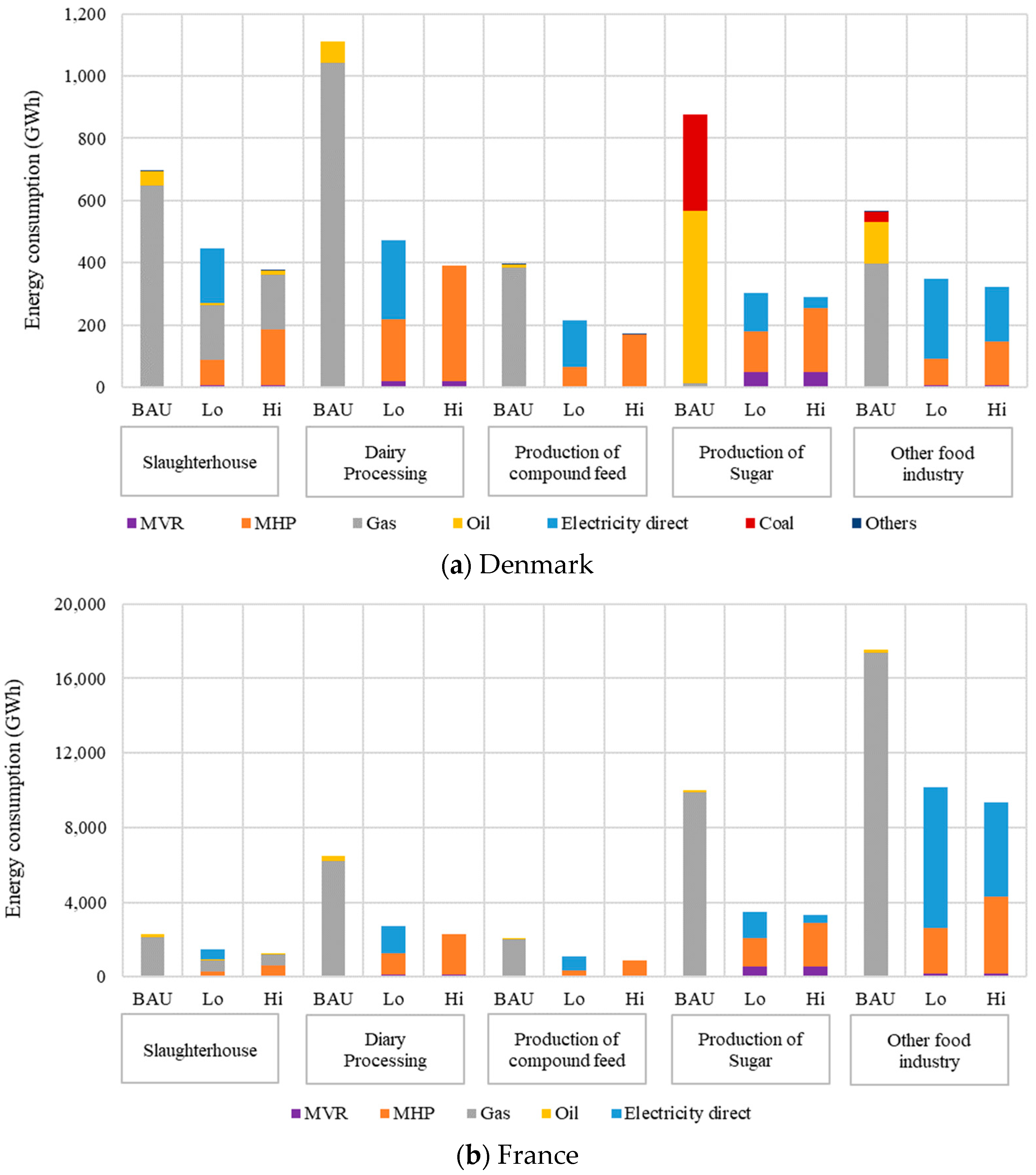

2.2.2. Danish and French Consumption Scenarios

2.2.3. Electricity Mix

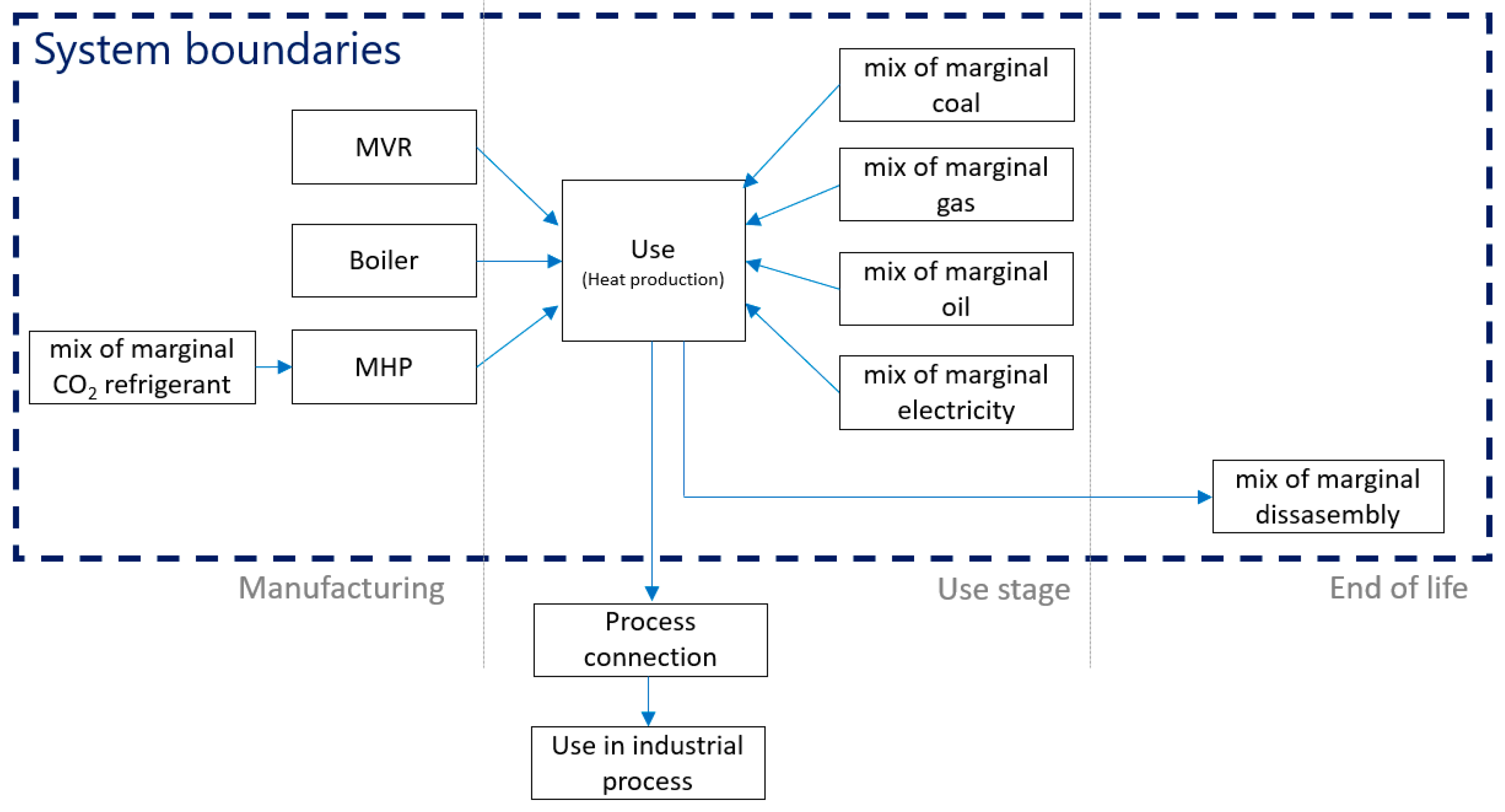

2.3. Environmental Model Description

2.4. Environmental Sustainability Assessment

- The simplest approach is to use the share of the current sector impact in relation to the total environmental impact, as presented in Equation (8):

- The second approach is based on the economic importance of the sector considered in relation to all human activities. It is calculated using the economic value added (EVA) of the process compared to the global value added (EVAtot):

2.5. Contribution Level

3. Results

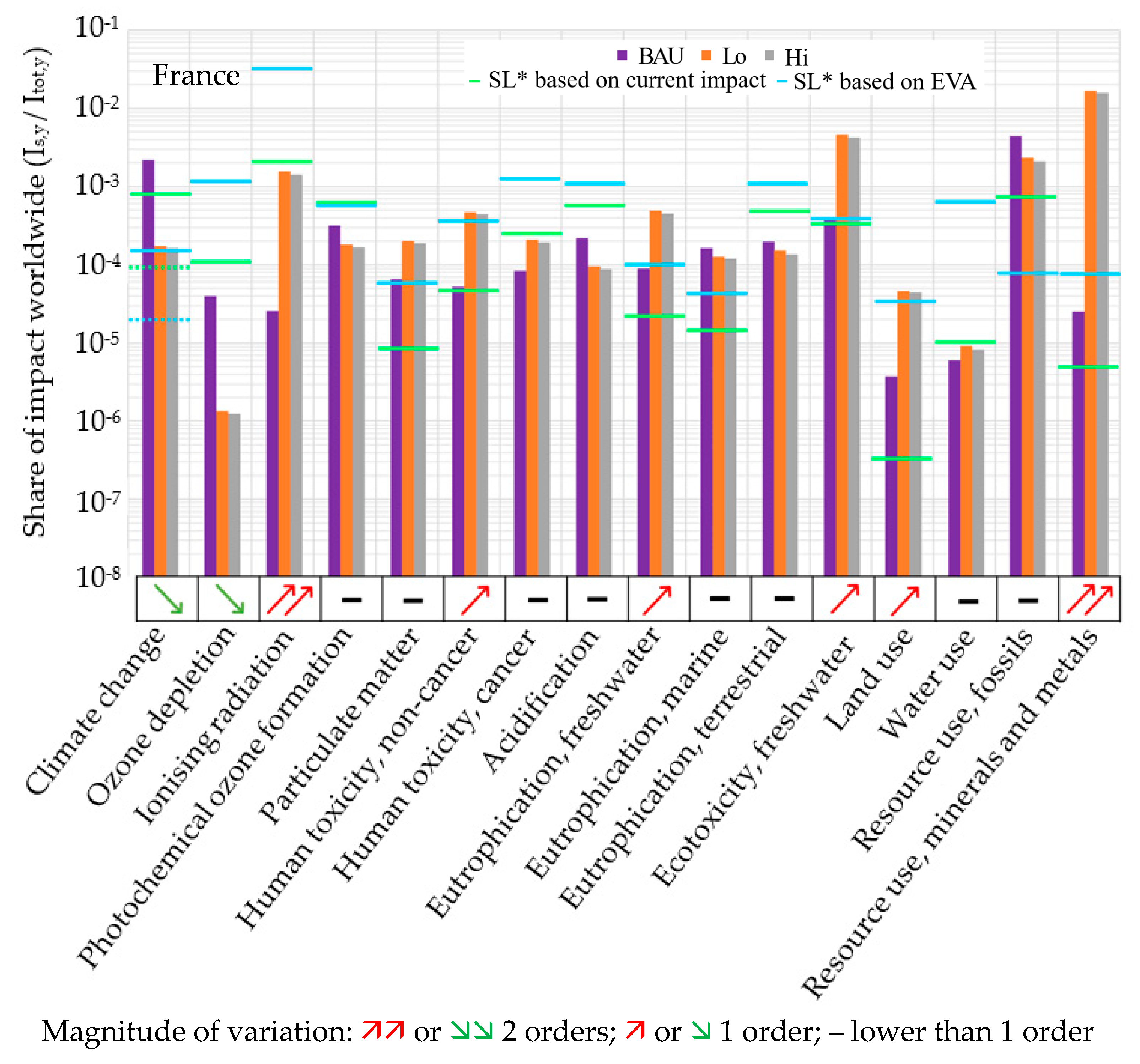

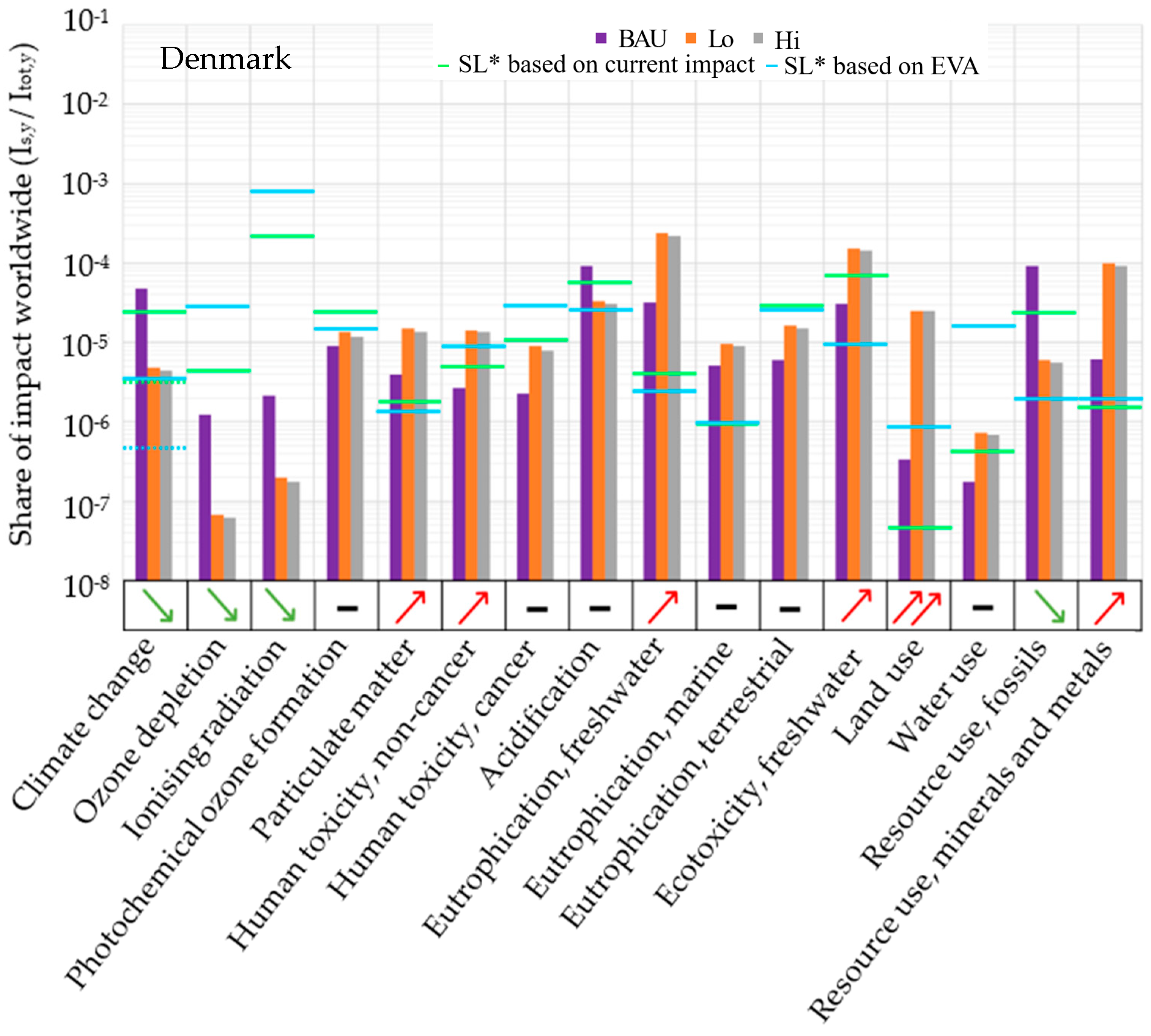

3.1. Environmental Assessment of the Scenarios Compared to the Sustainable Level

- “Ionizing radiation”. The use of nuclear power leads to a significant increase in this indicator for France, while it decreases for Denmark due to the prevalence of wind and biomass in the mix. It is noteworthy that, despite this increase, the impact remains below sustainable levels.

- “Land use”. Both countries see a significant increase because current fossil-based mixes are the most efficient solutions for this indicator. However, the extent of the increase depends heavily on the transformation strategy. The difference between the 11-fold increase for France and the 59-fold for Denmark is mainly due to the use of biomass.

- “Resource use, fossil”. As the use of fissile material is included in this contribution, the presence of nuclear power impacts the French industry by maintaining a level close to the current one, while for the Danish mix, a significant decrease is observed.

- “Resource use, mineral and metal”. The increase is more significant for France, with a higher share of non-controllable energy (Table 3) and, therefore, a more significant use of batteries. Similar to the “land use” impact, it is observed that the sustainable level is overtaken by the sector because electrification leads to increased consumption of mineral resources.

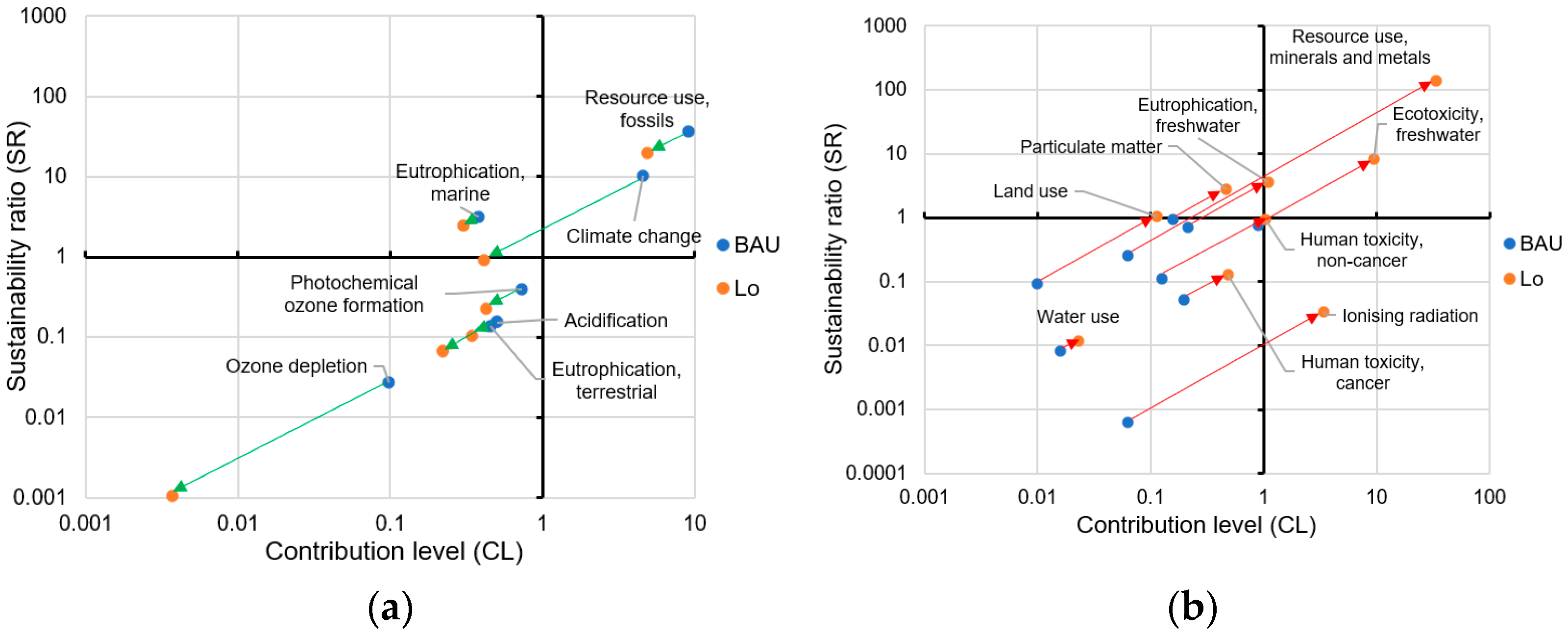

3.2. Combined Sustainable Ratio and Contribution Level

- Bottom-left zone. The sustainability ratio as well as the contribution level are lower than 1, meaning the reported impacts (e.g., “ozone depletion”) correspond to a sustainable level and to a contribution share below the average of human activities, i.e., the considered sector is not a major contributor in the global economy for these impact categories and is hence of less importance. Even if this sector grows in the future, it is not expected to have a major global impact for the considered environmental indicator.

- Bottom-right zone. The sustainability ratio is lower than 1, while the contribution level is greater than 1. This is the case for impacts for which a sustainable level is reached but with a contribution share above the average. Hence, despite their sustainability, the significance of these categories in the global economy implies the need to look carefully at them. While no impact category is present in this zone for France, some can be found for Denmark, such as “acidification”, because of the importance of the agri-food sector.

- Top-left zone. The sustainability ratio is greater than 1 while the contribution level is lower than 1. In this case, the resulting impacts are unsustainable, but the contribution share is low compared to that of the other activities. Consequently, the growth or decline in this economic sector is not expected to result in a major modification in compliance with global sustainability thresholds for the considered impact. “Eutrophication” for France and “resource use, mineral and metal” for Denmark are in this configuration.

- Top-right zone. In this zone, both the sustainability ratios and the contribution level are greater than 1, meaning the impact categories concerned are both unsustainable, contributing more than the average of human activities. Categories such as “resource use, minerals and metals” are the most critical after electrification as the sector makes a major contribution to the unsustainability of these indicators. For Denmark, “land use” is also in this category due to the high share of biomass in the electricity mix.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

- (i)

- This study does not consider increased or decreased process need;

- (ii)

- The environmental threshold needs to be adapted for every process to consider this specificity;

- (iii)

- The solutions proposed in this study are a set of non-dominated solutions and there is no single dominant solution.

| Source | Impact Category | Units | Description |

|---|---|---|---|

| EF 3.0 | Climate change | kg CO2 eq | Radiative forcing as Global Warming Potential GWP100 Baseline model of the IPCC 2013 with some factors adapted from EF guidance. |

| Ozone depletion | kg CFC11 eq | Ozone Depletion Potential calculating the destructive effects on the stratospheric ozone layer over a time horizon of 100 years. | |

| Ionising radiation | kBq U-235 eq | Ionizing Radiation Potentials: Quantification of the impact of ionizing radiation on the population, in comparison to Uranium 235. | |

| Photochemical ozone formation | kg NMVOC eq | Expression of the potential contribution to photochemical ozone formation. | |

| Particulate matter | disease incidence | Disease incidence due to kg of PM2.5 emitted. The indicator is calculated applying the average slope between the Emission Response Function (ERF) working point and the theoretical minimum-risk level. Exposure model based on archetypes that include urban environments, rural environments, and indoor environments within urban and rural areas. | |

| Human toxicity, non-cancer | CTUh | Comparative Toxic Unit for humans. Using USEtox consensus multimedia model. It spans two spatial scales: continental scale consisting of six compartments (urban air, rural air, agricultural soil, natural soil, freshwater and costal marine water), and the global scale with the same structure but without the urban air. | |

| Human toxicity, cancer | CTUh | ||

| Acidification | mol H+ eq | Accumulated Exceedance characterising the change in critical load exceedance of the sensitive area in terrestrial and main freshwater ecosystems, to which acidifying substances deposit. | |

| Eutrophication, freshwater | kg P eq | ||

| Eutrophication, marine | kg N eq | Nitrogen equivalents: Expression of the degree to which the emitted nutrients reach the marine end compartment (nitrogen considered as limiting factor in marine water). | |

| Eutrophication, terrestrial | mol N eq | Accumulated Exceedance characterising the change in critical load exceedance of the sensitive area, to which eutrophying substances deposit. | |

| Ecotoxicity, freshwater | CTUe | Comparative Toxic Unit for ecosystems. Using USEtox consensus multimedia model. It spans two spatial scales: continental scale consisting of six compartments (urban air, rural air, agricultural soil, natural soil, freshwater and costal marine water), and the global scale with the same structure but without the urban air. | |

| Land use | Pt | Soil quality index. Calculated by JRC starting from LANCA® v 2.2 as baseline model. | |

| Water use | m3 deprivation | User deprivation potential (deprivation-weighted water consumption) Relative Available WAter REmaining (AWARE) per area in a watershed, after the demand of humans and aquatic ecosystems has been met. Blue water consumption only is considered, where consumption is defined as the difference between withdrawal and release of blue water. Green water, fossil water, sea water, and rainwater are not to be characterised with this methodology. | |

| Resource use, fossils | MJ | Abiotic resource depletion fossil fuels; based on lower heating value ADP for energy carriers, based on van Oers et al., 2002 as implemented in CML, v. 4.8 (2016). | |

| Resource use, minerals and metals | kg Sb eq | Abiotic resource depletion (ADP ultimate reserve) ADP for mineral and metal resources, based on van Oers et al., 2002 as implemented in CML, v. 4.8 (2016). | |

| Ecoinvent | Cumulative energy demand | MJ | Method to calculate Cumulative Energy Demand (CED), based on the method published by Ecoinvent version 2.0 and expanded by PRé Consultants for raw materials available in the SimaPro 7 database. The method is based on higher heating values (HHVs). |

| Cumulative exergy demand | MJ | In this method exergy is used as a measure of the potential loss of “useful” energy resources. |

References

- European Commission. Masterplan for a Competitive Transformation of EU Energy-Intensive Industries Enabling a Climate-Neutral, Circular Economy by 2050. In Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs; EU Publications: Luxembourg, 2019. [Google Scholar] [CrossRef]

- Obrist, M.D.; Kannan, R.; Schmidt, T.J.; Kober, T. Long-Term Energy Efficiency and Decarbonization Trajectories for the Swiss Pulp and Paper Industry. Sustain. Energy Technol. Assess. 2022, 52, 101937. [Google Scholar] [CrossRef]

- Bogdanov, D.; Gulagi, A.; Fasihi, M.; Breyer, C. Full Energy Sector Transition towards 100% Renewable Energy Supply: Integrating Power, Heat, Transport and Industry Sectors Including Desalination. Appl. Energy 2021, 283, 116273. [Google Scholar] [CrossRef]

- Directorate-General for Energy (European Commission); DTU; Trinomics; Öko-Institut e. V; Gerard, F.; Smit, T.; Rademaekers, K.; Braungardt, S.; Monejar Montagud, M.E.; Guevara Opinska, L. Policy Support for Heating and Cooling Decarbonisation: Roadmap; Publications Office of the European Union: Luxembourg, 2022; ISBN 978-92-76-52342-0. [Google Scholar]

- Aughinish Alumina Ltd. AAL SEB: Using Flexible Electrical Demand to Facilitate Higher Levels of Renewable Energy. Available online: https://climate.ec.europa.eu/document/download/02c679ea-43c7-4c9b-85f0-537e243ece6b_en?filename=if_pf_2021_aal_seb_en.pdf (accessed on 22 May 2024).

- Jibran, S.; Zuberi, M.; Hasanbeigi, A.; Morrow, W. Bottom-up Assessment of Industrial Heat Pump Applications in U.S. Food Manufacturing. Energy Convers. Manag. 2022, 272, 116349. [Google Scholar] [CrossRef]

- Jovet, Y.; Lefèvre, F.; Laurent, A.; Clausse, M. Combined Energetic, Economic and Climate Change Assessment of Heat Pumps for Industrial Waste Heat Recovery. Appl. Energy 2022, 313, 118854. [Google Scholar] [CrossRef]

- Schoeneberger, C.; Zhang, J.; McMillan, C.; Dunn, J.B.; Masanet, E. Electrification Potential of U.S. Industrial Boilers and Assessment of the GHG Emissions Impact. Adv. Appl. Energy 2022, 5, 100089. [Google Scholar] [CrossRef]

- Furszyfer Del Rio, D.D.; Sovacool, B.K.; Foley, A.M.; Griffiths, S.; Bazilian, M.; Kim, J.; Rooney, D. Decarbonizing the Glass Industry: A Critical and Systematic Review of Developments, Sociotechnical Systems and Policy Options. Renew. Sustain. Energy Rev. 2022, 155, 111885. [Google Scholar] [CrossRef]

- Furszyfer Del Rio, D.D.; Sovacool, B.K.; Foley, A.M.; Griffiths, S.; Bazilian, M.; Kim, J.; Rooney, D. Decarbonizing the Ceramics Industry: A Systematic and Critical Review of Policy Options, Developments and Sociotechnical Systems. Renew. Sustain. Energy Rev. 2022, 157, 112081. [Google Scholar] [CrossRef]

- Laurent, A.; Olsen, S.I.; Hauschild, M.Z. Limitations of Carbon Footprint as Indicator of Environmental Sustainability. Environ. Sci. Technol. 2012, 46, 4100–4108. [Google Scholar] [CrossRef]

- Laurent, A.; Owsianiak, M. Potentials and Limitations of Footprints for Gauging Environmental Sustainability. Curr. Opin. Environ. Sustain. 2017, 25, 20–27. [Google Scholar] [CrossRef]

- Jovet, Y.; Lefevre, F.; Laurent, A.; Clausse, M. Assessing the Relevance of Energy Indicators as Sustainability Screening Metrics for the Decarbonisation of Industrial Heat through Electrification. Energy 2024, 292, 130440. [Google Scholar] [CrossRef]

- Terlouw, T.; Gabrielli, P.; AlSkaif, T.; Bauer, C.; McKenna, R.; Mazzotti, M. Optimal Economic and Environmental Design of Multi-Energy Systems. Appl. Energy 2023, 347, 121374. [Google Scholar] [CrossRef]

- Urbano, D.G.; Aquino, A.; Scrucca, F. Energy Performance, Environmental Impacts and Costs of a Drying System: Life Cycle Analysis of Conventional and Heat Recovery Scenarios. Energies 2023, 16, 1523. [Google Scholar] [CrossRef]

- Marttila, M.P.; Uusitalo, V.; Linnanen, L.; Mikkilä, M.H. Agro-Industrial Symbiosis and Alternative Heating Systems for Decreasing the Global Warming Potential of Greenhouse Production. Sustainability 2021, 13, 9040. [Google Scholar] [CrossRef]

- Calero, M.; Clemente, G.; Fartdinov, D.; Bañón, S.; Muñoz, I.; Sanjuán, N. Upscaling via a Prospective LCA: A Case Study on Tomato Homogenate Using a Near-to-Market Pasteurisation Technology. Sustainability 2022, 14, 1716. [Google Scholar] [CrossRef]

- Fagerström, A.; Abdelaziz, O.; Poulikidou, S.; Lewrén, A.; Hulteberg, C.; Wallberg, O.; Rydberg, T. Economic and Environmental Potential of Large-Scale Renewable Synthetic Jet Fuel Production through Integration into a Biomass CHP Plant in Sweden. Energies 2022, 15, 1114. [Google Scholar] [CrossRef]

- Volkart, K.; Weidmann, N.; Bauer, C.; Hirschberg, S. Multi-Criteria Decision Analysis of Energy System Transformation Pathways: A Case Study for Switzerland. Energy Policy 2017, 106, 155–168. [Google Scholar] [CrossRef]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S.I.; Lambin, E.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. Planetary Boundaries: Exploring the Safe Operating Space for Humanity. Ecol. Soc. 2009, 14, 32. [Google Scholar] [CrossRef]

- Rubio Rodríguez, M.A.; Feitó Cespón, M.; De Ruyck, J.; Ocaña Guevara, V.S.; Verma, V.K. Life Cycle Modeling of Energy Matrix Scenarios, Belgian Power and Partial Heat Mixes as Case Study. Appl. Energy 2013, 107, 329–337. [Google Scholar] [CrossRef]

- Vargas-Gonzalez, M.; Witte, F.; Martz, P.; Gilbert, L.; Humbert, S.; Jolliet, O.; van Zelm, R.; L’Haridon, J. Operational Life Cycle Impact Assessment Weighting Factors Based on Planetary Boundaries: Applied to Cosmetic Products. Ecol. Indic. 2019, 107, 105498. [Google Scholar] [CrossRef]

- Sala, S.; Crenna, E.; Secchi, M.; Sanyé-Mengual, E. Environmental Sustainability of European Production and Consumption Assessed against Planetary Boundaries. J. Environ. Manag. 2020, 269, 110686. [Google Scholar] [CrossRef]

- Ryberg, M.W.; Andersen, M.M.; Owsianiak, M.; Hauschild, M.Z. Downscaling the Planetary Boundaries in Absolute Environmental Sustainability Assessments—A Review. J. Clean. Prod. 2020, 276, 123287. [Google Scholar] [CrossRef]

- Bjørn, A.; Chandrakumar, C.; Boulay, A.-M.; Doka, G.; Fang, K.; Gondran, N.; Hauschild, M.Z.; Kerkhof, A.; King, H.; Margni, M.; et al. Review of Life-Cycle Based Methods for Absolute Environmental Sustainability Assessment and Their Applications. Environ. Res. Lett. 2020, 15, 083001. [Google Scholar] [CrossRef]

- Hjalsted, A.W.; Laurent, A.; Andersen, M.M.; Olsen, K.H.; Ryberg, M.; Hauschild, M. Sharing the Safe Operating Space: Exploring Ethical Allocation Principles to Operationalize the Planetary Boundaries and Assess Absolute Sustainability at Individual and Industrial Sector Levels. J. Ind. Ecol. 2021, 25, 6–19. [Google Scholar] [CrossRef]

- Elmegaard, B.; Arjomand Kermani, N.; Bühler, F.; Nguyen, T.-V.; Bergamini, R.; Zühlsdorf, B.; Dupond Holdt, F. Electrification of Processes and Technologies for Danish Industry: Elforsk Project 350-038: Final Report; Technical University of Denmark: Lyngby, Denmark, 2021; p. 349. [Google Scholar]

- Bühler, F. Energy Efficiency in the Industry: A Study of the Methods, Potentials and Interactions with the Energy System, DTU Mechanical Engineering; DCAMM: Lyngby, Denmark, 2018. [Google Scholar]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. (Eds.) Life Cycle Assessment; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-56474-6. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Bühler, F.; Müller Holm, F.; Elmegaard, B. Potentials for the Electrification of Industrial Processes in Denmark: 32nd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems. In Proceedings of the ECOS 2019: 32nd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Wroclaw, Poland, 23–28 June 2019. [Google Scholar]

- AGRESTE. Consommation d’énergie Dans Les Industries Agroalimentaires et Les Scieries En 2019; Ministère de l’agriculture et de l’alimentation: Paris, France, 2021. [Google Scholar]

- RTE Futurs Énergétiques 2050: Les Scénarios de Mix de Production à l’étude Permettant d’atteindre La Neutralité Carbone à l’horizon 2050-Chap. 11 2021. Available online: https://www.rte-france.com/analyses-tendances-et-prospectives/bilan-previsionnel-2050-futurs-energetiques (accessed on 23 May 2024).

- RTE Futurs Énergétiques 2050: Les Scénarios de Mix de Production à l’étude Permettant d’atteindre La Neutralité Carbone à l’horizon 2050-Chap. 5 2021. Available online: https://www.rte-france.com/analyses-tendances-et-prospectives/bilan-previsionnel-2050-futurs-energetiques (accessed on 23 May 2024).

- Hesse, H.; Schimpe, M.; Kucevic, D.; Jossen, A. Lithium-Ion Battery Storage for the Grid—A Review of Stationary Battery Storage System Design Tailored for Applications in Modern Power Grids. Energies 2017, 10, 2107. [Google Scholar] [CrossRef]

- Suryatna, A.; Raya, I.; Thangavelu, L.; Alhachami, F.R.; Kadhim, M.M.; Altimari, U.S.; Mahmoud, Z.H.; Mustafa, Y.F.; Kianfar, E. A Review of High-Energy Density Lithium-Air Battery Technology: Investigating the Effect of Oxides and Nanocatalysts. J. Chem. 2022, 2022, 2762647. [Google Scholar] [CrossRef]

- Asian Development Bank Handbook on Battery Energy Storage System; Asian Development Bank: Manila, Philippines, 2018.

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- European Commission; Joint Research Centre. Supporting Information to the Characterisation Factors of Recommended EF Life Cycle Impact Assessment Methods: New Methods and Differences with ILCD; Publications Office: Luxembourg, 2018. [Google Scholar]

- IPCC/TEAP; Metz, B.; Kuijpers, L.; Solomon, S.; Andersen, S.O.; Davidson, O.; Pons, J.; de Jager, D.; Kestin, T.; Manning, M.; et al. (Eds.) Safeguarding the Ozone Layer and the Global Climate System: Issues Related to Hydrofluorocarbons and Perfluorocarbons; Cambridge University Press: Cambridge, UK, 2005; p. 246. [Google Scholar]

- Yang, C.; Seo, S.; Takata, N.; Thu, K.; Miyazaki, T. The Life Cycle Climate Performance Evaluation of Low-GWP Refrigerants for Domestic Heat Pumps. Int. J. Refrig. 2021, 121, 33–42. [Google Scholar] [CrossRef]

- Willett, W.; Rockström, J.; Loken, B.; Springmann, M.; Lang, T.; Vermeulen, S.; Garnett, T.; Tilman, D.; DeClerck, F.; Wood, A.; et al. Food in the Anthropocene: The EAT–Lancet Commission on Healthy Diets from Sustainable Food Systems. Lancet 2019, 393, 447–492. [Google Scholar] [CrossRef]

- Riahi, K.; Bertram, C.; Huppmann, D.; Rogelj, J.; Bosetti, V.; Cabardos, A.-M.; Deppermann, A.; Drouet, L.; Frank, S.; Fricko, O.; et al. Cost and Attainability of Meeting Stringent Climate Targets without Overshoot. Nat. Clim. Chang. 2021, 11, 1063–1069. [Google Scholar] [CrossRef]

- Shukla, P.R.; Al Khourdajie, A.; van Diemen, R.; McCollum, D.; Pathak, M.; Some, S.; Vyas, P.; Fradera, R.; Belkacemi, M.; Hasija, A.; et al. (Eds.) AR6 Climate Change 2022: Mitigation of Climate Change—IPCC; IPCC: Geneva, Switzerland, 2022. [Google Scholar]

- Statistics Denmark Production and Generation of Income (117-Grouping) by Transaction, Industry and Price Unit 2019. Available online: https://m.statbank.dk/TableInfo/NABP117 (accessed on 23 May 2024).

- E World Bank Gross Value Added at Basic Prices (GVA). Available online: https://databank.worldbank.org/metadataglossary/world-development-indicators/series/NY.GDP.FCST.CN#:~:text=Gross%20value%20added%20at%20basic%20prices%20(formerly%20GDP%20at%20factor,net%20product%20taxes%20from%20GDP (accessed on 23 May 2024).

- Rockström, J.; Gupta, J.; Qin, D.; Lade, S.J.; Abrams, J.F.; Andersen, L.S.; Armstrong McKay, D.I.; Bai, X.; Bala, G.; Bunn, S.E.; et al. Safe and Just Earth System Boundaries. Nature 2023, 619, 102–111. [Google Scholar] [CrossRef]

- Gailani, A.; Cooper, S.; Allen, S.; Pimm, A.; Taylor, P.; Gross, R. Assessing the Potential of Decarbonization Options for Industrial Sectors. Joule 2024, 8, 576–603. [Google Scholar] [CrossRef]

- Andersen, P.D.; Borup, M.; Krogh, T. Managing Long-Term Environmental Aspects of Wind Turbines: A Prospective Case Study. IJTPM 2007, 7, 339. [Google Scholar] [CrossRef]

| Range [°C] | Direct Electrical Heating [%] | Other Fuel Efficiency (Gas, Oil or Coal) [%] |

|---|---|---|

| ≤120 | 0 | 0 |

| 120–380 | 10 | 15 |

| ≥380 | 25 | 30 |

| Denmark | France | |

|---|---|---|

| Wind power | 61% | 76% |

| Bio-energy | 39% | 0% |

| Hydro power | 0% | 1% |

| Nuclear | 0% | 23% |

| Others | <1% | <1% |

| (a) | Controllable rate | Battery requirement (BR) (kgbat/GWhgrid) | ||

| French electricity | 23% | 668.8 | ||

| Danish electricity | 39% | 368.8 | ||

| (b) | Battery power capacity (GW) | Battery power to electricity consumption ratio (GWbat/GWhgrid) | Controllable electricity rate | |

| Sc. N03 | 1 | 1.5 × 10−6 | 62% | |

| Sc. N2 | 2 | 3.0 × 10−6 | 42% | |

| Sc. N1 | 9 | 1.3 × 10−5 | 38% | |

| Sc. M1 | 21 | 3.0 × 10−5 | 24% | |

| Sc. M0 | 26 | 3.6 × 10−5 | 11% | |

| Impact Category | Reduction Factor | Source |

|---|---|---|

| Climate change (budgeting 2015–2040) | 1.23 | [44] |

| Climate change (budgeting 2040–2065) | 2.22 | [44] |

| Climate change (budgeting 2065–2090) | 16.08 | [44] |

| Ozone depletion | 0.28 | [22] |

| Ionizing radiation | 0.01 | [22] |

| Photochemical ozone formation | 0.54 | [22] |

| Particulate matter | 5.97 | [22] |

| Human toxicity, non-cancer | 0.9 | [22] |

| Human toxicity, cancer | 0.26 | [22] |

| Acidification | 0.3 | [22] |

| Eutrophication, freshwater | 3.22 | [22] |

| Eutrophication, marine | 8.2 | [43] |

| Eutrophication, terrestrial | 0.3 | [22] |

| Ecotoxicity, freshwater | 0.85 | [22] |

| Land use | 9.33 | [22] |

| Water use | 0.51 | [22] |

| Resource use, fossils | 4.08 | [22] |

| Resource use, minerals and metals | 4.08 | [22] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jovet, Y.; Laurent, A.; Lefevre, F.; Clausse, M. Assessing the Potential for Electrification of the Food Industry and Its Implications for Environmental Sustainability. Energies 2024, 17, 2602. https://doi.org/10.3390/en17112602

Jovet Y, Laurent A, Lefevre F, Clausse M. Assessing the Potential for Electrification of the Food Industry and Its Implications for Environmental Sustainability. Energies. 2024; 17(11):2602. https://doi.org/10.3390/en17112602

Chicago/Turabian StyleJovet, Yoann, Alexis Laurent, Frédéric Lefevre, and Marc Clausse. 2024. "Assessing the Potential for Electrification of the Food Industry and Its Implications for Environmental Sustainability" Energies 17, no. 11: 2602. https://doi.org/10.3390/en17112602

APA StyleJovet, Y., Laurent, A., Lefevre, F., & Clausse, M. (2024). Assessing the Potential for Electrification of the Food Industry and Its Implications for Environmental Sustainability. Energies, 17(11), 2602. https://doi.org/10.3390/en17112602