Comparative Life Cycle Assessment of Electric and Internal Combustion Engine Vehicles

Abstract

:1. Introduction

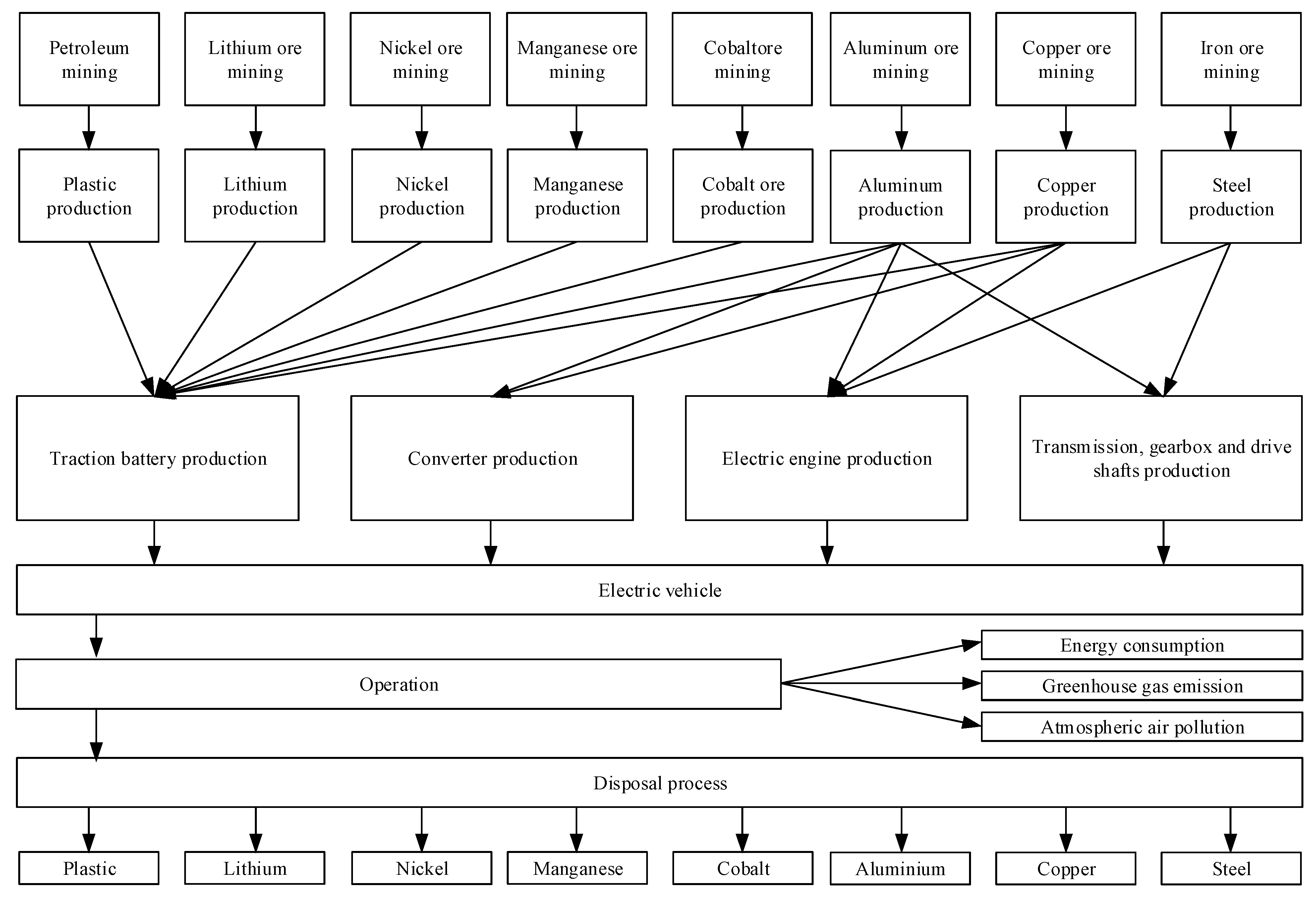

2. Methodology of Vehicles Integrated Environmental Assessment

2.1. Life Cycle Diagram Compilation

2.2. Defining the System Boundaries and Dividing It into Single Processes

- Minerals mining (ores of non-ferrous and ferrous metals, oil, and coal);

- Materials production (non-ferrous and ferrous metals, plastics, graphite, and fuel);

- Vehicles production (with gasoline and electric engines);

- Disposal process.

- Input streams of raw materials and other input streams;

- Products, related products, and waste products;

- Input electric energy flows;

- Emissions into the air; discharges into water and soil.

- Mass;

- Energy;

- Environmental significance.

- Mass—during mass criterion application, it is necessary to include all flows, the share of which in the total mass of the system does not exceed a certain percentage in the research;

- Energy—during energy criterion application, it is necessary to include all energy flows in the research, the share of which in the total energy flow of the system does not exceed a certain percentage;

2.3. Inventory Analysis Carrying Out

- -

- During cast iron production—from blast furnace slag, grate dust, sludge from blast furnace gas cleaners, and sludge from bunker rooms;

- -

- During steel production—from steelmaking slags to sludge from gas cleaners of steelmaking furnaces.

- Natural resources consumption;

- Waste product formation;

- Water consumption;

- Wastewater discharge;

- Harmful substance emissions into the atmospheric air;

- Greenhouse gas emissions;

- Electric energy consumption.

2.4. Determination of the Environmental Impact Degree

- Natural resources consumption;

- Electric energy consumption;

- Summary environmental assessment.

2.5. Results Interpretation

3. LCA Mathematical Apparatus

- In the first stage, it is determined which materials and in what quantity are used in the vehicle production process;

- In the second stage, specific indicators (soil pollution, water pollution, atmospheric emissions, and electric energy consumption) per unit mass of products are determined according to the Russian reference data;

- In the third stage, the material masses at each production level are calculated based on specific parameters and the material mass at the previous level;

- In the fourth stage, the formed waste products’ environmental impacts, emissions of harmful substances, etc., are calculated (using existing and developed formulas);

- In the fifth stage, the total environmental impact on the environment at all stages is determined;

- In the sixth stage, the received data analysis is carried out, and conclusions are drawn about the degree of environmental impact of the production process on the environment on its basis.

3.1. Atmospheric Pollution-Specific Indicators

- Correction λi is for the probability of a secondary injection of impurities into the atmosphere after they settle on surfaces;

- Correction βi is for the probability of formation, with the participation of initial impurities released into the atmosphere, of other pollutants more dangerous than the initial ones.

3.2. Water Pollution-Specific Indicators

3.3. Soil Pollution-Specific Indicators

3.4. Electric Energy Consumption

4. Initial Data for Analysis

5. Results and Discussion

5.1. Natural Resources Consumption

5.2. Waste Products Formation

5.3. Water Consumption and Wastewater Discharge

5.4. Harmful Substance Emissions into the Atmospheric Air

5.5. Greenhouse Gas Emissions

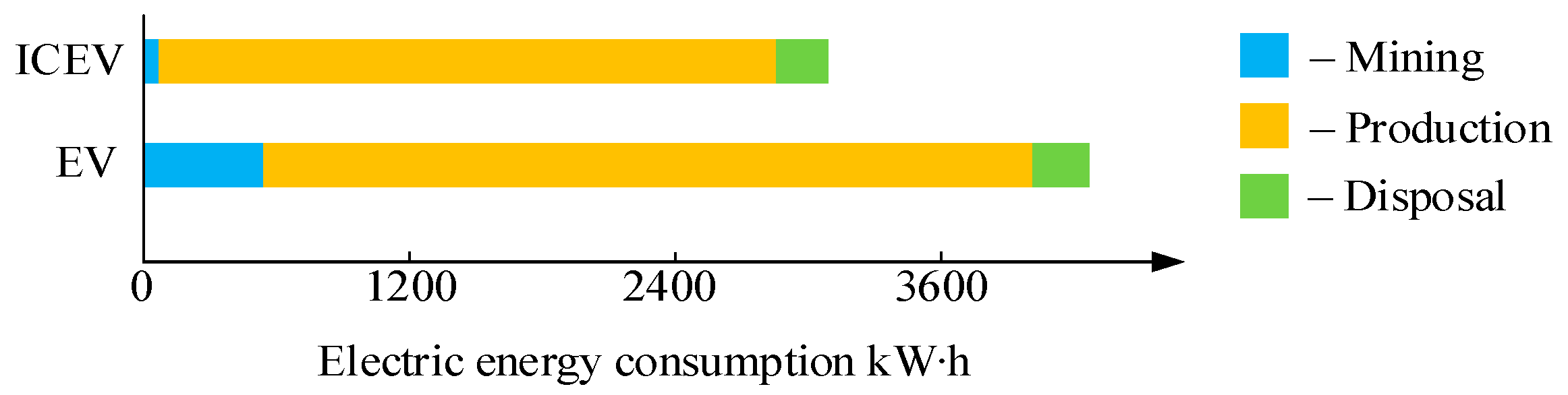

5.6. Electric Energy Consumtion

5.7. Exploitation Process

5.8. Comprehensive Environmental Assessment

- A transition from ICEVs to EVs will lead to an increase in the environmental burden at all life cycle stages due to the use of additional materials such as nickel, manganese, and cobalt;

- The mass of extracted natural resources and formed waste products for EV production is 6 times greater than for the ICEV due to the use of ores with a low metal content;

- Reduced masses of harmful substances in waste products, wastewater, and atmospheric air are significantly higher for EV production due to the use of technological processes with more toxic emissions;

- The freshwater consumption volume and wastewater volume for EVs are higher due to production processes with high water capacity;

- Electric energy consumption during EV production is higher than that of the ICEV due to the energy-intensive processes of materials extraction and production.

6. Conclusions

- Batteries’ environmental characteristics increased by the lithium-ion batteries’ technical specifications, improving and developing alternative battery technologies based on other materials such as sodium and calcium;

- EV design improvement can be achieved by enhancing the structural elements’ technical characteristics, increasing the electric motor efficiency, and reducing losses in the energy transmission to the movement of the wheels;

- Reducing the environmental impact of electric energy generation by increasing the use of renewable energy sources and improving fuel combustion technology in coal-fired thermal power plants. Improving energy efficiency by transitioning from non-ecological fuels like coal to natural gas at thermal power plants, using modern gas turbine and combined-cycle designs.

- Improving the life quality and health of the population;

- Environmental situation improvement;

- Natural resources consumption reduction;

- Electric energy consumption reduction;

- Organic fuel consumption reduction.

- Selection of materials and technological processes in the power plant design;

- Choice of methods for cleaning emissions before they enter into the atmospheric air and wastewater, and a method of formed waste products disposal;

- Environmental situation strategic planning;

- Implementation of a state program on resource and energy conservation;

- Marketing environmental research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| mi | emission mass of the i-th impurity |

| Ai | relative aggressiveness indicator of the i-th substance |

| n | number of impurities emitted by the source |

| ai | an indicator of the relative danger of the presence of an impurity in the air inhaled by humans |

| αi | an amendment that takes into account the probability of accumulation of initial impurities or secondary pollutants in environmental components and in food chains, as well as the ingress of impurities into the human body through non-inhalation pathways |

| δi | amendment that takes into account the effect on various recipients other than a person |

| Msp_wp | specific indicator of production waste formation |

| K | waste product danger degree indicator |

| M | mass of material at each life cycle stage |

| qsp | specific requirement of consumption of water or wastewater per unit of production |

| MPCf.i | maximum permissible concentration of the i-th substance of water bodies in the water for fisheries purposes |

| MPCd.a.i | “daily average” maximum permissible concentration of the i-th impurity in the atmospheric air |

| MPCw.a.i | maximum permissible concentration of the i-th impurity in the air of the working area |

| MPCd.a.CM | “daily average” maximum permissible concentration of carbon monoxide (CM) in the atmospheric air of populated areas |

| MPCw.a.CM | CM maximum permissible concentration in the air of the working area |

References

- Meydani, A.; Meidani, A.; Shahablavasani, S. The Performance of Electric and Hybrid Cars and the Effect of Their Use in the Environmental Cycle. In Proceedings of the 2023 8th International Conference on Technology and Energy Management (ICTEM), Babol, Mazandaran, Iran, 8–9 February 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Tintelecan, A.; Dobra, A.C.; Marțiș, C. Literature Review—Electric Vehicles Life Cycle Assessment. In Proceedings of the 2020 ELEKTRO, Taormina, Italy, 9 September 2020; pp. 1–6. [Google Scholar] [CrossRef]

- European Commission. “Fit for 55”: Delivering the EU’s 2030 Climate Target on the way to climate neutrality. In Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; COM (2021) 550 Final; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Concept for the Development of Production and Use of Electric Vehicles in the Country for the Period up to 2030. Order of the Russian Federation No. 2290-r dated 08/23/2021. Available online: https://legalacts.ru/doc/rasporjazhenie-pravitelstva-rf-ot-23082021-n-2290-r-ob-utverzhdenii/ (accessed on 16 April 2024).

- Tang, B.; Xu, Y.; Wang, M. Life Cycle Assessment of Battery Electric and Internal Combustion Engine Vehicles Considering the Impact of Electricity Generation Mix: A Case Study in China. Atmosphere 2022, 13, 252. [Google Scholar] [CrossRef]

- Franzò, S.; Nasca, A. The environmental impact of electric vehicles: A comparative LCA-based evaluation framework and its application to the Italian context. In Proceedings of the 15th International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 10–12 September 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Rapa, M.; Gobbi, L.; Ruggieri, R. Environmental and Economic Sustainability of Electric Vehicles: Life Cycle Assessment and Life Cycle Costing Evaluation of Electricity Sources. Energies 2020, 13, 6292. [Google Scholar] [CrossRef]

- Raugei, M. Update on the Life-Cycle GHG Emissions of Passenger Vehicles: Literature Review and Harmonization. Energies 2022, 15, 7163. [Google Scholar] [CrossRef]

- Jursova, S.; Burchart-Korol, D.; Pustejovska, P. Carbon Footprint and Water Footprint of Electric Vehicles and Batteries Charging in View of Various Sources of Power Supply in the Czech Republic. Environments 2019, 6, 38. [Google Scholar] [CrossRef]

- Markowska, K.; Flizikowski, J.; Bieliński, K.; Tomporowski, A.; Kruszelnicka, W.; Kasner, R.; Bałdowska-Witos, P.; Mazur, Ł. The Comparative Assessment of Effects on the Power System and Environment of Selected Electric Transport Means in Poland. Materials 2021, 14, 4556. [Google Scholar] [CrossRef] [PubMed]

- Kawamoto, R.; Mochizuki, H.; Moriguchi, Y.; Nakano, T.; Motohashi, M.; Sakai, Y.; Inaba, A. Estimation of CO2 Emissions of Internal Combustion Engine Vehicle and Battery Electric Vehicle Using LCA. Sustainability 2019, 11, 2690. [Google Scholar] [CrossRef]

- Petrauskienė, K.; Galinis, A.; Kliaugaitė, D.; Dvarionienė, J. Comparative Environmental Life Cycle and Cost Assessment of Electric, Hybrid, and Conventional Vehicles in Lithuania. Sustainability 2021, 13, 957. [Google Scholar] [CrossRef]

- Smit, R.; Kennedy, D.W. Greenhouse Gas Emissions Performance of Electric and Fossil-Fueled Passenger Vehicles with Uncertainty Estimates Using a Probabilistic Life-Cycle Assessment. Sustainability 2022, 14, 3444. [Google Scholar] [CrossRef]

- Kosai, S.; Zakaria, S.; Che, H.S.; Hasanuzzaman, M.; Rahim, N.A.; Tan, C.; Ahmad, R.D.R.; Abbas, A.R.; Nakano, K.; Yamasue, E. Estimation of Greenhouse Gas Emissions of Petrol, Biodiesel and Battery Electric Vehicles in Malaysia Based on Life Cycle Approach. Sustainability 2022, 14, 5783. [Google Scholar] [CrossRef]

- Hirz, M.; Nguyen, T.T. Life-Cycle CO2-Equivalent Emissions of Cars Driven by Conventional and Electric Propulsion Systems. World Electr. Veh. J. 2022, 13, 61. [Google Scholar] [CrossRef]

- Tintelecan, A.; Dobra, A.C.; Marţiş, C. LCA Indicators in Electric Vehicles Environmental Impact Assessment. In Proceedings of the 2019 Electric Vehicles International Conference (EV), Bucharest, Romania, 3–4 October 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Madhu, K.; Pauliuk, S. Integrating Life Cycle Assessment into the Framework of Environmental Impact Assessment for Urban Systems: Framework and Case Study of Masdar City, Abu Dhabi. Environments 2019, 6, 105. [Google Scholar] [CrossRef]

- Dolganova, I.; Rödl, A.; Bach, V.; Kaltschmitt, M.; Finkbeiner, M. A Review of Life Cycle Assessment Studies of Electric Vehicles with a Focus on Resource Use. Resources 2020, 9, 32. [Google Scholar] [CrossRef]

- Temporelli, A.; Carvalho, M.L.; Girardi, P. Life Cycle Assessment of Electric Vehicle Batteries: An Overview of Recent Literature. Energies 2020, 13, 2864. [Google Scholar] [CrossRef]

- Freire, F.; Marques, P. Electric vehicles in Portugal: An integrated energy, greenhouse gas and cost life-cycle analysis. In Proceedings of the 2012 IEEE International Symposium on Sustainable Systems and Technology (ISSST), Boston, MA, USA, 16–18 May 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2012, 17, 53–64. [Google Scholar] [CrossRef]

- Accardo, A.; Dotelli, G.; Miretti, F.; Spessa, E. End-of-Life Impact on the Cradle-to-Grave LCA of Light-Duty Commercial Vehicles in Europe. Appl. Sci. 2023, 13, 1494. [Google Scholar] [CrossRef]

- Yang, X. Research on Evaluation of New Energy Vehicles Based on Life Cycle and Efficiency Assessments. In Proceedings of the 2022 International Conference on Computation, Big-Data and Engineering (ICCBE), Yunlin, Taiwan, 27–29 May 2022; pp. 264–266. [Google Scholar] [CrossRef]

- Xiong, S.; Ji, J.; Ma, X. Comparative Life Cycle Energy and GHG Emission Analysis for BEVs and PhEVs: A Case Study in China. Energies 2019, 12, 834. [Google Scholar] [CrossRef]

- Wang, R.; Song, Y.; Xu, H.; Li, Y.; Liu, J. Life Cycle Assessment of Energy Consumption and CO2 Emission from HEV, PHEV and BEV for China in the Past, Present and Future. Energies 2022, 15, 6853. [Google Scholar] [CrossRef]

- Wu, Q.; Sun, S. Energy and Environmental Impact of the Promotion of Battery Electric Vehicles in the Context of Banning Gasoline Vehicle Sales. Energies 2022, 15, 8388. [Google Scholar] [CrossRef]

- Oliveri, L.M.; D’Urso, D.; Trapani, N.; Chiacchio, F. Electrifying Green Logistics: A Comparative Life Cycle Assessment of Electric and Internal Combustion Engine Vehicles. Energies 2023, 16, 7688. [Google Scholar] [CrossRef]

- Pipitone, E.; Caltabellotta, S.; Occhipinti, L. A Life Cycle Environmental Impact Comparison between Traditional, Hybrid, and Electric Vehicles in the European Context. Sustainability 2021, 13, 10992. [Google Scholar] [CrossRef]

- Wang, N.; Tang, G. A Review on Environmental Efficiency Evaluation of New Energy Vehicles Using Life Cycle Analysis. Sustainability 2022, 14, 3371. [Google Scholar] [CrossRef]

- Yang, Y.; Lan, L.; Hao, Z.; Zhao, J.; Luo, G.; Fu, P.; Chen, Y. Life Cycle Prediction Assessment of Battery Electrical Vehicles with Special Focus on Different Lithium-Ion Power Batteries in China. Energies 2022, 15, 5321. [Google Scholar] [CrossRef]

- Almeida, A.; Sousa, N.; Coutinho-Rodrigues, J. Quest for Sustainability: Life-Cycle Emissions Assessment of Electric Vehicles Considering Newer Li-Ion Batteries. Sustainability 2019, 11, 2366. [Google Scholar] [CrossRef]

- Zhang, H.; Xue, B.; Li, S.; Yu, Y.; Li, X.; Chang, Z.; Wu, H.; Hu, Y.; Huang, K.; Liu, L.; et al. Life cycle environmental impact assessment for battery-powered electric vehicles at the global and regional levels. Sci. Rep. 2023, 13, 7952. [Google Scholar] [CrossRef]

- Raugei, M.; Kamran, M.; Hutchinson, A. Environmental implications of the ongoing electrification of the UK light duty vehicle fleet. Resources 2021, 174, 105818. [Google Scholar] [CrossRef]

- Sosnina, E.N.; Masleeva, O.V.; Kryukov, E.V. Comparative environmental assessment of unconventional power installations. Therm. Eng. 2015, 62, 539–546. [Google Scholar] [CrossRef]

- Sosnina, E.; Masleeva, O.; Kryukov, E.; Erdili, N. Methodology of the Renewable Energy Sources Life Cycle Environmental Assessment. In Proceedings of the 2021 IEEE PES Innovative Smart Grid Technologies Europe (ISGT Europe), Espoo, Finland, 18–21 October 2021; pp. 1–5. [Google Scholar] [CrossRef]

| Flow Name | Resource Name | Measurement Units |

|---|---|---|

| Material input flows | Raw material | t |

| Water consumption | m3 | |

| Energy input flows | Electric energy consumption | kW∙h |

| Output material flow | Products | t |

| Waste products | t | |

| Wastewater | m3 |

| Pollution | Measurement Units | |

|---|---|---|

| Emissions into the atmosphere | Gases—carbon monoxide, nitrogen oxides, sulfur dioxide, hydrogen sulfide Dust—oxides of iron, silicon, manganese, magnesium, aluminum, calcium | kg/t |

| Greenhouse gases | Carbon dioxide | kg/t |

| Discharges into the water | Suspended solids, chlorides, sulfates, nitrites, ammonium, calcium | mg/L |

| Soil pollution (waste products composition) | Silicon dioxide, aluminum oxides, iron, calcium, magnesium, manganese, sulfides, sulfates | kg/t |

| Indicator | Mining | Metallurgy | Mechanical Engineering | Disposal |

|---|---|---|---|---|

| Values of specific indicators of waste products formation and coefficient K K | ||||

| Waste products’ specific indicators, t/t | 0.5 | 0.758 | 0.29 | 0.25 |

| Waste products’ danger degree indicator, K | 1 | 116.8 | 1 | 116.8 |

| Water consumption, wastewater discharge, and harmful substances in water | ||||

| Specific consumption of fresh water from the source m3/t | 2.82 | 33 | 43 | 14.1 |

| Wastewater-specific discharge, m3/t | 0.17 | 4 | 13 | 5.5 |

| Harmful substances’ reduced specific mass, g/t | 69.02 | 20,000 | 2606.07 | 167.2 |

| Relative aggressiveness indicator | ||||

| Reduced specific emissions, kg/t | 3.92 | – | 118 | 44 |

| CO2 emissions | ||||

| Specific emissions, t CO2/t | 1.06 | – | – | 0.08 |

| Specific norms of elec energy consumption in industry | ||||

| Specific electric energy consumption, kW∙h/t | 68 | 547 | 300 | 219 |

| ICEV | EV |

|---|---|

| Tank volume, l: 52 | Traction battery capacity, kW∙h: 53 |

| Engine type: gasoline | Traction battery type: Li-NMC |

| Engine volume, cm3: 1997 | Engine type: synchronous motor with permanent magnets |

| Power, h.p./kW/at rpm: 143/105/5200 | Power, h.p./kW: 150/110 |

| Torque moment/at rpm.: 190/4400 | Torque moment, newton-meters 210 |

| Maximum speed, km/h: 190 | Maximum speed, km/h: 145 |

| Overspeed to 100 km/h, s: 10.7 | Overspeed to 100 km/h, s: 9.5 |

| ICEV | EV |

| Transmission torque moment, Nm: up to 250 | Gear ratio in the gearbox: 10 |

| Ecological class: IV | |

| Fuel consumption, l/100 km (city/combined/track): 9.9/6.5/7.7 |

| Weight of Components and Materials, kg | |

|---|---|

| ICEV | EV |

| Internal combustion engine | Electric motor |

| Aluminum: 100 | Steel: 108 |

| Cast iron: 13 | Copper: 27 |

| Steel: 7 | Aluminum: 15 |

| Engine cooling system | Transmissions, reduction gear, drive shafts |

| Aluminum: 5 | Aluminum: 10 |

| Rubber hoses: 2 | Steel: 20 |

| Starter, ignition system | Converter |

| Steel: 3 | Copper: 0.6 |

| Copper: 2 | Aluminum: 8.4 |

| Exhaust system Steel: 20 | Traction battery Aluminum: 43 Copper: 130 Plastic: 10 Lithium: 8 Nickel: 35 Manganese: 20 Cobalt: 14 |

| Gas tank Plastic: 5 | |

| Transmission, connecting shaft, gearbox Aluminum: 10 Steel: 20 | |

| Total mass: 1290 | Total mass: 1577 |

| EV | ||||||

|---|---|---|---|---|---|---|

| Steel | Copper | Aluminum | Nickel | Manganese | ||

| Mining | Input | 581 | 6902 | 2409.7 | 7040.7 | 107.6 |

| Waste products | 290 | 6349 | 2216.9 | 6477.4 | 49.1 | |

| Output | 290 | 552 | 192.8 | 563.3 | 58.5 | |

| Metallurgy | Input | 290 | 552 | 192.8 | 563.3 | 58.5 |

| Waste products | 125 | 442 | 72.3 | 512.1 | 29.3 | |

| Output | 165.1 | 110 | 120.5 | 51.2 | 29.3 | |

| Mechanical engineering | Input | 165.1 | 110 | 120.5 | 51.2 | 29.3 |

| Waste products | 37.12 | 25 | 27.1 | 16.2 | 9.3 | |

| Output | 128 | 85.6 | 93.4 | 35 | 20 | |

| Disposal | Input | 128 | 85.6 | 93.4 | – | – |

| Waste products | 32.5 | 14.3 | 15.6 | – | – | |

| Output | 95.5 | 71.3 | 77.8 | – | – | |

| Cobalt | Plastic | Copper foil | Aluminum foil | Graphite | ||

| Mining | Input | 1280.1 | 15.3 | 1828.75 | 292.6 | 34.3 |

| Waste products | 1177.7 | 0.15 | 1682.45 | 269.2 | 3.1 | |

| Output | 102.4 | 15.1 | 146.3 | 23.4 | 31.2 | |

| Metallurgy | Input | 102.4 | 15.1 | 146.3 | 23.4 | 31.2 |

| Waste products | 81.9 | 0.11 | 117.04 | 8.8 | 5.2 | |

| Output | 20.5 | 15 | 29.26 | 14.6 | 26 | |

| Mechanical engineering | Input | 20.5 | – | 29.26 | 14.6 | 26 |

| Waste products | 6.5 | 0 | 9.26 | 4.6 | 6 | |

| Output | 14 | 15 | 20 | 10 | 20 | |

| Disposal | Input | – | 15 | – | – | – |

| Waste products | – | 1.4 | – | – | – | |

| Output | – | 13.6 | – | – | – | |

| ICEV | ||||||

| Steel | Cast iron | Copper | Aluminum | Plastic | ||

| Mining | Input | 227 | 52 | 161 | 2967 | 5.09 |

| Waste products | 113 | 26 | 148 | 2730 | 0.05 | |

| Output | 113 | 26 | 13 | 237 | 5.035 | |

| Metallurgy | Input | 113 | 26 | 13 | 237 | 5.035 |

| Waste products | 49 | 9 | 10 | 89 | 0.035 | |

| Output | 65 | 17 | 3 | 148 | 5 | |

| Mechanical engineering | Input | 65 | 17 | 3 | 148 | – |

| Waste products | 15 | 4 | 1 | 33 | – | |

| Output | 50 | 13 | 2 | 115 | 5 | |

| Disposal | Input | 50 | 13 | 2 | 115 | 5 |

| Waste products | 13 | 0.50 | 0.333 | 19.17 | 0.5 | |

| Output | 37 | 12.5 | 1.667 | 95.8 | 4.5 | |

| Natural Resources | Natural Resources Mass, kg | |

|---|---|---|

| EV | ICEV | |

| Iron ore (steel, cast iron) | 581 | 279 |

| Copper ore | 6902 | 161 |

| Aluminum | 2409.7 | 2967 |

| Nickel ore | 7040.7 | – |

| Manganese ore | 107.6 | – |

| Cobalt ore | 1280.1 | – |

| Natural gas (plastic) | 15.3 | 5 |

| Coal (graphite) | 34.3 | – |

| Total | 20,491 | 3412 |

| Material | Stage | Waste Products Mass, kg | Waste Products Danger Degree Indicator | Waste Products Conditional Mass, kg |

|---|---|---|---|---|

| Steel | Mining | 290 | 1 | 290 |

| Metallurgy | 125 | 116.8 | 14,625 | |

| Mechanical engineering | 37 | 1 | 37 | |

| Disposal | 32 | 116.8 | 3795 | |

| Copper | Mining | 6349 | 1 | 6349 |

| Metallurgy | 442 | 56.5 | 24,956 | |

| Mechanical engineering | 25 | 888.9 | 22,066 | |

| Disposal | 14 | 56.5 | 806 |

| Material | Stage | Output Mass, t | Specific Consumption of Fresh Water from the Source, m3/t | Fresh Water, m3 |

|---|---|---|---|---|

| Steel | Mining | 0.581 | 2.820 | 2 |

| Metallurgy | 0.165 | 33 | 5 | |

| Mechanical engineering | 0.128 | 43 | 6 | |

| Disposal | 0.096 | 14.1 | 1 | |

| Copper | Mining | 6.902 | 3.23 | 22.3 |

| Metallurgy | 0.110 | 12.1 | 1.3 | |

| Mechanical engineering | 0.086 | 43 | 3.7 | |

| Disposal | 0.071 | 0.950 | 0.1 |

| Material | Stage | Output Mass, t | Wastewater-Specific Discharge, m3/t | Harmful Substances Reduced Specific Mass, g/t | Wastewater Consumption, m3 | The Harmful Substances Reduced Mass, g |

|---|---|---|---|---|---|---|

| Steel | Mining | 0.581 | 0.17 | 69.02 | 0.1 | 40 |

| Metallurgy | 0.165 | 4 | 20,000 | 1 | 3302 | |

| Mechanical engineering | 0.128 | 13 | 2606.07 | 2 | 334 | |

| Disposal | 0.096 | 5.5 | 167.2 | 1 | 16 | |

| Copper | Mining | 6.902 | 0.15 | 5359.64 | 1.0 | 36,990 |

| Metallurgy | 0.110 | 1.4 | 5364.20 | 0.15 | 59,234 | |

| Mechanical engineering | 0.086 | 13 | 2606.07 | 1 | 223 | |

| Disposal | 0.071 | 0.5 | 12.5 | 0.04 | 0.9 |

| Material | Stage | Output Mass, t | Reduced Specific Emissions, kg/t | Pollution Emissions Reduced Mass, kg |

|---|---|---|---|---|

| Steel | Mining | 581 | 3.92 | 2.3 |

| Production | 128 | 118 | 15.1 | |

| Recycling | 95.5 | 44 | 4.2 | |

| Copper | Mining | 6902 | 3.92 | 27.1 |

| Production | 85.6 | 2717 | 232.6 | |

| Recycling | 71 | 1222 | 87.2 |

| Material | Stage | Output Mass, kg | Specific Emissions, t CO2/t | Reduced Emissions, kg CO2 |

|---|---|---|---|---|

| Steel | Production | 165 | 1.06 | 175 |

| Disposal | 128 | 0.08 | 10 | |

| Copper | Production | 110 | 1 | 110 |

| Material | Stage | Output Mass, kg | Specific Electric Energy Consumption, kW∙h/t | Electric Energy Consumption, kW∙h |

|---|---|---|---|---|

| Steel | Mining | 581 | 68 | 39.5 |

| Metallurgy | 165.12 | 547 | 90.3 | |

| Mechanical engineering | 128 | 300 | 38.4 | |

| Disposal | 128 | 219 | 28.0 | |

| Copper | Mining | 6902 | 15 | 103.5 |

| Metallurgy | 110 | 400 | 44.2 | |

| Mechanical engineering | 85.6 | 300 | 25.7 | |

| Disposal | 85.6 | 400 | 34.2 |

| EV | ICEV | |

|---|---|---|

| Electric energy consumption/fuel | 4676 kW∙h | 1260 kg |

| Energy consumption, GJ | 73.6 | 55.4 |

| Harmful Substances Specific Reduced Emissions | Annual Electric Energy Consumption/Mileage | Reduced Emissions, kg | |

|---|---|---|---|

| EV | 96.28 g/kW·h | 7160 kW·h | 689 |

| ICEV | 14.38 g/km | 16,700 km | 240 |

| Specific Greenhouse Gas Emissions | Annual Electric Energy Consumption/Mileage | Greenhouse Gas Emission, t CO2 | |

|---|---|---|---|

| EV | 0.449 kg CO2/kW·h | 7160 kW·h | 3.21 |

| ICEV | 0.228 kg/km | 16,700 km | 3.75 |

| Parameter | EV | ICEV |

|---|---|---|

| Natural resources mass, t | 20.5 | 3.4 |

| Waste products mass, t | 20 | 3.3 |

| Reduced waste mass, t | 188 | 30.5 |

| Water consumption, m3 | 112 | 25 |

| Wastewater volume, m3 | 12 | 5.6 |

| Conditional mass of harmful substances in wastewater, kg | 132 | 55 |

| Reduced mass of harmful substances released into the atmospheric air, kg | 1526 | 957 |

| Greenhouse gas emissions, t CO2 | 1.4 | 0.8 |

| Electric energy consumption, MW∙h | 4.2 | 3.1 |

| Environmental Factor | EV | ICEV |

|---|---|---|

| Reduced mass of harmful substances released into the atmospheric air, kg | 689 | 240 |

| Greenhouse gas emissions, t CO2 | 3.21 | 3.75 |

| Energy, GJ | 73.6 | 55.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurkin, A.; Kryukov, E.; Masleeva, O.; Petukhov, Y.; Gusev, D. Comparative Life Cycle Assessment of Electric and Internal Combustion Engine Vehicles. Energies 2024, 17, 2747. https://doi.org/10.3390/en17112747

Kurkin A, Kryukov E, Masleeva O, Petukhov Y, Gusev D. Comparative Life Cycle Assessment of Electric and Internal Combustion Engine Vehicles. Energies. 2024; 17(11):2747. https://doi.org/10.3390/en17112747

Chicago/Turabian StyleKurkin, Andrey, Evgeny Kryukov, Olga Masleeva, Yaroslav Petukhov, and Daniil Gusev. 2024. "Comparative Life Cycle Assessment of Electric and Internal Combustion Engine Vehicles" Energies 17, no. 11: 2747. https://doi.org/10.3390/en17112747

APA StyleKurkin, A., Kryukov, E., Masleeva, O., Petukhov, Y., & Gusev, D. (2024). Comparative Life Cycle Assessment of Electric and Internal Combustion Engine Vehicles. Energies, 17(11), 2747. https://doi.org/10.3390/en17112747