Smart System for Reducing Standby Energy Consumption in Residential Appliances

Abstract

1. Introduction

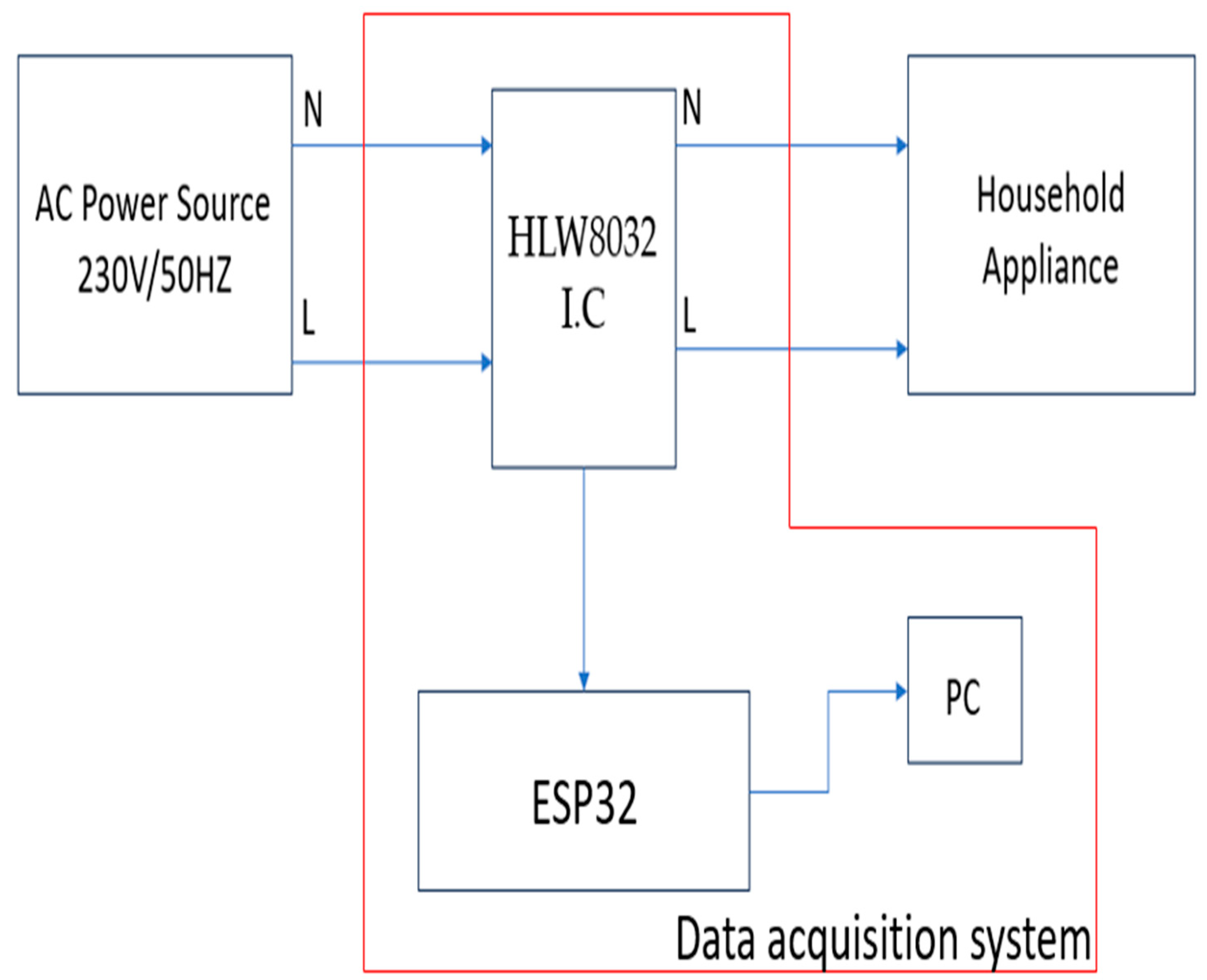

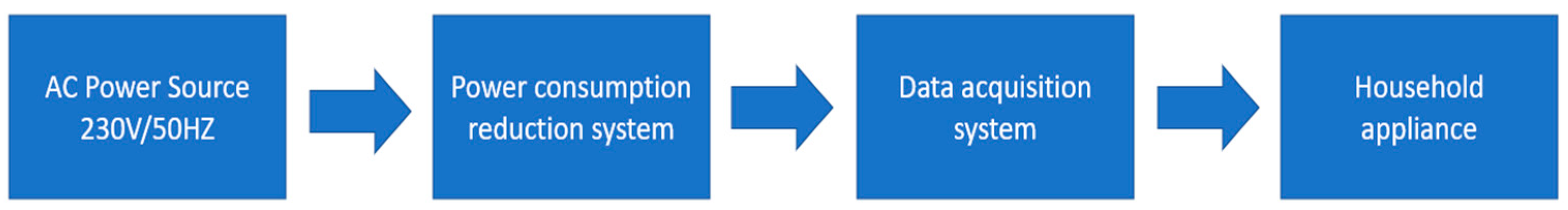

2. Materials and Methods

2.1. Standby Power Consumption Data Measurement

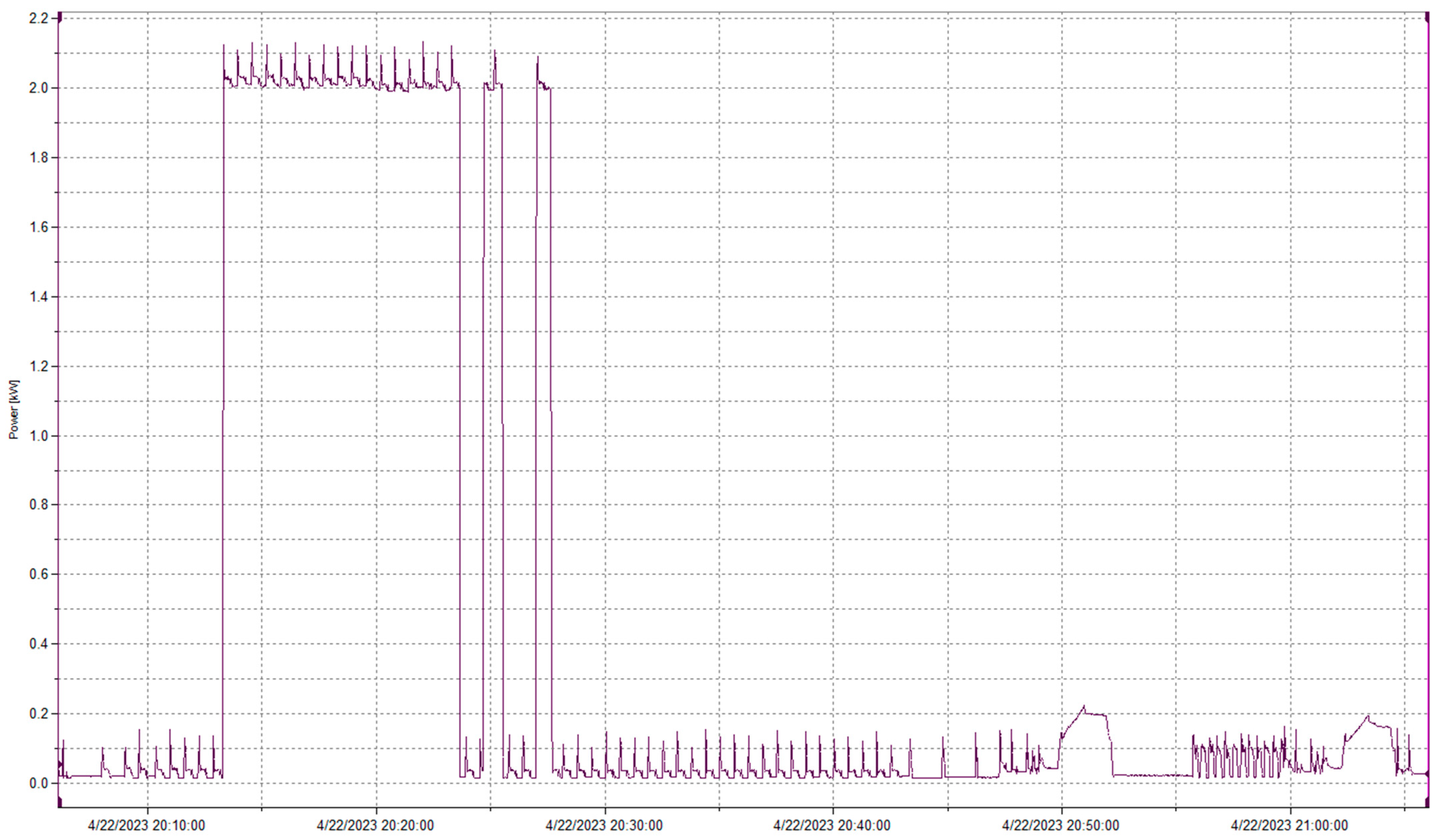

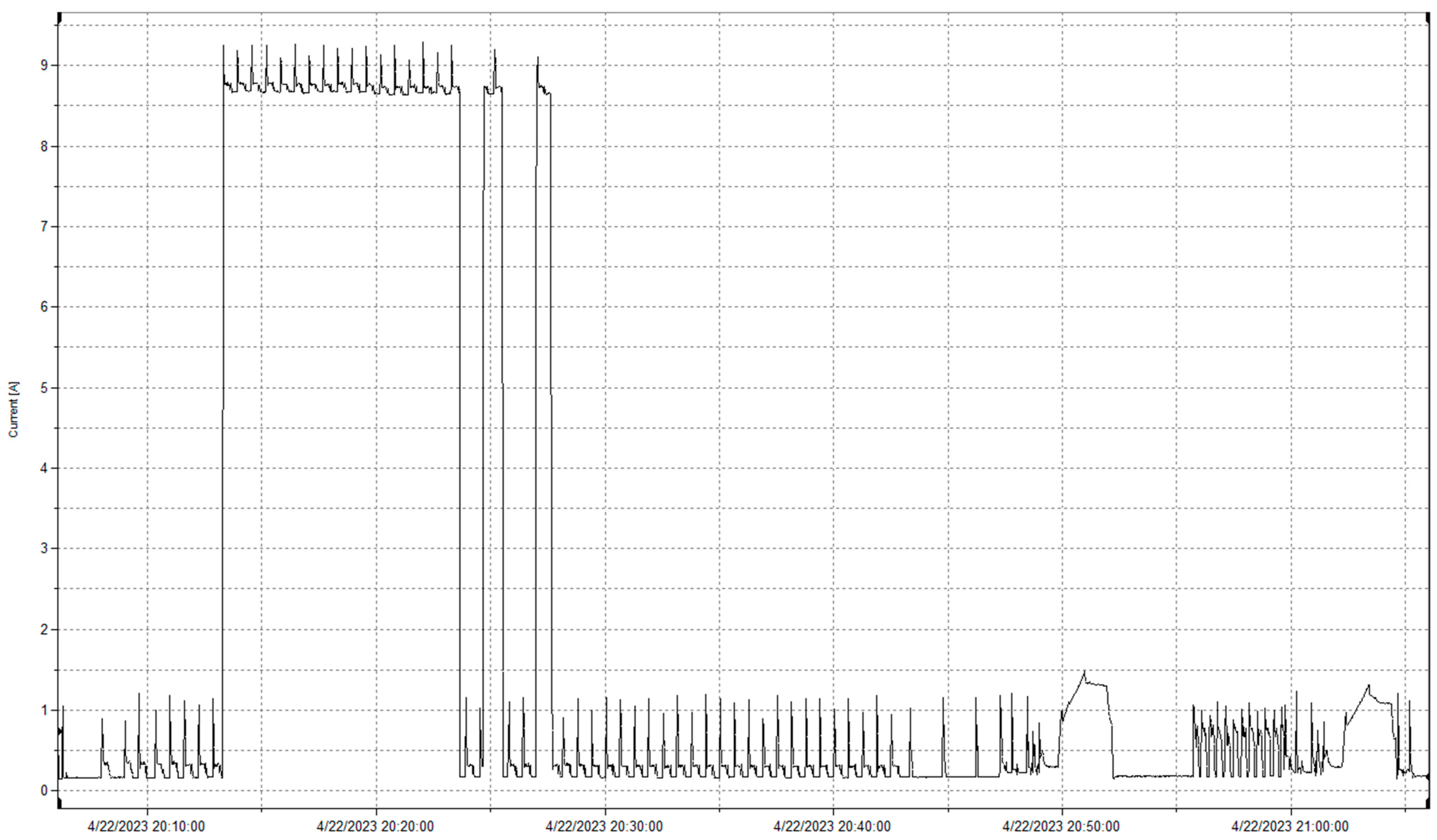

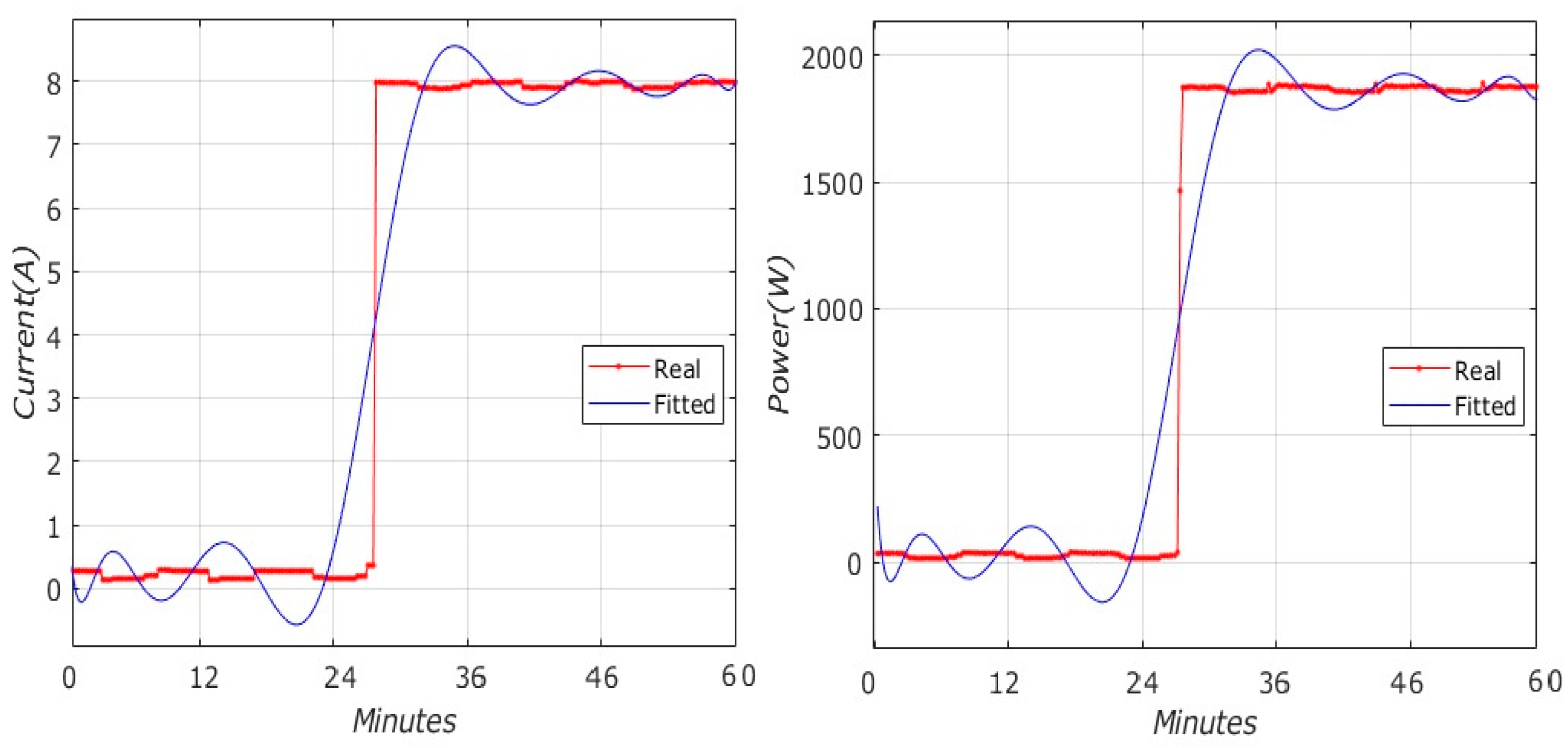

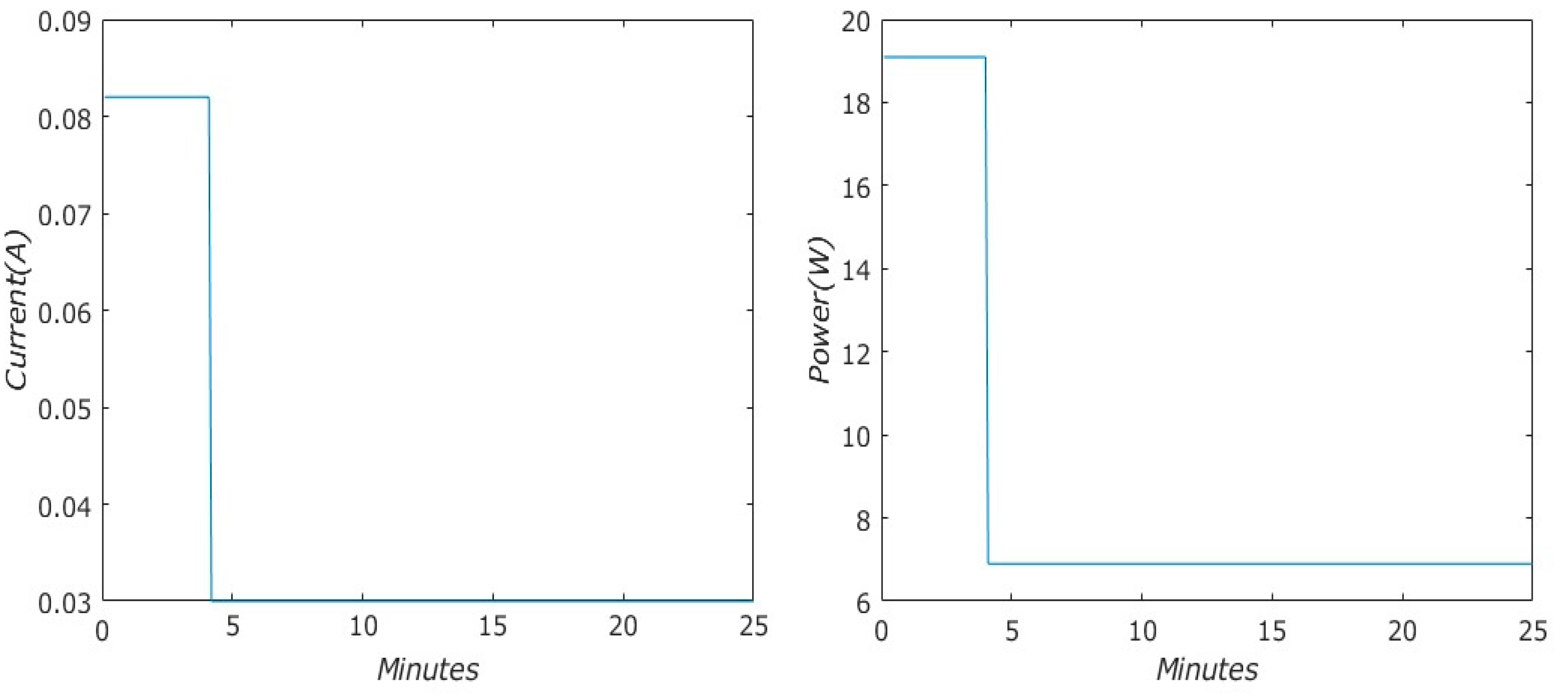

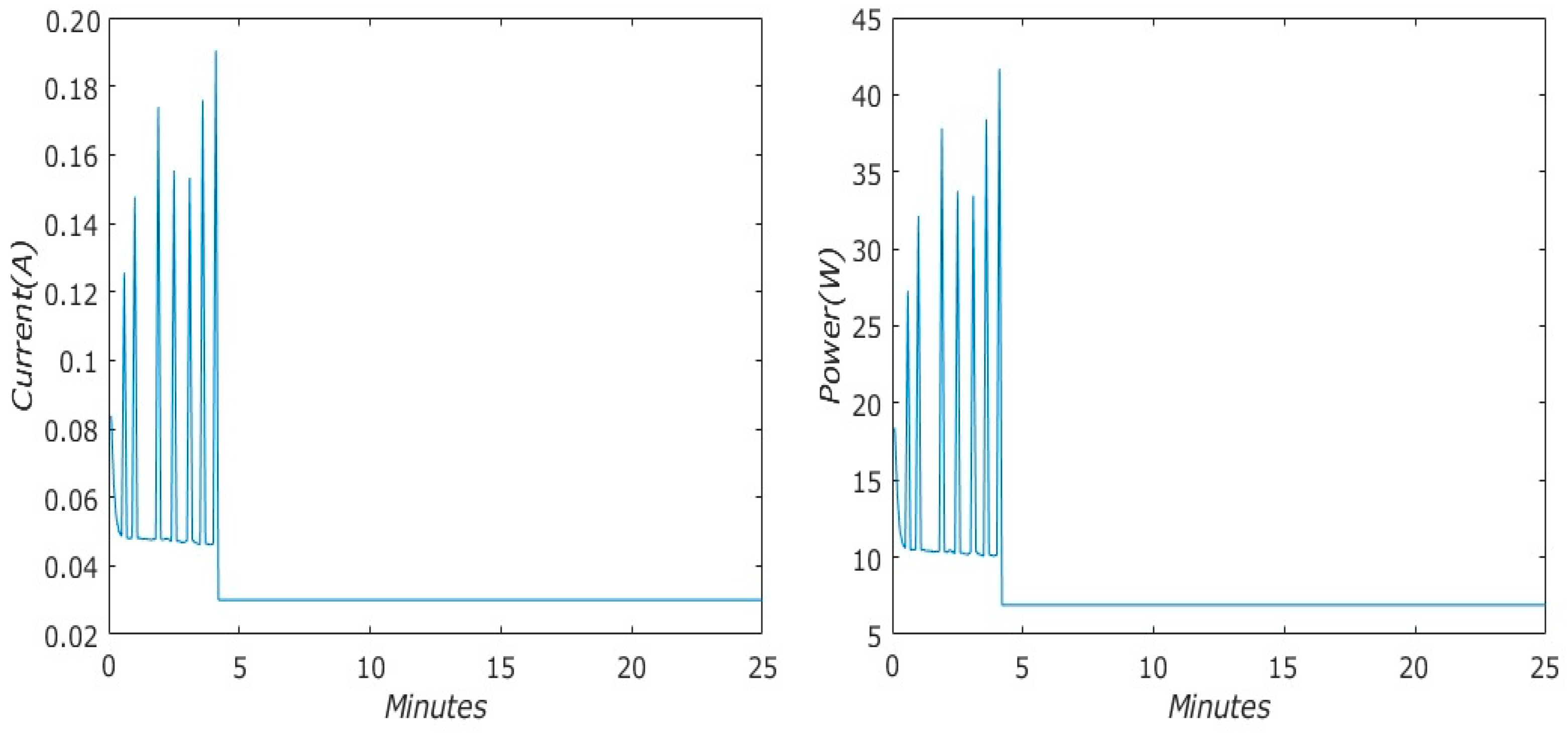

2.1.1. Data Measurement and MATLAB Interpolation of Washing Machine Current and Power Consumption

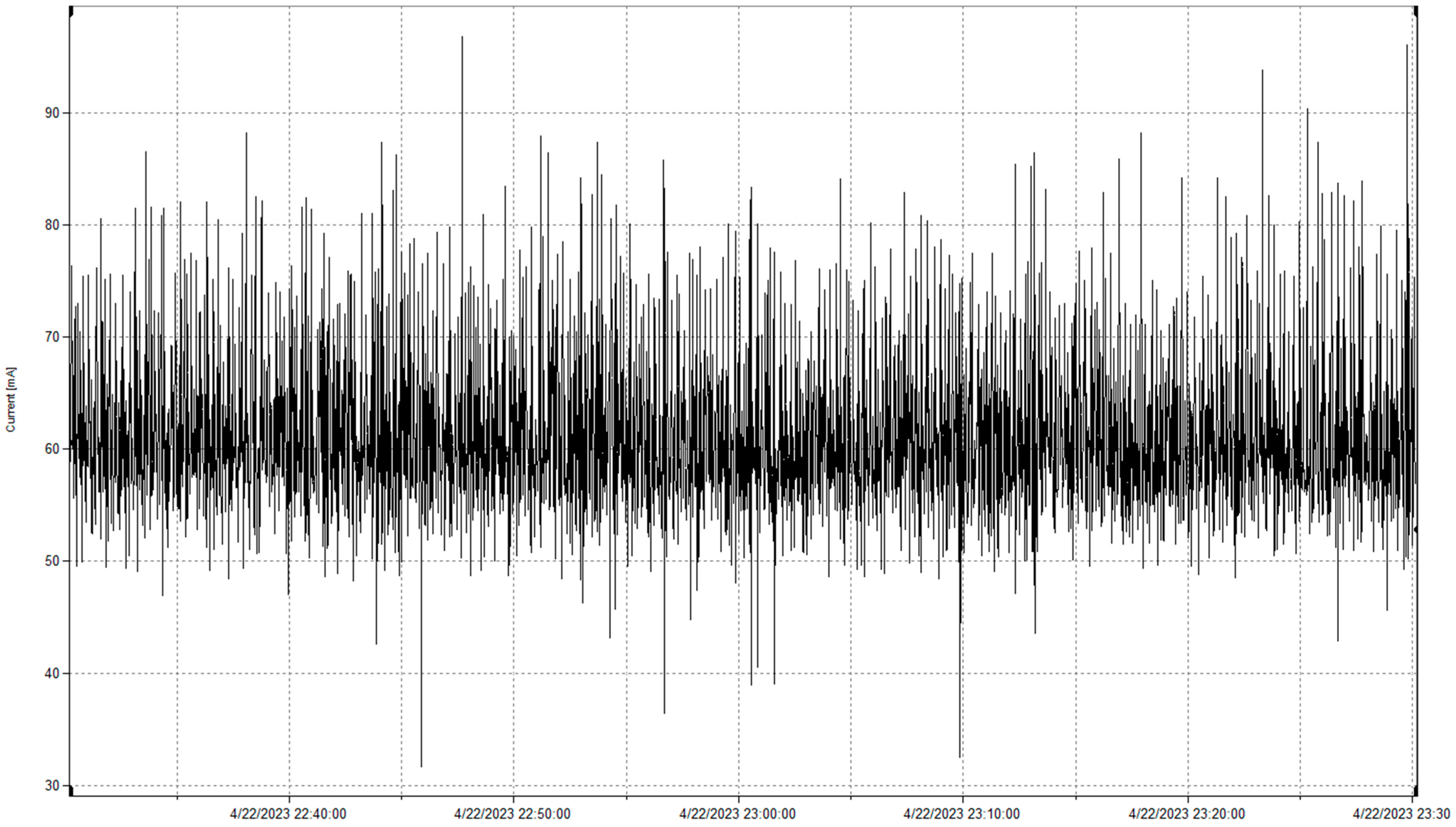

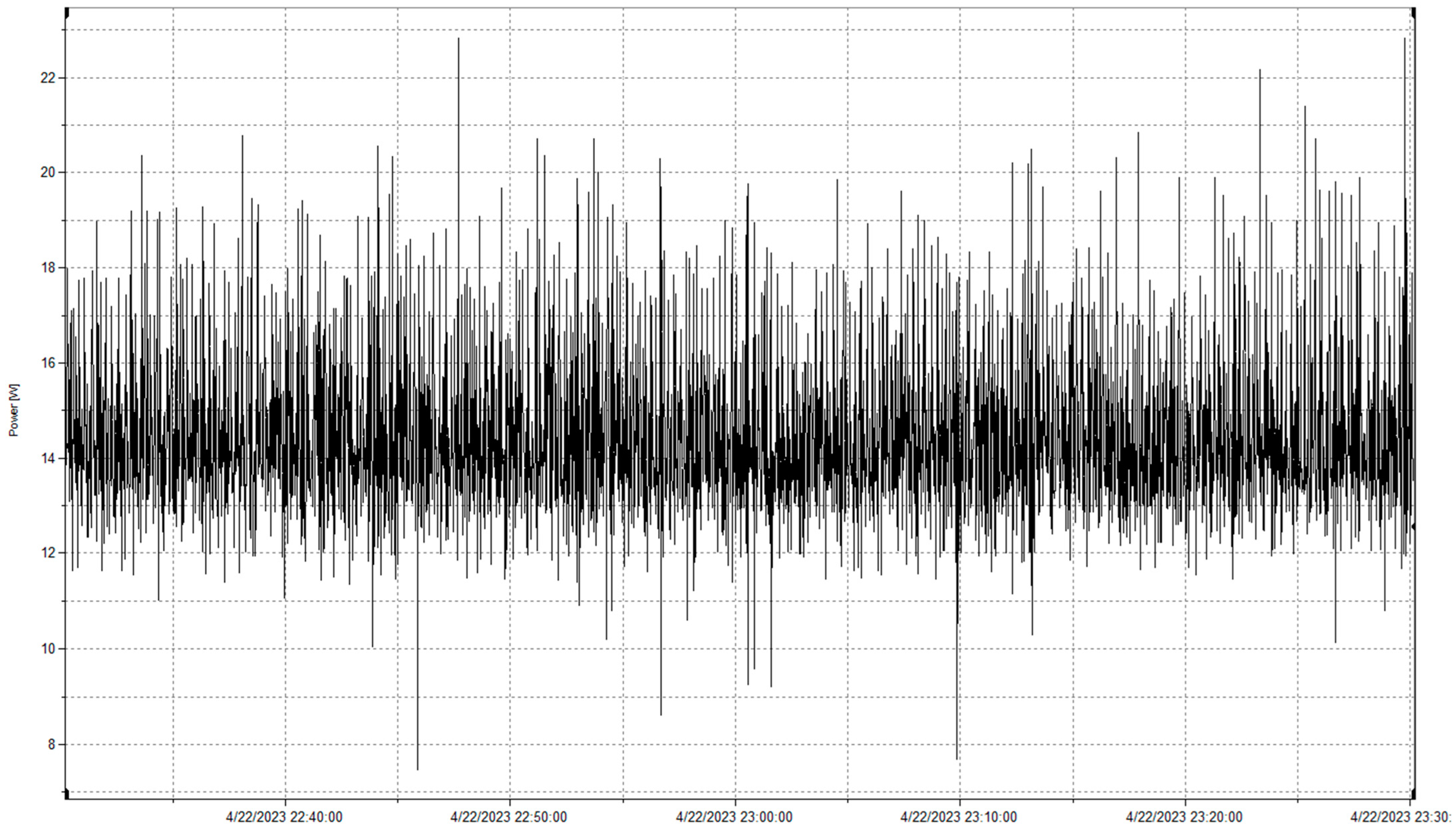

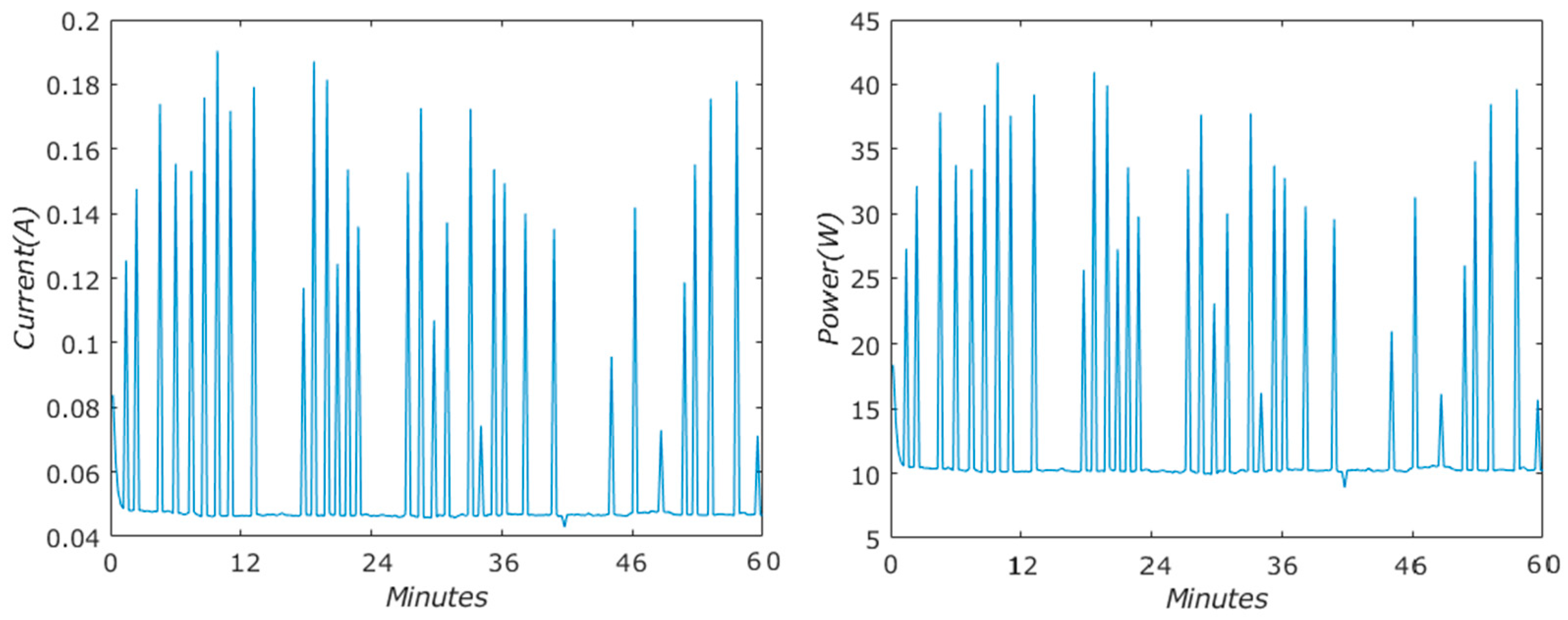

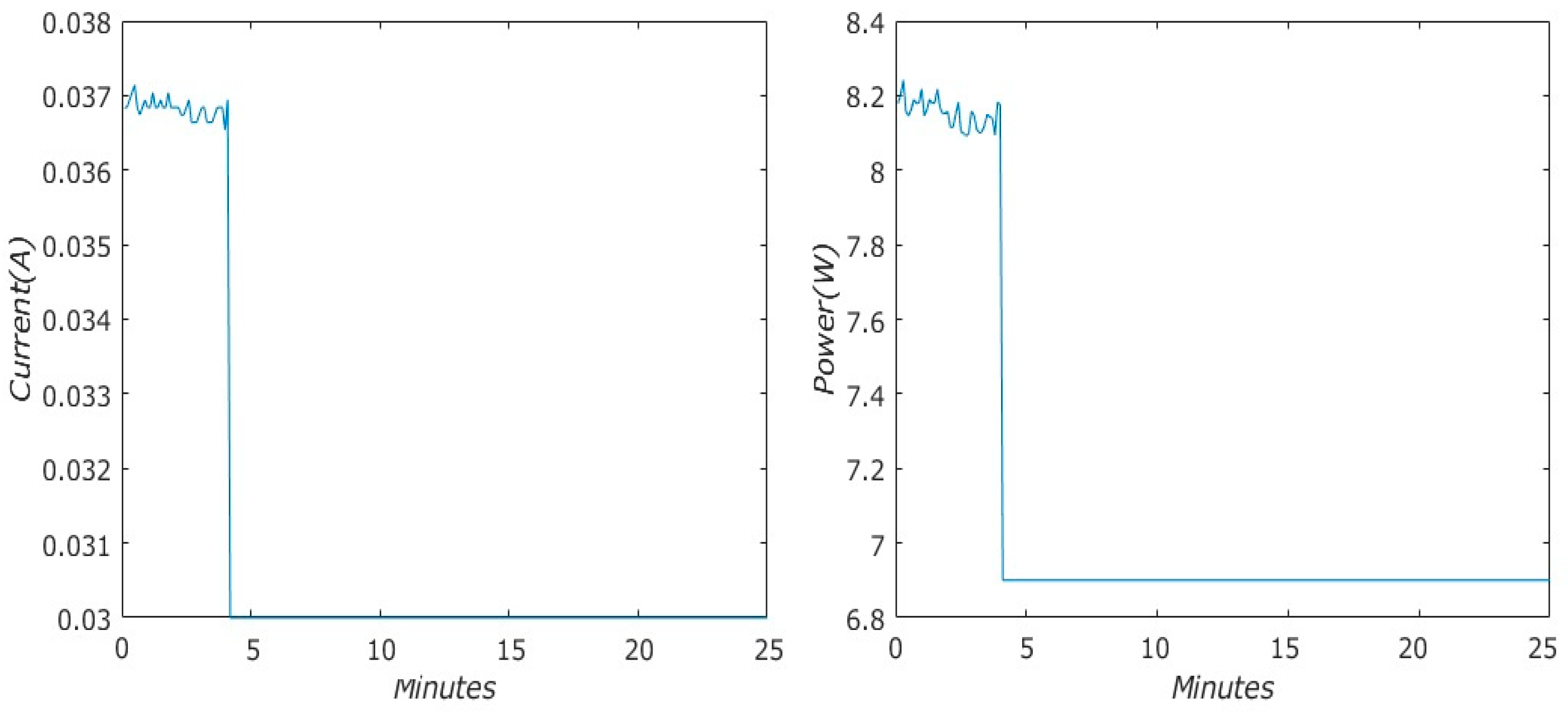

2.1.2. Data Measurement of Laptop Current and Power Consumption

2.1.3. Data Measurement of TV Current and Power Consumption

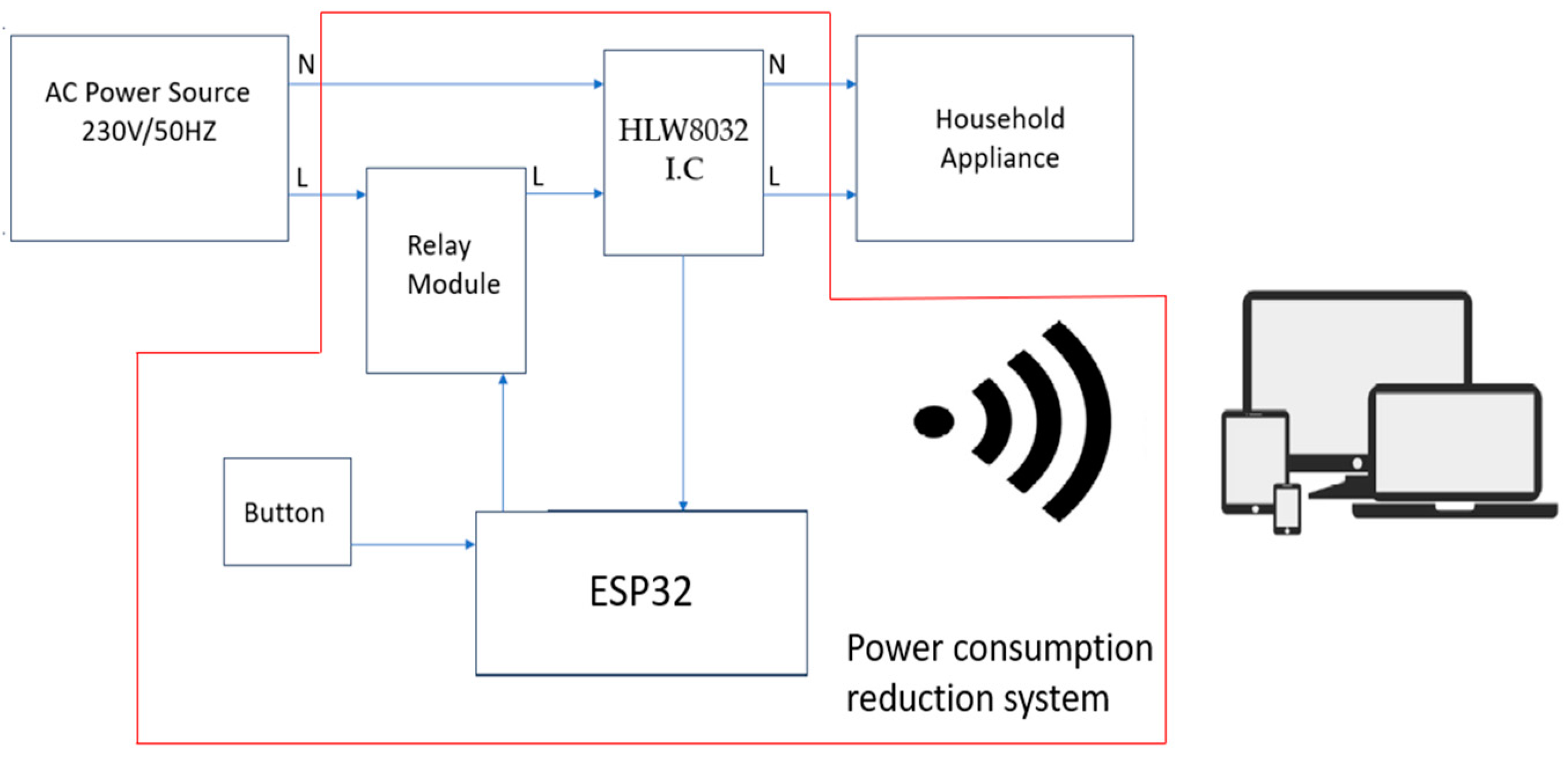

2.2. Proposed System for Power Consumption Reduction

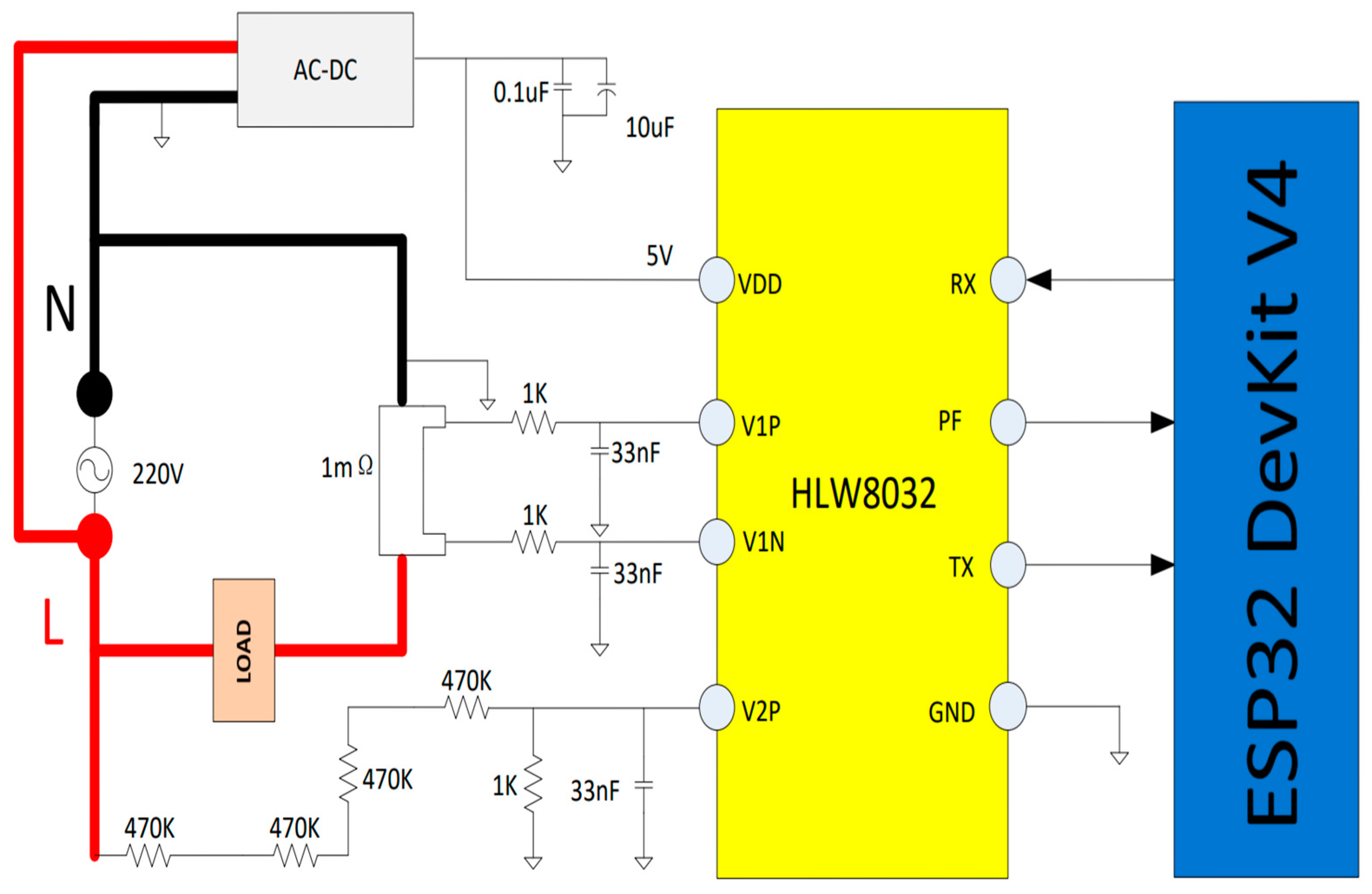

2.2.1. Hardware Architecture

- (A)

- ESP32 DevKit V4

- (B)

- Relay module

- (C)

- HLW8032 IC

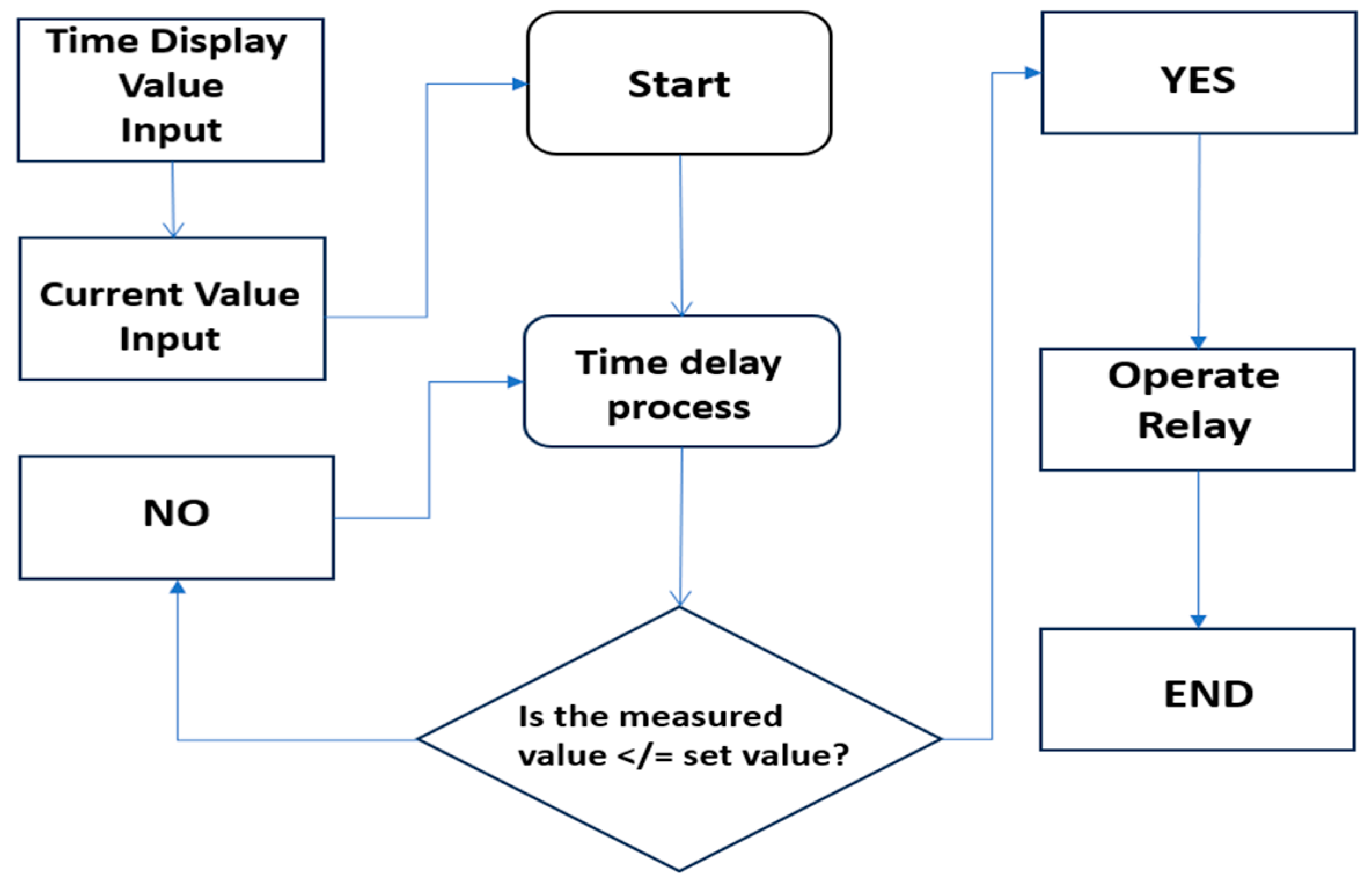

2.2.2. Software Flow Chart

2.2.3. Web Application

3. Results and Discussion

- (A)

- Beko washing machine (WUE81436

- (B)

- Lenovo Legion laptop (15ACH6H)

- (C)

- LG TV (40UH630V)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Data Acquisition Made by the Fluke 1738 Power Logger for a Washing Machine and Laptop

Appendix B. MATLAB Application Code

Appendix C. Data Acquisition for Washing Machine through Proposed System

| Measurement Frequency (Time) | Normal Operation Current Values | Normal Operation Power Values | Standby Operation Current Values | Standby Operation Power Values |

| Every 5 s | 0.273 | 60.06 | 0.082 | 19.27 |

| 0.273 | 60.06 | 0.082 | 19.27 | |

| 0.273 | 60.06 | 0.082 | 19.27 | |

| 0.174 | 38.28 | 0.082 | 19.27 | |

| 0.174 | 38.28 | 0.082 | 19.27 | |

| 0.174 | 38.28 | 0.082 | 19.27 | |

| 0.174 | 38.28 | 0.082 | 19.27 | |

| 0.154 | 33.88 | 0.082 | 19.27 | |

| 0.154 | 33.88 | 0.082 | 19.27 | |

| 0.154 | 33.88 | 0.082 | 19.27 | |

| 0.154 | 33.88 | 0.082 | 19.27 | |

| 0.154 | 33.88 | 0.082 | 19.27 | |

| 0.154 | 33.88 | 0.082 | 19.27 | |

| 0.154 | 33.88 | 0.082 | 19.27 | |

| 0.154 | 33.88 | 0.082 | 19.27 | |

| 0.154 | 33.88 | 0.082 | 19.27 | |

| 0.154 | 33.88 | 0.082 | 19.27 | |

| 0.154 | 33.88 | 0.082 | 19.27 | |

| 0.154 | 33.88 | 0.082 | 19.27 | |

| 0.192 | 42.68 | 0.082 | 19.27 | |

| 0.192 | 42.68 | 0.082 | 19.27 | |

| 0.192 | 42.68 | 0.082 | 19.27 | |

| 0.192 | 42.68 | 0.082 | 19.27 | |

| 0.361 | 79.42 | 0.082 | 19.27 | |

| 0.361 | 79.42 | 0.082 | 19.27 | |

| 0.361 | 79.42 | 0.082 | 19.27 | |

| 7.981 | 1465.46 | 0.082 | 19.27 | |

| 7.981 | 1872.42 | 0.082 | 19.27 | |

| 7.981 | 1872.42 | 0.082 | 19.27 | |

| 7.981 | 1873.69 | 0.082 | 19.27 | |

| 7.977 | 1875.39 | 0.082 | 19.27 | |

| 7.977 | 1874.11 | 0.082 | 19.27 | |

| 7.977 | 1873.69 | 0.082 | 19.27 | |

| 7.977 | 1870.73 | 0.082 | 19.27 | |

| 7.977 | 1872.84 | 0.082 | 19.27 | |

| 7.977 | 1872.84 | 0.082 | 19.27 | |

| 7.977 | 1870.3 | 0.082 | 19.27 | |

| 7.977 | 1874.11 | 0.082 | 19.27 | |

| 7.977 | 1874.11 | 0.082 | 19.27 | |

| 7.962 | 1876.24 | 0.082 | 19.27 | |

| 7.962 | 1874.54 | 0.082 | 19.27 | |

| 7.962 | 1874.11 | 0.082 | 19.27 | |

| 7.897 | 1872 | 0.082 | 19.27 | |

| 7.897 | 1864.83 | 0.082 | 19.27 | |

| 7.897 | 1857.71 | 0.082 | 19.27 | |

| 7.897 | 1855.22 | 0.082 | 19.27 | |

| 7.892 | 1851.48 | 0.082 | 19.27 | |

| 7.892 | 1854.39 | 0.082 | 19.27 | |

| 7.892 | 1856.05 | 0.082 | 19.27 | |

| 7.883 | 1855.63 | 0.082 | 19.27 |

References

- Vasiliu, A.; Nedelcu, O.; Magdun, O.; Salisteanu, I.C. A study on theenergy consumption of the electrical and electronic household and officeequipment in standby and off-mode. Sci. Bull. Electr. Eng. Fac. 2021, 21, 26–30. [Google Scholar]

- Daragmeh, S.M.; Karslen, A.T.; Hameed, I.A. Heuristic Techniques for Reducing Energy Consumption of Household. In Proceedings of the 36th ECMS International Conference on Modelling and Simulation ECMS 2022, Ålesund, Norway, 30 May–3 June 2022. [Google Scholar]

- Matsumoto, S.; Mizobuchi, K.; Managi, S. Household energy consumption. Env. Econ Policy Stud. 2022, 24, 1–5. [Google Scholar] [CrossRef]

- Desiderio, R.J.; Del Rio, P. Analysing the drivers of the efficiency of households in electricity consumption. Energy Policy 2022, 164, 43–61. [Google Scholar]

- Eurostat. Energy Consumption in Households. 2023. Available online: https://ec.europa.eu/eurostat/news/euro-indicators (accessed on 28 March 2024).

- Villanueva, D.; San-Facundo, D.; Miguez-Garcia, E.; Fernandez-Otero, A. Modeling and Simulation of Household Appliances Power Consumption. Appl. Sci. 2022, 12, 3689. [Google Scholar] [CrossRef]

- Hubert, P.; Gerber, M.; Rumsch, A.; Paice, A. Prediction of domestic appliances usage based on electrical consumption. Energy Inform. 2018, 1, 16. [Google Scholar] [CrossRef]

- Moldovan, D.; Slowik, A. Energy consumption prediction of appliances using machine learning and multi-objective binary grey wolf optimization for feature selection. Appl. Soft Comput. 2021, 111, 103–121. [Google Scholar] [CrossRef]

- Chauhan, R.K.; Chaucan, K.; Badar, A. Optimization of electrical energy waste in house using smart appliances management System-A case study. J. Build. Eng. 2021, 2, 37–45. [Google Scholar] [CrossRef]

- Molla, T.; Khan, B.; Moges, B.; Alhelou, H.; Zamani, R.; Siano, P. Integrated energy optimization of smart home appliances with cost-effective energy management system. CSEE J. Power Energy Syst. 2019, 2, 249–258. [Google Scholar]

- Eirianki, M.; Varlamis, I.; Dahihande, J.; Jaiswal, A.; Pagar, A.A.; Thakare, A.T. Real-time recommendations for energy-efficient appliance usage in households. Front. Big Data 2022, 5, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Alsalemi, A.; Himeur, Y.; Bensaali, F.; Amira, A.; Sardianos, C.; Varlamis, I.; Dimitrakopoulos, G. Achieving Domestic Energy Efficiency Using Micro-Moments and Intelligent Recommendations. IEEE Access 2020, 8, 15047–15055. [Google Scholar] [CrossRef]

- Codispoti, J.; Khamesi A., R.; Penn, N.; Silvestri, S.; Shin, E. Learning from non-experts: An interactive and adaptive learning approach for appliance recognition in smart homes. ACM Trans. Cyber-Phys. Syst. 2022, 6, 1–22. [Google Scholar] [CrossRef]

- Mursid, S.; Santaso, H. Analysis of the Effectiveness of the Utilization of Power Monitoring Devices in Reducing Electric Energy Consumption. J. Phys. Conf. Ser. 2019, 1364, 012055. [Google Scholar] [CrossRef]

- Rahman, K.A.; Leman, A.M.; Mubin, F.M.; Yusof, M.Z.M.; Harir, A.; Salleh, M.N.M. Energy Consumption Analysis Based on Energy Efficiency Approach: A Case of Suburban Area. In Proceedings of the MATEC Web Conference, Sarawak, Malaysia, 12 December 2016. [Google Scholar]

- Issi, F.; Kaplan, O. The Determination of Load Profiles and Power Consumptions of Home Appliances. Energies 2018, 11, 607. [Google Scholar] [CrossRef]

- Gheorghe, A.C.; Andrei, H.; Diaconu, E. Data measurement and modeling method of electrical parameters of basic household equipment. In Proceedings of the 14th International Conference on Electronics, Computers and Artificial Intelligence (ECAI), Ploiesti, Romania, 30 June 2022—1 July 2022. [Google Scholar]

- Gheorghe, A.C.; Andrei, H.; Diaconu, E. Système Intelligent Pour la Réduction de la Consommation Electrique en Veille Des Équipements Ménagers. Revue Roumaine des Sciences Techniques. Série Électrotech. Énerg. 2023, 68, 413–418. [Google Scholar] [CrossRef]

- Gheorghe, A.C.; Udroiu, I.; Stan, E. Electricity Consumption Measurement System Using ESP32. Sci. Bull. Electr. Eng. Fac. 2021, 21, 23–26. [Google Scholar] [CrossRef]

- ESP32 Datasheet. Available online: https://www.espressif.com/sites/default/files/documentation/esp32_datasheet_en.pdf (accessed on 14 December 2023).

- Fluke User Manual. Available online: https://dam-assets.fluke.com/s3fs-public/173x____umeng0200_0.pdf?2JZuc3jb6JoHuQ163Haf5bzCdt1HSMvE (accessed on 1 June 2024).

- HLW8032 Datasheet at JLCPCB. Available online: https://github.com/Khaalidi/HLW8032/blob/master/Docs/DS_HLW8032_EN_Rev1.5.pdf (accessed on 14 December 2023).

- Introduction to ESP32. Available online: https://www.electronicshub.org/getting-started-with-esp32/ (accessed on 16 December 2023).

- ESP32 for IoT: A Complete Guide. Available online: https://www.nabto.com/guide-to-iot-esp-32/ (accessed on 16 December 2023).

- Espressif ESP32 Development Board—Developer Edition. Available online: https://www.adafruit.com/product/3269 (accessed on 17 December 2023).

- HLW8032 ESP-IDF Component. Available online: https://github.com/ucukertz/IDF-HLW8032 (accessed on 17 December 2023).

- HLW8032 I.C Datasheet. Available online: https://www.lcsc.com/datasheet/lcsc_datasheet_2307271600_Hiliwei-Tech-HLW8032_C128023.pdf (accessed on 18 December 2023).

- ESP32-DevKitC V4 Getting Started Guide. Available online: https://docs.espressif.com/projects/esp-idf/en/v3.3/get-started/get-started-devkitc.html (accessed on 3 January 2024).

- What Is Relay and How It Works? Available online: https://www.electronicshub.org/what-is-relay-and-how-it-works/ (accessed on 4 January 2024).

- 5V Single-Channel Relay Module Description. Available online: https://www.theengineeringprojects.com/ (accessed on 10 January 2024).

- HLW8032 Energy Metering IC. Available online: https://www.dnatechindia.com/hlw-8032-single-phase-energy-meter-ic-buy-india.html (accessed on 20 January 2024).

- HLW8032 Energy Metering IC—SOIC-8 Package. Available online: https://sharvielectronics.com/product/hlw8032-energy-metering-ic-soic-8-package/ (accessed on 20 January 2024).

- A Lightweight Library for the HLW8032 SOP8 High Precision Energy Metering IC. Available online: https://github.com/Khaalidi/HLW8032 (accessed on 20 January 2024).

- (UE) 2023/826 Regulation. Available online: https://eur-lex.europa.eu/legal-content/RO/TXT/?uri=CELEX:32023R0826 (accessed on 28 May 2024).

| Equipment | Standby Consumption kWh | Standby Consumption with System kWh | Standby Consumption kWh/Day | Standby Consumption with System kWh/Day | Standby Consumptionk Wh/Month | Standby Consumption with System kWh/Month |

|---|---|---|---|---|---|---|

| Washing machine | 0.02139 | 0.00178 | 0.51336 | - | 15.40080 | - |

| Laptop | 0.01373 | 0.00114 | 0.32952 | - | 10.21512 | - |

| Tv | 0.00815 | 0.00067 | 0.1956 | - | 6.0636 | - |

| Proposed system | - | - | - | - | - | 4.968 |

| Total | 0.04327 | 0.00359 | 1.0384 | - | 31.65192 | 4.968 |

| Household Equipment with System | Standby Consumption Achieved (kWh) | Standby Consumption Regulation EU 2025 (kWh) | Standby Consumption Regulation EU 2027 (kWh) |

|---|---|---|---|

| Washing machine | 0.0017 | 0.0005–0.0008 | 0.0003–00005 |

| TV | 0.0011 | ||

| Laptop | 0.0006 |

| Parts | Price (EUR) |

|---|---|

| ESP32 | 20 |

| Relay module | 3 |

| HLW8032 IC | 5 |

| PCB + Component assembly service (external service) | 10 |

| Total (EUR) | 38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gheorghe, A.C.; Andrei, H.; Diaconu, E.; Andrei, P.C. Smart System for Reducing Standby Energy Consumption in Residential Appliances. Energies 2024, 17, 2989. https://doi.org/10.3390/en17122989

Gheorghe AC, Andrei H, Diaconu E, Andrei PC. Smart System for Reducing Standby Energy Consumption in Residential Appliances. Energies. 2024; 17(12):2989. https://doi.org/10.3390/en17122989

Chicago/Turabian StyleGheorghe, Andrei Cosmin, Horia Andrei, Emil Diaconu, and Paul Cristian Andrei. 2024. "Smart System for Reducing Standby Energy Consumption in Residential Appliances" Energies 17, no. 12: 2989. https://doi.org/10.3390/en17122989

APA StyleGheorghe, A. C., Andrei, H., Diaconu, E., & Andrei, P. C. (2024). Smart System for Reducing Standby Energy Consumption in Residential Appliances. Energies, 17(12), 2989. https://doi.org/10.3390/en17122989