Turning Food Loss and Food Waste into Watts: A Review of Food Waste as an Energy Source

Abstract

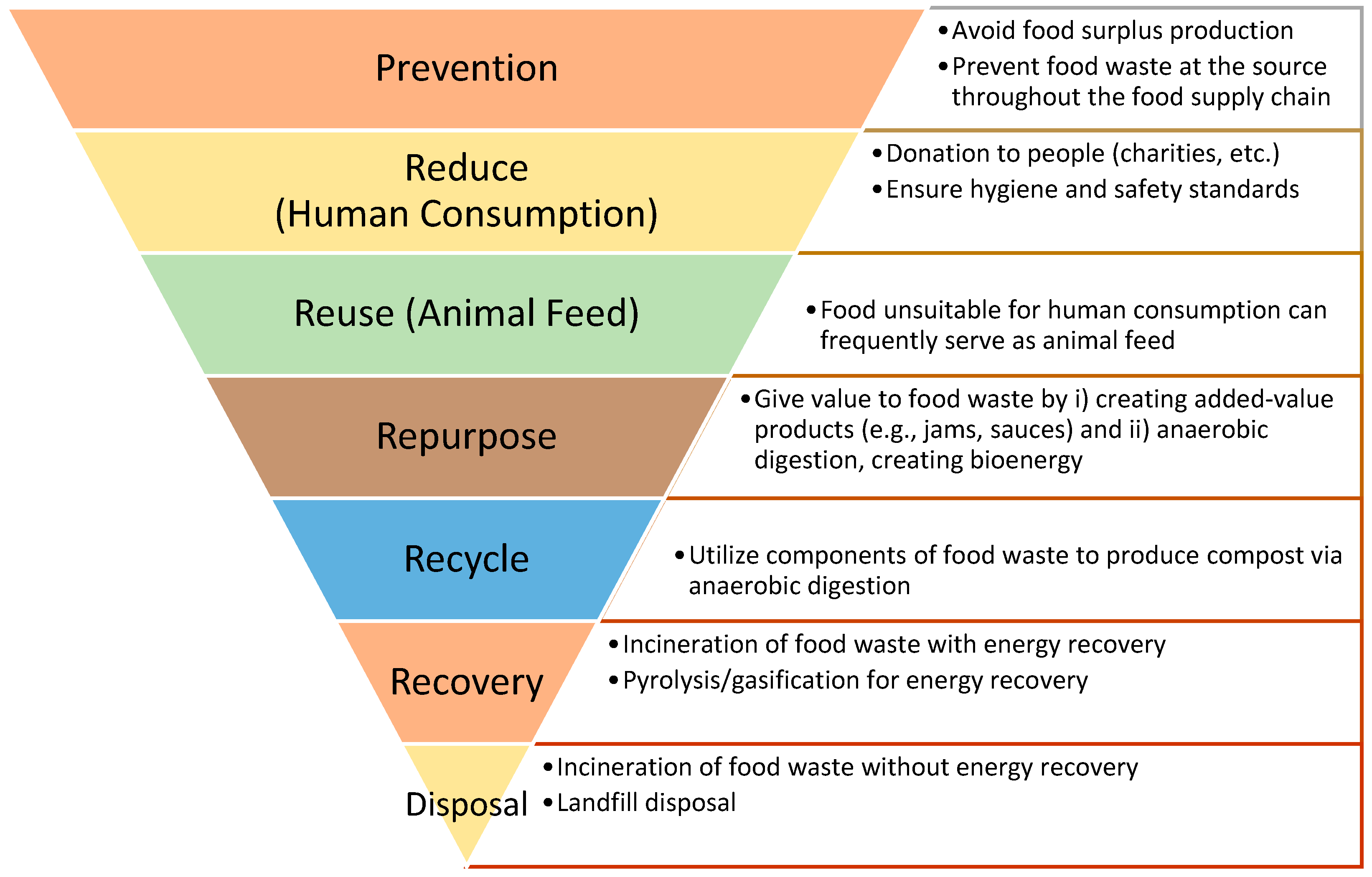

:1. Introduction

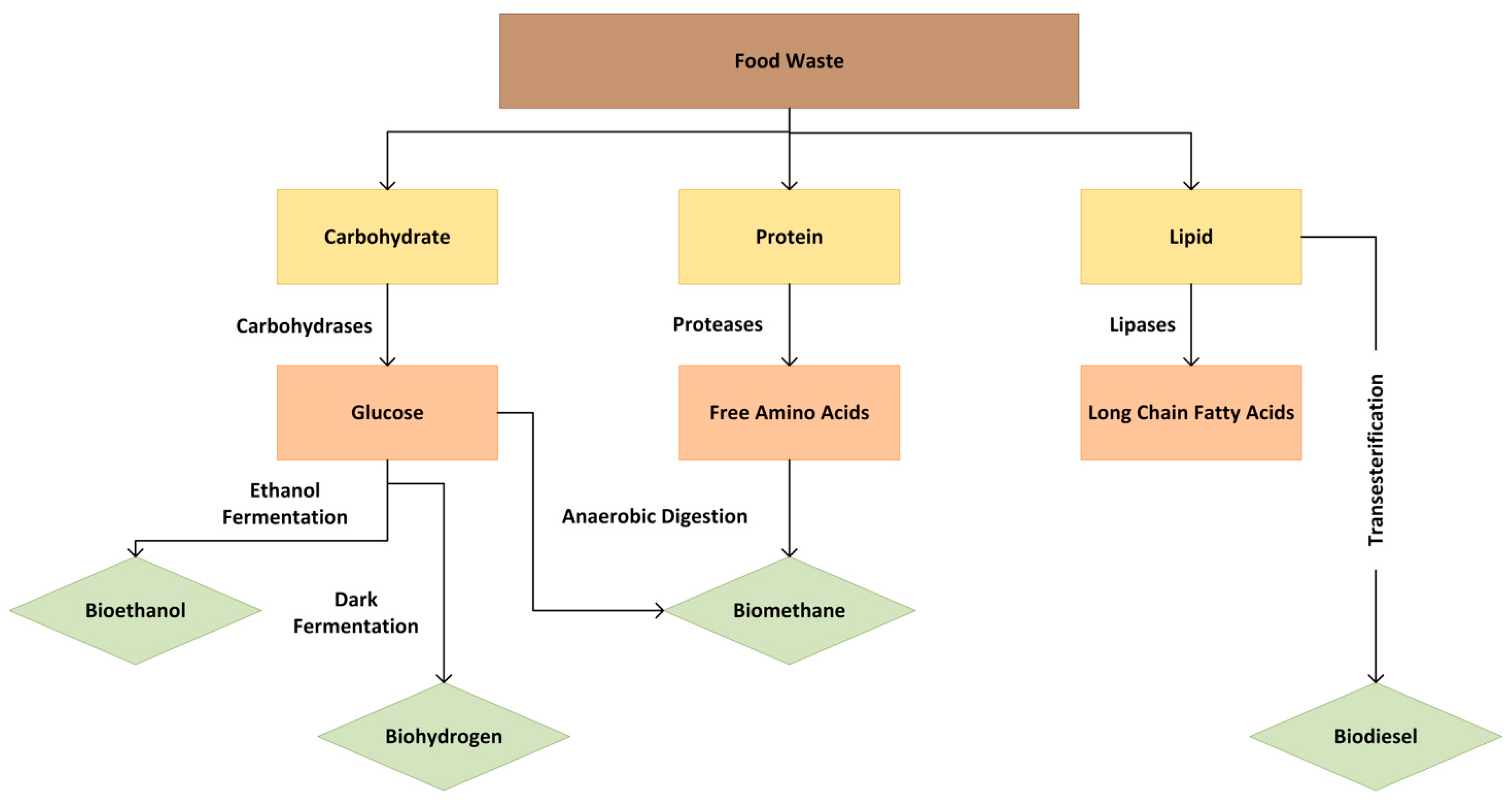

FL and FW Composition

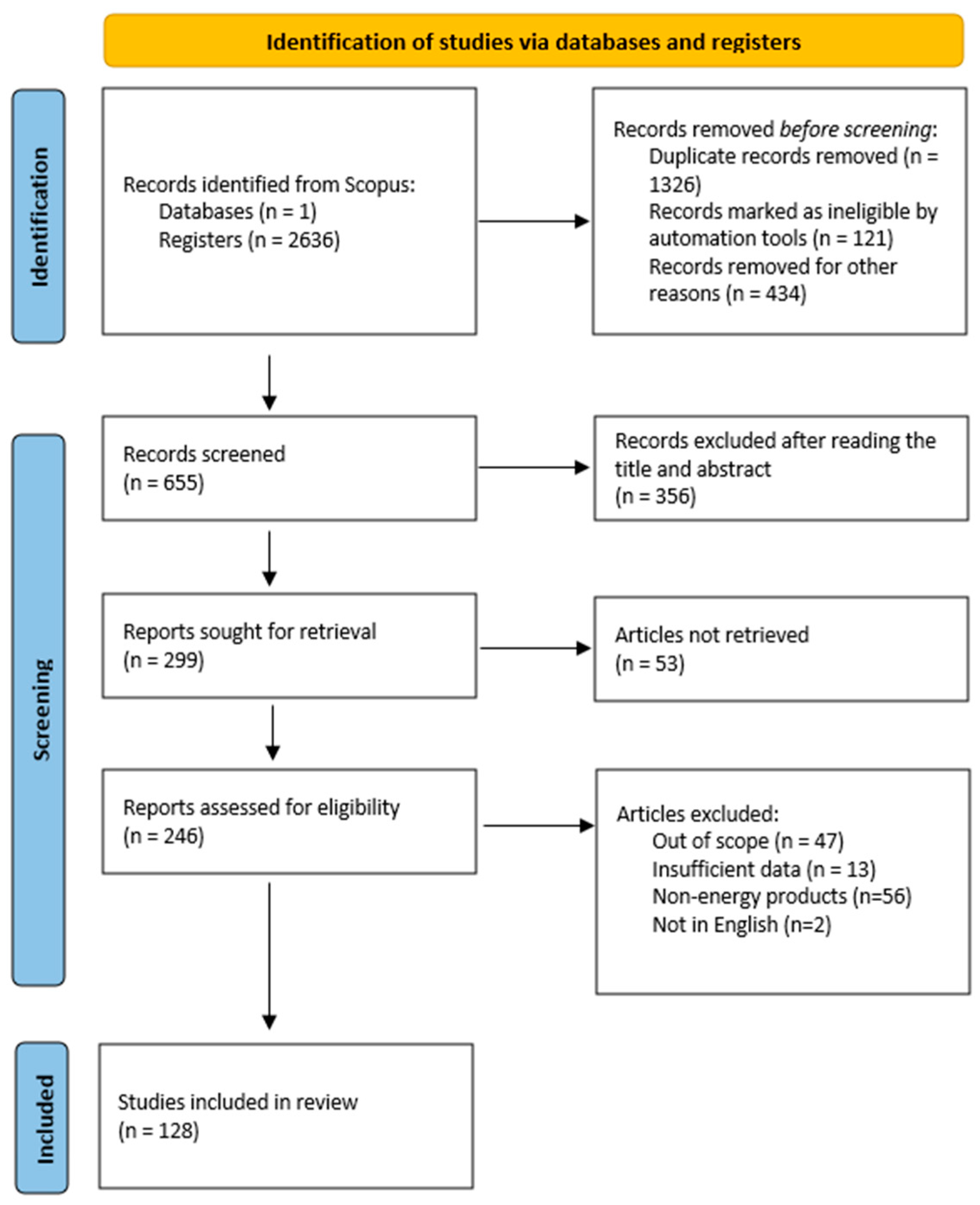

2. Methodology

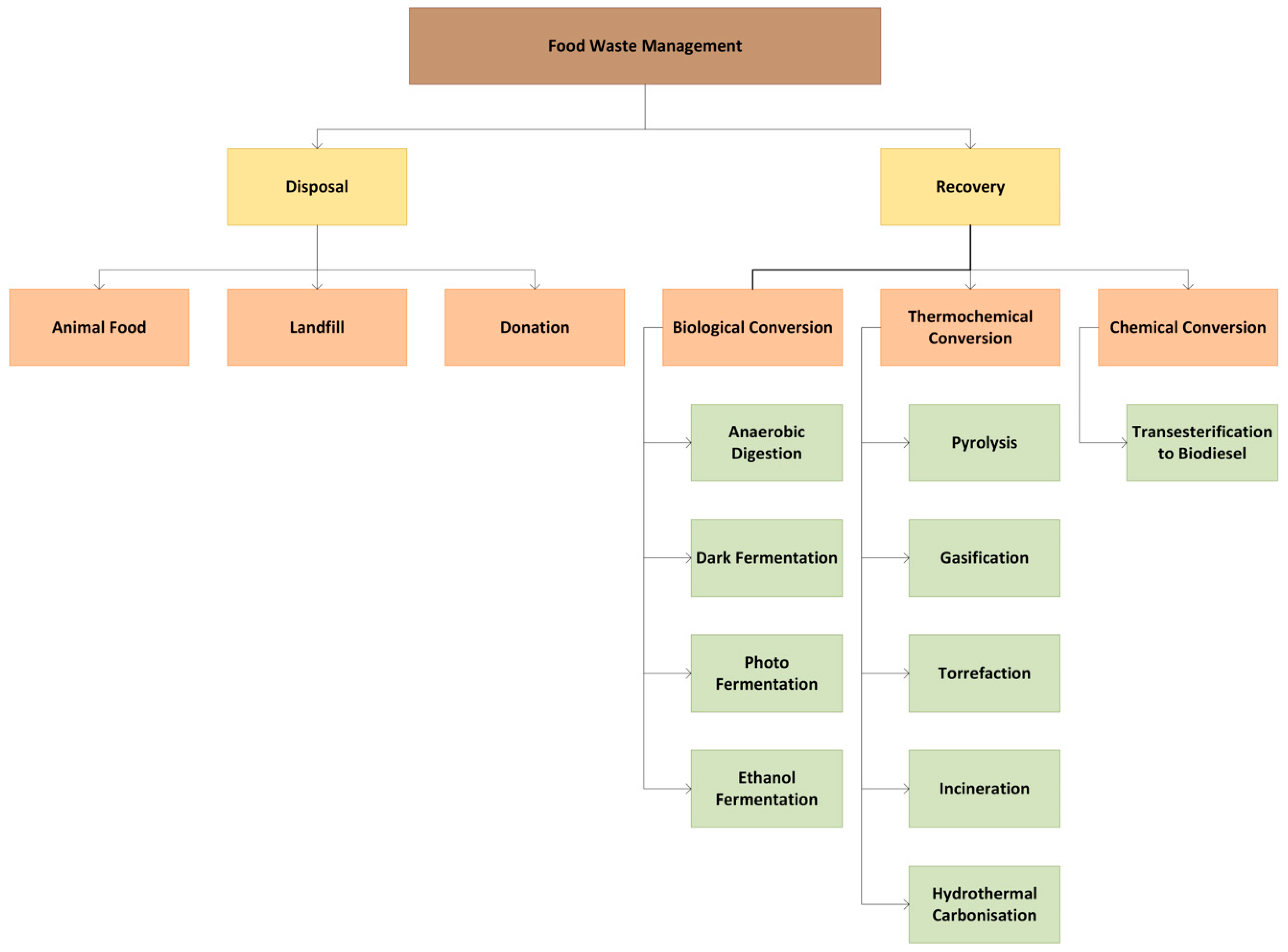

3. Energy Recovery from FL and FW

- Biological Conversion Processes

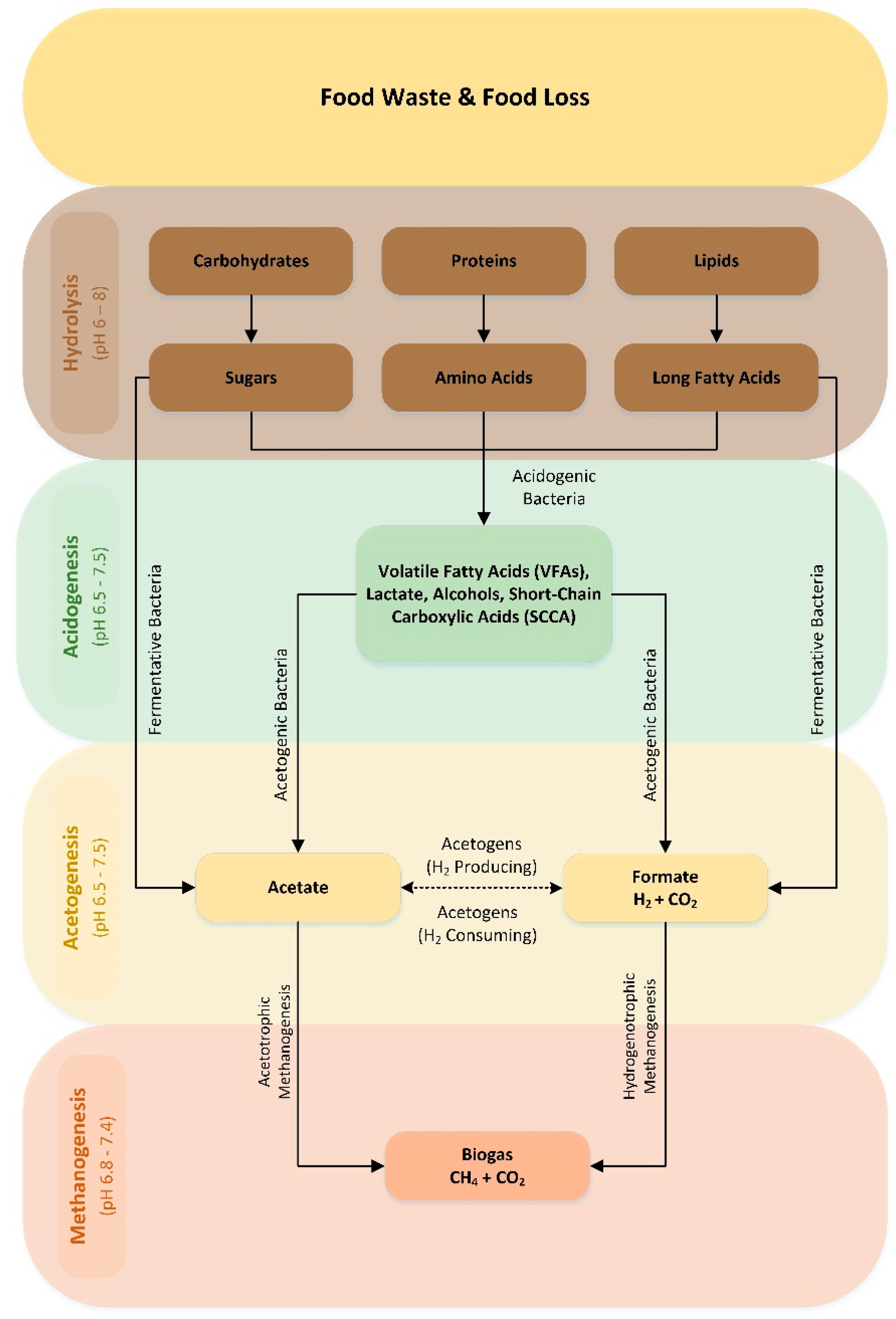

3.1. Anaerobic Digestion (AD)

3.1.1. Hydrolysis

3.1.2. Acidogenesis

3.1.3. Acetogenesis

3.1.4. Methanogenesis

3.1.5. One-Stage vs. Two-Stage Anaerobic Digestion

3.1.6. Co-Digestion in Anaerobic Treatment (AcoD)

3.2. Dark Fermentation

3.3. Photofermentation

- Chemical Conversion Processes

3.4. Transesterification

- Thermochemical Conversion Processes

3.5. Incineration

3.6. Pyrolysis

| Slow Pyrolysis | Intermediate Pyrolysis | Fast Pyrolysis | Flash Pyrolysis | |

|---|---|---|---|---|

| Target | High biochar yield | Separable bio-oil, high-quality biochar | High bio-oil yield | High bio-oil yield |

| Heating rate | 0.1–1 °C/min | 1–10 °C/min | 1000 °C/min | >700 °C/s |

| Vapor residence time | 5–30 min | 0.5–20 s | <2 s | <0.5 s |

| Temperature | <400 °C | 400–500 °C | 500 °C | 750–1050 °C |

| Biochar yield (%) | 20–50 | 35–50 | 60–75 | 60–75 |

| Bio-oil yield (%) | 25–35 | 25–40 | 10–25 | 10–25 |

| Biogas yield (%) | 20–50 | 20–30 | 10–30 | 10–30 |

3.6.1. Co-Pyrolysis

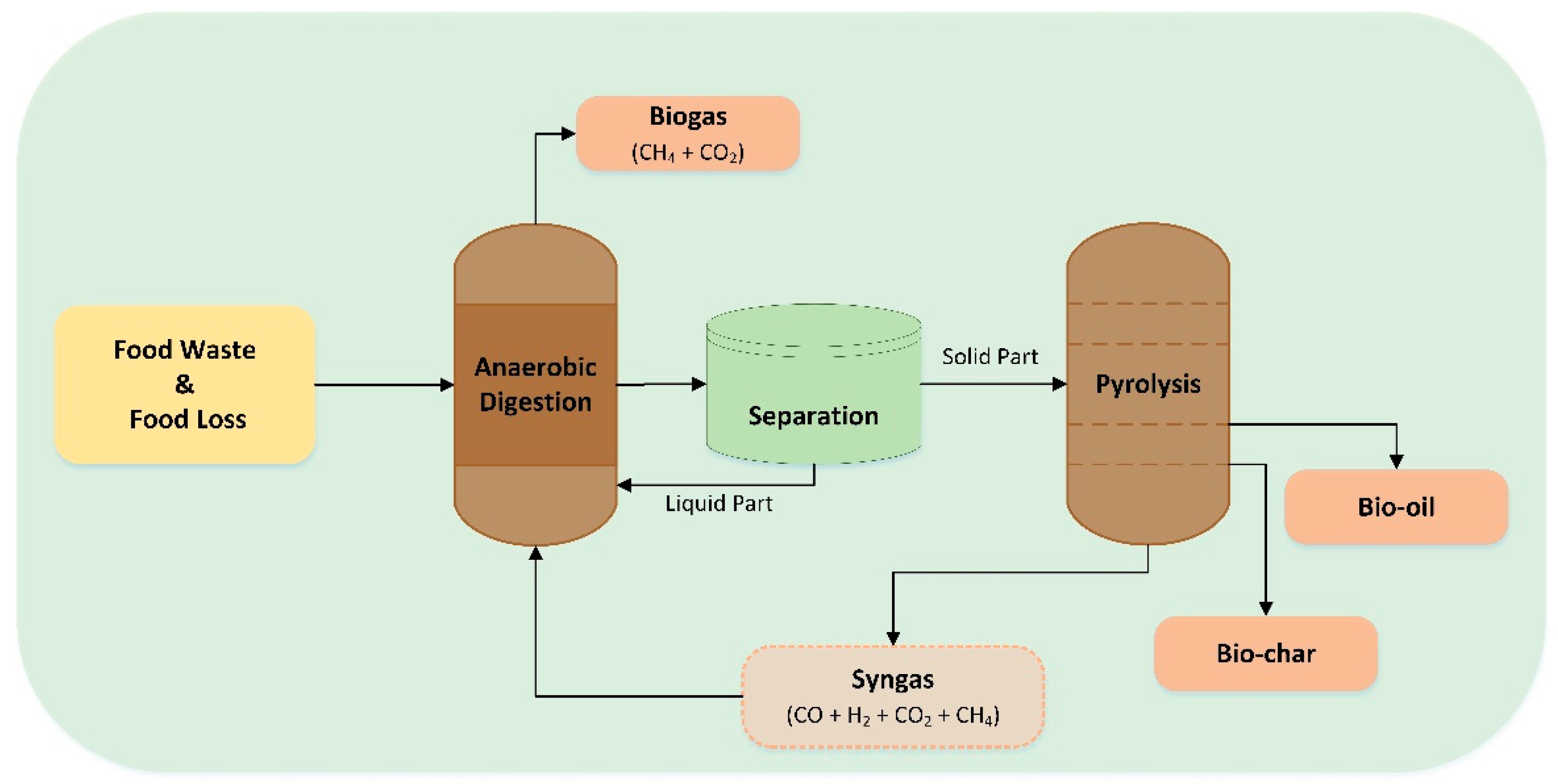

3.6.2. Integrated Pyrolysis and Anaerobic Digestion System

3.7. Torrefaction

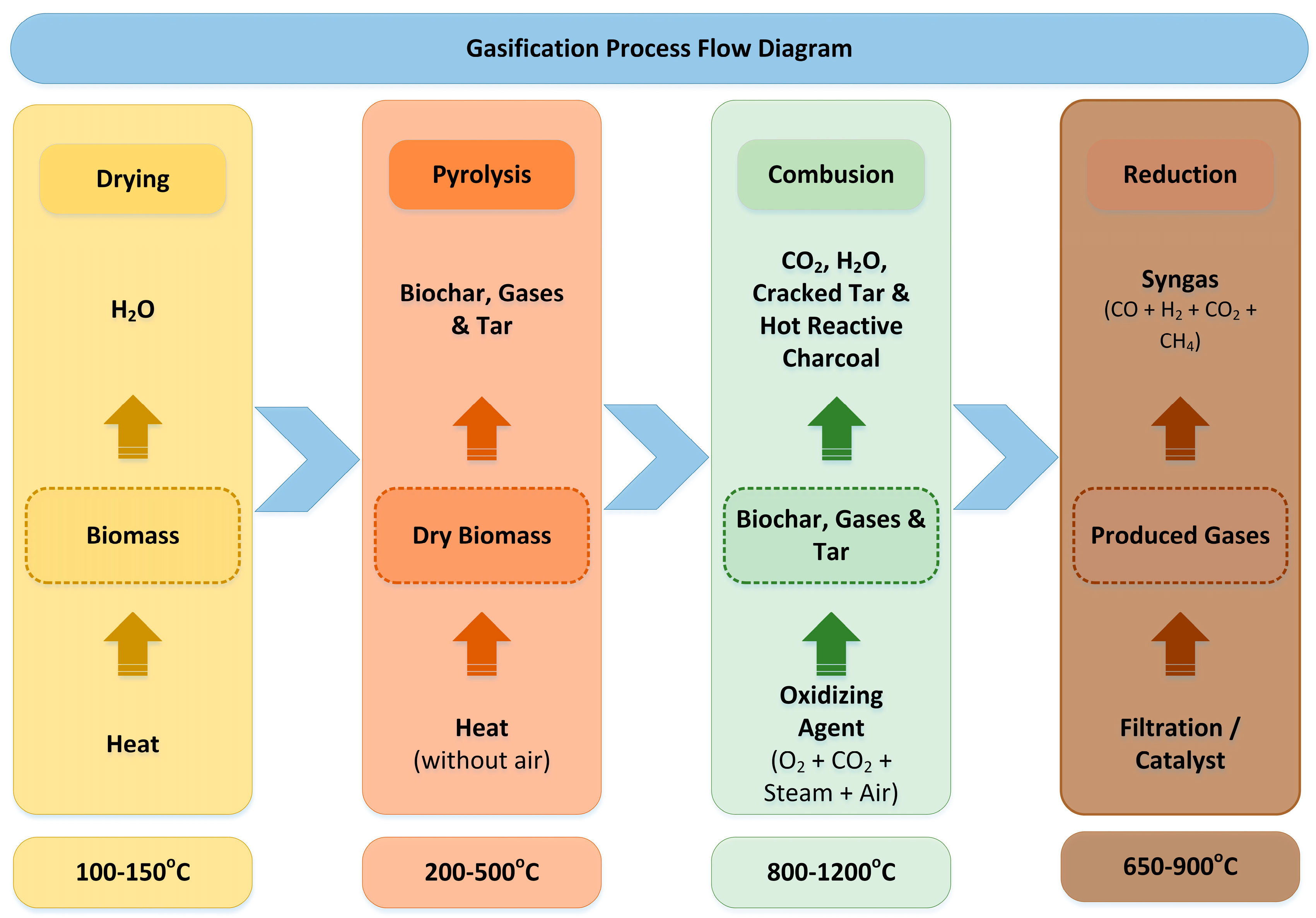

3.8. Gasification

3.8.1. Steam Gasification

3.8.2. Fischer–Tropsch

3.8.3. Plasma Gasification

3.8.4. Supercritical Water Gasification (SCWG)

3.9. Hydrothermal Carbonization (HTC)

3.9.1. Co-Hydrothermal Carbonization (co-HTC)

3.9.2. Hydrothermal Liquification

3.10. Ethanol Fermentation

3.11. Ongoing Advancements, Future Research and Recommendations

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- FAO. Global Food Losses and Food Waste 2011. Available online: https://www.fao.org/3/i2697e/i2697e.pdf (accessed on 4 May 2024).

- Zorpas, A.A. Strategy development in the framework of waste management. Sci. Total Environ. 2020, 716, 137088. [Google Scholar] [CrossRef] [PubMed]

- Economou, F.; Chatziparaskeva, G.; Papamichael, I.; Loizia, P.; Voukkali, I.; Navarro-Pedreño, J.; Klontza, E.; Lekkas, D.F.; Naddeo, V.; Zorpas, A.A. The concept of food waste and food loss prevention and measuring tools. Waste Manag. Res. J. A Sustain. Circ. Econ. 2024, 21, 734242X241237187. [Google Scholar] [CrossRef] [PubMed]

- Loizia, P.; Voukkali, I.; Zorpas, A.A.; Navarro Pedreño, J.; Chatziparaskeva, G.; Inglezakis, V.J.; Vardopoulos, I.; Doula, M. Measuring the level of environmental performance in insular areas, through key performed indicators, in the framework of waste strategy development. Sci. Total Environ. 2021, 753, 141974. [Google Scholar] [CrossRef] [PubMed]

- Environmental Protection Agency, U.S. 2018 Wasted Food Report Estimates of Generation and Management of Wasted Food in the United States in 2018. 2018. Available online: https://www.epa.gov/sites/default/files/2020-11/documents/2018_wasted_food_report-11-9-20_final_.pdf (accessed on 4 May 2024).

- Tiseo, I. Annual Food Waste by Select Country Worldwide|Statista 2023. Available online: https://www.statista.com/statistics/933083/food-waste-of-selected-countries/ (accessed on 4 May 2024).

- Tiseo, I. Food Waste per Capita of Selected Countries Worldwide 2020|Statista 2023. Available online: https://www.statista.com/statistics/933059/per-capita-food-waste-of-selected-countries/ (accessed on 4 May 2024).

- European Commission. Food Waste—European Commission 2024. Available online: https://food.ec.europa.eu/safety/food-waste_en (accessed on 4 May 2024).

- EUROSTAT. Food Waste and Food Waste Prevention—Estimates—Statistics Explained 2023. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Food_waste_and_food_waste_prevention_-_estimates (accessed on 4 May 2024).

- Economou, F.; Papamichael, I.; Rodríguez-Espinosa, T.; Voukkali, I.; Pérez-Gimeno, A.; Zorpas, A.A.; Navarro-Pedreño, J. The Impact of Food Overproduction on Soil: Perspectives and Future Trends. In Planet Earth: Scientific Proposals to Solve Urgent Issues; Springer International Publishing: Cham, Switzerland, 2024; pp. 263–292. [Google Scholar] [CrossRef]

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Towards transparent valorization of food surplus, waste and loss: Clarifying definitions, food waste hierarchy, and role in the circular economy. Sci. Total Environ. 2020, 706, 136033. [Google Scholar] [CrossRef] [PubMed]

- European Parliament and Council of the European Union. Directive 2008/98/EC on Waste 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32018L0851 (accessed on 5 May 2024).

- European Commission. Sustainable EU Food System—New Initiative 2023. Available online: https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/13174-Sustainable-EU-food-system-new-initiative_en (accessed on 5 May 2024).

- European Commission. Waste Framework Directive 2023. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/waste-framework-directive_en (accessed on 5 May 2024).

- European Commission. Circular Economy Action Plan 2023. Available online: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en (accessed on 5 May 2024).

- Stylianou, M.; Papamichael, I.; Voukkali, I.; Tsangas, M.; Omirou, M.; Ioannides, I.M.; Zorpas, A.A. LCA of Barley Production: A Case Study from Cyprus. Int. J. Environ. Res. Public Health 2023, 20, 2417. [Google Scholar] [CrossRef] [PubMed]

- Ortiz-Sanchez, M.; Inocencio-García, P.-J.; Alzate-Ramírez, A.F.; Alzate, C.A.C. Potential and Restrictions of Food-Waste Valorization through Fermentation Processes. Fermentation 2023, 9, 274. [Google Scholar] [CrossRef]

- Nguyen, K.L.P.; Chuang, Y.H.; Chen, H.W.; Chang, C.C. Impacts of socioeconomic changes on municipal solid waste characteristics in Taiwan. Resour. Conserv. Recycl. 2020, 161, 104931. [Google Scholar] [CrossRef]

- Sarker, A.; Ghosh, M.K.; Islam, T.; Bilal, M.; Nandi, R.; Raihan, M.L.; Hossain, M.N.; Rana, J.; Barman, S.K.; Kim, J.E. Sustainable Food Waste Recycling for the Circular Economy in Developing Countries, with Special Reference to Bangladesh. Sustainability 2022, 14, 12035. [Google Scholar] [CrossRef]

- Phasha, L.; Molelekwa, G.F.; Mokgobu, M.I.; Morodi, T.J.; Mokoena, M.M.; Mudau, L.S. Influence of cultural practices on food waste in South Africa—A review. J. Ethn. Foods 2020, 7, 37. [Google Scholar] [CrossRef]

- Roufou, S.; Griffin, S.; Katsini, L.; Polańska, M.; Van Impe, J.F.M.; Valdramidis, V.P. The (potential) impact of seasonality and climate change on the physicochemical and microbial properties of dairy waste and its management. Trends Food Sci. Technol. 2021, 116, 1–10. [Google Scholar] [CrossRef]

- Braguglia, C.M.; Gallipoli, A.; Gianico, A.; Pagliaccia, P. Anaerobic bioconversion of food waste into energy: A critical review. Bioresour. Technol. 2018, 248, 37–56. [Google Scholar] [CrossRef] [PubMed]

- Slopiecka, K.; Liberti, F.; Massoli, S.; Bartocci, P.; Fantozzi, F. Chemical and physical characterization of food waste to improve its use in anaerobic digestion plants. Energy Nexus 2022, 5, 100049. [Google Scholar] [CrossRef]

- Zhu, K.; Zhang, L.; Mu, L.; Ma, J.; Li, C.; Li, A. Anaerobic digestion of surfactant and lipid co-existing organic waste: Focusing on the antagonistic enhancement. Chem. Eng. J. 2019, 371, 96–106. [Google Scholar] [CrossRef]

- Shamseer; Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Mayer, F.; Bhandari, R.; Gäth, S. Critical review on life cycle assessment of conventional and innovative waste-to-energy technologies. Sci. Total Environ. 2019, 672, 708–721. [Google Scholar] [CrossRef] [PubMed]

- Ali, J.; Rasheed, T.; Afreen, M.; Anwar, M.T.; Nawaz, Z.; Anwar, H.; Rizwan, K. Modalities for conversion of waste to energy—Challenges and perspectives. Sci. Total Environ. 2020, 727, 138610. [Google Scholar] [CrossRef] [PubMed]

- Pan, S.-Y.; Du, M.A.; Huang, I.-T.; Liu, I.-H.; Chang, E.-E.; Chiang, P.-C. Strategies on implementation of waste-to-energy (WTE) supply chain for circular economy system: A review. J. Clean. Prod. 2015, 108, 409–421. [Google Scholar] [CrossRef]

- Qazi, W.A.; Abushammala, M.F.M.; Mohammed-HashamAzam Younes, M.K. Waste-to-Energy Technologies: A Literature Review. J. Solid. Waste Technol. Manag. 2018, 44, 387–409. [Google Scholar] [CrossRef]

- Vieira, S.; Schneider, J.; Burgos, M.W.J.; Magalhães, A.; Medeiros, A.B.P.; de Carvalho, J.C.; Vandenberghe, L.P.S.; Soccol, C.D.; Sydney, E.B. Pretreatments of Solid Wastes for Anaerobic Digestion and Its Importance for the Circular Economy. In Handbook of Solid Waste Management; Springer Nature: Singapore, 2022; pp. 69–94. [Google Scholar] [CrossRef]

- Fernández, L. UK: Anaerobic Digestion Installed Capacity 2013–2019|Statista 2019. Available online: https://www.statista.com/statistics/498683/anaerobic-digestion-installed-capacity-quaterly-uk/ (accessed on 4 May 2024).

- EBA. 2023 EBA Statistical Report Tracking Biogas and Biomethane Deployment across Europe 2023. Available online: https://www.europeanbiogas.eu/wp-content/uploads/2023/12/EBA-Statistical-Report-2023-Excerpt.pdf (accessed on 4 May 2024).

- Statista Research Department. Germany: Anaerobic Fermentation Energy Production|Statista 2024. Available online: https://www.statista.com/statistics/863132/anaerobic-fermentation-biogas-energy-production-in-germany/ (accessed on 4 May 2024).

- Slorach, P.C.; Jeswani, H.K.; Cuéllar-Franca, R.; Azapagic, A. Environmental sustainability of anaerobic digestion of household food waste. J. Environ. Manag. 2019, 236, 798–814. [Google Scholar] [CrossRef]

- Chen, Y.; Pinegar, L.; Immonen, J.; Powell, K.M. Conversion of food waste to renewable energy: A techno-economic and environmental assessment. J. Clean. Prod. 2023, 385, 135741. [Google Scholar] [CrossRef]

- Algapani, D.E.; Qiao, W.; Ricci, M.; Bianchi, D.; M Wandera, S.; Adani, F.; Dong, R. Bio-hydrogen and bio-methane production from food waste in a two-stage anaerobic digestion process with digestate recirculation. Renew. Energy 2019, 130, 1108–1115. [Google Scholar] [CrossRef]

- Zhang, J.; Gu, D.; Chen, J.; He, Y.; Dai, Y.; Loh, K.-C.; Ton, W.T. Assessment and optimization of a decentralized food-waste-to-energy system with anaerobic digestion and CHP for energy utilization. Energy Convers. Manag. 2021, 228, 113654. [Google Scholar] [CrossRef]

- Xiao, B.; Qin, Y.; Zhang, W.; Wu, J.; Qiang, H.; Liu, J.; Li, Y.-Y. Temperature-phased anaerobic digestion of food waste: A comparison with single-stage digestions based on performance and energy balance. Bioresour. Technol. 2018, 249, 826–834. [Google Scholar] [CrossRef] [PubMed]

- Xiao, B.; Zhang, W.; Yi, H.; Qin, Y.; Wu, J.; Liu, J.; Li, Y.-Y. Biogas production by two-stage thermophilic anaerobic co-digestion of food waste and paper waste: Effect of paper waste ratio. Renew. Energy 2019, 132, 1301–1309. [Google Scholar] [CrossRef]

- Pohl, M.; Sánchez-Sánchez, M.; Mumme, J. Anaerobic digestion of wheat straw and rape oil cake in a two-stage solid-state system. Renew. Energy 2019, 141, 359–367. [Google Scholar] [CrossRef]

- Wu, C.; Huang, Q.; Yu, M.; Ren, Y.; Wang, Q.; Sakai, K. Effects of digestate recirculation on a two-stage anaerobic digestion system, particularly focusing on metabolite correlation analysis. Bioresour. Technol. 2018, 251, 40–48. [Google Scholar] [CrossRef] [PubMed]

- Gaby, J.C.; Zamanzadeh, M.; Horn, S.J. The effect of temperature and retention time on methane production and microbial community composition in staged anaerobic digesters fed with food waste. Biotechnol. Biofuels 2017, 10, 302. [Google Scholar] [CrossRef] [PubMed]

- Ingrao, C.; Faccilongo, N.; Di Gioia, L.; Messineo, A. Food waste recovery into energy in a circular economy perspective: A comprehensive review of aspects related to plant operation and environmental assessment. J. Clean. Prod. 2018, 184, 869–892. [Google Scholar] [CrossRef]

- Yang, S.; Xue, W.; Liu, P.; Lu, X.; Wu, X.; Sun, L.; Zan, F. Revealing the methanogenic pathways for anaerobic digestion of key components in food waste: Performance, microbial community, and implications. Bioresour. Technol. 2022, 347, 126340. [Google Scholar] [CrossRef]

- Li, R.; Gong, M.; Biney, B.W.; Chen, K.; Xia, W.; Liu, H.; Guo, A. Three-stage pretreatment of food waste to improve fuel characteristics and incineration performance with recovery of process by-products. Fuel 2022, 330, 125655. [Google Scholar] [CrossRef]

- Atelge, M.R.; Krisa, D.; Kumar, G.; Eskicioglu, C.; Nguyen, D.D.; Chang, S.W.; Atabani, A.; Al-Muhtaseb, A.; Ünalan, S. Biogas Production from Organic Waste: Recent Progress and Perspectives. Waste Biomass Valorization 2020, 11, 1019–1040. [Google Scholar] [CrossRef]

- Arelli, V.; Juntupally, S.; Begum, S.; Anupoju, G.R. Solid state anaerobic digestion of organic waste for the generation of biogas and bio manure. In Advanced Organic Waste Management; Elsevier: Amsterdam, The Netherlands, 2022; pp. 247–277. [Google Scholar] [CrossRef]

- Rafiee, A.; Khalilpour, K.R.; Prest, J.; Skryabin, I. Biogas as an energy vector. Biomass Bioenergy 2021, 144, 105935. [Google Scholar] [CrossRef]

- Xiong, X.; Yu, I.K.M.; Tsang, D.C.W.; Bolan, N.S.; Sik Ok, Y.; Igalavithana, A.D.; Kirkham, M.B.; Kim, K.-H.; Vikrant, K. Value-added chemicals from food supply chain wastes: State-of-the-art review and future prospects. Chem. Eng. J. 2019, 375, 121983. [Google Scholar] [CrossRef]

- Ren, Y.; Yu, M.; Wu, C.; Wang, Q.; Gao, M.; Huang, Q.; Liu, Y. A comprehensive review on food waste anaerobic digestion: Research updates and tendencies. Bioresour. Technol. 2018, 247, 1069–1076. [Google Scholar] [CrossRef] [PubMed]

- Abreu, A.A.; Tavares, F.; Alves, M.M.; Cavaleiro, A.J.; Pereira, M.A. Garden and food waste co-fermentation for biohydrogen and biomethane production in a two-step hyperthermophilic-mesophilic process. Bioresour. Technol. 2019, 278, 180–186. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.S.; Karim T ul Onik, M.H.; Kumar, D.; Rahman, M.A.; Yousuf, A.; Uddin, M.R. Impact of temperature, inoculum flow pattern, inoculum type, and their ratio on dry anaerobic digestion for biogas production. Sci. Rep. 2022, 12, 6162. [Google Scholar] [CrossRef] [PubMed]

- Menzel, T.; Neubauer, P.; Junne, S. Role of Microbial Hydrolysis in Anaerobic Digestion. Energies 2020, 13, 5555. [Google Scholar] [CrossRef]

- Meegoda, J.; Li, B.; Patel, K.; Wang, L. A Review of the Processes, Parameters, and Optimization of Anaerobic Digestion. Int. J. Environ. Res. Public Health 2018, 15, 2224. [Google Scholar] [CrossRef]

- Park, C.; Lee, C.; Kim, S.; Chen, Y.; Chase, H.A. Upgrading of anaerobic digestion by incorporating two different hydrolysis processes. J. Biosci. Bioeng. 2005, 100, 164–167. [Google Scholar] [CrossRef]

- Jin, W.; Zhang, M.; Shi, W. Evaluation of ultrasound pretreatment and drying methods on selected quality attributes of bitter melon (Momordica charantia L.). Dry. Technol. 2019, 37, 387–396. [Google Scholar] [CrossRef]

- Li, X.; Mettu, S.; Martin, G.J.O.; Ashokkumar, M.; Lin, C.S.K. Ultrasonic pretreatment of food waste to accelerate enzymatic hydrolysis for glucose production. Ultrason. Sonochem. 2019, 53, 77–82. [Google Scholar] [CrossRef] [PubMed]

- Morales-Polo, C.; del Mar Cledera-Castro, M.; Moratilla Soria, B.Y. Reviewing the Anaerobic Digestion of Food Waste: From Waste Generation and Anaerobic Process to Its Perspectives. Appl. Sci. 2018, 8, 1804. [Google Scholar] [CrossRef]

- Varjani, S.; Sivashanmugam, P.; Tyagi, V.K.; Gunasekaran, M. Breakthrough in hydrolysis of waste biomass by physico-chemical pretreatment processes for efficient anaerobic digestion. Chemosphere 2022, 294, 133617. [Google Scholar] [CrossRef]

- Paritosh, K.; Kushwaha, S.K.; Yadav, M.; Pareek, N.; Chawade, A.; Vivekanand, V. Food Waste to Energy: An Overview of Sustainable Approaches for Food Waste Management and Nutrient Recycling. Biomed. Res. Int. 2017, 2017, 2370927. [Google Scholar] [CrossRef] [PubMed]

- Caruso, M.; Braghieri, A.; Capece, A.; Napolitano, F.; Romano, P.; Galgano, F.; Altieri, G.; Genovese, F. Recent Updates on the Use of Agro-Food Waste for Biogas Production. Appl. Sci. 2019, 9, 1217. [Google Scholar] [CrossRef]

- Liebetrau, J.; Sträuber, H.; Kretzschmar, J.; Denysenko, V.; Nelles, M. Anaerobic Digestion. In Biorefineries. Advances in Biochemical Engineering/Biotechnology; Springer: Cham, Switzerland, 2017; pp. 281–299. [Google Scholar] [CrossRef]

- Chew, K.R.; Leong, H.Y.; Khoo, K.S.; Vo, D.-V.N.; Anjum, H.; Chang, C.-K.; Show, P.L. Effects of anaerobic digestion of food waste on biogas production and environmental impacts: A review. Environ. Chem. Lett. 2021, 19, 2921–2939. [Google Scholar] [CrossRef]

- Kumar, V.; Nabaterega, R.; Khoei, S.; Eskicioglu, C. Insight into interactions between syntrophic bacteria and archaea in anaerobic digestion amended with conductive materials. Renew. Sustain. Energy Rev. 2021, 144, 110965. [Google Scholar] [CrossRef]

- Liu, C.; Ren, L.; Yan, B.; Luo, L.; Zhang, J.; Awasthi, M.K. Electron transfer and mechanism of energy production among syntrophic bacteria during acidogenic fermentation: A review. Bioresour. Technol. 2021, 323, 124637. [Google Scholar] [CrossRef]

- Zou, H.; Gao, M.; Yu, M.; Zhang, W.; Zhang, S.; Wu, C.; Tashiro, Y.; Wang, Q. Methane production from food waste via mesophilic anaerobic digestion with ethanol pre-fermentation: Methanogenic pathway and microbial community analyses. Bioresour. Technol. 2020, 297, 122450. [Google Scholar] [CrossRef]

- Zabranska, J.; Pokorna, D. Bioconversion of carbon dioxide to methane using hydrogen and hydrogenotrophic methanogens. Biotechnol. Adv. 2018, 36, 707–720. [Google Scholar] [CrossRef]

- Xiao, L.; Zheng, S.; Lichtfouse, E.; Luo, M.; Tan, Y.; Liu, F. Carbon nanotubes accelerate acetoclastic methanogenesis: From pure cultures to anaerobic soils. Soil Biol. Biochem. 2020, 150, 107938. [Google Scholar] [CrossRef]

- Cavalcante, W.A.; Gehring, T.A.; Zaiat, M. Stimulation and inhibition of direct interspecies electron transfer mechanisms within methanogenic reactors by adding magnetite and granular actived carbon. Chem. Eng. J. 2021, 415, 128882. [Google Scholar] [CrossRef]

- Zhang, D.; Wei, Y.; Wu, S.; Zhou, L. Rapid initiation of methanogenesis in the anaerobic digestion of food waste by acclimatizing sludge with sulfidated nanoscale zerovalent iron. Bioresour. Technol. 2021, 341, 125805. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Du, S.; Xie, L. Effects of pH on ex-situ biomethanation with hydrogenotrophic methanogens under thermophilic and extreme-thermophilic conditions. J. Biosci. Bioeng. 2021, 131, 168–175. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, D.; Karthikeyan, O.P.; Selvam, A.; Palani, S.G.; Ghangrekar, M.M.; Wong, J.W.C. Two-phase anaerobic digestion of food waste: Effect of semi-continuous feeding on acidogenesis and methane production. Bioresour. Technol. 2022, 346, 126396. [Google Scholar] [CrossRef] [PubMed]

- Rajendran, K.; Mahapatra, D.; Venkatraman, A.V.; Muthuswamy, S.; Pugazhendhi, A. Advancing anaerobic digestion through two-stage processes: Current developments and future trends. Renew. Sustain. Energy Rev. 2020, 123, 109746. [Google Scholar] [CrossRef]

- Xiao, B.; Qin, Y.; Wu, J.; Chen, H.; Yu, P.; Liu, J.; Li, Y.-Y. Comparison of single-stage and two-stage thermophilic anaerobic digestion of food waste: Performance, energy balance and reaction process. Energy Convers. Manag. 2018, 156, 215–223. [Google Scholar] [CrossRef]

- García-Depraect, O.; Martínez-Mendoza, L.J.; Diaz, I.; Muñoz, R. Two-stage anaerobic digestion of food waste: Enhanced bioenergy production rate by steering lactate-type fermentation during hydrolysis-acidogenesis. Bioresour. Technol. 2022, 358, 127358. [Google Scholar] [CrossRef] [PubMed]

- Feng, K.; Li, H.; Deng, Z.; Wang, Q.; Zhang, Y.; Zheng, C. Effect of pre-fermentation types on the potential of methane production and energy recovery from food waste. Renew. Energy 2020, 146, 1588–1595. [Google Scholar] [CrossRef]

- Xu, M.; Zhou, H.; Yang, X.; Angelidaki, I.; Zhang, Y. Sulfide restrains the growth of Methylocapsa acidiphila converting renewable biogas to single cell protein. Water Res. 2020, 184, 116138. [Google Scholar] [CrossRef]

- Cheng, F.; Brewer, C.E. Conversion of protein-rich lignocellulosic wastes to bio-energy: Review and recommendations for hydrolysis + fermentation and anaerobic digestion. Renew. Sustain. Energy Rev. 2021, 146, 111167. [Google Scholar] [CrossRef]

- Li, X.; Huang, J.; Liu, Y.; Huang, T.; Maurer, C.; Kranert, M. Effects of Salt on Anaerobic Digestion of Food Waste with Different Component Characteristics and Fermentation Concentrations. Energies 2019, 12, 3571. [Google Scholar] [CrossRef]

- Kunatsa, T.; Xia, X. A review on anaerobic digestion with focus on the role of biomass co-digestion, modelling and optimisation on biogas production and enhancement. Bioresour. Technol. 2022, 344, 126311. [Google Scholar] [CrossRef] [PubMed]

- Xu, R.; Zhang, K.; Liu, P.; Khan, A.; Xiong, J.; Tian, F.; Li, X. A critical review on the interaction of substrate nutrient balance and microbial community structure and function in anaerobic co-digestion. Bioresour. Technol. 2018, 247, 1119–1127. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Yuan, X.; Wang, S.; Sun, F.; Hou, Z.; Hu, Q.; Zhail, L.; Cui, Z.; Zoy, Y. Methane production and characteristics of the microbial community in the co-digestion of spent mushroom substrate with dairy manure. Bioresour. Technol. 2018, 250, 611–620. [Google Scholar] [CrossRef]

- Tayyab, A.; Ahmad, Z.; Mahmood, T.; Khalid, A.; Qadeer, S.; Mahmood, S.; Andleep, S.; Anjum, S. Anaerobic co-digestion of catering food waste utilizing Parthenium hysterophorus as co-substrate for biogas production. Biomass Bioenergy 2019, 124, 74–82. [Google Scholar] [CrossRef]

- Baldi, F.; Pecorini, I.; Iannelli, R. Comparison of single-stage and two-stage anaerobic co-digestion of food waste and activated sludge for hydrogen and methane production. Renew. Energy 2019, 143, 1755–1765. [Google Scholar] [CrossRef]

- Johnravindar, D.; Kaur, G.; Liang, J.; Lou, L.; Zhao, J.; Manu, M.K.; Kumar, R.; Varjani, S.; Wong, J.W.C. Impact of total solids content on biochar amended co-digestion of food waste and sludge: Microbial community dynamics, methane production and digestate quality assessment. Bioresour. Technol. 2022, 361, 127682. [Google Scholar] [CrossRef] [PubMed]

- Ahn, Y.; Lee, W.; Kang, S.; Kim, S.-H. Enhancement of Sewage Sludge Digestion by Co-digestion with Food Waste and Swine Waste. Waste Biomass Valorization 2020, 11, 2421–2430. [Google Scholar] [CrossRef]

- Chow, W.L.; Chong, S.; Lim, J.W.; Chan, Y.J.; Chong, M.F.; Tiong, T.J.; Chin, J.K.; Pan, G.-T. Anaerobic Co-Digestion of Wastewater Sludge: A Review of Potential Co-Substrates and Operating Factors for Improved Methane Yield. Processes 2020, 8, 39. [Google Scholar] [CrossRef]

- Suárez, E.; Tobajas, M.; Mohedano, A.F.; de la Rubia, M.A. Biowaste management by hydrothermal carbonization and anaerobic co-digestion: Synergistic effects and comparative metagenomic analysis. Waste Manag. 2024, 180, 1–8. [Google Scholar] [CrossRef]

- Soares, J.F.; Confortin, T.C.; Todero, I.; Mayer, F.D.; Mazutti, M.A. Dark fermentative biohydrogen production from lignocellulosic biomass: Technological challenges and future prospects. Renew. Sustain. Energy Rev. 2020, 117, 109484. [Google Scholar] [CrossRef]

- Toledo-Alarcón, J.; Capson-Tojo, G.; Marone, A.; Paillet, F.; Júnior, A.D.N.F.; Chatellard, L.; Bernet, N.; Trably, E. Basics of Bio-hydrogen Production by Dark Fermentation. In Bioreactors for Microbial Biomass and Energy Conversiony; Springer: Berlin/Heidelberg, Germany, 2018; pp. 199–220. [Google Scholar] [CrossRef]

- Łukajtis, R.; Hołowacz, I.; Kucharska, K.; Glinka, M.; Rybarczyk, P.; Przyjazny, A.; Kaminski, M. Hydrogen production from biomass using dark fermentation. Renew. Sustain. Energy Rev. 2018, 91, 665–694. [Google Scholar] [CrossRef]

- Huang, W.; Wang, Z.; Zhou, Y.; Ng, W.J. The role of hydrogenotrophic methanogens in an acidogenic reactor. Chemosphere 2015, 140, 40–46. [Google Scholar] [CrossRef] [PubMed]

- Dahiya, S.; Chatterjee, S.; Sarkar, O.; Mohan, S.V. Renewable hydrogen production by dark-fermentation: Current status, challenges and perspectives. Bioresour. Technol. 2021, 321, 124354. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Basu, S.; Shetti, N.P.; Kamali, M.; Walvekar, P.; Aminabhavi, T.M. Waste-to-energy nexus: A sustainable development. Environ. Pollut. 2020, 267, 115501. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Basu, S.; Shetti, N.P.; Aminabhavi, T.M. Waste-to-energy nexus for circular economy and environmental protection: Recent trends in hydrogen energy. Sci. Total Environ. 2020, 713, 136633. [Google Scholar] [CrossRef] [PubMed]

- Turhal, S.; Turanbaev, M.; Argun, H. Hydrogen production from melon and watermelon mixture by dark fermentation. Int. J. Hydrogen Energy 2019, 44, 18811–18817. [Google Scholar] [CrossRef]

- Karim, A.; Islam, M.A.; Mohammad Faizal, C.K.; Yousuf, A.; Howarth, M.; Dubey, B.N.; Cheng, C.K.; Khan, M.R. Enhanced Biohydrogen Production from Citrus Wastewater Using Anaerobic Sludge Pretreated by an Electroporation Technique. Ind. Eng. Chem. Res. 2019, 58, 573–580. [Google Scholar] [CrossRef]

- Yang, G.; Yin, Y.; Wang, J. Microbial community diversity during fermentative hydrogen production inoculating various pretreated cultures. Int. J. Hydrogen Energy 2019, 44, 13147–13156. [Google Scholar] [CrossRef]

- Reungsang, A.; Zhong, N.; Yang, Y.; Sittijunda, S.; Xia, A.; Liao, Q. Hydrogen from Photo Fermentation. In Bioreactors for Microbial Biomass and Energy Conversion; Springer: Berlin/Heidelberg, Germany, 2018; pp. 221–317. [Google Scholar] [CrossRef]

- Melitos, G.; Voulkopoulos, X.; Zabaniotou, A. Waste to Sustainable Biohydrogen Production Via Photo-Fermentation and Biophotolysis—A Systematic Review. Renew. Energy Environ. Sustain. 2021, 6, 45. [Google Scholar] [CrossRef]

- Das, S.R.; Basak, N. Molecular biohydrogen production by dark and photo fermentation from wastes containing starch: Recent advancement and future perspective. Bioprocess. Biosyst. Eng. 2021, 44, 1–25. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Fernandes, A.; Lopes, A.; Grasa, L.; Salafranca, J. Photo-Fermentative Bacteria Used for Hydrogen Production. Appl. Sci. 2024, 14, 1191. [Google Scholar] [CrossRef]

- Wu, Y.-N.; Wen, H.-Q.; Zhu, J.-N.; Ding, J.; Ren, N.-Q.; Liu, B.-F. Best mode for photo-fermentation hydrogen production: The semi-continuous operation. Int. J. Hydrogen Energy 2016, 41, 16048–16054. [Google Scholar] [CrossRef]

- Mıynat, M.E.; Ören, İ.; Özkan, E.; Argun, H. Sequential dark and photo-fermentative hydrogen gas production from agar embedded molasses. Int. J. Hydrogen Energy 2020, 45, 34730–34738. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Li, Y.; Lu, C.; Zhu, S.; He, C.; Ai, F.; Zhang, Q. Investigation of the interaction between lighting and mixing applied during the photo-fermentation biohydrogen production process from agricultural waste. Bioresour. Technol. 2020, 312, 123570. [Google Scholar] [CrossRef]

- Turon, V.; Anxionnaz-Minvielle, Z.; Willison, J.C. Replacing incandescent lamps with an LED panel for hydrogen production by photofermentation: Visible and NIR wavelength requirements. Int. J. Hydrogen Energy 2018, 43, 7784–7794. [Google Scholar] [CrossRef]

- Guo, S.; Lu, C.; Wang, K.; Wang, J.; Zhang, Z.; Jing, Y.; Zhang, Q. Enhancement of pH values stability and photo-fermentation biohydrogen production by phosphate buffer. Bioengineered 2020, 11, 291–300. [Google Scholar] [CrossRef]

- Zagrodnik, R.; Łaniecki, M. The effect of pH on cooperation between dark- and photo-fermentative bacteria in a co-culture process for hydrogen production from starch. Int. J. Hydrogen Energy 2017, 42, 2878–2888. [Google Scholar] [CrossRef]

- Zhang, T.; Jiang, D.; Zhang, H.; Jing, Y.; Tahir, N.; Zhang, Y.; Zhang, Q. Comparative study on bio-hydrogen production from corn stover: Photo-fermentation, dark-fermentation and dark-photo co-fermentation. Int. J. Hydrogen Energy 2020, 45, 3807–3814. [Google Scholar] [CrossRef]

- Barghash, H.; Okedu, K.E.; Al Balushi, A. Bio-Hydrogen Production Using Landfill Leachate Considering Different Photo-Fermentation Processes. Front. Bioeng. Biotechnol. 2021, 9. [Google Scholar] [CrossRef]

- Adessi, A.; Venturi, M.; Candeliere, F.; Galli, V.; Granchi, L.; De Philippis, R. Bread wastes to energy: Sequential lactic and photo-fermentation for hydrogen production. Int. J. Hydrogen Energy 2018, 43, 9569–9576. [Google Scholar] [CrossRef]

- Cai, J.; Zhao, Y.; Fan, J.; Li, F.; Feng, C.; Guan, Y.; Wang, R.; Tang, N. Photosynthetic bacteria improved hydrogen yield of combined dark- and photo-fermentation. J. Biotechnol. 2019, 302, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Orege, J.I.; Oderinde, O.; Kifle, G.A.; Ibikunle, A.A.; Raheem, S.A.; Ejeromedoghene, O.; Okeke, E.S.; Olukwi, O.M.; Orege, O.B.; Fagbohun, E.O. Recent advances in heterogeneous catalysis for green biodiesel production by transesterification. Energy Convers. Manag. 2022, 258, 115406. [Google Scholar] [CrossRef]

- Bardhan, P.; Deka, A.; Bhattacharya, S.S.; Mandal, M.; Kataki, R. Economical aspect in biomass to biofuel production. In Value-Chain of Biofuels; Elsevier: Amsterdam, The Netherlands, 2022; pp. 395–427. [Google Scholar] [CrossRef]

- Rezania, S.; Oryani, B.; Park, J.; Hashemi, B.; Yadav, K.K.; Kwon, E.E.; Hur, J.; Cho, J. Review on transesterification of non-edible sources for biodiesel production with a focus on economic aspects, fuel properties and by-product applications. Energy Convers. Manag. 2019, 201, 112155. [Google Scholar] [CrossRef]

- Biernat, K.; Matuszewska, A.; Samson-Bręk, I.; Owczuk, M. Biological Methods in Biodiesel Production and Their Environmental Impact. Appl. Sci. 2021, 11, 10946. [Google Scholar] [CrossRef]

- Silva, J.D.; Martins, L.H.; Moreira, D.K.; Silva, L.D.; Barbosa, P.D.; Komesu, A.; Ferreira, N.R.; Oliveira, J.A. Microbial Lipid Based Biorefinery Concepts: A Review of Status and Prospects. Foods 2023, 12, 2074. [Google Scholar] [CrossRef] [PubMed]

- Ghazani, S.M.; Marangoni, A.G. Microbial lipids for foods. Trends Food Sci. Technol. 2022, 119, 593–607. [Google Scholar] [CrossRef]

- Vasaki, M.; Sithan, M.; Ravindran, G.; Paramasivan, B.; Ekambaram, G.; Karri, R.R. Biodiesel production from lignocellulosic biomass using Yarrowia lipolytica. Energy Convers. Manag. X 2022, 13, 100167. [Google Scholar] [CrossRef]

- Bušić, A.; Kundas, S.; Morzak, G.; Belskaya, H.; Marđetko, N.; Ivančić Šantek, M.; Komes, D.; Novak, S.; Santek, B. Recent Trends in Biodiesel and Biogas Production. Food Technol. Biotechnol. 2018, 56, 152. [Google Scholar] [CrossRef]

- Chozhavendhan, S.; Vijay Pradhap Singh, M.; Fransila, B.; Praveen Kumar, R.; Karthiga Devi, G. A review on influencing parameters of biodiesel production and purification processes. Curr. Res. Green Sustain. Chem. 2020, 1–2, 1–6. [Google Scholar] [CrossRef]

- Jain, S. Biodiesel production from food waste using insitu transesterification method. Sustain. Energy Technol. Assess. 2023, 58, 103380. [Google Scholar] [CrossRef]

- Oliva, G.; Buonerba, A.; Grassi, A.; Hasan, S.W.; Korshin, G.V.; Zorpas, A.A.; Belgiorno, V.; Naddeo, V.; Zarra, T. Microalgae to biodiesel: A novel green conversion method for high-quality lipids recovery and in-situ transesterification to fatty acid methyl esters. J. Environ. Manag. 2024, 357, 120830. [Google Scholar] [CrossRef] [PubMed]

- Baskar, G.; Kalavathy, G.; Aiswarya, R.; Abarnaebenezer Selvakumari, I. Advances in bio-oil extraction from nonedible oil seeds and algal biomass. In Advances in Eco-Fuels for a Sustainable Environment; Elsevier: Amsterdam, The Netherlands, 2019; pp. 187–210. [Google Scholar] [CrossRef]

- Kumar, S.; Sani, R.K. (Eds.) Biorefining of Biomass to Biofuels; Springer International Publishing: Cham, Switzerland, 2018; Volume 4. [Google Scholar] [CrossRef]

- Moazeni, F.; Chen, Y.-C.; Zhang, G. Enzymatic transesterification for biodiesel production from used cooking oil, a review. J. Clean. Prod. 2019, 216, 117–128. [Google Scholar] [CrossRef]

- Carmona-Cabello, M.; Sáez-Bastante, J.; Pinzi, S.; Dorado, M.P. Optimization of solid food waste oil biodiesel by ultrasound-assisted transesterification. Fuel 2019, 255, 115817. [Google Scholar] [CrossRef]

- Jung, S.; Jung, J.-M.; Tsang, Y.F.; Bhatnagar, A.; Chen, W.-H.; Lin, K.-Y.A.; Kwon, E.E. Biodiesel production from black soldier fly larvae derived from food waste by non-catalytic transesterification. Energy 2022, 238, 121700. [Google Scholar] [CrossRef]

- Patel, A.; Hrůzová, K.; Rova, U.; Christakopoulos, P.; Matsakas, L. Sustainable biorefinery concept for biofuel production through holistic volarization of food waste. Bioresour. Technol. 2019, 294, 122247. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, Y. Turning food waste to energy and resources towards a great environmental and economic sustainability: An innovative integrated biological approach. Biotechnol. Adv. 2019, 37, 107414. [Google Scholar] [CrossRef] [PubMed]

- Bueta, G.R.P. Chapter 5: Circular Economy Policy Initiatives and Experiences in the Philippines: Lessons for Asia and the Pacific and Beyond. 2022. Available online: https://www.adb.org/sites/default/files/publication/774936/adbi-transitioning-linear-circular-economy-developing-asia-web.pdf (accessed on 5 May 2024).

- Kaur, A.; Bharti, R.; Sharma, R. Municipal solid waste as a source of energy. Mater. Today Proc. 2023, 81, 904–915. [Google Scholar] [CrossRef]

- Ren, X.; Song, K.; Xiao, Y.; Chen, W.; Liu, D. Constituent transformation mechanism of concentrated leachate after incineration at different temperatures. Environ. Sci. Pollut. Res. 2019, 26, 34613–34621. [Google Scholar] [CrossRef]

- Pham, T.P.T.; Kaushik, R.; Parshetti, G.K.; Mahmood, R.; Balasubramanian, R. Food waste-to-energy conversion technologies: Current status and future directions. Waste Manag. 2015, 38, 399–408. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Samadder, S.R. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef] [PubMed]

- Assi, A.; Bilo, F.; Federici, S.; Zacco, A.; Depero, L.E.; Bontempi, E. Bottom ash derived from municipal solid waste and sewage sludge co-incineration: First results about characterization and reuse. Waste Manag. 2020, 116, 147–156. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Hu, Y.; Cheng, H. Municipal solid waste (MSW) incineration fly ash as an important source of heavy metal pollution in China. Environ. Pollut. 2019, 252, 461–475. [Google Scholar] [CrossRef] [PubMed]

- Ashraf, M.S.; Ghouleh, Z.; Shao, Y. Production of eco-cement exclusively from municipal solid waste incineration residues. Resour. Conserv. Recycl. 2019, 149, 332–342. [Google Scholar] [CrossRef]

- Abdullah, M.H.; Rashid, A.S.A.; Anuar, U.H.M.; Marto, A.; Abuelgasim, R. Bottom ash utilization: A review on engineering applications and environmental aspects. IOP Conf. Ser. Mater. Sci. Eng. 2019, 527, 012006. [Google Scholar] [CrossRef]

- Wang, C.; Liu, K.; Huang, D.; Chen, Q.; Tu, M.; Wu, K.; Shui, Z. Utilization of fly ash as building material admixture: Basic properties and heavy metal leaching. Case Stud. Constr. Mater. 2022, 17, e01422. [Google Scholar] [CrossRef]

- Tait, P.W.; Brew, J.; Che, A.; Costanzo, A.; Danyluk, A.; Davis, M.; Khalaf, A.; McMahon, K.; Watson, L.; Rowcliff, K.; et al. The health impacts of waste incineration: A systematic review. Aust. N. Z. J. Public Health 2020, 44, 40–48. [Google Scholar] [CrossRef]

- Prata, J.C.; Silva, A.L.P.; da Costa, J.P.; Mouneyrac, C.; Walker, T.R.; Duarte, A.C.; Rocha-Santos, T. Solutions and Integrated Strategies for the Control and Mitigation of Plastic and Microplastic Pollution. Int. J. Environ. Res. Public Health 2019, 16, 2411. [Google Scholar] [CrossRef]

- Slorach, P.C.; Jeswani, H.K.; Cuéllar-Franca, R.; Azapagic, A. Environmental and economic implications of recovering resources from food waste in a circular economy. Sci. Total Environ. 2019, 693, 133516. [Google Scholar] [CrossRef]

- Jabeen, F.; Adrees, M.; Ibrahim, M.; Mahmood, A.; Khalid, S.; Sipra, H.F.K.; Bokhari, A.; Mubashir, M.; Kho, K.S.; Show, P.L. Trash to Energy: A Measure for the Energy Potential of Combustible content of Domestic solid waste generated from an industrialized city of Pakistan. J. Taiwan Inst. Chem. Eng. 2022, 137, 104223. [Google Scholar] [CrossRef]

- Statista Research Department. Global Municipal Waste Energy Production|Statista n.d. Available online: https://www.statista.com/statistics/481722/municipal-waste-to-energy-production-globally/ (accessed on 5 May 2024).

- Kumar, A.; Singh, E.; Mishra, R.; Kumar, S. Solid Waste to Energy: Existing Scenario in Developing and Developed Countries. In Handbook of Solid Waste Management; Springer Nature: Singapore, 2022; pp. 2023–2045. [Google Scholar] [CrossRef]

- Stöcker, M. Perspectives for Thermochemical Conversions of Lignocellulosic Biomass. Small 2023, 2302495. [Google Scholar] [CrossRef] [PubMed]

- Kostas, E.T.; Durán-Jiménez, G.; Shepherd, B.J.; Meredith, W.; Stevens, L.A.; Williams, O.S.A.; Robinson, J.P. Microwave pyrolysis of olive pomace for bio-oil and bio-char production. Chem. Eng. J. 2020, 387, 123404. [Google Scholar] [CrossRef]

- Qing, M.; Long, Y.; Liu, L.; Yi, Y.; Li, W.; He, R.; Yin, Y.; Tian, H.; He, J.; Cheng, S.; et al. Pyrolysis of the food waste collected from catering and households under different temperatures: Assessing the evolution of char structure and bio-oil composition. J. Anal. Appl. Pyrolysis 2022, 164, 105543. [Google Scholar] [CrossRef]

- Świechowski, K.; Matyjewicz, B.; Telega, P.; Białowiec, A. The Influence of Low-Temperature Food Waste Biochars on Anaerobic Digestion of Food Waste. Materials 2022, 15, 945. [Google Scholar] [CrossRef] [PubMed]

- Kazawadi, D.; Ntalikwa, J.; Kombe, G. A Review of Intermediate Pyrolysis as a Technology of Biomass Conversion for Coproduction of Biooil and Adsorption Biochar. J. Renew. Energy 2021, 2021, 5533780. [Google Scholar] [CrossRef]

- Wang, X.; Guo, Z.; Hu, Z.; Zhang, J. Recent advances in biochar application for water and wastewater treatment: A review. PeerJ 2020, 8, e9164. [Google Scholar] [CrossRef] [PubMed]

- Tan, K.; Qin, Y.; Wang, J. Evaluation of the properties and carbon sequestration potential of biochar-modified pervious concrete. Constr. Build. Mater. 2022, 314, 125648. [Google Scholar] [CrossRef]

- Vijay, V.; Shreedhar, S.; Adlak, K.; Payyanad, S.; Sreedharan, V.; Gopi, G.; Voort, T.S.; Malarvizhi, P.P.; Yi, S.; Gebert, J. Review of Large-Scale Biochar Field-Trials for Soil Amendment and the Observed Influences on Crop Yield Variations. Front. Energy Res. 2021, 9, 710766. [Google Scholar] [CrossRef]

- Ahmad Farid, M.A.; Hassan, M.A.; Roslan, A.M.; Samsudin, M.H.; Mohamad, Z.J.J.; Othman, M.R.; Shirai, Y. Carbon monoxide reduction in the flue gas during biochar production from oil palm empty fruit bunch. J. Clean. Prod. 2020, 258, 120580. [Google Scholar] [CrossRef]

- Legan, M.; Gotvajn, A.Ž.; Zupan, K. Potential of biochar use in building materials. J. Environ. Manag. 2022, 309, 114704. [Google Scholar] [CrossRef] [PubMed]

- Adrados, A.; Merchán, M.; Obregón, A.; Artola, A.; Iparraguirre, J.A.; García de Cortázar, M.; Eguizabal, D.; Demey, H. Development of a Sustainable Metallurgical Process to Valorize Copper Smelting Wastes with Olive Stones-Based Biochar. Metals 2022, 12, 1756. [Google Scholar] [CrossRef]

- Murtaza, G.; Ahmed, Z.; Eldin, S.M.; Ali, B.; Bawazeer, S.; Usman, M.; Iqbal, S.; Neupane, D.; Ullah, A.; Khan, A. Biochar-Soil-Plant interactions: A cross talk for sustainable agriculture under changing climate. Front. Environ. Sci. 2023, 11, 1059449. [Google Scholar] [CrossRef]

- Stylianou, M.; Laifi, T.; Bennici, S.; Dutournie, P.; Limousy, L.; Agapiou, A.; Zorpas, A.A. Tomato waste biochar in the framework of circular economy. Sci. Total Environ. 2023, 871, 161959. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Lee, Y.; Andrew Lin, K.-Y.; Hong, E.; Kwon, E.E.; Lee, J. The valorization of food waste via pyrolysis. J. Clean. Prod. 2020, 259, 120816. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Z.; Li, J.; Yan, B.; Chen, G. Pyrolysis of food waste and food waste solid digestate: A comparative investigation. Bioresour. Technol. 2022, 354, 127191. [Google Scholar] [CrossRef] [PubMed]

- Grycová, B.; Koutník, I.; Pryszcz, A. Pyrolysis process for the treatment of food waste. Bioresour. Technol. 2016, 218, 1203–1207. [Google Scholar] [CrossRef] [PubMed]

- Su, G.; Ong, H.C.; Fattah, I.M.R.; Ok, Y.S.; Jang, J.-H.; Wang, C.-T. State-of-the-art of the pyrolysis and co-pyrolysis of food waste: Progress and challenges. Sci. Total Environ. 2022, 809, 151170. [Google Scholar] [CrossRef] [PubMed]

- Elkhalifa, S.; AlNouss, A.; Al-Ansari, T.; Mackey, H.R.; Parthasarathy, P.; Mckay, G. Simulation of Food Waste Pyrolysis for the Production of Biochar: A Qatar Case Study. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 901–906. [Google Scholar] [CrossRef]

- Patra, B.R.; Nanda, S.; Dalai, A.K.; Meda, V. Slow pyrolysis of agro-food wastes and physicochemical characterization of biofuel products. Chemosphere 2021, 285, 131431. [Google Scholar] [CrossRef]

- Wijitkosum, S. Biochar derived from agricultural wastes and wood residues for sustainable agricultural and environmental applications. Int. Soil Water Conserv. Res. 2022, 10, 335–341. [Google Scholar] [CrossRef]

- Park, C.; Lee, N.; Kim, J.; Lee, J. Co-pyrolysis of food waste and wood bark to produce hydrogen with minimizing pollutant emissions. Environ. Pollut. 2021, 270, 116045. [Google Scholar] [CrossRef]

- Neha, S.; Remya, N. Optimization of bio-oil production from microwave co-pyrolysis of food waste and low-density polyethylene with response surface methodology. J. Environ. Manag. 2021, 297, 113345. [Google Scholar] [CrossRef] [PubMed]

- Sridhar, A.; Kapoor, A.; Senthil Kumar, P.; Ponnuchamy, M.; Balasubramanian, S.; Prabhakar, S. Conversion of food waste to energy: A focus on sustainability and life cycle assessment. Fuel 2021, 302, 121069. [Google Scholar] [CrossRef]

- Sim, C.-K.; Majid, S.R.; Mahmood, N.Z. Electrochemical Performance of Activated Carbon Derived from Treated Food-Waste. Int. J. Electrochem. Sci. 2015, 10, 10157–10172. [Google Scholar] [CrossRef]

- Xu, S.; Zhu, S.; Li, C.; Bu, J.; Wei Tiong, Y.; Sharma, P.; Kong, W.; Shao, C.; Xie, H.; Tong, Y.W. Succession of biochar in integrated pyrolysis, anaerobic digestion, and solid–state fermentation towards closed loop valorization of food waste. Fuel 2024, 369, 131719. [Google Scholar] [CrossRef]

- Okopi, S.I.; Wang, J.; Liang, W.; Kong, W.; Hu, Y.; Cui, J.; Guo, X.; Zhao, W.; Che, L.; Gu, Z. Experimental study and techno-economic analysis of co-processing system for treatment of food waste with various impurities. Bioresour. Technol. 2024, 394, 130020. [Google Scholar] [CrossRef]

- Inalegwu Okopi, S.; Zeng, J.; Fan, X.; Lu, J.; Cui, J.; Hu, Y.; Wang, J.; Chen, J.; Djandja, O.S.; Ma, Y. Environmental sustainability assessment of a new food waste anaerobic digestion and pyrolysis hybridization system. Waste Manag. 2024, 179, 130–143. [Google Scholar] [CrossRef]

- Zhao, W.; Yang, H.; He, S.; Zhao, Q.; Wei, L. A review of biochar in anaerobic digestion to improve biogas production: Performances, mechanisms and economic assessments. Bioresour. Technol. 2021, 341, 125797. [Google Scholar] [CrossRef]

- Piersa, P.; Unyay, H.; Szufa, S.; Lewandowska, W.; Modrzewski, R.; Ślężak, R.; Ledakowicz, S. An Extensive Review and Comparison of Modern Biomass Torrefaction Reactors vs. Biomass Pyrolysis—Part 1. Energies 2022, 15, 2227. [Google Scholar] [CrossRef]

- Hidalgo, D.; Castro, J.; Díez, D.; Martín-Marroquín, J.M.; Gómez, M.; Pérez, E. Torrefaction at low temperature as a promising pretreatment of lignocellulosic biomass in anaerobic digestion. Energy 2023, 263, 125822. [Google Scholar] [CrossRef]

- Pour, F.H.; Makkawi, Y.T. A review of post-consumption food waste management and its potentials for biofuel production. Energy Rep. 2021, 7, 7759–7784. [Google Scholar] [CrossRef]

- Huang, J.; Qiao, Y.; Wang, Z.; Liu, H.; Wang, B.; Yu, Y. Valorization of Food Waste via Torrefaction: Effect of Food Waste Type on the Characteristics of Torrefaction Products. Energy Fuels 2020, 34, 6041–6051. [Google Scholar] [CrossRef]

- Jagodzińska, K.; Czerep, M.; Kudlek, E.; Wnukowski, M.; Pronobis, M.; Yang, W. Torrefaction of Agricultural Residues: Effect of Temperature and Residence Time on the Process Products Properties. J. Energy Resour. Technol. 2020, 142, 070912. [Google Scholar] [CrossRef]

- Abdul Rahman, R.N.U.; Ismail, M.; Rasid, R.A.; Ahamad Nordin, N.I.A. Torrefaction of Food Waste as a Potential Biomass Energy Source. Indones. J. Chem. 2019, 19, 993. [Google Scholar] [CrossRef]

- Frolov, S.M. Organic Waste Gasification: A Selective Review. Fuels 2021, 2, 556–650. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, M.; Raheem, A.; Wang, F.; Wei, J.; Xu, D.; Song, X.; Bao, W.; Huang, A.; Zhang, S. Syngas Production from Biomass Gasification: Influences of Feedstock Properties, Reactor Type, and Reaction Parameters. ACS Omega 2023, 8, 31620–31631. [Google Scholar] [CrossRef] [PubMed]

- Qi, T.; Lei, T.; Zhang, Q.; Jin, T.; Zhu, S.; Zhu, Y.; Hu, X.; Cheng, C. Production of H 2 -Rich Syngas from Oxygen-Steam Gasification of Biomass Using Modified Red Mud Extract as Catalyst. J. Biobased Mater. Bioenergy 2021, 15, 278–286. [Google Scholar] [CrossRef]

- Abdoulmoumine, N.; Adhikari, S.; Kulkarni, A.; Chattanathan, S. A review on biomass gasification syngas cleanup. Appl. Energy 2015, 155, 294–307. [Google Scholar] [CrossRef]

- de Oliveira, D.C.; Lora, E.E.S.; Venturini, O.J.; Maya, D.M.Y.; Garcia-Pérez, M. Gas cleaning systems for integrating biomass gasification with Fischer-Tropsch synthesis—A review of impurity removal processes and their sequences. Renew. Sustain. Energy Rev. 2023, 172, 113047. [Google Scholar] [CrossRef]

- Koshariya, A.K.; Krishnan, M.S.; Jaisankar, S.; Loganathan, G.B.; Sathish, T.; Ağbulut, Ü.; Saravanan, R.; Tuan, L.T.; Pham, N.D.K. Waste to energy: An experimental study on hydrogen production from food waste gasification. Int. J. Hydrogen Energy 2024, 54, 1–12. [Google Scholar] [CrossRef]

- Sajid, M.; Raheem, A.; Ullah, N.; Asim, M.; Ur Rehman, M.S.; Ali, N. Gasification of municipal solid waste: Progress, challenges, and prospects. Renew. Sustain. Energy Rev. 2022, 168, 112815. [Google Scholar] [CrossRef]

- Lopes, E.J.; Okamura, L.A.; Maruyama, S.A.; Yamamoto, C.I. Evaluation of energy gain from the segregation of organic materials from municipal solid waste in gasification processes. Renew. Energy 2018, 116, 623–629. [Google Scholar] [CrossRef]

- AlNouss, A.; McKay, G.; Al-Ansari, T. A comparison of steam and oxygen fed biomass gasification through a techno-economic-environmental study. Energy Convers. Manag. 2020, 208, 112612. [Google Scholar] [CrossRef]

- Valizadeh, S.; Lam, S.S.; Ko, C.H.; Lee, S.H.; Farooq, A.; Yu, Y.J.; Jeon, K.-J.; Jung, S.-C.; Rhee, G.H.; Park, Y.-K. Biohydrogen production from catalytic conversion of food waste via steam and air gasification using eggshell- and homo-type Ni/Al2O3 catalysts. Bioresour. Technol. 2021, 320, 124313. [Google Scholar] [CrossRef] [PubMed]

- Singh, D.; Yadav, S.; Bharadwaj, N.; Verma, R. Low temperature steam gasification to produce hydrogen rich gas from kitchen food waste: Influence of steam flow rate and temperature. Int. J. Hydrogen Energy 2020, 45, 20843–20850. [Google Scholar] [CrossRef]

- Shayan, E.; Zare, V.; Mirzaee, I. Hydrogen production from biomass gasification; a theoretical comparison of using different gasification agents. Energy Convers. Manag. 2018, 159, 30–41. [Google Scholar] [CrossRef]

- Huynh CVan Kong, S.-C. Performance characteristics of a pilot-scale biomass gasifier using oxygen-enriched air and steam. Fuel 2013, 103, 987–996. [Google Scholar] [CrossRef]

- Xu, Z.; Qi, H.; Yao, D.; Zhang, J.; Zhu, Z.; Wang, Y.; Cui, P. Modeling and comprehensive analysis of food waste gasification process for hydrogen production. Energy Convers. Manag. 2022, 258, 115509. [Google Scholar] [CrossRef]

- Nagy, G.; Dobó, Z. Experimental investigation of fixed-bed pyrolysis and steam gasification of food waste blended with woody biomass. Biomass Bioenergy 2020, 139, 105580. [Google Scholar] [CrossRef]

- dos Santos, R.G.; Alencar, A.C. Biomass-derived syngas production via gasification process and its catalytic conversion into fuels by Fischer Tropsch synthesis: A review. Int. J. Hydrogen Energy 2020, 45, 18114–18132. [Google Scholar] [CrossRef]

- Piazzi, S.; Patuzzi, F.; Baratieri, M. Energy and exergy analysis of different biomass gasification coupled to Fischer-Tropsch synthesis configurations. Energy 2022, 249, 123642. [Google Scholar] [CrossRef]

- Munir, M.T.; Mardon, I.; Al-Zuhair, S.; Shawabkeh, A.; Saqib, N.U. Plasma gasification of municipal solid waste for waste-to-value processing. Renew. Sustain. Energy Rev. 2019, 116, 109461. [Google Scholar] [CrossRef]

- Okati, A.; Reza Khani, M.; Shokri, B.; Monteiro, E.; Rouboa, A. Parametric studies over a plasma co-gasification process of biomass and coal through a restricted model in Aspen plus. Fuel 2023, 331, 125952. [Google Scholar] [CrossRef]

- Li, H.; Sun, C.; Zhang, Y.; Li, T.; Wei, X. Performance investigation of the gasification for the kitchen waste powder in a direct current plasma reactor. J. Energy Inst. 2022, 100, 170–176. [Google Scholar] [CrossRef]

- Xu, Z.; Zhou, Y.; Yin, K.; Zhang, J.; Zhu, Z.; Wang, Y.; Cui, P. Exergy, techno-economic and environment analysis of food waste plasma gasification and syngas chemical looping processes. J. Clean. Prod. 2023, 386, 135835. [Google Scholar] [CrossRef]

- Hu, Y.; Gong, M.; Xing, X.; Wang, H.; Zeng, Y.; Xu, C.C. Supercritical water gasification of biomass model compounds: A review. Renew. Sustain. Energy Rev. 2020, 118, 109529. [Google Scholar] [CrossRef]

- Reddy, S.N.; Nanda, S.; Dalai, A.K.; Kozinski, J.A. Supercritical water gasification of biomass for hydrogen production. Int. J. Hydrogen Energy 2014, 39, 6912–6926. [Google Scholar] [CrossRef]

- Su, W.; Cai, C.; Liu, P.; Lin, W.; Liang, B.; Zhang, H.; Ma, Z.; Ma, H.; Xing, Y.; Liu, W. Supercritical water gasification of food waste: Effect of parameters on hydrogen production. Int. J. Hydrogen Energy 2020, 45, 14744–14755. [Google Scholar] [CrossRef]

- Shen, Y.; Yu, S.; Ge, S.; Chen, X.; Ge, X.; Chen, M. Hydrothermal carbonization of medical wastes and lignocellulosic biomass for solid fuel production from lab-scale to pilot-scale. Energy 2017, 118, 312–323. [Google Scholar] [CrossRef]

- Mannarino, G.; Sarrion, A.; Diaz, E.; Gori, R.; De la Rubia, M.A.; Mohedano, A.F. Improved energy recovery from food waste through hydrothermal carbonization and anaerobic digestion. Waste Manag. 2022, 142, 9–18. [Google Scholar] [CrossRef]

- Matsakas, L.; Gao, Q.; Jansson, S.; Rova, U.; Christakopoulos, P. Green conversion of municipal solid wastes into fuels and chemicals. Electron. J. Biotechnol. 2017, 26, 69–83. [Google Scholar] [CrossRef]

- Sangaré, D.; Moscosa-Santillan, M.; Aragón Piña, A.; Bostyn, S.; Belandria, V.; Gökalp, I. Hydrothermal carbonization of biomass: Experimental study, energy balance, process simulation, design, and techno-economic analysis. Biomass Convers. Biorefin 2024, 14, 2561–2576. [Google Scholar] [CrossRef]

- Benavente, V.; Calabuig, E.; Fullana, A. Upgrading of moist agro-industrial wastes by hydrothermal carbonization. J. Anal. Appl. Pyrolysis 2015, 113, 89–98. [Google Scholar] [CrossRef]

- Wüst, D.; Rodriguez Correa, C.; Suwelack, K.U.; Köhler, H.; Kruse, A. Hydrothermal carbonization of dry toilet residues as an added-value strategy—Investigation of process parameters. J. Environ. Manag. 2019, 234, 537–545. [Google Scholar] [CrossRef] [PubMed]

- Pauline, A.L.; Joseph, K. Hydrothermal carbonization of organic wastes to carbonaceous solid fuel—A review of mechanisms and process parameters. Fuel 2020, 279, 118472. [Google Scholar] [CrossRef]

- Idowu, I.; Li, L.; Flora, J.R.V.; Pellechia, P.J.; Darko, S.A.; Ro, K.S.; Berge, N.D. Hydrothermal carbonization of food waste for nutrient recovery and reuse. Waste Manag. 2017, 69, 480–491. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Wang, S.; Yang, J.; Xu, D.; Li, Y.; Li, J.; Zhang, Y. Hydrothermal liquefaction and gasification of biomass and model compounds: A review. Green. Chem. 2020, 22, 8210–8232. [Google Scholar] [CrossRef]

- Picone, A.; Volpe, M.; Messineo, A. Process Water Recirculation during Hydrothermal Carbonization of Waste Biomass: Current Knowledge and Challenges. Energies 2021, 14, 2962. [Google Scholar] [CrossRef]

- Tradler, S.B.; Mayr, S.; Himmelsbach, M.; Priewasser, R.; Baumgartner, W.; Stadler, A.T. Hydrothermal carbonization as an all-inclusive process for food-waste conversion. Bioresour. Technol. Rep. 2018, 2, 77–83. [Google Scholar] [CrossRef]

- Motavaf, B.; Dean, R.A.; Nicolas, J.; Savage, P.E. Hydrothermal carbonization of simulated food waste for recovery of fatty acids and nutrients. Bioresour. Technol. 2021, 341, 125872. [Google Scholar] [CrossRef]

- Saqib, N.U.; Baroutian, S.; Sarmah, A.K. Physicochemical, structural and combustion characterization of food waste hydrochar obtained by hydrothermal carbonization. Bioresour. Technol. 2018, 266, 357–363. [Google Scholar] [CrossRef]

- McGaughy, K.; Toufiq Reza, M. Hydrothermal carbonization of food waste: Simplified process simulation model based on experimental results. Biomass Convers. Biorefin 2018, 8, 283–292. [Google Scholar] [CrossRef]

- Wu, S.; Wang, Q.; Fang, M.; Wu, D.; Cui, D.; Pan, S.; Bai, J.; Xu, F.; Wang, Z. Hydrothermal carbonization of food waste for sustainable biofuel production: Advancements, challenges, and future prospects. Sci. Total Environ. 2023, 897, 165327. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Zhai, Y.; Li, H.; Zhu, Y.; Li, S.; Peng, C.; Wang, B.; Wang, Z.; Xi, Y.; Wang, S.; et al. Co-hydrothermal carbonization of food waste-woody biomass blend towards biofuel pellets production. Bioresour. Technol. 2018, 267, 371–377. [Google Scholar] [CrossRef] [PubMed]

- Sharma, H.B.; Dubey, B.K. Co-hydrothermal carbonization of food waste with yard waste for solid biofuel production: Hydrochar characterization and its pelletization. Waste Manag. 2020, 118, 521–533. [Google Scholar] [CrossRef] [PubMed]

- Zheng, C.; Ma, X.; Yao, Z.; Chen, X. The properties and combustion behaviors of hydrochars derived from co-hydrothermal carbonization of sewage sludge and food waste. Bioresour. Technol. 2019, 285, 121347. [Google Scholar] [CrossRef]

- Silva Thomsen, L.B.; Anastasakis, K.; Biller, P. Wet oxidation of aqueous phase from hydrothermal liquefaction of sewage sludge. Water Res. 2022, 209, 117863. [Google Scholar] [CrossRef]

- Lee, J.; Lee, K.; Sohn, D.; Kim, Y.M.; Park, K.Y. Hydrothermal carbonization of lipid extracted algae for hydrochar production and feasibility of using hydrochar as a solid fuel. Energy 2018, 153, 913–920. [Google Scholar] [CrossRef]

- Skaggs, R.L.; Coleman, A.M.; Seiple, T.E.; Milbrandt, A.R. Waste-to-Energy biofuel production potential for selected feedstocks in the conterminous United States. Renew. Sustain. Energy Rev. 2018, 82, 2640–2651. [Google Scholar] [CrossRef]

- Aslanbay Guler, B.; Deniz, I.; Ozmihci, S.; Imamoglu, E. Biological conversion technologies: Enzyme hydrolysis, ethanol fermentation. In Bioenergy Engineering; Elsevier: Amsterdam, The Netherlands, 2023; pp. 171–200. [Google Scholar] [CrossRef]

- Wang, Q.; Li, H.; Feng, K.; Liu, J. Oriented Fermentation of Food Waste towards High-Value Products: A Review. Energies 2020, 13, 5638. [Google Scholar] [CrossRef]

- Wu, B.; Wang, Y.-W.; Dai, Y.-H.; Song, C.; Zhu, Q.-L.; Qin, H.; Tan, F.-R.; Chen, H.-C.; Dai, L.-C.; Hu, G.-Q.; et al. Current status and future prospective of bio-ethanol industry in China. Renew. Sustain. Energy Rev. 2021, 145, 111079. [Google Scholar] [CrossRef]

- Ayas, N. 2.13 Solvent Materials. Comprehensive Energy Systems; Elsevier: Amsterdam, The Netherlands, 2018; pp. 368–395. [Google Scholar] [CrossRef]

- Statista Research Department, J. Ethanol Consumption Worldwide 2030|Statista 2024. Available online: https://www.statista.com/statistics/1440979/worldwide-consumption-of-ethanol/ (accessed on 5 May 2024).

- Ma, Y.; Cai, W.; Liu, Y. An integrated engineering system for maximizing bioenergy production from food waste. Appl. Energy 2017, 206, 83–89. [Google Scholar] [CrossRef]

- Zhang, Q.; Lu, Y.; Zhou, X.; Wang, X.; Zhu, J. Effect of different vegetable wastes on the performance of volatile fatty acids production by anaerobic fermentation. Sci. Total Environ. 2020, 748, 142390. [Google Scholar] [CrossRef] [PubMed]

- Chatterjee, S.; Venkata Mohan, S. Refining of vegetable waste to renewable sugars for ethanol production: Depolymerization and fermentation optimization. Bioresour. Technol. 2021, 340, 125650. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.; Lin, Y.; Wang, P.; Jin, R.; Gao, M.; Wang, Q.; Chang, T.-C.; Ma, C. Volatile fatty acids production from saccharification residue from food waste ethanol fermentation: Effect of pH and microbial community. Bioresour. Technol. 2019, 292, 121957. [Google Scholar] [CrossRef] [PubMed]

- Anwar Saeed, M.; Ma, H.; Yue, S.; Wang, Q.; Tu, M. Concise review on ethanol production from food waste: Development and sustainability. Environ. Sci. Pollut. Res. 2018, 25, 28851–28863. [Google Scholar] [CrossRef] [PubMed]

- Ochieng, R.; Gebremedhin, A.; Sarker, S. Integration of Waste to Bioenergy Conversion Systems: A Critical Review. Energies 2022, 15, 2697. [Google Scholar] [CrossRef]

- Kataya, G.; Cornu, D.; Bechelany, M.; Hijazi, A.; Issa, M. Biomass Waste Conversion Technologies and Its Application for Sustainable Environmental Development—A Review. Agronomy 2023, 13, 2833. [Google Scholar] [CrossRef]

| Product | Method | Production | Efficiency Rate | Reference |

|---|---|---|---|---|

| Biohydrogen and Biomethane | Continuous two-stage anaerobic digestate recirculation system (recirculation rate at 0.3) | 135 mL H2 per g Vs 510 mL CH4 per g Vs | 70% | [36] |

| Biogas | Combination of anaerobic digester and biogas engine | 550 mL CH4 per g Vs | 47% (biogas engine) | [37] |

| Biogas and Biomethane | Temperature-phased (two-stage) anaerobic digestion | 0.759 L biogas per g Vs and 0.454 L methane per g Vs | 78.55% | [38] |

| Biogas | Two-stage anaerobic co-digestion (+paper waste) | 2.75 L/L/d | 67% | [39] |

| Biomethane | Two-stage anaerobic digestion (wheat straw + rape oil cake) | 28 mL CH4 per g Vs | 58.3% | [40] |

| Biohydrogen and Biomethane | Two-stage anaerobic digestion (vinasse) | 14.8 mL H2 per g Vs 274 mL CH4 per g Vs | 64.5% Vs | [36] |

| Biomethane | Two-stage anaerobic digestate recirculation system | 438 mL per g Vs | 82.3% | [41] |

| Biomethane | Two-stage anaerobic digestate system | 478 mL per g Vs | 70.1% Vs | [42] |

| Biohydrogen and Biomethane | Two-stage anaerobic co-digestion with the addition of brown water | 99.8 mL H2 per g Vs 728 mL CH4 per g Vs | 52.5% Vs | [36] |

| Biogas | Anaerobic digestion coupled with combined heat and power (CHP) unit | 120 m3 per ton FW | [43] | |

| Biomethane | Mesophilic anaerobic digester | 254 to 630 mL CH4 per g Vs | [44] | |

| Biogas | Three-stage anaerobic digestion system | 0.52 m3 per kg Vs | 77.5% | [45] |

| Pretreatment Method | Category | Benefits | Limitations | Reference |

|---|---|---|---|---|

| Size Reduction | Mechanical | Increases surface area for digestion | Energy-intensive operation | |

| Ultrasonic | Mechanical | Reduces hydrolysis time by 50% | Non-uniform heating and limited penetration depth | [56,57] |

| Acidification and Alkalization | Chemical | Able to break down lignocellulosic substrates | Has the potential to corrode the equipment. Not suitable for substrates with higher carbohydrate content, like FW | [58] |

| Microbial Activity | Biological | Environmentally friendly approach | Requires longer processing times. Relies on the environmental conditions and microorganism’s activity | [52] |

| Thermal Treatment | Physical | Breaks down complex organic compounds and cell membranes | Requires large energy expenditure | [57] |

| Microwave Treatment | Physical | Reduces volatile solids | Bulky feedstock makes uniform heating challenging | [59] |

| Thermochemical Hydrolysis | Physicochemical | Rapid treatment and high efficiency | Requires specialized equipment and use of chemical reagents | [57] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Economou, F.; Voukkali, I.; Papamichael, I.; Phinikettou, V.; Loizia, P.; Naddeo, V.; Sospiro, P.; Liscio, M.C.; Zoumides, C.; Țîrcă, D.M.; et al. Turning Food Loss and Food Waste into Watts: A Review of Food Waste as an Energy Source. Energies 2024, 17, 3191. https://doi.org/10.3390/en17133191

Economou F, Voukkali I, Papamichael I, Phinikettou V, Loizia P, Naddeo V, Sospiro P, Liscio MC, Zoumides C, Țîrcă DM, et al. Turning Food Loss and Food Waste into Watts: A Review of Food Waste as an Energy Source. Energies. 2024; 17(13):3191. https://doi.org/10.3390/en17133191

Chicago/Turabian StyleEconomou, Florentios, Irene Voukkali, Iliana Papamichael, Valentina Phinikettou, Pantelitsa Loizia, Vincenzo Naddeo, Paolo Sospiro, Marco Ciro Liscio, Christos Zoumides, Diana Mihaela Țîrcă, and et al. 2024. "Turning Food Loss and Food Waste into Watts: A Review of Food Waste as an Energy Source" Energies 17, no. 13: 3191. https://doi.org/10.3390/en17133191

APA StyleEconomou, F., Voukkali, I., Papamichael, I., Phinikettou, V., Loizia, P., Naddeo, V., Sospiro, P., Liscio, M. C., Zoumides, C., Țîrcă, D. M., & Zorpas, A. A. (2024). Turning Food Loss and Food Waste into Watts: A Review of Food Waste as an Energy Source. Energies, 17(13), 3191. https://doi.org/10.3390/en17133191