Research on Gas Injection Limits and Development Methods of CH4/CO2 Synergistic Displacement in Offshore Fractured Condensate Gas Reservoirs

Abstract

1. Introduction

2. Experiment Study on Gas Injection of Fractured Cores

2.1. Fluid and Core Preparation

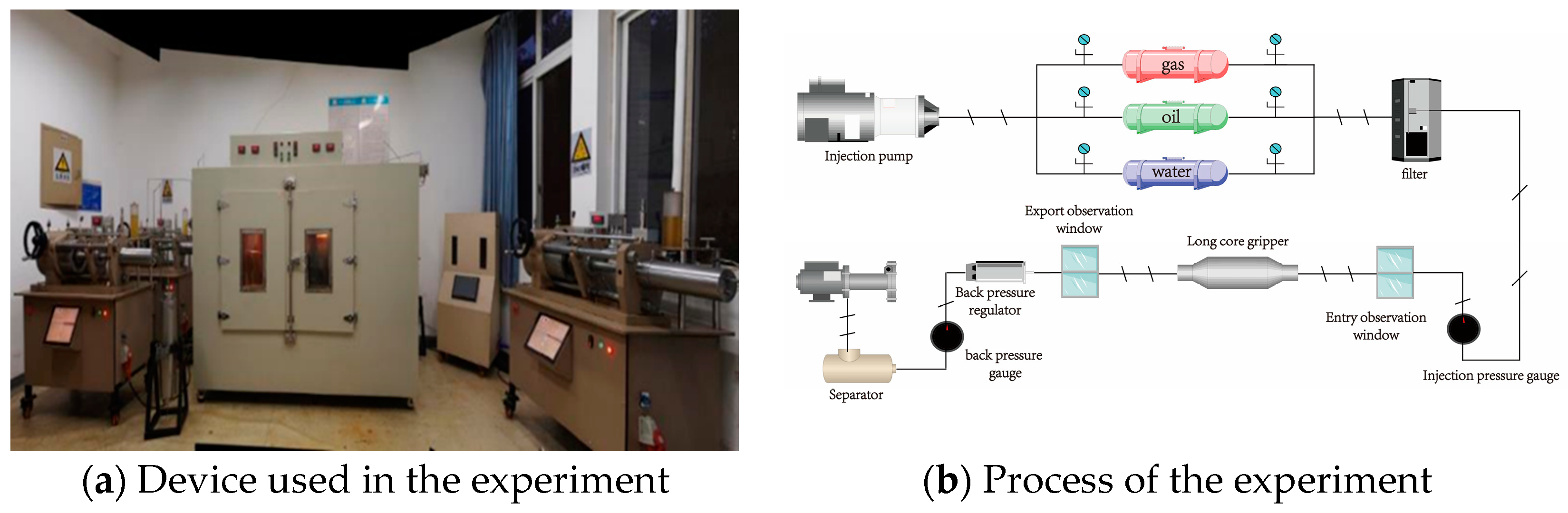

2.2. Experimental Setup and Process

3. Experiment Results

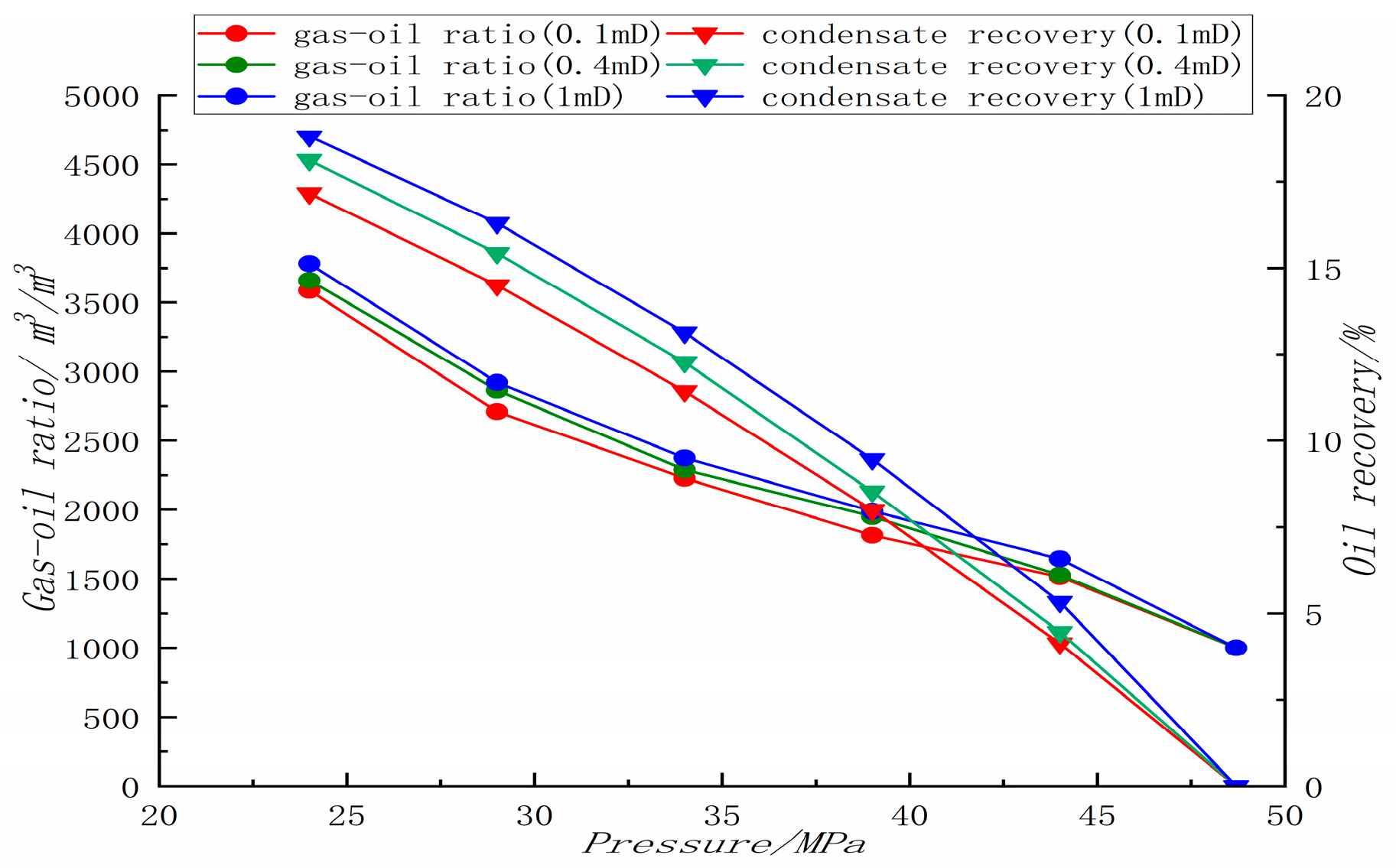

3.1. Effect of Matrix Permeability

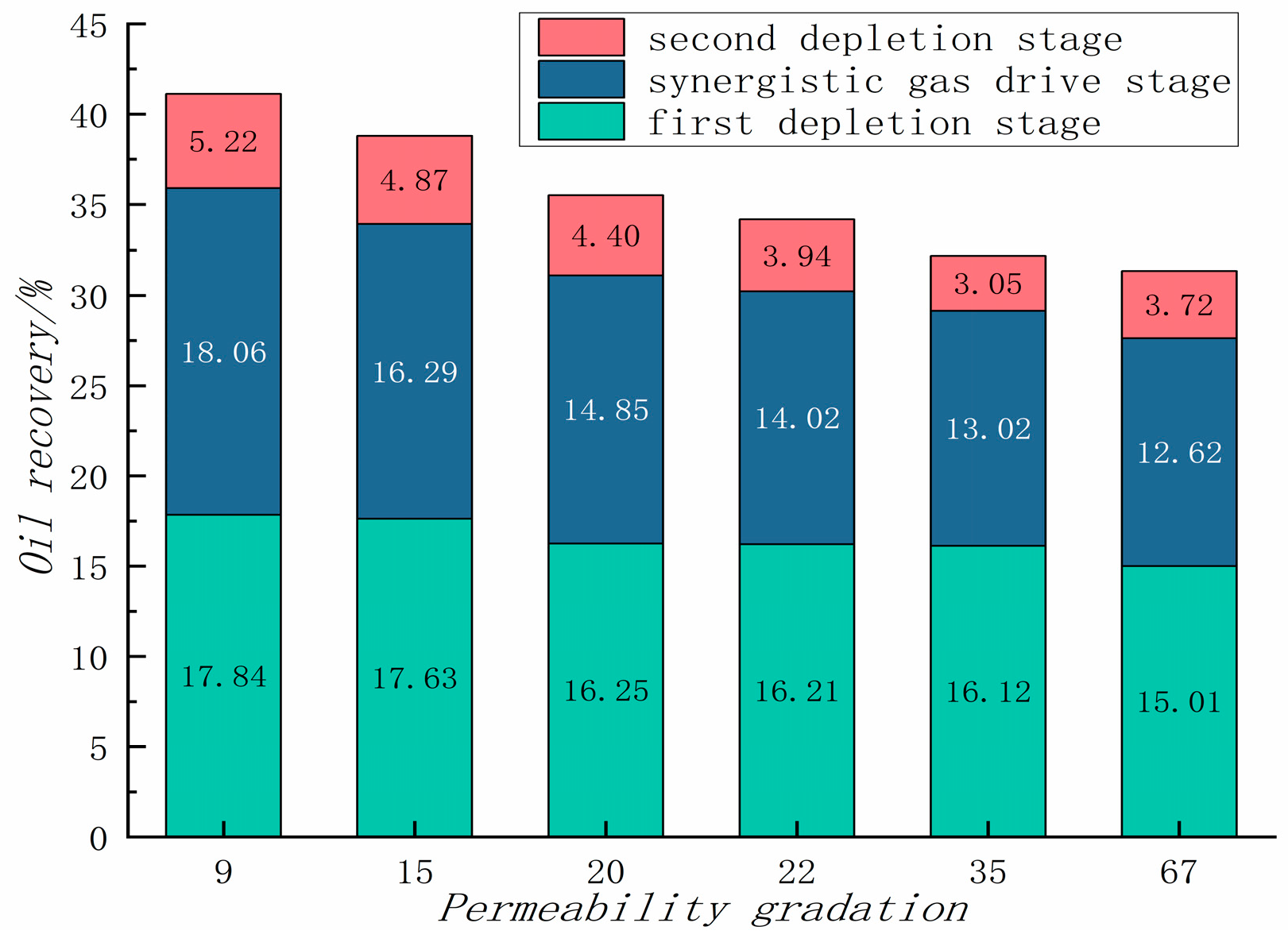

3.2. Effect of Permeability Gradation

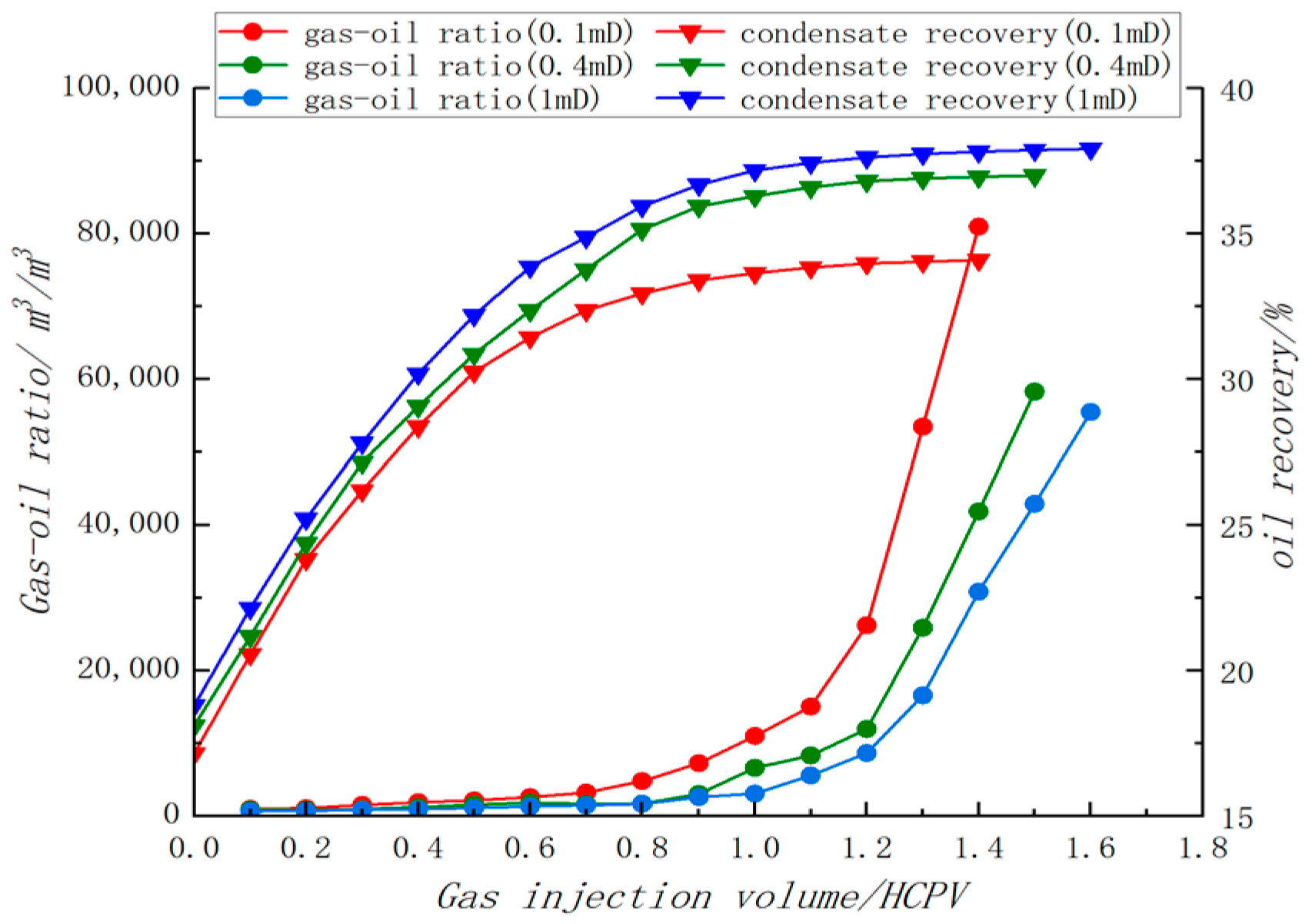

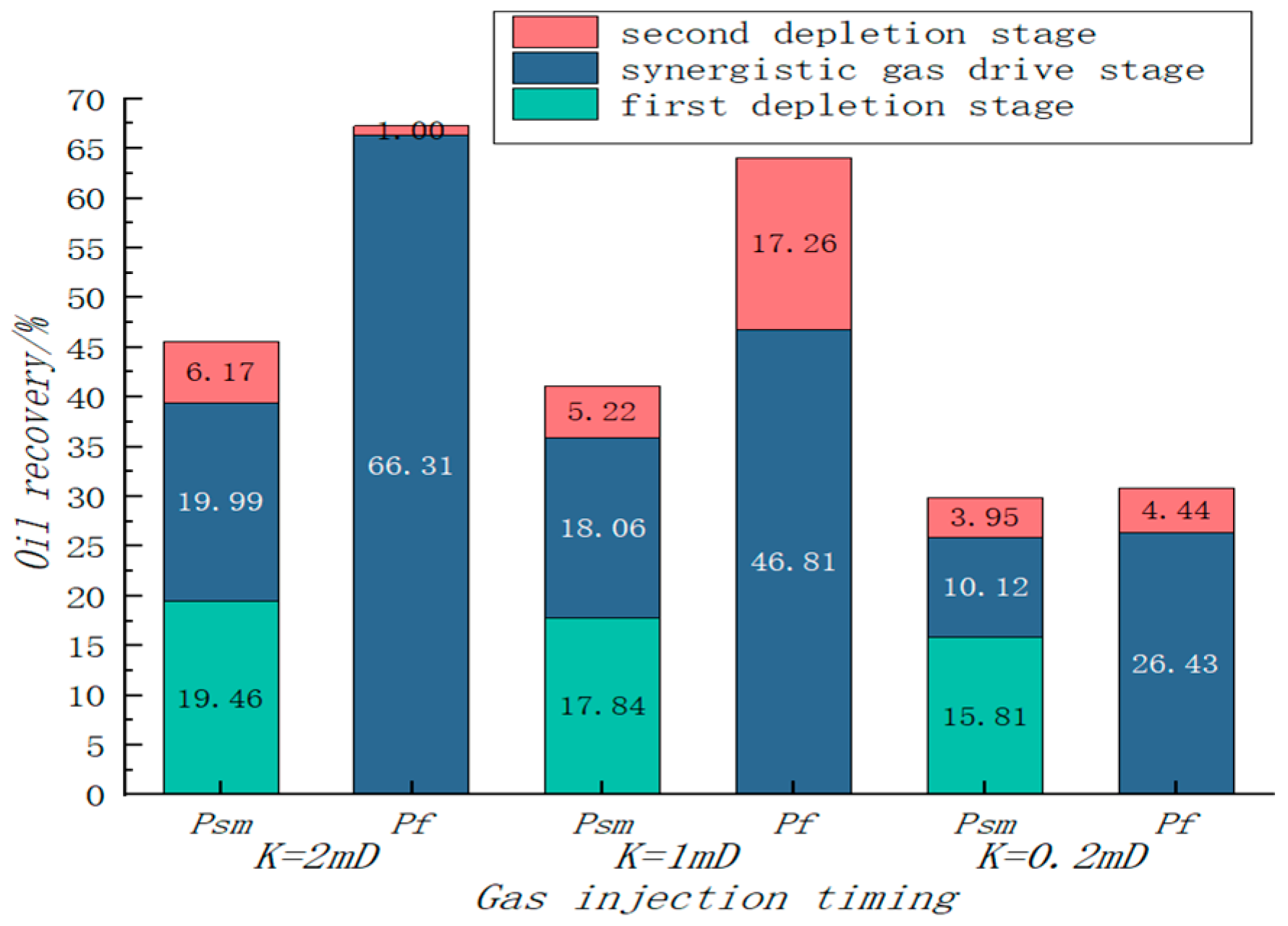

3.3. Effect of Gas Injection Timing

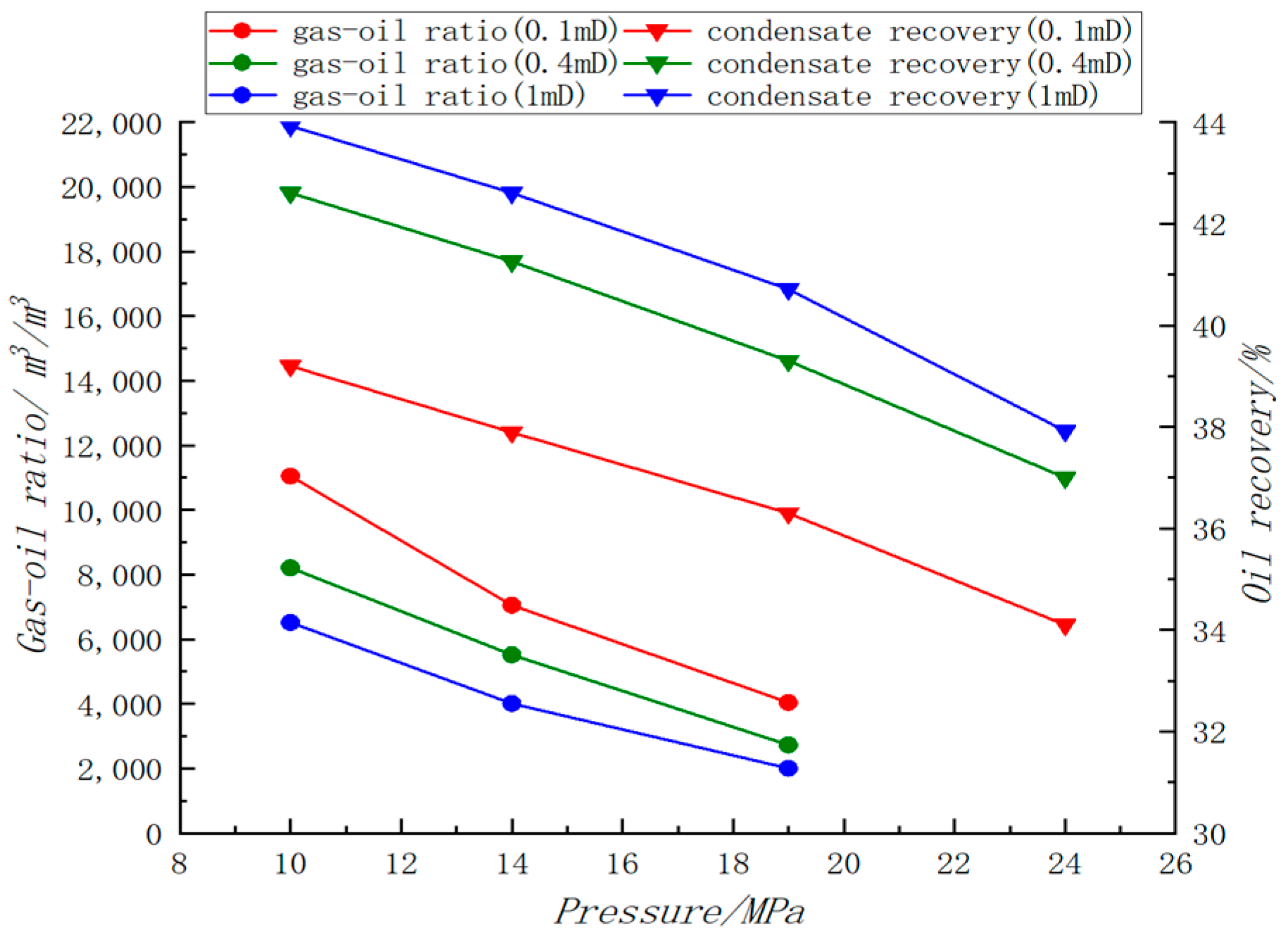

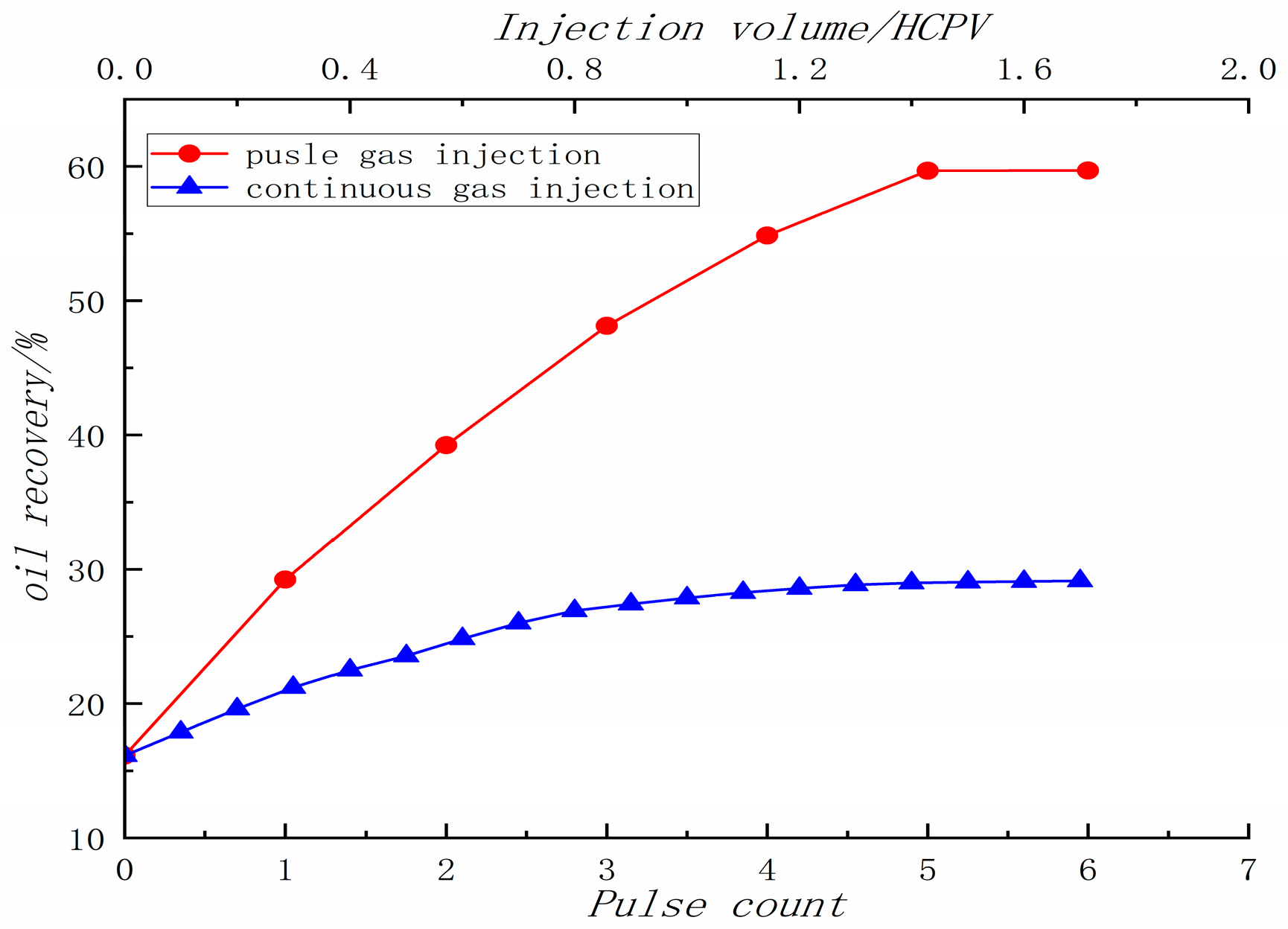

3.4. Effect of injection method

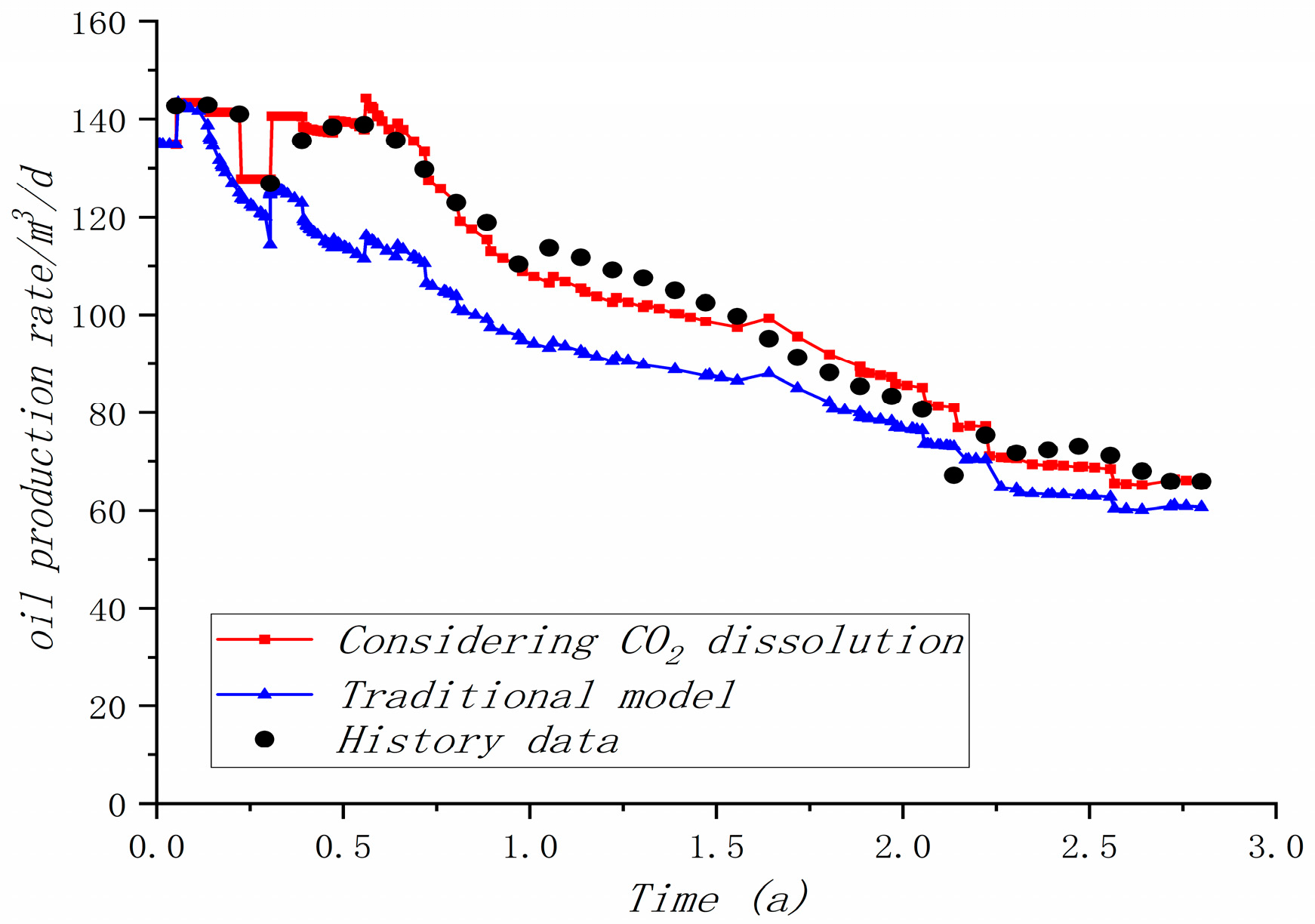

4. Field Application

4.1. Geological Characteristics of B6 Gas Reservoir

4.2. Basic Parameters and Characterization of Oil–Gas Relative Permeability

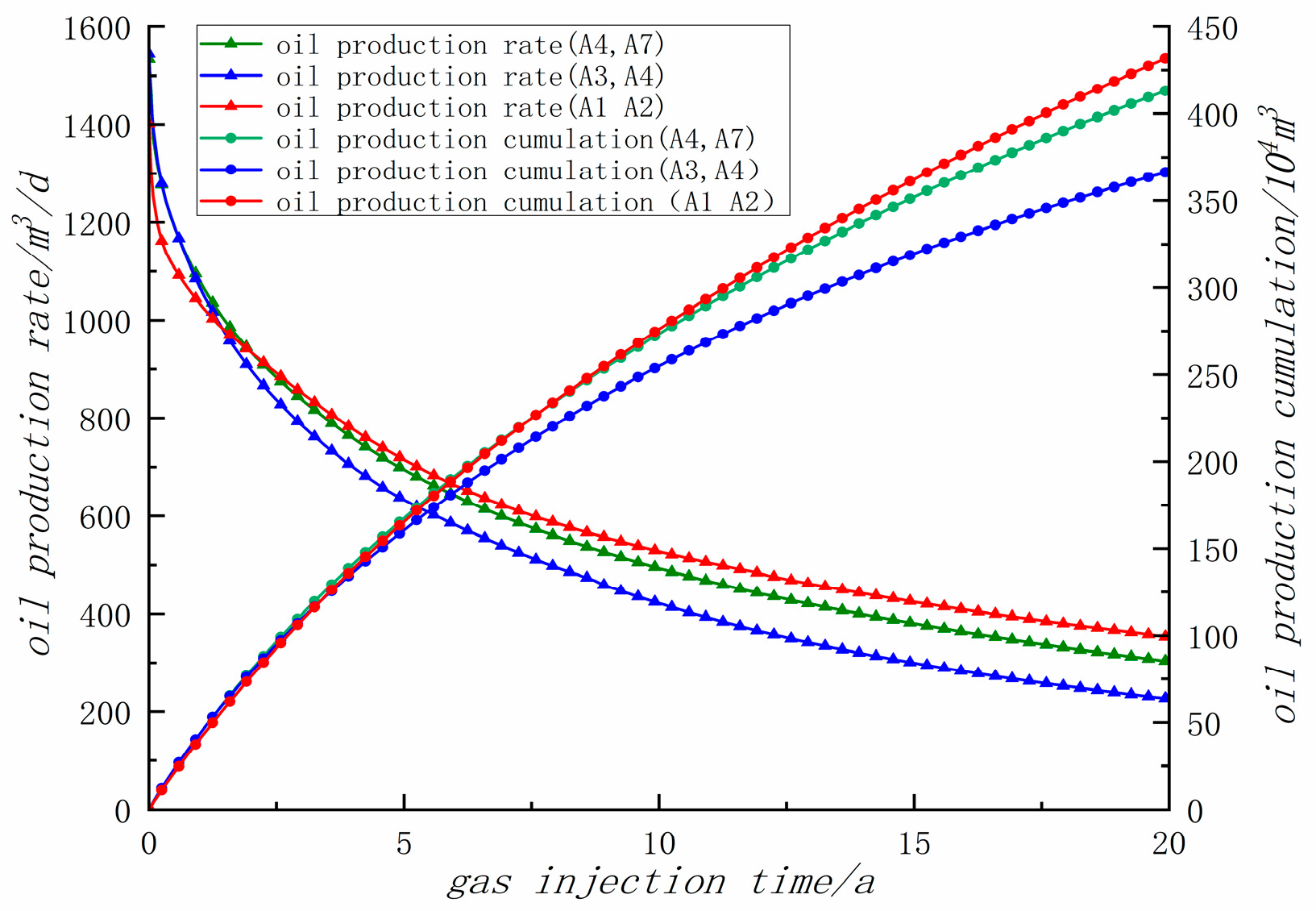

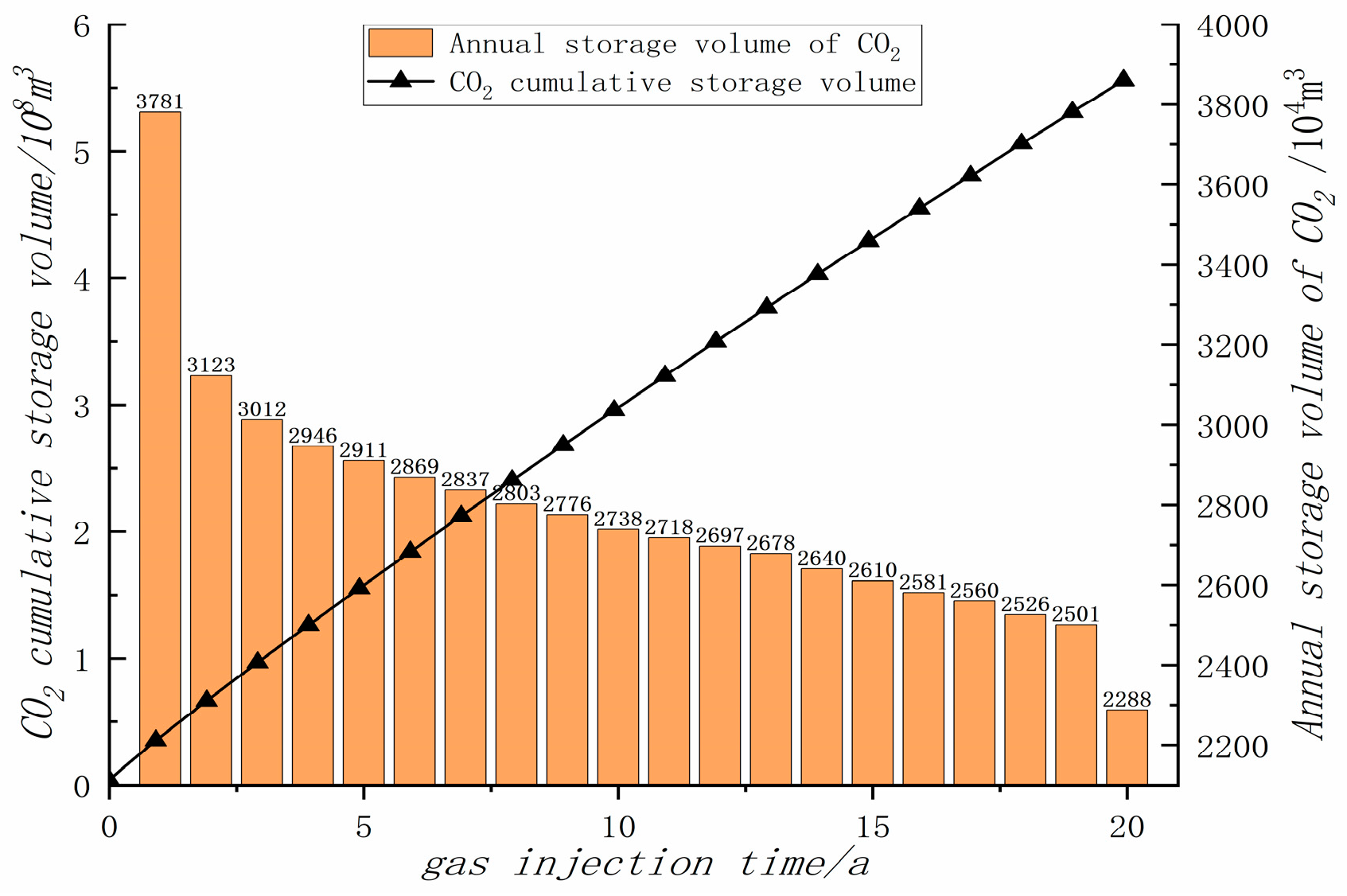

4.3. Prediction of Gas Injection Development Effect

5. Conclusions

- (1)

- For the first time, an experimental study of gas injection with varying permeability gradations was conducted. The results indicate that fractures readily form dominant channels for gas channeling. The findings demonstrate that larger permeability gradations lead to lower recovery rates of condensate oil. Optimal development outcomes are achieved when permeability gradation is maintained below 15.

- (2)

- Higher matrix permeability correlates with increased recovery of condensate oil. Earlier gas injection significantly enhances these recovery rates. Additionally, smaller permeability gradations result in greater increases in condensate oil recovery. Pulse gas injection markedly improves oil recovery in buried hill reservoirs.

- (3)

- In the B6 condensate gas field, maintaining formation pressure via gas injection is recommended, particularly in the weathering zone with weak fracture connectivity. Wells A1 and A2 were recommended early gas injection to mitigate retrograde condensation through numerical simulation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, P.; Wang, J.; Liu, W.; Du, J.F.; Wang, Z.H. Dynamic Experiment Study on Depletion Development of Condensate Gas Reservoir with Fracture and Cave. Oil Drill. Prod. Technol. 2013, 35, 67–70. [Google Scholar]

- Guo, P.; Liu, H.; Wang, C.X.; Du, J.F.; Fan, B.C.; Jing, M.Q.; Wang, Z.H.; Deng, Z.L.; Zhan, S.Y. The Determination of Phase Behavior Properties of High-Temperature High-Pressure and Rich Condensate Gases. Fuel 2020, 280, 118568. [Google Scholar] [CrossRef]

- Najafi-Marghmaleki, A.; Tatar, A.; Barati-Harooni, A.; Arabloo, M.; Rafiee-Taghanaki, S.; Mohammadi, A.H. Reliable Modeling of Constant Volume Depletion (CVD) Behaviors in Gas Condensate Reservoirs. Fuel 2018, 231, 146–156. [Google Scholar] [CrossRef]

- Arabloo, M.; Heidari Sureshjani, M.; Gerami, S. A New Approach for Analysis of Production Data from Constant Production Rate Wells in Gas Condensate Reservoirs. J. Nat. Gas Sci. Eng. 2014, 21, 725–731. [Google Scholar] [CrossRef]

- Bennion, D.B.; Thomas, F.B.; Schulmeister, B. Retrograde Condensate Dropout Phenomena in Rich Gas Reservoirs—Impact on Recoverable Reserves, Permeability, Diagnosis, and Stimulation Techniques. J. Can. Pet. Technol. 2001, 40, 5–8. [Google Scholar] [CrossRef]

- Wu, Y.M.; Yao, K.; Liu, Y.; Li, X.Y.; Wu, M.M.; Cheng, R.H.; Wang, B. Experimental Study on Enhanced Condensate Recovery by Gas Injection in Yaha Condensate Gas Reservoir. Geofluids 2021, 2021, 7698970. [Google Scholar] [CrossRef]

- Sanger, P.; Hagoort, J. Recovery of Gas-Condensate by Nitrogen Injection Compared with Methane Injection. SPE J. 1988, 3, 26–33. [Google Scholar] [CrossRef]

- Guo, P.; Jing, S.S.; Peng, C.Z. Technology and Countermeasures for Gas Recovery Enhancement. Nat. Gas Ind. 2014, 34, 48–55. [Google Scholar]

- Tang, Y.; Long, K.J.; Wang, J.M.; Xu, H.C.; Wang, Y.; He, Y.W.; Shi, L.; Zhu, H.Y. Change of Phase State During Multi-Cycle Injection and Production Process of Condensate Gas Reservoir Based Underground Gas Storage. Pet. Explor. Dev. 2021, 48, 395–406. [Google Scholar] [CrossRef]

- Taheri, A.; Hoier, L.; Torsaeter, O. Miscible and Immiscible Gas Injection for Enhancing of Condensate Recovery in Fractured Gas Condensate Reservoirs. Presented at the EAGE Annual Conference & Exhibition Incorporating SPE Europec, London, UK, 10–13 June 2013. SPE-164934-MS. [Google Scholar]

- Jiang, T.W. Study on the Supercritical Phase Behavior of Yaha Condensate Gas Reservoir in the Tarim Basin. Petroleum 2021, 9, 390–394. [Google Scholar] [CrossRef]

- Liu, F.Y.; Ellett, K.; Xiao, Y.T.; Rupp, J.A. Assessing the Feasibility of CO2 Storage in the New Albany Shale (Devonian-Mississippian) with Potential Enhanced Gas Recovery Using Reservoir Simulation. International J. Greenh. Gas Control 2013, 17, 111–126. [Google Scholar] [CrossRef]

- Hannis, S.; Lu, J.; Chadwick, A.; Hovorka, S.; Kirk, K.; Romanak, K.; Pearce, J. CO2 Storage in Depleted or Depleting Oil and Gas Fields: What Can We Learn from Existing Projects? Energy Procedia 2017, 114, 5680–5690. [Google Scholar] [CrossRef]

- Underschultz, J.; Boreham, C.; Dance, T.; Stalker, L.; Freifeld, B.; Kirste, D.; Ennis-King, J. CO2 Storage in a Depleted Gas Field: An Overview of the CO2CRC Otway Project and Initial Results. Int. J. Greenh. Gas Control 2011, 5, 922–932. [Google Scholar] [CrossRef]

- Zangeneh, H.; Jamshidi, S.; Soltanieh, M. Coupled Optimization of Enhanced Gas Recovery and Carbon Dioxide Sequestration in Natural Gas Reservoirs: Case Study in a Real Gas Field in the South of Iran. Int. J. Greenh. Gas Control 2013, 17, 515–522. [Google Scholar] [CrossRef]

- Du, F.; Nojabaei, B. A Review of Gas Injection in Shale Reservoirs: Enhanced Oil/Gas Recovery Approaches and Greenhouse Gas Control. Energies 2019, 12, 2355. [Google Scholar] [CrossRef]

- Kumar, N.; Sampaio, M.A.; Ojha, K.; Hoteit, H.; Mandal, A. Fundamental Aspects, Mechanisms, and Emerging Possibilities of CO2 Miscible Flooding in Enhanced Oil Recovery: A Review. Fuel 2022, 330, 125633. [Google Scholar] [CrossRef]

- Shtepani, E. CO2 Sequestration in Depleted Gas/Condensate Reservoirs. Paper presented at the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 24–27 September 2006. [Google Scholar]

- Shen, C.H.; Hsieh, B.-Z.; Tseng, C.C. Case Study of CO2-IGR and Storage in a Nearly Depleted Gas-Condensate Reservoir in Taiwan. Energy Procedia 2014, 63, 7740–7749. [Google Scholar] [CrossRef]

- Scanziani, A.; Singh, K.; Menke, H.; Bijeljic, B.; Blunt, M.J. Dynamics of Enhanced Gas Trapping Applied to CO2 Storage in the Presence of Oil Using Synchrotron X-ray Micro Tomography. Appl. Energy 2020, 259, 114136. [Google Scholar] [CrossRef]

- Narinesingh, J.; Alexander, D. CO2 Enhanced Gas Recovery and Geologic Sequestration in Condensate Reservoir: A Simulation Study of the Effects of Injection Pressure on Condensate Recovery from Reservoir and CO2 Storage Efficiency. Energy Procedia 2014, 63, 3107–3115. [Google Scholar] [CrossRef]

- Yuan, C.; Zhang, Z.; Liu, K. Assessment of the Recovery and Front Contrast of CO2 EOR and Sequestration in a New Gas Condensate Reservoir by Compositional Simulation and Seismic Modeling. Fuel 2015, 142, 81–86. [Google Scholar] [CrossRef]

- Sayed, M.A.; Al-Muntasheri, G.A. Mitigation of the Effects of Condensate Banking: A Critical Review. SPE Prod. Oper. 2016, 31, 85–102. [Google Scholar] [CrossRef]

- Chen, C.; Balhoff, M.; Mohanty, K.K. Effect of Reservoir Heterogeneity on Primary Recovery and CO2 Huff ‘n’ Puff Recovery in Shale-Oil Reservoirs. SPE Reserv. Eval. Eng. 2014, 17, 404–413. [Google Scholar] [CrossRef]

- Al-Abri, A.; Sidiq, H.; Amin, R. Mobility Ratio, Relative Permeability and Sweep Efficiency of Supercritical CO2 and Methane Injection to Enhance Natural Gas and Condensate Recovery: Coreflooding Experimentation. J. Nat. Gas Sci. Eng. 2012, 9, 166–171. [Google Scholar] [CrossRef]

- Qu, M.; Hou, J.; Wen, Y.; Liang, T. Nitrogen gas channeling characteristics in fracture-vuggy carbonate reservoirs. J. Pet. Sci. Eng. 2020, 186, 106723. [Google Scholar] [CrossRef]

- Tran, S.; Yassin, M.R.; Eghbali, S.; Doranehgard, M.H.; Dehghanpour, H. Quantifying oil-recovery mechanisms during natural-gas huff ‘n’ puff experiments on ultratight core plugs. SPE J. 2021, 26, 498–514. [Google Scholar] [CrossRef]

- Chen, X.; Mohanty, K.K. Pore-Scale Mechanisms of Immiscible and Miscible Gas Injection in Fractured Carbonates. Fuel 2020, 275, 117909. [Google Scholar] [CrossRef]

- Zhao, S.X.; Wang, R.; Lv, C.Y.; Lun, Z.M.; Zhou, Y. Influences of the dissolution on the relative permeabilities for CO2 flooded low-permeability oil reservoirs. Pet. Geol. Oilfield Dev. Daqing 2016, 35, 126–129. (In Chinese) [Google Scholar]

| Parameters | Value |

|---|---|

| Formation temperature, °C | 172 |

| Initial formation pressure, MPa | 48.7 |

| Dew point pressure, MPa | 44.3 |

| Maximum retrograde condensation pressure, MPa | 24 |

| Condensate density, g/cm3 | 0.799 |

| Gas–oil radio, m3/m3 | 1000 |

| No | Core Length (m) | Matrix Permeability (mD) | Fracture Permeability (mD) | Permeability Gradation |

|---|---|---|---|---|

| 1 | 99.73 | 0.15 | - | 1 |

| 2 | 89.64 | 0.16 | 10.11 | 67 |

| 3 | 89.88 | 0.16 | 3.26 | 20 |

| 4 | 99.68 | 0.41 | - | 1 |

| 5 | 99.70 | 0.41 | 14.27 | 35 |

| 6 | 89.95 | 0.41 | 6.2 | 15 |

| 7 | 94.66 | 1.47 | - | 1 |

| 8 | 89.75 | 1.02 | 22.41 | 22 |

| 9 | 89.79 | 1.01 | 9.5 | 9 |

| Parameters | Value |

|---|---|

| Fracture density of strong weathering zone, /m | 6.78 |

| Fracture density of secondary weathering zone, /m | 4.22 |

| Average porosity of strong weathering zone, % | 4.9 |

| Average porosity of strong weathering zone, % | 3.6 |

| CO2 content, % | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Wu, J.; Wu, H.; Jiang, Y.; Song, X.; Guo, P.; Zhang, Q.; Tian, H. Research on Gas Injection Limits and Development Methods of CH4/CO2 Synergistic Displacement in Offshore Fractured Condensate Gas Reservoirs. Energies 2024, 17, 3326. https://doi.org/10.3390/en17133326

Yang C, Wu J, Wu H, Jiang Y, Song X, Guo P, Zhang Q, Tian H. Research on Gas Injection Limits and Development Methods of CH4/CO2 Synergistic Displacement in Offshore Fractured Condensate Gas Reservoirs. Energies. 2024; 17(13):3326. https://doi.org/10.3390/en17133326

Chicago/Turabian StyleYang, Chenxu, Jintao Wu, Haojun Wu, Yong Jiang, Xinfei Song, Ping Guo, Qixuan Zhang, and Hao Tian. 2024. "Research on Gas Injection Limits and Development Methods of CH4/CO2 Synergistic Displacement in Offshore Fractured Condensate Gas Reservoirs" Energies 17, no. 13: 3326. https://doi.org/10.3390/en17133326

APA StyleYang, C., Wu, J., Wu, H., Jiang, Y., Song, X., Guo, P., Zhang, Q., & Tian, H. (2024). Research on Gas Injection Limits and Development Methods of CH4/CO2 Synergistic Displacement in Offshore Fractured Condensate Gas Reservoirs. Energies, 17(13), 3326. https://doi.org/10.3390/en17133326