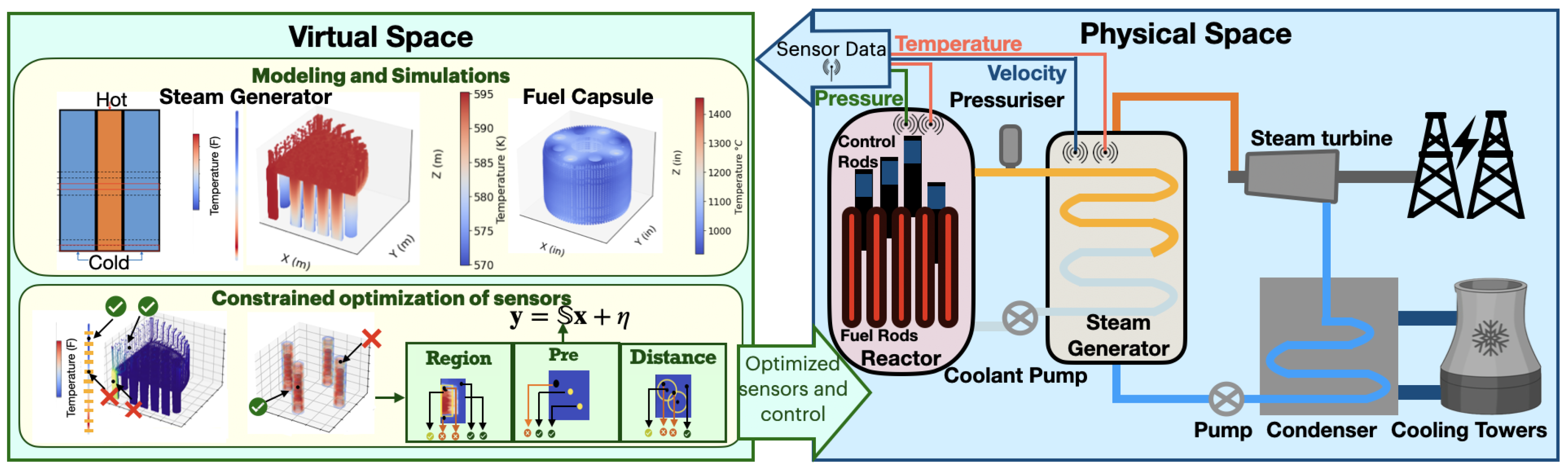

Leveraging Optimal Sparse Sensor Placement to Aggregate a Network of Digital Twins for Nuclear Subsystems

Abstract

:1. Introduction

2. Materials and Methods

2.1. Modeling and Simulation for Reactor Components

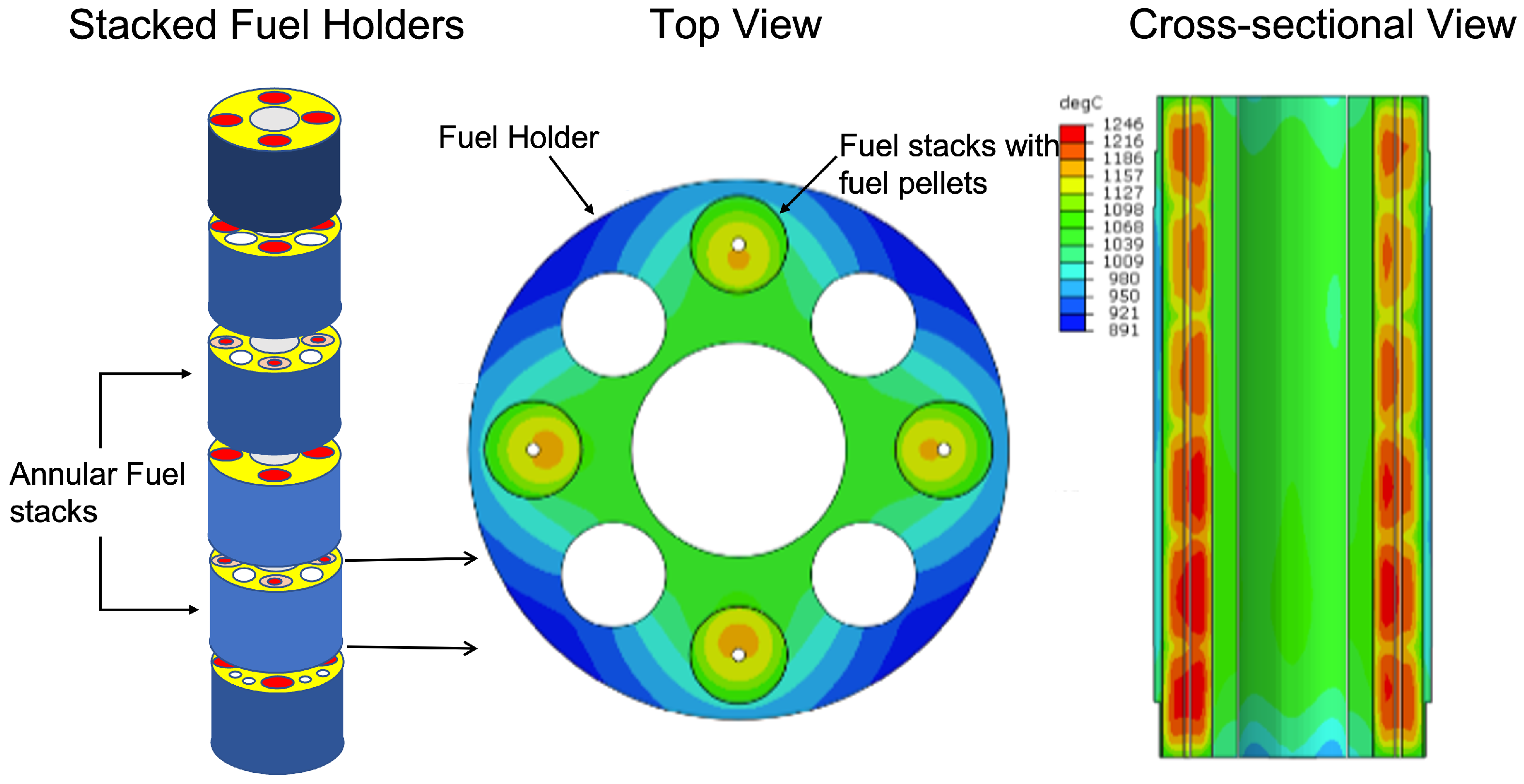

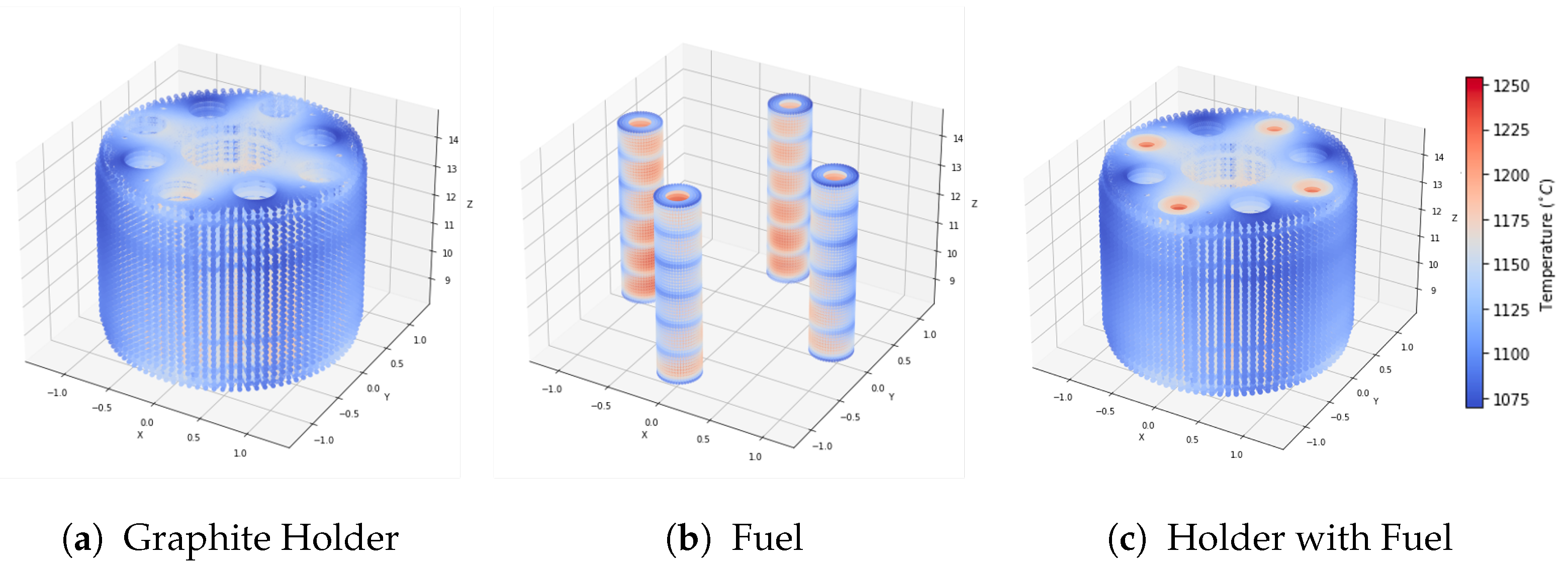

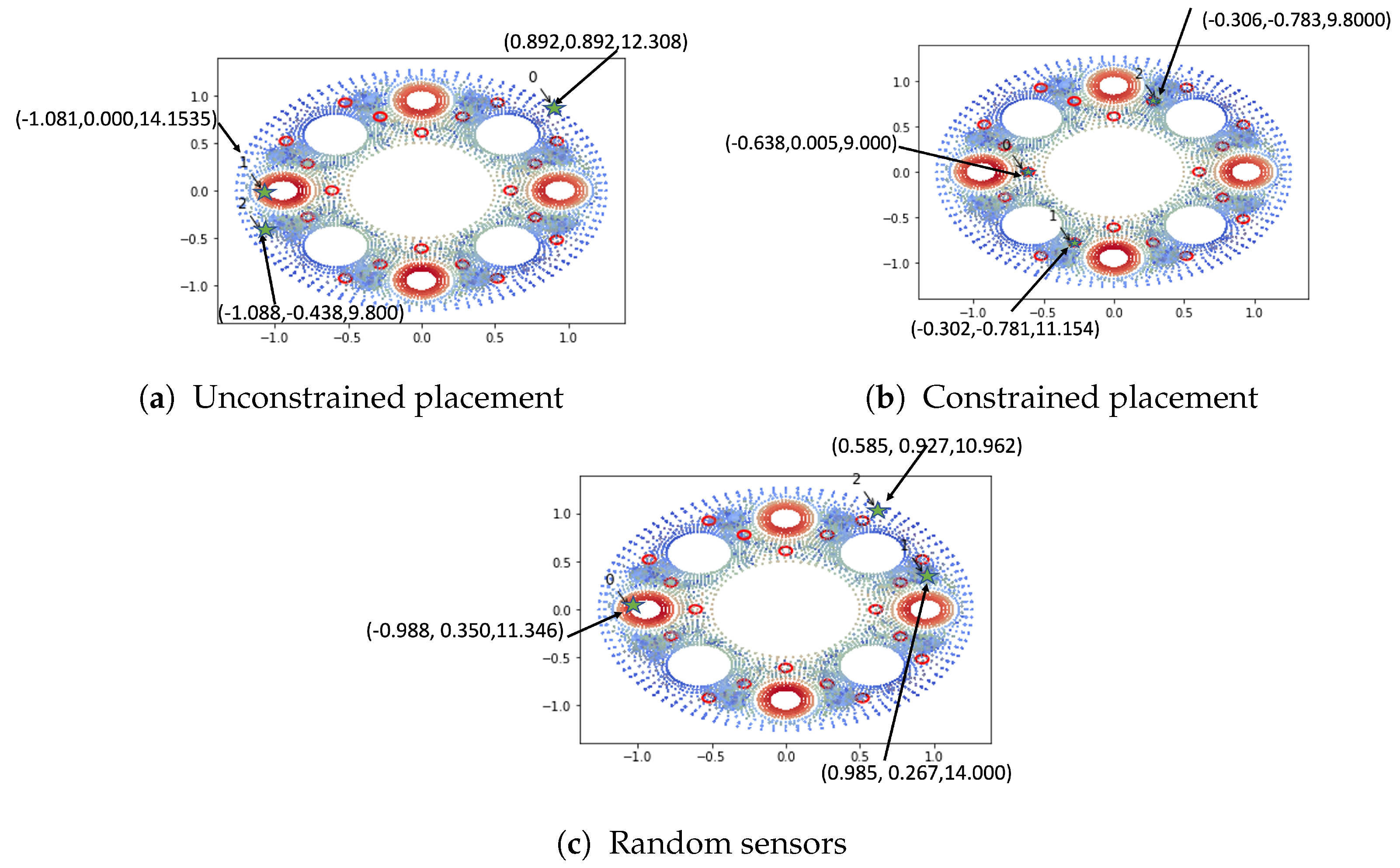

2.1.1. Three-Dimensional Modeling of Fuel Capsules

2.1.2. Lumped-Parameter Model of OPTI-TWIST

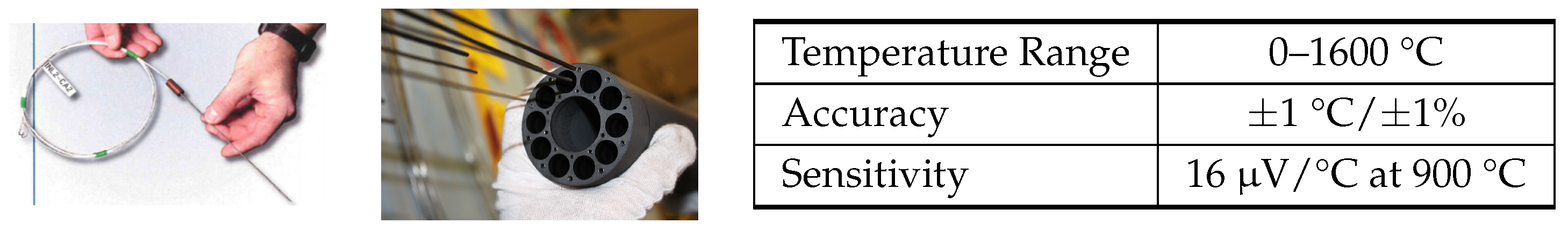

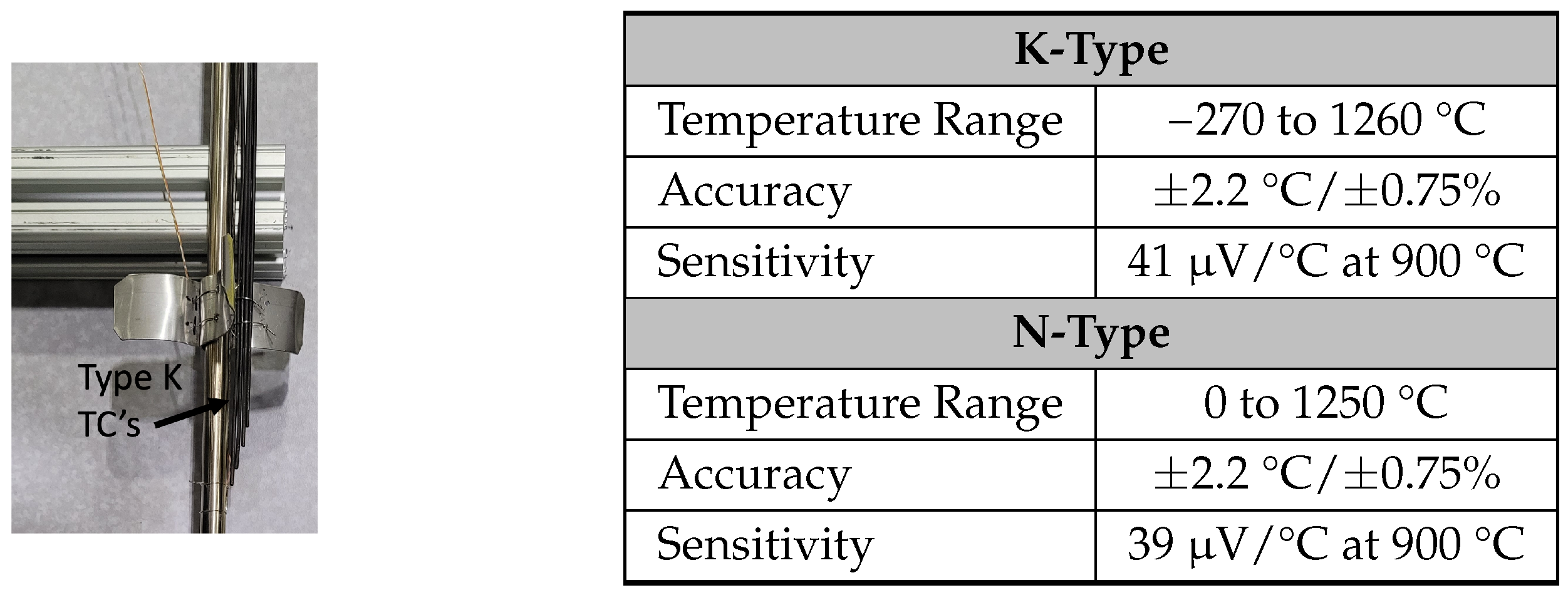

2.1.3. Instrumentation for TRISO Fuel Irradiation and OPTI-TWIST

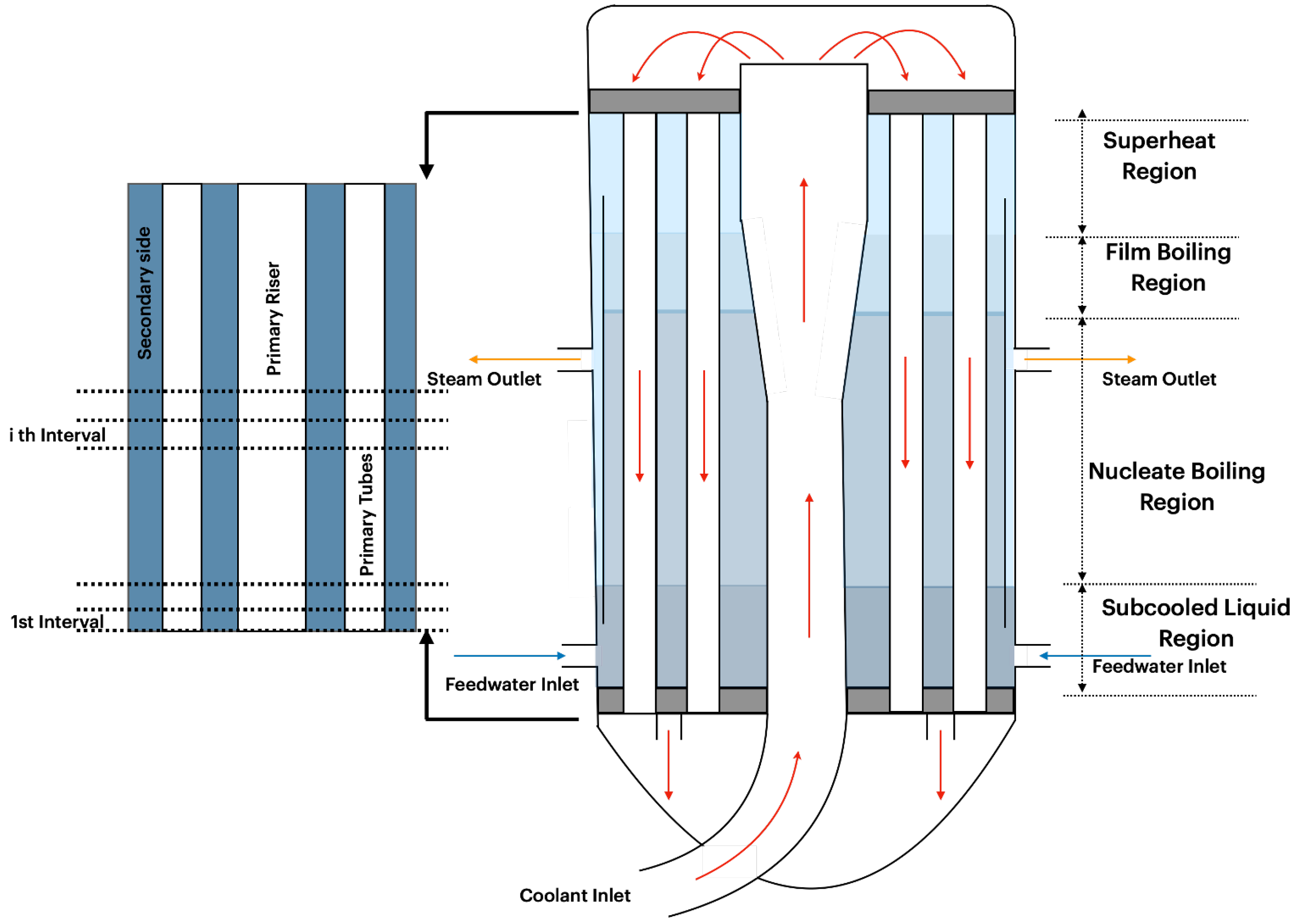

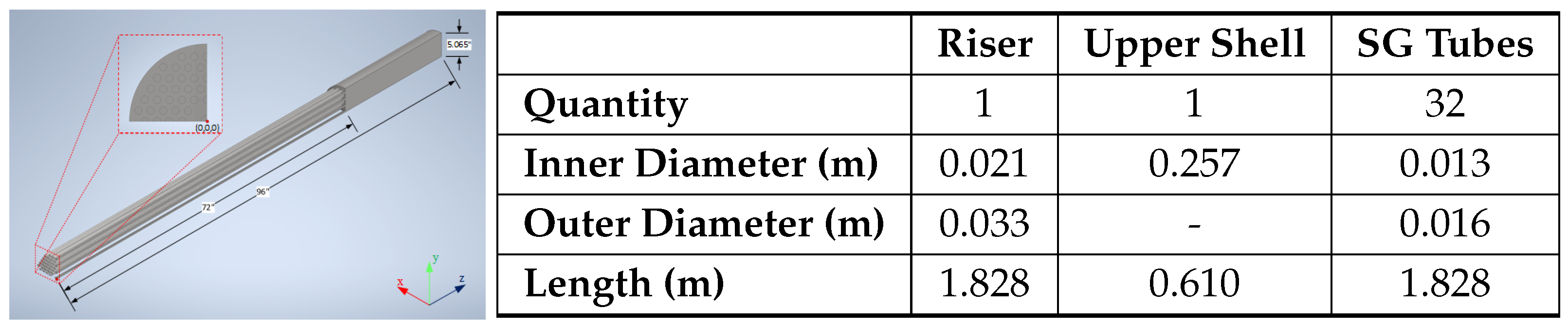

2.2. Modeling and Simulation for Steam Generators

2.2.1. One-Dimensional Python Model of Steam Generator

2.2.2. Three-Dimensional CFD Model of Steam Generator

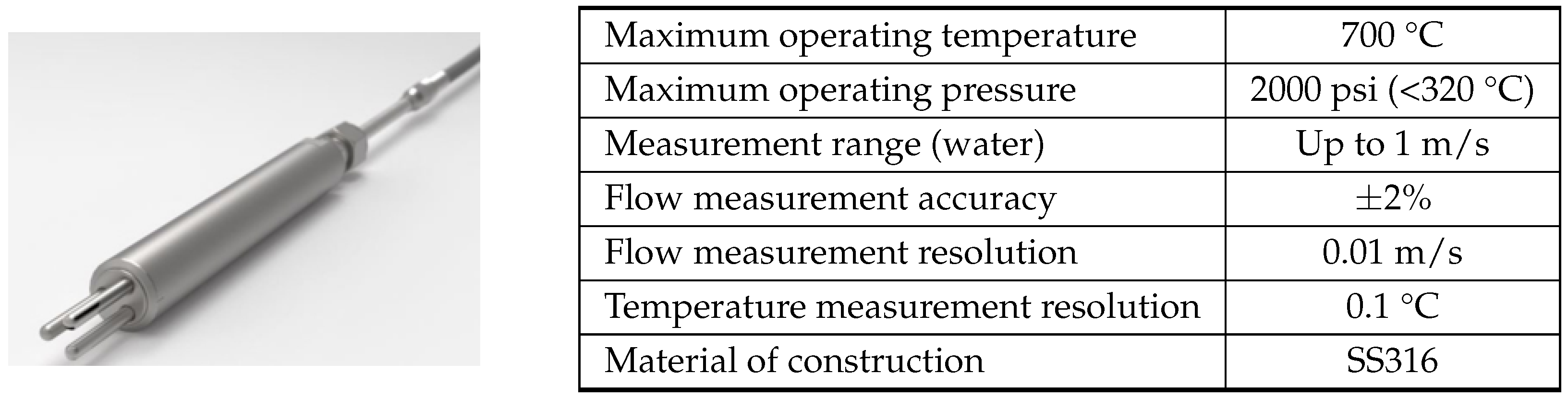

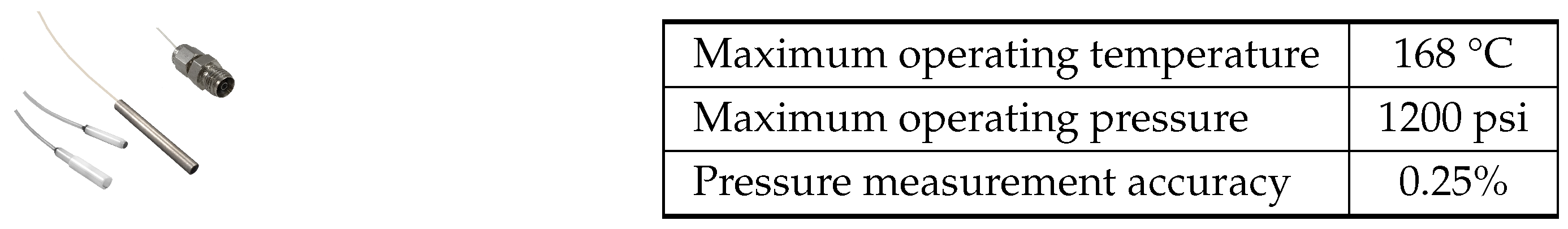

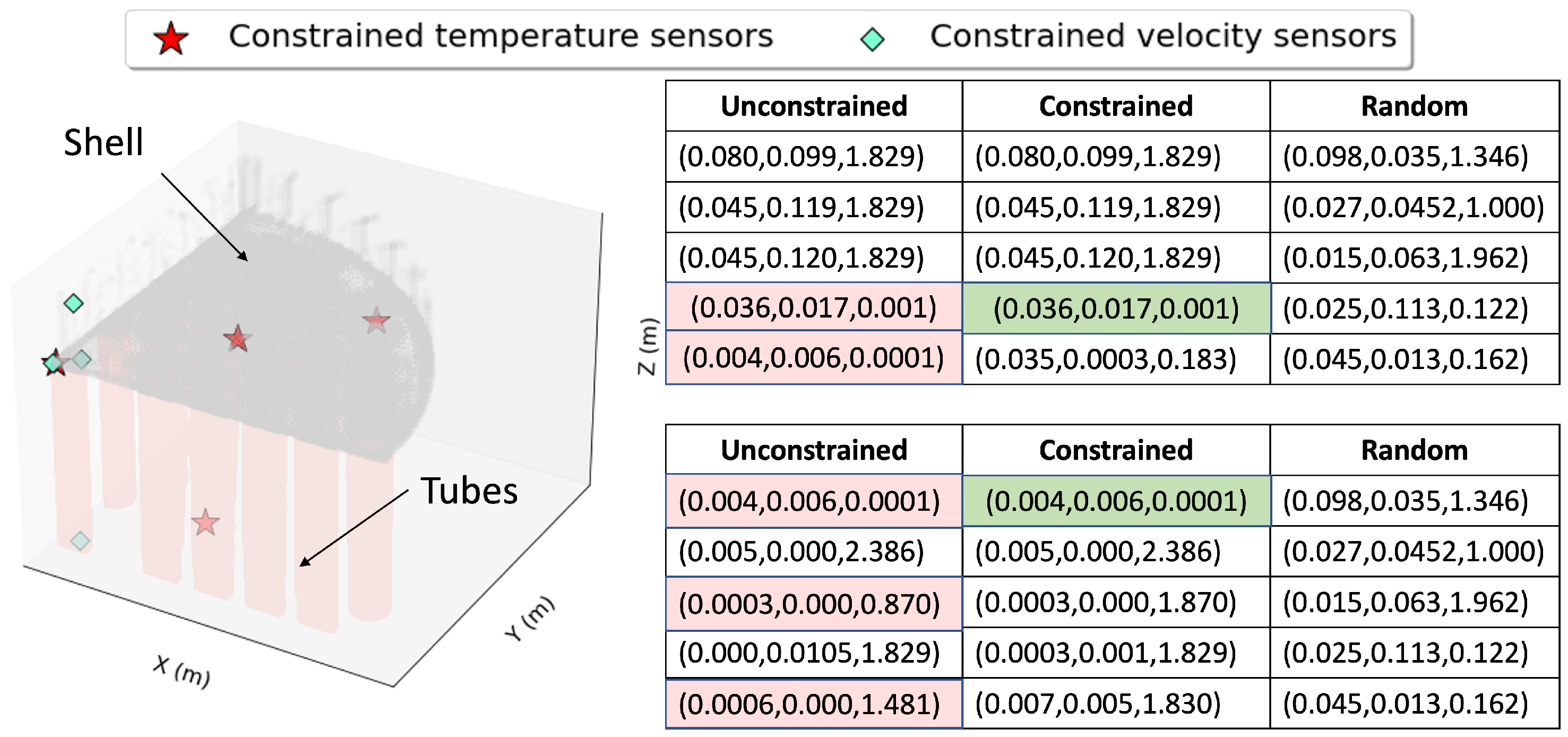

2.2.3. Instrumentation for Steam Generators

2.3. Constrained Sensor Placement for Reconstruction

2.4. Uncertainty Estimation in Digital Twins

3. Results

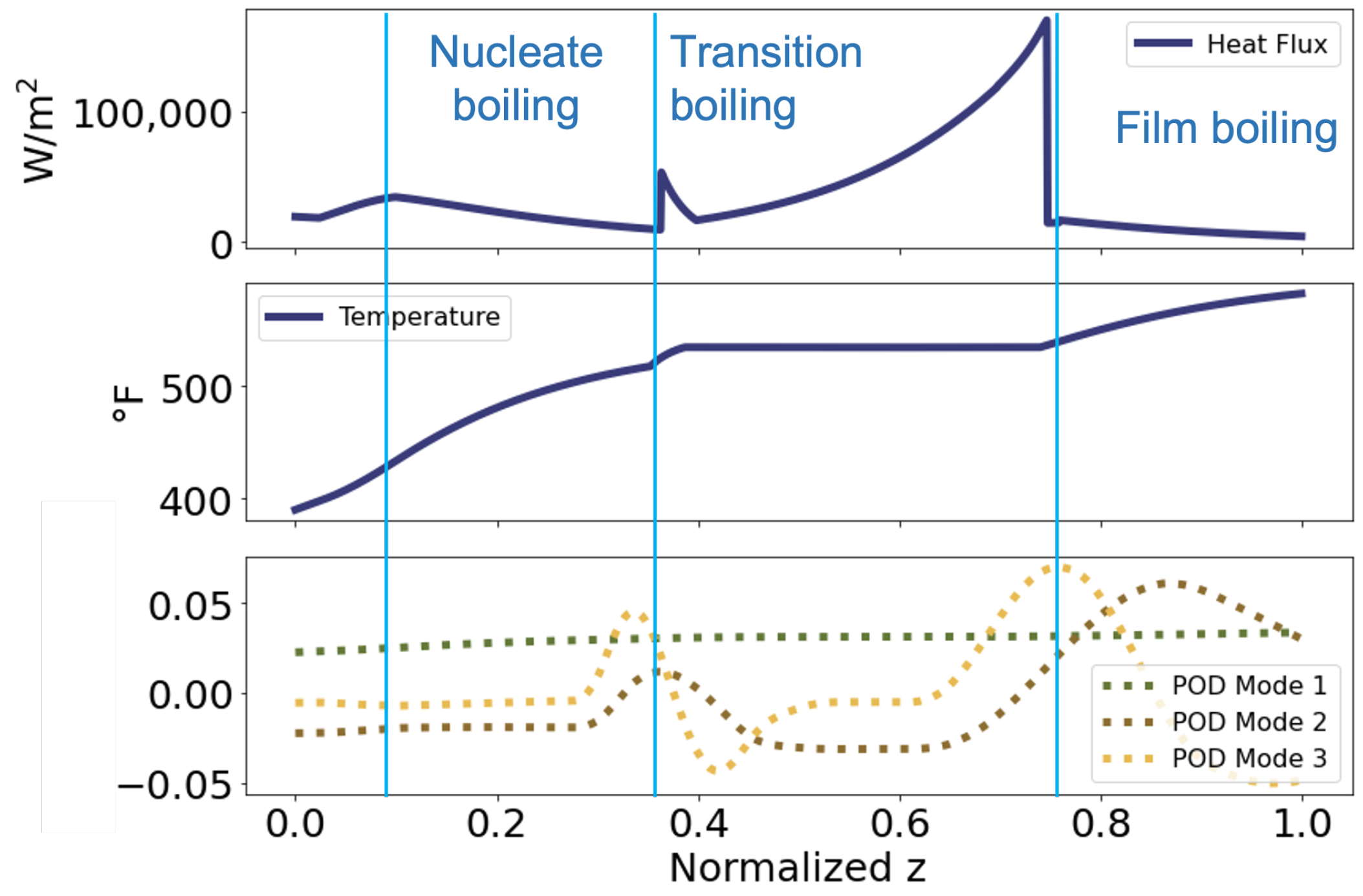

3.1. One-Dimensional Steam Generator Model

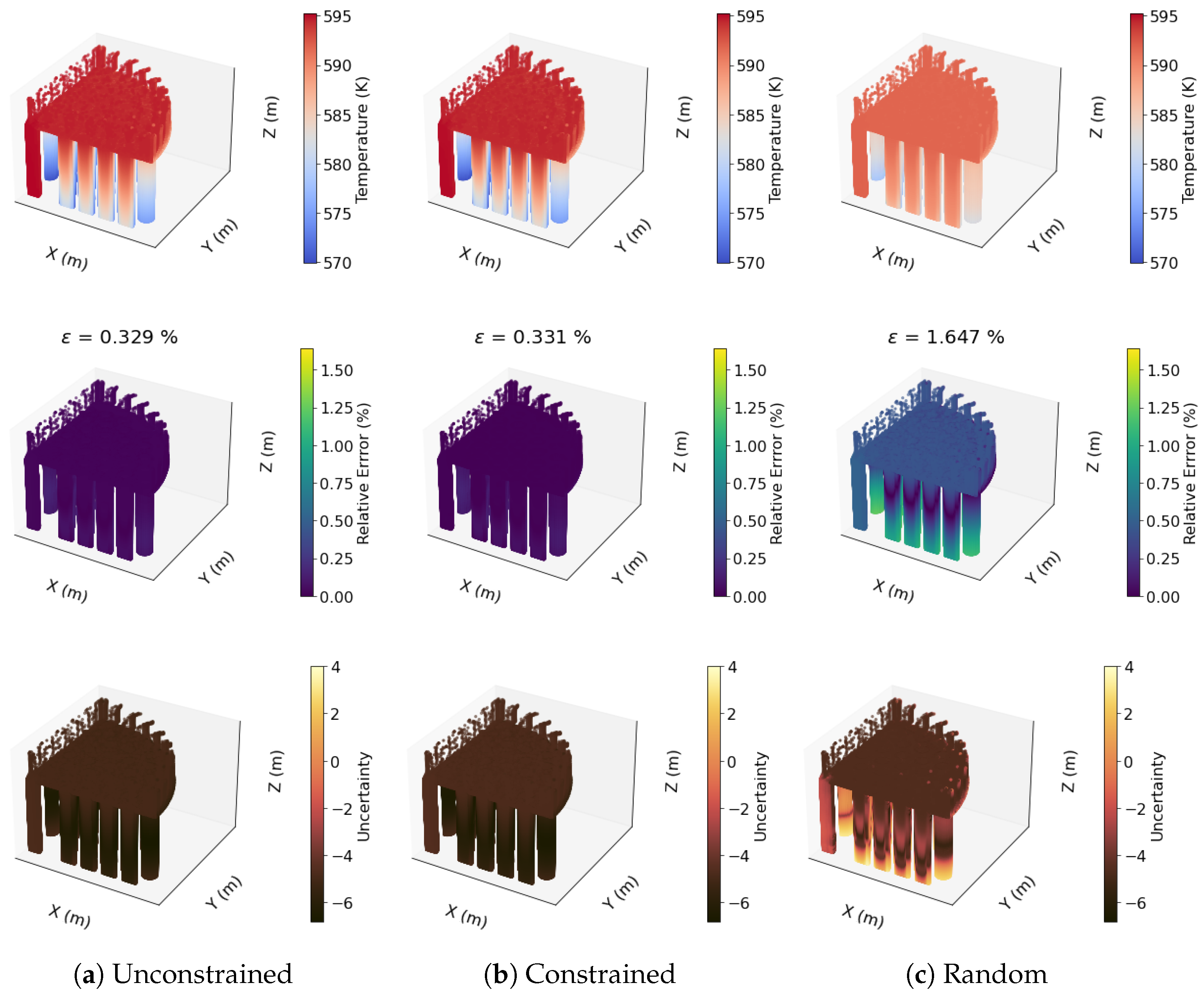

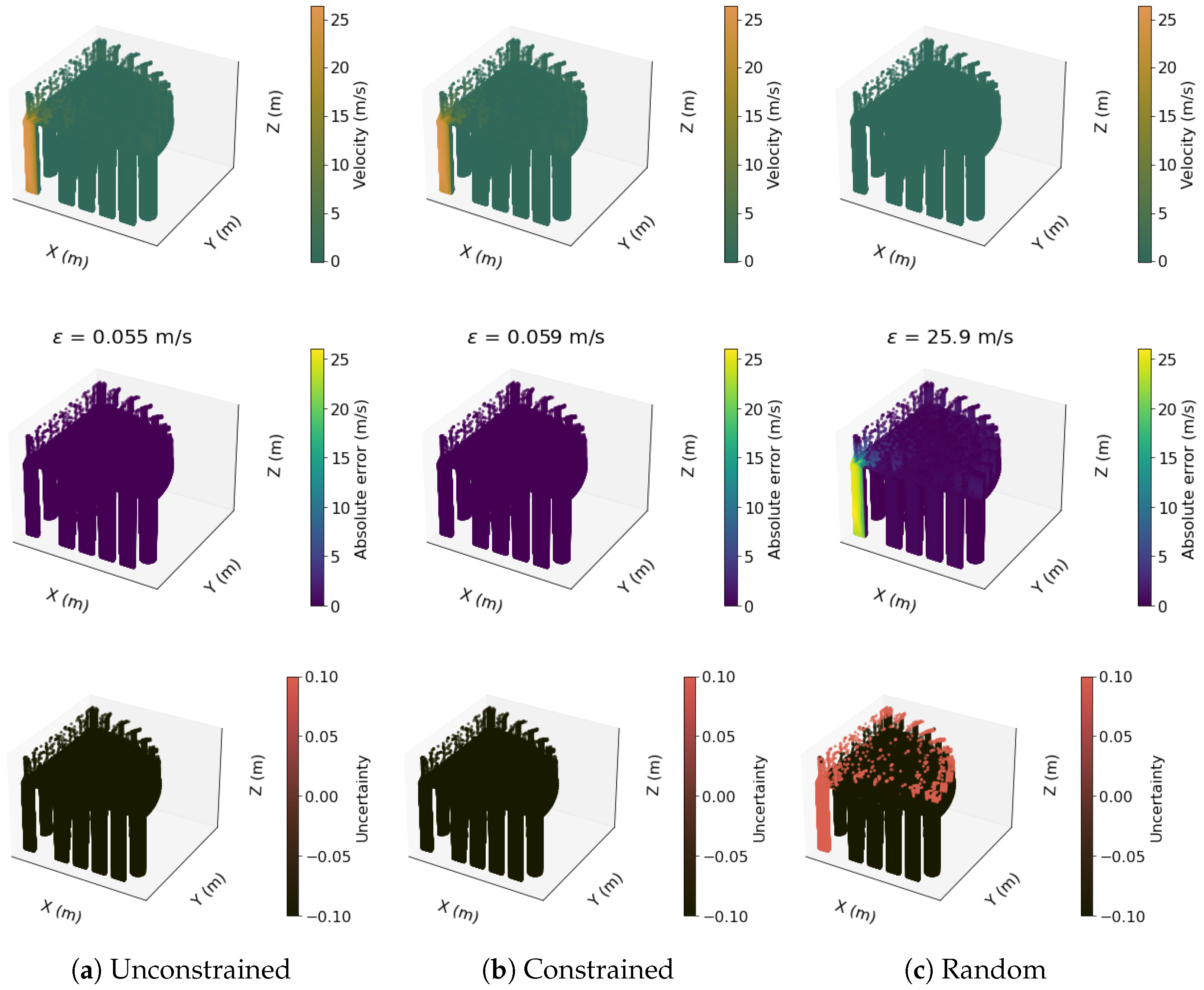

Three-Dimensional Steam Generator Model

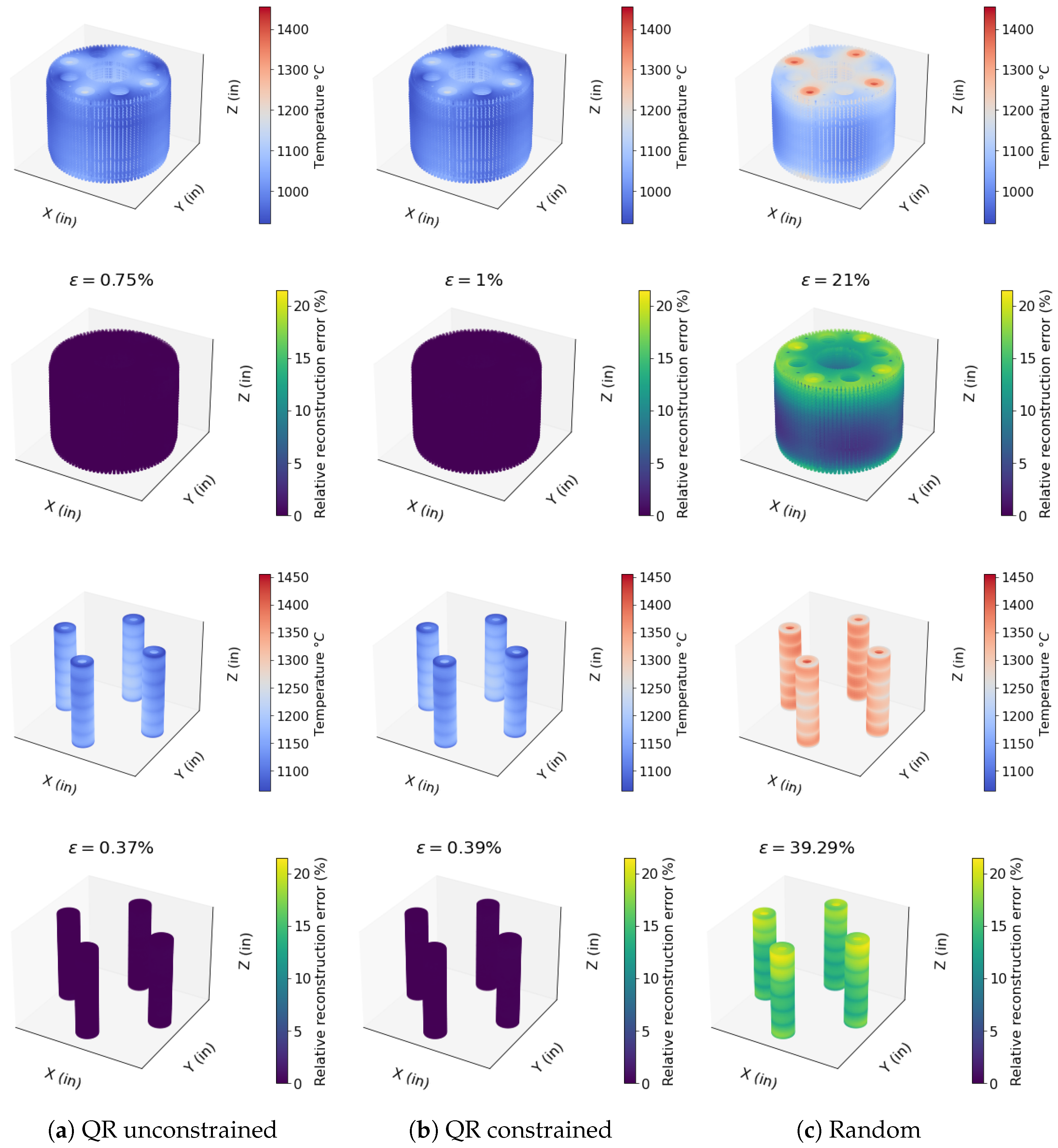

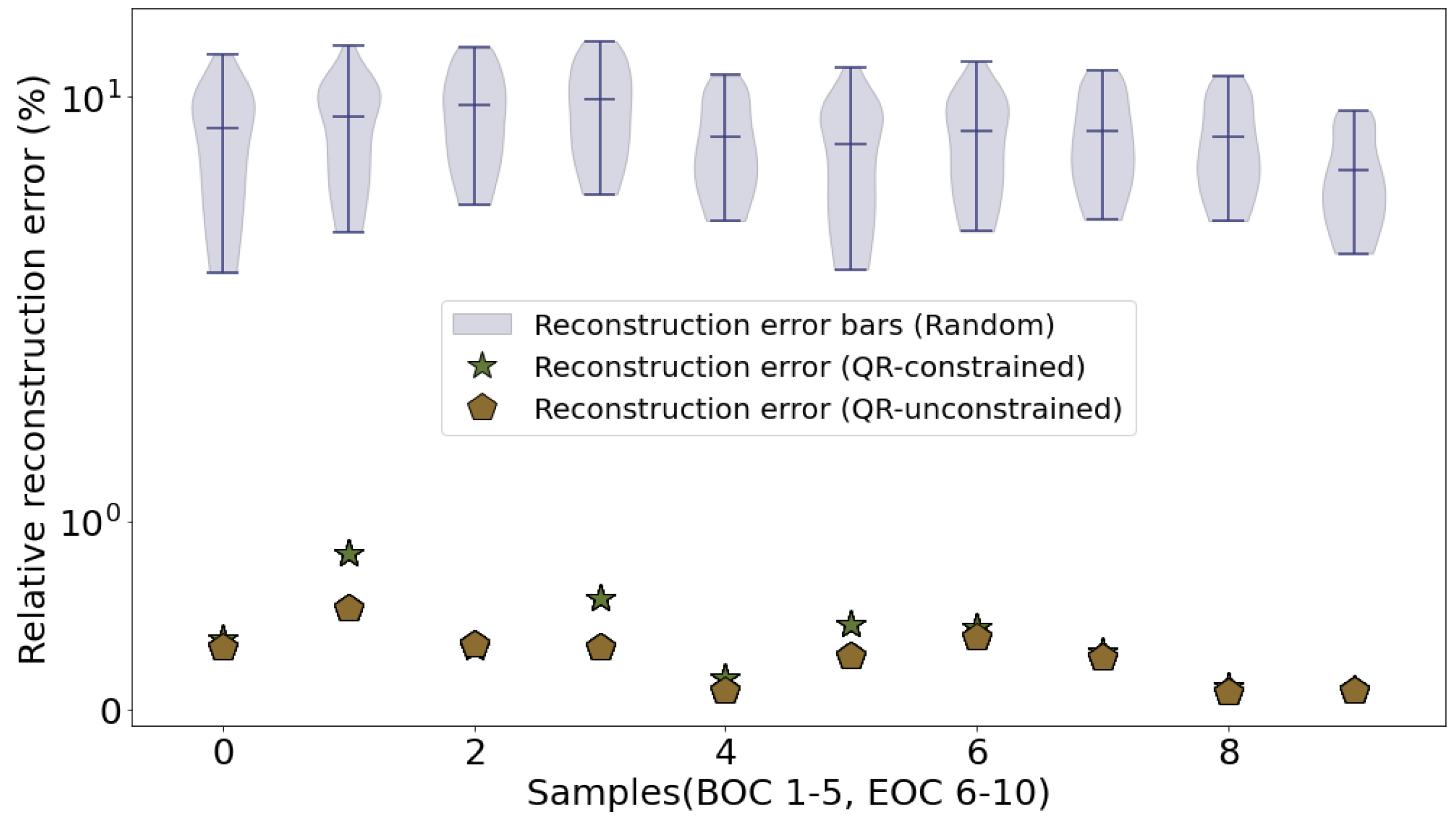

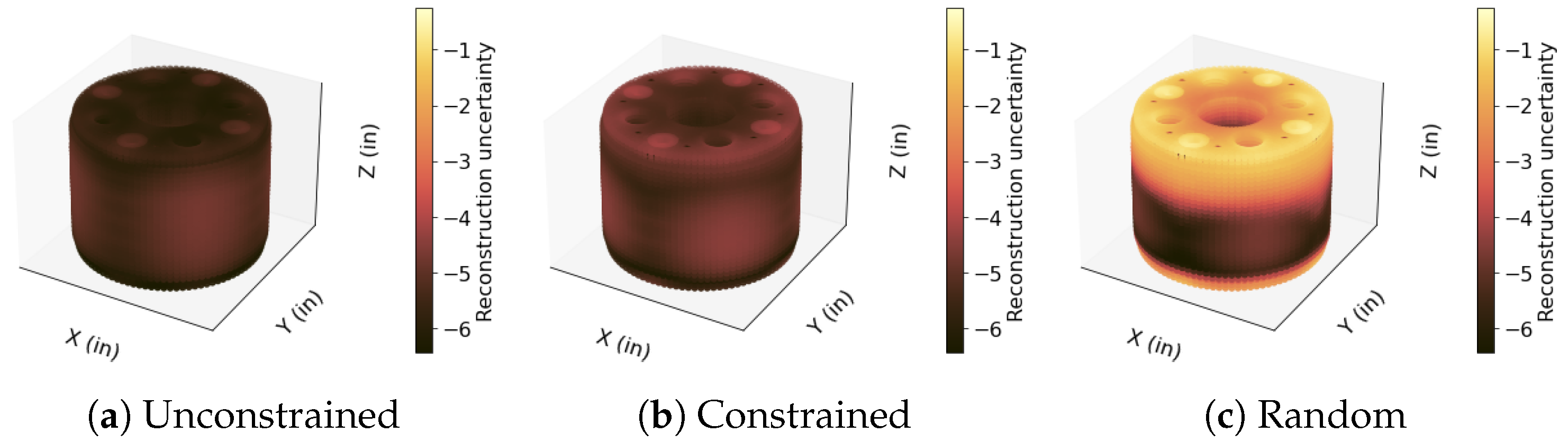

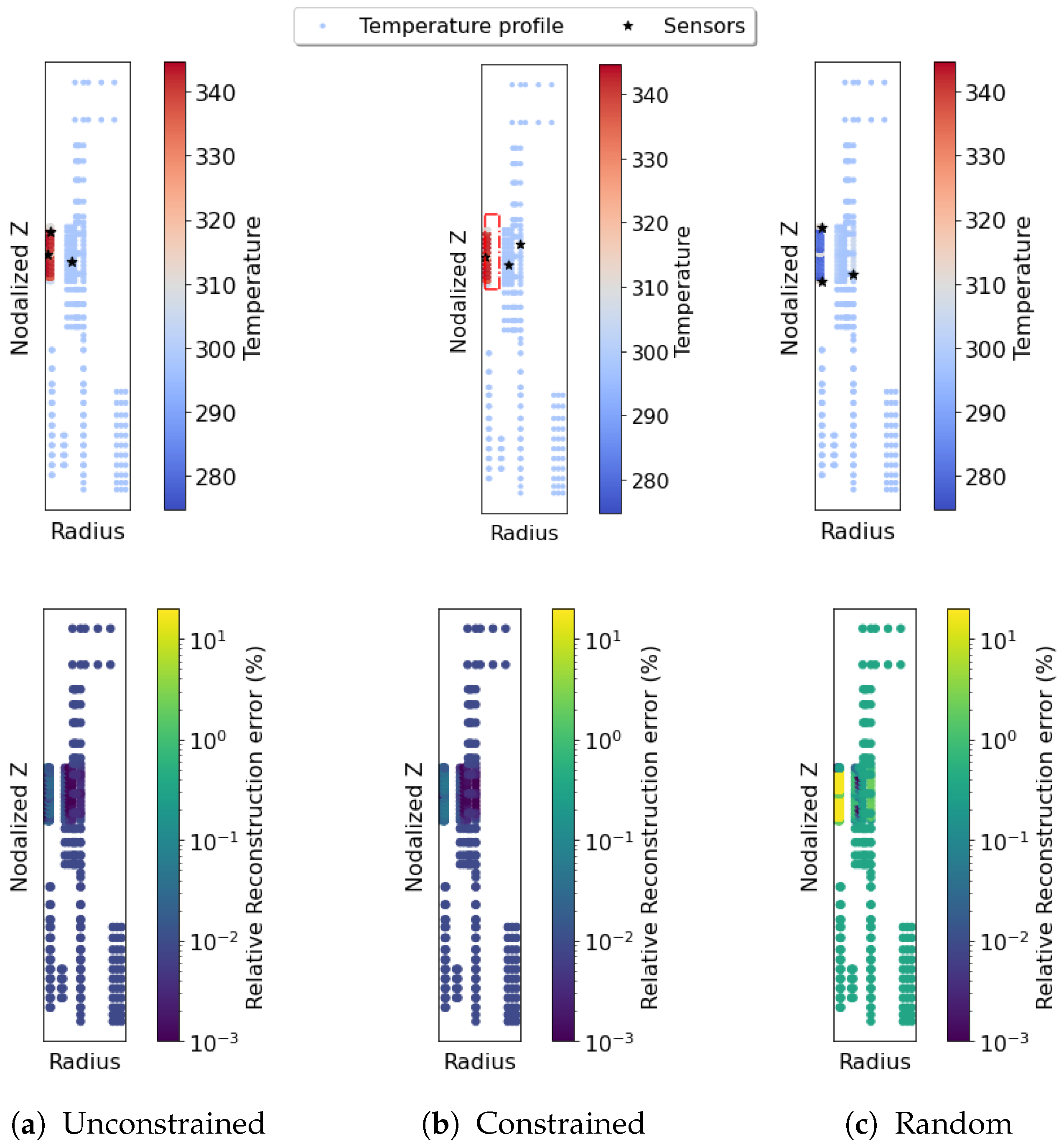

3.2. Irradiation of TRISO Fuel

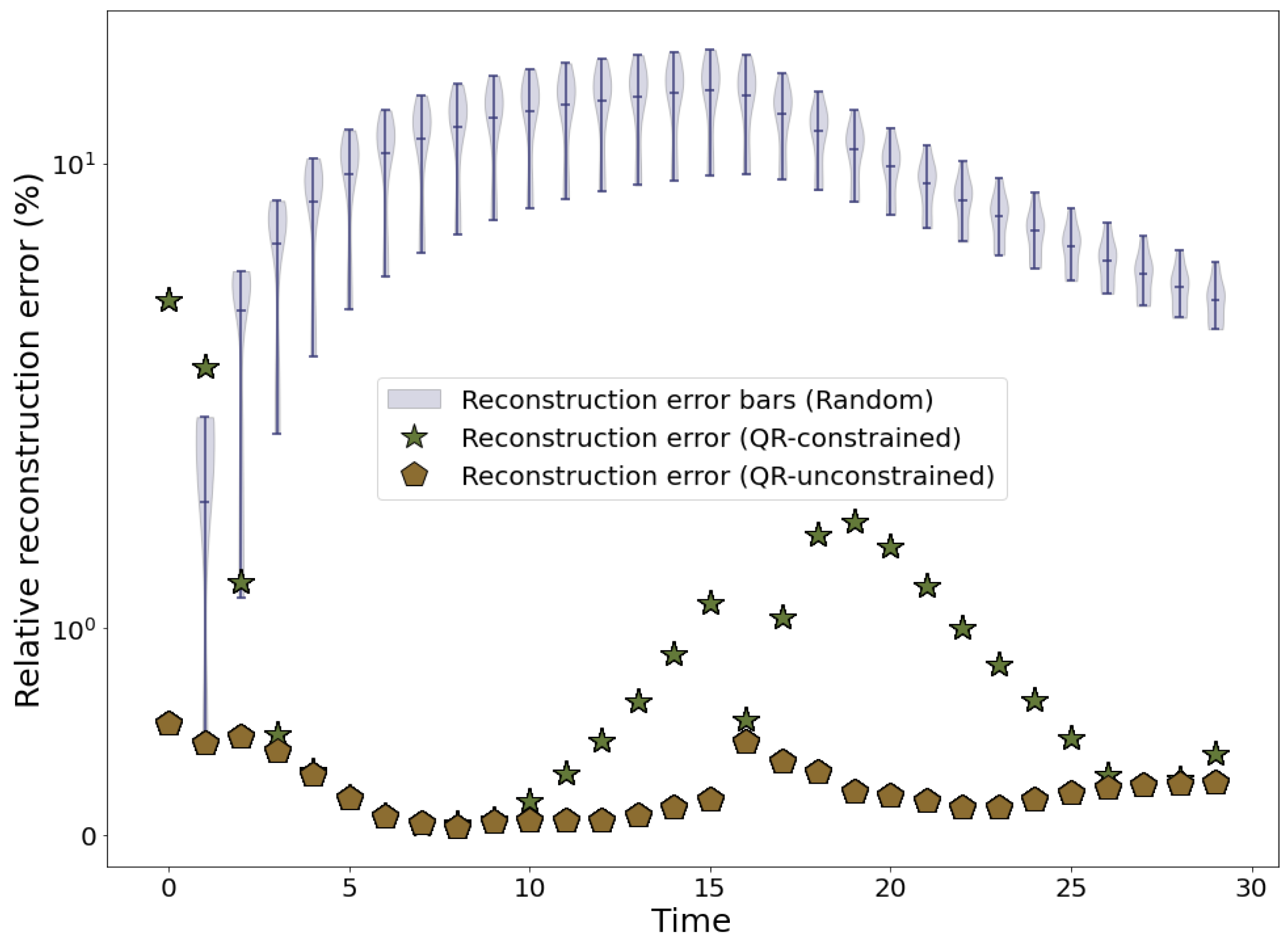

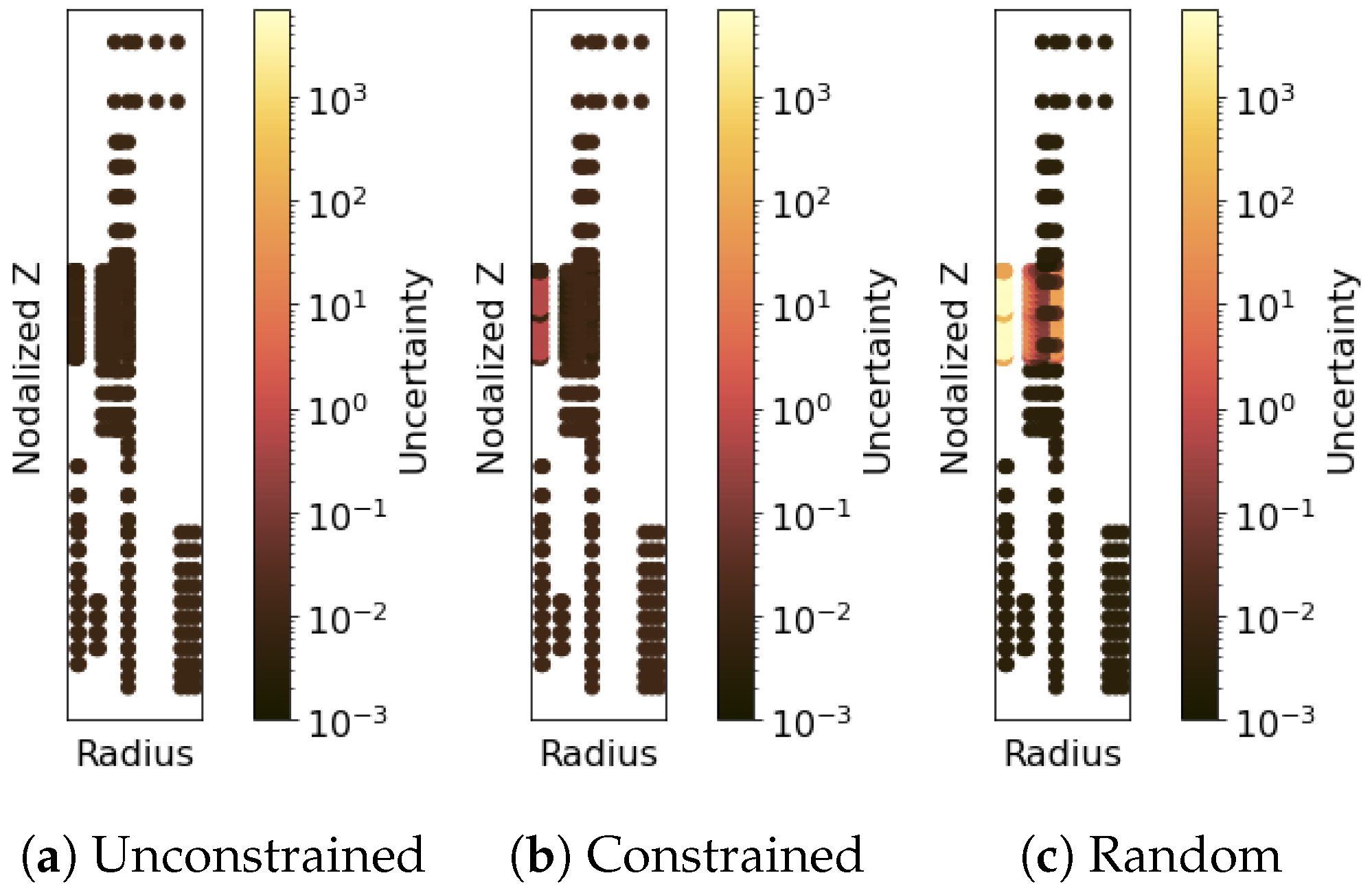

3.3. Electrically Heated Prototype Capsule- OPTI-TWIST

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 1D | One-dimensional |

| 3D | Three-dimensional |

| ATR | Advanced test reactor |

| BOC | Beginning of cycle |

| BWR | Boiling water reactor |

| CAD | Computer-aided design |

| CFD | Computational fluid dynamics |

| DT | Digital twin |

| EOC | End of cycle |

| FEM | Finite element method |

| INL | Idaho National Laboratory |

| NPP | Nuclear power plant |

| OTSG | Once-through steam generator |

| OPTI-TWIST | Out-of-pile testing and instrumentation transient water irradiation system |

| POD | Proper orthogonal decomposition |

| PWR | Pressurized water reactor |

| SG | Steam generator |

| TC | Thermocouple |

| TRISO | Tri-structural isotropic particle |

References

- International Atomic Energy Agency. Core Knowledge on Instrumentation and Control Systems in Nuclear Power Plants; IAEA Nuclear Energy Series; No. NP-T-3.12, Technical Report; International Atomic Energy Agency: Vienna, Austria, 2011. [Google Scholar]

- Fernandez, A.F.; Gusarov, A.I.; Brichard, B.t.; Bodart, S.; Lammens, K.; Berghmans, F.; Decreton, M.; Megret, P.; Blondel, M.; Delchambre, A. Temperature monitoring of nuclear reactor cores with multiplexed fiber Bragg grating sensors. Opt. Eng. 2002, 41, 1246–1254. [Google Scholar]

- Messai, A.; Mellit, A.; Abdellani, I.; Pavan, A.M. On-line fault detection of a fuel rod temperature measurement sensor in a nuclear reactor core using ANNs. Prog. Nucl. Energy 2015, 79, 8–21. [Google Scholar] [CrossRef]

- Hashemian, H.M. On-line monitoring applications in nuclear power plants. Prog. Nucl. Energy 2011, 53, 167–181. [Google Scholar] [CrossRef]

- Upadhyaya, B.; Perillo, S.; Xu, X.; Li, F. Advanced control design, optimal sensor placement, and technology demonstration for small and medium nuclear power reactors. In Proceedings of the International Conference on Nuclear Engineering, Brussels, Belgium, 12–16 July 2009; Volume 43550, pp. 763–773. [Google Scholar]

- Argaud, J.P.; Bouriquet, B.; De Caso, F.; Gong, H.; Maday, Y.; Mula, O. Sensor placement in nuclear reactors based on the generalized empirical interpolation method. J. Comput. Phys. 2018, 363, 354–370. [Google Scholar] [CrossRef]

- Li, F.; Upadhyaya, B.R. Design of sensor placement for an integral pressurized water reactor using fault diagnostic observability and reliability criteria. Nucl. Technol. 2011, 173, 17–25. [Google Scholar] [CrossRef]

- Upadhyaya, B.R.; Li, F. Optimal sensor placement strategy for anomaly detection and isolation. In Proceedings of the 2011 Future of Instrumentation International Workshop (FIIW) Proceedings, Oak Ridge, TN, USA, 7–8 November 2011; pp. 95–98. [Google Scholar]

- Khalil Ur, R.; Shin, J.; Zubair, M.; Heo, G.; Son, H. Sensitivity study on availability of I&C components using bayesian network. Sci. Technol. Nucl. Install. 2013, 2013, 656548. [Google Scholar]

- Li, W.; Peng, M.; Wang, Q. Improved PCA method for sensor fault detection and isolation in a nuclear power plant. Nucl. Eng. Technol. 2019, 51, 146–154. [Google Scholar] [CrossRef]

- Oh, D.Y.; No, H.C. Determination of the minimal number and optimal sensor location in a nuclear system with fixed incore detectors. Nucl. Eng. Des. 1994, 152, 197–212. [Google Scholar] [CrossRef]

- Hashemian, H.; Bean, W.C. Sensors for next-generation nuclear plants: Fiber-optic and wireless. Nucl. Sci. Eng. 2011, 169, 262–278. [Google Scholar] [CrossRef]

- He, R.; Chen, G.; Dong, C.; Sun, S.; Shen, X. Data-driven digital twin technology for optimized control in process systems. ISA Trans. 2019, 95, 221–234. [Google Scholar] [CrossRef]

- Willcox, K. Unsteady flow sensing and estimation via the gappy proper orthogonal decomposition. Comput. Fluids 2006, 35, 208–226. [Google Scholar] [CrossRef]

- Yildirim, B.; Chryssostomidis, C.; Karniadakis, G. Efficient sensor placement for ocean measurements using low-dimensional concepts. Ocean Model. 2009, 27, 160–173. [Google Scholar] [CrossRef]

- Manohar, K.; Brunton, B.W.; Kutz, J.N.; Brunton, S.L. Data-driven sparse sensor placement for reconstruction: Demonstrating the benefits of exploiting known patterns. IEEE Control Syst. Mag. 2018, 38, 63–86. [Google Scholar]

- Brunton, B.W.; Brunton, S.L.; Proctor, J.L.; Kutz, J.N. Sparse sensor placement optimization for classification. SIAM J. Appl. Math. 2016, 76, 2099–2122. [Google Scholar] [CrossRef]

- Mohren, T.L.; Daniel, T.L.; Brunton, S.L.; Brunton, B.W. Neural-inspired sensors enable sparse, efficient classification of spatiotemporal data. Proc. Natl. Acad. Sci. USA 2018, 115, 10564–10569. [Google Scholar] [CrossRef]

- Bigoni, C.; Zhang, Z.; Hesthaven, J.S. Systematic sensor placement for structural anomaly detection in the absence of damaged states. Comput. Methods Appl. Mech. Eng. 2020, 371, 113315. [Google Scholar] [CrossRef]

- Jamei, M.; Scaglione, A.; Roberts, C.; Stewart, E.; Peisert, S.; McParland, C.; McEachern, A. Anomaly Detection Using Optimally Placed μPMU Sensors in Distribution Grids. IEEE Trans. Power Syst. 2017, 33, 3611–3623. [Google Scholar] [CrossRef]

- Krause, A.; Singh, A.; Guestrin, C. Near-optimal sensor placements in Gaussian processes: Theory, efficient algorithms and empirical studies. J. Mach. Learn. Res. 2008, 9, 235–284. [Google Scholar]

- Pei, X.Y.; Yi, T.H.; Qu, C.X.; Li, H.N. Conditional information entropy based sensor placement method considering separated model error and measurement noise. J. Sound Vib. 2019, 449, 389–404. [Google Scholar] [CrossRef]

- Paninski, L. Asymptotic theory of information-theoretic experimental design. Neural Comput. 2005, 17, 1480–1507. [Google Scholar] [CrossRef]

- Wang, S.; Lai, X.; He, X.; Li, K.; Lv, L.; Song, X. Optimal sensor placement for digital twin based on mutual information and correlation with multi-fidelity data. Eng. Comput. 2024, 40, 1289–1308. [Google Scholar] [CrossRef]

- Caselton, W.F.; Zidek, J.V. Optimal monitoring network designs. Stat. Probab. Lett. 1984, 2, 223–227. [Google Scholar] [CrossRef]

- Lin, X.; Chowdhury, A.; Wang, X.; Terejanu, G. Approximate computational approaches for Bayesian sensor placement in high dimensions. Inf. Fusion 2019, 46, 193–205. [Google Scholar] [CrossRef]

- Donoho, D.L. Compressed sensing. IEEE Trans. Inf. Theory 2006, 52, 1289–1306. [Google Scholar] [CrossRef]

- Candes, E.J.; Tao, T. Near-optimal signal recovery from random projections: Universal encoding strategies? IEEE Trans. Inf. Theory 2006, 52, 5406–5425. [Google Scholar] [CrossRef]

- Akbarzadeh, V.; Gagné, C.; Parizeau, M.; Mostafavi, M.A. Black-box optimization of sensor placement with elevation maps and probabilistic sensing models. In Proceedings of the 2011 IEEE International Symposium on Robotic and Sensors Environments (ROSE), Montreal, QC, Canada, 17–18 September 2011; pp. 89–94. [Google Scholar]

- Summers, T.H.; Cortesi, F.L.; Lygeros, J. On submodularity and controllability in complex dynamical networks. IEEE Trans. Control Netw. Syst. 2015, 3, 91–101. [Google Scholar] [CrossRef]

- Joshi, S.; Boyd, S. Sensor selection via convex optimization. IEEE Trans. Signal Process. 2008, 57, 451–462. [Google Scholar] [CrossRef]

- Chepuri, S.P.; Leus, G. Continuous sensor placement. IEEE Signal Process. Lett. 2014, 22, 544–548. [Google Scholar] [CrossRef]

- Liu, S.; Chepuri, S.P.; Fardad, M.; Maşazade, E.; Leus, G.; Varshney, P.K. Sensor selection for estimation with correlated measurement noise. IEEE Trans. Signal Process. 2016, 64, 3509–3522. [Google Scholar] [CrossRef]

- Chaturantabut, S.; Sorensen, D.C. Nonlinear model reduction via discrete empirical interpolation. SIAM J. Sci. Comput. 2010, 32, 2737–2764. [Google Scholar] [CrossRef]

- Drmac, Z.; Gugercin, S. A new selection operator for the discrete empirical interpolation method—Improved a priori error bound and extensions. SIAM J. Sci. Comput. 2016, 38, A631–A648. [Google Scholar] [CrossRef]

- Manohar, K.; Kutz, J.N.; Brunton, S.L. Optimal sensor and actuator selection using balanced model reduction. IEEE Trans. Autom. Control 2021, 67, 2108–2115. [Google Scholar] [CrossRef]

- Clark, E.; Kutz, J.N.; Brunton, S.L. Sensor selection with cost constraints for dynamically relevant bases. IEEE Sens. J. 2020, 20, 11674–11687. [Google Scholar] [CrossRef]

- Clark, E.; Askham, T.; Brunton, S.L.; Kutz, J.N. Greedy sensor placement with cost constraints. IEEE Sens. J. 2018, 19, 2642–2656. [Google Scholar] [CrossRef]

- Clark, E.; Brunton, S.L.; Kutz, J.N. Multi-fidelity sensor selection: Greedy algorithms to place cheap and expensive sensors with cost constraints. IEEE Sens. J. 2020, 21, 600–611. [Google Scholar] [CrossRef]

- Manohar, K.; Kaiser, E.; Brunton, S.L.; Kutz, J.N. Optimized sampling for multiscale dynamics. Multiscale Model. Simul. 2019, 17, 117–136. [Google Scholar] [CrossRef]

- Klishin, A.A.; Kutz, J.N.; Manohar, K. Data-Induced Interactions of Sparse Sensors. arXiv 2023, arXiv:2307.11838. [Google Scholar]

- Karnik, N.; Abdo, M.G.; Estrada-Perez, C.E.; Yoo, J.S.; Cogliati, J.J.; Skifton, R.S.; Calderoni, P.; Brunton, S.L.; Manohar, K. Constrained optimization of sensor placement for nuclear digital twins. IEEE Sens. J. 2024, 24, 15501–15516. [Google Scholar] [CrossRef]

- RELAP5-3D© Code Development Team. RELAP5-3D© Code Manual Volume II: User’s Guide and Input Requirements; Technical Report; Idaho National Lab. (INL): Idaho Falls, ID, USA, 2015. [Google Scholar]

- Palmer, A.; Skifton, R.; Scervini, M.; Haggard, D.; Swank, W. Performance of custom-made very high temperature thermocouples in the advanced gas reactor experiment AGR-5/6/7 during irradiation in the advanced test reactor. EPJ Web Conf. 2020, 225, 04010. [Google Scholar] [CrossRef]

- Sporian Microsystems, Inc. ThermalFlow 700; Sporian Microsystems Inc.: Lafayette, CO, USA, 2024. [Google Scholar]

- Everson, R.; Sirovich, L. Karhunen–Loeve procedure for gappy data. JOSA A 1995, 12, 1657–1664. [Google Scholar] [CrossRef]

- Fisher, R.A. Statistical Methods for Research Workers. In Breakthroughs in Statistics: Methodology and Distribution; Springer: New York, NY, USA, 1970; pp. 66–70. [Google Scholar]

- Businger, P.; Golub, G.H. Linear least squares solutions by Householder transformations. Numer. Math. 1965, 7, 269–276. [Google Scholar] [CrossRef]

- Gu, M.; Eisenstat, S.C. Efficient algorithms for computing a strong rank-revealing QR factorization. SIAM J. Sci. Comput. 1996, 17, 848–869. [Google Scholar] [CrossRef]

- Kochunas, B.; Huan, X. Digital twin concepts with uncertainty for nuclear power applications. Energies 2021, 14, 4235. [Google Scholar] [CrossRef]

- Wilkins, S.C. Low Cross-Section Mo-Nb Thermocouples for Nuclear Application: The State-of-the-Art; Technical report; EG and G Idaho, Inc.: Idaho Falls, ID, USA, 1988. [Google Scholar]

- Skifton, R. High-temperature irradiation-resistant thermocouple instability model for in-pile reactor use. Front. Energy Res. 2023, 11, 1099584. [Google Scholar] [CrossRef]

- Gong, H.; Cheng, S.; Chen, Z.; Li, Q. Data-enabled physics-informed machine learning for reduced-order modeling digital twin: Application to nuclear reactor physics. Nucl. Sci. Eng. 2022, 196, 668–693. [Google Scholar] [CrossRef]

- Kaheman, K.; Kaiser, E.; Strom, B.; Kutz, J.N.; Brunton, S.L. Learning discrepancy models from experimental data. arXiv 2019, arXiv:1909.08574. [Google Scholar]

- Ebers, M.R.; Steele, K.M.; Kutz, J.N. Discrepancy modeling framework: Learning missing physics, modeling systematic residuals, and disambiguating between deterministic and random effects. arXiv 2022, arXiv:2203.05164. [Google Scholar] [CrossRef]

- de Silva, B.M.; Manohar, K.; Clark, E.; Brunton, B.W.; Kutz, J.N.; Brunton, S.L. PySensors: A Python package for sparse sensor placement. J. Open Source Softw. 2021, 6, 2828. [Google Scholar] [CrossRef]

- Rabiti, C.; Alfonsi, A.; Mandelli, D.; Cogliati, J.J.; Wang, C.; Talbot, P.W.; Malijovec, D.P.; Kinoshita, R.A.; Abdo, M.G.; Sen, S.; et al. RAVEN User Manual; Technical report; Idaho National Lab. (INL): Idaho Falls, ID, USA, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karnik, N.; Wang, C.; Bhowmik, P.K.; Cogliati, J.J.; Balderrama Prieto, S.A.; Xing, C.; Klishin, A.A.; Skifton, R.; Moussaoui, M.; Folsom, C.P.; et al. Leveraging Optimal Sparse Sensor Placement to Aggregate a Network of Digital Twins for Nuclear Subsystems. Energies 2024, 17, 3355. https://doi.org/10.3390/en17133355

Karnik N, Wang C, Bhowmik PK, Cogliati JJ, Balderrama Prieto SA, Xing C, Klishin AA, Skifton R, Moussaoui M, Folsom CP, et al. Leveraging Optimal Sparse Sensor Placement to Aggregate a Network of Digital Twins for Nuclear Subsystems. Energies. 2024; 17(13):3355. https://doi.org/10.3390/en17133355

Chicago/Turabian StyleKarnik, Niharika, Congjian Wang, Palash K. Bhowmik, Joshua J. Cogliati, Silvino A. Balderrama Prieto, Changhu Xing, Andrei A. Klishin, Richard Skifton, Musa Moussaoui, Charles P. Folsom, and et al. 2024. "Leveraging Optimal Sparse Sensor Placement to Aggregate a Network of Digital Twins for Nuclear Subsystems" Energies 17, no. 13: 3355. https://doi.org/10.3390/en17133355

APA StyleKarnik, N., Wang, C., Bhowmik, P. K., Cogliati, J. J., Balderrama Prieto, S. A., Xing, C., Klishin, A. A., Skifton, R., Moussaoui, M., Folsom, C. P., Palmer, J. J., Sabharwall, P., Manohar, K., & Abdo, M. G. (2024). Leveraging Optimal Sparse Sensor Placement to Aggregate a Network of Digital Twins for Nuclear Subsystems. Energies, 17(13), 3355. https://doi.org/10.3390/en17133355