Transformation towards a Low-Emission and Energy-Efficient Economy Realized in Agriculture through the Increase in Controllability of the Movement of Units Mowing Crops While Simultaneously Discing Their Stubble

Abstract

:1. Introduction

2. Theoretical Premises

; ; ; ; ; ; ; ; ; ; − Laplace operator. | ; ; ; ; ; ; ; ; ; ; ; |

3. Materials

4. Results and Discussion

4.1. Checking the Mathematical Model for Adequacy

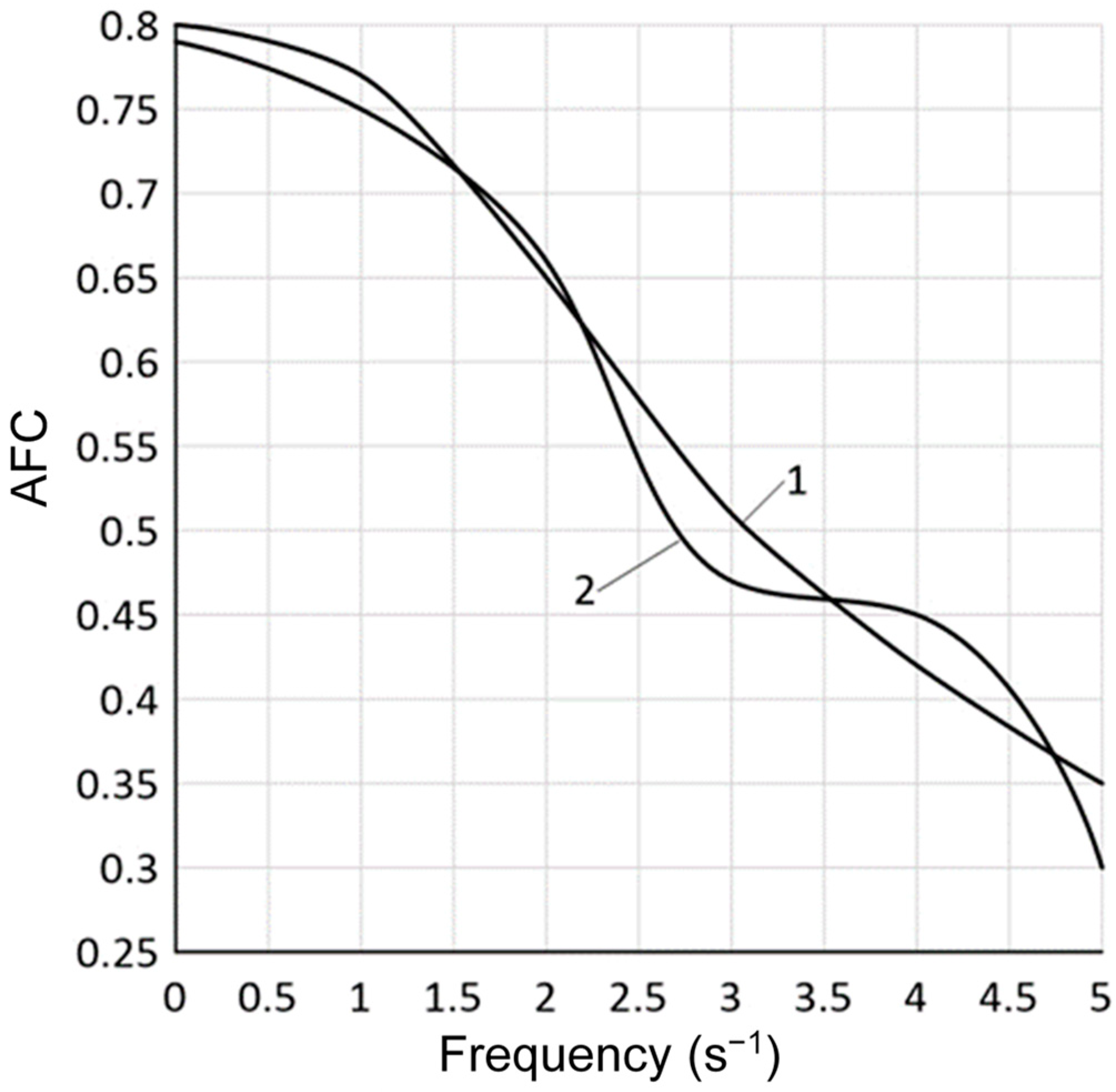

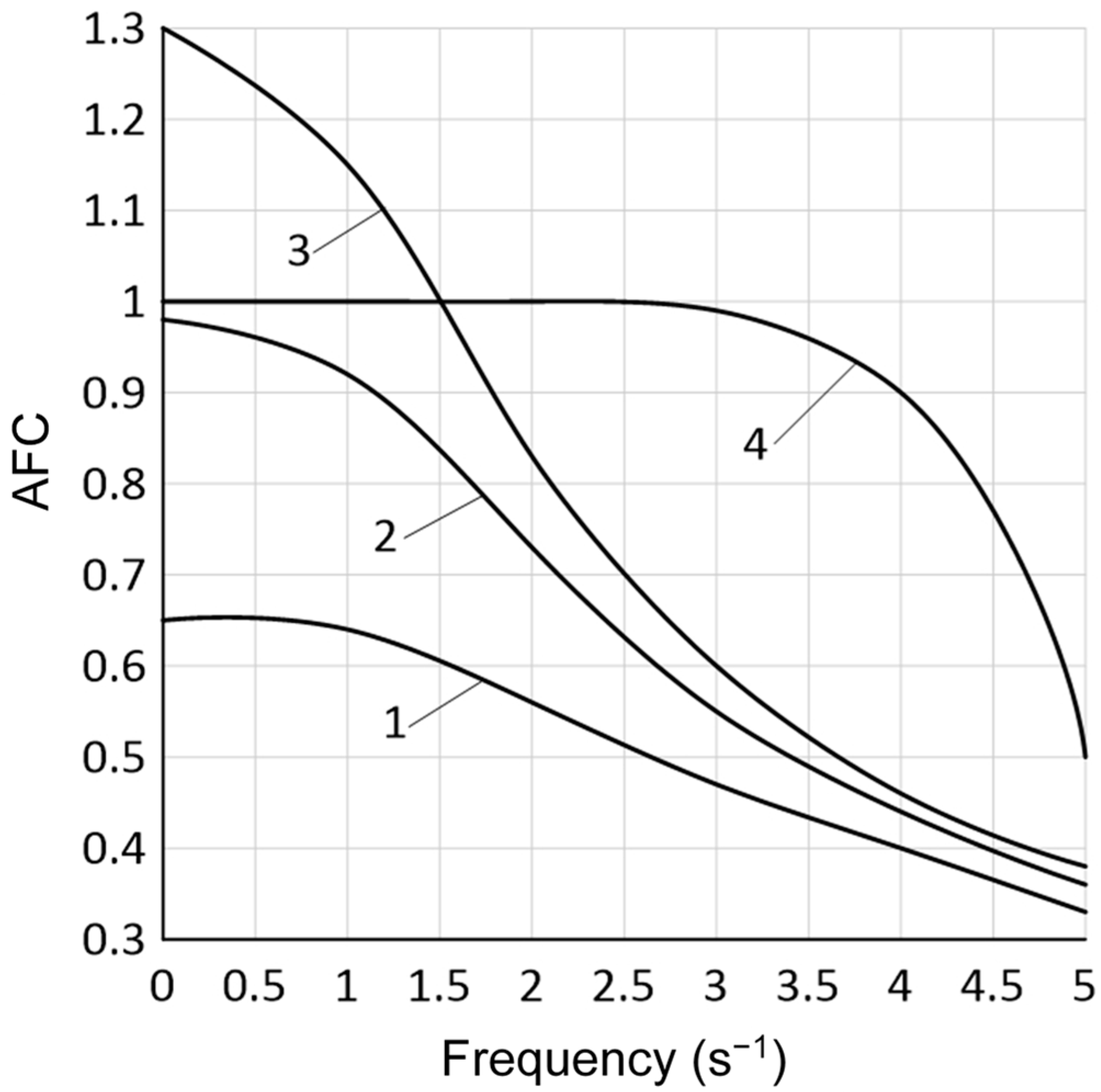

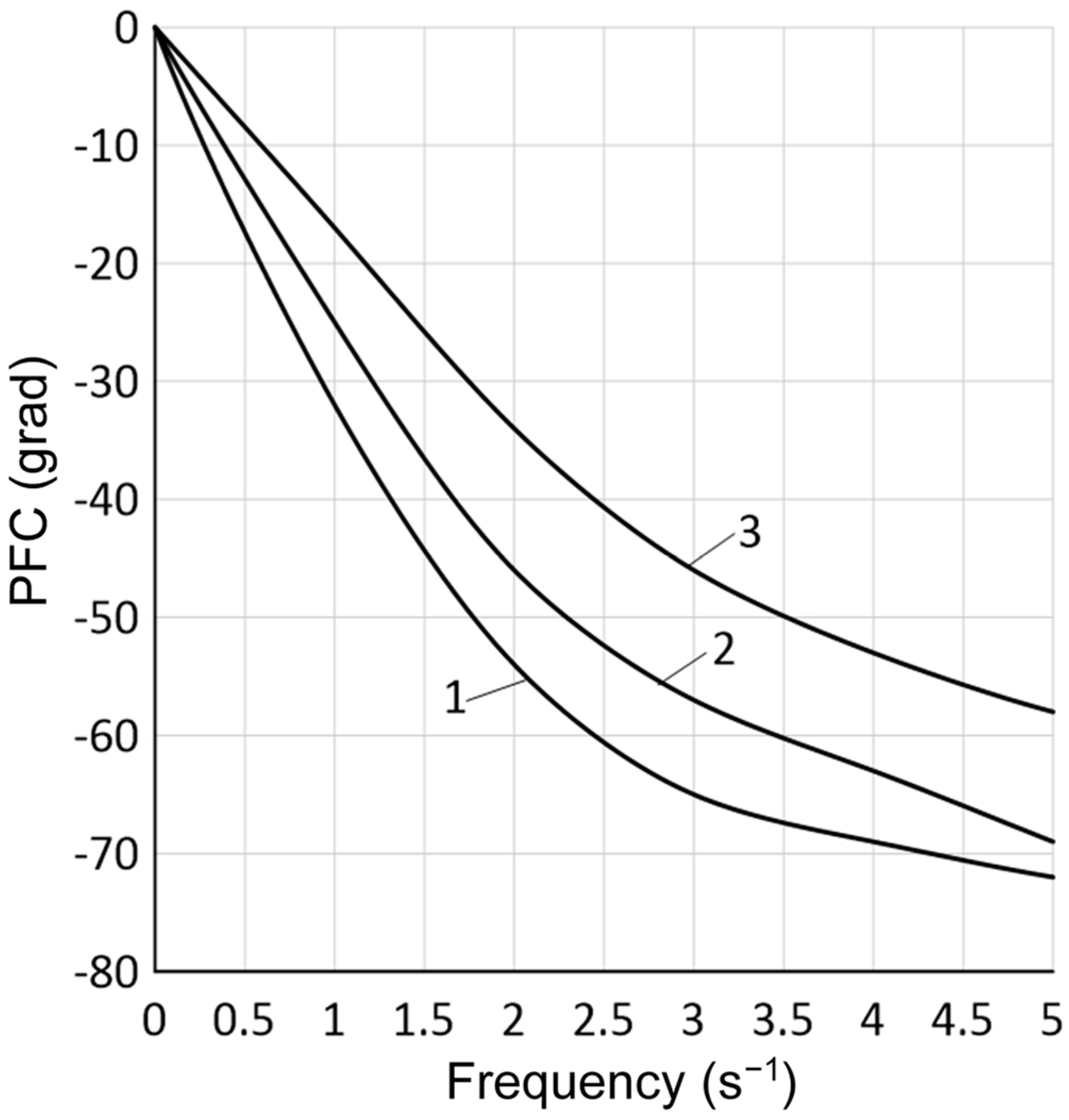

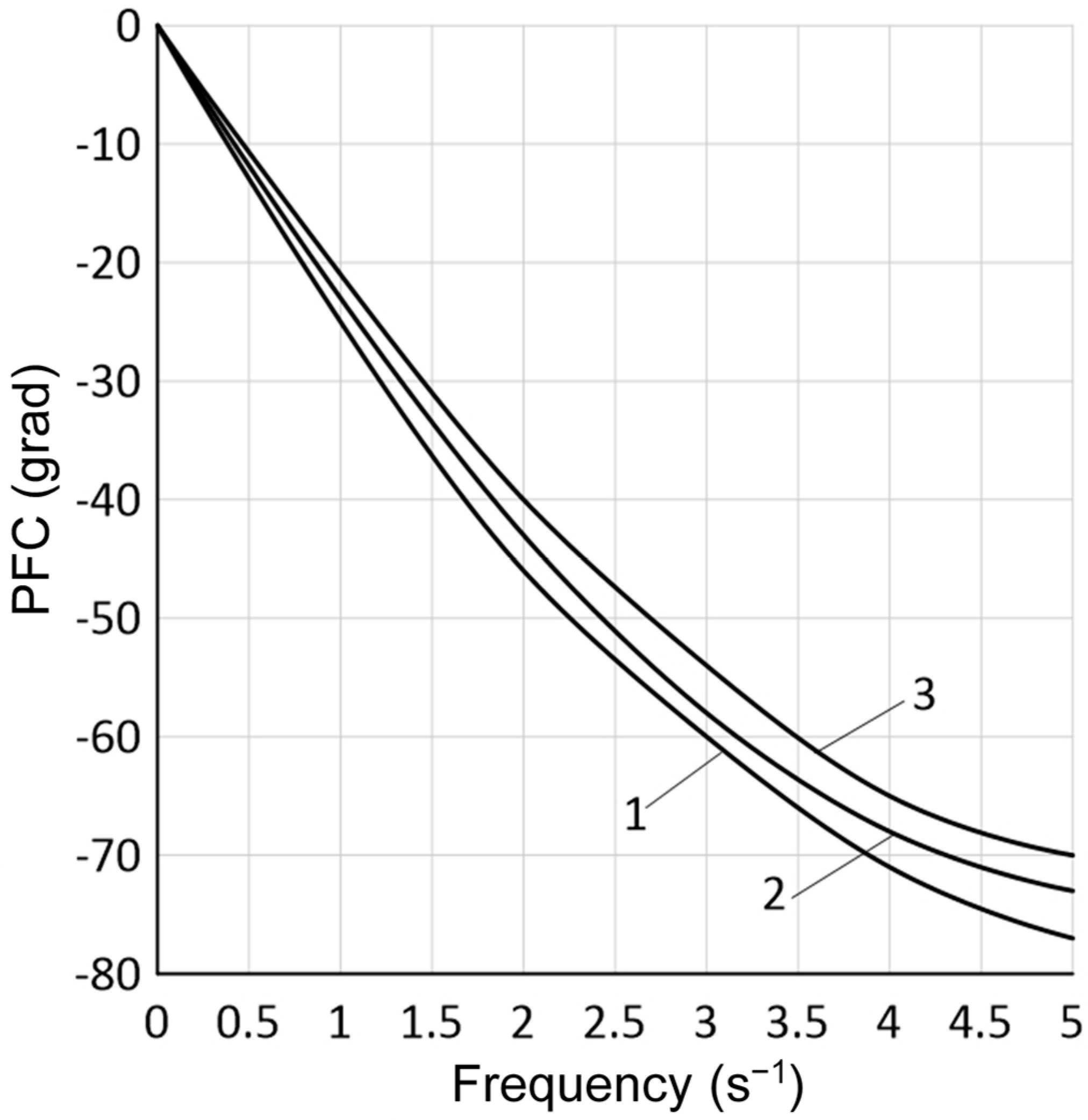

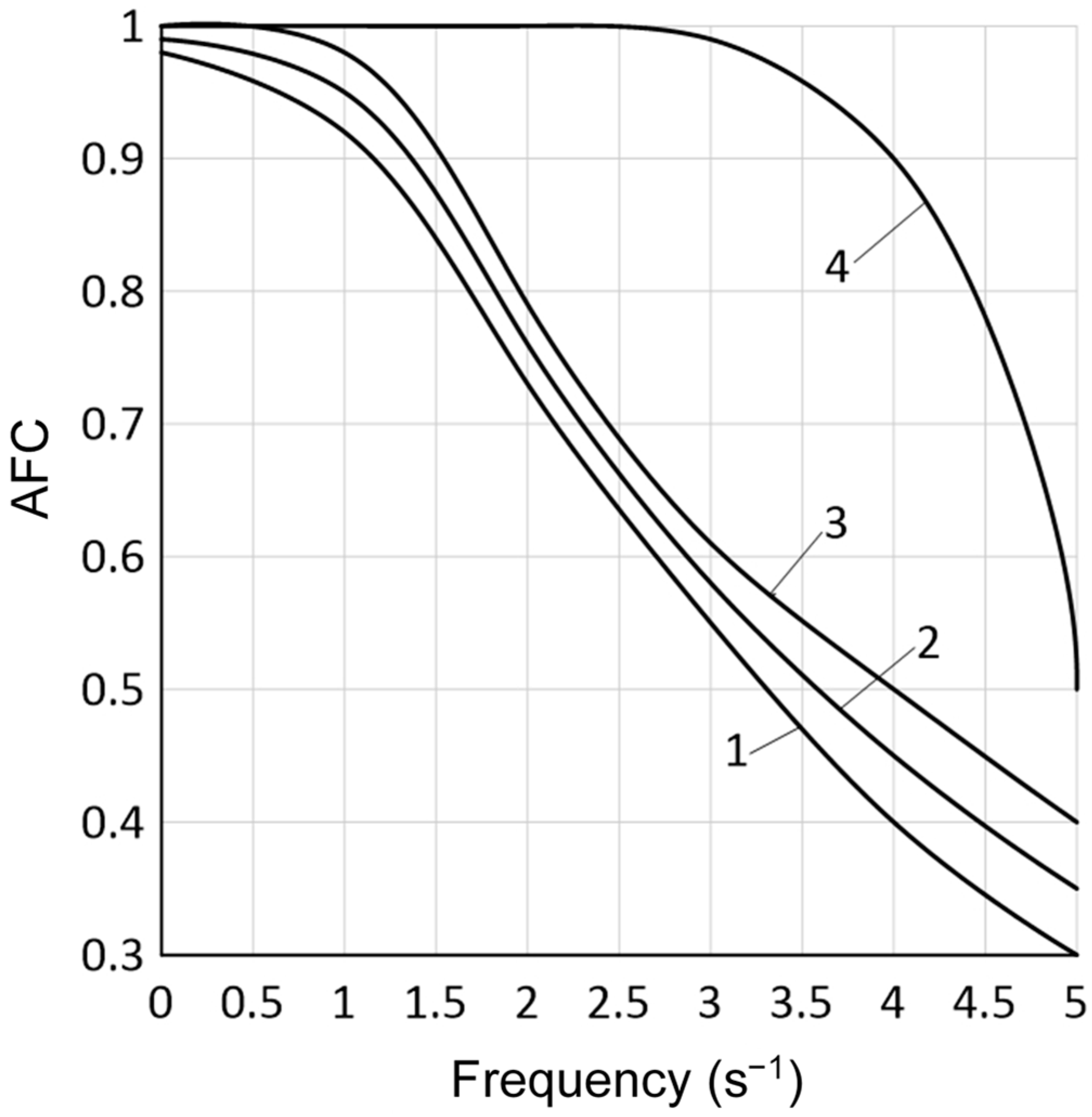

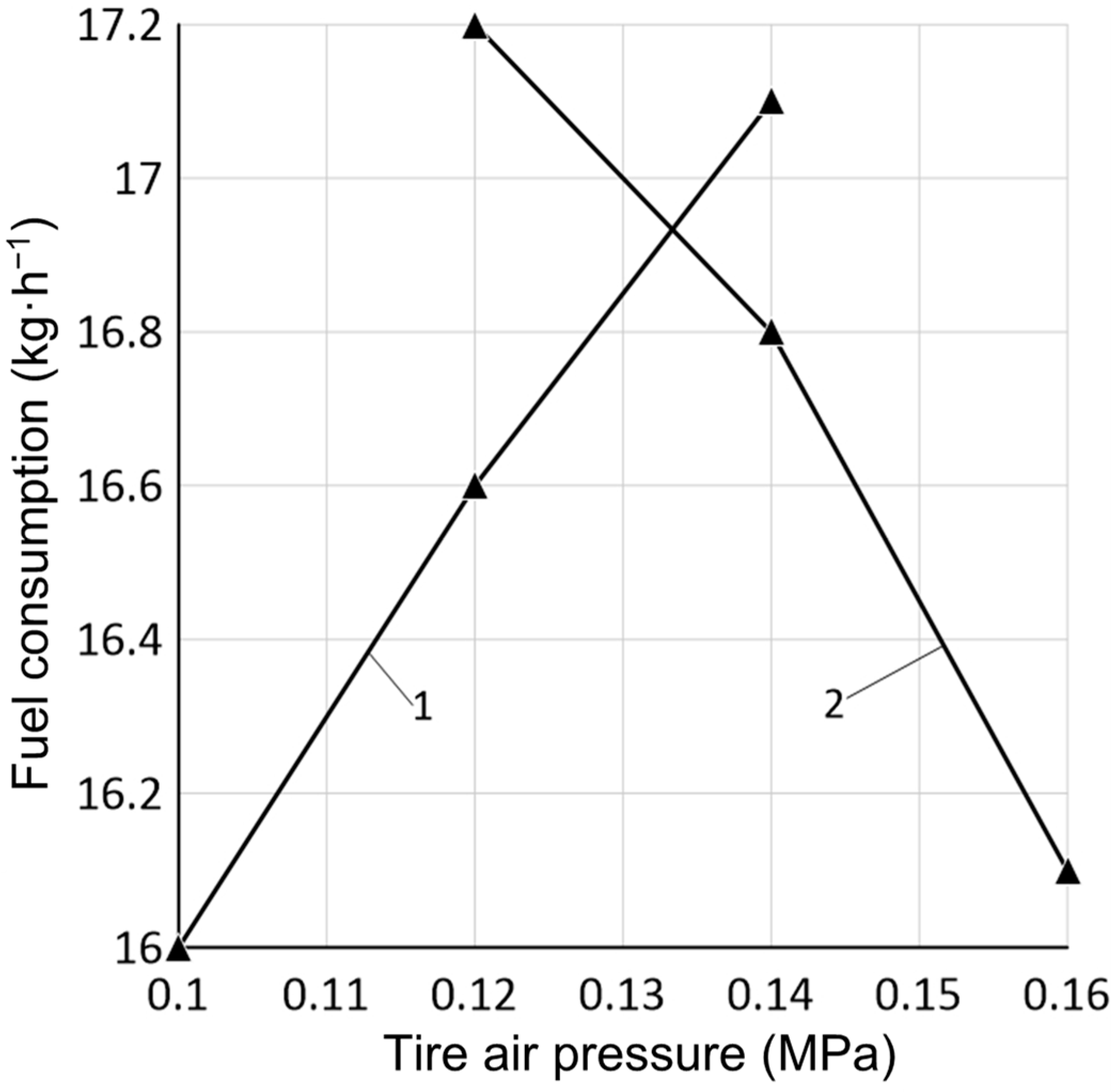

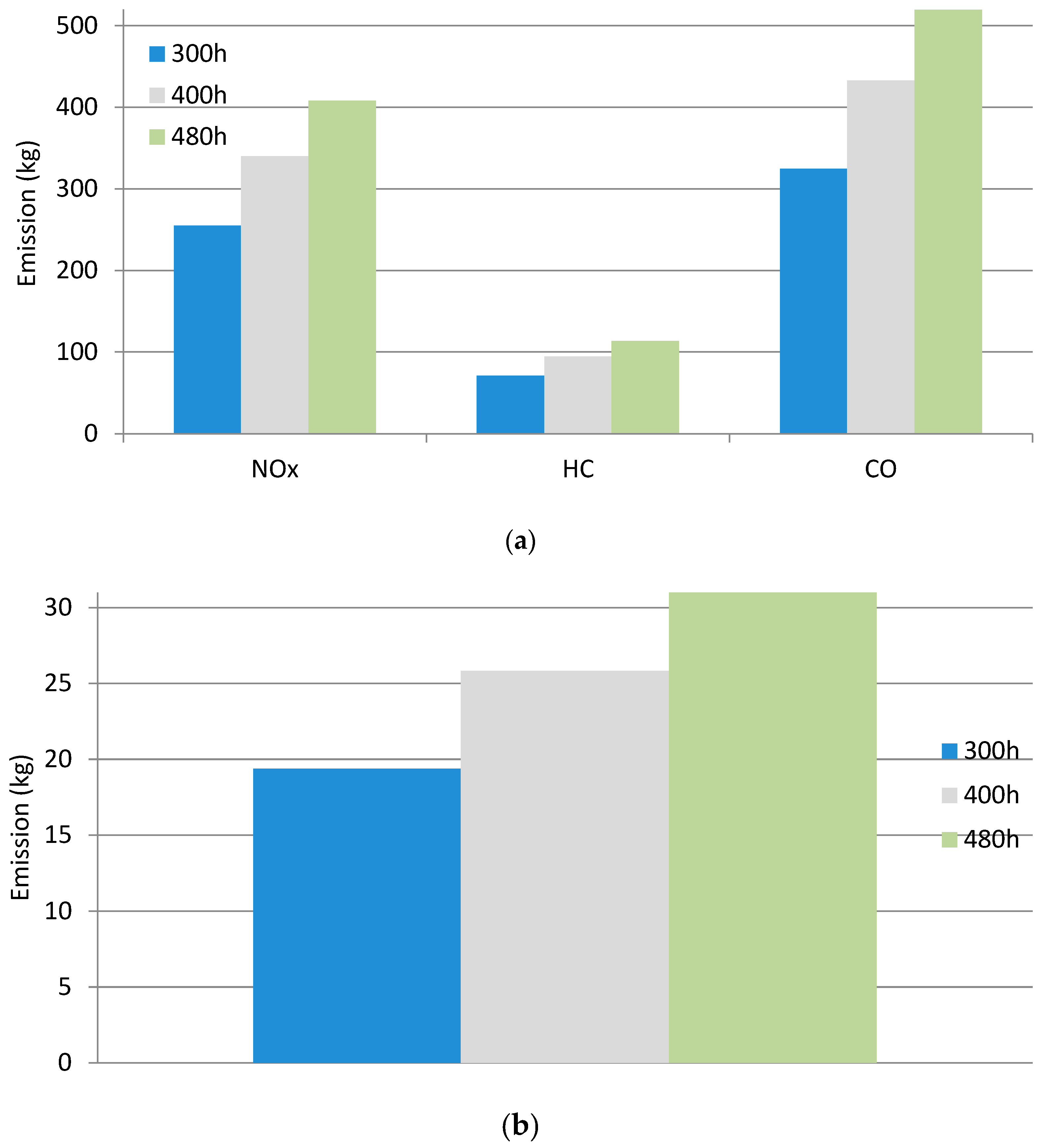

4.2. Results of Mathematical Modelling

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Santeramo, F.G.; Kang, M. Food Security Threats and Policy Responses in EU and Africa. Sustain. Horiz. 2022, 4, 100044. [Google Scholar] [CrossRef]

- Ranta, R.; Mulrooney, H. Pandemics, food (in)security, and leaving the EU: What does the COVID-19 pandemic tell us about food insecurity and Brexit. Soc. Sci. Humanit. Open 2021, 3, 100125. [Google Scholar] [CrossRef]

- Granato, D.; Zabetakis, I.; Koidis, A. Sustainability, nutrition, and scientific advances of functional foods under the new EU and global legislation initiatives. J. Funct. Foods 2023, 109, 105793. [Google Scholar] [CrossRef]

- Saboori, B.; Alhattali, N.A.; Gibreel, T. Agricultural products diversification-food security nexus in the GCC countries; introducing a new index. J. Agric. Food Res. 2023, 12, 100592. [Google Scholar] [CrossRef]

- European Parliament Resolution of 13 December 2022 on a Long-Term Vision for EU Rural Areas—Towards Stronger, Better Connected, Resilient and Prosperous Rural Areas by 2040 (2021/2254(INI)). Available online: https://www.prawo.pl/akty/dz-u-ue-c-2023-177-35,72165028.html (accessed on 26 September 2023).

- Farms and Farmland in the European Union—Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/SEPDF/cache/73319.pdf (accessed on 26 September 2023).

- New Report Highlights Biomethane Ramp-up and Best Pathways for Full Renewable Gas Deployment. Available online: https://www.europeanbiogas.eu/new-report-highlights-biomethane-ramp-up-and-best-pathways-for-full-renewable-gas-deployment/ (accessed on 26 September 2023).

- Hughes, H.M.; Koolen, S.; Kuhnert, M.; Baggs, E.M.; Maund, S.; Mullier, G.W.; Hillier, J. Towards a farmer-feasible soil health assessment that is globally applicable. J. Environ. Manag. 2023, 345, 118582. [Google Scholar] [CrossRef] [PubMed]

- Bocci, R.; Bussi, B.; Petitti, M.; Franciolini, R.; Altavilla, V.; Galluzzi, G.; Luzio, P.; Migliorini, P.; Spagnolo, S.; Floriddia, R.; et al. Yield, yield stability and farmers’ preferences of evolutionary populations of bread wheat: A dynamic solution to climate change. Eur. J. Agron. 2020, 121, 126156. [Google Scholar] [CrossRef]

- Akimowicz, M.; Corso, J.P.; Gallai, N.; Képhaliacos, C. Adopt to adapt? Farmers’ varietal innovation adoption in a context of climate change. The case of sunflower hybrids in France. J. Clean. Prod. 2021, 279, 123654. [Google Scholar] [CrossRef]

- Beitnes, S.S.; Kopainsky, B.; Potthoff, K. Climate change adaptation processes seen through a resilience lens: Norwegian farmers’ handling of the dry summer of 2018. Environ. Sci. Policy 2022, 133, 146–154. [Google Scholar] [CrossRef]

- Castellari, E.; Soregaroli, C.; Venus, T.J.; Wesseler, J. Food processor and retailer non-GMO standards in the US and EU and the driving role of regulations. Food Policy 2018, 78, 26–37. [Google Scholar] [CrossRef]

- Eriksson, D.; Custers, R.; Björnberg, K.E.; Hansson, S.O.; Purnhagen, K.; Qaim, M.; Romeis, J.; Schiemann, J.; Schleissing, S.; Tosun, J.; et al. Options to Reform the European Union Legislation on GMOs: Post-authorization and Beyond. Trends Biotechnol. 2020, 38, 465–467. [Google Scholar] [CrossRef]

- CEMA. Report. European Agricultural Machinery Industry. Available online: https://www.cema-agri.org/images/publications/brochures/CEMA_Industry_Report_2022-.pdf (accessed on 26 September 2023).

- Anastasiou, E.; Fountas, S.; Voulgaraki, M.; Psiroukis, V.; Koutsiaras, M.; Kriezi, O.; Lazarou, E.; Vatsanidou, A.; Fu, L.; Bartolo, F.; et al. Precision farming technologies for crop protection: A meta-analysis. Smart Agric. Technol. 2023, 5, 100323. [Google Scholar] [CrossRef]

- Krisnawijaya, N.N.K.; Tekinerdogan, B.; Catal, C.; Tol, R. Multi-Criteria decision analysis approach for selecting feasible data analytics platforms for precision farming. Comput. Electron. Agric. 2023, 209, 107869. [Google Scholar] [CrossRef]

- Sharma, V.; Tripathi, A.K.; Mittal, H. Technological revolutions in smart farming: Current trends, challenges & future directions. Comput. Electron. Agric. 2022, 201, 107217. [Google Scholar] [CrossRef]

- Kostencki, P.; Stawicki, T.; Królicka, A. Wear of the working parts of agricultural tools in the context of the mass of chemical elements introduced into soil during its cultivation. Int. Soil Water Conserv. Res. 2021, 9, 229–240. [Google Scholar] [CrossRef]

- Herrera, H.; Schütz, L.; Paas, W.; Reidsma, P.; Kopainsky, B. Understanding resilience of farming systems: Insights from system dynamics modelling for an arable farming system in the Netherlands. Ecol. Model. 2022, 464, 109848. [Google Scholar] [CrossRef]

- Biagini, L.; Antonioli, F.; Severini, S. The impact of CAP subsidies on the productivity of cereal farms in six European countries: A historical perspective (2008–2018). Food Policy 2023, 119, 102473. [Google Scholar] [CrossRef]

- Wu, C.; Xiao, S.; Jin, M. Comparation on rape combine harvesting and two-stage harvesting. Trans. Chin. Soc. Agric. Eng. 2014, 30, 10–16. [Google Scholar]

- Rudoy, D.; Egyan, M.; Kulikova, N.; Chigvintsev, V. Review and analysis of technologies for harvesting perennial grain crops. IOP Conf. Ser. Earth Environ. Sci. 2021, 937, 022112. [Google Scholar] [CrossRef]

- Bulgakov, V.; Nadykto, V.; Kaletnik, H.; Ivanovs, S. Field experimental investigations of performance and technological indicators of operation of swath header asymmetric machine-and-tractor aggregate. Eng. Rural Dev. 2018, 17, 227–233. Available online: https://www.tf.lbtu.lv/conference/proceedings2018/Papers/N269.pdf (accessed on 26 September 2023). [CrossRef]

- Konstantinov, K.; Gluchkov, I.; Ognev, I. Justification Optimal Operating Parameters of the Conveyor, Which Is the Mechanism of the Header for Two–Phase Harvesting by Batch Method, Taking into Account the Minimization of Losses of Grain. Available online: https://www.e3s-conferences.org/articles/e3sconf/pdf/2019/52/e3sconf_icmtmte2019_00046.pdf (accessed on 26 September 2023).

- Alfalfa Management Guide. Available online: https://www.agronomy.org/files/publications/alfalfa-management-guide.pdf (accessed on 26 September 2023).

- Bulgakov, V.; Pascuzzi, S.; Nadykto, V.; Ivanovs, S. A Mathematical Model of the Plane-Parallel Movement of an Asymmetric Machine-and-Tractor Aggregate. Agriculture 2018, 8, 151. [Google Scholar] [CrossRef]

- Bulgakov, V.; Nadykto, V.; Ivanovs, S.; Nowak, J. Research of variants to improve steerability of movement of trailed asymmetric harvesting aggregate. Eng. Rural Dev. 2019, 18, 136–143. Available online: https://www.tf.lbtu.lv/conference/proceedings2019/Papers/N169.pdf (accessed on 26 September 2023). [CrossRef]

- Shu, C.; Lei, Y.; Lei, L.; Han, C.; Jiang, Y.; Ding, Y.; Liao, Q. Pipeline Design and Simulation Optimization of Hydraulic Driving System for Rape Windrower. J. Syst. Simul. 2015, 27, 3087–3095. [Google Scholar]

- Foster, A.A.; Strosser, R.P.; Peters, J.; Sun, J.-Q. Automatic velocity control of a self-propelled windrower. Comput. Electron. Agric. 2005, 47, 41–58. [Google Scholar] [CrossRef]

- Gesce, D.M. New windrower series added to Hesston lineup. Diesel Prog. N. Am. Ed. 2004, 70, 76–77. [Google Scholar]

- Li, J.; Zhao, J.; Liu, S.; Hou, X.; Chen, X.; Zhang, X. Design and Experiment of Self-propelled Pea Windrower. Trans. Chin. Soc. Agric. Mach. 2021, 52, 107–116. [Google Scholar]

- Jin, M.; Zhang, M.; Wang, G.; Liang, S.; Wu, C.; He, R. Analysis and Simulation of Wheel-Track High Clearance Chassis of Rape Windrower. Agriculture 2022, 12, 1150. [Google Scholar] [CrossRef]

- Shinners, T.J.; Digman, M.F.; Panuska, J.C. Overlap loss of manually and automatically guided mowers. Appl. Eng. Agric. 2012, 28, 5–8. [Google Scholar] [CrossRef]

- Roper, M.M.; Ward, P.R.; Keulen, A.F.; Hill, J.R. Under no-tillage and stubble retention, soil water content and crop growth are poorly related to soil water repellency. Soil Tillage Res. 2013, 126, 143–150. [Google Scholar] [CrossRef]

- Konstantinov, M.; Glushkov, I.; Mukhamedov, V.; Lovchikov, A. Increase in Soil Moisture Reserves due to the Formation of High Stubble Residues for the Accumulation of Snow Precipitation. Available online: https://iopscience.iop.org/article/10.1088/1755-1315/666/5/052049/pdf (accessed on 26 September 2023).

- Tsibulka, N.N.; Youkhnovets, A.V.; Tzhukova, I.I. Influence of Mechanical Processing Methods and Techniques on the Soil Dynamics Moisture. Bull. MDU Named After A.A. Kulyashova 2005, 1, 111–119. Available online: https://libr.msu.by/bitstream/123456789/14389/1/5414n.pdf (accessed on 26 September 2023).

- Nosalewicz, A.; Kuś, J.; Lipiec, J. Effect of tillage methods on soil penetration resistance. Acta Agrophysica 2009, 14, 675–682. [Google Scholar]

- Pabin, J. Cultivation of the Role and Physical Properties of the Soil and the Yielding of Plants. Available online: https://iung.pl/sir/zeszyt08_13.pdf (accessed on 10 July 2024).

- Buliński, J.; Sergiel, L. Soil considerations in cultivation of plants. Ann. Wars. Univ. Life Sci.-SGGW Agric. 2013, 61, 5–15. [Google Scholar]

- Magnuszewski, A.; Soczyńska, U. International Hydrological Dictionary, 1st ed.; Wydawnictwo Naukowe PWN (Państwowe Wydawnictwo Naukowe): Warszawa, Poland, 2001; pp. 1–250. [Google Scholar]

- Pabin, J.; Włodek, S.; Biskupski, A. Water Content in Different Agrosystems. Ecol. Chem. Eng. 2003, 10, 319–325. [Google Scholar]

- Gąsior, J.; Kaniuczek, J.; Hajduk, E.; Właśniewski, S.; Nazarkiewicz, M.; Bilek, M. Methods of studying the physical properties of soils. Acta Carpathica 2013, 6, 43–50. [Google Scholar]

- Maslov, G.; Remizov, I.; Semyakov, G.; Karakai, I. Harvesting and soil-cultivating unit based on the TORUM combine. Mach. Equip. Village 2010, 2, 18–19. [Google Scholar]

- Average Area of Agricultural Land on the Holding in 2023. Available online: https://www.gov.pl/web/arimr/srednia-powierzchnia-gruntow-rolnych-w-gospodarstwie-w-2023-roku (accessed on 26 September 2023).

- 2014–2020 Rural Development Programme for Poland. Available online: https://ec.europa.eu/commission/presscorner/detail/en/MEMO_14_2621 (accessed on 26 September 2023).

- ACI EUROPE Environmental Strategy Committee. Ultrafine Particles at Airports. Discussion and Assessment of Ultrafine Particles (UFP) in Aviation and at Airports in 2012. Available online: https://www.cph.dk/48da29/globalassets/8.-om-cph/stoj-trafik-og-miljo/rapporter/7_ultrafine-particles-at-airports-aci.pdf (accessed on 26 September 2023).

- World Health Statistics 2016: Monitoring Health for the SDGs, Sustainable Development Goals. Available online: https://www.who.int/publications/i/item/9789241565264 (accessed on 26 September 2023).

- 1st Meeting of the Commission Expert Group on Inland Waterway Transport (Naiades II Implementation Group). Available online: https://ec.europa.eu/transparency/expert-groups-register/screen/meetings/consult?lang=en&meetingId=1555&fromExpertGroups=true (accessed on 26 September 2023).

- European Union Emission Inventory Report 1990–2016. Available online: https://www.eea.europa.eu/publications/european-union-emission-inventory-report-1990-2016 (accessed on 26 September 2023).

- Air Quality in Europe—2018 Report. Available online: https://www.eea.europa.eu/publications/air-quality-in-europe-2018 (accessed on 26 September 2023).

- One Logo Missing in the Move Louisville Consultation. Available online: https://badwaterjournal.com/Bad_Water_Journal/Transportation_policy.html (accessed on 26 September 2023).

- Shepel, O.; Matijošius, J.; Rimkus, A.; Orynycz, O.; Tucki, K.; Świć, A. Combustion, Ecological, and Energetic Indicators for Mixtures of Hydrotreated Vegetable Oil (HVO) with Duck Fat Applied as Fuel in a Compression Ignition Engine. Energies 2022, 15, 7892. [Google Scholar] [CrossRef]

- Rules for the Selection of Agricultural Machinery under the RDP for the Years 2014–2020. Available online: https://jakiciagnik.pl/zasady-doboru-maszyn.html (accessed on 26 September 2023).

- Popovich, M.G.; Kovalchuk, O.V. Automatic Control Theory, 2nd ed.; Lybid: Moscow, Russia, 2007; 656p. [Google Scholar]

- Bulgakov, V.; Pascuzzi, S.; Nadykto, V.; Ivanovs, S.; Adamchuk, V. Experimental study of the implement-and-tractor aggregate used for laying tracks of permanent traffic lanes inside controlled traffic farming systems. Soil Tillage Res. 2021, 208, 104895. [Google Scholar] [CrossRef]

- Xie, L.; Claar, P. Simulation of Agricultural Tractor-Trailer System Stability. SAE Tech. Paper 1985, 1, 851530. [Google Scholar] [CrossRef]

- EMEP/EEA Air Pollutant Emission Inventory Guidebook. 2023. Available online: https://www.eea.europa.eu/publications/emep-eea-guidebook-2023 (accessed on 26 September 2023).

- IFEU(2004) Energy Savings by Light-Weighting. Available online: https://recycling.world-aluminium.org/uploads/media/1274789777IFEU2004_Energy_savings_by_light-weighting_-_II_04.pdf (accessed on 26 September 2023).

- Regulation of the Minister of Economy of October 9, 2015 on Quality Requirements for Liquid Fuels. Available online: https://sip.lex.pl/akty-prawne/dzu-dziennik-ustaw/metody-badania-jakosci-paliw-cieklych-17610160 (accessed on 26 September 2023).

- Petroleum and Related Products from Natural or Synthetic Sources—Determination of Distillation Characteristics at Atmospheric Pressure (ISO 3405:2019). Available online: https://standards.iteh.ai/catalog/standards/cen/7dbab39f-a7eb-4b15-a659-6d3ce48e12ce/en-iso-3405-2019 (accessed on 26 September 2023).

- Petroleum Products—Transparent and Opaque Liquids—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity (PN-EN ISO 3104:2024-01). Available online: https://shop.standards.ie/en-ie/standards/pn-en-iso-3104-2024-01-954486_saig_pkn_pkn_3365272/ (accessed on 26 September 2023).

- Petroleum Products—Determination of Sulfur Content in Automotive Fuels—X-ray Fluorescence Spectrometry with Wave Dispersion (PN-EN ISO 20884:2020-03). Available online: https://shop.standards.ie/en-ie/standards/pn-en-iso-20884-2020-03-939725_saig_pkn_pkn_2821927/ (accessed on 26 September 2023).

- Petroleum Products—Determination of Ash (PN EN ISO 6245:2008). Available online: https://shop.standards.ie/en-ie/standards/pn-en-iso-6245-2008-923841_saig_pkn_pkn_2180679/ (accessed on 26 September 2023).

- Petroleum Products—Determination of Carbon Residue—Micro Method (ISO 10370:2014). Available online: https://shop.standards.ie/en-ie/standards/iso-10370-2014-588255_saig_iso_iso_1347425/ (accessed on 26 September 2023).

- Crude Petroleum and Petroleum Products—Determination of Density—Oscillating U-Tube Method (PN EN ISO 12185:2002). Available online: https://shop.standards.ie/en-ie/standards/pn-en-iso-12185-2002-922700_saig_pkn_pkn_2178397/ (accessed on 26 September 2023).

- Crude Petroleum and Liquid Petroleum Products—Laboratory Determination of Density—Hydrometer Method (PN EN ISO 3675:2004). Available online: https://shop.standards.ie/en-ie/standards/pn-en-iso-3675-2004-955315_saig_pkn_pkn_2243627/ (accessed on 26 September 2023).

- Determination of the Ignition Temperature—Method of a Closed Pensky-Martens Crucible (PN EN ISO 2719:2016). Available online: https://shop.standards.ie/en-ie/standards/pn-en-iso-2719-2016-953837_saig_pkn_pkn_2240671/ (accessed on 26 September 2023).

- Petroleum Products—Determination of Water—Coulometric Karl Fischer Titration Method (PN EN ISO 12937:2005). Available online: https://shop.standards.ie/en-ie/standards/pn-en-iso-12937-2005-923774_saig_pkn_pkn_2180545/ (accessed on 26 September 2023).

- VERVA ON—Premium Fuel (Only in the ORLEN Network). Available online: https://www.orlen.pl/pl/dla-biznesu/produkty/paliwa/oleje-napedowe/verva-on (accessed on 26 September 2023).

- Dybich, K. Principle of the method of marking the cetane number of motor fuel samples at the test site with the Dresser Waukesha CFR engine (USA). Nafta-Gas 2013, 1, 84–87. [Google Scholar]

| Index | Value |

|---|---|

| Soil moisture in 0–10 cm layer (%) | 14.2 |

| Soil bulk density in the 0–10 cm (g·m−3) layer | 1.26 |

| Winter wheat yield (ton·ha−1) | 4.08 |

| Mean plant height (m) | 0.68 |

| Weed density (g·m−2) | 16.8 |

| Wheat stubble height (cm) | 14.8 |

| Stubble disc depth (cm) | 8.6 |

| No. | pa | pb | Measurement |

|---|---|---|---|

| 1 | 1 | 1 | 17.3 |

| 2 | 1 | 2 | 17.1 |

| 3 | 2 | 1 | 16.05 |

| 4 | 2 | 2 | 16.8 |

| Tested Object (BF6M1013E) | Parameter |

|---|---|

| Stroke (travel) volume [dm3] | 7.2 |

| Number and arrangement of cylinders [–] | 6, inline |

| Maximum power [kW] | 137 at 2300 rpm |

| Maximum torque [Nm] | 720 at 1400 rpm |

| Exhaust gas treatment systems | DOC |

| Homologation standard | Stage II |

| Stage II | Engine Size [kW] | CO [g/kWh] | VOC [g/kWh] | NOx [g/kWh] | VOC + NOx [g/kWh] | PM [g/kWh] | Tractors | |

|---|---|---|---|---|---|---|---|---|

| EU Directive | Implement. Date | |||||||

| E | 3.5 | 1 | 6 | - | 0.2 | 2000/25 | 1/7 2002 | |

| Fuel | NFR Sector | Pollutant | Units | Technology Stage II |

|---|---|---|---|---|

| Diesel | Agriculture | BC | g/ton fuel | 482 |

| CH4 | g/ton fuel | 29 | ||

| CO | g/ton fuel | 6104 | ||

| CO2 | g/ton fuel | 3160 | ||

| N2O | g/ton fuel | 138 | ||

| NH3 | g/ton fuel | 8 | ||

| NMVOC | g/ton fuel | 1181 | ||

| NOx | g/ton fuel | 20,612 | ||

| PM10 | g/ton fuel | 624 | ||

| PM2.5 | g/ton fuel | 624 | ||

| TSP | g/ton fuel | 624 |

| Engine Power (kW) | Technology Level | NOx | VOC | CH4 | CO | N2O | NH3 | PM | PM10 | PM2.5 | BC | FC |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stage II | 5.2 | 0.3 | 0.007 | 1.5 | 0.035 | 0.002 | 0.1 | 0.1 | 0.1 | 0.07 | 250 | |

| Stage V | 0.4 | 0.13 | 0.003 | 1.5 | 0.035 | 0.002 | 0.015 | 0.015 | 0.015 | 0.002 | 250 |

| Emission Level | NOx | VOC | CO | TSP |

|---|---|---|---|---|

| Stage II | 0.009 | 0.034 | 0.101 | 0.473 |

| Stage IIIA, IIIB, IV, V | 0.008 | 0.027 | 0.151 | 0.473 |

| Technology Level | Load | Load Factor | NOx | VOC | CO | TSP | FC |

|---|---|---|---|---|---|---|---|

| Stage II and prior | High | >0.45 | 0.95 | 1.05 | 1.53 | 1.23 | 1.01 |

| Middle | 0.25 ≤ LF < 0.45 | 1.025 | 1.67 | 2.05 | 1.6 | 1.095 | |

| Low | <0.25 | 1.1 | 2.29 | 2.57 | 1.97 | 1.18 |

| Indicator Name | Value for GOST 305-82, Class L |

|---|---|

| Cetane number not less than: | 45 |

| Factional composition: Up to 50% is distilled at a temperature of °C, not higher than: A total of 95% is distilled at a temperature of °C, not higher than: | 280 360 |

| Kinematic viscosity at 20° (mm2/s): | 3.0–6.0 |

| Mass fraction of sulphur, %, not more than: Type I Type II | 0.2 0.05 |

| The actual soot concentration in mg per 100 cm3 of fuel, not more than: | 40 |

| mg KOH per 100 cm3 of fuel, not more than: | 5 |

| Iodine number, g of iodine per 100 g of fuel, not more than: | 6 |

| Residue after incineration [%], not more than: | 0.01 |

| Degree of coking, 10% residue, %, not more than: | 0.20 |

| Filterability factor, not more than: | 3 |

| Density at 20 °C, kg/m3, not more than: | 860 |

| Ignition point [°C]: | 56 |

| Water content: | No data available |

| Indicator Name | Verva-on Premium (Class B0) | GOST 305-82 (Class L) |

|---|---|---|

| Cetane number not less than: | 52.6 (test method PN-EN ISO 5165) | 51 (test method PN-EN ISO 5165) |

| Factional composition: Up to 65% is distilled at a temperature of °C, not higher than: minimum 5% to a temperature of °C: 95% is distilled to a temperature of °C: | 250 350 (test method PN-EN ISO 3405) Max. 360 | 250 350 (test method PN-EN ISO 3405) Max. 360 |

| Kinematic viscosity at 40° (mm2/s): | 2.0–4.5 (test method PN-EN ISO 3104) | 2.15 (test method PN-EN ISO 3104) |

| Sulphur content [mg/kg]: | Max. 10 (test method as per PN-EN ISO 20846, PN-EN ISO 20884) | 8.8 (test method as per PN-EN ISO 20846, PN-EN ISO 20884) |

| Residue after incineration [%], not more than: | 0.01 (test method PN-EN ISO 6245) | 0.01 (test method PN-EN ISO 6245) |

| Residue after coking in 10% of the distilled residue: | 0.30 (test method PN-EN ISO 10370) | 0.27 (test method PN-EN ISO 10370) |

| Density at 15 °C, kg/m3: | 820–845 (test method as per PN-EN ISO 12185, PN-EN ISO 3675) | 833.6 (test method as per PN-EN ISO 12185, PN-EN ISO 3675) |

| Ignition temperature [°C]: | Minimum 56 (test method PN-EN ISO 2719) | 61 (test method PN-EN ISO 2719) |

| Water content mg/kg/%: | Max. 200/0.02 (test method PN-EN ISO 12937) | 22 (test method PN-EN ISO 12937) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orynycz, O.; Nadykto, V.; Kyurchev, V.; Tucki, K.; Kulesza, E. Transformation towards a Low-Emission and Energy-Efficient Economy Realized in Agriculture through the Increase in Controllability of the Movement of Units Mowing Crops While Simultaneously Discing Their Stubble. Energies 2024, 17, 3467. https://doi.org/10.3390/en17143467

Orynycz O, Nadykto V, Kyurchev V, Tucki K, Kulesza E. Transformation towards a Low-Emission and Energy-Efficient Economy Realized in Agriculture through the Increase in Controllability of the Movement of Units Mowing Crops While Simultaneously Discing Their Stubble. Energies. 2024; 17(14):3467. https://doi.org/10.3390/en17143467

Chicago/Turabian StyleOrynycz, Olga, Volodymyr Nadykto, Volodymyr Kyurchev, Karol Tucki, and Ewa Kulesza. 2024. "Transformation towards a Low-Emission and Energy-Efficient Economy Realized in Agriculture through the Increase in Controllability of the Movement of Units Mowing Crops While Simultaneously Discing Their Stubble" Energies 17, no. 14: 3467. https://doi.org/10.3390/en17143467