Gas Free Dissipation Characteristics Analysis and Safety Repair Time Determination of Buried Pipeline Leakage Based on CFD

Abstract

1. Introduction

2. Research Methods

2.1. Physical Model

2.2. Mathematical Model

2.2.1. Flow Governing Equation

- (1)

- Continuity equation

- (2)

- Equation of motion

- (3)

- Component transport equation

- (4)

- PVT equation

2.2.2. Turbulence Equation

2.3. Boundary Conditions

- (1)

- Stable operation stage: The phase before the leakage of the underground gas pipeline, during which the pipeline is filled with natural gas at the operating pressure of the pipeline. The soil porous medium pores are filled with air at atmospheric pressure. This stage serves as the initial condition for the gas leakage diffusion stage.

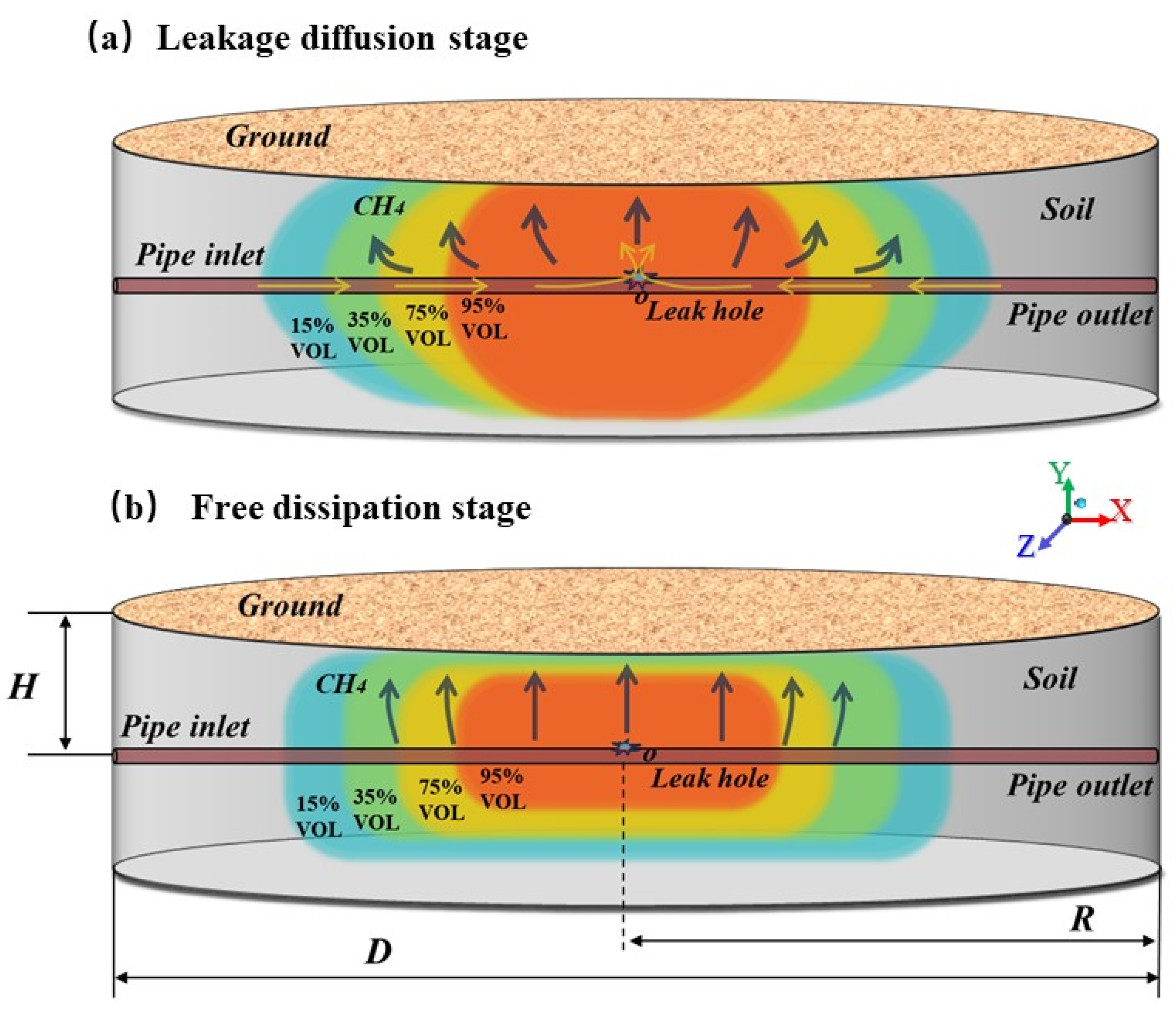

- (2)

- Leakage diffusion stage: After the undetected leakage of the underground gas pipeline in a timely manner, the natural gas on the inlet side of the pipeline will continue to be supplied, and the natural gas will continue to spray into the soil from the leakage port. At this point, the entrance of pressure is set as the underground pipeline inlet, while its exit is designated as the pipeline outlet, and the leakage outlet is at the interior boundary. This stage is the initial condition for the free dissipation of gas.

- (3)

- Free dissipation stage: Upon discovery of the leakage in the underground gas pipeline, the upstream valve of the pipeline is closed, halting the supply of natural gas. At this point, there is a leakage of residual subterranean natural gas inside the pipeline, and the free dissipation process of residual natural gas into the soil and the pipeline inlet is specified as the wall boundary.

2.4. Simulation Scenarios

2.5. Grid Generation

2.6. Numerical Method

3. Results and Discussion

3.1. Grid Independence

3.2. Validation of Numerical Model

3.3. Analysis of the Characteristics of Free Dissipation Stage of Natural Gas in Soil

3.3.1. Concentration Distribution during the Gas Leakage Diffusion Stage

3.3.2. Pressure Distribution during the Free Dissipation Stage of Natural Gas

3.3.3. Velocity Distribution during the Gas Free Dissipation Stage

3.3.4. Streamline Distribution during the Gas Free Dissipation Stage

3.3.5. Concentration Distribution during the Free Dissipation Stage of Natural Gas

3.4. Analysis of Influencing Factors during the Free Dissipation Stage of Natural Gas

3.4.1. Leakage Time

3.4.2. Pipeline Operating Pressure

3.4.3. Leakage Diameter

3.4.4. Pipeline Burial Depth

3.4.5. Leakage Direction

3.4.6. Soil Type

3.5. Determination of Safety Repair Time for Buried Gas Pipeline Leakage Accidents

3.5.1. Natural Gas Concentration Prediction Model

3.5.2. Calculation Model for Safety Repair Time of Buried Gas Pipeline Leakage Accidents

4. Conclusions

- (1)

- After the gas supply valve is closed, the residual natural gas in the buried pipeline and soil begins to enter the free dissipation stage, and the internal pressure of the pipeline drops sharply, basically dropping to atmospheric pressure within one minute. Compared to the gas leakage diffusion stage, the velocity and pressure distribution in the pipeline and soil are significantly reduced due to the cessation of gas supply at the gas supply end during the free dissipation stage; the pressure in the tube dropped from 300,000 to 0 Pa within one minute of the leak. Meanwhile, during the preliminary phase of free dissipation, natural gas with lower density continues to rapidly spread to the surrounding areas. There is a lack of natural gas supply in the rear and the surrounding air enters slowly, forming a negative pressure zone in the soil near the leakage port; with the increase in leakage time, the negative pressure area near the pipeline increases from −50 to −25 Pa.

- (2)

- Unlike the diffusion stage of leakage, the gas free dissipation stage after closing the supply end valve of a buried gas pipeline leakage is a very slow process, and the concentration of gas inside the pipeline remains basically unchanged. The natural gas concentration on the monitoring line for 60 min of free dissipation within the research scope is still mostly above the lower explosive limit. In contrast, the concentration of natural gas at the ground surface decreases at a faster rate.

- (3)

- The increase in leakage time, pressure, diameter, and pipeline burial depth leads to a large accumulation of gas in the soil, which increases the spatial distribution range and concentration of gas on the same free dissipation time monitoring line. In the initial stage of free dissipation, with the extension of time, the hazard spatial distribution range of natural gas at the lower explosive limit of 5% VOL of methane at the monitoring line increases.

- (4)

- Based on various factors influencing the gas concentration above the monitoring line, we have developed a predictive model for forecasting the gas concentration during the free dissipation stage after closing the gas supply end valve. Furthermore, a calculation model for the safety repair time of buried gas pipeline leakage accidents was derived, which can determine the safety repair time of accidents under corresponding leakage conditions.

- (5)

- The free dissipation process of natural gas in soil has a slow concentration reduction rate, which prolongs the safety repair time of pipelines and is not conducive to the rapid repair of buried gas pipeline leakage accidents. To shorten the security repair time, a method of layer-by-layer excavation and layer-by-layer dissipation can be adopted. By excavating the upper layer of soil with low natural gas concentration, we can achieve the rapid diffusion of natural gas between the lower soil and the air, thereby shortening the time required for safety repairs.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Porosity | |

| Density (kg/m3) | |

| Time (s) | |

| Displacement (m) | |

| Velocity (m/s) | |

| Absolute pressure (Pa) | |

| Stress tensor (Pa) | |

| Gravitational acceleration (m/s2) | |

| Viscosity (kg/ms) | |

| Permeability (m2) | |

| Viscous resistance coefficient (1/m2) | |

| Inertial resistance coefficient (1/m) | |

| Particle diameter mean (mm) | |

| Mass fraction of component (%) | |

| Diffusion coefficient (m2/s) | |

| Specific volume (m3/kg) | |

| Gas constant (J/kgK) | |

| Temperature (K) | |

| Turbulence kinetic energy (J/kg) | |

| Turbulence dissipation rate (J/kgs) | |

| Turbulent viscosity | |

| Turbulence kinetic energy generation due to the mean velocity gradient | |

| Turbulence kinetic energy generation due to buoyancy | |

| Effect of fluctuating expansion on total dissipation rate in compressible turbulence | |

| Source term for turbulent kinetic energy | |

| Prandtl number corresponding to turbulent kinetic energy | |

| Prandtl number corresponding to turbulent dissipation rate | |

| Empirical constant | |

| Empirical constant |

References

- Li, J.F.; Ye, J.L.; Qin, X.W.; Qiu, H.J.; Wu, N.Y.; Lu, H.L.; Xie, W.W.; Lu, J.A.; Peng, F.; Xu, Z.Q.; et al. The first offshore natural gas hydrate production test in South China Sea. China Geol. 2018, 1, 5–16. [Google Scholar] [CrossRef]

- Ye, J.L.; Qin, X.W.; Xie, W.W.; Lu, H.L.; Ma, B.J.; Qiu, H.J.; Liang, J.Q.; Lu, J.A.; Kuang, Z.G.; Lu, C.; et al. The second natural gas hydrate production test in the South China Sea. China Geol. 2020, 3, 197–209. [Google Scholar] [CrossRef]

- Li, N.; Wang, J.L.; Liu, R.; Tang, X. Multi-scenario conception on the development of natural gas industry under the goal of carbon neutrality. Nat. Gas Ind. 2021, 41, 183–192. [Google Scholar]

- Bu, F.X.; Liu, Y.; Chen, S.Q.; Wu, J.; Guan, B.; Zhang, N.; Lin, X.Q.; Liu, L.; Cheng, T.C.; Shi, Z.C.; et al. Real scenario analysis of buried natural gas pipeline leakage based on soil-atmosphere coupling. Int. J. Press. Vessel. Pip. 2022, 199, 104713. [Google Scholar]

- Guo, Y.B.; Liu, C.C.; Wang, D.G.; He, R.Y. Numerical study and safety spacing of buried parallel gas pipelines: A study based on TNT equivalent method. Int. J. Press. Vessel. Pip. 2018, 168, 246–257. [Google Scholar] [CrossRef]

- Li, S.Y.; Wen, Y.M.; Li, P.; Yang, J.; Dong, X.X.; Mu, Y.H. Leak location in gas pipelines using cross-time-frequency spectrum of leakage-induced acoustic vibrations. J. Sound Vib. 2014, 333, 3889–3903. [Google Scholar] [CrossRef]

- Jo, Y.D.; Ahn, B.J. A method of quantitative risk assessment for transmission pipeline carrying natural gas. J. Hazard. Mater. 2005, 123, 1–12. [Google Scholar] [CrossRef]

- Ramírez-Camacho, J.G.; Carbone, F.; Pastor, E.; Bubbico, R.; Casal, J. Assessing the consequences of pipeline accidents to support land-use planning. Saf. Sci. 2017, 97, 34–42. [Google Scholar] [CrossRef]

- Han, Z.; Weng, W. Comparison study on qualitative and quantitative risk assessment methods for urban natural gas pipeline network. J. Hazard. Mater. 2011, 189, 509–518. [Google Scholar] [CrossRef]

- Wang, K.; Shi, T.T.; He, Y.R.; Li, M.Z.; Qian, X.M. Case analysis and CFD numerical study on gas explosion and damage processing caused by aging urban subsurface pipeline failures. Eng. Fail. Anal. 2019, 97, 201–219. [Google Scholar] [CrossRef]

- Liu, C.W.; Wang, Y.Z.; Li, X.H.; Li, Y.X.; Khan, F.; Cai, B.P. Quantitative assessment of leakage orifices within gas pipelines using a Bayesian network. Reliab. Eng. Syst. Safe 2021, 209, 107438. [Google Scholar] [CrossRef]

- Ma, L.; Cheng, L.; Li, M. Quantitative risk analysis of urban natural gas pipeline networks using geographical information systems. J. Loss Prev. Process Ind. 2013, 26, 1183–1192. [Google Scholar] [CrossRef]

- Olvera, H.A.; Choudhuri, A.R. Numerical simulation of hydrogen dispersion in the vicinity of a cubical building in stable stratified atmospheres. Int. J. Hydrog. Energy 2006, 31, 2356–2369. [Google Scholar] [CrossRef]

- Barros, P.L.; Luiz, A.M.; Nascimento, C.A.; Neto, A.T.P.; Alves, J.J.N. On the non-monotonic wind influence on flammable gas cloud from CFD simulations for hazardous area classification. J. Loss Prev. Process Ind. 2020, 68, 104278. [Google Scholar] [CrossRef]

- Mishra, K.B. CFD model for large hazardous dense cloud spread predictions, with particular reference to Bhopal disaster. Atmos. Environ. 2015, 117, 74–91. [Google Scholar] [CrossRef]

- Dasgotra, A.; Teja, V.G.; Sharma, A.; Mishra, K. CFD modeling of large-scale flammable cloud dispersion using FLACS. J. Loss Prev. Process Ind. 2018, 56, 531–536. [Google Scholar] [CrossRef]

- Agarwal, A.; Molwane, O.B.; Pitso, I. Analytical investigation of the influence of natural gas leakage & safety zone in a pipeline flow. Mater. Today Proc. 2021, 39, 547–552. [Google Scholar]

- Lu, H.F.; Huang, K.; Fu, L.D.; Zhang, Z.H.; Wu, S.J.; Lyu, Y.; Zhang, X.L. Study on leakage and ventilation scheme of gas pipeline in tunnel. J. Nat. Gas Sci. Eng. 2018, 53, 347–358. [Google Scholar] [CrossRef]

- Wang, X.M.; Tan, Y.F.; Zhang, T.T.; Zhang, J.; Yu, K. Diffusion process simulation and ventilation strategy for small-hole natural gas leakage in utility tunnels. Tunn. Undergr. Space Technol. 2020, 97, 103276. [Google Scholar] [CrossRef]

- Bu, F.X.; Liu, Y.; Wang, Z.X.; Xu, Z.; Chen, S.Q.; Hao, G.W.; Guan, B. Analysis of natural gas leakage diffusion characteristics and prediction of invasion distance in utility tunnels. J. Nat. Gas Sci. Eng. 2021, 96, 104270. [Google Scholar] [CrossRef]

- Yuan, S.Q.; Wu, J.S.; Zhang, X.L.; Liu, W.Y. EnKF-based estimation of natural gas release and dispersion in an underground tunnel. J. Loss Prev. Process Ind. 2019, 62, 103931. [Google Scholar] [CrossRef]

- Wu, J.S.; Liu, Z.; Yuan, S.Q.; Cai, J.T.; Hu, X.F. Source term estimation of natural gas leakage in utility tunnel by combining CFD and Bayesian inference method. J. Loss Prev. Process Ind. 2020, 62, 104328. [Google Scholar] [CrossRef]

- Wang, W.H.; Zhu, Z.X.; Jiao, Z.R.; Mi, H.F.; Wang, Q.S. Characteristics of fire and smoke in the natural gas cabin of urban underground utility tunnels based on CFD simulations. Tunn. Undergr. Space Technol. 2021, 109, 103748. [Google Scholar] [CrossRef]

- Zhang, S.H.; Ma, H.T.; Huang, X.M.; Peng, S.N. Numerical simulation on methane-hydrogen explosion in gas compartment in utility tunnel. Process Saf. Environ. Prot. 2020, 140, 100–110. [Google Scholar] [CrossRef]

- Wang, X.M.; Tan, Y.F.; Zhang, T.T.; Xiao, R.; Yu, K.C.; Zhang, J.D. Numerical study on the diffusion process of pinhole leakage of natural gas from underground pipelines to the soil. J. Nat. Gas Sci. Eng. 2021, 87, 103792. [Google Scholar] [CrossRef]

- Wakoh, H.; Hirano, T. Diffusion of leaked flammable-gas in soil. J. Loss Prev. Process Ind. 2011, 4, 260–264. [Google Scholar] [CrossRef]

- Bonnaud, C.; Cluzel, V.; Corcoles, P.; Dubois, J.P.; Louvet, V.; Maury, M.; Narbonne, A.; Oréfice, H.; Perez, A.; Ranty, J.; et al. Experimental study and modelling of the consequences of small leaks on buried transmission gas pipeline. J. Loss Prev. Process Ind. 2018, 55, 303–312. [Google Scholar] [CrossRef]

- Chamindu, K.; Smits, K.M.; Oldenburg, C.M. Effect of subsurface soil moisture variability and atmospheric conditions on methane gas migration in shallow subsurface. Int. J. Greenh. Gas Control 2016, 55, 105–117. [Google Scholar] [CrossRef]

- Bezaatpour, J.; Fatehifar, E.; Rasoulzadeh, A. CFD investigation of natural gas leakage and propagation from buried pipeline for anisotropic and partially saturated multi-layer soil. J. Clean. Prod. 2020, 277, 123940. [Google Scholar] [CrossRef]

- Ebrahimi-Moghadam, A.; Farzaneh-Gord, M.; Deymi-Dashtebayaz, M. Correlations for estimating natural gas leakage from above-ground and buried urban distribution pipelines. J. Nat. Gas Sci. Eng. 2016, 34, 185–196. [Google Scholar] [CrossRef]

- Ebrahimi-Moghadam, A.; Farzaneh-Gord, M.; Arabkoohsar, A.; Moghadam, A.J. CFD analysis of natural gas emission from damaged pipelines: Correlation development for leakage estimation. J. Clean. Prod. 2018, 199, 257–271. [Google Scholar] [CrossRef]

- Bu, F.X.; Chen, S.Q.; Liu, Y.; Guan, B.; Wang, X.W.; Shi, Z.C.; Hao, G.W. CFD analysis and calculation models establishment of leakage of natural gas pipeline considering real buried environment. Energy Rep. 2022, 8, 3789–3808. [Google Scholar] [CrossRef]

- Bu, F.X.; Liu, Y.; Chen, S.Q.; Xu, Z.; Liu, Y.B.; Jiang, M.H.; Guan, B. Analysis and prediction of methane invasion distance considering real ground boundary. ACS Omega 2021, 6, 29111–29125. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.L.; Pan, J.; Zhang, Y.X.; Li, Y.X.; Li, H.; Feng, H.; Chen, D.S.; Kou, Y.M.; Yang, R. Leakage and diffusion behavior of a buried pipeline of hydrogen-blended natural gas. Int. J. Hydrog. Energy 2023, 48, 11592–11610. [Google Scholar] [CrossRef]

- Fu, H.; Yang, L.; Liang, H.R.; Wang, S.; Ling, K.G. Diagnosis of the single leakage in the fluid pipeline through experimental study and CFD simulation. J. Pet. Sci. Eng. 2020, 193, 107437. [Google Scholar] [CrossRef]

- Deng, Y.J.; Hu, H.B.; Yu, B.; Sun, D.L.; Hou, L.; Liang, Y.T. A method for simulating the release of natural gas from the rupture of high-pressure pipelines in any terrain. J. Hazard. Mater. 2018, 342, 418–428. [Google Scholar] [CrossRef] [PubMed]

- Bu, F.X.; Liu, Y.; Liu, Y.B.; Xu, Z.; Chen, S.Q.; Jiang, M.H.; Guan, B. Leakage diffusion characteristics and harmful boundary analysis of buried natural gas pipeline under multiple working conditions. J. Nat. Gas Sci. Eng. 2021, 94, 104047. [Google Scholar] [CrossRef]

- Montiel, H.; Vílchez, J.A.; Casal, J.; Arnaldos, J. Mathematical modelling of accidental gas releases. J. Hazard. Mater. 1998, 59, 211–233. [Google Scholar] [CrossRef]

- Luo, J.H.; Zheng, M.; Zhao, X.W.; Huo, C.Y.; Yang, L. Simplified expression for estimating release rate of hazardous gas from a hole on high-pressure pipelines. J. Loss Prev. Process Ind. 2006, 19, 362–366. [Google Scholar] [CrossRef]

- GB 50028-2006; Code for Design of City Gas Engineering. Ministry of Construction of the People’s Republic of China: Beijing, China, 2006.

- Su, Y.; Li, J.F.; Yu, B.; Zhao, Y.L.; Han, D.X.; Sun, D.L. Modeling of Hydrogen Blending on the Leakage and Diffusion of Urban Buried Hydrogen-Enriched Natural Gas Pipeline. CMES-Comput. Model. Eng. Sci. 2023, 136, 1315–1337. [Google Scholar] [CrossRef]

- Launder, B.E. Current capabilities for modeling turbulence in industrial flows. Appl. Sci. Res. 1991, 48, 247–269. [Google Scholar] [CrossRef]

- Choi, S.K.; Kim, S.O. Turbulence modeling of natural convection in enclosures: A review. J. Mech. Sci. Technol. 2012, 26, 283–297. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. Comput. Methods Appl. Math. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Zhang, J.W.; Yin, X.X.; Xin, Y.A.; Zhang, J.; Zheng, X.P.; Jiang, C.M. Numerical investigation on three-dimensional dispersion and conversion behaviors of silicon tetrachloride release in the atmosphere. J. Hazard. Mater. 2015, 288, 1–16. [Google Scholar]

- Wei, N.; Qiao, Y.; Liu, A.Q.; Zhao, J.Z.; Zhang, L.H.; Xue, J. Study on structure optimization and applicability of hydrocyclone in natural gas hydrate exploitation. Front. Earth Sci. 2022, 10, 991208. [Google Scholar] [CrossRef]

- Liu, Y.; Bu, F.X.; Chen, S.Q.; Jiang, M.H. Investigating effect of polymer concentrations on separation performance of hydrocyclone by sensitivity analysis. Energy Sci. Eng. 2021, 9, 1202–1215. [Google Scholar] [CrossRef]

- Nordlund, M.; Stanic, M.; Kuczaj, A.K.; Frederix, E.M.A.; Geurts, B.J. Improved PISO algorithms for modeling density varying flow in conjugate fluid-porous domains. J. Comput. Phys. 2016, 306, 199–215. [Google Scholar] [CrossRef]

- Jarrahian, A.; Heidaryan, E. A new cubic equation of state for sweet and sour natural gases even when composition is unknown. Fuel 2014, 134, 333–342. [Google Scholar] [CrossRef]

- Yan, Y.T.; Dong, X.Q.; Li, J.M. Experimental study of methane diffusion in soil for an underground gas pipe leak. J. Nat. Gas Sci. Eng. 2015, 27, 82–89. [Google Scholar] [CrossRef]

| Boundary | Type | Setting Parameters |

|---|---|---|

| Pipe inlet | Pressure inlet/wall | Pipeline operation pressure |

| Pipe outlet | Pressure outlet | Pipeline operation pressure |

| Leak hole | Interior | / |

| Ground surface | Pressure outlet | Atmospheric pressure |

| Soil boundary | Pressure outlet | Atmospheric pressure |

| Pipe wall | Wall | No slip, wall roughness |

| Case | Leakage Time (T/min) | Pressure (p/MPa) | Leakage Diameter (d/mm) | Buried Depth (H/m) | Leakage Direction | Soil Types |

|---|---|---|---|---|---|---|

| 1 | 10 | 0.3 | 50 | 0.9 | Up | Loam |

| 2 | 20 | 0.3 | 50 | 0.9 | Up | Loam |

| 3 | 30 | 0.3 | 50 | 0.9 | Up | Loam |

| 4 | 40 | 0.3 | 50 | 0.9 | Up | Loam |

| 5 | 50 | 0.3 | 50 | 0.9 | Up | Loam |

| 6 | 30 | 0.2 | 50 | 0.9 | Up | Loam |

| 7 | 30 | 0.25 | 50 | 0.9 | Up | Loam |

| 8 | 30 | 0.35 | 50 | 0.9 | Up | Loam |

| 9 | 30 | 0.4 | 50 | 0.9 | Up | Loam |

| 10 | 30 | 0.3 | 10 | 0.9 | Up | Loam |

| 11 | 30 | 0.3 | 30 | 0.9 | Up | Loam |

| 12 | 30 | 0.3 | 70 | 0.9 | Up | Loam |

| 13 | 30 | 0.3 | 90 | 0.9 | Up | Loam |

| 14 | 30 | 0.3 | 50 | 0.3 | Up | Loam |

| 15 | 30 | 0.3 | 50 | 0.6 | Up | Loam |

| 16 | 30 | 0.3 | 50 | 1.2 | Up | Loam |

| 17 | 30 | 0.3 | 50 | 1.5 | Up | Loam |

| 18 | 30 | 0.3 | 50 | 0.9 | Down | Loam |

| 19 | 30 | 0.3 | 50 | 0.9 | Side | Loam |

| 20 | 30 | 0.3 | 50 | 0.9 | Up | Sand |

| 21 | 30 | 0.3 | 50 | 0.9 | Up | Clay |

| Level | Number | Leakage Rate (kg/s) | Error (%) |

|---|---|---|---|

| Level 1 | 598,862 | 0.006112 | / |

| Level 2 | 980,641 | 0.005803 | 5.06 |

| Level 3 | 1,423,010 | 0.005655 | 2.56 |

| Level 4 | 1,799,113 | 0.005591 | 1.13 |

| Level 5 | 2,231,005 | 0.005546 | 0.80 |

| Coefficient | Estimated Value | Confidence Interval |

|---|---|---|

| −21.69 | [−43.11, −3.58] | |

| 18.26 | [−4.37, 41.80] | |

| 41.88 | [21.65, 57.92] | |

| 39.47 | [29.01, 52.48] | |

| −25.46 | [−30.08, −19.01] | |

| −34.72 | [−37.20, −32.69] | |

| R2 = 0.93 | F = 1.96 × 103 | p = 0.001 < 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bu, F.; He, Y.; Liu, M.; Lv, Z.; Bai, J.; Leng, C.; Wang, Z. Gas Free Dissipation Characteristics Analysis and Safety Repair Time Determination of Buried Pipeline Leakage Based on CFD. Energies 2024, 17, 3507. https://doi.org/10.3390/en17143507

Bu F, He Y, Liu M, Lv Z, Bai J, Leng C, Wang Z. Gas Free Dissipation Characteristics Analysis and Safety Repair Time Determination of Buried Pipeline Leakage Based on CFD. Energies. 2024; 17(14):3507. https://doi.org/10.3390/en17143507

Chicago/Turabian StyleBu, Fanxi, Yuheng He, Ming Liu, Zhuoran Lv, Jinyu Bai, Chunmiao Leng, and Zhihua Wang. 2024. "Gas Free Dissipation Characteristics Analysis and Safety Repair Time Determination of Buried Pipeline Leakage Based on CFD" Energies 17, no. 14: 3507. https://doi.org/10.3390/en17143507

APA StyleBu, F., He, Y., Liu, M., Lv, Z., Bai, J., Leng, C., & Wang, Z. (2024). Gas Free Dissipation Characteristics Analysis and Safety Repair Time Determination of Buried Pipeline Leakage Based on CFD. Energies, 17(14), 3507. https://doi.org/10.3390/en17143507