An Up-to-Date Review of Passive Building Envelope Technologies for Sustainable Design

Abstract

:1. Introduction

1.1. Identification of the Problem

1.2. Energy Use in the Building Sector

1.3. Thermal Comfort and Energy Poverty and Heat-Related Mortality

1.4. Energy Efficiency in the Building Sector

1.5. Scope of the Present Study

2. Insulation Materials

2.1. Conventional Insulation Materials

2.2. Novel Insulation Materials

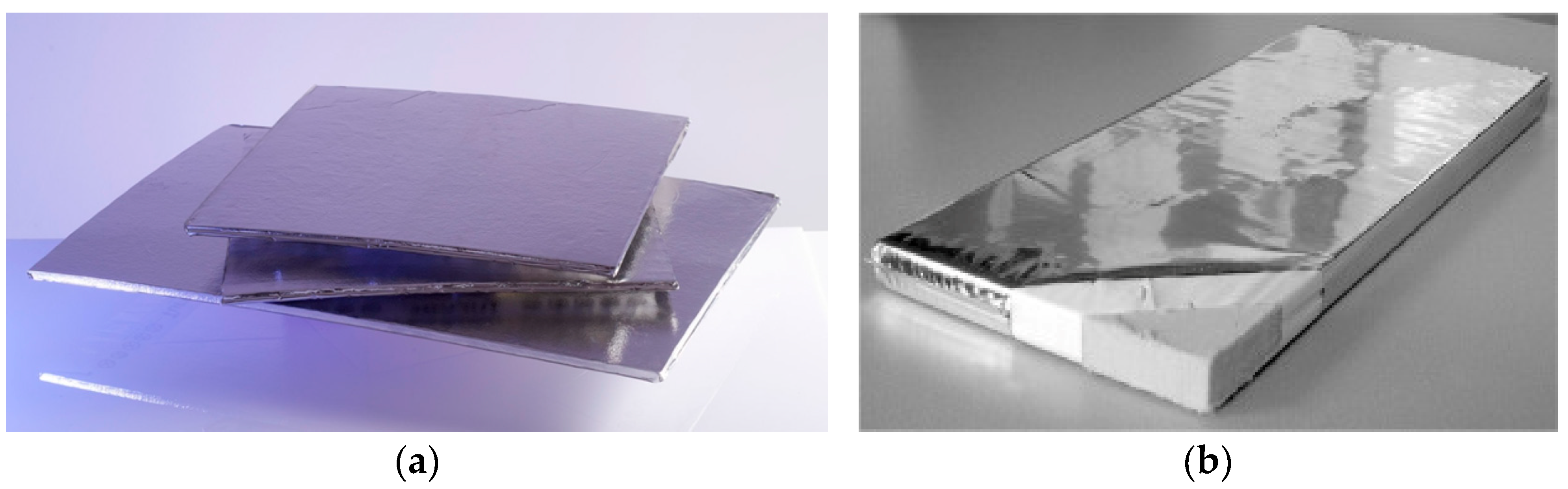

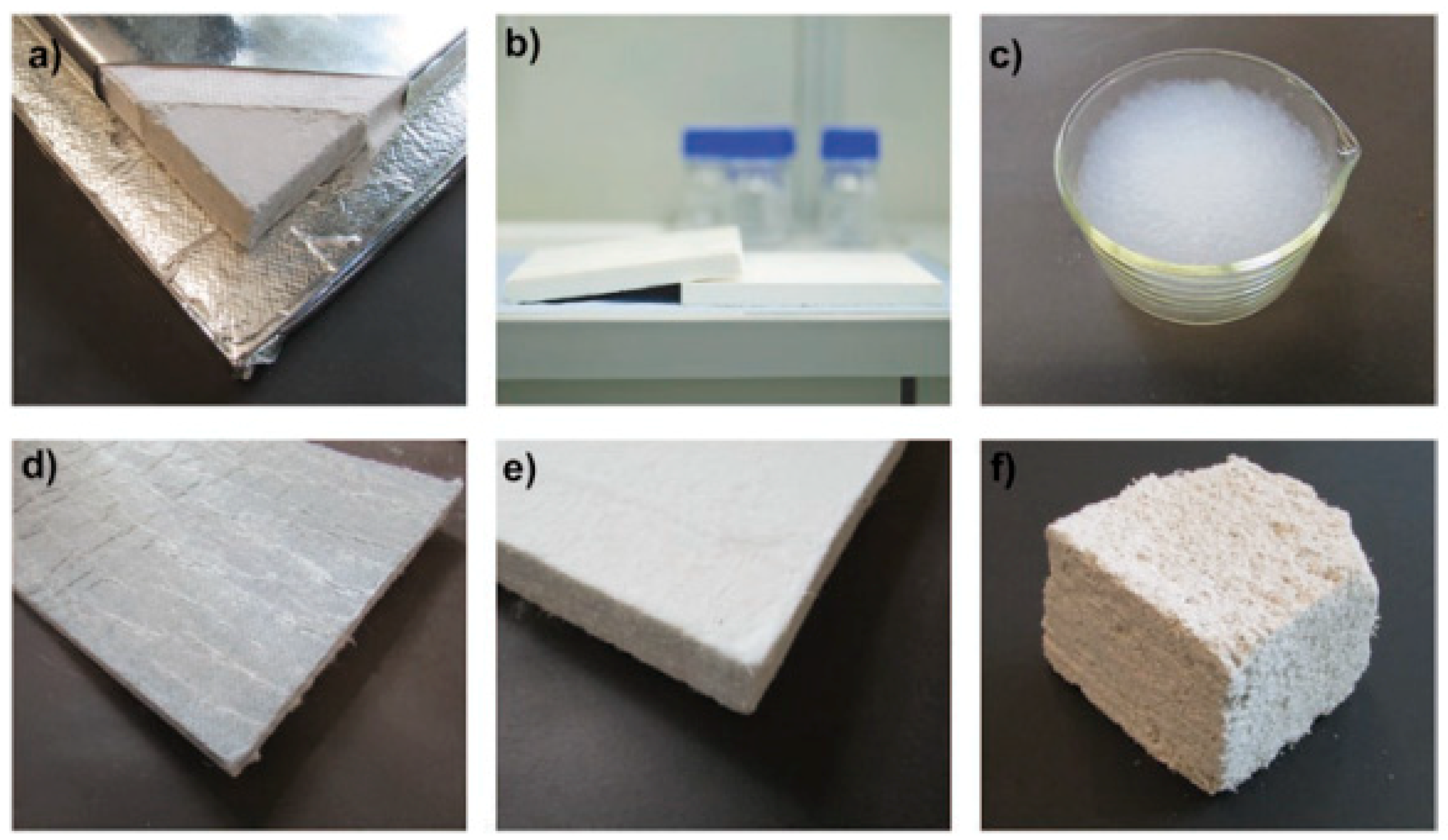

- (a)

- Vacuum-insulating panels

- (b)

- Aerogels

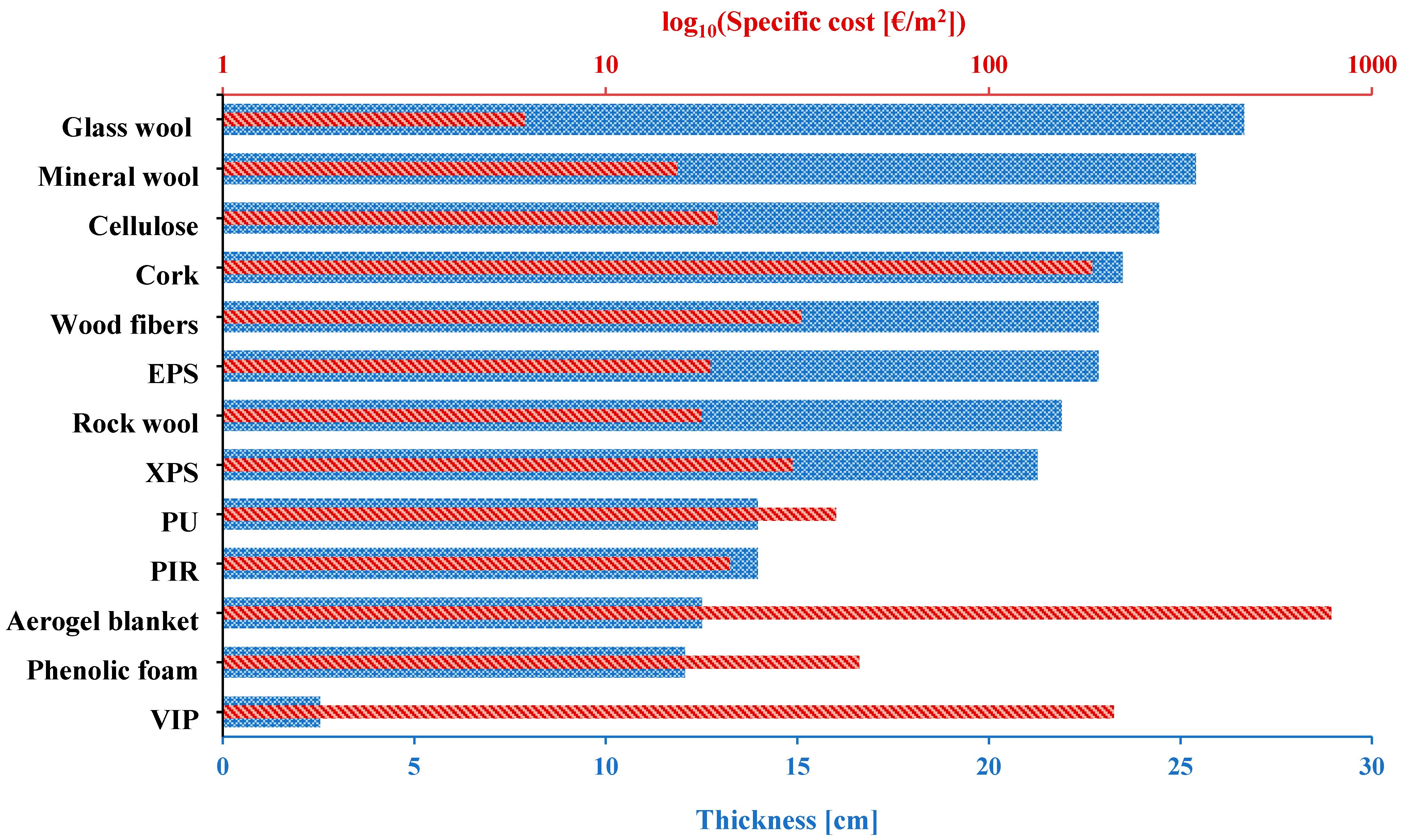

2.3. Techno-Economic Comparison of Insulation Materials

2.4. Trends and Challenges of Insulating Materials

3. Innovative Window Technologies

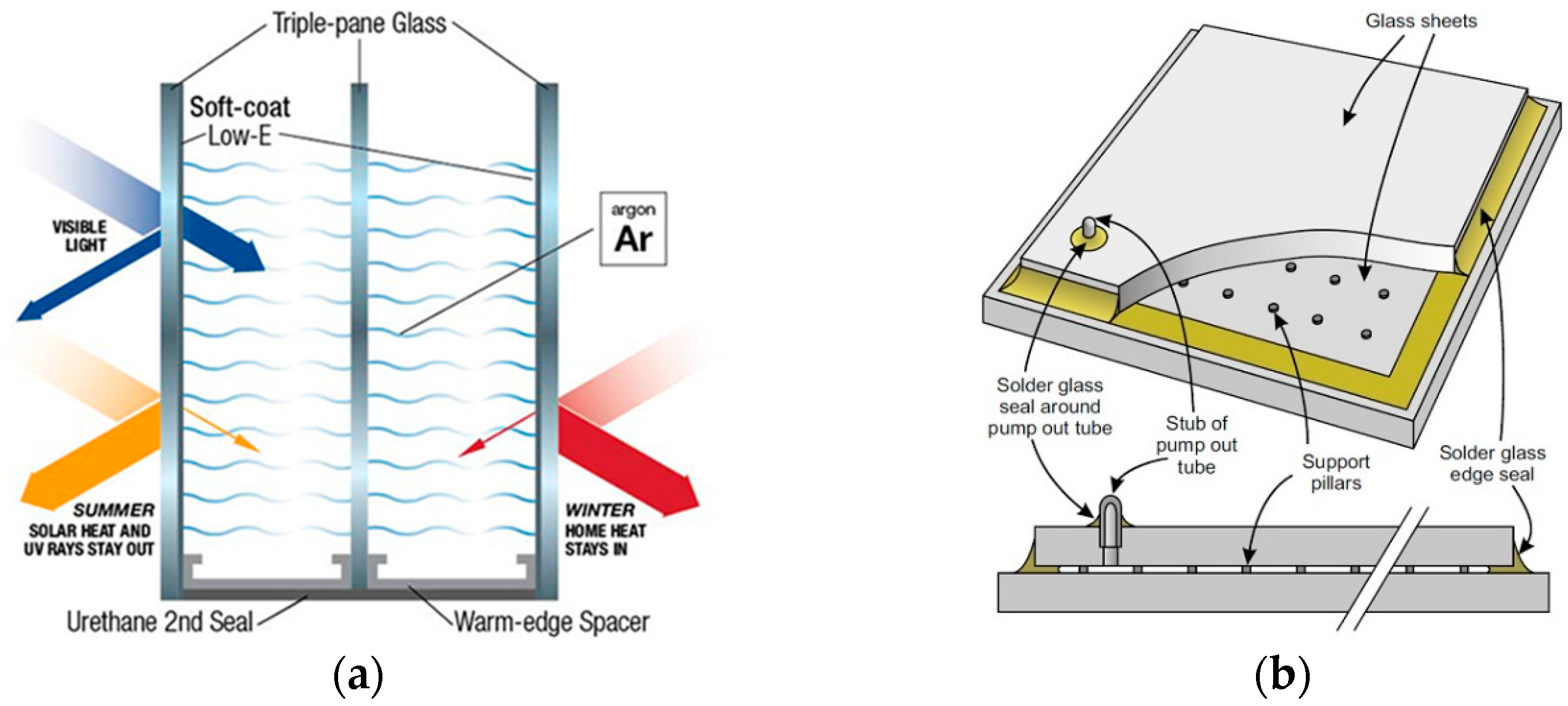

3.1. Multi-Glazed Windows and Low-Emittance Coatings

3.2. Chromogenic Materials

3.2.1. Thermochromic Films

3.2.2. Electrochromic Films

3.3. Techno-Economic Comparison of Window Installations

3.4. Trends and Challenges of Window Systems

4. High Thermal Mass Technologies

4.1. Phase Change Materials

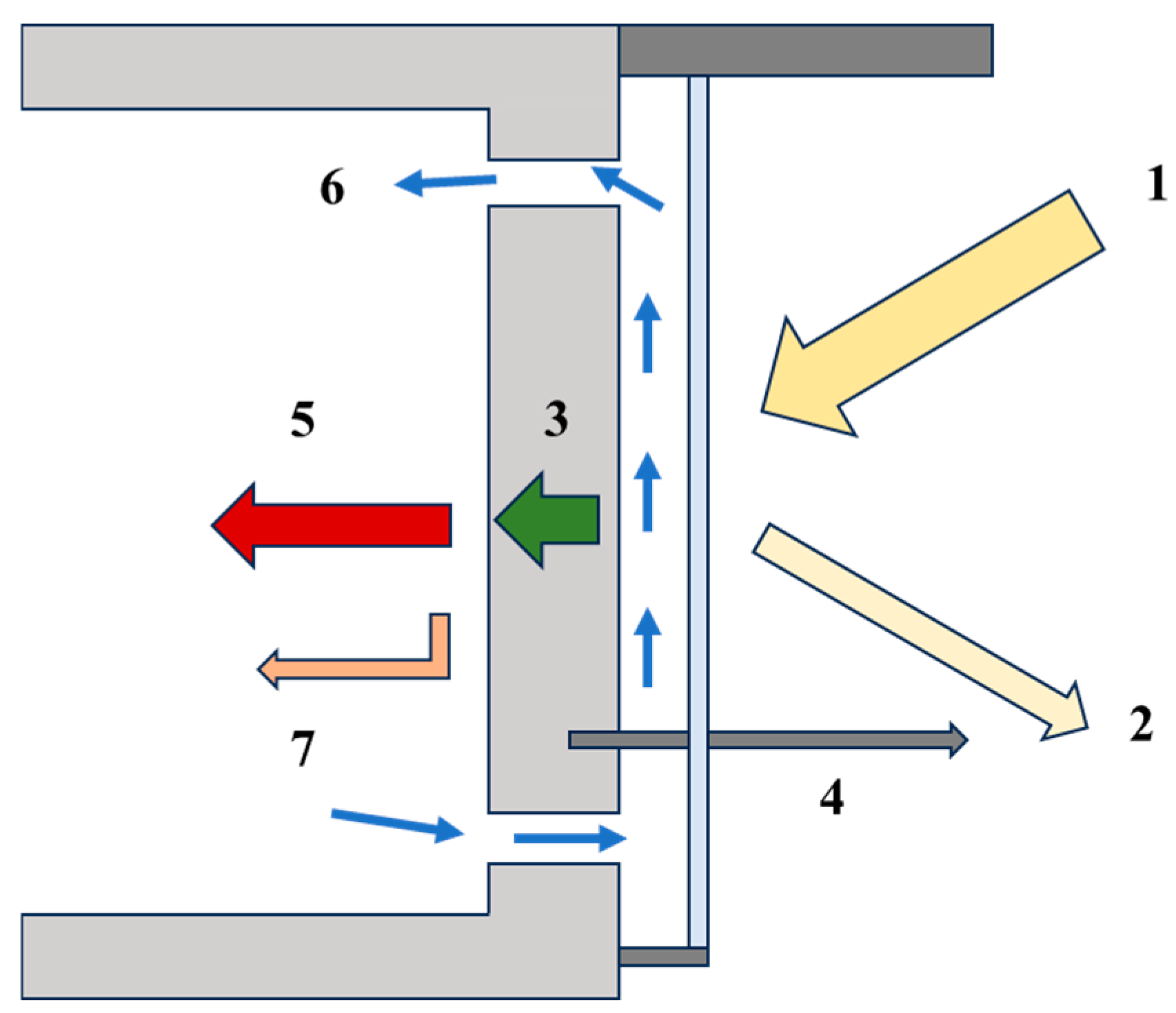

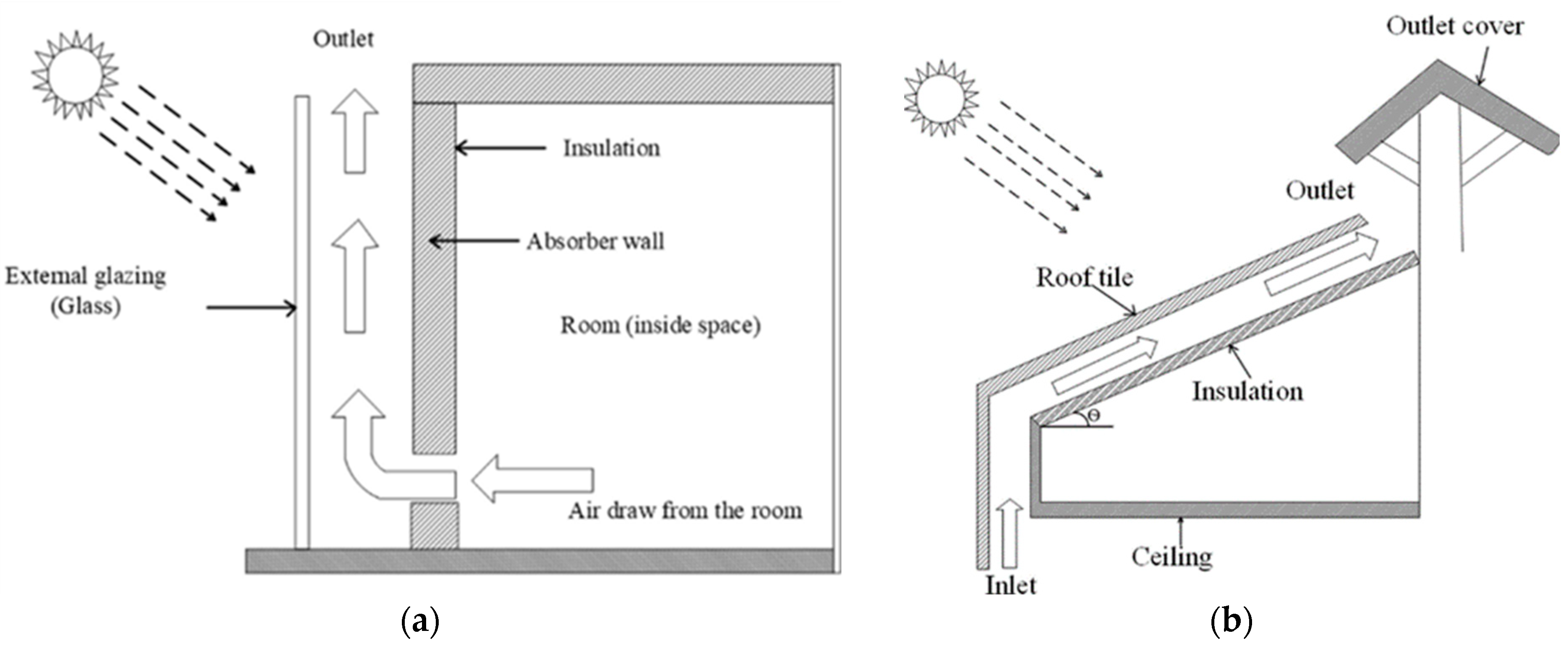

4.2. Trombe Wall

4.3. Trends and Challenges of High Thermal Mass Technologies

5. Optically Advanced Coatings with Cooling Potential

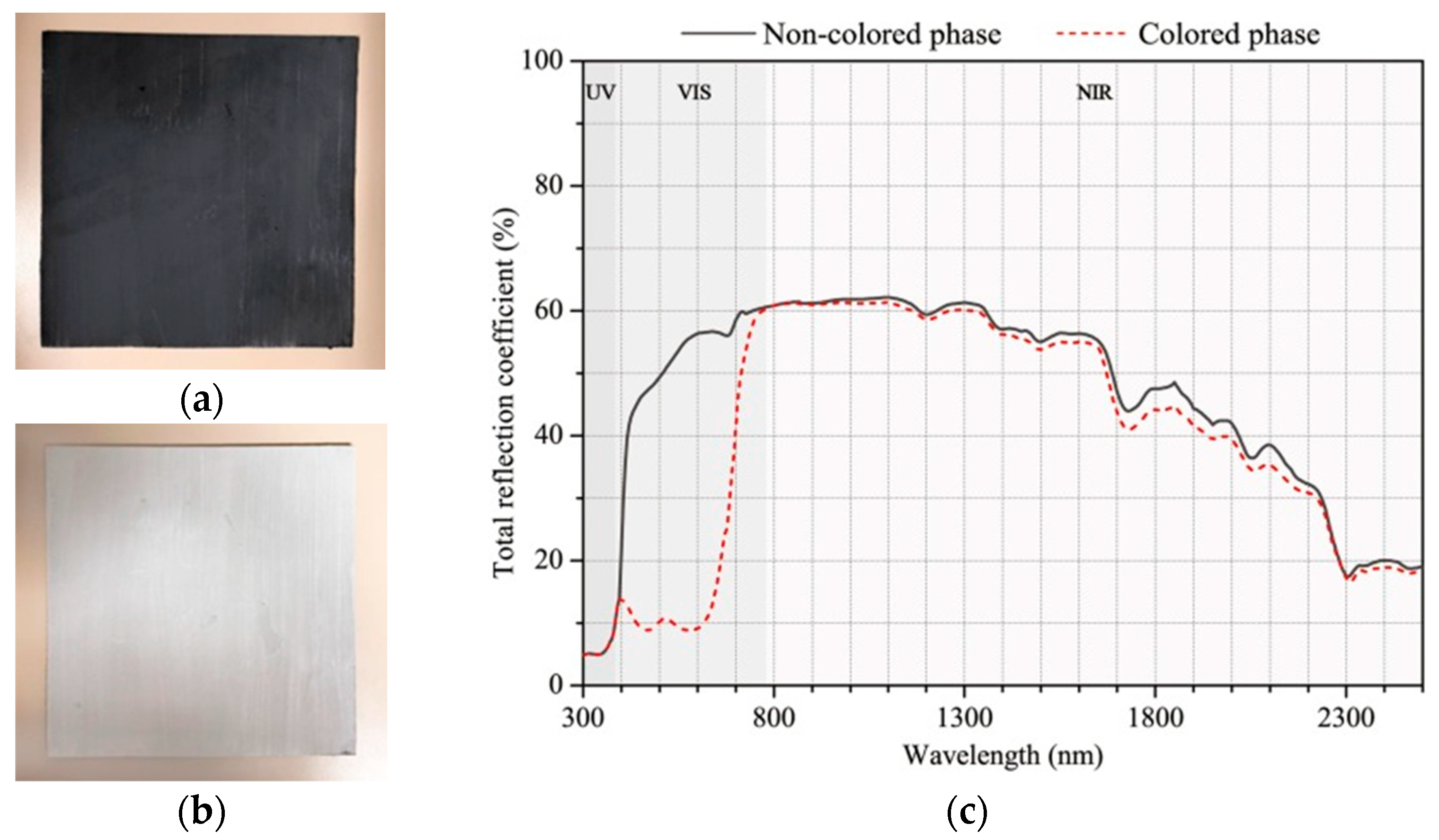

5.1. Cool Materials with Static Optical Properties

5.2. Cooling Materials of Dynamic Optical Properties

5.3. Trends and Challenges of Optically Advanced Coatings with Cooling Potential

6. Mechanical Ventilation and Bioclimatic Design Technologies

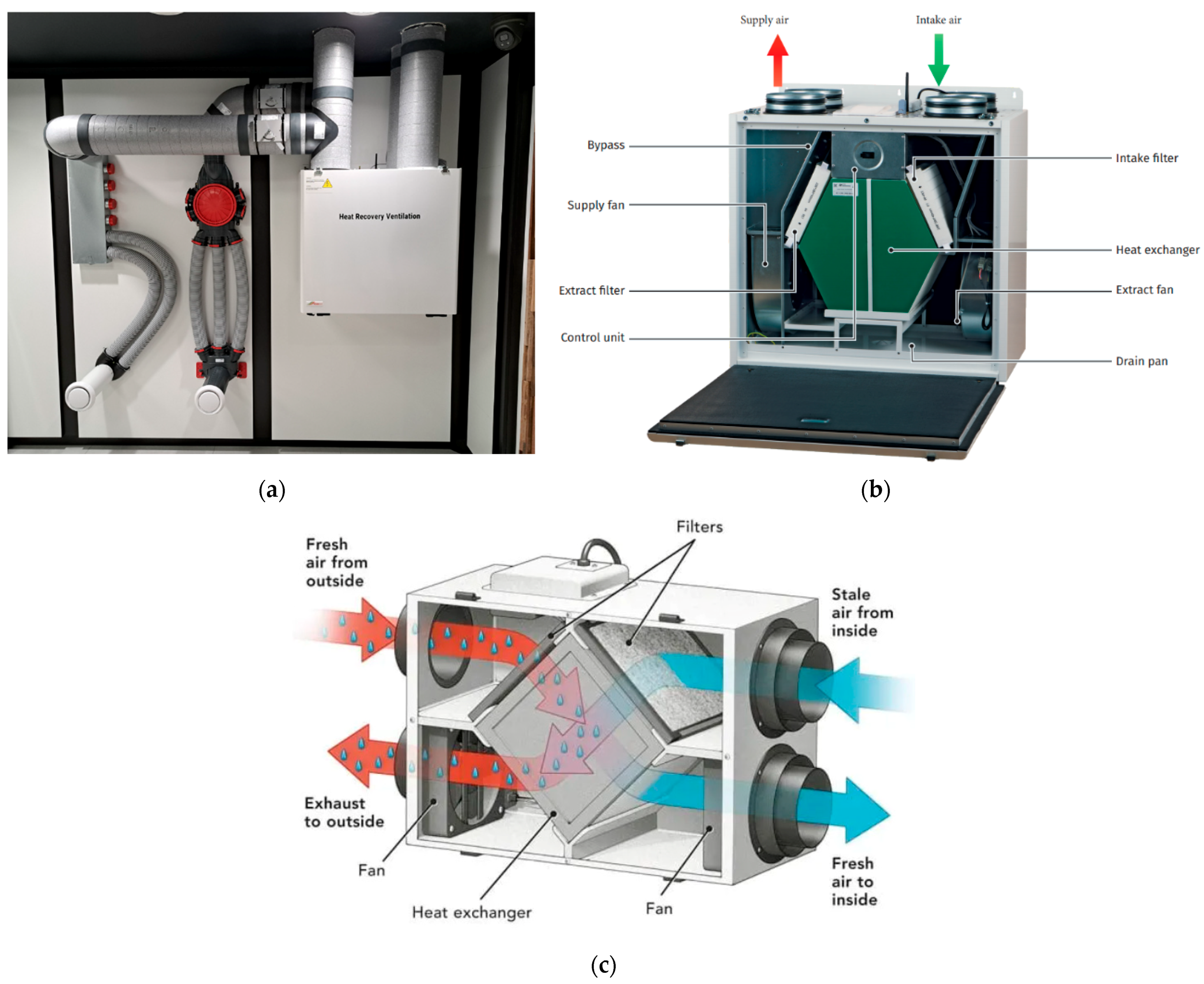

6.1. Mechanical Ventilation

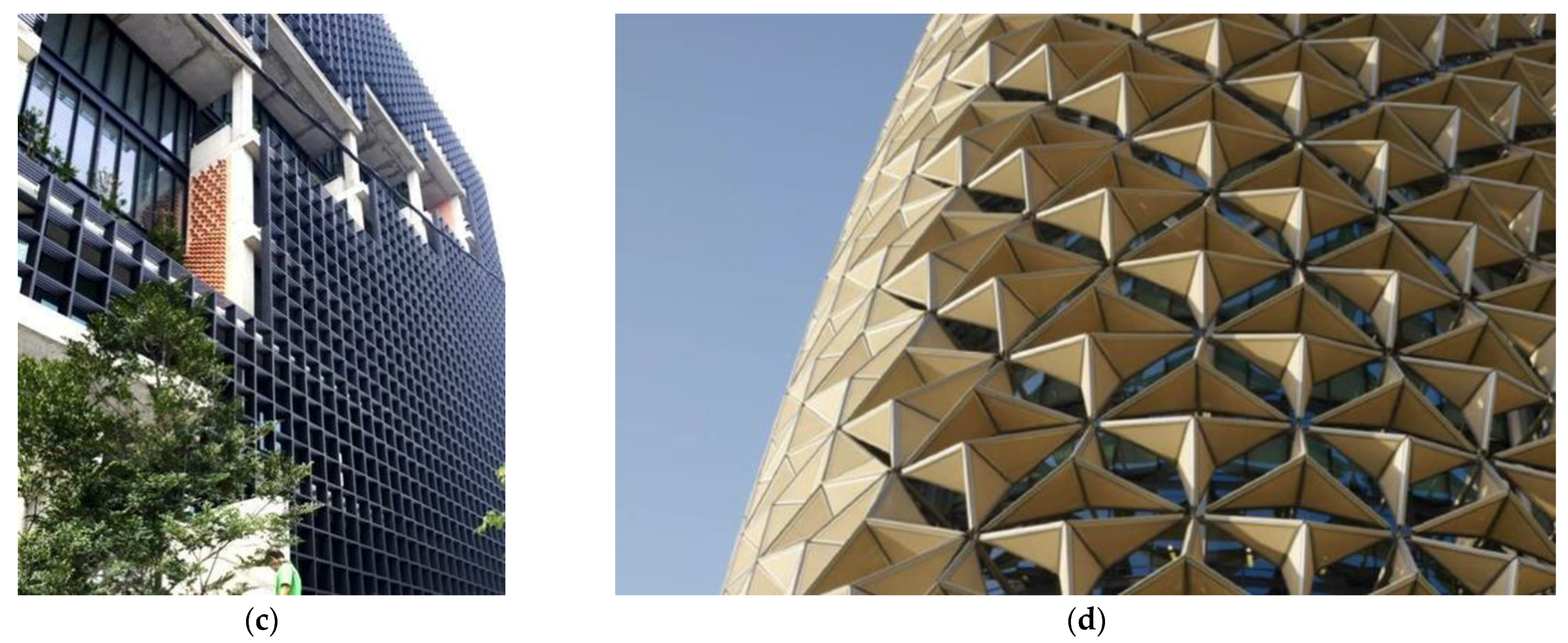

6.2. External Shading

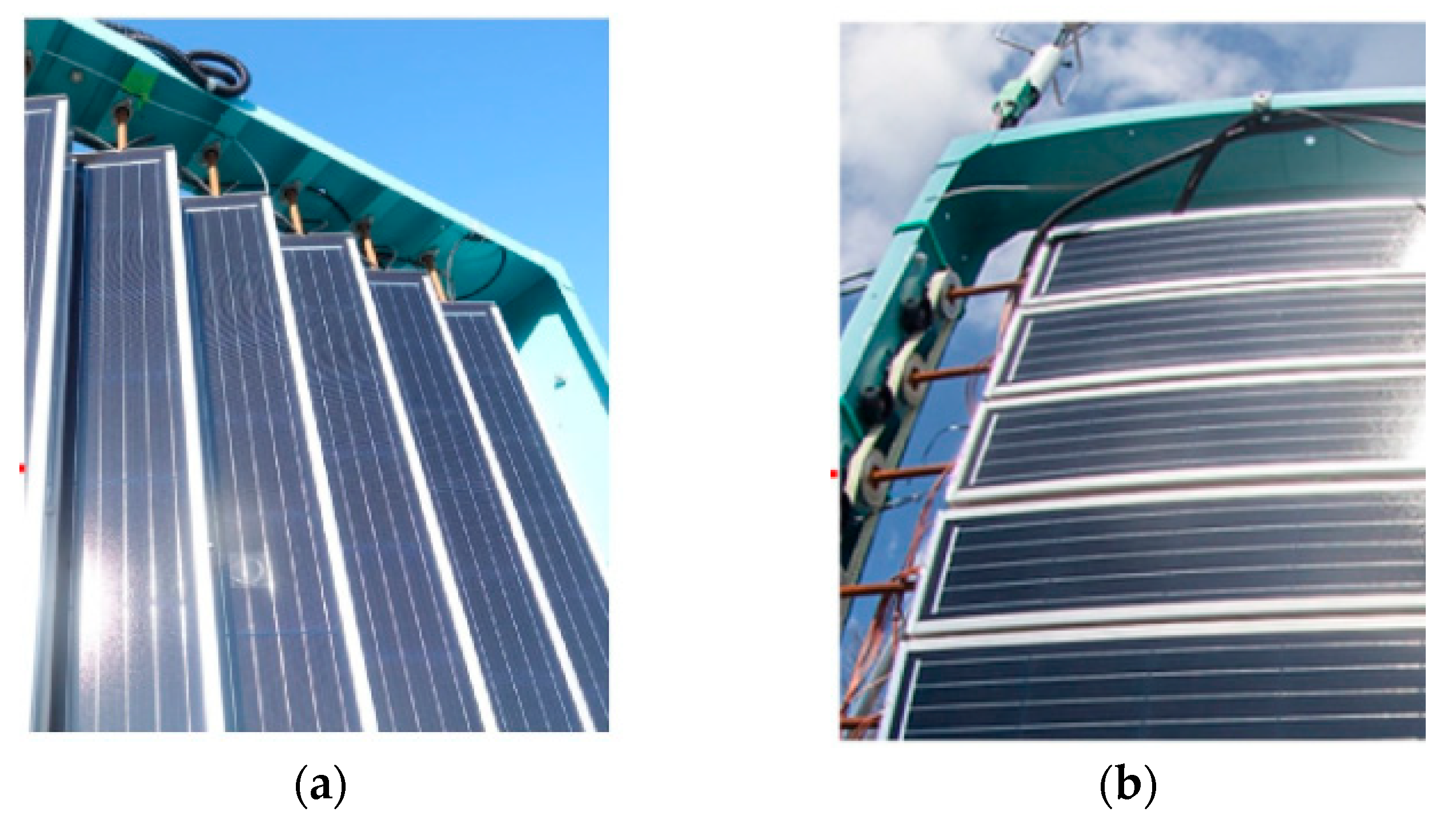

6.3. Solar Chimney

6.4. Green Façades and Green Roof Systems

6.5. Trends and Challenges of Mechanical Ventilation and Bioclimatic Design Technologies

7. Discussion

7.1. Comparative Analysis Regarding Energy Savings

7.2. Challenges and Future Work

8. Conclusions

- -

- The incorporation of highly insulative, innovative solutions of vacuum-insulating panels and aerogel-based materials can result in important yearly energy savings (68.7% for the winter period and 30.0% for the summer period) but are affected by severe difficulties during the installation process because of their high brittleness and the risk of diminishing their thermal superiority in the case of perforation. High thermal performance can also be achieved with the selection of conventional, fire-resistant, and less expensive mineral wool and rock wool insulation materials. The future of insulating materials lies in the proper combination of their exceptional thermal properties, lightweight construction, minimum environmental footprint, and easy and fast installation. This trend is geared toward further research to minimize the risk of thermal degradation during the installation and to extend the lifespan of aerogels and vacuum insulation panels.

- -

- Advanced, multi-glazed, gas-filled, solid insulation-filled, or vacuum window systems are heavy, highly efficient expensive constructions that can minimize radiation and convection thermal losses through openings of up to 55.0% (aerogel-filled) or even 76.0% (vacuum-filled). Window replacement combined with external thermal insulation addition belongs among the most economical and energy-saving optimum retrofit strategies for residences. An alternative but not commercially widespread solution, with satisfactory energy-saving potential, is electrochromic (18.5%) and thermochromic (50.0%) window systems that involve the use of appropriate control systems and chromogenic materials. Future window systems are smart, dynamic, and highly insulative windows that can properly adapt to environmental conditions and indoor thermal and optical comfort standards, integrated into building automation systems with real-time stimulus–response.

- -

- Composite construction materials incorporating phase change materials are an innovative energy-efficient solution that secures high thermal mass exploitation, and easy and minimum-invasive application on the building envelope, protects the material from ambient conditions, and extends the phase change materials’ lifespan. The induced decrease in cooling thermal load is reported to reach 54.0% for PCM-doped voided roof slabs. Future research should focus on the creation of organic-based PCM composite materials with expanded available temperature range options to fit the energy demand of any climatological conditions. Innovation in encapsulation techniques will be crucial for the extension of the lifespan of the materials and the enhancement of their thermal behavior and cost-effectiveness.

- -

- Important thermal efficiency upgrades of the high thermal mass designs of the Trombe wall and solar chimney can be achieved through the incorporation of various components, for instance, thermal insulation, phase change materials (79.0%), highly insulative window systems (12.2%), cool-colored materials (55.2%), or ventilation systems. This upgrade transforms two simple passive solutions into multi-parameter, dynamic systems, a suitable passive envelope energy-efficient solution to be integrated into future smart buildings.

- -

- Cool-colored materials with static or dynamic optical properties applied on a building’s external envelope in the form of coatings can induce important seasonal (17.0% cooling savings with cool-colored materials of static properties) or annual energy savings (19.0% annual savings with cool-colored materials of dynamic properties). Despite the domain’s important progression, further research is demanded for the abatement of optical degradation and success of optical stability and greater lifespan of these materials.

- -

- The enhancement of a building’s thermal performance and indoor thermal comfort can be achieved through the incorporation of mechanical ventilation systems with heat recovery (instantaneous load energy savings of up to 50.0%), green façades and green walls (annual energy savings of 45.0%), shading components (annual energy savings of 50.4%), and cool-colored materials. Parallelly, the incorporation of these passive envelope technologies will guarantee more energy-sufficient buildings, while their incorporation in a city’s wider building infrastructure, for instance, pavements or open public spaces, will result in the heat mitigation and alleviation of heat extremes and peak city-level air temperatures.

Funding

Conflicts of Interest

Nomenclature

| R | Thermal resistance, m2∙K/W |

| t | Thickness, m |

| U | Thermal conductance (transmittance), W/(m2∙K) |

Superscripts and Subscripts

| Cond | Conduction |

Greek Symbols

| λ | Thermal conductivity, W/(m∙K) |

Abbreviations

| DS | Double sash |

| EU | European Union |

| EPS | Expanded Polystyrene |

| MVS | Mechanical ventilation system |

| PCM | Phase change materials |

| PIR | Polyisocyanurate |

| PU | Polyurethane |

| PVC | Polyvinyl chloride |

| SS | Single sash |

| uPVC | unplasticized polyvinyl chloride |

| VIP | Vacuum-insulating panel |

| XPS | Extruded Polystyrene |

References

- IPCC—Intergovernmental Panel on Climate Change. Available online: https://www.ipcc.ch/ (accessed on 23 April 2024).

- Gulev, S.K.; Thorne, P.W.; Ahn, J.; Dentener, F.J.; Domingues, C.M.; Gerland, S.; Gong, D.; Kaufman, D.S.; Nnamchi, H.C.; Quaas, J.; et al. Changing state of the climate system. In Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V., Zhai, P., Pirani, A., Connors, S.L., Péan, C., Berger, S., Caud, N., Chen, Y., Goldfarb, L., Gomis, M.I., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2021; pp. 287–422. [Google Scholar]

- Fischer, E.; Knutti, R. Anthropogenic contribution to global occurrence of heavy-precipitation and high-temperature extremes. Nat. Clim. Change 2015, 5, 560–564. [Google Scholar] [CrossRef]

- Santamouris, M. On the energy impact of urban heat island and global warming on buildings. Energy Build. 2014, 82, 100–113. [Google Scholar] [CrossRef]

- Santamouris, M. Cooling the buildings—Past, present and future. Energy Build. 2016, 128, 617–638. [Google Scholar] [CrossRef]

- Santamouris, M.; Synnefa, A.; Karlessi, T. Using advanced cool materials in the urban built environment to mitigate heat islands and improve thermal comfort conditions. Sol. Energy 2011, 85, 3085–3102. [Google Scholar] [CrossRef]

- Garshasbi, S.; Santamouris, M. Using advanced thermochromic technologies in the built environment: Recent development and potential to decrease the energy consumption and fight urban overheating. Sol. Energy Mater. Sol. Cells 2019, 191, 21–32. [Google Scholar] [CrossRef]

- Isaac, M.; van Vuuren, D.P. Modeling global residential sector energy demand for heating and air conditioning in the context of climate change. Energy Policy 2009, 37, 507–521. [Google Scholar] [CrossRef]

- Buildings—Energy System. Available online: https://www.iea.org/energy-system/buildings (accessed on 21 April 2024).

- Shares of Residential Energy Consumption by End Use in Selected IEA Countries, 2018—Charts—Data & Statistics. Available online: https://www.iea.org/data-and-statistics/charts/shares-of-residential-energy-consumption-by-end-use-in-selected-iea-countries-2018 (accessed on 16 January 2023).

- Renovation Wave. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_20_1835 (accessed on 16 January 2023).

- Perspectives for the Clean Energy Transition—Analysis. Available online: https://www.iea.org/reports/the-critical-role-of-buildings (accessed on 21 April 2024).

- Santamouris, M.; Vasilakopoulou, K. Present and future energy consumption of buildings: Challenges and opportunities towards decarbonisation. e-Prime—Adv. Electr. Eng. Electron. Energy 2021, 1, 100002. [Google Scholar] [CrossRef]

- Energy Statistics—An Overview. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Energy_statistics_-_an_overview (accessed on 29 March 2024).

- Final Energy Consumption by Energy Sector in EU|ODYSSEE-MURE. Available online: https://www.odyssee-mure.eu/publications/efficiency-by-sector/overview/final-energy-consumption-by-sector.html (accessed on 29 March 2024).

- Database—Eurostat. Available online: https://ec.europa.eu/eurostat/data/database (accessed on 4 April 2024).

- IEA Annual Growth in Sales of Heat Pumps in Buildings Worldwide and in Selected Markets, 2021 and 2022, 2024. Available online: https://www.iea.org/data-and-statistics/charts/annual-growth-in-sales-of-heat-pumps-in-buildings-worldwide-and-in-selected-markets-2021-and-2022 (accessed on 21 April 2024).

- Kola-Bezka, M. One size fits all? Prospects for developing a common strategy supporting European Union households in times of energy crisis. Energy Rep. 2023, 10, 319–332. [Google Scholar] [CrossRef]

- Regulation (EU) 2023/955 of the European Parliament and of the Council of 10 May 2023 Establishing a Social Climate Fund and Amending Regulation (EU) 2021/1060. 2023, Volume 130. Available online: http://data.europa.eu/eli/reg/2023/955/oj/eng (accessed on 23 April 2024).

- European Commission, Official Website—European Commission. Available online: https://commission.europa.eu/index_en (accessed on 29 January 2024).

- Home—Eurostat. Available online: https://ec.europa.eu/eurostat/en/ (accessed on 29 January 2024).

- Ballester, J.; Quijal-Zamorano, M.; Méndez Turrubiates, R.F.; Pegenaute, F.; Herrmann, F.R.; Robine, J.M.; Basagaña, X.; Tonne, C.; Antó, J.M.; Achebak, H. Heat-related mortality in Europe during the summer of 2022. Nat. Med. 2023, 29, 1857–1866. [Google Scholar] [CrossRef]

- Bellos, E. Progress in beam-down solar concentrating systems. Prog. Energy Combust. Sci. 2023, 97, 101085. [Google Scholar] [CrossRef]

- On the Role of Construction in Achieving the SDGs. Available online: https://sustainability.hapres.com/htmls/JSR_1126_Detail.html (accessed on 11 December 2023).

- Attia, S. Chapter 1—Introduction to NZEB and Market Accelerators. In Net Zero Energy Buildings (NZEB); Attia, S., Ed.; Butterworth-Heinemann: Oxford, UK, 2018; pp. 1–20. ISBN 978-0-12-812461-1. [Google Scholar]

- Ongpeng, J.M.C.; Rabe, B.I.B.; Razon, L.F.; Aviso, K.B.; Tan, R.R. A multi-criterion decision analysis framework for sustainable energy retrofit in buildings. Energy 2022, 239, 122315. [Google Scholar] [CrossRef]

- Cao, J.; Hong, X.; Zheng, Z.; Asim, M.; Hu, M.; Wang, Q.; Pei, G.; Leung, M.K.H. Performance characteristics of variable conductance loop thermosyphon for energy-efficient building thermal control. Appl. Energy 2020, 275, 115337. [Google Scholar] [CrossRef]

- Pavel, C.; Blagoeva, D. Competitive Landscape of the EU’s Insulation Materials Industry for Energy-Efficient Buildings. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC108692 (accessed on 27 May 2024).

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Technical Guidelines of Technical Chamber of Greece. TEE 2020. Available online: https://web.tee.gr/ (accessed on 9 January 2024).

- Koebel, M.M.; Wernery, J.; Malfait, W.J. Energy in buildings—Policy, materials and solutions. MRS Energy Sustain. 2017, 4, E12. [Google Scholar] [CrossRef]

- Kan, A.; Zheng, N.; Wu, Y.; Wang, W.; Zhang, X.; Cai, H.; Cao, D. Theoretical prediction and aging experimental verification of the service life of vacuum insulation panels. Clean. Eng. Technol. 2022, 8, 100484. [Google Scholar] [CrossRef]

- Alam, M.; Singh, H.; Suresh, S.; Redpath, D.A.G. Energy and economic analysis of Vacuum Insulation Panels (VIPs) used in non-domestic buildings. Appl. Energy 2017, 188, 1–8. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Brunner, S.; Ghazi Wakili, K.; Stahl, T.; Binder, B. Vacuum insulation panels for building applications—Continuous challenges and developments. Energy Build. 2014, 85, 592–596. [Google Scholar] [CrossRef]

- Kalnæs, S.E.; Jelle, B.P. Vacuum insulation panel products: A state-of-the-art review and future research pathways. Appl. Energy 2014, 116, 355–375. [Google Scholar] [CrossRef]

- ltd, R. and M. Vacuum Insulation Panels—Global Strategic Business Report. Available online: https://www.researchandmarkets.com/reports/4806375/vacuum-insulation-panels-global-strategic (accessed on 28 May 2024).

- Gonçalves, M.; Simões, N.; Serra, C.; Flores-Colen, I. A review of the challenges posed by the use of vacuum panels in external insulation finishing systems. Appl. Energy 2020, 257, 114028. [Google Scholar] [CrossRef]

- Mandilaras, I.; Atsonios, I.; Zannis, G.; Founti, M. Thermal performance of a building envelope incorporating ETICS with vacuum insulation panels and EPS. Energy Build. 2014, 85, 654–665. [Google Scholar] [CrossRef]

- Simões, N.; Gonçalves, M.; Serra, C.; Resalati, S. Can vacuum insulation panels be cost-effective when applied in building façades? Build. Environ. 2021, 191, 107602. [Google Scholar] [CrossRef]

- Vacuum Insulation Panels TURVAC. Available online: https://en.turna.si/Programmes/VacuumInsulationPanelsTurvac.aspx (accessed on 29 May 2024).

- Batard, A.; Duforestel, T.; Flandin, L.; Yrieix, B. Modelling of long-term hygro-thermal behaviour of vacuum insulation panels. Energy Build. 2018, 173, 252–267. [Google Scholar] [CrossRef]

- Yuk, H.; Choi, J.Y.; Kim, Y.U.; Chang, S.J.; Kim, S. Historic building energy conservation with wooden attic using vacuum insulation panel retrofit technology. Build. Environ. 2023, 230, 110004. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, T.; Zhang, T.; Zhang, Y.; Dai, Z.; Liu, X. An investigation on the energy-saving potential of thermal insulating walls constructed with super thin vacuum insulated panels. Case Stud. Therm. Eng. 2023, 51, 103581. [Google Scholar] [CrossRef]

- Uriarte, A.; Garai, I.; Ferdinando, A.; Erkoreka, A.; Nicolas, O.; Barreiro, E. Vacuum insulation panels in construction solutions for energy efficient retrofitting of buildings. Two case studies in Spain and Sweden. Energy Build. 2019, 197, 131–139. [Google Scholar] [CrossRef]

- Alam, M.; Picco, M.; Resalati, S. Comparative holistic assessment of using vacuum insulated panels for energy retrofit of office buildings. Build. Environ. 2022, 214, 108934. [Google Scholar] [CrossRef]

- He, Y.-L.; Xie, T. Advances of thermal conductivity models of nanoscale silica aerogel insulation material. Appl. Therm. Eng. 2015, 81, 28–50. [Google Scholar] [CrossRef]

- van Bommel, M.J.; den Engelsen, C.W.; van Miltenburg, J.C. A Thermoporometry Study of Fumed Silica/aerogel Composites. J. Porous Mater. 1997, 4, 143–150. [Google Scholar] [CrossRef]

- Hrubesh, L.W. Aerogel applications. J. Non-Cryst. Solids 1998, 225, 335–342. [Google Scholar] [CrossRef]

- Aerogel Market Size, Share, Growth & Trends Repot, 2030. Available online: https://www.grandviewresearch.com/industry-analysis/aerogel-market (accessed on 29 May 2024).

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Aerogel insulation for building applications: A state-of-the-art review. Energy Build. 2011, 43, 761–769. [Google Scholar] [CrossRef]

- Neugebauer, A.; Chen, K.; Tang, A.; Allgeier, A.; Glicksman, L.R.; Gibson, L.J. Thermal conductivity and characterization of compacted, granular silica aerogel. Energy Build. 2014, 79, 47–57. [Google Scholar] [CrossRef]

- Bashir, A.W.; Leite, B.C.C. Performance of aerogel as a thermal insulation material towards a sustainable design of residential buildings for tropical climates in Nigeria. Energy Built Environ. 2022, 3, 291–315. [Google Scholar] [CrossRef]

- Song, Z.; Su, L.; Yuan, M.; Shang, S.; Cui, S. Self-cleaning, energy-saving aerogel composites possessed sandwich structure: Improving indoor comfort with excellent thermal insulation and acoustic performance. Energy Build. 2024, 310, 114098. [Google Scholar] [CrossRef]

- Yin, Y.; Song, Y.; Chen, W.; Yan, Y.; Wang, X.; Hu, J.; Zhao, B.; Ren, S. Thermal environment analysis of enclosed dome with double-layered PTFE fabric roof integrated with aerogel-glass wool insulation mats: On-site test and numerical simulation. Energy Build. 2022, 254, 111621. [Google Scholar] [CrossRef]

- Yue, X.; Wu, H.; Zhang, T.; Yang, D.; Qiu, F. Superhydrophobic waste paper-based aerogel as a thermal insulating cooler for building. Energy 2022, 245, 123287. [Google Scholar] [CrossRef]

- Liu, Y.; Bu, X.; Liu, R.; Feng, M.; Zhang, Z.; He, M.; Huang, J.; Zhou, Y. Construction of robust silica-hybridized cellulose aerogels integrating passive radiative cooling and thermal insulation for year-round building energy saving. Chem. Eng. J. 2024, 481, 148780. [Google Scholar] [CrossRef]

- Atsonios, I. Experimental and Numerical Methods for the Energy Assessment of Building Envelope Focusing on Super Insulation Materials. Ph.D. Thesis, National Technical University of Athens, Thermal Engineering Department Heterogeneous Mixtures And Combustion Systems, 2018. Available online: http://hdl.handle.net/10442/hedi/44416 (accessed on 26 June 2024).

- Knauf Combi-Cut Insulation Roll. Available online: https://insulation4less.co.uk/products/knauf-combi-cut (accessed on 25 June 2024).

- etheme.com Ursa 10 Diverso Loft Insulation 200 mm. Available online: https://www.cutpriceinsulation.co.uk/products/ursa-10-diverso-loft-insulation-roll-200mm (accessed on 25 June 2024).

- Buy Rockwool RWA45 Acoustic Insulation Slab 100 mm. Available online: https://insulation4less.co.uk/products/rockwool-rwa45-1200mm-x-600mm (accessed on 21 June 2024).

- 100 mm Rockwool NyRock Cavity 032|Rockwool Insulation. Available online: https://www.insulationhub.co.uk/product/100mm-rockwool-nyrock-cavity-032-2-18m2-per-pack/ (accessed on 25 June 2024).

- Knauf DriTherm 37|Cavity Wall Insulation. Available online: https://insulation4less.co.uk/products/knauf-dritherm-37-all-sizes (accessed on 25 June 2024).

- 100mm Isover APR Acoustic Partition Roll|Isover Insulation. Available online: https://www.insulationhub.co.uk/product/isover-acoustic-partition-roll-apr-100mm/ (accessed on 25 June 2024).

- Thermofloc|Recycled Cellulose Insulation. Mike Wye. Available online: https://www.mikewye.co.uk/product/thermofloc/ (accessed on 21 June 2024).

- Thermofloc Loose Fill Cellulose Insulation 12 kg. Available online: https://www.ecomerchant.co.uk/thermofloc-loose-fill-cellulose-insulation-12kg.html (accessed on 25 June 2024).

- Kingspan Kooltherm K103 Floorboard Insulation|2400 mm × 1200 mm (Packs). Available online: https://www.insulationuk.co.uk/products/kingspan-kooltherm-k103-phenolic-insulation (accessed on 21 June 2024).

- etheme.com Kingspan Kooltherm K5 External Wall Insulation 1200 mm × 600 mm × 50 mm (Pack of 10). Available online: https://www.cutpriceinsulation.co.uk/products/kingspan-kooltherm-k5-external-wall-insulation-1200mm-x-600mm-50mm (accessed on 25 June 2024).

- Jablite EPS Insulation. Available online: https://www.insulationuk.co.uk/collections/jablite-insulation (accessed on 21 June 2024).

- 100 mm Jablite HP+ 70E External Wall Insulation Board 1200 mm × 600 mm (4′ × 2′) Pack of 6|Insulation Wholesale. Available online: https://insulationwholesale.co.uk/100mm-jablite-hp-70e-external-wall-insulation-board-1200mm-x-600mm/ (accessed on 25 June 2024).

- Buy Danosa Danopren TR XPS Insulation Boards Online. Available online: https://insulation4less.co.uk/products/danosa-danopren-tr-xps-insulation-all-sizes (accessed on 25 June 2024).

- 100 mm Kingspan GreenGuard GG300 XPS Insulation Board. Available online: https://materialsmarket.com/products/100mm-kingspan-greenguard-extruded-polystyrene-insulation-300kpa-3m2-pack (accessed on 25 June 2024).

- Vermiculite 100 L Bag (Insulation). Available online: https://www.fluesupplies.com/vermiculite-back-fill-insulation.html (accessed on 25 June 2024).

- Expanded insulation cork board 30 × 500 × 1000 mm. Available online: https://www.fellos24.gr/shop/32-expanded-insulation-cork-boards/327-expanded-insulation-cork-board-30x500x1000mm/ (accessed on 26 June 2024).

- Cork Board Insulation. Mike Wye. Available online: https://www.mikewye.co.uk/product/cork-board-insulation/ (accessed on 26 June 2024).

- Steico Flex 036 Wood Fibre Insulation Batts—575 mm and 375 mm Wide. Available online: https://www.buyinsulationonline.co.uk/product/steico-flex-036-wood-fibre-insulation-batts (accessed on 25 June 2024).

- Buy Celotex 100 mm GA4100 Insulation Online (Lowest Price)|100 mm Celotex. Available online: https://insulation4less.co.uk/products/100mm-celotex-ga4100-2-4m-x-1-2m (accessed on 26 June 2024).

- 100 mm Celotex GA4100 PIR Insulation Board 2400 mm × 1200 mm (8′ × 4′)|Insulation Wholesale. Available online: https://insulationwholesale.co.uk/100mm-celotex-ga4100-pir-insulation-board-2400mm-x-1200mm-8%e2%80%b2-x-4%e2%80%b2/ (accessed on 26 June 2024).

- RMax Thermasheath 4ft × 8ft Polyiso Rigid Foam Insulation Board—All. Available online: https://insulation4us.com/products/rmax-4ft-x-8ft-polyiso-rigid-foam-insulation-board-thermasheath-3 (accessed on 27 June 2024).

- INSULOPETM Vacuum Insulation Panel (VIP). Available online: https://acquireindustries.com/products/insulope%e2%84%a2-vacuum-insulation-panel-vip (accessed on 26 June 2024).

- AEROLLTM Aerogel Insulation Blanket. Available online: https://acquireindustries.com/products/aeroll%e2%84%a2-aerogel-insulation (accessed on 26 June 2024).

- Kim, J.-H.; Kim, S.-M.; Kim, J.-T. Simulation Performance of Building Wall with Vacuum Insulation Panel. Procedia Eng. 2017, 180, 1247–1255. [Google Scholar] [CrossRef]

- Zenginis, D.G.; Kontoleon, K.J. Influence of orientation, glazing proportion and zone aspect ratio on the thermal performance of buildings during the winter period. Environ. Sci. Pollut. Res. 2018, 25, 26736–26746. [Google Scholar] [CrossRef]

- De Masi, R.F.; Festa, V.; Gigante, A.; Ruggiero, S.; Peter Vanoli, G. The role of windows on building performance under current and future weather conditions of European climates. Energy Build. 2023, 292, 113177. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M. Optimised performance of a thermally resistive PV glazing technology: An experimental validation. Energy Rep. 2019, 5, 1185–1195. [Google Scholar] [CrossRef]

- Winter, J. Glass in Architecture by Michael Wigginton; Phaidon Press: New York, NY, USA, 1997; Volume 2. [Google Scholar] [CrossRef]

- Granqvist, C.G. Solar Energy Materials. Adv. Mater. 2003, 15, 1789–1803. [Google Scholar] [CrossRef]

- Energy Efficient Windows Market, Industry Size Forecast Report [Latest]. Available online: https://www.marketsandmarkets.com/Market-Reports/energy-efficient-window-market-16858759.html (accessed on 24 July 2024).

- Nageib, A.; Elzafarany, A.M.; Elhefnawy, M.H.; Mohamed, F.O. Using smart glazing for reducing energy consumption on existing office building in hot dry climate. HBRC J. 2020, 16, 157–177. [Google Scholar] [CrossRef]

- Kaklauskas, A.; Zavadskas, E.K.; Raslanas, S.; Ginevicius, R.; Komka, A.; Malinauskas, P. Selection of low-e windows in retrofit of public buildings by applying multiple criteria method COPRAS: A Lithuanian case. Energy Build. 2006, 38, 454–462. [Google Scholar] [CrossRef]

- Su, J.; Yin, L.; Qin, L.; Ma, N.; Huang, J. Preparation and performance of ZrAlN anti-reflective coatings for low-emissivity glasses. Ceram. Int. 2017, 43, 14616–14622. [Google Scholar] [CrossRef]

- Transparent Conductors as Solar Energy Materials: A Panoramic Review—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S092702480700205X (accessed on 1 June 2024).

- Gordon, J.M. Solar Energy: The State of the Art; Routledge: London, UK, 2013; ISBN 978-1-134-27582-3. [Google Scholar]

- Jelle, B.P.; Kalnæs, S.E.; Gao, T. Low-emissivity materials for building applications: A state-of-the-art review and future research perspectives. Energy Build. 2015, 96, 329–356. [Google Scholar] [CrossRef]

- Pu, J.; Shen, C.; Wang, J.; Zhang, Y.; Zhang, C.; Kalogirou, S.A. Near-infrared absorbing glazing for energy-efficient windows: A critical review and performance assessments from the building requirements. Nano Energy 2023, 110, 108334. [Google Scholar] [CrossRef]

- Kitsopoulou, A.; Bellos, E.; Lykas, P.; Vrachopoulos, M.G.; Tzivanidis, C. Multi-objective evaluation of different retrofitting scenarios for a typical Greek building. Sustain. Energy Technol. Assess. 2023, 57, 103156. [Google Scholar] [CrossRef]

- Somasundaram, S.; Chong, A.; Wei, Z.; Thangavelu, S.R. Energy saving potential of low-e coating based retrofit double glazing for tropical climate. Energy Build. 2020, 206, 109570. [Google Scholar] [CrossRef]

- Yuk, H.; Choi, J.Y.; Yang, S.; Kim, S. Balancing preservation and utilization: Window retrofit strategy for energy efficiency in historic modern building. Build. Environ. 2024, 259, 111648. [Google Scholar] [CrossRef]

- Berardi, U. The development of a monolithic aerogel glazed window for an energy retrofitting project. Appl. Energy 2015, 154, 603–615. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E. Experimental performance evaluation of aerogel glazing systems. Appl. Energy 2012, 97, 430–437. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E. Glazing systems with silica aerogel for energy savings in buildings. Appl. Energy 2012, 98, 396–403. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, W.; Li, D.; Zhang, C.; Arıcı, M.; Yıldız, Ç.; Zhang, X.; Ma, Y. Energy efficiency optimization of PCM and aerogel-filled multiple glazing windows. Energy 2021, 222, 119916. [Google Scholar] [CrossRef]

- Ramana, M.V.; Saboor, S. A novel glazing system filled with hydrogel granules: Energy saving, diurnal illumination, color rendering, and CO2 emission mitigation prospective. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–16. [Google Scholar] [CrossRef]

- Huang, M.; Tang, G.H.; Si, Q.; Pu, J.H.; Sun, Q.; Du, M. Plasmonic aerogel window with structural coloration for energy-efficient and sustainable building envelopes. Renew. Energy 2023, 216, 119006. [Google Scholar] [CrossRef]

- Khaled Mohammad, A.; Ghosh, A. Exploring energy consumption for less energy-hungry building in UK using advanced aerogel window. Sol. Energy 2023, 253, 389–400. [Google Scholar] [CrossRef]

- Tiwari, R.; Kim, J. Multi-cell, triple pane, vacuum insulated glazing. Sol. Energy 2022, 245, 340–352. [Google Scholar] [CrossRef]

- Collins, R.E.; Simko, T.M. Current status of the science and technology of vacuum glazing. Sol. Energy 1998, 62, 189–213. [Google Scholar] [CrossRef]

- Fang, Y.; Arya, F. Evacuated glazing with tempered glass. Sol. Energy 2019, 183, 240–247. [Google Scholar] [CrossRef]

- Fang, Y.; Hyde, T.; Hewitt, N.; Eames, P.C.; Norton, B. Thermal performance analysis of an electrochromic vacuum glazing with low emittance coatings. Sol. Energy 2010, 84, 516–525. [Google Scholar] [CrossRef]

- Vacuum Insulating Glass—Past, Present and Prognosis|glassonweb.com. Available online: http://www.glassonweb.com/article/vacuum-insulating-glass-past-present-and-prognosis (accessed on 2 June 2024).

- Katsura, T.; Memon, S.; Radwan, A.; Nakamura, M.; Nagano, K. Thermal performance analysis of a new structured-core translucent vacuum insulation panel in comparison to vacuum glazing: Experimental and theoretically validated analyses. Sol. Energy 2020, 199, 326–346. [Google Scholar] [CrossRef]

- Investigation of Thermal and Electrical Performances of a Combined Semi-Transparent PV-Vacuum Glazing—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0306261918310687 (accessed on 4 June 2024).

- Granqvist, C.G. Chromogenic materials for transmittance control of large-area windows. Crit. Rev. Solid State Mater. Sci. 1990, 16, 291–308. [Google Scholar] [CrossRef]

- Granqvist, C.G. Recent progress in thermochromics and electrochromics: A brief survey. Thin Solid Film. 2016, 614, 90–96. [Google Scholar] [CrossRef]

- Li, S.-Y.; Niklasson, G.A.; Granqvist, C.G. Thermochromic fenestration with VO2-based materials: Three challenges and how they can be met. Thin Solid Film. 2012, 520, 3823–3828. [Google Scholar] [CrossRef]

- Li, S.-Y.; Mlyuka, N.R.; Primetzhofer, D.; Hallén, A.; Possnert, G.; Niklasson, G.A.; Granqvist, C.G. Bandgap widening in thermochromic Mg-doped VO2 thin films: Quantitative data based on optical absorption. Appl. Phys. Lett. 2013, 103, 161907. [Google Scholar] [CrossRef]

- Ji, Y.-X.; Niklasson, G.A.; Granqvist, C.G. Durability of VO2-based thin films at elevated temperature: Towards thermochromic fenestration. J. Phys. Conf. Ser. 2014, 559, 012005. [Google Scholar] [CrossRef]

- Smith, G.B. Green nanotechnology. In Proceedings of the Nanostructured Thin Films IV, San Diego, CA, USA, 23–25 August 2011; SPIE: Bellingham, WA, USA, 2011; Volume 8104, pp. 9–22. [Google Scholar]

- Teixeira, H.; Glória Gomes, M.; Moret Rodrigues, A.; Aelenei, D. Assessment of the visual, thermal and energy performance of static vs thermochromic double-glazing under different European climates. Build. Environ. 2022, 217, 109115. [Google Scholar] [CrossRef]

- Aburas, M.; Ebendorff-Heidepriem, H.; Lei, L.; Li, M.; Zhao, J.; Williamson, T.; Wu, Y.; Soebarto, V. Smart windows—Transmittance tuned thermochromic coatings for dynamic control of building performance. Energy Build. 2021, 235, 110717. [Google Scholar] [CrossRef]

- Khaled, K.; Berardi, U.; Liao, Z. Energy modelling and saving potential of polymeric solar-responsive thermochromic window films. Sol. Energy 2022, 244, 84–103. [Google Scholar] [CrossRef]

- Pehlivan, İ.B.; Marsal, R.; Pehlivan, E.; Runnerstrom, E.L.; Milliron, D.J.; Granqvist, C.G.; Niklasson, G.A. Electrochromic devices with polymer electrolytes functionalized by SiO2 and In2O3:Sn nanoparticles: Rapid coloring/bleaching dynamics and strong near-infrared absorption. Sol. Energy Mater. Sol. Cells 2014, 126, 241–247. [Google Scholar] [CrossRef]

- Arvizu, M.A.; Triana, C.A.; Stefanov, B.I.; Granqvist, C.G.; Niklasson, G.A. Electrochromism in sputter-deposited W–Ti oxide films: Durability enhancement due to Ti. Sol. Energy Mater. Sol. Cells 2014, 125, 184–189. [Google Scholar] [CrossRef]

- Detsi, M.; Manolitsis, A.; Atsonios, I.; Mandilaras, I.; Founti, M. Energy Savings in an Office Building with High WWR Using Glazing Systems Combining Thermochromic and Electrochromic Layers. Energies 2020, 13, 3020. [Google Scholar] [CrossRef]

- Fathi, S.; Kavoosi, A. Effect of electrochromic windows on energy consumption of high-rise office buildings in different climate regions of Iran. Sol. Energy 2021, 223, 132–149. [Google Scholar] [CrossRef]

- Hoon Lee, J.; Jeong, J.; Tae Chae, Y. Optimal control parameter for electrochromic glazing operation in commercial buildings under different climatic conditions. Appl. Energy 2020, 260, 114338. [Google Scholar] [CrossRef]

- ELVIAL EL4600. Available online: https://www.alcon.com.gr/elvial-el4600/ (accessed on 2 July 2024).

- Doors, J.V. Sleek and Modern Flush Casement Windows—UPVC and Aluminium Options. Available online: https://www.justvaluedoors.co.uk/flush-casement-windows (accessed on 27 June 2024).

- Michael Krech Online UPVC Double/Triple Window/Door Prices/Quotes, Supply/Install. Available online: https://www.modernupvcwindows.co.uk (accessed on 27 June 2024).

- KÖMMERLING 76 MD standard|KÖMMERLING. Available online: https://www.koemmerling.gr/gr/products/window-residential-door-systems/76-mm-systems/md-standard/ (accessed on 2 July 2024).

- Media, L. MB-104 PASSIVE Window & Door System that Provides the Highest Thermal Insulation Performance—Aluprof. Available online: https://aluprof.com/en/product/mb-104-passive (accessed on 27 June 2024).

- Smart Glass Cost and Smart Film Price. Available online: https://www.smartglasscountry.com/news/smart-glass-cost-and-smart-film-price (accessed on 27 June 2024).

- SageGlass Classic® Product|Smart Windows|SageGlass. Available online: https://www.sageglass.com/smart-windows/sageglass-classic (accessed on 27 June 2024).

- How Much Does Smart Glass Cost? 2024. Available online: https://homeguide.com/costs/smart-glass-cost (accessed on 27 June 2024).

- Wilson, H.R. Chromogenic Glazing: Performance and Durability Issues as Addressed in IEA Task 27. Available online: https://w.iea-shc.org/Data/Sites/1/publications/b2_Chromogenic_Glazing_Performance_21.pdf (accessed on 6 June 2024).

- Reilly, A.; Kinnane, O. The impact of thermal mass on building energy consumption. Appl. Energy 2017, 198, 108–121. [Google Scholar] [CrossRef]

- Feng, D.; Feng, Y.; Qiu, L.; Li, P.; Zang, Y.; Zou, H.; Yu, Z.; Zhang, X. Review on nanoporous composite phase change materials: Fabrication, characterization, enhancement and molecular simulation. Renew. Sustain. Energy Rev. 2019, 109, 578–605. [Google Scholar] [CrossRef]

- Weng, K.; Xu, X.; Chen, Y.; Li, X.; Qing, C.; Zou, D. Development and applications of multifunctional microencapsulated PCMs: A comprehensive review. Nano Energy 2024, 122, 109308. [Google Scholar] [CrossRef]

- Chang, Z.; Wang, K.; Wu, X.; Lei, G.; Wang, Q.; Liu, H.; Wang, Y.; Zhang, Q. Review on the preparation and performance of paraffin-based phase change microcapsules for heat storage. J. Energy Storage 2022, 46, 103840. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, X.; Hua, W. Review of preparation technologies of organic composite phase change materials in energy storage. J. Mol. Liq. 2021, 336, 115923. [Google Scholar] [CrossRef]

- Himran, S.; Suwono, A.; Mansoori, G.A. Characterization of Alkanes and Paraffin Waxes for Application as Phase Change Energy Storage Medium. Energy Sources 1994, 16, 117–128. [Google Scholar] [CrossRef]

- Preparation and Thermal Characterization of Expanded Graphite/Paraffin Composite Phase Change Material—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0008622310001958 (accessed on 7 June 2024).

- Xie, N.; Niu, J.; Wu, T.; Gao, X.; Fang, Y.; Zhang, Z. Fabrication and characterization of CaCl2·6H2O composite phase change material in the presence of CsxWO3 nanoparticles. Sol. Energy Mater. Sol. Cells 2019, 200, 110034. [Google Scholar] [CrossRef]

- Zhang, P.; Ma, F.; Xiao, X. Thermal energy storage and retrieval characteristics of a molten-salt latent heat thermal energy storage system. Appl. Energy 2016, 173, 255–271. [Google Scholar] [CrossRef]

- Shamberger, P.J.; Bruno, N.M. Review of metallic phase change materials for high heat flux transient thermal management applications. Appl. Energy 2020, 258, 113955. [Google Scholar] [CrossRef]

- Wang, S.; Lei, K.; Wang, Z.; Wang, H.; Zou, D. Metal-based phase change material (PCM) microcapsules/nanocapsules: Fabrication, thermophysical characterization and application. Chem. Eng. J. 2022, 438, 135559. [Google Scholar] [CrossRef]

- Kravvaritis, E.D.; Antonopoulos, K.A.; Tzivanidis, C. Experimental determination of the effective thermal capacity function and other thermal properties for various phase change materials using the thermal delay method. Appl. Energy 2011, 88, 4459–4469. [Google Scholar] [CrossRef]

- Microencapsulated Phase Change Materials/PCM Grain Composition ANDOR/AND/OR. Available online: https://www.andores.com/sale-9516697-microencapsulated-phase-change-materials-pcm-grain-composition-andor-and-or.html (accessed on 7 June 2024).

- Rubitherm GmbH. Available online: https://www.rubitherm.eu/en/productcategory/organische-pcm-rt (accessed on 6 October 2023).

- Salt Hydrate Phase Change Material/Solar Heat Energy Storage in Phase Change Materials for Microencapsulated. Available online: https://www.andores.com/sale-9516690-salt-hydrate-phase-change-material-solar-heat-energy-storage-in-phase-change-materials-for-microenca.html (accessed on 7 June 2024).

- Alshuraiaan, B. Efficient utilization of PCM in building envelope in a hot environment condition. Int. J. Thermofluids 2022, 16, 100205. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castell, A.; Barreneche, C.; De Gracia, A.; Fernández, A.I. Materials used as PCM in thermal energy storage in buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Dardouri, S.; Mankai, S.; Almoneef, M.M.; Mbarek, M.; Sghaier, J. Energy performance based optimization of building envelope containing PCM combined with insulation considering various configurations. Energy Rep. 2023, 10, 895–909. [Google Scholar] [CrossRef]

- Lachheb, M.; Younsi, Z.; Youssef, N.; Bouadila, S. Enhancing building energy efficiency and thermal performance with PCM-Integrated brick walls: A comprehensive review. Build. Environ. 2024, 256, 111476. [Google Scholar] [CrossRef]

- Reddy, V.J.; Ghazali, M.F.; Kumarasamy, S. Advancements in phase change materials for energy-efficient building construction: A comprehensive review. J. Energy Storage 2024, 81, 110494. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Soares, N.; Ferreira, V. Experimental testing and numerical modelling of masonry wall solution with PCM incorporation: A passive construction solution. Energy Build. 2012, 49, 235–245. [Google Scholar] [CrossRef]

- Meng, E.; Yang, J.; Zhou, B.; Wang, C.; Li, J. Preparation and thermal performance of phase change material (PCM) foamed cement used for the roof. J. Build. Eng. 2022, 53, 104579. [Google Scholar] [CrossRef]

- Abass, P.J.; Muthulingam, S. Thermal energy storage performance of biaxial voided RCC roof slab integrated with macroencapsulated PCM for passive cooling of buildings. J. Energy Storage 2024, 88, 111478. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Hang, Z.; Feng, T.; Yang, H. Research on the development of green foaming fluid and the improvement in the performance of foamed cement. Constr. Build. Mater. 2024, 411, 134722. [Google Scholar] [CrossRef]

- Wang, X.; Ma, B.; Li, S.; Si, W.; Wei, K.; Zhang, H.; Zhou, X.; Fang, Y.; Kang, X.; Shi, W. Review on application of phase change materials in asphalt pavement. J. Traffic Transp. Eng. (Engl. Ed.) 2023, 10, 185–229. [Google Scholar] [CrossRef]

- Mizwar, I.K.; Napiah, M.; Sutanto, M.H. Thermal properties of cool asphalt concrete containing phase change material. IOP Conf. Ser. Mater. Sci. Eng. 2019, 527, 012049. [Google Scholar] [CrossRef]

- Chen, Z.; Li, J.; Tang, G.; Zhang, J.; Zhang, D.; Gao, P. High-efficiency heating and cooling technology with embedded pipes in buildings and underground structures: A review. Renew. Sustain. Energy Rev. 2024, 192, 114209. [Google Scholar] [CrossRef]

- Kitsopoulou, A.; Ziozas, N.; Iliadis, P.; Bellos, E.; Tzivanidis, C.; Nikolopoulos, N. Energy performance analysis of alternative building retrofit interventions for the four climatic zones of Greece. J. Build. Eng. 2024, 87, 109015. [Google Scholar] [CrossRef]

- Beemkumar, N.; Yuvarajan, D.; Arulprakasajothi, M.; Elangovan, K.; Arunkumar, T. Control of room temperature fluctuations in the building by incorporating PCM in the roof. J. Therm. Anal. Calorim. 2021, 143, 3039–3046. [Google Scholar] [CrossRef]

- Pasupathy, A.; Athanasius, L.; Velraj, R.; Seeniraj, R.V. Experimental investigation and numerical simulation analysis on the thermal performance of a building roof incorporating phase change material (PCM) for thermal management. Appl. Therm. Eng. 2008, 28, 556–565. [Google Scholar] [CrossRef]

- Liu, Z.-A.; Hou, J.; Mo, W.; Liu, Z.; Wang, D. Parameters/configurations adaptability and economic evaluation of PCM for reducing energy demands with lightweight buildings under different climates/cities based on orthogonal experiment and EnergyPlus: China-Japan comparison. Therm. Sci. Eng. Prog. 2023, 45, 102143. [Google Scholar] [CrossRef]

- Nurlybekova, G.; Memon, S.A.; Adilkhanova, I. Quantitative evaluation of the thermal and energy performance of the PCM integrated building in the subtropical climate zone for current and future climate scenario. Energy 2021, 219, 119587. [Google Scholar] [CrossRef]

- Dardouri, S.; Tunçbilek, E.; Khaldi, O.; Arıcı, M.; Sghaier, J. Optimizing PCM Integrated Wall and Roof for Energy Saving in Building under Various Climatic Conditions of Mediterranean Region. Buildings 2023, 13, 806. [Google Scholar] [CrossRef]

- Panayiotou, G.P.; Kalogirou, S.A.; Tassou, S.A. Evaluation of the application of Phase Change Materials (PCM) on the envelope of a typical dwelling in the Mediterranean region. Renew. Energy 2016, 97, 24–32. [Google Scholar] [CrossRef]

- Energies|Free Full-Text|Assessing the Energy Performance of Prefabricated Buildings Considering Different Wall Configurations and the Use of PCMs in Greece. Available online: https://www.mdpi.com/1996-1073/13/19/5026 (accessed on 11 December 2023).

- Duan, S.; Jing, C.; Zhao, Z. Energy and exergy analysis of different Trombe walls. Energy Build. 2016, 126, 517–523. [Google Scholar] [CrossRef]

- Xiao, Y.; Yang, Q.; Fei, F.; Li, K.; Jiang, Y.; Zhang, Y.; Fukuda, H.; Ma, Q. Review of Trombe wall technology: Trends in optimization. Renew. Sustain. Energy Rev. 2024, 200, 114503. [Google Scholar] [CrossRef]

- Xiong, Q.; Alshehri, H.M.; Monfaredi, R.; Tayebi, T.; Majdoub, F.; Hajjar, A.; Delpisheh, M.; Izadi, M. Application of phase change material in improving trombe wall efficiency: An up-to-date and comprehensive overview. Energy Build. 2022, 258, 111824. [Google Scholar] [CrossRef]

- Hu, Z.; He, W.; Ji, J.; Zhang, S. A review on the application of Trombe wall system in buildings. Renew. Sustain. Energy Rev. 2017, 70, 976–987. [Google Scholar] [CrossRef]

- Zhou, S.; Bai, F.; Razaqpur, G.; Wang, B. Effect of key parameters on the transient thermal performance of a building envelope with Trombe wall containing phase change material. Energy Build. 2023, 284, 112879. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Zisopoulou, E.; Mitsopoulos, G.; Antonopoulos, K.A. An innovative Trombe wall as a passive heating system for a building in Athens—A comparison with the conventional Trombe wall and the insulated wall. Energy Build. 2016, 133, 754–769. [Google Scholar] [CrossRef]

- Liu, H.; Tan, Q.; Shi, Y.; Yu, B.; Zhang, M. Enhancing indoor thermal comfort and energy efficiency: A comparative study of RC-PCM Trombe wall performance. Renew. Energy 2024, 227, 120542. [Google Scholar] [CrossRef]

- Zhou, S.; Razaqpur, A.G. Efficient heating of buildings by passive solar energy utilizing an innovative dynamic building envelope incorporating phase change material. Renew. Energy 2022, 197, 305–319. [Google Scholar] [CrossRef]

- Zhou, S.; Razaqpur, A.G. CFD modeling and experimental validation of the thermal performance of a novel dynamic PCM Trombe wall: Comparison with the companion static wall with and without PCM. Appl. Energy 2024, 353, 121985. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhang, T.; Liu, Z.; Fukuda, H. Thermal performance study of low-e glass Trombe wall assisted with the temperature-controlled ventilation system in Hot-Summer/Cold-Winter Zone of China. Case Stud. Therm. Eng. 2023, 45, 102882. [Google Scholar] [CrossRef]

- Pourghorban, A.; Asoodeh, H. The impacts of advanced glazing units on annual performance of the Trombe wall systems in cold climates. Sustain. Energy Technol. Assess. 2022, 51, 101983. [Google Scholar] [CrossRef]

- Wang, C.; Ji, J.; Zhang, C.; Ke, W.; Tang, Y.; Tian, X. Experimental and numerical investigation of a multi-functional photovoltaic/thermal wall: A practical application in the civil building. Energy 2022, 241, 122896. [Google Scholar] [CrossRef]

- Santamouris, M.; Yun, G.Y. Recent development and research priorities on cool and super cool materials to mitigate urban heat island. Renew. Energy 2020, 161, 792–807. [Google Scholar] [CrossRef]

- Mauri, L.; Battista, G.; de Lieto Vollaro, E.; de Lieto Vollaro, R. Retroreflective materials for building’s façades: Experimental characterization and numerical simulations. Sol. Energy 2018, 171, 150–156. [Google Scholar] [CrossRef]

- Garshasbi, S.; Huang, S.; Valenta, J.; Santamouris, M. On the combination of quantum dots with near-infrared reflective base coats to maximize their urban overheating mitigation potential. Sol. Energy 2020, 211, 111–116. [Google Scholar] [CrossRef]

- Zinzi, M.; Agnoli, S.; Ulpiani, G.; Mattoni, B. On the potential of switching cool roofs to optimize the thermal response of residential buildings in the Mediterranean region. Energy Build. 2021, 233, 110698. [Google Scholar] [CrossRef]

- Morales-Inzunza, S.; González-Trevizo, M.E.; Martínez-Torres, K.E.; Luna-León, A.; Tamayo-Pérez, U.J.; Fernández-Melchor, F.; Santamouris, M. On the potential of cool materials in the urban heat island context: Scalability challenges and technological setbacks towards building decarbonization. Energy Build. 2023, 296, 113330. [Google Scholar] [CrossRef]

- Utilisation of Waste Marble Powder as Low-Cost Cementing Materials in the Production of Mortar—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S2352710220320623 (accessed on 9 June 2024).

- Rosati, A.; Fedel, M.; Rossi, S. NIR reflective pigments for cool roof applications: A comprehensive review. J. Clean. Prod. 2021, 313, 127826. [Google Scholar] [CrossRef]

- Infrastructures|Free Full-Text|Impact of Incorporating NIR Reflective Pigments in Finishing Coatings of ETICS. Available online: https://www.mdpi.com/2412-3811/6/6/79 (accessed on 9 June 2024).

- Characterization and Thermal Performance Evaluation of Infrared Reflective Coatings Compatible with Historic Buildings—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0360132318301069 (accessed on 9 June 2024).

- Qi, Y.; Zhao, H.; Wu, Y.; Ren, Y. Facile preparation of solar reflective cool colored material with desired superhydrophobicity. Sol. Energy Mater. Sol. Cells 2022, 242, 111761. [Google Scholar] [CrossRef]

- Mastrapostoli, E.; Santamouris, M.; Kolokotsa, D.; Vassilis, P.; Venieri, D.; Gompakis, K. On the ageing of cool roofs: Measure of the optical degradation, chemical and biological analysis and assessment of the energy impact. Energy Build. 2016, 114, 191–199. [Google Scholar] [CrossRef]

- Yang, N.; Liu, J.-H.; Kai, M.-F.; Dai, J.-G. Geopolymer-based radiative cooling coating: Tailoring surface hydrophobic properties while retaining optical characteristics. Constr. Build. Mater. 2024, 428, 136373. [Google Scholar] [CrossRef]

- Levinson, R.; Chen, S.; Slack, J.; Goudey, H.; Harima, T.; Berdahl, P. Design, characterization, and fabrication of solar-retroreflective cool-wall materials. Sol. Energy Mater. Sol. Cells 2020, 206, 110117. [Google Scholar] [CrossRef]

- Santamouris, M.; Feng, J. Recent Progress in Daytime Radiative Cooling: Is It the Air Conditioner of the Future? Buildings 2018, 8, 168. [Google Scholar] [CrossRef]

- Suichi, T.; Ishikawa, A.; Hayashi, Y.; Tsuruta, K. Performance limit of daytime radiative cooling in warm humid environment. AIP Adv. 2018, 8, 055124. [Google Scholar] [CrossRef]

- Recent Advances in Quantum Dot Surface Chemistry|ACS Applied Materials & Interfaces. Available online: https://pubs.acs.org/doi/10.1021/am405196u (accessed on 9 June 2024).

- Garshasbi, S.; Huang, S.; Valenta, J.; Santamouris, M. Can quantum dots help to mitigate urban overheating? An experimental and modelling study. Sol. Energy 2020, 206, 308–316. [Google Scholar] [CrossRef]

- Hu, J.; Yu, X. (Bill) Design and characterization of energy efficient roofing system with innovative TiO2 enhanced thermochromic films. Constr. Build. Mater. 2019, 223, 1053–1062. [Google Scholar] [CrossRef]

- Khan, A.; Carlosena, L.; Khorat, S.; Khatun, R.; Doan, Q.-V.; Feng, J.; Santamouris, M. On the winter overcooling penalty of super cool photonic materials in cities. Sol. Energy Adv. 2021, 1, 100009. [Google Scholar] [CrossRef]

- Vakilinezhad, R.; Khabir, S. Evaluation of thermal and energy performance of cool envelopes on low-rise residential buildings in hot climates. J. Build. Eng. 2023, 72, 106643. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, J.; Gao, Z. A case study of the effect of building surface cool and super cool materials on residential neighbourhood energy consumption in Nanjing. Renew. Sustain. Energy Rev. 2024, 189, 114027. [Google Scholar] [CrossRef]

- Kolokotsa, D.-D.; Giannariakis, G.; Gobakis, K.; Giannarakis, G.; Synnefa, A.; Santamouris, M. Cool roofs and cool pavements application in Acharnes, Greece. Sustain. Cities Soc. 2018, 37, 466–474. [Google Scholar] [CrossRef]

- Carlosena, L.; Ruiz-Pardo, Á.; Rodríguez-Jara, E.Á.; Santamouris, M. Worldwide potential of emissive materials based radiative cooling technologies to mitigate urban overheating. Build. Environ. 2023, 243, 110694. [Google Scholar] [CrossRef]

- Suhendri, S.; Hu, M.; Su, Y.; Darkwa, J.; Riffat, S. Performance evaluation of combined solar chimney and radiative cooling ventilation. Build. Environ. 2022, 209, 108686. [Google Scholar] [CrossRef]

- Cheng, Y.; Chen, X.; Xu, B.; Pei, G.; Jiao, D. Experimental analysis of building envelope integrating phase change material and cool paint under a real environment in autumn. J. Clean. Prod. 2024, 461, 142674. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhou, D.; Wang, Y.; Ma, D.; Meng, X. Assessment of urban surface and canopy cooling strategies in high-rise residential communities. J. Clean. Prod. 2021, 288, 125599. [Google Scholar] [CrossRef]

- Carlosena, L.; Andueza, Á.; Torres, L.; Irulegi, O.; Hernández-Minguillón, R.J.; Sevilla, J.; Santamouris, M. Experimental development and testing of low-cost scalable radiative cooling materials for building applications. Sol. Energy Mater. Sol. Cells 2021, 230, 111209. [Google Scholar] [CrossRef]

- Thermochromism in Commercial Products|Journal of Chemical Education. Available online: https://pubs.acs.org/doi/10.1021/ed076p1201?src=getftr (accessed on 11 June 2024).

- Panák, O.; Držková, M.; Kaplanová, M. Insight into the evaluation of colour changes of leuco dye based thermochromic systems as a function of temperature. Dye. Pigment. 2015, 120, 279–287. [Google Scholar] [CrossRef]

- Aklujkar, P.S.; Kandasubramanian, B. A review of microencapsulated thermochromic coatings for sustainable building applications. J. Coat. Technol. Res. 2021, 18, 19–37. [Google Scholar] [CrossRef]

- Karlessi, T.; Santamouris, M.; Apostolakis, K.; Synnefa, A.; Livada, I. Development and testing of thermochromic coatings for buildings and urban structures. Sol. Energy 2009, 83, 538–551. [Google Scholar] [CrossRef]

- Yu, X.B.; Hu, J.; Case Western Reserve University Department of Civil Engineering. Polymeric Thermochromic Dye for Improvement of Asphalt Pavement Durability: Final Report; 2017. Available online: https://rosap.ntl.bts.gov/view/dot/32189 (accessed on 13 May 2023).

- Ma‡, Y.; Zhu, B.; Wu, K. Preparation and solar reflectance spectra of chameleon-type building coatings. Sol. Energy 2001, 70, 417–422. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, X.; Zhu, B.; Wu, K. Research on reversible effects and mechanism between the energy-absorbing and energy-reflecting states of chameleon-type building coatings. Sol. Energy 2002, 72, 511–520. [Google Scholar] [CrossRef]

- Fujita, K.; Senga, K. Thermochromic Microencapsulated Pigments. US6494950B1, 17 December 2002. Available online: https://patents.google.com/patent/US6494950B1/en (accessed on 13 May 2023).

- Clayton, T.S.; Owen, T.J.; Small, L. Small Scale Microencapsulated Pigments and Uses Thereof. US8883049B2, 11 November 2014. Available online: https://patents.google.com/patent/US8883049B2/en (accessed on 13 May 2023).

- White, M.A.; LeBlanc, M. Thermochromism in Commercial Products. J. Chem. Educ. 1999, 76, 1201. [Google Scholar] [CrossRef]

- Sharma, M.; Whaley, M.; Chamberlain, J.; Oswald, T.; Schroden, R.; Graham, A.; Barger, M.; Richey, B. Evaluation of thermochromic elastomeric roof coatings for low-slope roofs. Energy Build. 2017, 155, 459–466. [Google Scholar] [CrossRef]

- Hu, J.; Yu, X. Thermo and light-responsive building envelope: Energy analysis under different climate conditions. Sol. Energy 2019, 193, 866–877. [Google Scholar] [CrossRef]

- Fabiani, C.; Pisello, A.L.; Bou-Zeid, E.; Yang, J.; Cotana, F. Adaptive measures for mitigating urban heat islands: The potential of thermochromic materials to control roofing energy balance. Appl. Energy 2019, 247, 155–170. [Google Scholar] [CrossRef]

- Zheng, S.; Xu, Y.; Shen, Q.; Yang, H. Preparation of thermochromic coatings and their energy saving analysis. Sol. Energy 2015, 112, 263–271. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhai, X. Preparation and testing of thermochromic coatings for buildings. Sol. Energy 2019, 191, 540–548. [Google Scholar] [CrossRef]

- Perez, G.; Allegro, V.R.; Alonso, C.; Martín-Consuegra, F.; Oteiza, I.; Frutos, B.; Guerrero, A. Selection of suitable materials for the development of an innovative thermochromic Trombe wall. Adv. Build. Energy Res. 2021, 15, 146–160. [Google Scholar] [CrossRef]

- Venkataraman, K. The Chemistry of Synthetic Dyes V4; Elsevier: Amsterdam, The Netherlands, 2012; ISBN 978-0-323-14570-1. [Google Scholar]

- Karlessi, T.; Santamouris, M. Improving the performance of thermochromic coatings with the use of UV and optical filters tested under accelerated aging conditions. Int. J. Low-Carbon Technol. 2015, 10, 45–61. [Google Scholar] [CrossRef]

- Soudian, S.; Berardi, U.; Laschuk, N.O. Effects of Long-Term UV Exposure on the Performance of Cement Plasters Integrated with Thermochromic Paint and PCMs for Building Facade Applications. In Proceedings of the XV International Conference on Durability of Building Materials and Components (DBMC 2020), Barcelona, Spain, 20–23 October 2020. [Google Scholar] [CrossRef]

- Song, J.; Zhang, W.; Sun, Z.; Pan, M.; Tian, F.; Li, X.; Ye, M.; Deng, X. Durable radiative cooling against environmental aging. Nat. Commun. 2022, 13, 4805. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.; Huang, X.; Li, X.; Feng, C. Impact of aging, precipitation, and orientation on performance of radiative cooling for building envelope: A field investigation. Energy Build. 2023, 279, 112716. [Google Scholar] [CrossRef]

- Di Giuseppe, A.; Cardinali, M.; Castellani, B.; Filipponi, M.; Nicolini, A.; Rossi, F. The impact of outdoor aging and soiling on the optic features of glass beads retro-reflective coatings. Sol. Energy 2023, 258, 28–36. [Google Scholar] [CrossRef]

- Wang, J.; Xie, M.; An, Y.; Tao, Y.; Sun, J.; Ji, C. All-season thermal regulation with thermochromic temperature-adaptive radiative cooling coatings. Sol. Energy Mater. Sol. Cells 2022, 246, 111883. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.; Xie, N.; Jia, M.; Yang, B.; Li, S. Laboratorial Investigation on Optical and Thermal Properties of Thermochromic Pavement Coatings for Dynamic Thermoregulation and Urban Heat Island Mitigation. Sustain. Cities Soc. 2022, 83, 103950. [Google Scholar] [CrossRef]

- Liu, S.; Liu, Z.; Wang, J.; Ding, X.; Meng, X. Effect of the material color on optical properties of thermochromic coatings employed in buildings. Case Stud. Therm. Eng. 2023, 45, 102916. [Google Scholar] [CrossRef]

- Badino, E.; Autretto, G.; Fantucci, S.; Serra, V.; Zinzi, M. Development of testing procedures for assessing the thermal and optical performance of thermochromic coatings for buildings. Sol. Energy 2023, 263, 111950. [Google Scholar] [CrossRef]

- Kitsopoulou, A.; Bellos, E.; Sammoutos, C.; Lykas, P.; Vrachopoulos, M.G.; Tzivanidis, C. A detailed investigation of thermochromic dye-based roof coatings for Greek climatic conditions. J. Build. Eng. 2024, 84, 108570. [Google Scholar] [CrossRef]

- Kitsopoulou, A.; Pallantzas, D.; Sammoutos, C.; Lykas, P.; Bellos, E.; Vrachopoulos, M.; Tzivanidis, C. A comparative investigation of building rooftop retrofit actions using an energy and computer fluid dynamics approach. Energy Build. 2024, 315, 114326. [Google Scholar] [CrossRef]

- Butt, A.A.; de Vries, S.B.; Loonen, R.C.G.M.; Hensen, J.L.M.; Stuiver, A.; van den Ham, J.E.J.; Erich, B.S.J.F. Investigating the energy saving potential of thermochromic coatings on building envelopes. Appl. Energy 2021, 291, 116788. [Google Scholar] [CrossRef]

- Berardi, U.; Garai, M.; Morselli, T. Preparation and assessment of the potential energy savings of thermochromic and cool coatings considering inter-building effects. Sol. Energy 2020, 209, 493–504. [Google Scholar] [CrossRef]

- Gonçalves, A.; Resende, J.; Marques, A.C.; Pinto, J.V.; Nunes, D.; Marie, A.; Goncalves, R.; Pereira, L.; Martins, R.; Fortunato, E. Smart optically active VO2 nanostructured layers applied in roof-type ceramic tiles for energy efficiency. Sol. Energy Mater. Sol. Cells 2016, 150, 1–9. [Google Scholar] [CrossRef]

- Sirvent, P.; Perez, G.; Guerrero, A. VO2 sprayed cementitious materials for thermochromic building envelopes. Sol. Energy 2022, 243, 13–21. [Google Scholar] [CrossRef]

- Jeon, B.-H.; Yang, S.-K.; Ahn, Y.-C.; Kang, Y.-H. Policies and Energy Efficiency of Heat Recovery Ventilators in South Korea. Energies 2023, 16, 7539. [Google Scholar] [CrossRef]

- Ji, Y.; Duanmu, L.; Hu, S. Measurement and analysis of airtightness safeguard measures for typical ultra-low energy buildings. Energy Built Environ. 2024, 5, 348–363. [Google Scholar] [CrossRef]

- Meiss, A.; Feijó-Muñoz, J. The energy impact of infiltration: A study on buildings located in north central Spain. Energy Effic. 2015, 8, 51–64. [Google Scholar] [CrossRef]

- Brinks, P.; Kornadt, O.; Oly, R. Air infiltration assessment for industrial buildings. Energy Build. 2015, 86, 663–676. [Google Scholar] [CrossRef]

- 2019 Version of ASHRAE Standard 62.2 Released|ashrae.org. Available online: https://www.ashrae.org/news/esociety/2019-version-of-ashrae-standard-62-2-released (accessed on 21 June 2024).

- Sauer, H.J.; Howell, R.H. Promise and potential of air-to-air energy recovery systems. Int. J. Refrig. 1981, 4, 182–194. [Google Scholar] [CrossRef]

- Passive House Portal Component Database. Available online: https://database.passivehouse.com/el/components/ (accessed on 21 June 2024).

- Domestic Heat Pumps—HRV—Energywise Ireland. Available online: https://energywiseireland.ie/hrv/ (accessed on 21 June 2024).

- Bellos, E.; Iliadis, P.; Papalexis, C.; Rotas, R.; Mamounakis, I.; Sougkakis, V.; Nikolopoulos, N.; Kosmatopoulos, E. Holistic renovation of a multi-family building in Greece based on dynamic simulation analysis. J. Clean. Prod. 2022, 381, 135202. [Google Scholar] [CrossRef]

- Ferdyn-Grygierek, J.; Grygierek, K. Ventilation Methods for Improving the Indoor Air Quality and Energy Efficiency of Multi-Family Buildings in Central Europe. Energies 2024, 17, 2232. [Google Scholar] [CrossRef]

- Cheng, S.; Ma, Y.; Qin, M. The energy saving performance of heat recovery ventilation system in residential buildings in the summer of hot-summer and cold-winter zone in China. In Proceedings of the Healthy, Intelligent and Resilient Buildings and Urban Environments; International Association of Building Physics (IABP), Syracuse, NY, USA, 23–26 September 2018; pp. 427–433. [Google Scholar]

- Karaiskos, P.; Martinez-Molina, A.; Alamaniotis, M. Examining the Impact of Natural Ventilation versus Heat Recovery Ventilation Systems on Indoor Air Quality: A Tiny House Case Study. Buildings 2024, 14, 1802. [Google Scholar] [CrossRef]

- Kong, X.; Guo, C.; Lin, Z.; Duan, S.; He, J.; Ren, Y.; Ren, J. Experimental study on the control effect of different ventilation systems on fine particles in a simulated hospital ward. Sustain. Cities Soc. 2021, 73, 103102. [Google Scholar] [CrossRef] [PubMed]

- Sha, H.; Qi, D. Investigation of mechanical ventilation for cooling in high-rise buildings. Energy Build. 2020, 228, 110440. [Google Scholar] [CrossRef]

- Sha, H.; Zhang, X.; Qi, D. Optimal control of high-rise building mechanical ventilation system for achieving low risk of COVID-19 transmission and ventilative cooling. Sustain. Cities Soc. 2021, 74, 103256. [Google Scholar] [CrossRef] [PubMed]

- Shi, B.; Yu, X.; Pu, Y.; Wang, D. A theoretical study on the filtration efficiency and dust holding performance of pleated air filters. Heliyon 2023, 9, e17944. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Hu, E. Optimization of night mechanical ventilation strategy in summer for cooling energy saving based on inverse problem method. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 232, 1093–1102. [Google Scholar] [CrossRef]

- Motuzienė, V.; Lapinskienė, V.; Rynkun, G. Optimizing Ventilation Systems for Sustainable Office Buildings: Long-Term Monitoring and Environmental Impact Analysis. Sustainability 2024, 16, 984. [Google Scholar] [CrossRef]

- Maask, V.; Rosin, A.; Korõtko, T.; Thalfeldt, M.; Syri, S.; Ahmadiahangar, R. Aggregation ready flexibility management methods for mechanical ventilation systems in buildings. Energy Build. 2023, 296, 113369. [Google Scholar] [CrossRef]

- Alajmi, A.; Aba-alkhail, F.; ALAnzi, A. Determining the optimum fixed solar-shading device for minimizing the energy consumption of a side-lit office building in a scorching climate. J. Eng. Res. 2021, 9. [Google Scholar] [CrossRef]

- Alhuwayil, W.K.; Abdul Mujeebu, M.; Algarny, A.M.M. Impact of external shading strategy on energy performance of multi-story hotel building in hot-humid climate. Energy 2019, 169, 1166–1174. [Google Scholar] [CrossRef]

- Shah, I.; Su, X.; Talami, R.; Ghahramani, A. Enhancing building envelopes: Parametric analysis of shading systems for opaque facades and their comparison with cool paints. Energy Built Environ. 2024; in press. [Google Scholar] [CrossRef]

- Tabadkani, A.; Tsangrassoulis, A.; Roetzel, A.; Li, H.X. Innovative control approaches to assess energy implications of adaptive facades based on simulation using EnergyPlus. Sol. Energy 2020, 206, 256–268. [Google Scholar] [CrossRef]

- Krarti, M. Impact of PV integrated rotating overhangs for US residential buildings. Renew. Energy 2021, 174, 835–849. [Google Scholar] [CrossRef]

- Do, C.T.; Chan, Y.-C. Daylighting performance analysis of a facade combining daylight-redirecting window film and automated roller shade. Build. Environ. 2021, 191, 107596. [Google Scholar] [CrossRef]

- Le-Thanh, L.; Le-Duc, T.; Ngo-Minh, H.; Nguyen, Q.-H.; Nguyen-Xuan, H. Optimal design of an Origami-inspired kinetic façade by balancing composite motion optimization for improving daylight performance and energy efficiency. Energy 2021, 219, 119557. [Google Scholar] [CrossRef]

- Vazquez, E.; Correa, D.; Poppinga, S. A review of and taxonomy for elastic kinetic building envelopes. J. Build. Eng. 2024, 82, 108227. [Google Scholar] [CrossRef]

- Kirimtat, A.; Manioğlu, G. A simulation-based performance evaluation of new generation dynamic shading devices with multi-objective optimization. J. Build. Eng. 2024, 90, 109322. [Google Scholar] [CrossRef]

- Pinto, M.C.; Crespi, G.; Dell’Anna, F.; Becchio, C. Combining energy dynamic simulation and multi-criteria analysis for supporting investment decisions on smart shading devices in office buildings. Appl. Energy 2023, 332, 120470. [Google Scholar] [CrossRef]

- Development of the Eco Town Model in the ASEAN Region through Adoption of Energy-Efficient Building Technologies, Sustainable Transport, and Smart Grids. Available online: https://www.eria.org/research/development-of-the-eco-town-model-in-the-asean-region-through-adoption-of-energy-efficient-building-technologies-sustainable-transport-and-smart-grids (accessed on 16 June 2024).

- Building Facades and Vertical Shade—Specialty Fabrics Review. Available online: https://specialtyfabricsreview.com/2018/02/01/peeling-back-the-facade/ (accessed on 16 June 2024).

- Louvers House/MIA Design Studio|ArchDaily. Available online: https://www.archdaily.com/891532/louvers-house-mia-design-studio (accessed on 16 June 2024).

- Al Bahar Towers Responsive Facade/Aedas. Available online: https://www.archdaily.com/270592/al-bahar-towers-responsive-facade-aedas (accessed on 16 June 2024).

- Kader, A. Climate Adapted Façades in Zero-Waste and Cradle to Cradle Buildings—Comparison, Evaluation and Future Recommendations, e.g., in Regard to U-Values, G-Values, Photovoltaic Integration, Thermal Performance and Solar Orientation. IOP Conf. Ser. Mater. Sci. Eng. 2020, 960, 032105. [Google Scholar] [CrossRef]

- Méndez, J.I.; Ibarra, L.; Ponce, P.; Meier, A.; Molina, A. A static rooftop shading system for year-round thermal comfort and energy savings in hot climates. Heliyon 2024, 10, e31599. [Google Scholar] [CrossRef]

- Loche, I.; Bre, F.; Gimenez, J.M.; Loonen, R.; Neves, L.O. Balcony design to improve natural ventilation and energy performance in high-rise mixed-mode office buildings. Build. Environ. 2024, 258, 111636. [Google Scholar] [CrossRef]

- Hua, Y.; Luo, L.; Le Corre, S.; Fan, Y. An Online Learning Framework for Self-Adaptive Dynamic Thermal Modeling of Building Envelopes. SSRN 2022. [Google Scholar] [CrossRef]

- Ito, R.; Lee, S. Development of adjustable solar photovoltaic system for integration with solar shading louvers on building façades. Appl. Energy 2024, 359, 122711. [Google Scholar] [CrossRef]

- Garcia-Nevado, E.; Beckers, B.; Coch, H. Assessing the cooling effect of urban textile shading devices through time-lapse thermography. Sustain. Cities Soc. 2020, 63, 102458. [Google Scholar] [CrossRef]

- Yang, S.; Cannavale, A.; Di Carlo, A.; Prasad, D.; Sproul, A.; Fiorito, F. Performance assessment of BIPV/T double-skin façade for various climate zones in Australia: Effects on energy consumption. Sol. Energy 2020, 199, 377–399. [Google Scholar] [CrossRef]

- Jiang, Y.; Qi, Z.; Ran, S.; Ma, Q. A Study on the Effect of Dynamic Photovoltaic Shading Devices on Energy Consumption and Daylighting of an Office Building. Buildings 2024, 14, 596. [Google Scholar] [CrossRef]

- Lee, H.; Han, S.; Seo, J. Light Shelf Development Using Folding Technology and Photovoltaic Modules to Increase Energy Efficiency in Building. Buildings 2022, 12, 81. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, T. Optimal design of complex dynamic shadings: Towards sustainable built environment. Sustain. Cities Soc. 2022, 86, 104109. [Google Scholar] [CrossRef]

- Shi, L.; Zhang, G.; Yang, W.; Huang, D.; Cheng, X.; Setunge, S. Determining the influencing factors on the performance of solar chimney in buildings. Renew. Sustain. Energy Rev. 2018, 88, 223–238. [Google Scholar] [CrossRef]

- Bacharoudis, E.; Vrachopoulos, M.G.; Koukou, M.K.; Margaris, D.; Filios, A.E.; Mavrommatis, S.A. Study of the natural convection phenomena inside a wall solar chimney with one wall adiabatic and one wall under a heat flux. Appl. Therm. Eng. 2007, 27, 2266–2275. [Google Scholar] [CrossRef]

- Zhai, X.Q.; Song, Z.P.; Wang, R.Z. A review for the applications of solar chimneys in buildings. Renew. Sustain. Energy Rev. 2011, 15, 3757–3767. [Google Scholar] [CrossRef]

- Alkaragoly, M.; Maerefat, M.; Targhi, M.Z.; Abdljalel, A. An innovative hybrid system consists of a photovoltaic solar chimney and an earth-air heat exchanger for thermal comfort in buildings. Case Stud. Therm. Eng. 2022, 40, 102546. [Google Scholar] [CrossRef]

- Li, A.; Ming, T.; Xiong, H.; Wu, Y.; Shi, T.; Li, W.; de Richter, R.; Chen, Y.; Tang, X.; Yuan, Y. A high-performance solar chimney in building integrated with photocatalytic technology for atmospheric methane removal. Sol. Energy 2023, 260, 126–136. [Google Scholar] [CrossRef]

- Suhendri, S.; Hu, M.; Su, Y.; Darkwa, J.; Riffat, S. Parametric study of a novel combination of solar chimney and radiative cooling cavity for natural ventilation enhancement in residential buildings. Build. Environ. 2022, 225, 109648. [Google Scholar] [CrossRef]

- Luque, G.P.; Arpon, J.C. Newly created ecosystems for a green built environment: Green roofs and green walls/facades. Nat.-Based Solut. 2024, 5, 100111. [Google Scholar] [CrossRef]

- Green Roof Market Trends, Size, Share, Report 2024–2032. Available online: https://www.imarcgroup.com/green-roof-market (accessed on 24 July 2024).

- Manso, M.; Castro-Gomes, J. Green wall systems: A review of their characteristics. Renew. Sustain. Energy Rev. 2015, 41, 863–871. [Google Scholar] [CrossRef]

- de Oliveira Santos, T.D.; Pacheco, F.A.L.; Fernandes, L.F.S. A systematic analysis on the efficiency and sustainability of green facades and roofs. Sci. Total Environ. 2024, 932, 173107. [Google Scholar] [CrossRef]

- Santamouris, M. Cooling the cities—A review of reflective and green roof mitigation technologies to fight heat island and improve comfort in urban environments. Sol. Energy 2014, 103, 682–703. [Google Scholar] [CrossRef]

- Vijayaraghavan, K. Green roofs: A critical review on the role of components, benefits, limitations and trends. Renew. Sustain. Energy Rev. 2016, 57, 740–752. [Google Scholar] [CrossRef]

- Algarni, S.; Almutairi, K.; Alqahtani, T. Investigating the performance of energy management in office buildings by using a suitable green roof design to reduce the building’s energy consumption. Sustain. Energy Technol. Assess. 2022, 54, 102825. [Google Scholar] [CrossRef]

- Santamouris, M. Analyzing the heat island magnitude and characteristics in one hundred Asian and Australian cities and regions. Sci. Total Environ. 2015, 512–513, 582–598. [Google Scholar] [CrossRef]

- Rizwan, A.M.; Dennis, L.Y.C.; Liu, C. A review on the generation, determination and mitigation of Urban Heat Island. J. Environ. Sci. 2008, 20, 120–128. [Google Scholar] [CrossRef] [PubMed]

- Alsaad, H.; Hartmann, M.; Hilbel, R.; Voelker, C. The potential of facade greening in mitigating the effects of heatwaves in Central European cities. Build. Environ. 2022, 216, 109021. [Google Scholar] [CrossRef]

- Huang, J.; Kong, F.; Yin, H.; Middel, A.; Liu, H.; Meadows, M.E. Green roof effects on urban building surface processes and energy budgets. Energy Convers. Manag. 2023, 287, 117100. [Google Scholar] [CrossRef]

- Besir, A.B.; Cuce, E. Green roofs and facades: A comprehensive review. Renew. Sustain. Energy Rev. 2018, 82, 915–939. [Google Scholar] [CrossRef]

- Ketut Acwin Dwijendra, N.; Muda, I.; Milanes, C.B.; Bharath Kumar, N.; Abosinnee, A.S.; Akhmadeev, R. How do green roofs affect per capita energy consumption in residential buildings under various climate conditions? Sustain. Energy Technol. Assess. 2023, 56, 103127. [Google Scholar] [CrossRef]

- Borràs, J.G.; Lerma, C.; Mas, Á.; Vercher, J.; Gil, E. Contribution of green roofs to energy savings in building renovations. Energy Sustain. Dev. 2022, 71, 212–221. [Google Scholar] [CrossRef]

- Zinzi, M.; Agnoli, S. Cool and green roofs. An energy and comfort comparison between passive cooling and mitigation urban heat island techniques for residential buildings in the Mediterranean region. Energy Build. 2012, 55, 66–76. [Google Scholar] [CrossRef]

- Wang, M.; Yu, H.; Liu, Y.; Lin, J.; Zhong, X.; Tang, Y.; Guo, H.; Jing, R. Unlock city-scale energy saving and peak load shaving potential of green roofs by GIS-informed urban building energy modelling. Appl. Energy 2024, 366, 123315. [Google Scholar] [CrossRef]

- Báez-García, W.G.; Simá, E.; Chagolla-Aranda, M.A.; Carlos Sandoval Herazo, L.; Carreto-Hernandez, L.G. Numerical-experimental study of the thermal behavior of a green facade in a warm climate in Mexico. Energy Build. 2024, 311, 114156. [Google Scholar] [CrossRef]

- Sharbafian, M.; Yeganeh, M.; Baradaran Motie, M. Evaluation of shading of green facades on visual comfort and thermal load of the building. Energy Build. 2024, 317, 114303. [Google Scholar] [CrossRef]

- Convertino, F.; Vox, G.; Schettini, E. Evaluation of the cooling effect provided by a green façade as nature-based system for buildings. Build. Environ. 2021, 203, 108099. [Google Scholar] [CrossRef]

- Pappa, V.; Bouris, D.; Theurer, W.; Gromke, C. A wind tunnel study of aerodynamic effects of façade and roof greening on air exchange from a cubic building. Build. Environ. 2023, 231, 110023. [Google Scholar] [CrossRef]

- Nagdeve, S.S.; Manchanda, S.; Dewan, A. Thermal performance of indirect green façade in composite climate of India. Build. Environ. 2023, 230, 109998. [Google Scholar] [CrossRef]

- Maier, D. Perspective of using green walls to achieve better energy efficiency levels. A bibliometric review of the literature. Energy Build. 2022, 264, 112070. [Google Scholar] [CrossRef]

- Bevilacqua, P. The effectiveness of green roofs in reducing building energy consumptions across different climates. A summary of literature results. Renew. Sustain. Energy Rev. 2021, 151, 111523. [Google Scholar] [CrossRef]

- Larochelle, H.; Foster, O.K.; Schade, R.M.; Ringer-Silva, T.F. Green High Five: Vertical Gardens along the Egnatia Corridor. 2019. Available online: https://www.semanticscholar.org/paper/Green-High-Five%3A-Vertical-Gardens-along-the-Egnatia-Larochelle-Foster/c81b5dac591f1816e75ce34b1146885fad9874f2 (accessed on 30 May 2024).

- Brears, R.C. Green Roofs: A Sustainable Solution for Urban Development. Mark and Focus. 2023. Available online: https://medium.com/mark-and-focus/green-roofs-a-sustainable-solution-for-urban-development-f639a1a39dc1 (accessed on 30 May 2024).

- Kitsopoulou, A.; Bellos, E.; Lykas, P.; Sammoutos, C.; Vrachopoulos, M.G.; Tzivanidis, C. A Systematic Analysis of Phase Change Material and Optically Advanced Roof Coatings Integration for Athenian Climatic Conditions. Energies 2023, 16, 7521. [Google Scholar] [CrossRef]

| Insulation Material | Density [kg/m3] | Thermal Conductivity [W/(m∙K)] | Specific Heat Capacity [J/(kg∙K)] |

|---|---|---|---|

| Cellulose | 30–80 | 0.037–0.042 | 1300–1600 |

| Wood fibers | 50–270 | 0.038–0.050 | 1900–2100 |

| Cork | 110–170 | 0.037–0.050 | 1500–1700 |

| Polyisocyanurate (PIR) | 30–45 | 0.018–0.028 | 1400–1500 |

| Expanded polystyrene (EPS) | 15–35 | 0.031–0.038 | 1250 |

| Extruded polystyrene (XPS) | 32–40 | 0.032–0.037 | 1450–1700 |

| Polyurethane (PU) | 15–45 | 0.022–0.040 | 1300–1450 |

| Phenolic foam | 40–160 | 0.018–0.024 | 1300–1400 |

| Glass wool | 15–75 | 0.031–0.037 | 900–1000 |

| Rock wool | 40–200 | 0.033–0.040 | 800–1000 |

| Expanded perlite | 80–150 | 0.040–0.052 | 900–1000 |

| Expanded vermiculite | 30–150 | 0.062–0.100 | 800–1100 |

| Lightweight expanded clay aggregate | 290–750 | 0.08–0.200 | 900–1000 |

| Mineralized wood fibers | 320–600 | 0.060–0.107 | 1800–2100 |

| Insulation Material | Thermal Conductivity [W/(m∙K)] | Cost per Area per Thickness [EUR/m2/cm] | Low Flammability | References |

|---|---|---|---|---|

| Glass wool or fiberglass | 0.040–0.044 | 0.22–0.24 | [59,60] | |

| Rock wool | 0.034–0.035 | 0.74–0.88 | ✓ | [61,62] |

| Mineral wool | 0.037–0.043 | 0.56–0.65 | ✓ | [63,64] |

| Cellulose | 0.038–0.039 | 0.78–0.82 | [65,66] | |

| Phenolic foam | 0.019 | 3.8 | ✓ | [67,68] |

| Expanded polystyrene (EPS) | 0.036 | 0.82 | [69,70] | |

| Extruded polystyrene (XPS) | 0.033–0.034 | 1.41–1.48 | [71,72] | |

| Expanded vermiculite | 0.62–0.1 | 2.85 | ✓ | [73] |

| Cork | 0.037 | 7.79–8.04 | [74,75] | |

| Wood fibers | 0.036 | 1.42 | [76] | |

| Polyisocyanurate (PIR) board | 0.022 | 1.52–1.54 | [77,78] | |

| Polyurethane (PU) board | 0.022 | 2.86 | [79] | |

| Vacuum insulation panel (VIP) * | 0.004 | 212.1 [€/m2] | ✓ | [80] |

| Aerogel blanket | 0.0197 | 62.64 | ✓ | [81] |

| Description | Total U-Value [W/(m2∙K)] | Specific Cost [EUR/m2] | Reference |

|---|---|---|---|

| Aluminum SS low-e double-glazed side-hinged window * | 2.10 | 420 | [127] |

| Aluminum DS low-e double-glazed side-hinged window * | 2.10 | 470 | [127] |

| Aluminum DS double-glazed side-hinged window | 1.30 | 760 | [128] |

| uPVC DS double-glazed argon-filled side-hinged window | 1.40 | 283 | [129] |

| uPVC DS low-e double-glazed argon-filled side-hinged window * | 1.10 | 550 | [130] |