Sustainable Carbon Utilization for a Climate-Neutral Economy–Framework Necessities and Assessment Criteria

Abstract

1. Introduction

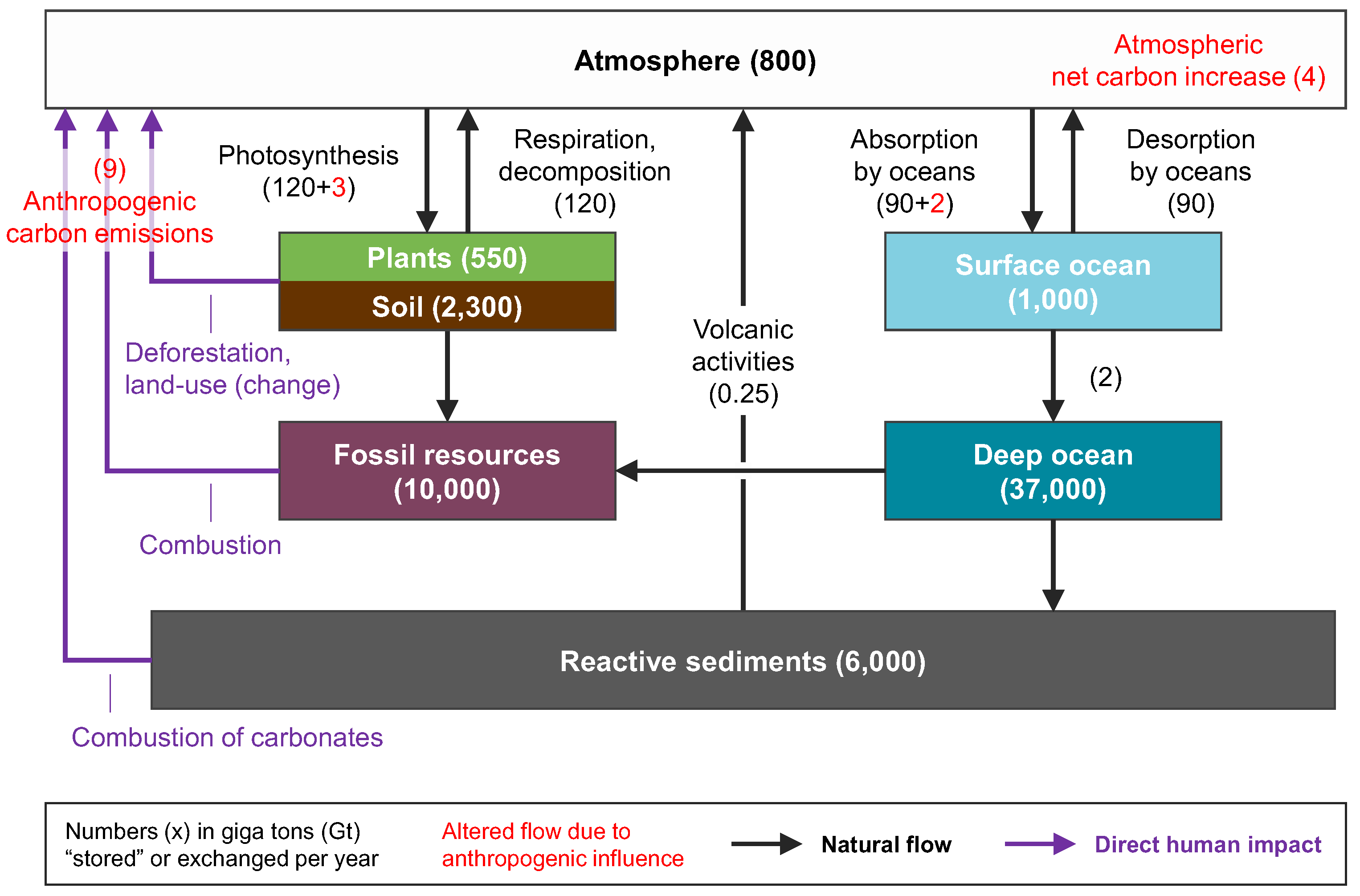

2. Carbon Cycle

- The fast carbon cycle consists of the carbon removed by plants from the atmosphere during their growth and released again into the atmosphere during the degradation of biomass.

- The slow carbon cycle describes the carbon embedded in geological formations and released back into the atmosphere/biosphere over geological time intervals.

2.1. Slow Carbon Cycle

2.2. Fast Carbon Cycle

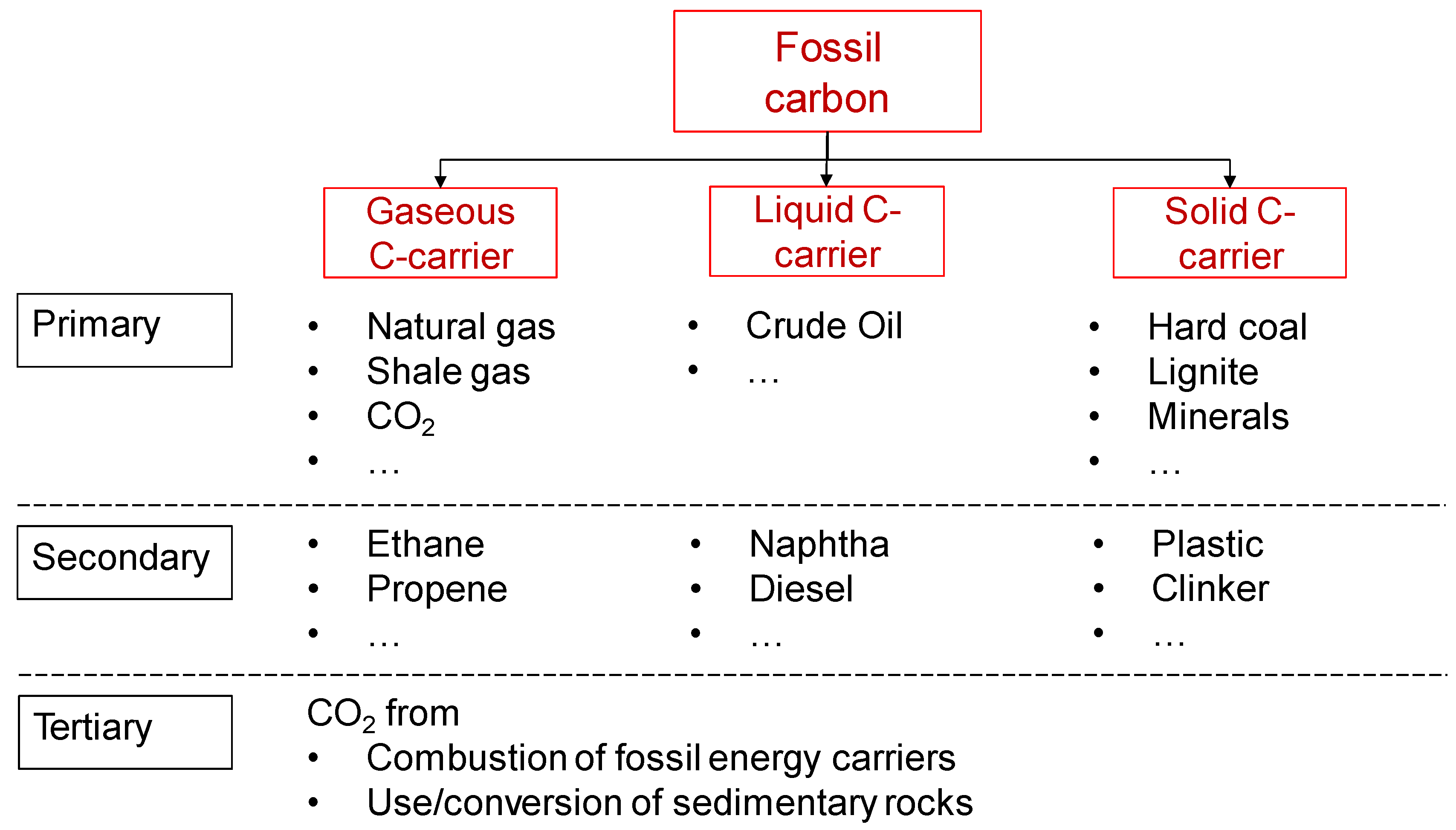

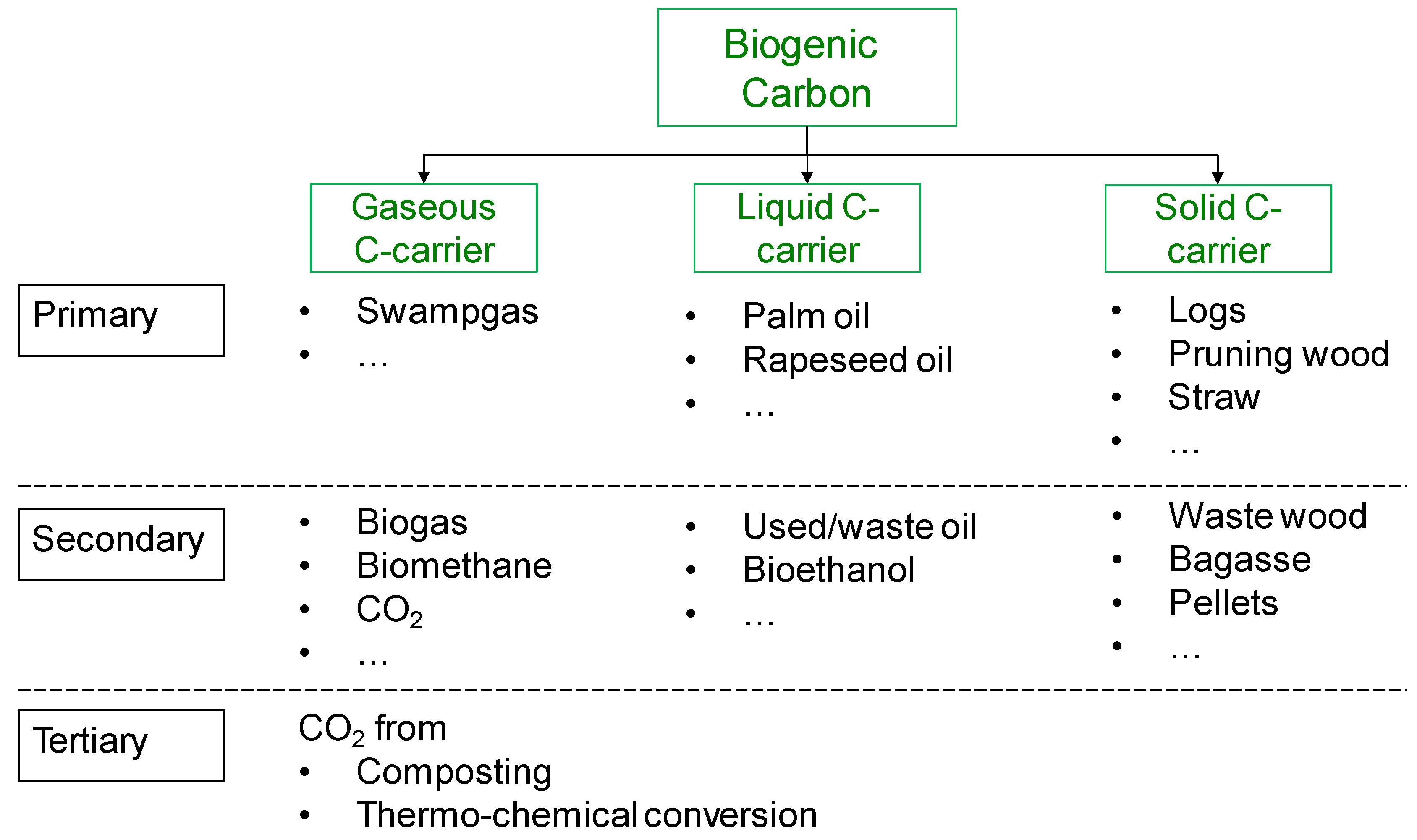

2.3. Carbon Classification

- Fossil carbon is defined as carbon circulating within the slow carbon cycle; i.e., mainly from rocks or minerals as well as crude oil, natural gas and coal (hard coal and lignite).

- Biogenic carbon is defined as carbon that circulates within the fast carbon cycle; i.e., this type of carbon is primarily bound in organic matter/biomass.

- Carbon contained within ambient air/the atmosphere (mainly CO2) is, according to this definition, a mixture of fossil and biogenic carbon. The same applies for CO2 from the incineration of mixed carbon stocks (e.g., municipal solid waste incineration).

3. Carbon Demand within a Defossilized Society

3.1. Carbon Demand

3.2. CO2 Demand

4. Framework and Criteria for the Use of Carbon

4.1. Carbon Source Classification

- From the point of view of the physico-chemical processes realized within the atmosphere/the natural environment, it makes no difference whether the CO2 comes from energy-related processes or is released during the production of goods (e.g., production of cement).

- The atmosphere/the natural environment “sees” only the overall sum of CO2 released. Thus, a removal and use of CO2 from ambient air (DAC—Direct Air Capture) is equivalent to a use of CO2 from biomass as long as the biomass is produced in a sustainable way; i.e., the living (plant-based) carbon stock stays stable on average over several years.

4.1.1. Fossil Carbon

4.1.2. Biogenic Carbon

- Gaseous carbon carrier. Gases containing carbon of biogenic origin are, e.g., biogas consisting of methane und carbon dioxide, CO2 from bioethanol production, CO2 from composting processes and CO2 from biomass combustion/thermal conversion. A further distinction can be made between energy-related (e.g., thermal conversion of solid biofuels) and process/product-related CO2 (e.g., bioethanol, biomethane).

- Liquid carbon carrier. Plant-based biomass can also be used as a source for the provision of liquid carbon carriers. This is true for, e.g., plant-based oils and fats as well as for different types of alcohols.

- Solid carbon carrier. Lignocelluloses, like wood, are also a carbon carrier. Therefore, the overall existing solid (lignocellulosic) biomass—available as a product, as a by-product, as a waste-product and/or as a residue—could be potentially used as a biogenic carbon source.

- Biomass must be provided in a sustainable way; i.e., organic carbon coming from rainforest being converted into grassland does not count as this because the carbon stock active on a specific piece of land is reduced due to its conversion into a less carbon-demanding use.

- Most likely, all biomass waste streams, organic residues and by-products emerging throughout the overall provision chain from agricultural production via the food processing industry until final use can be used, as long as the food production is realized in a sustainable way.

- The same is true in a figurative sense for wood from forests, if the latter are managed under sustainability criteria.

4.1.3. Mixed Carbon Sources

4.2. Literature Review

4.3. Assessment Related to Technical Demands and Availability

4.3.1. Technology Readiness Level

4.3.2. Energy Demand

4.3.3. Availability

4.4. Assessment Related to Regulatory Demands

- Development of a standard methodology allowing a robust and transparent quantification of the climate benefit of sustainable wood construction products as well as other building materials that show the possibility of carbon storage.

- Development of a methodology and an integrated evaluation of land use for EU bioeconomy aiming to ensure the accordance of aggregated national and EU policies and targets.

- Providing financial support for industrial carbon removals via the Innovation Fund.

- Extend the Horizon Europe calls in its next work program to support CO2 capture, transport, use and storage.

- Initiate a study on the development of CO2 transport networks.

- Update the guidance documents for the Carbon Capture and Storage (CCS) Directive, including risk management, monitoring, as well as financing.

- Organization of an annual carbon capture utilization and storage (CCUS) forum.

- Carbon farming (including temporary carbon storage activities and soil emission reduction activities).

- Temporary carbon storage in long-lasting products.

- Permanent carbon removal.

- Deployment of a CO2 transport infrastructure

- ○

- Development of a regulatory framework, market structure, and infrastructure planning system

- ○

- Implementation of emissions accounting rules under the EU ETS to facilitate the transportation of CO2

- ○

- Baseline standards for CO2 streams applicable across all industrial carbon management solutions

- ○

- Evaluation of the feasibility of reusing or repurposing existing infrastructure for CO2 transportation and storage

- ○

- Appointment of European coordinators to assist in the initial development of infrastructure

- Boosting carbon capture and storage

- ○

- Creation of a dedicated voluntary platform for demand assessment and aggregation to connect CO2 transport and storage providers with emitters

- ○

- Investment atlas of possible CO2 storage locations

- ○

- Sequential instructions for navigating permission procedures for CCS net-zero strategic projects

- ○

- Formulation of sector-specific roadmaps through a knowledge-sharing platform for industrial CCUS projects

- Supporting carbon removals

- ○

- Evaluation of overarching goals aligned with the 2040 climate ambition

- ○

- Creation of policy alternatives to bolster industrial carbon removals

- ○

- Enhancement of research and innovation efforts via Horizon Europe and the Innovation Fund

- Fostering carbon utilization

- ○

- Increasing adoption of sustainable carbon as a resource within industrial sectors

- ○

- Setting regulations for accounting all industrial carbon management activities

- (a)

- The CO2 has been captured in an activity listed in Annex I of Directive 2003/87/EC (ETS), is included in an effective carbon price upstream, and has entered the chemical composition of the fuel before the year 2036. CO2 resulting from other cases than from the combustion of fuels for electricity production can enter the chemical composition (i.e., be used) until 2041.

- (b)

- CO2 from the atmosphere.

- (c)

- CO2 from geological sources that are naturally released anyway.

- (d)

- CO2 from the production and combustion of biofuels or biomass that meet sustainability and GHG criteria and whose CO2 capture has not yet received credit (under RED II Annex V and VI).

- (e)

- CO2 from the combustion of renewable liquid and gaseous transport fuels of non-biological origin or recycled carbon fuels complying with the GHG saving criteria, set out in Article 25(2) and Article 28(5) of Directive (EU) 2018/2001.

4.5. Summary

- The TRL of capture and utilization technologies for fossil and biogenic carbon is greater than the TRL of DAC technologies, which is why point sources (e.g., bioethanol production sites) are more favorable for the short-term application of CCU compared to ambient air/DAC.

- The energy demand for capturing CO2 from the flue gas released by utilizing fossil and/or biogenic sources is clearly lower than for DAC. Even when the maturity of DAC technologies improves in the coming years, concentrated sources will most likely show a (much) better energy performance due to higher partial pressure of CO2, thus resulting in a clear thermodynamic advantage.

- At the moment, fossil carbon sources are available in a great variety and quantity; but most likely, they will decrease in the future as a result of alternative green technologies gaining market shares due to the legally binding GHG reduction goals. However, the current availability of biogenic carbon sources is limited. This might change to some extent in the future by exploiting more biogenic waste streams, especially CO2 of biogenic origin. Nevertheless, the total amount of sustainable biogenic carbon will most likely remain limited. In general, carbon from DAC shows a great availability today and in the future—but at the expense of a relatively high energy demand for the provision of a pure CO2 stream easily usable in technological processes. Considering regulatory aspects, carbon from biogenic sources and ambient air have no restriction.

- The use of fossil carbon is possible to a certain extent and the use of carbon from mixed sources has not yet been addressed in the existing regulatory framework. However, there are currently no binding regulations in place and therefore substantial changes might still be possible in the time to come.

5. Conclusions

- Only biogenic and mixed carbon from the ambient air can be defined as truly sustainable in terms of the Earth’s (fast) carbon cycle. Mixed carbon streams, such as those from waste recycling, form a gray area. The same applies to certain process-related emissions originating originally from fossil fuel energy.

- From an energy perspective, the level of technical maturity, and the size of the exploitable potentials, biogenic carbon sources should be utilized with priority for the time being. This applies above all to CO2, resulting as a by-product in the refinement or use of primary and secondary biogenic carbon carriers. Additionally, the free delivery of nature provided through photosynthesis during plant growth can be used to the benefit of humankind.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pörtner, H.-O.; Roberts, D.C.; Tignor, M.; Poloczanska, E.S.; Mintenbeck, K.; Alegría, A.; Craig, M.; Langsdorf, S.; Löschke, S.; Möller, V.; et al. (Eds.) IPCC, 2022: Climate Change 2022: Impacts, Adaptation, Vulnerability: Contribution of Working Group II to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2022. [Google Scholar]

- Shukla, P.R.; Skea, J.; Slade, R.; Al Khourdajie, A.; van Diemen, R.; McCollum, D.; Pathak, M.; Some, S.; Vyas, P.; Fradera, R.; et al. (Eds.) Climate Change 2022—Mitigation of Climate Change. Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2023. [Google Scholar]

- Purr, K.; Garvens, H.-J.; Bernicke, M.; Brieschke, J.; Kaliske, J.; Kessler, H.; Malsch, D.; Plickert, S.; Proske, C.; Rothe, B. Contribution to the Discussion on the Evaluation of Carbon Capture and Utilisation. Dessau-Roßlau, Background, September 2021. Available online: https://www.umweltbundesamt.de/en/publikationen/contribution-to-the-discussion-on-the-evaluation-of (accessed on 25 March 2024).

- Gabrielli, P.; Gazzani, M.; Mazzotti, M. The Role of Carbon Capture and Utilization, Carbon Capture and Storage, and Biomass to Enable a Net-Zero-CO2 Emissions Chemical Industry. Ind. Eng. Chem. Res. 2020, 59, 7033–7045. [Google Scholar] [CrossRef]

- Galimova, T.; Ram, M.; Bogdanov, D.; Fasihi, M.; Khalili, S.; Gulagi, A.; Karjunen, H.; Mensah, T.N.O.; Breyer, C. Global demand analysis for carbon dioxide as raw material from key industrial sources and direct air capture to produce renewable electricity-based fuels and chemicals. J. Clean. Prod. 2022, 373, 133920. [Google Scholar] [CrossRef]

- Verband der Chemischen Industrie e.V. Daten und Fakten zu Energie und Rohstoffen: Energiestatistik im Überblick. Available online: https://www.vci.de/die-branche/zahlen-berichte/vci-statistik-grafiken-energie-klima-rohstoffe-chemie.jsp (accessed on 27 March 2023).

- Fleiter, T.; Rehfeldt, M.; Neuwirth, M.; Herbst, A. Deep Decarbonisation of the German Industry via Electricity or Gas? A Scenario-Based Comparison of Pathways. 2020. Available online: https://publica.fraunhofer.de/handle/publica/409071 (accessed on 1 April 2024).

- Joas, F.; Witecka, W.K.; Lenck, T.; Peter, F.; Seiler, F.; Samadi, S.; Schneider, C.; Holtz, G.; Kobiela, G.; Lechtenböhmer, S.; et al. Klimaneutrale Industrie: Schlüsseltechnologien und Politikoptionen für Stahl, Chemie und Zement; Studie; Agora Energiewende: Berlin, Germany, 2020; Available online: http://nbn-resolving.de/urn/resolver.pl?urn:nbn:de:bsz:wup4-opus-76758 (accessed on 20 March 2023).

- Benndorf, R.; Bernicke, M.; Bertram, A.; Butz, W.; Dettling, F.; Drotleff, J.; Elsner, C.; Fee, E.; Gabler, C.; Galander, C.; et al. Treibhausgasneutrales Deutschland im Jahr 2050. Dessau-Roßlau. 2014. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/378/publikationen/07_2014_climate_change_dt.pdf (accessed on 1 April 2024).

- Stolz, B.; Held, M.; Georges, G.; Boulouchos, K. Techno-economic analysis of renewable fuels for ships carrying bulk cargo in Europe. Nat. Energy 2022, 7, 203–212. [Google Scholar] [CrossRef]

- Breuer, J.L.; Scholten, J.; Koj, J.C.; Schorn, F.; Fiebrandt, M.; Samsun, R.C.; Albus, R.; Görner, K.; Stolten, D.; Peters, R. An Overview of Promising Alternative Fuels for Road, Rail, Air, Inland Waterway Transport in Germany. Energies 2022, 15, 1443. [Google Scholar] [CrossRef]

- Kistner, L.; Bensmann, A.; Minke, C.; Hanke-Rauschenbach, R. Comprehensive techno-economic assessment of power technologies and synthetic fuels under discussion for ship applications. Renew. Sustain. Energy Rev. 2023, 183, 113459. [Google Scholar] [CrossRef]

- He, M.; Sun, Y.; Han, B. Green Carbon Science: Efficient Carbon Resource Processing, Utilization, and Recycling towards Carbon Neutrality. Angew. Chem. 2022, 134, 15. [Google Scholar] [CrossRef]

- Wang, F.; Harindintwali, J.D.; Yuan, Z.; Wang, M.; Wang, F.; Li, S.; Yin, Z.; Huang, L.; Fu, Y.; Li, L.; et al. Technologies and perspectives for achieving carbon neutrality. Innovation 2021, 2, 100180. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y. Worldwide carbon neutrality transition? Energy efficiency, renewable, carbon trading and advanced energy policies. Energy Rev. 2023, 2, 100026. [Google Scholar] [CrossRef]

- Carus, M.; Dammer, L.; Raschka, A.; Skoczinski, P. Renewable carbon: Key to a sustainable and future-oriented chemical and plastic industry: Definition, strategy, measures and potential. Greenh. Gases 2020, 10, 488–505. [Google Scholar] [CrossRef]

- Archer, D. The Global Carbon Cycle; Princeton University Press: Princeton, NJ, USA, 2011. [Google Scholar]

- The Global Carbon Cycle and Climate Change; Elsevier: Amsterdam, The Netherlands, 2023.

- Riebeek, H. The Carbon Cycle. Available online: https://www.earthobservatory.nasa.gov/features/CarbonCycle (accessed on 24 January 2023).

- Berner, R.A. The long-term carbon cycle, fossil fuels and atmospheric composition. Nature 2003, 426, 323–326. [Google Scholar] [CrossRef]

- Houghton, R.A. Balancing the Global Carbon Budget. Annu. Rev. Earth Planet. Sci. 2007, 35, 313–347. [Google Scholar] [CrossRef]

- Canadell, J.G.; Le Quéré, C.; Raupach, M.R.; Field, C.B.; Buitenhuis, E.T.; Ciais, P.; Conway, T.J.; Gillett, N.P.; Houghton, R.A.; Marland, G. Contributions to accelerating atmospheric CO2 growth from economic activity, carbon intensity, and efficiency of natural sinks. Proc. Natl. Acad. Sci. USA 2007, 104, 18866–18870. [Google Scholar] [CrossRef] [PubMed]

- Intergovernmental Panel on Climate Change 2007 (Ed.) The Physical Science Basis: Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Kähler, F.; Carus, M.; Porc, O.; vom Berg, C. Turning off the tap for fossil carbon: Future Prospects for a Global Chemical and Derived Material Sector Based on Renewable Carbon. April 2021. Available online: https://renewable-carbon.eu/publications/product/turning-off-the-tap-for-fossil-carbon-future-prospects-for-a-global-chemical-and-derived-material-sector-based-on-renewable-carbon/ (accessed on 18 March 2024).

- Pales, A.F.; Levi, P. The Future of Petrochemicals: Towards a More Sustainable Chemical Industry. Paris, France. October 2018. Available online: https://www.iea.org/reports/the-future-of-petrochemicals#overview (accessed on 18 March 2024).

- Aguilar, P.; Groß, B. Battery electric vehicles and fuel cell electric vehicles, an analysis of alternative powertrains as a mean to decarbonise the transport sector. Sustain. Energy Technol. Assess. 2022, 53, 102624. [Google Scholar] [CrossRef]

- Peng, R.; Tang, J.H.C.G.; Yang, X.; Meng, M.; Zhang, J.; Zhuge, C. Investigating the factors influencing the electric vehicle market share: A comparative study of the European Union and United States. Appl. Energy 2024, 355, 122327. [Google Scholar] [CrossRef]

- Bringezu, S.; Kaiser, S.; Turnau, S. Zukünftige Nutzung von CO2 als Rohstoffbasis der deutschen Chemie- und Kunststoffindustrie. 2020. Available online: https://kobra.uni-kassel.de/bitstream/handle/123456789/11483/ZukuenftigeNutzungVonCO2AlsRohstoffbasis.pdf;jsessionid=BE40A417B043E88C3820EF39DF618840?sequence=4 (accessed on 27 March 2023).

- International Energy Agency (IEA). Putting CO2 to Use: Creating Value from Emissions; IEA: Paris, France, 2019.

- Huo, J.; Wang, Z.; Oberschelp, C.; Guillén-Gosálbez, G.; Hellweg, S. Net-zero transition of the global chemical industry with CO2-feedstock by 2050: Feasible yet challenging. Green Chem. Int. J. Green Chem. Resour. GC 2023, 25, 415–430. [Google Scholar] [CrossRef]

- Hepburn, C.; Adlen, E.; Beddington, J.; Carter, E.A.; Fuss, S.; Mac Dowell, N.; Minx, J.C.; Smith, P.; Williams, C.K. The technological and economic prospects for CO2 utilization and removal. Nature 2019, 575, 87–97. [Google Scholar] [CrossRef]

- Schmid, C.; Hahn, A. Potential CO2 utilisation in Germany: An analysis of theoretical CO2 demand by 2030. J. CO2 Util. 2021, 50, 101580. [Google Scholar] [CrossRef]

- Viebahn, P.; Horst, J.; Scholz, A.; Zelt, O. Technologiebericht 4.4 Verfahren der CO2-Abtrennung aus Faulgasen und Umgebungsluft innerhalb des Forschungsprojekts TF_Energiewende. Wuppertal. 2018. Available online: https://nbn-resolving.org/urn:nbn:de:bsz:wup4-opus-70624 (accessed on 27 March 2023).

- Fröhlich, T.; Blömer, S.; Münter, D.; Brischke, L.-A. CO2-Quellen für die PtX-Herstellung in Deutschland—Technologien, Umweltwirkung, Verfügbarkeit; Institut für Energie- und Umweltforschung Heidelberg (IFEU): Heidelberg, Germany, 2019. [Google Scholar]

- Hobohm, J.; der Maur, A.A.; Dambeck, H.; Kemmler, A.; Koziel, S.; Kreidelmeyer, S.; Piégsa, A.; Wendring, P.; Meyer, B.; Apfelbacher, A.; et al. Status und Perspektiven flüssiger Energieträger in der Energiewende; Endbericht: Basel, Switzerland, 2018. [Google Scholar]

- Geres, R.; Kohn, A.; Lenz, S.; Ausfelder, F.; Bazzanella, A.M.; Möller, A. Roadmap Chemie 2050: Auf dem Weg zu einer Treibhausgasneutralen Chemischen Industrie in Deutschland; DECHEMA e.V.: München, Germany, 2019. [Google Scholar]

- DIRECTIVE (EU) 2018/2001 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 11 December 2018 on the Promotion of The Use of Energy from Renewable Sources (Recast). 2018. Available online: https://eur-lex.europa.eu/eli/dir/2018/2001/oj (accessed on 2 April 2024).

- DIRECTIVE (EU) 2023/2413 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 18 October 2023 Amending Directive (EU) 2018/2001, Regulation (EU) 2018/1999 and Directive 98/70/EC as Regards the Promotion of Energy from Renewable Sources, and Repealing Council Directive (EU) 2015/652. 18th 2023. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32023L2413&qid=1699364355105 (accessed on 2 April 2024).

- Andrew, R.M.; Peters, G.P. The Global Carbon Project’s Fossil CO2 Emissions Dataset. 2023. Available online: https://zenodo.org/records/10562476 (accessed on 2 April 2024).

- Ritchie, H.; Rosado, P.; Roser, M. Emissions by sector: Where do greenhouse gases come from? Our World in Data. 2020. Available online: https://ourworldindata.org/emissions-by-sector (accessed on 5 April 2024).

- Kost, C.; Shammugam, S.; Fluri, V.; Peper, D.; Memar, A.D.; Schlegl, T. Studie: Stromgestehungskosten erneuerbare Energien: Juni 2021. Freiburg. June 2021. Available online: https://www.ise.fraunhofer.de/de/veroeffentlichungen/studien/studie-stromgestehungskosten-erneuerbare-energien.html (accessed on 15 April 2023).

- IEA—International Energy Agency, Ed.; Renewable Energy Market Update: Outlook for 2023 and 2024. June 2023. Available online: https://iea.blob.core.windows.net/assets/63c14514-6833-4cd8-ac53-f9918c2e4cd9/RenewableEnergyMarketUpdate_June2023.pdf (accessed on 23 July 2024).

- Taylor, M.; Al-Zoghoul, S.; Ralon, P.; Sorokina, O. Renewable Power Generation: Costs in 2022. Abu Dhabi. 2023. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2023/Aug/IRENA_Renewable_power_generation_costs_in_2022.pdf?rev=cccb713bf8294cc5bec3f870e1fa15c2 (accessed on 10 April 2024).

- Bazzanella, A.; Krämer, D. (Eds.) Technologies for Sustainability and Climate Protection—Chemical Processes and Use of CO2: Results of the BMBF Funding Measure; DECHEMA Gesellschaft für Chemische Technik und Biotechnologie e.V.: Frankfurt/Main, Germany, 2019; Available online: https://dechema.de/en/energyandclimate/_/CO2_Buch_engl.pdf (accessed on 20 February 2023).

- Kähler, F.; Carus, M.; vom Berg, C.; Stratmann, M. CO2 Reduction Potential of the Chemical Industry through CCU: A Simplified Exploratory Scenario for Ccu-Based Supply of Embedded Carbon for the Global Chemicals and Derived Materials Sector. 2022. Available online: https://renewable-carbon-initiative.com/wp-content/uploads/2022/05/22-05-03-CO2_Reduction_Potential_of_the_Chemical_Industry_Through_CCU.pdf (accessed on 18 March 2024).

- Del Rio, D.D.F.; Sovacool, B.K.; Foley, A.M.; Griffiths, S.; Bazilian, M.; Kim, J.; Rooney, D. Decarbonizing the ceramics industry: A systematic and critical review of policy options, developments and sociotechnical systems. Renew. Sustain. Energy Rev. 2022, 157, 112081. [Google Scholar] [CrossRef]

- Korczak, K.; Kochański, M.; Skoczkowski, T. Mitigation options for decarbonization of the non-metallic minerals industry and their impacts on costs, energy consumption and GHG emissions in the EU—Systematic literature review. J. Clean. Prod. 2022, 358, 132006. [Google Scholar] [CrossRef]

- Zhang, C.-Y.; Han, R.; Yu, B.; Wei, Y.-M. Accounting process-related CO2 emissions from global cement production under Shared Socioeconomic Pathways. J. Clean. Prod. 2018, 184, 451–465. [Google Scholar] [CrossRef]

- Alassali, A.; Picuno, C.; Chong, Z.K.; Guo, J.; Maletz, R.; Kuchta, K. Towards Higher Quality of Recycled Plastics: Limitations from the Material’s Perspective. Sustainability 2021, 13, 13266. [Google Scholar] [CrossRef]

- Huang, K.; Peng, X.; Kong, L.; Wu, W.; Chen, Y.; Maravelias, C.T. Greenhouse Gas Emission Mitigation Potential of Chemicals Produced from Biomass. ACS Sustain. Chem. Eng. 2021, 9, 14480–14487. [Google Scholar] [CrossRef]

- Wiśniewski, P.; Kistowski, M. Greenhouse Gas Emissions from Cultivation of Plants Used for Biofuel Production in Poland. Atmosphere 2020, 11, 394. [Google Scholar] [CrossRef]

- Hiloidhari, M.; Sharno, M.A.; Baruah, D.C.; Bezbaruah, A.N. Green and sustainable biomass supply chain for environmental, social and economic benefits. Biomass Bioenergy 2023, 175, 106893. [Google Scholar] [CrossRef]

- Gasparatos, A.; Stromberg, P.; Takeuchi, K. Sustainability impacts of first-generation biofuels. Anim. Front. 2013, 3, 12–26. [Google Scholar] [CrossRef]

- Mohn, J.; Szidat, S.; Fellner, J.; Rechberger, H.; Quartier, R.; Buchmann, B.; Emmenegger, L. Determination of biogenic and fossil CO(2) emitted by waste incineration based on (14)CO(2) and mass balances. Bioresour. Technol. 2008, 99, 6471–6479. [Google Scholar] [CrossRef] [PubMed]

- Lan, X.; Tans, P.; Thoning, K.; NOAA Global Monitoring Laboratory. Trends in Globally-Averaged CO2 Determined from NOAA Global Monitoring Laboratory Measurements. 2023. Available online: https://gml.noaa.gov/ccgg/trends/global.html?doi=10.15138/9n0h-zh07 (accessed on 10 February 2023).

- IEAGHG (Ed.) CO2 as a Feedstock: Comparison of CCU Pathways. 2021-02; IEAGHG: Cheltenham, UK, November 2021. [Google Scholar]

- Lehtonen, J.; Järnefelt, V.; Alakurtti, S.; Arasto, A.; Hannula, I.; Harlin, A.; Koljonen, T.; Lantto, R.; Lienemann, M.; Onarheim, K.; et al. The Carbon Reuse Economy: Transforming CO2 from a Pollutant into a Resource; VTT Technical Research Centre of Finland: Espoo, Finland, 2019. [Google Scholar]

- Bradke, H.; Büdicker, K.; Deister, U.K.; Krämer, D.; Rinschede, A.; Zapp, P. Industrielle CO2-Kreisläufe. May 2021. Available online: https://www.vdi.de/ueber-uns/presse/publikationen/details/industrielle-co2-kreislaeufe (accessed on 8 March 2023).

- Gaseous Carbon Waste Streams Utilization; National Academies Press: Washington, DC, USA, 2019.

- Kasten, P.; Heinemann, C.; Seebach, D.; Sutter, J. Not to Be Taken for Granted: Climate Protection and Sustainability Through PtX: Discussion of Requirements for and First Approaches to Developing Verification Criteria for a Climate-Friendly and Sustainable Production of PtX. Impulse Paper on Behalf of BUND as Part of the Copernicus Project P2X, Berlin. September 2019. Available online: https://www.oeko.de/fileadmin/oekodoc/Impulse_paper_criteria_for_e-fuel_production.pdf (accessed on 10 February 2023).

- Terlouw, T.; Bauer, C.; Rosa, L.; Mazzotti, M. Life cycle assessment of carbon dioxide removal technologies: A critical review. Energy Environ. Sci. 2021, 14, 1701–1721. [Google Scholar] [CrossRef]

- Galán-Martín, Á.; Tulus, V.; Díaz, I.; Pozo, C.; Pérez-Ramírez, J.; Guillén-Gosálbez, G. Sustainability footprints of a renewable carbon transition for the petrochemical sector within planetary boundaries. One Earth 2021, 4, 565–583. [Google Scholar] [CrossRef]

- NASA. Definition of Technology Readiness Levels. Available online: https://esto.nasa.gov/files/trl_definitions.pdf (accessed on 10 February 2023).

- Fischedick, M.; Görner, K.; Thomeczek, M. CO2: Abtrennung, Speicherung, Nutzung; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Bisotti, F.; Hoff, K.A.; Mathisen, A.; Hovland, J. Direct Air capture (DAC) deployment: A review of the industrial deployment. Chem. Eng. Sci. 2024, 283, 119416. [Google Scholar] [CrossRef]

- Budinis, S.; McCulloch, S.; Bains, P.; Bennet, S.; Briens, F.; Fajardy, M.; Fernandez Pales, A.; Greenfield, C.; Hannula, I.; Kochhar, K.; et al. Direct Air Capture: A Key Technology for Net Zero. April 2022. Available online: https://www.iea.org/reports/direct-air-capture-2022 (accessed on 10 February 2023).

- Vaz, S.; de Souza, A.P.R.; Baeta, B.E.L. Technologies for carbon dioxide capture: A review applied to energy sectors. Clean. Eng. Technol. 2022, 8, 100456. [Google Scholar] [CrossRef]

- Leeson, D.; Dowell, N.M.; Shah, N.; Petit, C.; Fennell, P.S. A Techno-economic analysis and systematic review of carbon capture and storage (CCS) applied to the iron and steel, cement, oil refining and pulp and paper industries, as well as other high purity sources. Int. J. Greenh. Gas Control. 2017, 61, 71–84. [Google Scholar] [CrossRef]

- Psarras, P.C.; Comello, S.; Bains, P.; Charoensawadpong, P.; Reichelstein, S.; Wilcox, J. Carbon Capture and Utilization in the Industrial Sector. Environ. Sci. Technol. 2017, 51, 11440–11449. [Google Scholar] [CrossRef] [PubMed]

- Bains, P.; Psarras, P.; Wilcox, J. CO2 capture from the industry sector. Prog. Energy Combust. Sci. 2017, 63, 146–172. [Google Scholar] [CrossRef]

- Rodin, V.; Lindorfer, J.; Böhm, H.; Vieira, L. Assessing the potential of carbon dioxide valorisation in Europe with focus on biogenic CO2. J. CO2 Util. 2020, 41, 101219. [Google Scholar] [CrossRef]

- Madhu, K.; Pauliuk, S.; Dhathri, S.; Creutzig, F. Understanding environmental trade-offs and resource demand of direct air capture technologies through comparative life-cycle assessment. Nat. Energy 2021, 6, 1035–1044. [Google Scholar] [CrossRef]

- IEA—International Energy Agency. CO2 Emissions in 2023: A New Record High, But Is There Light at the End of the Tunnel? Paris, France. February 2024. Available online: https://www.iea.org/reports/co2-emissions-in-2023 (accessed on 4 April 2024).

- Bentsen, N.S.; Felby, C.; Thorsen, B.J. Agricultural residue production and potentials for energy and materials services. Prog. Energy Combust. Sci. 2014, 40, 59–73. [Google Scholar] [CrossRef]

- Syed-Hassan, S.S.A.; Wang, Y.; Hu, S.; Su, S.; Xiang, J. Thermochemical processing of sewage sludge to energy and fuel: Fundamentals, challenges and considerations. Renew. Sustain. Energy Rev. 2017, 80, 888–913. [Google Scholar] [CrossRef]

- Gao, N.; Kamran, K.; Quan, C.; Williams, P.T. Thermochemical conversion of sewage sludge: A critical review. Prog. Energy Combust. Sci. 2020, 79, 100843. [Google Scholar] [CrossRef]

- European Commission. A New Circular Economy Action Plan: For a Cleaner and More Competitive Europe. March 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN (accessed on 27 March 2023).

- Singh, N.; Ogunseitan, O.A.; Tang, Y. Medical waste: Current challenges and future opportunities for sustainable management. Crit. Rev. Environ. Sci. Technol. 2022, 52, 2000–2022. [Google Scholar] [CrossRef]

- National Oceanic and Atmospheric Administration. Carbon Dioxide Now More Than 50% Higher than Pre-Industrial Levels. Available online: https://www.noaa.gov/news-release/carbon-dioxide-now-more-than-50-higher-than-pre-industrial-levels (accessed on 27 March 2023).

- Friedlingstein, P.; O’Sullivan, M.; Jones, M.W.; Andrew, R.M.; Gregor, L.; Hauck, J.; Le Quéré, C.; Luijkx, I.T.; Olsen, A.; Peters, G.P.; et al. Global Carbon Budget 2022. Earth Syst. Sci. Data 2022, 14, 4811–4900. [Google Scholar] [CrossRef]

- European Commission. Sustainable Carbon Cycles. December 2021. Available online: https://climate.ec.europa.eu/system/files/2021-12/com_2021_800_en_0.pdf (accessed on 27 March 2023).

- REGULATION OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL Establishing a Union Certification Framework for Permanent Carbon Removals, Carbon Farming and Carbon Storage in Products. 20th 2024. Available online: https://www.europarl.europa.eu/meetdocs/2014_2019/plmrep/COMMITTEES/ENVI/DV/2024/03-11/Item9-Provisionalagreement-CFCR_2022-0394COD_EN.pdf (accessed on 4 April 2024).

- COMMUNICATION FROM THE COMMISSION TO THE EUROPEAN PARLIAMENT, THE COUNCIL, THE EUROPEAN ECONOMIC AND SOCIAL COMMITTEE AND THE COMMITTEE OF THE REGIONS—Towards an Ambitious Industrial Carbon MANAGEMENT for the EU. 6th 2024. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2024%3A62%3AFIN&qid=1707312980822 (accessed on 4 April 2024).

- COMMISSION DELEGATED REGULATION (EU) 2023/1185 of 10 February 2023 Supplementing Directive (EU) 2018/2001 of the European Parliament and of the Council by Establishing a Minimum Threshold for Greenhouse Gas Emissions Savings of recycled Carbon Fuels and by Specifying a Methodology for Assessing Greenhouse Gas Emissions Savings from Renewable Liquid and Gaseous Transport Fuels of Non-Biological Origin and from Recycled Carbon Fuels. 2023. Available online: http://data.europa.eu/eli/reg_del/2023/1185/oj (accessed on 4 April 2024).

| Industry | Application/Process |

|---|---|

| Food industry | Dry ice for blast freezing and cooling |

| Inert gas for packaging | |

| Carbonic acid in beverages | |

| Solvents for supercritical extraction | |

| Agriculture | Fumigation in greenhouses |

| Chemical industry | Urea production |

| Chemical intermediates: methane, methanol | |

| Polymers | |

| Oil/petro industry | Enhanced oil recovery |

| Methane | |

| Methanol | |

| Gasoline, diesel, kerosene | |

| Other industrial application | Refrigerant/heating agent |

| Inert gas for welding | |

| Construction industry | Cement |

| Concrete |

| Study | Scope | CO2 Demand |

|---|---|---|

| Putting CO2 to use–IEA [29] | World, total demand | 1 to 7 Gt/a by 2030 |

| Galimova et al. [5] | World, total demand | 6 Gt/a by 2050 |

| Nova Institut [24] | World, chemical industry | 918 Mt/a by 2050 |

| Huo et al. [30] | World, chemical industry | 2.2 to 3.1 Gt/a by 2050 |

| Hepburn et al. [31] | World, chemicals and fuels | 1.3 to 4.8 Gt/a by 2050 |

| Schmid et al. [32] | Germany, total demand | 420 Mt/a by 2030 |

| Wuppertal Institute [33] | Germany, total demand | 80.3 Mt/a by 2050 |

| Ifeu [34] | Germany, total demand | 8.3 Mt/a by 2050 |

| MWV [35] | Germany, total demand | 180.2 Mt/a by 2050 |

| VCI—Roadmap [36] | Germany, chemical industry | 10 to 41 Mt/a by 2050 |

| Zukünftige Nutzung von CO2 als Rohstoffbasis–Universität Kassel [28] | Germany, chemical industry | 3 to 17 Mt/a by 2030 12 to 49 Mt/a by 2050 |

| Study | CO2-Derived Products/Origin of CO2 | Consideration |

|---|---|---|

| IEA Putting CO2 to use [29] | CO2-derived product | Climate benefits:

|

| IEAGHG Technical Report CO2 as a feedstock: Comparison of CCU pathways [56] | Mainly CO2-derived product, also origin of CO2 is mentioned | CO2 mitigation potential:

|

| VTT [57] | CO2-derived products & origin of CO2 | Carbon reuse economy based on three drivers:

|

| Nova Institute [16] | Origin of CO2 | Carbon circular economy (where CO2 comes from)

|

| VDI Industrielle CO2 Kreisläufe [58] | CO2-derived products & origin of CO2 | Environmental aspects:

|

| National academic press—gaseous carbon waste streams utilization [59] | CO2-derived products | Environmental aspects:

|

| Öko-Institut [60] | CO2-derived products & origin of CO2 | Climate benefits and resource criticality:

|

| Origin of Carbon | Process | CO2 Concentration [Vol-%] |

|---|---|---|

| Fossil carbon | Power | |

| Coal combustion | 12–15 | |

| Natural gas combustion | 3–10 | |

| Fuel oil combustion | 3–8 | |

| Industries | ||

| Cement production | 14–33 | |

| Refineries | 3–20 | |

| Integrated steel mills | 20–27 | |

| Ethylene production | 12 | |

| Ammonia production process | up to 100 | |

| Aluminum production | 1–10 | |

| Ethylene oxide | 8 | |

| Carbonates production | 20 | |

| Glass production | 7–10 | |

| Lead production | 15 | |

| Lime/quicklime production | 20 | |

| Magnesium production | 15 | |

| Soda ash production | 36–40 | |

| TiO2 production | 13 | |

| Zinc production | 15 | |

| Biogenic carbon | Power | |

| Bioenergy/Biomass combustion | 3–8 | |

| Biomethane production | 40–50 | |

| Industries | ||

| Fermentation process | up to 100 | |

| Mixed carbon | ||

| Waste incineration | 6–12 | |

| Pulp and paper production | 10–15 | |

| Atmosphere | 0.04 |

| Carbon Sources | RED III DA Ex-Use Compliant Sources | Carbon Cycle |

|---|---|---|

| Iron and steel production | (a) | Fossil |

| Cement production | (a) | Fossil |

| Quicklime production | (a) | Fossil |

| Pulp and paper production | (a) or (c) | Fossil/biogen |

| Ceramic and glass production | (a) * | Fossil |

| Aluminium production | (a) | Fossil |

| Zinc production | (a) | Fossil |

| Lead production | (a) | Fossil |

| Copper and silica production | (a) | Fossil |

| Soda production | (a) | Fossil |

| Carbon black production | (a) | Fossil |

| Fossil fuel production | (a) | Fossil |

| Bulk chemicals production | (a) | Fossil |

| Plastic production | (a) | Fossil |

| Ammonia production | (a) | Fossil |

| Ethylen oxide production | (a) | Fossil |

| Bioethanol production | (c) | Biogen |

| Biogas production | (c) | Biogen |

| Biomass-fired power plants | (c) | Biogen |

| Coal-fired power plants | (a) | Fossil |

| Gas-fired power plants | (a) | Fossil |

| Fuel oil-fired power plants | (a) | Fossil |

| Waste incineration plants | Not defined * | Fossil/biogen |

| Hazardous waste incineration plant | Not defined * | Fossil/biogen |

| RDF plant | Not defined * | Fossil/biogen |

| Direct Air Capture | (b) | Biogen |

| Origin/Sources of Carbon | Technical Readiness Level | Energy Demand | Availability Status Quo | Availability Defossilized Society | Regulatory |

|---|---|---|---|---|---|

| Fossil | |||||

| Tertiary gaseous | + | + | + | - | o/- |

| Secondary solid | + | + | + | +/o | +/o |

| Biogen | |||||

| Gaseous | + | o | o | + | + |

| Liquid | + | + | - | - | + |

| Solid | + | + | o | - | + |

| Mixed carbon sources | |||||

| Ambient air | o | o/- | + | + | + |

| Other sources | + | + | o | o/- | Undefined |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zitscher, T.; Kaltschmitt, M. Sustainable Carbon Utilization for a Climate-Neutral Economy–Framework Necessities and Assessment Criteria. Energies 2024, 17, 4118. https://doi.org/10.3390/en17164118

Zitscher T, Kaltschmitt M. Sustainable Carbon Utilization for a Climate-Neutral Economy–Framework Necessities and Assessment Criteria. Energies. 2024; 17(16):4118. https://doi.org/10.3390/en17164118

Chicago/Turabian StyleZitscher, Tjerk, and Martin Kaltschmitt. 2024. "Sustainable Carbon Utilization for a Climate-Neutral Economy–Framework Necessities and Assessment Criteria" Energies 17, no. 16: 4118. https://doi.org/10.3390/en17164118

APA StyleZitscher, T., & Kaltschmitt, M. (2024). Sustainable Carbon Utilization for a Climate-Neutral Economy–Framework Necessities and Assessment Criteria. Energies, 17(16), 4118. https://doi.org/10.3390/en17164118