Revolution in Renewables: Integration of Green Hydrogen for a Sustainable Future

Abstract

1. Introduction

2. Green Hydrogen Foundations

2.1. Green Hydrogen Value Chain

2.1.1. Production through Electrolysis

2.1.2. Purification

2.1.3. Storage

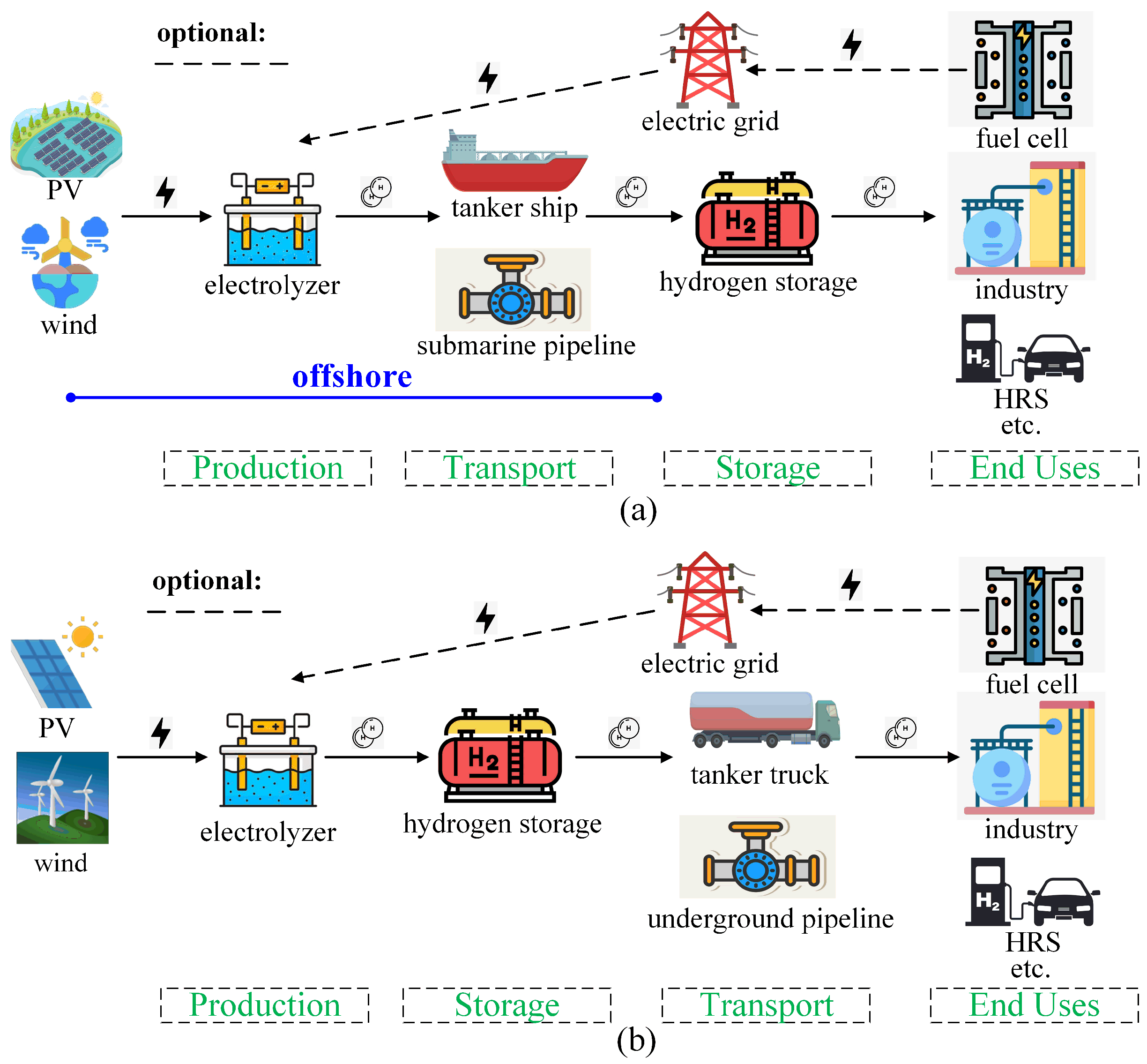

2.1.4. Transport

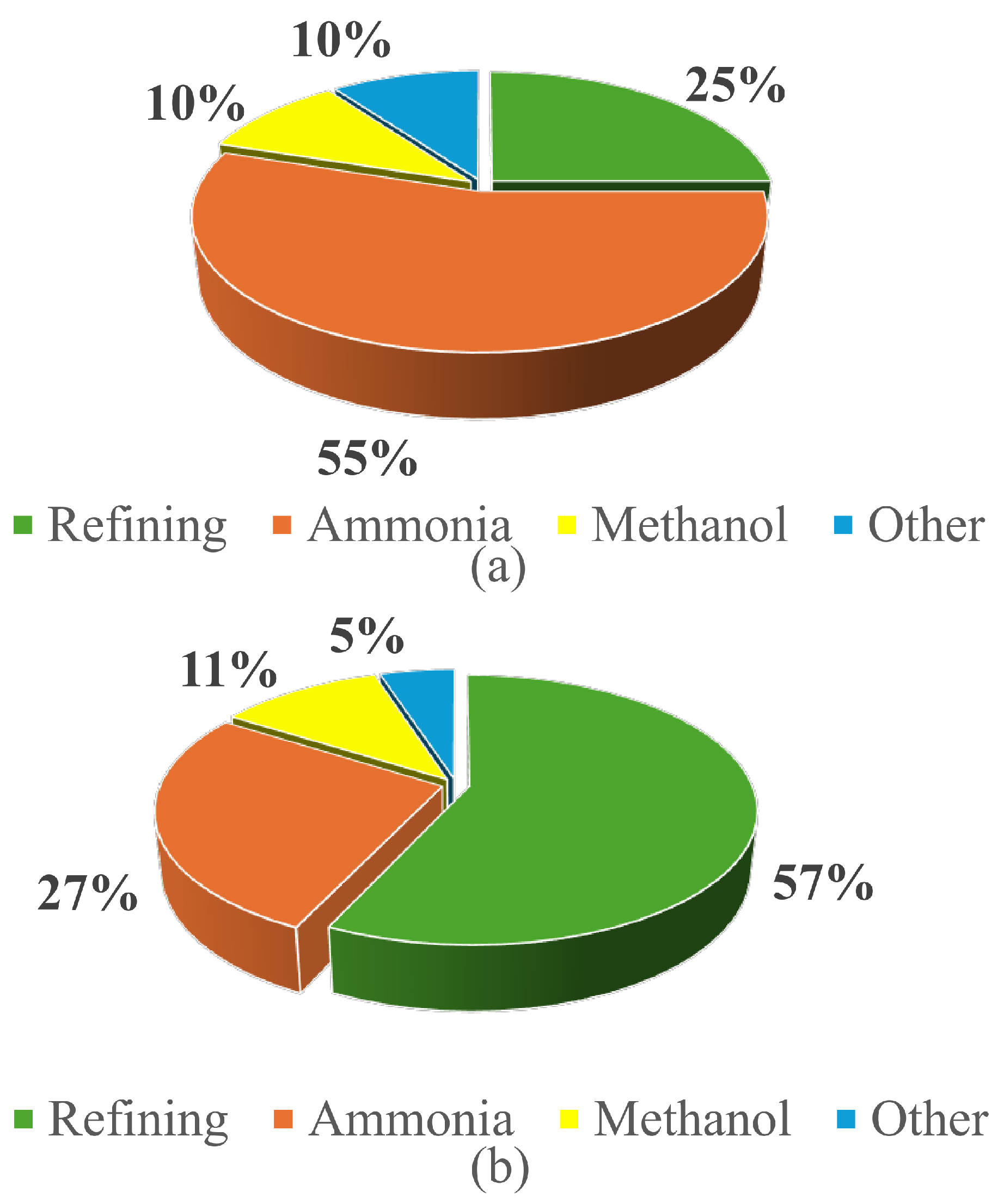

2.1.5. End Uses

2.2. RESs for Green Hydrogen Production

3. Evolving Market Dynamics

| Project Name | Capacity | Status | Country | Brief Description |

|---|---|---|---|---|

| NortH2 Project [123] | 10 GW | Developing | Netherlands | Consortium with Shell, aims to produce 1 MMT of hydrogen annually using offshore wind. |

| H2Mare Project [124] | Not specified | Developing | Germany | 32 partners, adding electrolyzers to wind turbines for green hydrogen, operational by 2025. |

| AquaVentus [125] | 10 GW | Developing | Germany | Generates hydrogen using offshore wind for a European network, completion by 2035. |

| Murchison Renewable Hydrogen Project [126] | 5 GW | Developing | Australia | Uses wind and solar for hydrogen, targets 2 MMT of ammonia by 2028. |

| Western Green Energy Hub (WGEH) [127] | 50 GW | Developing | Australia | Integrates wind and solar for 3.5 MMT of hydrogen and 20 MMT of ammonia annually. |

| Beijing Jingneng Inner Mongolia [128] | 5 GW | Operational | China | Utilizes wind and solar for 0.4–0.5 MMT hydrogen yearly. |

| NEOM Green Hydrogen Plant [129] | 4 GW | Developing | Saudi Arabia | Combines solar and wind for daily production of 600 MMT hydrogen, operational by 2026. |

| Appalachian Hydrogen Hub (ARCH2) [130] | Not specified | Developing | USA | Uses natural gas for clean hydrogen, includes infrastructure for CO2 storage. |

| Mid-Atlantic Hydrogen Hub (MACH2) [130] | Not specified | Developing | USA | Focuses on renewable hydrogen for decarbonization, reducing 1 MMT carbon per year. |

| California Hydrogen Hub (ARCHES) [130] | Not specified | Developing | USA | Produces hydrogen from renewables and biomass, reducing 2 MMT carbon annually. |

| Gulf Coast Hydrogen Hub (HyVelocity) [130] | Not specified | Developing | USA | Uses gas with carbon capture for hydrogen, aims to cut 7 MMT carbon yearly. |

| St. Gabriel Green Hydrogen Plant [131] | Not specified | Operational | USA | Plug Power and Olin Corp project, initially producing 15 MMT of hydrogen daily. |

| Calistoga Resiliency Center [132] | 293 MWh | Developing | USA | The largest utility-scale green hydrogen energy storage project in the USA, designed to provide long-duration storage. |

4. Long-Term Operational Strategies

4.1. Long-Term Operational Strategies for Grid-Connected Hydrogen Systems

4.2. Long-Term Operational Strategies for Islanded Hydrogen Systems

5. Short-Term Operational Strategies

5.1. Short-Term Operational Strategies for Grid-Connected Hydrogen Systems

5.2. Short-Term Operational Strategies for Islanded Hydrogen Systems

6. Conclusions and Outlook

6.1. Conclusions

6.2. Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- The Paris Agreement. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement (accessed on 22 May 2024).

- Renewables 2023: Executive Summary. Available online: https://iea.blob.core.windows.net/assets/96d66a8b-d502-476b-ba94-54ffda84cf72/Renewables_2023.pdf (accessed on 22 May 2024).

- Introduction: Weaving China’s Climate Policy Tapestry. Available online: https://asiasociety.org/policy-institute/china-climate-introduction-weaving-chinas-climate-policy-tapestry (accessed on 22 May 2024).

- Biden-Harris Administration Announces Significant Progress to Catalyze Solar Energy Development throughout the West. Available online: https://www.doi.gov/pressreleases/biden-harris-administration-announces-significant-progress-catalyze-solar-energy-0 (accessed on 22 May 2024).

- FACT SHEET: Biden Administration Jumpstarts Offshore Wind Energy Projects to Create Jobs. Available online: https://www.whitehouse.gov/briefing-room/statements-releases/2021/03/29/fact-sheet-biden-administration-jumpstarts-offshore-wind-energy-projects-to-create-jobs (accessed on 22 May 2024).

- Renewable Energy Directive. Available online: https://energy.ec.europa.eu/topics/renewable-energy/renewable-energy-directive-targets-and-rules/renewable-energy-directive_en (accessed on 23 May 2024).

- Renewable Energy. Available online: https://www.investindia.gov.in/sector/renewable-energy (accessed on 23 May 2024).

- Zhang, J.; Li, J. Decentralized control Coordination of PV-BSS Systems in Islanded DC Nanogrids. In Proceedings of the 2021 North American Power Symposium (NAPS), College Station, TX, USA, 14–16 November 2021; pp. 1–6. [Google Scholar]

- Otto, M.; Chagoya, K.L.; Blair, R.G.; Hick, S.M.; Kapat, J.S. Optimal hydrogen carrier: Holistic evaluation of hydrogen storage and transportation concepts for power generation, aviation, and transportation. J. Energy Storage 2022, 55, 105714. [Google Scholar] [CrossRef]

- Ferrara, M.; Mottola, F.; Proto, D.; Ricca, A.; Valenti, M. Local Energy Community to Support Hydrogen Production and Network Flexibility. Energies 2024, 17, 3663. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Shchegolkov, A.V.; Zemtsova, N.V.; Stanishevskiy, Y.M.; Vetcher, A.A. Recent Advantages on Waste Management in Hydrogen Industry. Polymers 2022, 14, 4992. [Google Scholar] [CrossRef] [PubMed]

- Qureshi, F.; Yusuf, M.; Ibrahim, H.; Kamyab, H.; Chelliapan, S.; Pham, C.Q.; Vo, D.V.N. Contemporary avenues of the Hydrogen industry: Opportunities and challenges in the eco-friendly approach. Environ. Res. 2023, 229, 115963. [Google Scholar] [CrossRef]

- Kang, J.; Park, E.D. Partial oxidation of methane over Fe/ZSM-5 with hydrogen peroxide generated in situ over Pd/C in the presence of halide ions. Catal. Today 2024, 426, 114367. [Google Scholar] [CrossRef]

- Spallina, V.; Melchiori, T.; Gallucci, F.; Van Sint Annaland, M. Auto-Thermal Reforming Using Mixed Ion-Electronic Conducting Ceramic Membranes for a Small-Scale H2 Production Plant. Molecules 2015, 20, 4998–5023. [Google Scholar] [CrossRef] [PubMed]

- Dai, F.; Zhang, S.; Luo, Y.; Wang, K.; Liu, Y.; Ji, X. Recent Progress on Hydrogen-Rich Syngas Production from Coal Gasification. Processes 2023, 11, 1765. [Google Scholar] [CrossRef]

- Lepage, T.; Kammoun, M.; Schmetz, Q.; Richel, A. Biomass-to-hydrogen: A review of main routes production, processes evaluation and techno-economical assessment. Biomass Bioenergy 2021, 144, 105920. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Ghorbani, B.; Khodaverdi, M. Hydrogen production by thermochemical water splitting cycle using low-grade solar heat and phase change material energy storage system. Int. J. Energy Res. 2022, 46, 7590–7609. [Google Scholar] [CrossRef]

- Holmes-Gentle, I.; Tembhurne, S.; Suter, C.; Haussener, S. Kilowatt-scale solar hydrogen production system using a concentrated integrated photoelectrochemical device. Nat. Energy 2023, 8, 586–596. [Google Scholar] [CrossRef]

- U.S. National Clean Hydrogen Strategy and Roadmap. Available online: https://www.hydrogen.energy.gov/library/roadmaps-vision/clean-hydrogen-strategy-roadmap (accessed on 24 May 2024).

- China Maps 2021–2035 Plan on Hydrogen Energy Development. Available online: https://en.ndrc.gov.cn/news/pressreleases/202203/t20220329_1321487.html (accessed on 24 May 2024).

- India: Green Hydrogen Vision. Available online: https://gh2.org/countries/india (accessed on 24 May 2024).

- The National Hydrogen Strategy. Available online: https://www.bmwk.de/Navigation/EN/hydrogen/national-hydrogen-strategy.html (accessed on 24 May 2024).

- Basic Hydrogen Strategy. Available online: https://www.meti.go.jp/shingikai/enecho/shoene_shinene/suiso_seisaku/20230606_report.html (accessed on 24 May 2024).

- Hossain, M.B.; Islam, M.R.; Muttaqi, K.M.; Sutanto, D.; Agalgaonkar, A.P. Advancement of fuel cells and electrolyzers technologies and their applications to renewable-rich power grids. J. Energy Storage 2023, 62, 106842. [Google Scholar] [CrossRef]

- Bollmann, J.; Pitchaimuthu, S.; Kühnel, M.F. Challenges of Industrial-Scale Testing Infrastructure for Green Hydrogen Technologies. Energies 2023, 16, 3604. [Google Scholar] [CrossRef]

- Dash, S.K.; Chakraborty, S.; Elangovan, D. A Brief Review of Hydrogen Production Methods and Their Challenges. Energies 2023, 16, 1141. [Google Scholar] [CrossRef]

- Li, W.; Tian, H.; Ma, L.; Wang, Y.; Liu, X.; Gao, X. Low-temperature water electrolysis: Fundamentals, progress, and new strategies. Mater. Adv. 2022, 3, 5598–5644. [Google Scholar] [CrossRef]

- Cengel, Y.A.; Boles, M.A.; Kanoglu, M. Thermodynamics: An Engineering Approach, 9th ed.; McGraw-Hill: New York, NY, USA, 2019; pp. 776–797. [Google Scholar]

- Sharshir, S.W.; Joseph, A.; Elsayad, M.M.; Tareemi, A.A.; Kandeal, A.; Elkadeem, M.R. A review of recent advances in alkaline electrolyzer for green hydrogen production: Performance improvement and applications. Int. J. Hydrogen Energy 2023, 49, 458–488. [Google Scholar] [CrossRef]

- Li, H.; Nakajima, H.; Inada, A.; Ito, K. Effect of flow-field pattern and flow configuration on the performance of a polymer-electrolyte-membrane water electrolyzer at high temperature. Int. J. Hydrogen Energy 2018, 43, 8600–8610. [Google Scholar] [CrossRef]

- Heard, D.M.; Lennox, A.J. Electrode materials in modern organic electrochemistry. Angew. Chem. Int. Ed. 2020, 59, 18866–18884. [Google Scholar] [CrossRef]

- Cao, X.; Wang, J.; Zhao, P.; Xia, H.; Li, Y.; Sun, L.; He, W. Hydrogen Production System Using Alkaline Water Electrolysis Adapting to Fast Fluctuating Photovoltaic Power. Energies 2023, 16, 3308. [Google Scholar] [CrossRef]

- Xia, Y.; Cheng, H.; He, H.; Hu, Z.; Wei, W. Efficiency enhancement for alkaline water electrolyzers directly driven by fluctuating PV power. IEEE Trans. Ind. Electron. 2023, 71, 5755–5765. [Google Scholar] [CrossRef]

- Li, L.; Laan, P.C.; Yan, X.; Cao, X.; Mekkering, M.J.; Zhao, K.; Ke, L.; Jiang, X.; Wu, X.; Li, L.; et al. High-rate alkaline water electrolysis at industrially relevant conditions enabled by superaerophobic electrode assembly. Adv. Sci. 2023, 10, 2206180. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhang, T.; Deng, X.; Liu, B.; Ma, J.; Yang, F.; Ouyang, M. Active pressure and flow rate control of alkaline water electrolyzer based on wind power prediction and 100% energy utilization in off-grid wind-hydrogen coupling system. Appl. Energy 2022, 328, 120172. [Google Scholar] [CrossRef]

- Lin, Y.; Dong, Y.; Wang, X.; Chen, L. Electrocatalysts for the oxygen evolution reaction in acidic media. Adv. Mater. 2023, 35, 2210565. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.S.; Himabindu, V. Hydrogen production by PEM water electrolysis—A review. Mater. Sci. Energy Technol. 2019, 2, 442–454. [Google Scholar]

- Gollasch, M.; Schmeling, J.; Harms, C.; Wark, M. Comparative Analysis of Synthesis Routes for Antimony-Doped Tin Oxide-Supported Iridium and Iridium oxide Catalysts for OER in PEM Water Electrolysis. Adv. Mater. Interfaces 2023, 10, 2300036. [Google Scholar] [CrossRef]

- Hou, S.; Jiang, J.; Wang, Y.; He, X.; Ge, J.; Xing, W. High-Performance RuOx Catalyst with Advanced Mesoporous Structure for Oxygen Evolution Reaction. Langmuir 2022, 38, 12118–12123. [Google Scholar] [CrossRef]

- Wolf, S.E.; Winterhalder, F.E.; Vibhu, V.; de Haart, L.B.; Guillon, O.; Eichel, R.A.; Menzler, N.H. Solid oxide electrolysis cells–current material development and industrial application. J. Mater. Chem. A 2023, 11, 17977–18028. [Google Scholar] [CrossRef]

- Amaya-Dueñas, D.M.; Riegraf, M.; Nenning, A.; Opitz, A.K.; Costa, R.; Friedrich, K.A. Operational aspects of a perovskite chromite-based fuel electrode in solid oxide electrolysis cells (SOEC). ACS Appl. Energy Mater. 2022, 5, 8143–8156. [Google Scholar] [CrossRef]

- Yuan, J.; Li, Z.; Yuan, B.; Xiao, G.; Li, T.; Wang, J.Q. Optimization of High-Temperature Electrolysis System for Hydrogen Production Considering High-Temperature Degradation. Energies 2023, 16, 2616. [Google Scholar] [CrossRef]

- Shen, F.; Reisert, M.; Wang, R.; Singh, P.; Tucker, M.C. Assessment of protective coatings for metal-supported solid oxide electrolysis cells. ACS Appl. Energy Mater. 2022, 5, 9383–9391. [Google Scholar] [CrossRef]

- Shen, F.; Welander, M.M.; Tucker, M.C. Metal-supported solid oxide electrolysis cell test standard operating procedure. Front. Energy Res. 2022, 10, 817981. [Google Scholar] [CrossRef]

- Li, Q.; Molina Villarino, A.; Peltier, C.R.; Macbeth, A.J.; Yang, Y.; Kim, M.J.; Shi, Z.; Krumov, M.R.; Lei, C.; Rodríguez-Calero, G.G.; et al. Anion exchange membrane water electrolysis: The future of green hydrogen. J. Phys. Chem. C 2023, 127, 7901–7912. [Google Scholar] [CrossRef]

- Li, J.; Liu, C.; Ge, J.; Xing, W.; Zhu, J. Challenges and Strategies of Anion Exchange Membranes in Hydrogen-electricity Energy Conversion Devices. Chem. Eur. J. 2023, 29, e202203173. [Google Scholar] [CrossRef] [PubMed]

- Santoro, C.; Lavacchi, A.; Mustarelli, P.; Di Noto, V.; Elbaz, L.; Dekel, D.R.; Jaouen, F. What is next in anion-exchange membrane water electrolyzers? Bottlenecks, benefits, and future. ChemSusChem 2022, 15, e202200027. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Huo, Y.; Wang, F.; Fang, F.; Sun, D. Direct Electrochemical Seawater Splitting for Green Hydrogen and Artificial Reefs. ACS Appl. Energy Mater. 2023, 6, 7636–7642. [Google Scholar] [CrossRef]

- Liu, X.; Chi, J.; Mao, H.; Wang, L. Principles of designing electrocatalyst to boost reactivity for seawater splitting. Adv. Energy Mater. 2023, 13, 2301438. [Google Scholar] [CrossRef]

- Wang, X.; Geng, M.; Sun, S.; Xiang, Q.; Dong, S.; Dong, K.; Yao, Y.; Wang, Y.; Yang, Y.; Luo, Y.; et al. Recent advances of bifunctional electrocatalysts and electrolyzers for overall seawater splitting. J. Mater. Chem. A 2024, 12, 634–656. [Google Scholar] [CrossRef]

- Bacquart, T.; Murugan, A.; Carré, M.; Gozlan, B.; Auprêtre, F.; Haloua, F.; Aarhaug, T.A. Probability of occurrence of ISO 14687-2 contaminants in hydrogen: Principles and examples from steam methane reforming and electrolysis (water and chlor-alkali) production processes model. Int. J. Hydrogen Energy 2018, 43, 11872–11883. [Google Scholar] [CrossRef]

- Kalman, V.; Voigt, J.; Jordan, C.; Harasek, M. Hydrogen purification by pressure swing adsorption: High-pressure PSA performance in recovery from seasonal storage. Sustainability 2022, 14, 14037. [Google Scholar] [CrossRef]

- Lider, A.; Kudiiarov, V.; Kurdyumov, N.; Lyu, J.; Koptsev, M.; Travitzky, N.; Hotza, D. Materials and techniques for hydrogen separation from methane-containing gas mixtures. Int. J. Hydrogen Energy 2023, 48, 28390–28411. [Google Scholar] [CrossRef]

- Bernardo, G.; Araújo, T.; da Silva Lopes, T.; Sousa, J.; Mendes, A. Recent advances in membrane technologies for hydrogen purification. Int. J. Hydrogen Energy 2020, 45, 7313–7338. [Google Scholar] [CrossRef]

- Kim, T.; Song, Y.; Kang, J.; Kim, S.K.; Kim, S. A review of recent advances in hydrogen purification for selective removal of oxygen: Deoxo catalysts and reactor systems. Int. J. Hydrogen Energy 2022, 47, 24817–24834. [Google Scholar] [CrossRef]

- Sullivan, N. Orientational order–disorder transitions in solid hydrogen. Can. J. Chem. 1988, 66, 908–914. [Google Scholar] [CrossRef]

- Tarkowski, R.; Uliasz-Misiak, B.; Tarkowski, P. Storage of hydrogen, natural gas, and carbon dioxide–Geological and legal conditions. Int. J. Hydrogen Energy 2021, 46, 20010–20022. [Google Scholar] [CrossRef]

- Ghorbani, B.; Zendehboudi, S.; Saady, N.M.C.; Dusseault, M.B. Hydrogen storage in North America: Status, prospects, and challenges. J. Environ. Chem. Eng. 2023, 11, 109957. [Google Scholar] [CrossRef]

- Usman, M.R. Hydrogen storage methods: Review and current status. Renew. Sustain. Energy Rev. 2022, 167, 112743. [Google Scholar] [CrossRef]

- Gholami, R. Hydrogen storage in geological porous media: Solubility, mineral trapping, H2S generation and salt precipitation. J. Energy Storage 2023, 59, 106576. [Google Scholar] [CrossRef]

- Chapter I: Hydrogen Fundamentals. Available online: http://www.hysafe.org/download/1196/BRHS_Chap1_V1p2.pdf (accessed on 4 August 2024).

- Avargani, V.M.; Zendehboudi, S.; Saady, N.M.C.; Dusseault, M.B. A comprehensive review on hydrogen production and utilization in North America: Prospects and challenges. Energy Convers. Manag. 2022, 269, 115927. [Google Scholar] [CrossRef]

- Hassan, I.; Ramadan, H.S.; Saleh, M.A.; Hissel, D. Hydrogen storage technologies for stationary and mobile applications: Review, analysis and perspectives. Renew. Sustain. Energy Rev. 2021, 149, 111311. [Google Scholar] [CrossRef]

- Patonia, A.; Poudineh, R. Hydrogen Storage for a Net-Zero Carbon Future; Number 23, OIES Paper: ET; The Oxford Institute for Energy Studies: Oxford, UK, 2023. [Google Scholar]

- Smolinka, T.; Garche, J. Electrochemical Power Sources: Fundamentals, Systems, and Applications: Hydrogen Production by Water Electrolysis; Elsevier: Cambridge, MA, USA, 2022. [Google Scholar]

- Al-Hamdani, Y.S.; Zen, A.; Michaelides, A.; Alfè, D. Mechanisms of adsorbing hydrogen gas on metal decorated graphene. Phys. Rev. Mater. 2023, 7, 035402. [Google Scholar] [CrossRef]

- Quine, C.M.; Smith, H.L.; Ahn, C.C.; Hasse-Zamudio, A.; Boyd, D.A.; Fultz, B. Hydrogen adsorption and isotope mixing on copper-functionalized activated carbons. J. Phys. Chem. C 2022, 126, 16579–16586. [Google Scholar] [CrossRef]

- Yang, X.; Bulushev, D.A.; Yang, J.; Zhang, Q. New liquid chemical hydrogen storage technology. Energies 2022, 15, 6360. [Google Scholar] [CrossRef]

- Bannenberg, L.; Heere, M.; Benzidi, H.; Montero, J.; Dematteis, E.; Suwarno, S.; Jaroń, T.; Winny, M.; Orłowski, P.; Wegner, W.; et al. Metal (boro-) hydrides for high energy density storage and relevant emerging technologies. Int. J. Hydrogen Energy 2020, 45, 33687–33730. [Google Scholar] [CrossRef]

- Zivar, D.; Kumar, S.; Foroozesh, J. Underground hydrogen storage: A comprehensive review. Int. J. Hydrogen Energy 2021, 46, 23436–23462. [Google Scholar] [CrossRef]

- Yang, M.; Hunger, R.; Berrettoni, S.; Sprecher, B.; Wang, B. A review of hydrogen storage and transport technologies. Clean Energy 2023, 7, 190–216. [Google Scholar] [CrossRef]

- Erdener, B.C.; Sergi, B.; Guerra, O.J.; Chueca, A.L.; Pambour, K.; Brancucci, C.; Hodge, B.M. A review of technical and regulatory limits for hydrogen blending in natural gas pipelines. Int. J. Hydrogen Energy 2023, 48, 5595–5617. [Google Scholar] [CrossRef]

- Penev, M.; Zuboy, J.; Hunter, C. Economic analysis of a high-pressure urban pipeline concept (HyLine) for delivering hydrogen to retail fueling stations. Transp. Res. Part D Transp. Environ. 2019, 77, 92–105. [Google Scholar] [CrossRef]

- Shi, J.; Zhu, Y.; Feng, Y.; Yang, J.; Xia, C. A prompt decarbonization pathway for shipping: Green hydrogen, ammonia, and methanol production and utilization in marine engines. Atmosphere 2023, 14, 584. [Google Scholar] [CrossRef]

- Niermann, M.; Timmerberg, S.; Drünert, S.; Kaltschmitt, M. Liquid Organic Hydrogen Carriers and alternatives for international transport of renewable hydrogen. Renew. Sustain. Energy Rev. 2021, 135, 110171. [Google Scholar]

- Southall, E.; Lukashuk, L. Hydrogen Storage and Transportation Technologies to Enable the Hydrogen Economy: Liquid Organic Hydrogen Carriers: Overview and perspectives on liquid organic hydrogen carriers technology. Johns. Matthey Technol. Rev. 2022, 66, 246–258. [Google Scholar] [CrossRef]

- Rao, P.C.; Yoon, M. Potential liquid-organic hydrogen carrier (LOHC) systems: A review on recent progress. Energies 2020, 13, 6040. [Google Scholar] [CrossRef]

- Global Hydrogen Trade to Meet the 1.5 °C Climate Goal: Technology Review of Hydrogen Carriers. Available online: https://www.irena.org/publications/2022/Apr/Global-hydrogen-trade-Part-II (accessed on 26 May 2024).

- Assessment of Hydrogen Delivery Options: Feasibility of Transport of Green Hydrogen within Europe. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC130442 (accessed on 26 May 2024).

- Top Industrial Uses of Hydrogen, and the Need for Industrial Hydrogen Safety. Available online: https://wha-international.com/hydrogen-in-industry/ (accessed on 26 May 2024).

- Distribution of Hydrogen Consumption in the United States in 2020, by Sector*. Available online: https://www.statista.com/statistics/1179429/us-hydrogen-consumption-share-by-sector/ (accessed on 26 May 2024).

- The Future of Hydrogen: Seizing Today’s Opportunities. Available online: https://www.iea.org/reports/the-future-of-hydrogen (accessed on 26 May 2024).

- Brown, T. Renewable hydrogen for sustainable ammonia production. Chem. Eng. Prog. 2019, 115, 47–53. [Google Scholar]

- Wang, R.; Zhao, Y.; Babich, A.; Senk, D.; Fan, X. Hydrogen direct reduction (H-DR) in steel industry—An overview of challenges and opportunities. J. Clean. Prod. 2021, 329, 129797. [Google Scholar] [CrossRef]

- Zheng, Y.; Hou, D.; Liu, Y.; Zhou, Y.; Xiao, J. Complex system analysis of the implications of hydrogen fuel cell trucks in China’s road freight transportation. Int. J. Hydrogen Energy 2024, 60, 1449–1461. [Google Scholar] [CrossRef]

- Fan, L.; Tu, Z.; Chan, S.H. Recent development of hydrogen and fuel cell technologies: A review. Energy Rep. 2021, 7, 8421–8446. [Google Scholar] [CrossRef]

- Global Energy Perspective 2023: Hydrogen Outlook. Available online: https://www.mckinsey.com/industries/oil-and-gas/our-insights/global-energy-perspective-2023-hydrogen-outlook (accessed on 26 May 2024).

- Renau, J.; García, V.; Domenech, L.; Verdejo, P.; Real, A.; Giménez, A.; Sánchez, F.; Lozano, A.; Barreras, F. Novel use of green hydrogen fuel cell-based combined heat and power systems to reduce primary energy intake and greenhouse emissions in the building sector. Sustainability 2021, 13, 1776. [Google Scholar] [CrossRef]

- Cristello, J.B.; Yang, J.M.; Hugo, R.; Lee, Y.; Park, S.S. Feasibility analysis of blending hydrogen into natural gas networks. Int. J. Hydrogen Energy 2023, 48, 17605–17629. [Google Scholar] [CrossRef]

- Hydrogen Fueled Gas Turbines. Available online: https://www.gevernova.com/gas-power/future-of-energy/hydrogen-fueled-gas-turbines (accessed on 27 May 2024).

- Niakolas, D.K.; Daletou, M.; Neophytides, S.G.; Vayenas, C.G. Fuel cells are a commercially viable alternative for the production of “clean” energy. Ambio 2016, 45, 32–37. [Google Scholar] [CrossRef]

- Combustion Turbine NOx Control Technology Memo. Available online: https://www.epa.gov/system/files/documents/2022-03/combustion-turbine-nox-technology-memo.pdf (accessed on 27 May 2024).

- Lal, A.; You, F. Climate sustainability through a dynamic duo: Green hydrogen and crypto driving energy transition and decarbonization. Proc. Natl. Acad. Sci. USA 2024, 121, e2313911121. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J. Hybrid Deloading Control Strategy in MMC-Based Wind Energy Conversion Systems for Enhanced Frequency Regulation. Energies 2024, 17, 1253. [Google Scholar] [CrossRef]

- Akhtar, N.; Geyer, B.; Schrum, C. Larger wind turbines as a solution to reduce environmental impacts. Sci. Rep. 2024, 14, 6608. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Lam, K.M.; Shum, K.M.; Li, Y. Wake effect of a horizontal axis wind turbine on the performance of a downstream turbine. Energies 2019, 12, 2395. [Google Scholar] [CrossRef]

- Ramli, M.A.; Bouchekara, H.R. Wind farm layout optimization considering obstacles using a binary most valuable player algorithm. IEEE Access 2020, 8, 131553–131564. [Google Scholar] [CrossRef]

- Archer, C.L.; Vasel-Be-Hagh, A. Wake steering via yaw control in multi-turbine wind farms: Recommendations based on large-eddy simulation. Sustain. Energy Technol. Assessments 2019, 33, 34–43. [Google Scholar] [CrossRef]

- Ye, M.; Chen, H.C.; Koop, A. High-fidelity CFD simulations for the wake characteristics of the NTNU BT1 wind turbine. Energy 2023, 265, 126285. [Google Scholar] [CrossRef]

- Wu, X.; Hu, Y.; Li, Y.; Yang, J.; Duan, L.; Wang, T.; Adcock, T.; Jiang, Z.; Gao, Z.; Lin, Z.; et al. Foundations of offshore wind turbines: A review. Renew. Sustain. Energy Rev. 2019, 104, 379–393. [Google Scholar] [CrossRef]

- Barooni, M.; Ashuri, T.; Velioglu Sogut, D.; Wood, S.; Ghaderpour Taleghani, S. Floating offshore wind turbines: Current status and future prospects. Energies 2022, 16, 2. [Google Scholar] [CrossRef]

- Ibrahim, O.S.; Singlitico, A.; Proskovics, R.; McDonagh, S.; Desmond, C.; Murphy, J.D. Dedicated large-scale floating offshore wind to hydrogen: Assessing design variables in proposed typologies. Renew. Sustain. Energy Rev. 2022, 160, 112310. [Google Scholar] [CrossRef]

- Yang, B.; Liu, B.; Zhou, H.; Wang, J.; Yao, W.; Wu, S.; Shu, H.; Ren, Y. A critical survey of technologies of large offshore wind farm integration: Summary, advances, and perspectives. Prot. Control Mod. Power Syst. 2022, 7, 17. [Google Scholar] [CrossRef]

- Li, K.; Liao, Y.; Lin, H.; Liu, R.; Zhang, J. Circulating current suppression with improved DC-link power quality for modular multilevel converter. IET Gener. Transm. Distrib. 2018, 12, 2220–2230. [Google Scholar] [CrossRef]

- DeSantis, D.; James, B.D.; Houchins, C.; Saur, G.; Lyubovsky, M. Cost of long-distance energy transmission by different carriers. IScience 2021, 24, 103495. [Google Scholar] [CrossRef]

- Miao, B.; Giordano, L.; Chan, S.H. Long-distance renewable hydrogen transmission via cables and pipelines. Int. J. Hydrogen Energy 2021, 46, 18699–18718. [Google Scholar] [CrossRef]

- Offshore Wind & Hydrogen Integration. Available online: https://www.adlittle.com/sites/default/files/reports/ADL_Offshore_wind_and_hydrogen_2023.pdf (accessed on 28 May 2024).

- Sarang, S.A.; Raza, M.A.; Panhwar, M.; Khan, M.; Abbas, G.; Touti, E.; Altamimi, A.; Wijaya, A.A. Maximizing solar power generation through conventional and digital MPPT techniques: A comparative analysis. Sci. Rep. 2024, 14, 8944. [Google Scholar] [CrossRef]

- Mahato, G.C.; Biswal, S.R.; Choudhury, T.R.; Nayak, B.; Santra, S.B. Review of active power control techniques considering the impact of MPPT and FPPT during high PV penetration. Sol. Energy 2023, 251, 404–419. [Google Scholar] [CrossRef]

- Wu, S.; Jiang, N.; Zhang, S.; Zhang, P.; Zhao, P.; Liu, Y.; Wang, Y. Discussion on the development of offshore floating photovoltaic plants, emphasizing marine environmental protection. Front. Mar. Sci. 2024, 11, 1336783. [Google Scholar] [CrossRef]

- Gordon, J.A.; Balta-Ozkan, N.; Haq, A.; Nabavi, S.A. Coupling green hydrogen production to community benefits: A pathway to social acceptance? Energy Res. Soc. Sci. 2024, 110, 103437. [Google Scholar] [CrossRef]

- Policy/International. Available online: https://research.csiro.au/hyresource/policy/international/ (accessed on 29 May 2024).

- Global Hydrogen Review 2023. Available online: https://www.iea.org/reports/global-hydrogen-review-2023 (accessed on 29 May 2024).

- Global Energy Transition Update: Active H2 Projects and Electrolyzer Capacity. Available online: https://h2-tech.com/articles/2024/january-2024/columns/global-energy-transition-update-active-h-sub-2-sub-projects-and-electrolyzer-capacity/ (accessed on 29 May 2024).

- Kumar, S.S.; Lim, H. An overview of water electrolysis technologies for green hydrogen production. Energy Rep. 2022, 8, 13793–13813. [Google Scholar] [CrossRef]

- Green Hydrogen to Undercut Gray Sibling by End of Decade. Available online: https://about.bnef.com/blog/green-hydrogen-to-undercut-gray-sibling-by-end-of-decade/ (accessed on 30 May 2024).

- Jayachandran, M.; Gatla, R.K.; Flah, A.; Milyani, A.H.; Milyani, H.M.; Blazek, V.; Prokop, L.; Kraiem, H. Challenges and Opportunities in Green Hydrogen Adoption for Decarbonizing Hard-to-Abate Industries: A Comprehensive Review. IEEE Access 2024, 12, 23363–23388. [Google Scholar] [CrossRef]

- Wappler, M.; Unguder, D.; Lu, X.; Ohlmeyer, H.; Teschke, H.; Lueke, W. Building the green hydrogen market–Current state and outlook on green hydrogen demand and electrolyzer manufacturing. Int. J. Hydrogen Energy 2022, 47, 33551–33570. [Google Scholar] [CrossRef]

- Kim, A.; Kim, H.; Lim, D.; Cheon, S.; Lim, H. Materializing International Trade of Decarbonized Hydrogen through Optimization in Both Economic and Environmental Aspects. ACS Sustain. Chem. Eng. 2022, 11, 155–167. [Google Scholar] [CrossRef]

- Eicke, L.; De Blasio, N. Green hydrogen value chains in the industrial sector—Geopolitical and market implications. Energy Res. Soc. Sci. 2022, 93, 102847. [Google Scholar] [CrossRef]

- Challenges to Chile Becoming a Green Hydrogen Superpower. Available online: https://energytransition.org/2024/01/challenges-to-chile-becoming-a-green-hydrogen-superpower/ (accessed on 31 May 2024).

- Green Hydrogen: Energizing the Path to Net Zero. Available online: https://www2.deloitte.com/content/dam/Deloitte/at/Documents/presse/at-deloitte-wasserstoffstudie-2023.pdf (accessed on 31 May 2024).

- NortH2—A Green Hydrogen Hub in Northwest Europe. Available online: https://www.rwe.com/en/research-and-development/hydrogen-projects/north2/ (accessed on 30 May 2024).

- Wind-to-Hydrogen Tech Goes to SEA. Available online: https://spectrum.ieee.org/green-hydrogen-2663997448 (accessed on 31 May 2024).

- Hydrogen Production in the North Sea—AquaVentus. Available online: https://www.rwe.com/en/research-and-development/hydrogen-projects/aquaventus/ (accessed on 31 May 2024).

- The Future of Green Energy|Murchison Green Hydrogen|MGH. Available online: https://www.murchisonrenewables.com.au/ (accessed on 1 June 2024).

- Western Green Energy Hub. Available online: https://wgeh.com.au/ (accessed on 1 June 2024).

- Green Hydrogen Project Begins Production in Inner Mongolia. Available online: https://www.ctg.com.cn/ctgenglish/news_media/news37/1471453/index.html (accessed on 2 June 2024).

- NEOM Green Hydrogen Complex. Available online: https://www.airproducts.com/energy-transition/neom-green-hydrogen-complex (accessed on 2 June 2024).

- Regional Clean Hydrogen Hubs Selections for Award Negotiations. Available online: https://www.energy.gov/oced/regional-clean-hydrogen-hubs-selections-award-negotiations (accessed on 3 June 2024).

- Plug, Olin Corporation Launch Joint Venture for 15-Ton-Per-Day Hydrogen Plant. Available online: https://www.ir.plugpower.com/press-releases/news-details/2022/Plug-Olin-Corporation-Launch-Joint-Venture-for-15-Ton-Per-Day-Hydrogen-Plant/default.aspx (accessed on 3 June 2024).

- Calistoga Resiliency Center. Available online: https://www.energyvault.com/projects/calistoga (accessed on 3 June 2024).

- Dimou, A.; Moustakas, K.; Vakalis, S. The Role of Hydrogen and H2 Mobility on the Green Transition of Islands: The Case of Anafi (Greece). Energies 2023, 16, 3542. [Google Scholar] [CrossRef]

- Komorowska, A.; Benalcazar, P.; Kamiński, J. Evaluating the competitiveness and uncertainty of offshore wind-to-hydrogen production: A case study of Poland. Int. J. Hydrogen Energy 2023, 48, 14577–14590. [Google Scholar] [CrossRef]

- Dispenza, G.; Sergi, F.; Napoli, G.; Antonucci, V.; Andaloro, L. Evaluation of hydrogen production cost in different real case studies. J. Energy Storage 2019, 24, 100757. [Google Scholar] [CrossRef]

- Ciancio, A.; Basso, G.L.; Pastore, L.M.; de Santoli, L. Carbon abatement cost evolution in the forthcoming hydrogen valleys by following different hydrogen pathways. Int. J. Hydrogen Energy 2024, 64, 80–97. [Google Scholar] [CrossRef]

- Ceran, B. Multi-Criteria comparative analysis of clean hydrogen production scenarios. Energies 2020, 13, 4180. [Google Scholar] [CrossRef]

- González Palencia, J.C.; Itoi, Y.; Araki, M. Design of a Hydrogen Production System Considering Energy Consumption, Water Consumption, CO2 Emissions and Cost. Energies 2022, 15, 7938. [Google Scholar] [CrossRef]

- Cao, B.; Wu, X.; Liu, B.; Wang, X.; Wang, P.; Wu, Y. Multi-stage stochastic long-term planning of grid-connected hydrogen-based energy system based on improved SDDIP. IET Gener. Transm. Distrib. 2023, 17, 3016–3029. [Google Scholar] [CrossRef]

- Lu, Z.; Li, Y.; Zhuo, G.; Xu, C. Configuration optimization of hydrogen-based multi-microgrid systems under electricity market trading and different hydrogen production strategies. Sustainability 2023, 15, 6753. [Google Scholar] [CrossRef]

- Giampieri, A.; Ling-Chin, J.; Roskilly, A.P. Techno-economic assessment of offshore wind-to-hydrogen scenarios: A UK case study. Int. J. Hydrogen Energy 2024, 52, 589–617. [Google Scholar] [CrossRef]

- Khezri, R.; Mahmoudi, A.; Aki, H. Multiobjective long-period optimal planning model for a grid-connected renewable-battery system. IEEE Trans. Ind. Appl. 2022, 58, 5055–5067. [Google Scholar] [CrossRef]

- Mukoni, E.; Garner, K.S. Multi-objective non-dominated sorting genetic algorithm optimization for optimal hybrid (wind and grid)-hydrogen energy system modelling. Energies 2022, 15, 7079. [Google Scholar] [CrossRef]

- Pan, G.; Gu, W.; Lu, Y.; Qiu, H.; Lu, S.; Yao, S. Optimal planning for electricity-hydrogen integrated energy system considering power to hydrogen and heat and seasonal storage. IEEE Trans. Sustain. Energy 2020, 11, 2662–2676. [Google Scholar] [CrossRef]

- Dadkhah, A.; Van Eetvelde, G.; Vandevelde, L. Optimal investment and flexible operation of power-to-hydrogen systems increasing wind power utilisation. In Proceedings of the 2022 IEEE International Conference on Environment and Electrical Engineering and 2022 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Prague, Czech Republic, 28 June–1 July 2022; pp. 1–6. [Google Scholar]

- Wu, D.; Wang, D.; Ramachandran, T.; Holladay, J. A techno-economic assessment framework for hydrogen energy storage toward multiple energy delivery pathways and grid services. Energy 2022, 249, 123638. [Google Scholar] [CrossRef]

- Schrotenboer, A.H.; Veenstra, A.A.; uit het Broek, M.A.; Ursavas, E. A Green Hydrogen Energy System: Optimal control strategies for integrated hydrogen storage and power generation with wind energy. Renew. Sustain. Energy Rev. 2022, 168, 112744. [Google Scholar] [CrossRef]

- Dadkhah, A.; Bozalakov, D.; De Kooning, J.D.; Vandevelde, L. On the optimal planning of a hydrogen refuelling station participating in the electricity and balancing markets. Int. J. Hydrogen Energy 2021, 46, 1488–1500. [Google Scholar] [CrossRef]

- Wu, T.; Wang, J. Reliability evaluation for integrated electricity-gas systems considering hydrogen. IEEE Trans. Sustain. Energy 2022, 14, 920–934. [Google Scholar] [CrossRef]

- Wang, S.; Hui, H.; Ding, Y.; Song, Y. Long-term reliability evaluation of integrated electricity and gas systems considering distributed hydrogen injections. Appl. Energy 2024, 356, 122374. [Google Scholar] [CrossRef]

- Wen, D.; Aziz, M. Data-driven energy management system for flexible operation of hydrogen/ammonia-based energy hub: A deep reinforcement learning approach. Energy Convers. Manag. 2023, 291, 117323. [Google Scholar] [CrossRef]

- Wang, Y.; Song, M.; Jia, M.; Li, B.; Fei, H.; Zhang, Y.; Wang, X. Multi-objective distributionally robust optimization for hydrogen-involved total renewable energy CCHP planning under source-load uncertainties. Appl. Energy 2023, 342, 121212. [Google Scholar] [CrossRef]

- Jiang, H.; Qi, B.; Du, E.; Zhang, N.; Yang, X.; Yang, F.; Wu, Z. Modeling hydrogen supply chain in renewable electric energy system planning. IEEE Trans. Ind. Appl. 2021, 58, 2780–2791. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Wang, N.; Wu, B. An enhanced predictive hierarchical power management framework for islanded microgrids. IET Gener. Transm. Distrib. 2022, 16, 503–516. [Google Scholar] [CrossRef]

- Assessing the Flexibility of Green Hydrogen in Power System Models. Available online: https://www.esig.energy/wp-content/uploads/2024/04/ESIG-Flexibility-Hydrogen-Power-System-Models-report-2024.pdf (accessed on 2 June 2024).

- Zhang, W.; Maleki, A.; Nazari, M.A. Optimal operation of a hydrogen station using multi-source renewable energy (solar/wind) by a new approach. J. Energy Storage 2022, 53, 104983. [Google Scholar] [CrossRef]

- Lu, J.; Li, M.; Li, Q. Modeling and optimal design of a grid-independent solutions based on solar-hydrogen storage feeding green building by optimization algorithm. J. Energy Storage 2023, 62, 106844. [Google Scholar] [CrossRef]

- Shao, Z.; Cao, X.; Zhai, Q.; Guan, X. Risk-constrained planning of rural-area hydrogen-based microgrid considering multiscale and multi-energy storage systems. Appl. Energy 2023, 334, 120682. [Google Scholar] [CrossRef]

- Giovanniello, M.A.; Wu, X.Y. Hybrid lithium-ion battery and hydrogen energy storage systems for a wind-supplied microgrid. Appl. Energy 2023, 345, 121311. [Google Scholar] [CrossRef]

- Florez, J.; AlAbbad, M.; Vazquez-Sanchez, H.; Morales, M.G.; Sarathy, S.M. Optimizing islanded green ammonia and hydrogen production and export from Saudi Arabia. Int. J. Hydrogen Energy 2024, 56, 959–972. [Google Scholar] [CrossRef]

- Wu, X.; Cao, B.; Liu, B.; Wang, X. A planning model of standalone hydrogenbased carbon-free microgrid through convex relaxation. IEEE Trans. Smart Grid 2022, 14, 2668–2680. [Google Scholar] [CrossRef]

- Babaei, R.; Ting, D.S.; Carriveau, R. Optimization of hydrogen-producing sustainable island microgrids. Int. J. Hydrogen Energy 2022, 47, 14375–14392. [Google Scholar] [CrossRef]

- Hasan, T.; Emami, K.; Shah, R.; Hassan, N.; Belokoskov, V.; Ly, M. Techno-economic assessment of a hydrogen-based islanded microgrid in north-east. Energy Rep. 2023, 9, 3380–3396. [Google Scholar] [CrossRef]

- Dong, W.; Sun, H.; Mei, C.; Li, Z.; Zhang, J.; Yang, H. Forecast-driven stochastic optimization scheduling of an energy management system for an isolated hydrogen microgrid. Energy Convers. Manag. 2023, 277, 116640. [Google Scholar] [CrossRef]

- Zhao, Y.; Huang, J.; Xu, E.; Wang, J.; Xu, X. A data-driven scheduling approach for integrated electricity-hydrogen system based on improved DDPG. IET Renew. Power Gener. 2024, 18, 442–455. [Google Scholar] [CrossRef]

- Cai, P.; Mi, Y.; Ma, S.; Li, H.; Li, D.; Wang, P. Hierarchical game for integrated energy system and electricity-hydrogen hybrid charging station under distributionally robust optimization. Energy 2023, 283, 128471. [Google Scholar] [CrossRef]

- Pu, Y.; Li, Q.; Luo, S.; Chen, W.; Breaz, E.; Gao, F. Peer-to-peer Electricity-hydrogen Trading Among Integrated Energy Systems Considering Hydrogen Delivery and Transportation. IEEE Trans. Power Syst. 2023, 39, 3895–3911. [Google Scholar] [CrossRef]

- Wu, X.; Li, H.; Wang, X.; Zhao, W. Cooperative operation for wind turbines and hydrogen fueling stations with on-site hydrogen production. IEEE Trans. Sustain. Energy 2020, 11, 2775–2789. [Google Scholar] [CrossRef]

- García-Triviño, P.; de Oliveira-Assís, L.; Soares-Ramos, E.P.; Sarrias-Mena, R.; García-Vázquez, C.A.; Fernández-Ramírez, L.M. Supervisory control system for a grid-connected MVDC microgrid based on Z-source converters with PV, battery storage, green hydrogen system and charging station of electric vehicles. IEEE Trans. Ind. Appl. 2023, 59, 2650–2660. [Google Scholar] [CrossRef]

- Zhao, W.; Nielsen, M.R.; Kjær, M.; Iov, F.; Nielsen, S.M. Grid integration of a 500 kW alkaline electrolyzer system for harmonic analysis and robust control. E-Prime Electr. Eng. Electron. Energy 2023, 5, 100217. [Google Scholar] [CrossRef]

- Iribarren, Á.; Elizondo, D.; Barrios, E.L.; Ibaiondo, H.; Sanchez-Ruiz, A.; Arza, J.; Sanchis, P.; Ursúa, A. Dynamic modeling of a pressurized alkaline water electrolyzer: A multiphysics approach. IEEE Trans. Ind. Appl. 2023, 59, 3741–3753. [Google Scholar] [CrossRef]

- Dozein, M.G.; Jalali, A.; Mancarella, P. Fast frequency response from utility-scale hydrogen electrolyzers. IEEE Trans. Sustain. Energy 2021, 12, 1707–1717. [Google Scholar] [CrossRef]

- Dozein, M.G.; De Corato, A.M.; Mancarella, P. Virtual inertia response and frequency control ancillary services from hydrogen electrolyzers. IEEE Trans. Power Syst. 2022, 38, 2447–2459. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, J.; Zhou, M.; Xia, Q.; Tan, C.W.; Li, G. Incentivizing frequency provision of power-to-hydrogen toward grid resiliency enhancement. IEEE Trans. Ind. Inform. 2022, 19, 9370–9381. [Google Scholar] [CrossRef]

- Electrolysis as a Potential Solution for Congestion Management (Use Case Study). Available online: https://ispt.eu/publications/electrolysis-as-a-potential-solution-for-congestion-management-use-case-study/ (accessed on 7 June 2024).

- Khan, M.; Wu, W.; Li, L. Grid-forming control for inverter-based resources in power systems: A review on its operation, system stability, and prospective. IET Renew. Power Gener. 2024, 18, 887–907. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J. Modeling and Control of an Islanded Campus Microgrid with Coordinated CHP and PV Systems. In Proceedings of the 2021 IEEE Power & Energy Society General Meeting (PESGM), Washington, DC, USA, 26–29 July 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Tavakoli, S.D.; Dozein, M.G.; Lacerda, V.A.; Mañe, M.C.; Prieto-Araujo, E.; Mancarella, P.; Gomis-Bellmunt, O. Grid-forming services from hydrogen electrolyzers. IEEE Trans. Sustain. Energy 2023, 14, 2205–2219. [Google Scholar] [CrossRef]

- Kim, J.; Muljadi, E.; Nelms, R.M. Modelling and control coordination scheme of a wind-to-hydrogen set for future renewable-based power systems. IET Renew. Power Gener. 2020, 14, 3317–3326. [Google Scholar] [CrossRef]

- Yin, W.; Liu, L.; Rui, X. Analysis, modeling and control of a hybrid drive wind turbine with hydrogen energy storage system. IEEE Access 2020, 8, 114795–114806. [Google Scholar] [CrossRef]

- Lim, A.; Lee, J.S.; Lee, S.; Lee, S.Y.; Kim, H.j.; Yoo, S.J.; Jang, J.H.; Sung, Y.E.; Park, H.S. Polymer electrolyte membrane unitized regenerative fuel cells: Operational considerations for achieving high round trip efficiency at low catalyst loading. Appl. Catal. B Environ. 2021, 297, 120458. [Google Scholar] [CrossRef]

- Prabakar, K.; Velaga, Y.N.; Flores, R.; Brouwer, J.; Chase, J.; Sen, P. Enhancing distribution system resiliency using grid-forming fuel cell inverter. In Proceedings of the 2022 IEEE Rural Electric Power Conference (REPC), Savannah, GA, USA, 5–8 April 2022; pp. 38–42. [Google Scholar] [CrossRef]

- Shahbazbegian, V.; Shafie-khah, M.; Laaksonen, H.; Strbac, G.; Ameli, H. Resilience-oriented operation of microgrids in the presence of power-to-hydrogen systems. Appl. Energy 2023, 348, 121429. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, W. Decentralized coordination control of PV generators, storage battery, hydrogen production unit and fuel cell in islanded DC microgrid. Int. J. Hydrogen Energy 2020, 45, 8243–8256. [Google Scholar] [CrossRef]

- Yıldız, S.; Gunduz, H.; Yildirim, B.; Özdemir, M.T. An islanded microgrid energy system with an innovative frequency controller integrating hydrogen-fuel cell. Fuel 2022, 326, 125005. [Google Scholar] [CrossRef]

- Lee, G.H.; Kim, Y.J. Frequency regulation of an islanded microgrid using hydrogen energy storage systems: A data-driven control approach. Energies 2022, 15, 8887. [Google Scholar] [CrossRef]

- Lin, Y.; Fu, L. A study for a hybrid wind-solar-battery system for hydrogen production in an islanded MVDC network. IEEE Access 2022, 10, 85355–85367. [Google Scholar] [CrossRef]

- Abdelghany, M.B.; Mariani, V.; Liuzza, D.; Glielmo, L. Hierarchical model predictive control for islanded and grid-connected microgrids with wind generation and hydrogen energy storage systems. Int. J. Hydrogen Energy 2024, 51, 595–610. [Google Scholar] [CrossRef]

- Abdelghany, M.B.; Al-Durra, A.; Zeineldin, H.; Hu, J. Integration of cascaded coordinated rolling horizon control for output power smoothing in islanded wind–solar microgrid with multiple hydrogen storage tanks. Energy 2024, 291, 130442. [Google Scholar] [CrossRef]

| AEL | PEM | SOEC | AEM | |

|---|---|---|---|---|

| Technological readiness | Mature | Commercialized | Demonstration | Prototype |

| OER | ||||

| HER | ||||

| Efficiency (%) | 50–78 | 50–83 | 70–90 | 40–70 |

| Current density (A/cm2) | 0.2–0.8 | 1–4 | 0.2–1 | 0.2–2 |

| Productivity index (kg H2/kWh) | 0.8–1.2 | 1.2–1.8 | 1.8–2.5 | 0.8–1.5 |

| Voltage ranges (V) | 1.4–3.0 | 1.4–2.5 | 1.0–1.5 | 1.4–2.0 |

| Response time at stand-by | seconds | milliseconds | minutes | seconds |

| Operating temperature (°C) | 60–90 | 50–80 | 700–1000 | 40–60 |

| Cell pressure (bar) | ≤30 | ≤100 | 1–25 | ≤35 |

| Hydrogen purity (%) | 99.5–99.9998 | 99.9–99.9999 | 99.9–99.999 | 99.9–99.9999 |

| Stack lifetime (hour) | 60,000–100,000 | 20,000–80,000 | <20,000 | >30,000 |

| Cost (U.S.$/kW) | 500–1400 | 1100–1800 | 2800–5600 | N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Li, J. Revolution in Renewables: Integration of Green Hydrogen for a Sustainable Future. Energies 2024, 17, 4148. https://doi.org/10.3390/en17164148

Zhang J, Li J. Revolution in Renewables: Integration of Green Hydrogen for a Sustainable Future. Energies. 2024; 17(16):4148. https://doi.org/10.3390/en17164148

Chicago/Turabian StyleZhang, Jimiao, and Jie Li. 2024. "Revolution in Renewables: Integration of Green Hydrogen for a Sustainable Future" Energies 17, no. 16: 4148. https://doi.org/10.3390/en17164148

APA StyleZhang, J., & Li, J. (2024). Revolution in Renewables: Integration of Green Hydrogen for a Sustainable Future. Energies, 17(16), 4148. https://doi.org/10.3390/en17164148