A Review of Biodiesel Cold Flow Properties and Its Improvement Methods: Towards Sustainable Biodiesel Application

Abstract

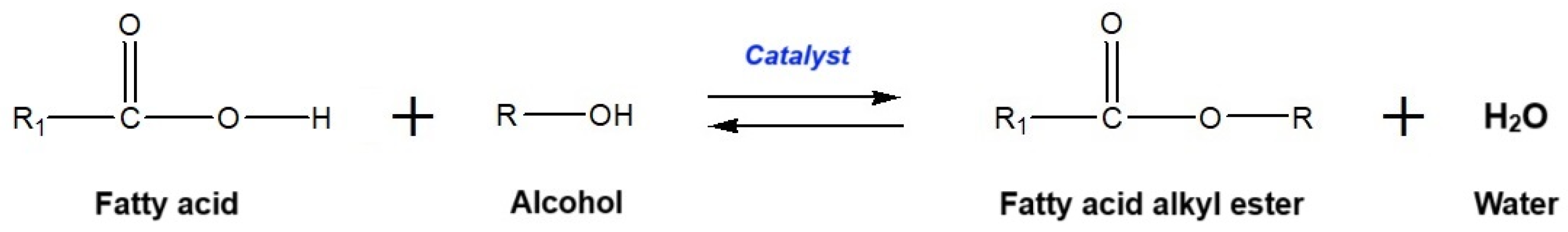

1. Introduction

1.1. Global Energy Outlook

1.2. Biodiesel as an Alternative Energy Source

| Properties | Unit | Petro-Diesel | Biodiesel | ||

|---|---|---|---|---|---|

| ASTM D975 [15,16] | EN 590 [16] | ASTM D6751 [17,18,19] | EN 14214 [13,20] | ||

| Chemical component [12,13] | - | Alkanes, alkenes (C10–C21) | Fatty acid alkyl esters (C8–C24 alkyl esters) | ||

| Phase [13] | - | Organic (insoluble in water) | Organic (insoluble in water) | ||

| Kinematic viscosity, at 40 °C | mm2/s | 1.9–4.1 | 2.0–4.5 | 1.9–6.0 | 3.5–5.0 |

| Density, at 15 °C | kg/m3 | n.s. *) | 820–845 | n.s. *) | 860–900 |

| Cetane number | - | ≥40 | ≥51 | ≥47 | ≥51 |

| Flash point | °C | ≥52 | ≥55 | ≥93 | ≥101 |

| Distillation temperature, at 90% | °C | 282–338 | n.s. *) | ≤360 | n.s. *) |

| Generation | Category | Feedstocks | Distinctive Characteristics | |

|---|---|---|---|---|

| First generation | Edible oils | |||

| Second generation | Non-edible oils |

| ||

| Animal fats | ||||

| Wastes |

| |||

| Third generation | Microalgae | |||

| Fourth generation | Genetically modified microorganism |

| ||

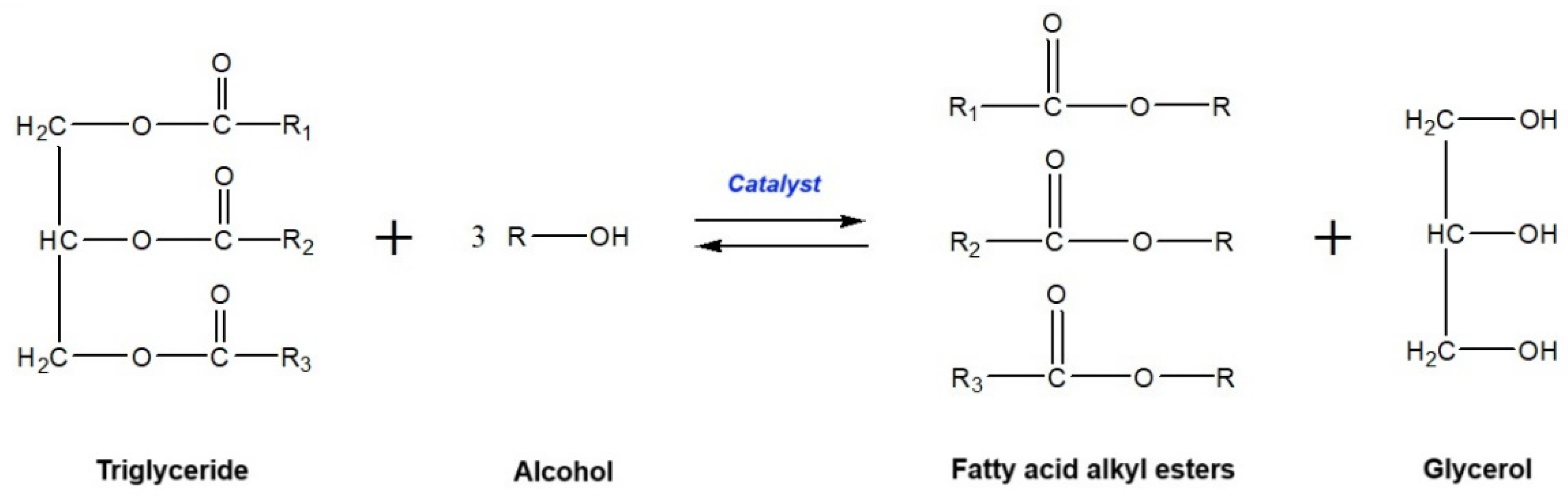

2. Physicochemical Properties of Biodiesel

2.1. Physical Properties of Biodiesel

2.2. Chemical Properties of Biodiesel

| Properties | Unit | Method | American Standard (ASTM D6751) [7,17,18,19] | European Standard (EN 14214) [7,13,20] | Indonesian Standard (195.K/EK.05/DJE/2022) [170] | Malaysian Standard (MS 2008:2014) [17,171] | Brazilian Standard (ANP N° 920/2023) [172] | Indian Standard (IS 15607) [173] | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |||

| Density at 15 °C | kg/m3 | EN 12185/ ISO 3675 | - | - | 860 | 900 | - | - | 860 | 900 | 850 a | 900 a | 860 | 900 |

| Density at 40 °C | kg/m3 | D4052 | - | - | - | - | 850 | 890 | - | - | - | - | - | - |

| Kinematic viscosity at 40 °C | mm2/s | D445/ EN ISO 3104 | 1.9 | 6.0 | 3.5 | 5.0 | 2.3 | 6.0 | 3.5 | 5.0 | 3.0 | 5.0 | 3.0 | 6.0 |

| Cetane number | - | D613/ EN ISO 5165 | 47 | - | 51 | - | 51 | - | 51 | - | report | - | 51 | - |

| Flash point (close cup) | °C | D93/ EN ISO 3679 | 93 | - | 101 | - | 130 | - | 120 | - | 100 | - | 120 | - |

| Cloud point | °C | D2500 | −3 | 12 | - | - | - | - | - | - | - | - | - | - |

| Pour point | °C | D97/ISO 3016 | −15 | 10 | - | - | - | - | - | - | - | - | - | - |

| Cold filter plugging point | °C | D6371/EN 116 | - | - | - | report | - | 15 | - | 15 | - | report | - | - |

Carbon residue

| wt% | D4530 D4530/ EN ISO 10370 | - - | 0.05 - | - - | - 0.3 | - - | 0.05 0.3 | - - | 0.05 0.3 | - - | - - | - - | 0.05 - |

| Copper strip corrosion, 3 h at 50 °C | Rating | D130/ EN ISO 2160 | - | No. 3 | Class 1 | Class 1 | Class 1 | Class 1 | Class 1 | |||||

| Distillation temperature, at 90% | °C | D1160 | - | 360 | - | - | - | 360 | - | - | - | - | - | - |

| Acid number | mg KOH/g | D664/ EN14104 | - | 0.5 | - | 0.5 | - | 0.4 | - | 0.5 | - | 0.5 | - | 0.5 |

| Iodine number | g I /100 g | EN14111/ AOCS Cd 1-25 | - | - | - | 120 | - | 115 | - | 110 | - | - | - | report |

| Oxidation stability, at 110 °C | h | EN14112/ EN15751 | 3 | - | 8 | - | 11 | - | 10 | - | 13 | - | 6 | - |

| Ester content | wt% | EN14103/ SNI 7182:2015 | - | - | 96.5 | - | 96.5 | - | 96.5 | - | 96.5 | - | 96.5 | - |

| Linolenic acid methyl ester | wt% | EN14103 | - | - | - | 12 | - | - | - | 12 | - | - | - | - |

| Polyunsaturated (≥4 double bonds) methyl esters | wt% | EN14103 | - | - | - | 1 | - | - | - | 1 | - | - | - | - |

| Methanol content | wt% | EN14110 | - | 0.2 | - | 0.2 | - | - | - | 0.2 | - | 0.2 | - | - |

| Monoglyceride content | wt% | D6584/ EN14105 | - | - | - | 0.7 | - | 0.525 | - | 0.7 | - | 0.5 | - | - |

| Diglyceride content | wt% | EN14105 | - | - | - | 0.2 | - | - | - | 0.2 | - | 0.2 | - | - |

| Triglyceride content | wt% | EN14105 | - | - | - | 0.2 | - | - | - | 0.2 | - | 0.2 | - | - |

| Free glycerol | wt% | D6584/ EN14105 | - | 0.02 | - | 0.02 | - | 0.02 | - | 0.02 | - | 0.02 | - | 0.02 |

| Total glycerol | wt% | D6584/ EN14105 | - | 0.24 | - | 0.25 | - | 0.24 | - | 0.25 | - | 0.20 | - | 0.25 |

| Alkaline metals (Na + K) | ppm | EN 14538 | - | 5 | - | 5 | - | 5 | - | 5 | - | 2.5 | - | report |

| Alkaline earth metals (Ca + Mg) | ppm | EN 14538 | - | 5 | - | 5 | - | 5 | - | 5 | - | 2.5 | - | report |

| Sulphur content | ppm | D5453/ EN ISO 20846 | - | - | - | 10 | - | 10 | - | 10 | - | 10 | - | 50 |

| Sulphur (S 15 Grade) | ppm | D5463 | - | 15 | - | - | - | - | - | - | - | - | - | - |

| Sulphur (S 500 Grade) | ppm | D5463 | - | 500 | - | - | - | - | - | - | - | - | - | - |

| Sulphated ash content | wt% | D874/ ISO 3987 | - | 0.02 | - | 0.02 | - | 0.02 | - | 0.02 | - | 0.02 | - | 0.02 |

| Phosphorus content | ppm | D4951/EN14107/AOCS Ca 12-55 | - | 10 | - | 4 | - | 4 | - | 4 | - | 3.0 | - | 10 |

| Water and sediment | %-v | D2709 | - | 0.05 | - | - | - | - | - | - | - | - | - | - |

| Water content | ppm | D6304/ EN ISO 12937 | - | - | - | 500 | - | 340 | - | 500 | - | 200 | - | 500 |

| Total contamination | ppm | D6217/EN12662 | - | - | - | 24 | - | 20 b | - | 24 | - | 24 | - | 24 |

| Cold soak filterability | s | Annex to D6751 | - | 360 | - | - | - | - | - | - | - | - | - | - |

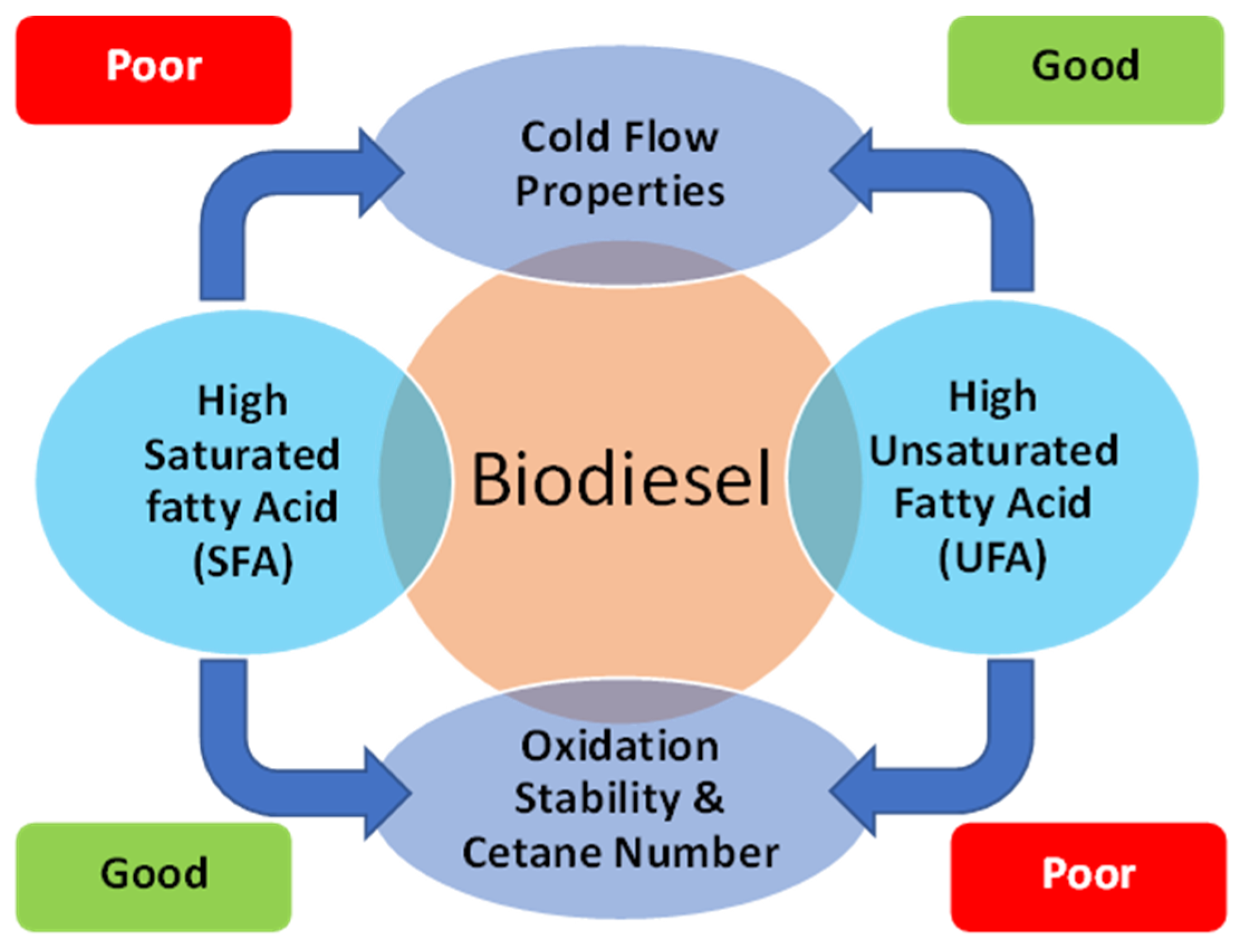

| Fatty Acids | Composition (wt%) and Physical Property Value | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P | S | R | SN | SF | CN | CS | C | J | JB | K | CI | UC | CF | BT | MS | MC | MT | ||

| Caprylic | C8:0 | - | - | - | - | - | 6.5 | - | - | - | - | - | - | - | - | - | - | - | - |

| Capric | C10:0 | - | - | - | - | - | 5.6 | - | - | - | - | - | - | - | - | 0.1 | - | - | - |

| Lauric | C12:0 | 0.2 | - | - | - | - | 46.9 | - | - | - | - | - | - | 0.4 | 0.1 | 0.2 | - | 9.8 | 3.1 |

| Myristic | C14:0 | 1.0 | 0.1 | - | 0.1 | - | 18.7 | 0.7 | - | 0.1 | 1.1 | - | - | 0.9 | 0.7 | 2.4 | 3.6 | - | - |

| Palmitic | C16:0 | 43.0 | 10.9 | 2.8 | 7.0 | 6.1 | 9.7 | 25.9 | 11.8 | 17.7 | 2.6 | 9.7 | 14.7 | 36.6 | 24.1 | 24.4 | 14.9 | 7.2 | 1.6 |

| Palmitoleic | C16:1 | - | 0.1 | 0.3 | 0.1 | - | 0.1 | 0.3 | 0.1 | 0.8 | - | - | 0.3 | 0.2 | 5.7 | 2.7 | 1.0 | 24.5 | 10.1 |

| Margaric | C17:0 | - | 0.1 | - | - | - | - | - | - | - | - | - | - | - | 0.2 | 0.9 | - | - | - |

| Stearic | C18:0 | 4.6 | 4.2 | 1.3 | 4.5 | 2.5 | 2.8 | 1.7 | 2.1 | 6.4 | 5.1 | 7.1 | 13.2 | 4.2 | 6.4 | 19.1 | 28.1 | 9.5 | 4.3 |

| Oleic | C18:1 | 40.0 | 25.0 | 64.4 | 18.7 | 29.6 | 6.8 | 15.9 | 27.3 | 41.8 | 45.8 | 52.4 | 46.1 | 42.4 | 41.4 | 41.7 | 5.4 | 11.6 | 16.8 |

| Linoleic | C18:2 | 10.1 | 52.7 | 22.3 | 67.5 | 59.2 | 2.2 | 55.1 | 57.6 | 32.9 | 31.5 | 16.5 | 24.7 | 9.9 | 18.8 | 5.9 | 1.1 | 3.2 | 1.2 |

| Linolenic | C18:3 | 0.3 | 6.2 | 7.3 | 0.8 | 0.7 | - | 0.2 | 0.6 | 0.2 | 6.1 | 5.2 | 0.2 | 0.2 | 1.1 | 0.7 | - | 0.7 | 1.1 |

| Arachidic | C20:0 | 0.4 | 0.3 | 0.6 | 0.4 | - | 0.1 | 0.2 | 0.3 | 0.1 | - | - | 0.8 | 0.3 | 0.1 | 0.4 | 32.4 | - | - |

| Eicosenoic | C20:1 | - | 0.1 | 1.0 | 0.1 | - | - | 0.1 | 0.3 | - | - | 3.5 | - | 0.2 | 0.4 | 0.5 | 1.9 | - | - |

| Eicosadienoic | C20:2 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 1.0 | - | - |

| Eicosatetraenoic | C20:4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 1.9 | 0.6 |

| Eicosapentaenoic | C20:5 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 5.3 | 1.7 |

| Behenic | C22:0 | - | 0.3 | - | 0.7 | - | - | 0.1 | - | - | - | 4.2 | - | - | 0.3 | 0.03 | 6.7 | - | - |

| Erucic | C22:1 | - | - | - | - | - | - | - | - | - | - | - | - | - | 0.4 | 0.06 | - | - | - |

| Docosapentaenoic | C22:5 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 8.1 | 0.9 |

| Docosahexaenoic | C22:6 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 6.2 | 0.7 |

| Total saturated (wt%) | 49.2 | 15.9 | 4.7 | 12.7 | 8.6 | 90.4 | 28.6 | 14.2 | 24.3 | 8.9 | 22.4 | 28.7 | 42.4 | 32.1 | 47.7 | 89.6 | 26.5 | 8.9 | |

| Total unsaturated (wt%) | 50.4 | 84.1 | 95.3 | 87.2 | 89.5 | 9.2 | 71.5 | 85.8 | 75.7 | 83.5 | 77.6 | 71.3 | 52.8 | 67.8 | 51.5 | 9.4 | 61.5 | 33.1 | |

| Total mono-unsaturated (wt%) | 40.0 | 25.2 | 65.7 | 18.9 | 29.6 | 6.9 | 16.3 | 27.6 | 42.6 | 45.8 | 55.9 | 46.4 | 42.7 | 47.9 | 44.8 | 8.3 | 36.1 | 26.9 | |

| Total poly-unsaturated (wt%) | 10.4 | 58.9 | 29.6 | 68.3 | 59.9 | 2.2 | 55.2 | 58.2 | 33.1 | 37.6 | 21.8 | 24.9 | 10.1 | 19.9 | 6.6 | 1.1 | 25.4 | 6.2 | |

| Pour point (°C) | 6 | −3.2 | −11 | −2 | −12 | −3.8 | −0.2 | −5.1 | 2 | −6.2 | 1 | 13 | −6.5 | 4.4 | 10 | −9 | n.a. | n.a. | |

| Cloud point (°C) | 6 | 0 | −3.5 | 1.3 | n.a. | −1.2 | 1.2 | −3 | 3 | 5.8 | 6 | 12 | n.a. | 7.5 | 13.8 | −3 | 6.2 | 10.6 | |

| CFPP (°C) | 4 | −2 | −11.3 | −2 | −11 | −4.7 | 4.8 | −7.5 | n.a. | n.a. | −7 | 11 | n.a. | 2.7 | 12.2 | n.a. | n.a. | n.a. | |

| Oxidation stability (h) | 20.3 | 4.08 | 7.4 | 1.3 | 1.4 | 11 | 1.8 | 3 | 3.1 | 15.5 | 4.1 | 6.1 | 3 | 8.7 | 0.45 | n.a. | n.a. | n.a. | |

| Cetane number | 61.2 | 51.8 | 54.1 | 51.9 | 54.8 | 61 | 53.3 | 52.5 | 53.5 | 54.4 | 55.4 | n.a. | 56.2 | 57 | 60.9 | 70 | 46.2 | 46.2 | |

| Reference | [54,69] | [13,69] | [13,69] | [13,69] | [64] | [69] | [69] | [69] | [85] | [33] | [32,69] | [91] | [69,129] | [69] | [69] | [146] | [145] | [145] | |

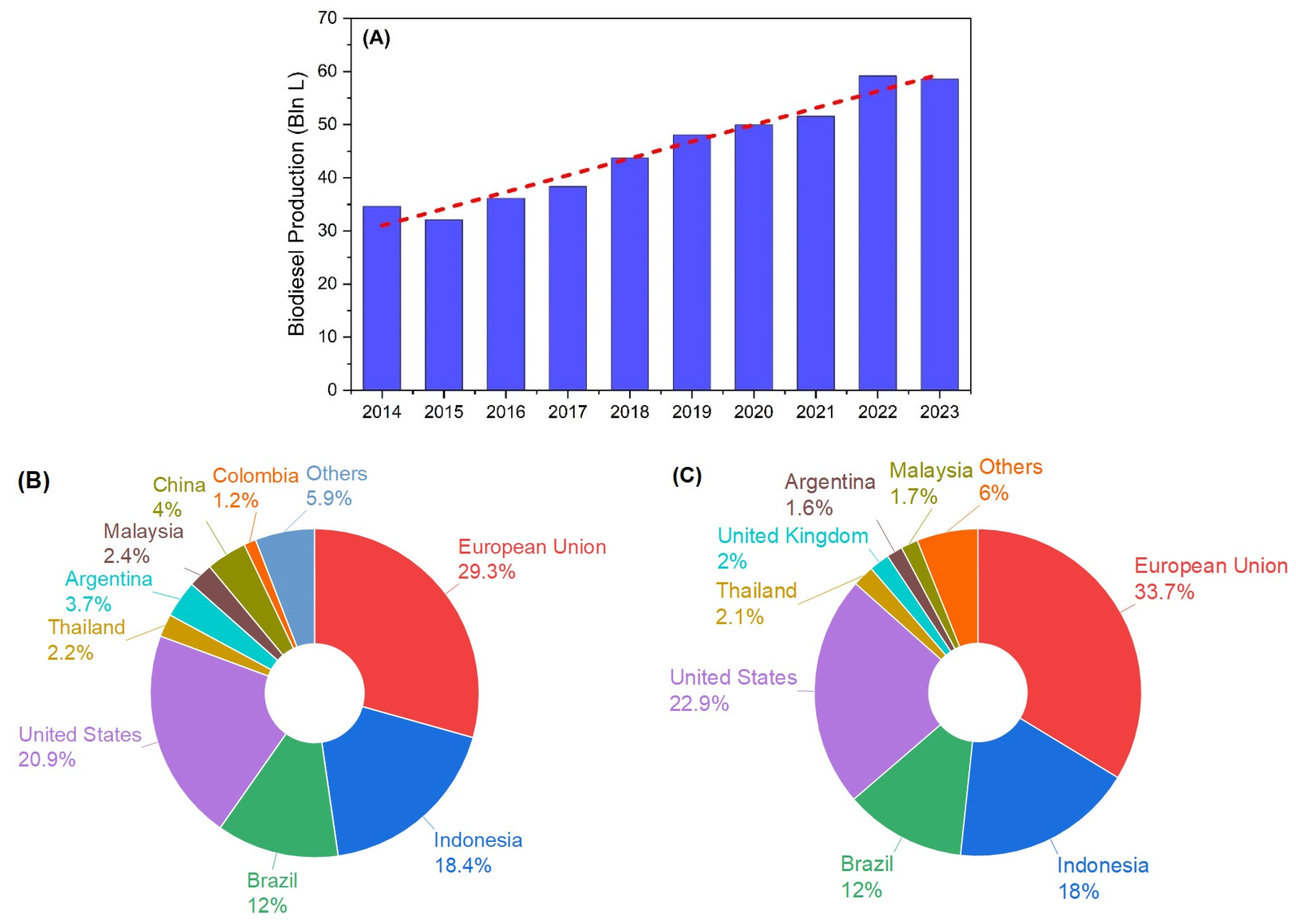

3. Cold Flow Properties of Biodiesel

3.1. Parameters of Cold Flow Properties

3.2. Effect of Fatty Acid Profiles on Cold Flow Properties

| Biodiesel | Additives | PP (°C) | CP (°C) | CFPP (°C) | Ref. | ||||

|---|---|---|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | ||||

| Palm biodiesel | B100 | Diethyl ether (5 vol%) | 16 | 10 | - | - | - | - | [176] |

| Ethanol (5 vol%) | 16 | 11 | - | - | - | - | |||

| n-butanol (5 vol%) | 16 | 12 | - | - | - | - | |||

| Palm biodiesel | B100 | Glycerol ketals (5 vol%) | 14 | 9 | 16 | 11 | - | - | [177] |

| Glycerol acetates (5 vol%) | 14 | 9 | 16 | 11 | - | - | |||

| Palm fatty acid isopropyl esters (5 vol%) | 14 | 10 | 16 | 11 | - | - | |||

| Palm fatty acid isobutyl esters (5 vol%) | 14 | 10 | 16 | 12 | - | - | |||

| Palm fatty acid 2-butyl esters (5 vol%) | 14 | 8 | 16 | 10 | - | - | |||

| Palm biodiesel | B100 | Ozonized palm oil (1 wt%) | 12 | 10 | 18 | 12 | - | - | [178] |

| Ozonized sunflower oil (1 wt%) | 12 | 11 | 18 | 13 | - | - | |||

| Ozonized soybean oil (1 wt%) | 12 | 13 | 18 | 13 | - | - | |||

| Ozonized rapeseed oil (1 wt%) | 12 | 13 | 18 | 13 | - | - | |||

| Soybean biodiesel | B100 | Oleyl alcohol (10 wt%) | - | - | 0 | −4 | - | - | [179] |

| Tert-butyl alcohol (10 wt%) | - | - | 0 | −4 | - | - | |||

| Soybean biodiesel | B10 | Tetradecyl methacrylate-citric anhydride-styrene co-polymer (0.15 wt%) | −13 | −24 | 0 | −3 | −1 | −8 | [180] |

| B20 | Tetradecyl methacrylate-citric anhydride-styrene co-polymer (0.15 wt%) | −13 | −23 | 1 | −3 | −1 | −9 | [180] | |

| B30 | Tetradecyl methacrylate-citric anhydride-styrene co-polymer (0.15 wt%) | −12 | −22 | 1 | −3 | 0 | −10 | ||

| Soybean biodiesel | B100 | Ozonized palm oil (1 wt%) | −2 | −10 | 1 | −2 | - | - | [178] |

| Ozonized sunflower oil (1 wt%) | −2 | −9 | 1 | 1 | - | - | |||

| Ozonized soybean oil (1 wt%) | −2 | −12 | 1 | 1 | - | - | |||

| Ozonized rapeseed oil (1 wt%) | −2 | −11 | 1 | −1 | - | - | |||

| Rapeseed biodiesel | B100 | Ozonized palm oil (1 wt%) | −13 | −10 | −4 | −6 | - | - | [178] |

| Ozonized sunflower oil (1 wt%) | −13 | −30 | −4 | −6 | - | - | |||

| Ozonized soybean oil (1 wt%) | −13 | −28 | −4 | −4 | - | - | |||

| Ozonized rapeseed oil (1 wt%) | −13 | −30 | −4 | −3 | - | - | |||

| Canola biodiesel | B100 | Oleyl alcohol (10 wt%) | - | - | −13 | −18 | - | - | [179] |

| Tert-butyl alcohol (10 wt%) | - | - | −13 | −16 | - | - | |||

| Sunflower biodiesel | B100 | Ozonized palm oil (1 wt%) | −5 | −15 | 1 | −2 | - | - | [178] |

| Ozonized sunflower oil (1 wt%) | −5 | −24 | 1 | 0 | - | - | |||

| Ozonized soybean oil (1 wt%) | −5 | −22 | 1 | 0 | - | - | |||

| Ozonized rapeseed oil (1 wt%) | −5 | −20 | 1 | 1 | - | - | |||

| Coconut biodiesel | B10 | Methyl acrylate polymer (0.03 wt%) | −13 | −21 | −3 | −11 | −5 | −16 | [181] |

| B20 | Methyl acrylate polymer (0.03 wt%) | −13 | −22 | −3 | −11 | −4 | −16 | ||

| B30 | Methyl acrylate polymer (0.03 wt%) | −10 | −12 | −3 | −7 | −4 | −9 | ||

| Polanga (Calophyllum inophyllum) biodiesel | B10 | Methyl acrylate polymer (0.03 wt%) | −2 | −9 | −1 | −5 | 0 | −8 | [181] |

| B20 | Methyl acrylate polymer (0.03 wt%) | 1 | −4 | 4 | −2 | 5 | −1 | ||

| B30 | Methyl acrylate polymer (0.03 wt%) | 4 | −3 | 7 | 1 | 5 | −2 | ||

| Used cooking biodiesel | B100 | Methyl acrylate polymer (0.04 wt%) | −11 | −19 | −8 | −9 | −9 | −15 | [182] |

| Ethylene vynil acetate co-polymer (0.04 wt%) | −11 | −17 | −8 | −8 | −9 | −11 | |||

| α-olefin polymer (0.04 wt%) | −11 | −14 | −8 | −9 | −9 | −10 | |||

| Maleic anhydride polymer (0.08 wt%) | −11 | −11 | −8 | −9 | −9 | −10 | |||

| Used cooking biodiesel | B100 | α-olefin polymer (0.06 wt%) | 5 | 2 | 7 | 5 | 6 | 3 | [183] |

| B20 | α-olefin polymer (0.04 wt%) | −10 | −17 | −2 | −9 | −1 | −11 | ||

3.3. Influence of Cold Flow Properties on Biodiesel Application

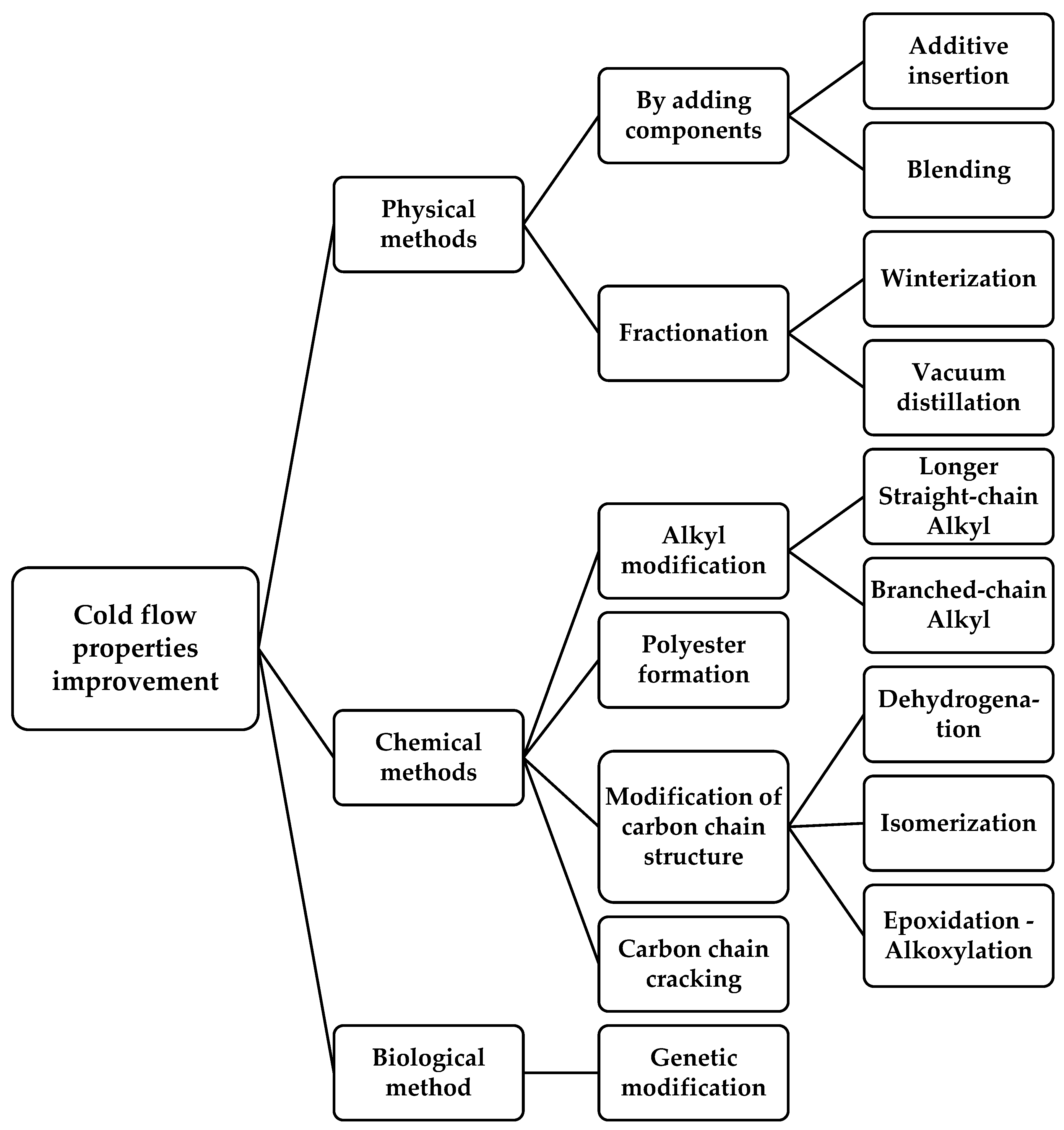

4. Methods for Improving Cold Flow Properties

4.1. By Adding Components

4.1.1. Additive Insertion

4.1.2. Blending

| Biodiesel | Blending Agent | PP (°C) | CP (°C) | CFPP (°C) | Ref. | |||

|---|---|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | |||

| Palm biodiesel | Soybean biodiesel (20 wt%) | - | - | - | - | 10 | 8 | [192] |

| Soybean biodiesel (40 wt%) | - | - | - | - | 10 | 5 | ||

| Soybean biodiesel (60 wt%) | - | - | - | - | 10 | 0 | ||

| Rapeseed biodiesel (20 wt%) | - | - | - | - | 10 | 7 | ||

| Rapeseed biodiesel (40 wt%) | - | - | - | - | 10 | 2 | ||

| Rapeseed biodiesel (60 wt%) | - | - | - | - | 10 | −3 | ||

| Soybean biodiesel (20 wt%) Rapeseed biodiesel (20 wt%) | - | - | - | - | 10 | 3 | ||

| Soybean biodiesel (40 wt%) Rapeseed biodiesel (20 wt%) | - | - | - | - | 10 | −2 | ||

| Soybean biodiesel (20 wt%) Rapeseed biodiesel (40 wt%) | - | - | - | - | 10 | −3 | ||

| Palm biodiesel | Methyl iso-stearat (25 wt%) | 16.7 | 10.3 | 14.2 | 8.6 | - | - | [188] |

| Methyl iso-stearat (50.1 wt%) | 16.7 | 4 | 14.2 | 3.1 | - | - | ||

| Methyl iso-oleat (25 wt%) | 16.7 | 11 | 14.2 | 8.7 | - | - | ||

| Methyl iso-oleat (49.8 wt%) | 16.7 | 4 | 14.2 | 2.2 | - | - | ||

| Soybean biodiesel | Rapeseed biodiesel (20 wt%) | - | - | - | - | −3 | −2 | [192] |

| Rapeseed biodiesel (40 wt%) | - | - | - | - | −3 | −4 | ||

| Rapeseed biodiesel (60 wt%) | - | - | - | - | −3 | −8 | ||

| Soybean biodiesel | Methyl iso-stearat (25 wt%) | 0.3 | −4.3 | 0.6 | −3.5 | - | - | [188] |

| Methyl iso-stearat (50 wt%) | 0.3 | −10 | 0.6 | −7.3 | - | - | ||

| Methyl iso-oleat (25 wt%) | 0.3 | −4 | 0.6 | −3.4 | - | - | ||

| Methyl iso-oleat (49.8 wt%) | 0.3 | −9.7 | 0.6 | −7.3 | - | - | ||

| Canola biodiesel | Methyl iso-stearat (24.7 wt%) | −10.7 | −14.7 | −2.5 | −5.7 | - | - | [188] |

| Methyl iso-stearat (49.8 wt%) | −10.7 | −17 | −2.5 | −10.1 | - | - | ||

| Methyl iso-oleat (24.9 wt%) | −10.7 | −18 | −2.5 | −5.7 | - | - | ||

| Methyl iso-oleat (48.5 wt%) | −10.7 | −27 | −2.5 | −8.7 | - | - | ||

| Rapeseed biodiesel | N-butanol (10 vol%) | - | - | −6 | −7 | −10 | −11 | [191] |

| N-butanol (20 vol%) | - | - | −6 | −8 | −10 | −13 | ||

| N-butanol (50 vol%) | - | - | −6 | −9 | −10 | −17 | ||

| Rapeseed biodiesel (butyl esters) | N-butanol (10 vol%) | - | - | −7 | −8 | −14 | −16 | [191] |

| N-butanol (20 vol%) | - | - | −7 | −8 | −14 | −16 | ||

| N-butanol (50 vol%) | - | - | −7 | −9 | −14 | −17 | ||

| Jatropha biodiesel | Petro-diesel (20 vol%) | 18 | 16.5 | 20.2 | 17 | - | - | [193] |

| Petro-diesel (40 vol%) | 18 | 15.5 | 20.2 | 17 | - | - | ||

| Petro-diesel (60 vol%) | 18 | 15 | 20.2 | 15.5 | - | - | ||

| Kerosene (20 vol%) | 18 | 14 | 20.2 | 15 | - | - | ||

| Kerosene (40 vol%) | 18 | 10 | 20.2 | 12 | - | - | ||

| Kerosene (60 vol%) | 18 | 7 | 20.2 | 8 | - | - | ||

| Used cooking palm biodiesel | Used cooking coconut biodiesel (50 vol%) | 12 | 4 | 13 | 5 | - | - | [194] |

| Used cooking sunflower biodiesel (50 vol%) | 12 | 3 | 13 | 4 | - | - | ||

4.2. Fractionation

4.2.1. Cold Fractionation (Winterization)

| Biodiesel | Winterization Agent | PP (°C) | CP (°C) | CFPP (°C) | Biodiesel Yield (wt%) | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | ||||

| Palm biodiesel | No agent | 7 | 5.5 | 7.5 | 6.5 | - | - | 65.5 | [199] |

| Palm biodiesel | Sorbitan palmitate (0.5 wt%) | - | - | 16 | 8.5 | - | - | 74.4 | [200] |

| Palm biodiesel-like mixture | Sorbitan palmitate (1 wt%) | - | - | 17 | 10 | - | - | 41.6 | [198] |

| Sorbitan monostearate (0.75%) | - | - | 17 | 12 | - | - | 73.4 | ||

| Sorbitan tristearate (1 wt%) | - | - | 17 | 11 | - | - | 50.5 | ||

| L-ascorbyl palmitate (1 wt%) | - | - | 17 | 14 | - | - | 42.9 | ||

| L-ascorbyl di-palmitate (1 wt%) | - | - | 17 | 16 | - | - | 35.6 | ||

| Cholesterol palmitate (1 wt%) | - | - | 17 | 16 | - | - | 56.9 | ||

| Soybean biodiesel | No agent | −2 | −21 | −0.3 | −20 | - | - | 33.4 | [201] |

| Isopropanol (0.2 wt%) | −2 | −9 | −0.3 | −8.7 | - | - | 86.0 | ||

| n-hexane (0.2 wt%) | −2 | −11.3 | −0.3 | −10.3 | - | - | 78.4 | ||

| Soybean biodiesel | Sorbitan palmitate (0.5 wt%) | - | - | −1.5 | −4.5 | - | - | 76.6 | [200] |

| Rice biodiesel | Sorbitan palmitate (0.5 wt%) | - | - | 1 | 0 | - | - | 23.1 | [200] |

| Cottonseed biodiesel | Sorbitan palmitate (0.5 wt%) | - | - | 1.5 | −4 | - | - | 46.0 | [200] |

| Jatropha biodiesel | No agent | 18 | 16.5 | 20.2 | 17.8 | - | - | - | [193] |

| Karanja biodiesel | No agent | 9 | 3 | 16 | 9 | - | - | 91.33 | [196] |

| Peanut biodiesel | No agent (one stage) | 15 | −3 | 20 | 12 | 17 | 6 | 91.46 | [202] |

| No agent (three stages) | 15 | −3 | 20 | 2 | 17 | −3 | 90.51 | ||

| Methanol (mass ratio 4:1; one stage) | 15 | −6 | 20 | 0 | 17 | −8 | 91.07 | ||

| Used cooking biodiesel | No agent | 13.7 | 10.6 | 14.5 | 11.5 | - | - | - | [193] |

| Used cooking biodiesel | Sodium dodecylsulfate (0.3 wt%) Magnesium sulfate (1 wt%) | - | - | - | - | −10 | −17 | 73.1 | [197] |

4.2.2. Vacuum Distillation

| Biodiesel | Pressure (kPa) | Temperature (°C) | PP (°C) | CP (°C) | CFPP (°C) | Biodiesel Yield (wt%) | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | |||||

| Rapeseed biodiesel (methyl ester) | 0.4–0.7 | 165–215 | −16 | −18.5 | - | - | - | - | - | [207] |

| Rapeseed biodiesel (ethyl ester) | 0.4–0.7 | 165–215 | −17 | −19 | - | - | - | - | - | [207] |

| Palm fatty acid distillate (PFAD) biodiesel | 1 | 194.8 | 15 | 9 | 20 | 13 | 19 | 11 | 59.6 | [205] |

| Microalgae Nannochloropsis oceania biodiesel | 5 | 255–259 | - | - | - | - | - | 5 | 57.8 | [204] |

4.3. Alkyl Modification

| Feedstock | Alcohol | Alkyl Ester | PP (°C) | CP (°C) | CFPP (°C) | Ref. |

|---|---|---|---|---|---|---|

| Palm oil | Methanol | Methyl ester | 14 | - | - | [209] |

| Ethanol | Ethyl ester | 8 | - | - | ||

| n-propanol | n-propyl ester | 6 | - | - | ||

| n-butanol | n-butyl ester | 4 | - | - | ||

| Isobutanol | Isobutyl ester | 0 | - | - | ||

| n-pentanol | n-pentyl ester | 4 | - | - | ||

| Isopentanol | Isopentyl ester | 2 | - | - | ||

| n-hexanol | n-hexyl ester | 6 | - | - | ||

| n-heptanol | n-heptyl ester | 10 | - | - | ||

| n-octanol | noctyl ester | 12 | - | - | ||

| Palm oil | Methanol | Methyl ester | 12 | 16 | - | [212] |

| Isopropanol | Isopropyl ester | −3 | 6 | - | ||

| 2-butanol | 2-butyl ester | −6 | 7 | - | ||

| Isobutanol | Isobutyl ester | −3 | 7 | - | ||

| Isopentanol | Isopentyl ester | −9 | 8 | - | ||

| Soybean oil | Methanol | Methyl ester | - | 0 | - | [213] |

| Isopropanol | Isopropyl ester | - | −10 | - | ||

| Soybean oil | Methanol | Methyl ester | −3 | −2 | - | [214] |

| Ethanol | Ethyl ester | −6 | −2 | |||

| Isopropanol | Isopropyl ester | −12 | −9 | - | ||

| 2-butanol | 2-butyl ester | −15 | −12 | |||

| Soybean oil | Methanol | Methyl ester | −2 | 0 | - | [187] |

| Ethanol | Ethyl ester | −4 | 1 | - | ||

| Isopropanol | Isopropyl ester | −12 | −9 | - | ||

| n-butanol | n-butyl ester | −7 | −3 | - | ||

| 2-butanol | 2-butyl ester | −15 | −12 | - | ||

| Rapeseed oil | Methanol | Methyl ester | −9 | −4 | −14 | [211] |

| Ethanol | Ethyl ester | −15 | −1 | −6 | ||

| Biobutanol | Butyl ester | −18 | −8 | −21 | ||

| Canola oil | Methanol | Methyl ester | −9 | 1 | - | [187] |

| Ethanol | Ethyl ester | −6 | −1 | - | ||

| Isopropanol | Isopropyl ester | −12 | 7 | - | ||

| n-butanol | n-butyl ester | −16 | −6 | - | ||

| Safflower oil | Methanol | Methyl ester | −6 | - | - | [187] |

| Ethanol | Ethyl ester | −6 | −6 | - | ||

| Sunflower oil | Methanol | Methyl ester | −3 | 2 | - | [187] |

| Ethanol | Ethyl ester | −5 | −1 | - | ||

| Beef tallow | Methanol | Methyl ester | 15 | 17 | - | [187] |

| Ethanol | Ethyl ester | 12 | 15 | - | ||

| n-propanol | n-propyl ester | 9 | 12 | - | ||

| Isopropanol | Isopropyl ester | 0 | 8 | - | ||

| n-butanol | n-butyl ester | 6 | 9 | - | ||

| Isobutanol | Isobutyl ester | 3 | 8 | - | ||

| Waste cooking oil | Methanol | Methyl ester | 2 | −3 | −3 | [211] |

| Ethanol | Ethyl ester | −0.5 | −3 | −1 | ||

| Biobutanol | Butyl ester | −8 | −3 | −9 |

4.4. Polyester Formation

| Feedstock | Polyol | PP (°C) | CP (°C) | Kinematic Viscosity at 40 °C (cSt) | Ref. |

|---|---|---|---|---|---|

| Palm oil | Trymethylolpropane | −1 | - | 49.7 | [217] |

| High oleic palm oil | Trymethylolpropane | −9–−37 | - | 45.5–50.7 | [217] |

| Canola oil | Trymethylolpropane | −66 | −27 | 40.5 | [218] |

| Palm kernel oil | Di-trymethylolpropane | −6 | - | 111.7 | [219] |

| Used cooking oil | Trymethylolpropane | −8 | - | 38.6 | [220] |

| Oleic acid | Trymethylolpropane | −51 | −21 | 48.9 | [218] |

| Oleic acid | Trymethylolpropane | −35 a | - | 47.4 | [216] |

| Pentaerythritil monophenyl ether | −19 a | - | 67.9 | ||

| Pentaerythritil monomethyl ether | −15 a | - | 47.8 | ||

| Pentaerythritil monoethyl ether | −35 a | - | 46.3 | ||

| Pentaerythritil monobutyl ether | −33 a | - | 45.9 | ||

| 3,3-bis(hydroxymethyl)-oxetane | −28 a | - | 35.4 |

4.5. Modification of Carbon Chain Structure

4.5.1. Dehydrogenation

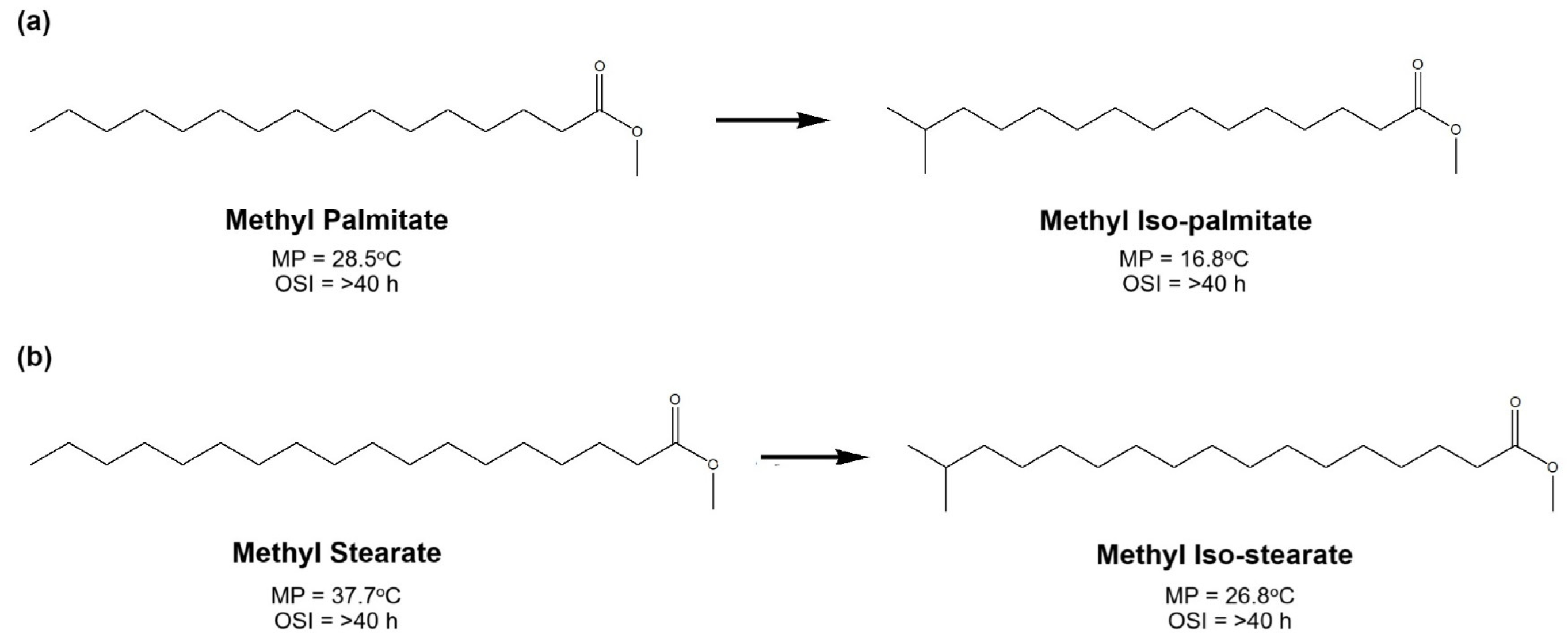

4.5.2. Isomerization

| Biodiesel | Catalyst | PP (°C) | CP (°C) | Ref. | ||

|---|---|---|---|---|---|---|

| Before | After | Before | After | |||

| Palm biodiesel | Pt/β-zeolite | 15 | 9 | 17.5 | 12.8 | [225] |

| Coconut biodiesel | Pt/β-zeolite | 9 | −3 | 14.2 | −2.3 | [225] |

| Soybean biodiesel | SO42−/ZrO2 | - | - | 5.2 | −1.5 | [226] |

| H-mordenite zeolite | - | - | 5.2 | 0 | ||

| Methyl palmitate | Pt/β-zeolite | - | - | 30 | 20 | [227] |

| Methyl stearate | H-ferrierite zeolite | 37.7 a | −25 | n.a. | −13.9 | [188] |

| Methyl oleate | H-ferrierite zeolite | −20.2 a | −34 | n.a. | −18.5 | [188] |

| Methyl oleate | H-ferrierite zeolite | −20.2 a | −34 | n.a. | −16 | [228] |

| Methyl oleate | β-zeolite | −15.6 | −15.2 | [229] | ||

| Methyl palmitate-methyl oleate mixture | Pt/β-zeolite | - | - | 17 | 9.5 | [230] |

- -

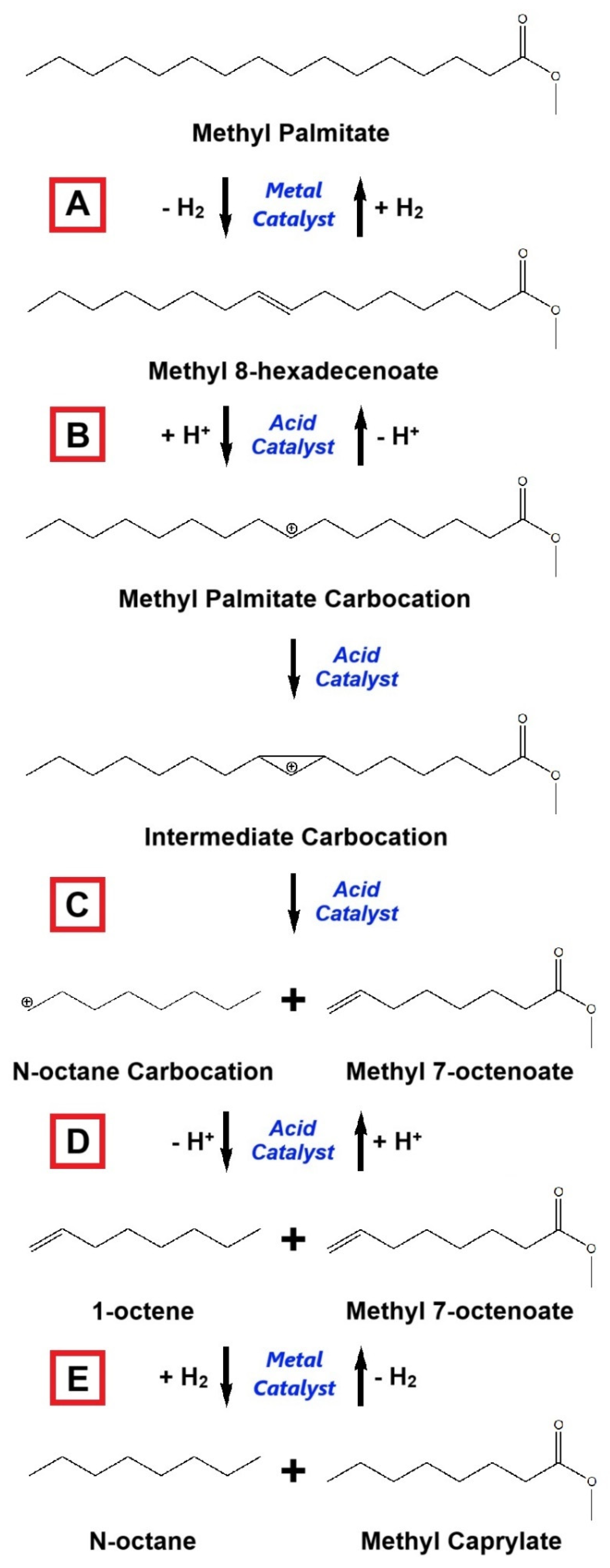

- Dehydrogenation of saturated linear-chain fatty ester using a metal catalyst to generate an unsaturated fatty ester. In this step, no branching is formed.

- -

- Attachment of protons (protonation) to the unsaturated linear-chain fatty ester to produce fatty ester carbocation. This step requires an acid-based catalyst to accelerate protonation.

- -

- Fatty ester carbocation is transformed into intermediate carbocation, and the carbon chain structure is then rearranged to create a new structure with branching (saturated branched-chain fatty ester carbocation). In this stage, the type of acid catalyst determines the reaction rate and product selectivity.

- -

- Release of protons (deprotonation) from branched-chain fatty ester carbocation to establish an unsaturated branched-chain fatty ester.

- -

- Hydrogenation of the unsaturated branched-chain fatty ester to promote the saturated form of the branched-chain fatty ester.

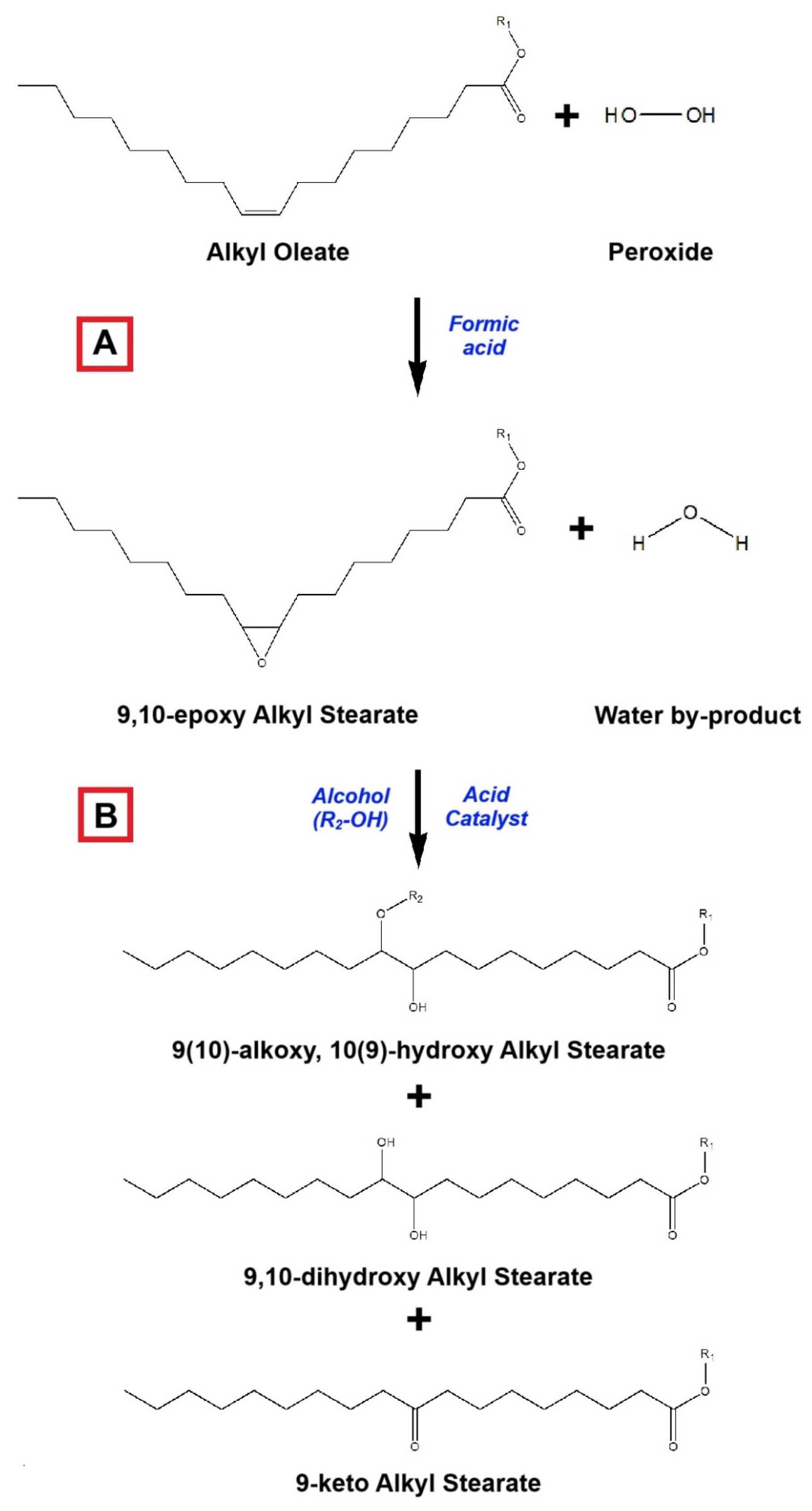

4.5.3. Epoxidation–Alkoxylation

| Biodiesel | Alkoxy | PP (°C) | CP (°C) | Ref. | ||

|---|---|---|---|---|---|---|

| Before | After | Before | After | |||

| Canola butyl ester | Methoxy | - | - | −3 | −4 | [236] |

| Canola butyl ester | n-buthoxy | - | - | −3 | −5 | [233] |

| Canola butyl ester | n-pentoxy | −12 | −12 | −3 | −5 | [235] |

| n-hexoxy | −12 | −12 | −3 | −5 | ||

| n-octoxy | −12 | −12 | −3 | −5 | ||

| 2-ethylhexoxy | −12 | −12 | −3 | −6 | ||

| Poultry fat methyl ester | Tert-butoxy | −3 | −3 | 2 | 3 | [234] |

| Used cooking methyl ester | 2-ethylhexoxy | 10 | −14 | - | - | [238] |

| High oleic acid methyl ester | Methoxy | 0 | −1 | 2 | 3 | [237] |

| Ethoxy | 0 | −4 | 2 | −2 | ||

| n-propoxy | 0 | −6 | 2 | −3 | ||

| Isopropoxy | 0 | −10 | 2 | −3 | ||

| n-butoxy | 0 | −6 | 2 | −4 | ||

| Isobutoxy | 0 | −8 | 2 | −4 | ||

| n-hexoxy | 0 | −10 | 2 | −7 | ||

| n-octoxy | 0 | −10 | 2 | −7 | ||

| n-decoxy | 0 | −14 | 2 | −11 | ||

| High oleic acid isopropyl ester | n-butoxy | −12 a | −22 | −9 b | −21 | [239] |

| Isobutoxy | −12 a | −23 | −9 b | −21 | ||

| n-hexoxy | −12 a | −23 | −9 b | −23 | ||

| n-octoxy | −12 a | −23 | −9 b | −23 | ||

| 2-ethylhexoxy | −12 a | −24 | −9 b | −23 | ||

| n-decoxy | −12 a | −24 | −9 b | −23 | ||

4.6. Carbon Chain Cracking

- -

- Dehydrogenation of saturated hydrocarbon to promote double-bond-containing hydrocarbon;

- -

- Protonation of unsaturated hydrocarbon to stimulate carbenium ion formation;

- -

- Carbenium ions are dissociated into shorter carbon chain carbocation and unsaturated hydrocarbon;

- -

- Deprotonation of carbocation to generate unsaturated hydrocarbon;

- -

- Unsaturated molecules are then hydrogenated to become saturated hydrocarbons.

| Biodiesel | Catalyst | PP (°C) | CP (°C) | Ref. | ||

|---|---|---|---|---|---|---|

| Before | After | Before | After | |||

| Soybean biodiesel | H-modenite zeolite | - | - | 5.2 | 0 | [226] |

| SO42−/ZrO2 | - | - | 5.2 | 0 | ||

| Soybean biodiesel | Not specified | −7 | −41 | - | - | [242] |

| Sunflower biodiesel | Not specified | −12 | −50 | - | - | [242] |

| Canola biodiesel | No catalyst | −9 | −23 | 1 | −21 | [243] |

| Canola biodiesel | No catalyst | - | - | −2 | −23 | [244] |

| Peanut biodiesel | Not specified | 7 | 1 | - | - | [242] |

| Cottonseed biodiesel | Not specified | 1 | 0 | - | - | [242] |

| Methyl oleate | SAPO-11 | 4 | −18 | - | - | [221] |

| H-ZSM-5 (30) | 4 | −15 | - | - | ||

| H-β-zeolite | 4 | −17 | - | - | ||

| H-Y-zeolite | 4 | −15 | - | - | ||

| H-MCM-22 | 4 | −17 | - | - | ||

4.7. Genetic Modification

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Stated Energy Information Administration. International Energy Outlook 2023 with Projections to 2050; United States Department of Energy: Washington, DC, USA, 2023.

- Adnan, M.A.; Susanto, H.; Binous, H.; Muraza, O.; Hossain, M.M. Feed compositions and gasification potential of several biomasses including a microalgae: A thermodynamic modeling approach. Int. J. Hydrog. Energy 2017, 42, 17009–17019. [Google Scholar] [CrossRef]

- Riyadi, T.W.B.; Spraggon, M.; Herawan, S.G.; Idris, M.; Paristiawan, P.A.; Putra, N.R.; Faizullizam, R.M.; Silambarasan, R.; Veza, I. Biodiesel for HCCI Engine: Prospects and Challenges of Sustainability Biodiesel for Energy Transition. Results Eng. 2023, 17, 100916. [Google Scholar] [CrossRef]

- Dey, S.; Reang, N.M.; Das, P.K.; Deb, M. A Comprehensive Study on Prospects of Economy, Environment, and Efficiency of Palm Oil Biodiesel as a Renewable Fuel. J. Clean. Prod. 2021, 286, 124981. [Google Scholar] [CrossRef]

- Syafiuddin, A.; Chong, J.H.; Yuniarto, A.; Hadibarata, T. The current scenario and challenges of biodiesel production in Asian countries: A review. Bioresource Technology Reports 2020, 12, 100608. [Google Scholar] [CrossRef]

- Babadi, A.A.; Rahmati, S.; Fakhlaei, R.; Barati, B.; Wang, S.; Doherty, W.; Ostrikov, K. Emerging Technologies for Biodiesel Production: Processes, Challenges, and Opportunities. Biomass Bioenergy 2022, 163, 106521. [Google Scholar] [CrossRef]

- Anwar, A.; Garforth, A. Challenges and Opportunities of Enhancing Cold Flow Properties of Biodiesel via Heterogeneous Catalysis. Fuel 2016, 173, 189–208. [Google Scholar] [CrossRef]

- Shirazi, H.M.; Karimi-Sabet, J.; Ghotbi, C. Biodiesel production from Spirulina microalgae feedstock using direct transesterification near supercritical methanol condition. Bioresour. Technol. 2017, 239, 378–386. [Google Scholar] [CrossRef]

- Raheem, A.; Prinsen, P.; Vuppaladadiyam, A.K.; Zhao, M.; Luque, R. A review on sustainable microalgae based biofuel and bioenergy production: Recent developments. J. Clean. Prod. 2018, 181, 42–59. [Google Scholar] [CrossRef]

- Pradana, Y.S.; Sadewo, B.R.; Haryanto, S.A.; Sudibyo, H. Selection of oil extraction process from Chlorella species of microalgae by using multi-criteria decision analysis technique for biodiesel production. Open Chem. 2021, 19, 1029–1042. [Google Scholar] [CrossRef]

- Azapagic, A.; Perdan, S.; Clift, R. Sustainable Development in Practice; Wiley: West Sussex, UK, 2004. [Google Scholar] [CrossRef]

- Pydimalla, M.; Husaini, S.; Kadire, A.; Verma, R.K. Sustainable biodiesel: A comprehensive review on feedstock, production methods, applications, challenges and opportunities. Mater. Today Proc. 2023, 92, 458–464. [Google Scholar] [CrossRef]

- Sia, C.B.; Kansedo, J.; Tan, Y.H.; Lee, K.T. Evaluation on biodiesel cold flow properties, oxidative stability and enhancement strategies: A review. Biocatal. Agric. Biotechnol. 2020, 24, 101514. [Google Scholar] [CrossRef]

- Pradana, Y.S.; Dewi, R.N.; Livia, K.D.; Arisa, F.; Rochmadi; Cahyono, R.B.; Budiman, A. Advancing biodiesel production from microalgae Spirulina sp. by a simultaneous extraction-transesterification process using palm oil as a co-solvent of methanol. Open Chem. 2020, 18, 833–842. [Google Scholar] [CrossRef]

- ASTM D975-23; Standard Specification for Diesel Fuel (D975-23). American Standard Testing and Material: West Conshohocken, PA, USA, 2023. [CrossRef]

- Sharma, B.K.; Moser, B.R.; Vermillion, K.E.; Doll, K.M.; Rajagopalan, N. Production, characterization and fuel properties of alternative diesel fuel from pyrolysis of waste plastic grocery bags. Fuel Process. Technol. 2014, 122, 79–90. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Cho, H.M.; Masjuki, H.H.; Kalam, M.A.; Ong, H.C.; Gul, M.; Harith, M.H.; Yusoff, M.N.A.M. Critical Review on Sesame Seed Oil and Its Methyl Ester on Cold Flow and Oxidation Stability. Energy Rep. 2020, 6, 40–54. [Google Scholar] [CrossRef]

- Yusoff, M.N.A.M.; Zulkifli, N.W.M.; Sukiman, N.L.; Chyuan, O.H.; Hassan, M.H.; Hasnul, M.H.; Zulkifli, M.S.A.; Abbas, M.M.; Zakaria, M.Z. Sustainability of Palm Biodiesel in Transportation: A Review on Biofuel Standard, Policy and International Collaboration Between Malaysia and Colombia. Bioenergy Res. 2021, 14, 43–60. [Google Scholar] [CrossRef]

- Haq, A.; Rehman, M.L.U.; Rana, Q.U.A.; Khan, A.; Sajjad, W.; Khan, H.; Khan, S.; Shah, A.A.; Hasan, F.; Ahmed, S.; et al. Production, optimization, and physicochemical characterization of biodiesel from seed oil of indigenously grown Jatropha curcas. Front. Energy Res. 2023, 11, 1225988. [Google Scholar] [CrossRef]

- Amri, K.; Kismanto, A.; Solikhah, M.D.; Pratiwi, F.T.; Arisanti, A.G. Study of biodiesel specifications for heavy-duty gas turbine application. In Journal of Physics: Conference Series; IOP Publishing Ltd.: Bristol, UK, 2021. [Google Scholar] [CrossRef]

- Pradana, Y.S.; Masruri, W.; Azmi, F.A.; Suyono, E.A.; Sudibyo, H.; Rochmadi, R. Extractive-transesterification of Microalgae Arthrospira sp. Using Methanol-Hexane Mixture as solvent. Int. J. Renew. Energy Res. 2018, 8, 1499–1507. [Google Scholar]

- Al-Jaberi, S.H.H.; Rashid, U.; Al-Doghachi, F.A.J.; Abdulkareem-Alsultan, G.; Taufiq-Yap, Y.H. Synthesis of MnO-NiO-SO4 −2/ZrO2 solid acid catalyst for methyl ester production from palm fatty acid distillate. Energy Convers. Manag. 2017, 139, 166–174. [Google Scholar] [CrossRef]

- Roy, D.K.; Abedin, M.Z. Potentiality of Biodiesel and Bioethanol Production from Feedstock in Bangladesh: A Review. Heliyon 2022, 8, e11213. [Google Scholar] [CrossRef]

- Souza, M.F.; Hirata, G.F.; Batista, E.A.C. Evaluation of kinetics and thermodynamic parameters for simulation of palm oil biodiesel production. Fluid. Phase Equilib. 2020, 525, 112792. [Google Scholar] [CrossRef]

- Wang, X.; Yang, K.; Cai, R.; ChenYang, Y.; Huang, Z.; Han, B. Optimization and kinetics of biodiesel production from soybean oil using new tetraethylammonium ionic liquids with amino acid-based anions as catalysts. Fuel 2022, 324, 124510. [Google Scholar] [CrossRef]

- Meng, Y.L.; Tian, S.J.; Li, S.F.; Wang, B.Y.; Zhang, M.H. Transesterification of rapeseed oil for biodiesel production in trickle-bed reactors packed with heterogeneous Ca/Al composite oxide-based alkaline catalyst. Bioresour. Technol. 2013, 136, 730–734. [Google Scholar] [CrossRef] [PubMed]

- Lima, A.C.; Hachemane, K.; Ribeiro, A.E.; Queiroz, A.; Gomes, M.C.S.; Brito, P. Evaluation and kinetic study of alkaline ionic liquid for biodiesel production through transesterification of sunflower oil. Fuel 2022, 324, 124586. [Google Scholar] [CrossRef]

- Siddiki, S.Y.A.; Mofijur, M.; Kumar, P.S.; Ahmed, S.F.; Inayat, A.; Kusumo, F.; Badruddin, I.A.; Khan, T.M.Y.; Nghiem, L.D.; Ong, H.C.; et al. Microalgae biomass as a sustainable source for biofuel, biochemical and biobased value-added products: An integrated biorefinery concept. Fuel 2022, 307, 121782. [Google Scholar] [CrossRef]

- Ziaei, S.M.; Szulczyk, K.R. Estimating the potential of algal biodiesel to improve the environment and mitigate palm oil mill effluents in Malaysia. J. Clean. Prod. 2022, 338, 130583. [Google Scholar] [CrossRef]

- Kim, T.-H.; Suh, W.I.; Yoo, G.; Mishra, S.K.; Farooq, W.; Moon, M.; Shrivastav, A.; Park, M.S.; Yang, J.W. Development of direct conversion method for microalgal biodiesel production using wet biomass of Nannochloropsis salina. Bioresour. Technol. 2015, 191, 438–444. [Google Scholar] [CrossRef]

- Gutiérrez-López, A.N.; Mena-Cervantes, V.Y.; Gonzalez-Espinosa, M.A.; Sosa-Rodriguez, F.S.; Vazquez-Arenas, J.; Rodriguez-Ramirezz, R.; Hernandez-Altamirano, R. Green and fast biodiesel production at room temperature using soybean and Jatropha curcas L. oils catalyzed by potassium ferrate. J. Clean. Prod. 2022, 372, 133739. [Google Scholar] [CrossRef]

- Anwar, F.; Tariq, M.; Nisar, J.; Ali, G.; Kanwal, H. Optimization of biodiesel yield from non-food karanja seed oil: Characterization and assessment of fuel properties. Sustain. Chem. Environ. 2023, 3, 100035. [Google Scholar] [CrossRef]

- Singh, N.K.; Singh, Y.; Sharma, A. Optimization of biodiesel synthesis from Jojoba oil via supercritical methanol: A response surface methodology approach coupled with genetic algorithm. Biomass Bioenergy 2022, 156, 106332. [Google Scholar] [CrossRef]

- Asif, M.; Javed, F.; Younas, M.; Gillani, M.A.; Zimmerman, W.B.; Rehman, F. Investigating biodiesel production from Chicken fat oil using bi-functional catalysts and microbubble mediated mass transfer. Fuel 2024, 358, 130125. [Google Scholar] [CrossRef]

- Olubunmi, B.E.; Alade, A.F.; Ebhodaghe, S.O.; Oladapo, O.T. Optimization and kinetic study of biodiesel production from beef tallow using calcium oxide as a heterogeneous and recyclable catalyst. Energy Convers. Manag. X 2022, 14, 100221. [Google Scholar] [CrossRef]

- Miladinović, M.R.; Krstic, J.B.; Zdujic, M.V.; Veselinovic, L.M.; Veljovic, D.N.; Bankovic-Ilic, I.B.; Dtamenkovic, O.S.; Veljkovic, V.B. Transesterification of used cooking sunflower oil catalyzed by hazelnut shell ash. Renew. Energy 2022, 183, 103–113. [Google Scholar] [CrossRef]

- Im-Orb, K.; Arpornwichanop, A.; Simasatitkul, L. Process intensification approach for design and optimization of biodiesel production from palm fatty acid distillate. Biotechnol. Rep. 2021, 30, e00622. [Google Scholar] [CrossRef] [PubMed]

- Pan, H.; Xia, Q.; Wang, Y.; Shen, Z.; Huang, H.; Ge, Z.; Li, X.; He, J.; Wang, X.; Li, L.; et al. Recent Advances in Biodiesel Production Using Functional Carbon Materials as Acid/Base Catalysts. Fuel Process. Technol. 2022, 237, 107421. [Google Scholar] [CrossRef]

- Wang, L.; Wang, H.; Fan, J.; Han, Z. Synthesis, Catalysts and Enhancement Technologies of Biodiesel from Oil Feedstock–A Review. Sci. Total Environ. 2023, 904, 166982. [Google Scholar] [CrossRef]

- Kusmayadi, A.; Leong, Y.K.; Yen, H.W.; Huang, C.Y.; Chang, J.S. Microalgae as sustainable food and feed sources for animals and humans–Biotechnological and environmental aspects. Chemosphere 2021, 271, 129800. [Google Scholar] [CrossRef]

- Dewati, P.R.; Rochmadi; Rohman, A.; Yuliestyan, A.; Budiman, A. Equilibrium modeling of astaxanthin extraction from haematococcus pluvialis. Indones. J. Chem. 2021, 21, 554–563. [Google Scholar] [CrossRef]

- Pradana, Y.S.; Sudibyo, H.; Suyono, E.A.; Indarto; Budiman, A. Oil Algae Extraction of Selected Microalgae Species Grown in Monoculture and Mixed Cultures for Biodiesel Production. In Energy Procedia; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; pp. 277–282. [Google Scholar] [CrossRef]

- Athar, M.; Zaidi, S. A review of the feedstocks, catalysts, and intensification techniques for sustainable biodiesel production. J. Environ. Chem. Eng. 2020, 8, 104523. [Google Scholar] [CrossRef]

- Gaurav, K.; Neeti, K.; Singh, R. Microalgae-based biodiesel production and its challenges and future opportunities: A review. Green. Technol. Sustain. 2024, 2, 100060. [Google Scholar] [CrossRef]

- Chisti, Y. Biodiesel from microalgae. Biotechnol. Adv. 2007, 25, 294–306. [Google Scholar] [CrossRef]

- Prasakti, L.; Pratama, S.H.; Fauzi, A.; Pradana, Y.S.; Budiman, A. Exergy analysis of conventional and hydrothermal liquefaction–esterification processes of microalgae for biodiesel production. Open Chem. 2020, 18, 874–881. [Google Scholar] [CrossRef]

- Kholssi, R.; Ramos, P.V.; Marks, E.A.N.; Montero, O.; Rad, C. Biotechnological uses of microalgae: A review on the state of the art and challenges for the circular economy. Biocatal. Agric. Biotechnol. 2021, 36, 102114. [Google Scholar] [CrossRef]

- Malek, A.; Alamoodi, N.; Almansoori, A.S.; Daoutidis, P. Optimal dynamic operation of microalgae cultivation coupled with recovery of flue gas CO2 and waste heat. Comput. Chem. Eng. 2017, 105, 317–327. [Google Scholar] [CrossRef]

- Ren, H.; Tuo, J.; Addy, M.M.; Zhang, R.; Lu, Q.; Anderson, E.; Chen, P.; Ruan, R. Cultivation of Chlorella vulgaris in a pilot-scale photobioreactor using real centrate wastewater with waste glycerol for improving microalgae biomass production and wastewater nutrients removal. Bioresour. Technol. 2017, 245, 1130–1138. [Google Scholar] [CrossRef]

- Yew, G.Y.; Khoo, K.S.; Chia, W.Y.; Ho, Y.C.; Law, C.L.; Leong, H.Y.; Show, P.L. A novel lipids recovery strategy for biofuels generation on microalgae Chlorella cultivation with waste molasses. J. Water Process Eng. 2020, 38, 101665. [Google Scholar] [CrossRef]

- Kalin, M.; Wheeler, W.N.; Meinrath, G. The removal of uranium from mining waste water using algal/microbial biomass. J. Environ. Radioact. 2005, 78, 151–177. [Google Scholar] [CrossRef] [PubMed]

- Farobie, O.; Sutarlan, I.F.I.; Sucahyo, L.; Bayu, A.; Hartulistiyoso, E. Biodiesel production from crude palm oil under subcritical methanol conditions: Experimental investigation and kinetic model. Bioresour. Technol. Rep. 2023, 22, 101441. [Google Scholar] [CrossRef]

- Qu, T.; Niu, S.; Zhang, X.; Han, K.; Lu, C. Preparation of calcium modified Zn-Ce/Al2O3 heterogeneous catalyst for biodiesel production through transesterification of palm oil with methanol optimized by response surface methodology. Fuel 2021, 284, 118986. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Masjuki, H.H.; Ong, H.C.; Kusumo, F.; Mahlia, T.M.I.; Bahar, A.H. Pilot-scale production and the physicochemical properties of palm and Calophyllum inophyllum biodiesels and their blends. J. Clean. Prod. 2016, 126, 654–666. [Google Scholar] [CrossRef]

- Essamlali, Y.; Amadine, O.; Fihri, A.; Zahouily, M. Sodium modified fluorapatite as a sustainable solid bi-functional catalyst for biodiesel production from rapeseed oil. Renew. Energy 2019, 133, 1295–1307. [Google Scholar] [CrossRef]

- Krstić, J.B.; Njetic, Z.B.; Kostoc, M.D.; Maric, B.D.; Simurina, O.D.; Stamenkovic, O.S.; Veljkovic, V.B. Biodiesel production from rapeseed oil over calcined waste filter cake from sugar beet processing. Process Saf. Environ. Prot. 2022, 168, 463–473. [Google Scholar] [CrossRef]

- Rashid, U.; Anwar, F. Production of biodiesel through optimized alkaline-catalyzed transesterification of rapeseed oil. Fuel 2008, 87, 265–273. [Google Scholar] [CrossRef]

- Rodríguez-Ramírez, R.; Sosa-Rodríguez, F.S.; Vazquez-Arenas, J. Zinc oxide-co-sodium zirconate: A fast heterogeneous catalyst for biodiesel production from soybean oil. J. Environ. Chem. Eng. 2022, 10, 108191. [Google Scholar] [CrossRef]

- Yusuf, B.O.; Oladepo, S.A.; Ganiyu, S.A. Zr-modified desilicated ZSM-5 catalysts as highly active and recyclable catalysts for production of biodiesel from soybean oil: Insight into improved catalyst properties, acidity and dispersion through desilication. Fuel 2023, 351, 128729. [Google Scholar] [CrossRef]

- Silva, A.L.; Farias, A.F.F.; Meneghetti, S.M.P.; Filho, E.A.D.S.; de Melo Costa, A.C.F. Optimization of biodiesel production via transesterification of soybean oil using α-MoO3 catalyst obtained by the combustion method. Arab. J. Chem. 2022, 15, 104012. [Google Scholar] [CrossRef]

- Cardoso, R.K.P.; Silva, G.V.A.; Alves, B.T.S.; Freire, V.A.; Alves, J.J.N.; Barbosa, B.V.S. Evaluation of the effect of Si/Mo and oil/alcohol ratios in the production of biodiesel from soybean oil. Arab. J. Chem. 2022, 15, 104074. [Google Scholar] [CrossRef]

- Elkelawy, M.; Bastawissi, H.A.E.; Esmaeil, K.K.; Rdawan, A.M.; Panchal, H.; Sadasivuni, K.K.; Suresh, M.; Israr, M. Maximization of biodiesel production from sunflower and soybean oils and prediction of diesel engine performance and emission characteristics through response surface methodology. Fuel 2020, 266, 117072. [Google Scholar] [CrossRef]

- Marinković, M.; Waisi, H.; Blagojevic, S.; Zarubica, A.; Ljupkovic, R.; Krstic, A.; Jankovic, B. The effect of process parameters and catalyst support preparation methods on the catalytic efficiency in transesterification of sunflower oil over heterogeneous KI/Al2O3-based catalysts for biodiesel production. Fuel 2022, 315, 123246. [Google Scholar] [CrossRef]

- Deviren, H.; Aydın, H. Production and physicochemical properties of safflower seed oil extracted using different methods and its conversion to biodiesel. Fuel 2023, 343, 128001. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Encinar, J.M.; Cortés, Á.G. High oleic safflower oil as a feedstock for stable biodiesel and biolubricant production. Ind. Crops Prod. 2021, 170, 113701. [Google Scholar] [CrossRef]

- Ejeromedoghene, O. Acid-catalyzed transesterification of Palm Kernel Oil (PKO) to biodiesel. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; pp. 1580–1583. [Google Scholar] [CrossRef]

- Kareem, S.O.; Falokun, E.I.; Balogun, S.A.; Akinloye, O.A.; Omeike, S.O. Enzymatic biodiesel production from palm oil and palm kernel oil using free lipase. Egypt. J. Pet. 2017, 26, 635–642. [Google Scholar] [CrossRef]

- Bambase, M.E.; Almazan, R.A.R.; Demafelis, R.B.; Sobremisana, M.J.; Dizon, L.S.H. Biodiesel production from refined coconut oil using hydroxide-impregnated calcium oxide by cosolvent method. Renew. Energy 2021, 163, 571–578. [Google Scholar] [CrossRef]

- Giakoumis, E.G. A statistical investigation of biodiesel physical and chemical properties, and their correlation with the degree of unsaturation. Renew. Energy 2013, 50, 858–878. [Google Scholar] [CrossRef]

- Sebayang, A.H.; Kusumo, F.; Milano, J.; Shamsuddin, A.H.; Silitonga, A.S.; Ideris, F.; Siswantoro, J.; Veza, I.; Mofijur, M.; Chia, S.R. Optimization of biodiesel production from rice bran oil by ultrasound and infrared radiation using ANN-GWO. Fuel 2023, 346, 128404. [Google Scholar] [CrossRef]

- Mazaheri, H.; Ong, H.C.; Masjuki, H.H.; Amini, Z.; Harrison, M.D.; Wang, C.T.; Kusumo, F.; Alwi, A. Rice bran oil based biodiesel production using calcium oxide catalyst derived from Chicoreus brunneus shell. Energy 2018, 144, 10–19. [Google Scholar] [CrossRef]

- Balamurugan, T.; Arun, A.; Sathishkumar, G.B. Biodiesel derived from corn oil–A fuel substitute for diesel. Renew. Sustain. Energy Rev. 2018, 94, 772–778. [Google Scholar] [CrossRef]

- Kaya, C.; Hamamci, C.; Baysal, A.; Akba, O.; Erdogan, S.; Saydut, A. Methyl ester of peanut (Arachis hypogea L.) seed oil as a potential feedstock for biodiesel production. Renew. Energy 2009, 34, 1257–1260. [Google Scholar] [CrossRef]

- Mahloujifar, M.; Mansournia, M. A comparative study on the catalytic performances of alkali metals-loaded KAlSiO4 for biodiesel production from sesame oil. Fuel 2021, 291, 120145. [Google Scholar] [CrossRef]

- Chizoo, E.; Okechukwu, M.F.; Dominic, O.O.; Kingsley, A.A.; Chimamkpam, A.S.; Mariagorretti, M.C.; Chinonso, E.P. Renewable diesel synthesis from sesame indicum (bene) seed oil using novel heterogeneous biocatalyst derived from the Chrysophyllum albidium seed coat. Heliyon 2023, 9, e22006. [Google Scholar] [CrossRef]

- Bilgin, A.; Gulum, M. Effects of various transesterification parameters on the some fuel properties of hazelnut oil methyl ester. In Energy Procedia; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; pp. 54–62. [Google Scholar] [CrossRef]

- Saydut, A.; Erdogan, S.; Kafadar, A.B.; Kaya, C.; Aydin, F.; Hamamci, C. Process optimization for production of biodiesel from hazelnut oil, sunflower oil and their hybrid feedstock. Fuel 2016, 183, 512–517. [Google Scholar] [CrossRef]

- Khatibi, M.; Khorasheh, F.; Larimi, A. Biodiesel production via transesterification of canola oil in the presence of Na–K doped CaO derived from calcined eggshell. Renew. Energy 2021, 163, 1626–1636. [Google Scholar] [CrossRef]

- Murguía-Ortiz, D.; Cordova, I.; Manriquez, M.E.; Ortiz-Islas, E.; Cabrera-Sierra, R.; Contreras, J.L.; Alcantar-Vazquez, B.; Trejo-Rubio, M.; Vazquez-Rodriguez, J.T.; Castro, L.V. Na-CaO/MgO dolomites used as heterogeneous catalysts in canola oil transesterification for biodiesel production. Mater. Lett. 2021, 291, 129587. [Google Scholar] [CrossRef]

- Kumar, V.; Kant, P. Biodiesel production from sorghum oil by transesterification using zinc oxide as catalyst. Pet. Coal 2014, 56, 35–40. [Google Scholar]

- Lin, L.; Cunshan, Z.; Vittayapadung, S.; Xiangqian, S.; Mingdong, D. Opportunities and Challenges for Biodiesel Fuel. Appl. Energy 2011, 88, 1020–1031. [Google Scholar] [CrossRef]

- Moser, B.R. Preparation of fatty acid methyl esters from hazelnut, high-oleic peanut and walnut oils and evaluation as biodiesel. Fuel 2012, 92, 231–238. [Google Scholar] [CrossRef]

- Gui, X.; Chen, S.; Yun, Z. Continuous production of biodiesel from cottonseed oil and methanol using a column reactor packed with calcined sodium silicate base catalyst. Chin. J. Chem. Eng. 2016, 24, 499–505. [Google Scholar] [CrossRef]

- Rizal, T.A.; Khairil; Mahidin; Husin, H.; Ahmadi; Nasution, F.; Umar, H. The Experimental Study of Pangium Edule Biodiesel in a High-Speed Diesel Generator for Biopower Electricity. Energies 2022, 15, 5405. [Google Scholar] [CrossRef]

- Ruhul, M.A.; Abedin, M.J.; Rahman, S.M.A.; Masjuki, B.H.H.; Alabdulkarem, A.; Kalam, M.A.; Shancita, I. Impact of fatty acid composition and physicochemical properties of Jatropha and Alexandrian laurel biodiesel blends: An analysis of performance and emission characteristics. J. Clean. Prod. 2016, 133, 1181–1189. [Google Scholar] [CrossRef]

- Safaripour, M.; Saidi, M.; Moradi, P. Ex-situ biodiesel production from Simmondsia chinensis (Jojoba) biomass: Process evaluation and optimization. J. Ind. Eng. Chem. 2023, 124, 392–401. [Google Scholar] [CrossRef]

- Kashyap, S.S.; Gogate, P.R.; Joshi, S.M. Ultrasound assisted intensified production of biodiesel from sustainable source as karanja oil using interesterification based on heterogeneous catalyst (Γ-alumina). Chem. Eng. Process.-Process Intensif. 2019, 136, 11–16. [Google Scholar] [CrossRef]

- Utami, M.; Setiawan, P.; Falah, I.I.; Suheryanto; Shidiq, M.; Wijaya, K.; Jarin, T.; Sumathijones, C.; Abd-Elkader, O.H.; Abd-Elkader, M.O.H.; et al. Synthesis of biodiesel from castor oil catalyzed by sodium hydroxide dispersed on bentonite. Sustain. Energy Technol. Assess. 2022, 53, 102526. [Google Scholar] [CrossRef]

- Foroutan, R.; Peighambardoust, S.J.; Mohammadi, R.; Peighambardoust, S.H.; Ramavandi, B. Investigation of kinetics, thermodynamics, and environmental factors of biodiesel generation from sunflower and castor oil using rice husk ash/CuO/K2CO3 heterogeneous catalyst. Environ. Technol. Innov. 2023, 32, 103307. [Google Scholar] [CrossRef]

- Naveenkumar, R.; Baskar, G. Optimization and techno-economic analysis of biodiesel production from Calophyllum inophyllum oil using heterogeneous nanocatalyst. Bioresour. Technol. 2020, 315, 123852. [Google Scholar] [CrossRef] [PubMed]

- Atabani, A.E.; César, A.D.S. Calophyllum inophyllum L.-A Prospective Non-Edible Biodiesel Feedstock. Study of Biodiesel Production, Properties, Fatty Acid Composition, Blending and Engine Performance. Renew. Sustain. Energy Rev. 2014, 37, 644–655. [Google Scholar] [CrossRef]

- Alsaiari, R.A.; Musa, E.M.; Rizk, M.A. Biodiesel production from date seed oil using hydroxyapatite-derived catalyst from waste camel bone. Heliyon 2023, 9, e15606. [Google Scholar] [CrossRef]

- Devarajan, Y.; Munuswamy, D.B.; Nalla, B.T.; Choubey, G.; Mishra, R.; Vellaiyan, S. Experimental analysis of Sterculia foetida biodiesel and butanol blends as a renewable and eco-friendly fuel. Ind. Crops Prod. 2022, 178, 114612. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Ong, H.C.; Masjuki, H.H.; Mahlia, T.M.I.; Chong, W.T.; Yusaf, T.F. Production of biodiesel from Sterculia foetida and its process optimization. Fuel 2013, 111, 478–484. [Google Scholar] [CrossRef]

- Farokhi, G.; Saidi, M.; Najafabadi, A.T. Application of spinel Type NixZn1−xFe2O4 magnetic nanocatalysts for biodiesel production from neem seed oil: Catalytic performance evaluation and optimization. Ind. Crops Prod. 2023, 192, 116035. [Google Scholar] [CrossRef]

- Badmus, J.A.; Oyelami, K.O.; Adedeji, A.L.; Adedosu, O.T.; Bolarinwa, I.F.; Marnewick, J.L. Comparative study of physicochemical properties, fatty acid composition, antioxidant and toxicological potential of Citrullus lanatus and Citrullus colocynthis seeds oils. S. Afr. J. Bot. 2021, 142, 156–164. [Google Scholar] [CrossRef]

- Ridwan, I.; Budiastuti, H.; Indarti, R.; Wahyuni, N.L.E.; Safitri, H.M.; Ramadhan, R.L. The optimization of tetrahydrofuran as a co-solvent on biodiesel production from rubber seeds using response surface methodology. Mater. Sci. Energy Technol. 2023, 6, 15–20. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Mahlia, T.M.I.; Kusumo, F.; Dharma, S.; Sebayang, A.H.; Sembiring, R.W.; Shamsuddin, A.H. Intensification of Reutealis trisperma biodiesel production using infrared radiation: Simulation, optimisation and validation. Renew. Energy 2019, 133, 520–527. [Google Scholar] [CrossRef]

- Fernandes, D.M.; Sousa, R.M.F.; De Oliveira, A.; Morais, S.A.L.; Richter, E.M.; Muñoz, R.A.A. Moringa oleifera: A potential source for production of biodiesel and antioxidant additives. Fuel 2015, 146, 75–80. [Google Scholar] [CrossRef]

- Pham, L.N.; Luu, B.V.; Phuoc, H.D.; Le, H.N.T.; Truong, H.T.; Luu, P.D.; Furuta, M.; Imamura, K.; Maeda, Y. Production of biodiesel from candlenut oil using a two-step co-solvent method and evaluation of its gaseous emissions. J. Oleo Sci. 2018, 67, 617–626. [Google Scholar] [CrossRef]

- Baskar, G.; Gurugulladevi, A.; Nishanthini, T.; Aiswarya, R.; Tamilarasan, K. Optimization and kinetics of biodiesel production from Mahua oil using manganese doped zinc oxide nanocatalyst. Renew. Energy 2017, 103, 641–646. [Google Scholar] [CrossRef]

- Hariram, V.; Prakash, S.; Seralathan, S.; Premkumar, T.M. Data set on optimized biodiesel production and formulation of emulsified Eucalyptus teriticornisis biodiesel for usage in compression ignition engine. Data Brief. 2018, 20, 6–13. [Google Scholar] [CrossRef] [PubMed]

- Munir, M.; Ahmad, M.; Rehan, M.; Saeed, M.; Lam, S.S.; Nizami, A.S.; Waseem, A.; Sultana, S.; Zafar, M. Production of high quality biodiesel from novel non-edible Raphnus raphanistrum L. seed oil using copper modified montmorillonite clay catalyst. Environ. Res. 2021, 193, 110398. [Google Scholar] [CrossRef]

- Islam, M.G.U.; Jan, M.T.; Farooq, M.; Naeem, A.; Khan, I.W.; Khattak, H.U. Biodiesel production from wild olive oil using TPA decorated Cr–Al acid heterogeneous catalyst. Chem. Eng. Res. Des. 2022, 178, 540–549. [Google Scholar] [CrossRef]

- Aguila, A.F.; Carlo, J.; Arellano, M.; Dowell, K.; Panganiban, D.; Magnaye, R.C. Production and evaluation of biodiesel from rambutan (Nephelium lappaceum L.) seed oil. Int. Res. J. Innov. Eng. Sci. Technol. 2020, 6, 25–31. [Google Scholar]

- Anggono, W.; Sutrisno, S.; Suprianto, F.D.; Setiyo, M.; Wibisono, R.; Gotama, G.J. Experimental investigation of the effect of Nephelium Lappaceum seed biodiesel to the automotive diesel engine performance. In IOP Conference Series: Earth and Environmental Science; Institute of Physics Publishing: Bristo, UK, 2019. [Google Scholar] [CrossRef]

- Rajan, A.G.; Sivasubramanian, M.; Gowthaman, S.; Ramkumar, P. Investigation of physical and chemical properties of tobacco seed oil fatty acid methyl ester for biodiesel production. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; pp. 7670–7675. [Google Scholar] [CrossRef]

- Anwar, M.; Rasul, M.G.; Ashwath, N.; Nabi, M.D.N. The Potential of Utilising Papaya Seed Oil and Stone Fruit Kernel Oil as Non-Edible Feedstock for Biodiesel Production in Australia—A Review. Energy Rep. 2019, 5, 280–297. [Google Scholar] [CrossRef]

- Reddy, S.R.; Sarangi, S.K. Optimizing the effect of using novel hydrogen enriched nano particles added emulsified waste mango seed biodiesel in diesel engine. Fuel 2023, 342, 127783. [Google Scholar] [CrossRef]

- Munir, M.; Ahmad, M.; Saeed, M.; Waseem, A.; Nizami, A.S.; Sultana, S.; Zafar, M.; Rehan, M.; Srinivasan, G.R.; Ali, A.M.; et al. Biodiesel production from novel non-edible caper (Capparis spinosa L.) seeds oil employing Cu–Ni doped ZrO2 catalyst. Renew. Sustain. Energy Rev. 2021, 138, 110558. [Google Scholar] [CrossRef]

- Aziz, M.A.A.; Puad, K.; Triwahyono, S.; Jalil, A.A.; Khayoon, M.S.; Atabani, A.E.; Ramli, Z.; Majid, Z.A.; Prasetyoko, D.; Hartanto, D. Transesterification of croton megalocarpus oil to biodiesel over WO3 supported on silica mesoporous-macroparticles catalyst. Chem. Eng. J. 2017, 316, 882–892. [Google Scholar] [CrossRef]

- Renish, R.R.; Selvam, M.A.J. A critical review on production process, physicochemical properties, performance and emission characteristics of sea mango biodiesel-diesel blends. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; pp. 2600–2605. [Google Scholar] [CrossRef]

- Gunawan, S.; Wasista, H.W.; Kuswandi, K.; Widjaja, A.; Ju, Y.H. The utilization of Xylocarpus moluccensis seed oil as biodiesel feedstock in Indonesia. Ind. Crops Prod. 2014, 52, 286–291. [Google Scholar] [CrossRef]

- Cao, L.; Zhang, S. Production and characterization of biodiesel derived from hodgsonia macrocarpa seed oil. Appl. Energy 2015, 146, 135–140. [Google Scholar] [CrossRef]

- Hasni, K.; Ilham, Z.; Dharma, S.; Varman, M. Optimization of biodiesel production from Brucea javanica seeds oil as novel non-edible feedstock using response surface methodology. Energy Convers. Manag. 2017, 149, 392–400. [Google Scholar] [CrossRef]

- Bahadorian, A.; Sadrameli, S.M.; Pahlavanzadeh, H.; Kashkouli, M.N.I. Optimization study of linseed biodiesel production via in-situ transesterification and slow pyrolysis of obtained linseed residue. Renew. Energy 2023, 203, 10–19. [Google Scholar] [CrossRef]

- Balamurugan, S.; Gokul, C.; Dheen, S.A.T.; Eashwar, S.J.; Kumar, N.A. Application of grey relational analysis in biodiesel production from linseed oil using novel eggshell catalyst. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; pp. 1962–1969. [Google Scholar] [CrossRef]

- Shobhana-Gnanaserkhar; Asikin-Mijan, N.; AbdulKareem-Alsultan, G.; Sivasangar-Seenivasagam; Izham, S.M.; Taufiq-Yap, Y.H. Biodiesel production via simultaneous esterification and transesterification of chicken fat oil by mesoporous sulfated Ce supported activated carbon. Biomass Bioenergy 2020, 141, 105714. [Google Scholar] [CrossRef]

- García-Morales, R.; Zuniga-Moreno, A.; Veronico-Sanchez, F.J.; Domenzain-Gonzalez, J.; Prez-Lopez, H.I.; Bouchot, C.; Elizalde-Solis, O. Fatty acid methyl esters from waste beef tallow using supercritical methanol transesterification. Fuel 2022, 313, 122706. [Google Scholar] [CrossRef]

- Papargyriou, D.; Broumidis, E.; Vere-Tucker, M.D.; Gavrielides, S.; Hilditch, P.; Irvine, J.T.S.; Bonaccorso, A.D. Investigation of solid base catalysts for biodiesel production from fish oil. Renew. Energy 2019, 139, 661–669. [Google Scholar] [CrossRef]

- El-Shafay, A.S.; Ağbulut, Ü.; Attia, E.A.; Touileb, K.L.; Gad, M.S. Waste to energy: Production of poultry-based fat biodiesel and experimental assessment of its usability on engine behaviors. Energy 2023, 262, 125457. [Google Scholar] [CrossRef]

- Chakraborty, R.; Sahu, H. Intensification of biodiesel production from waste goat tallow using infrared radiation: Process evaluation through response surface methodology and artificial neural network. Appl. Energy 2014, 114, 827–836. [Google Scholar] [CrossRef]

- Faleh, N.; Khila, Z.; Wahada, Z.; Pons, M.N.; Houas, A.; Hajjaji, N. Exergo-environmental life cycle assessment of biodiesel production from mutton tallow transesterification. Renew. Energy 2018, 127, 74–83. [Google Scholar] [CrossRef]

- Mutreja, V.; Singh, S.; Ali, A. Biodiesel from mutton fat using KOH impregnated MgO as heterogeneous catalysts. Renew. Energy 2011, 36, 2253–2258. [Google Scholar] [CrossRef]

- Suresh, T.; Sivarajasekar, N.; Balasubramani, K. Enhanced ultrasonic assisted biodiesel production from meat industry waste (pig tallow) using green copper oxide nanocatalyst: Comparison of response surface and neural network modelling. Renew. Energy 2021, 164, 897–907. [Google Scholar] [CrossRef]

- CEzekannagha, B.; Ude, C.N.; Onukwuli, O.D. Optimization of the methanolysis of lard oil in the production of biodiesel with response surface methodology. Egypt. J. Pet. 2017, 26, 1001–1011. [Google Scholar] [CrossRef]

- Oza, S.; Prajapati, N.; Kodgire, P.; Kachhwaha, S.S. An ultrasound-assisted process for the optimization of biodiesel production from waste cottonseed cooking oil using response surface methodology. Water-Energy Nexus 2021, 4, 187–198. [Google Scholar] [CrossRef]

- Ameen, F.; Mathivanan, K.; Zhang, R.; Ravi, G.; Rajasekar, S. One factor at a time and two-factor optimization of transesterification parameters through central composite design (CCD) for the conversion of used peanut oil (UPNO) to biodiesel. Fuel 2023, 352, 129065. [Google Scholar] [CrossRef]

- Thushari, I.; Babel, S.; Samart, C. Biodiesel production in an autoclave reactor using waste palm oil and coconut coir husk derived catalyst. Renew. Energy 2019, 134, 125–134. [Google Scholar] [CrossRef]

- Loh, J.M.; Amelia; Gourich, W.; Chew, C.L.; Song, C.P.; Chan, E.S. Improved biodiesel production from sludge palm oil catalyzed by a low-cost liquid lipase under low-input process conditions. Renew. Energy 2021, 177, 348–358. [Google Scholar] [CrossRef]

- Matinja, A.I.; Zain, N.A.M.; Suhaimi, M.S.; Alhassan, A.J. Optimization of biodiesel production from palm oil mill effluent using lipase immobilized in PVA-alginate-sulfate beads. Renew. Energy 2019, 135, 1178–1185. [Google Scholar] [CrossRef]

- Rajesh, K.; Natarajan, M.P.; Devan, P.K.; Ponnuvel, S. Coconut fatty acid distillate as novel feedstock for biodiesel production and its characterization as a fuel for diesel engine. Renew. Energy 2021, 164, 1424–1435. [Google Scholar] [CrossRef]

- Vernier, L.J.; Nunes, A.L.B.; Albarello, M.; de Castilhos, F. Continuous production of fatty acid methyl esters from soybean oil deodorized distillate and methyl acetate at supercritical conditions. J. Supercrit. Fluids 2022, 186, 105603. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L. Biodiesel production from rapeseed deodorizer distillate in a packed column reactor. Chem. Eng. Process. Process Intensif. 2009, 48, 1152–1156. [Google Scholar] [CrossRef]

- Akkarawatkhoosith, N.; Bangjang, T.; Kaewchada, A.; Jaree, A. Biodiesel production from rice bran oil fatty acid distillate via supercritical hydrolysis–esterification–transesterification in a microreactor. Energy Rep. 2023, 9, 5299–5305. [Google Scholar] [CrossRef]

- Heinzl, G.C.; Mota, D.A.; Martinis, V.; Martins, A.S.; Soares, C.M.F.; Osorio, N.; Gominho, J.; Nampoothiri, K.M.; Sukumaran, R.K.; Pereira, H.; et al. Integrated bioprocess for structured lipids, emulsifiers and biodiesel production using crude acidic olive pomace oils. Bioresour. Technol. 2022, 346, 126646. [Google Scholar] [CrossRef]

- Parandi, E.; Mousavi, M.; Kiani, H.; Nodeh, H.R.; Cho, J.; Rezania, S. Optimization of microreactor-intensified transesterification reaction of sesame cake oil (sesame waste) for biodiesel production using magnetically immobilized lipase nano-biocatalyst. Energy Convers. Manag. 2023, 295, 117616. [Google Scholar] [CrossRef]

- Rambabu, K.; Bharath, G.; Hai, A.; Show, P.L.; Banat, F.; Manickam, S. Enhancing biodiesel production from waste date seed oil through ultrasonic-assisted optimization: A sustainable approach using non-edible feedstocks. Chem. Eng. Process. -Process Intensif. 2023, 194, 109601. [Google Scholar] [CrossRef]

- Jain, S. Biodiesel production from food waste using insitu transesterification method. Sustain. Energy Technol. Assess. 2023, 58, 103380. [Google Scholar] [CrossRef]

- Rajendran, N.; Kang, D.; Han, J.; Gurunathan, B. Process optimization, economic and environmental analysis of biodiesel production from food waste using a citrus fruit peel biochar catalyst. J. Clean. Prod. 2022, 365, 132712. [Google Scholar] [CrossRef]

- Alonazi, M.; Al-Diahan, S.K.; Alzahrani, Z.R.A.; Bacha, A.B. Combined immobilized lipases for effective biodiesel production from spent coffee grounds. Saudi J. Biol. Sci. 2023, 30, 103772. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, F.; Zhang, R.; Zhao, L.; Qi, J. Recent Progress on Biodiesel Production from Municipal Sewage Sludge; Elsevier Ltd.: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Arazo, R.O.; de Luna, M.D.G.; Capareda, S.C. Assessing biodiesel production from sewage sludge-derived bio-oil. Biocatal. Agric. Biotechnol. 2017, 10, 189–196. [Google Scholar] [CrossRef]

- Yuliana, M.; Santoso, S.P.; Soetaredjo, F.E.; Ismadji, S.; Angkawijaya, A.E.; Irawaty, W.; Ju, Y.H.; Tran-Nguyen, P.L.; Hartono, S.B. Utilization of waste capiz shell-Based catalyst for the conversion of leather tanning waste into biodiesel. J. Environ. Chem. Eng. 2020, 8, 104012. [Google Scholar] [CrossRef]

- Hussain, S.B.; Muhammad, S.; Shah, U.; Nosheen, A. Sustainable Biodiesel Production via Chlorella vulgaris and Tetraselmis chuii in food-based brewery Industrial Wastewater. Waste Biomass Valorization, 2023in press. [CrossRef]

- Mostafa, S.S.M.; El-Gendy, N.S. Evaluation of fuel properties for microalgae Spirulina platensis bio-diesel and its blends with Egyptian petro-diesel. Arab. J. Chem. 2017, 10, S2040–S2050. [Google Scholar] [CrossRef]

- Vinitha, V.; Meignanalakshmi, S.; Tirumurugaan, K.G.; Sarathchandra, G.; Sundaram, S.M. Enhanced lipid production and analysis of properties of biodiesel produced from freshwater microalgae Scenedesmus obtusus ON089666.1. Bioresour. Technol. Rep. 2023, 21, 101286. [Google Scholar] [CrossRef]

- Shin, H.Y.; Shim, S.H.; Ryu, Y.J.; Yang, J.H.; Lim, S.M.; Lee, C.G. Lipid Extraction from Tetraselmis sp. Microalgae for Biodiesel Production Using Hexane-based Solvent Mixtures. Biotechnol. Bioprocess. Eng. 2018, 23, 16–22. [Google Scholar] [CrossRef]

- Khoobbakht, G.; Kheiralipour, K.; Karimi, M. Optimization of Chlamydomonas alga biodiesel percentage for reducing exhaust emission of diesel engine. Process Saf. Environ. Prot. 2021, 152, 25–36. [Google Scholar] [CrossRef]

- Das, V.; Dunford, N.; Deka, D. Waste utilization and biodiesel production from Desmodesmus maximus grown in swine wastewater using waste eggshells as a catalyst. Aquac. Eng. 2022, 99, 102293. [Google Scholar] [CrossRef]

- Bibi, F.; Ali, M.I.; Ahmad, M.; Bokhari, A.; Khoo, K.S.; Zafar, M.; Asif, S.; Mubashir, M.; Han, N.; Show, P.L. Production of lipids biosynthesis from Tetradesmus nygaardii microalgae as a feedstock for biodiesel production. Fuel 2022, 326, 124985. [Google Scholar] [CrossRef]

- Patel, A.; Gami, B.; Patel, P.; Patel, B. Biodiesel production from microalgae Dunaliella tertiolecta: A study on economic feasibility on large-scale cultivation systems. Biomass Convers Biorefin. 2023, 13, 1071–1085. [Google Scholar] [CrossRef]

- O’Neil, G.W.; Knothe, G.; Williams, J.R.; Burlow, N.P.; Reddy, C.M. Decolorization improves the fuel properties of algal biodiesel from Isochrysis sp. Fuel 2016, 179, 229–234. [Google Scholar] [CrossRef]

- Lakshmikandan, M.; Murugesan, A.G.; Ameen, F.; Maneeruttanarungroj, C.; Wang, S. Efficient bioflocculation and biodiesel production of microalgae Asterococcus limneticus on streptomyces two-stage co-cultivation strategy. Biomass Bioenergy 2023, 175, 106886. [Google Scholar] [CrossRef]

- Branco-Vieira, M.; Martin, S.S.; Agurto, C.; Santos, M.A.; Freitas, M.A.V.; Caetano, N.S. Analyzing Phaeodactylum tricornutum lipid profile for biodiesel production. In Energy Procedia; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; pp. 369–373. [Google Scholar] [CrossRef]

- Chaisutyakorn, P.; Praiboon, J.; Kaewsuralikhit, C. The effect of temperature on growth and lipid and fatty acid composition on marine microalgae used for biodiesel production. J. Appl. Phycol. 2018, 30, 37–45. [Google Scholar] [CrossRef]

- Wahlen, B.D.; Willis, R.M.; Seefeldt, L.C. Biodiesel production by simultaneous extraction and conversion of total lipids from microalgae, cyanobacteria, and wild mixed-cultures. Bioresour. Technol. 2011, 102, 2724–2730. [Google Scholar] [CrossRef] [PubMed]

- Tao, H.; Guo, D.; Zhang, Y.; Deng, Z.; Liu, T. Metabolic engineering of microbes for branched-chain biodiesel production with low-temperature property. Biotechnol. Biofuels 2015, 8, 92. [Google Scholar] [CrossRef]

- Haushalter, R.W.; Kim, W.; Chavkin, T.A.; The, L.; Garber, M.E.; Nhan, M.; Adamns, P.D.; Petzold, C.J.; Katz, L.; Keasling, J.D. Production of anteiso-branched fatty acids in Escherichia coli; next generation biofuels with improved cold-flow properties. Metab. Eng. 2014, 26, 111–118. [Google Scholar] [CrossRef]

- Bai, W.; Anthony, W.E.; Hartline, C.J.; Wang, S.; Wang, B.; Ning, J.; Hsu, F.F.; Dantas, G.; Zhang, F. Engineering diverse fatty acid compositions of phospholipids in Escherichia coli. Metab. Eng. 2022, 74, 11–23. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.-L.; Wang, Y.-Z.; Nong, F.-T.; Ma, W.; Huang, P.-W.; Sun, X.-M. Identification and characterization of fatty acid desaturases in Schizochytrium sp. HX-308. Algal Res. 2022, 67, 102861. [Google Scholar] [CrossRef]

- Jafarihaghighi, F.; Bahrami, H.; Ardjmand, M.; Mirzajanzadeh, M.; Haghighi, B.J.; Mahdavi, A. Comparing among second, third, and fourth generations (genetically modified) of biodiesel feedstocks from the perspective of engine, exhaust gasses and fatty acid: Comparative assessment. Clean. Chem. Eng. 2022, 2, 100025. [Google Scholar] [CrossRef]

- Vollmann, J.; Eynck, C. Camelina as a sustainable oilseed crop: Contributions of plant breeding and genetic engineering. Biotechnol. J. 2015, 10, 525–535. [Google Scholar] [CrossRef]

- Organisation for Economic Co-operation and Development (OECD); Food and Agriculture Organization (FAO). OECD-FAO Agricultural Outlook 2023–2032; OECD Publishing: Paris, France, 2023. [Google Scholar] [CrossRef]

- Organisation for Economic Co-operation and Development (OECD); Food and Agriculture Organization (FAO). OECD Agriculture Statistics (database). In OECD-FAO Agricultural Outlook 2023–2032; OECD Publishing: Paris, France, 2023. [Google Scholar] [CrossRef]

- Ministry of Energy and Mineral Resources of the Republic of Indonesia. FAQ: Program Mandatori Biodiesel 30% (Mandatory Program of Biodiesel 30%). Available online: https://ebtke.esdm.go.id/post/2019/12/19/2434/faq.program.mandatori.biodiesel.30.b30?lang=en (accessed on 25 June 2024).

- Ministry of Energy and Mineral Resources of the Republic of Indonesia. Program Bahan Bakar Nabati B35 Siap Implementasi Mulai 1 Februari 2023 (Program of Biofuel B35 is Ready for Implementation Starting 1st February 2023). Available online: https://ebtke.esdm.go.id/post/2023/01/09/3395/program.bahan.bakar.nabati.b35.siap.implementasi.mulai.1.februari.2023 (accessed on 25 June 2024).

- Ministry of Energy and Mineral Resources of the Republic of Indonesia. Persiapan Pelaksanaan Mandatori Biodiesel B40 (Preparation for Mandatory Implementation of Biodiesel B40). Available online: https://www.esdm.go.id/id/berita-unit/direktorat-jenderal-ebtke/persiapan-pelaksanaan-mandatori-biodiesel-b40 (accessed on 25 June 2024).

- Lanjekar, R.D.; Deshmukh, D. A Review of the Effect of the Composition of Biodiesel on NOx Emission, Oxidative Stability and Cold Flow Properties; Elsevier Ltd.: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Directorate General of New Renewable Energy and Energy Conservation, Ministry of Energy and Mineral Resources of the Republic of Indonesia. Standar dan Mutu (Spesifikasi) Bahan Bakar Nabati Jenis Biodiesel Sebagai bahan Bakar Lain yang Dipasarkan di Dalam Negeri. Available online: https://ebtke.esdm.go.id/post/2022/12/15/3376/telah.terbit.keputusan.dirjen.ebtke.nomor.195.kek.05dje2022.tentang.standard.dan.mutu.spesifikasi.bahan.bakar.nabati.jenis.biodiesel.sebagai.bahan.bakar.lain.yang.dipasarkan.di.dalam.negeri (accessed on 22 June 2024).

- Wen, P.Y. Process Synthesis and Optimisation for Multi-Biodiesel Mixture Production. Ph.D. Thesis, UTAR, Petaling Jaya, Malaysia, 2020. [Google Scholar]

- Ministry of Agriculture Livestock and Food Supply. Uses for Biodiesel in Brazil and Globally, 1st ed.; Livestock and Food Supply of Brazil; Ministry of Agriculture: Brasilia, Brazil, 2015. [Google Scholar]

- Lakshmi, G.; Rao, N.; Ramadhas, A.S.; Nallusamy, N.; Sakthivel, P. Relationships among the physical properties of biodiesel and engine fuel system design requirement. Int. J. Energy Environ. 2010, 1, 919–926. [Google Scholar]

- Sierra-Cantor, J.F.; Guerrero-Fajardo, C.A. Methods for Improving the Cold Flow Properties of Biodiesel with High Saturated Fatty Acids Content: A Review. Renew. Sustain. Energy Rev. 2017, 54, 1401–1411. [Google Scholar] [CrossRef]

- Rasimoglu, N.; Temur, H. Cold flow properties of biodiesel obtained from corn oil. Energy 2014, 68, 57–60. [Google Scholar] [CrossRef]

- Ali, O.; Yusaf, T.; Mamat, R.; Abdullah, N.; Abdullah, A. Influence of Chemical Blends on Palm Oil Methyl Esters’ Cold Flow Properties and Fuel Characteristics. Energies 2014, 7, 4364–4380. [Google Scholar] [CrossRef]

- Giraldo, S.Y.; Rios, L.A.; Suárez, N. Comparison of glycerol ketals, glycerol acetates and branched alcohol-derived fatty esters as cold-flow improvers for palm biodiesel. Fuel 2013, 108, 709–714. [Google Scholar] [CrossRef]

- Soriano, N.U.; Migo, V.P.; Matsumura, M. Ozonized vegetable oil as pour point depressant for neat biodiesel. Fuel 2006, 85, 25–31. [Google Scholar] [CrossRef]

- Abe, M.; Hirata, S.; Komatsu, H.; Yamagiwa, K.; Tajima, H. Thermodynamic selection of effective additives to improve the cloud point of biodiesel fuels. Fuel 2016, 171, 94–100. [Google Scholar] [CrossRef]

- Zhang, X.; Li, N.; Wei, Z.; Dai, B.; Han, S. Synthesis and evaluation of bifunctional polymeric agent for improving cold flow properties and oxidation stability of diesel-biodiesel blends. Renew. Energy 2022, 196, 737–748. [Google Scholar] [CrossRef]

- Islam, M.M.; Hassan, M.H.; Kalam, M.A.; Zulkifli, N.W.B.M.; Habibullah, M.; Hossain, M.M. Improvement of cold flow properties of Cocos nucifera and Calophyllum inophyllum biodiesel blends using polymethyl acrylate additive. J. Clean. Prod. 2016, 137, 322–329. [Google Scholar] [CrossRef]

- Wang, J.; Cao, L.; Han, S. Effect of polymeric cold flow improvers on flow properties of biodiesel from waste cooking oil. Fuel 2014, 117, 876–881. [Google Scholar] [CrossRef]

- Xue, Y.; Zhao, Z.; Xu, G.; Lian, X.; Yang, C.; Zhao, W.; Ma, P.; Lin, H.; Han, S. Effect of poly-alpha-olefin pour point depressant on cold flow properties of waste cooking oil biodiesel blends. Fuel 2016, 184, 110–117. [Google Scholar] [CrossRef]

- Knothe, G.; Dunn, R.O. A Comprehensive Evaluation of the Melting Points of Fatty Acids and Esters Determined by Differential Scanning Calorimetry. JAOCS J. Am. Oil Chem. Soc. 2009, 86, 843–856. [Google Scholar] [CrossRef]

- Amran, N.A.; Bello, U.; Ruslan, M.S.H. The Role of Antioxidants in Improving Biodiesel’s Oxidative Stability, Poor Cold Flow Properties, and the Effects of the duo on Engine Performance: A Review. Heliyon 2022, 8, e09846. [Google Scholar] [CrossRef]

- Dwivedi, G.; Sharma, M.P. Impact of Cold Flow Properties of Biodiesel on Engine Performance. Renew. Sustain. Energy Rev. 2014, 31, 650–656. [Google Scholar] [CrossRef]

- Smith, P.C.; Ngothai, Y.; Nguyen, Q.D.; O’Neill, B.K. Improving the low-temperature properties of biodiesel: Methods and consequences. Renew. Energy 2010, 35, 1145–1151. [Google Scholar] [CrossRef]

- Dunn, R.O.; Ngo, H.L.; Haas, M.J. Branched-chain fatty acid methyl esters as cold flow improvers for biodiesel. JAOCS J. Am. Oil Chem. Soc. 2015, 92, 853–869. [Google Scholar] [CrossRef]

- Moser, B.R. Fuel property enhancement of biodiesel fuels from common and alternative feedstocks via complementary blending. Renew. Energy 2016, 85, 819–825. [Google Scholar] [CrossRef]

- Verma, P.; Sharma, M.P.; Dwivedi, G. Evaluation and enhancement of cold flow properties of palm oil and its biodiesel. Energy Rep. 2016, 2, 8–13. [Google Scholar] [CrossRef]

- Makarevičienė, V.; Kazancev, K.; Kazanceva, I. Possibilities for improving the cold flow properties of biodiesel fuel by blending with butanol. Renew. Energy 2015, 75, 805–807. [Google Scholar] [CrossRef]

- Park, J.-Y.; Kim, D.-K.; Lee, J.-P.; Park, S.-C.; Kim, Y.-J.; Lee, J.-S. Blending effects of biodiesels on oxidation stability and low temperature flow properties. Bioresour. Technol. 2008, 99, 1196–1203. [Google Scholar] [CrossRef]

- Nainwal, S.; Sharma, N.; Sharma, A.S.; Jain, S.; Jain, S. Cold flow properties improvement of Jatropha curcas biodiesel and waste cooking oil biodiesel using winterization and blending. Energy 2015, 89, 702–707. [Google Scholar] [CrossRef]

- Niyas, M.M.; Shaija, A. Performance evaluation of diesel engine using biodiesels from waste coconut, sunflower, and palm cooking oils, and their hybrids. Sustain. Energy Technol. Assess. 2022, 53, 102681. [Google Scholar] [CrossRef]

- Knothe, G. Improving biodiesel fuel properties by modifying fatty ester composition. Energy Env. Sci. 2009, 2, 759. [Google Scholar] [CrossRef]

- Kumar, D.; Singh, B. Effect of winterization and plant phenolic-additives on the cold-flow properties and oxidative stability of Karanja biodiesel. Fuel 2020, 262, 116631. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, S.; Zhao, M.; Kuang, L.; Nie, J.; Riley, W.W. Improving the cold flow properties of biodiesel from waste cooking oil by surfactants and detergent fractionation. Fuel 2011, 90, 1036–1040. [Google Scholar] [CrossRef]

- Abe, M.; Nakamura, R.; Komatsu, H.; Yamagiwa, K.; Tajima, H. Effect of additive structure on the performance of biodiesel fuel winterization. Fuel 2021, 289, 119747. [Google Scholar] [CrossRef]

- Min, H.Y.; Amran, N.A.; Samsuri, S. Winterization of biodiesel through progressive freezing for cold flow properties improvement. IOP Conf. Ser. Earth Env. Sci. 2019, 268, 012096. [Google Scholar] [CrossRef]