Abstract

In the global effort for industrial decarbonization, repurposing closed coal-fired power plants into power-to-methanol (PtM) plants offers a promising pathway to reduce CO2 emissions while leveraging existing infrastructure. This study introduces a novel combined optimization approach using mixed-integer linear programming (MILP) to simultaneously optimize the investment and operation of a PtM plant, assessing its economic viability. The model incorporates the operational flexibility of proton exchange membrane (PEM) electrolyzers in response to fluctuating electricity prices through a piecewise linear representation of its load–efficiency characteristic curve. A case study of a repurposed coal plant in Austria demonstrates the model’s applicability and practical relevance. The results show that larger electrolyzer capacities, i.e., 434 MW, with flexible part-load operation can significantly reduce methanol production costs, i.e., EUR 0.8/kg, achieving competitiveness under high CO2 pricing scenarios, i.e., EUR 500/ton. A sensitivity analysis is performed to identify the critical factors influencing production costs. This study concludes that the combined investment and operational optimization approach effectively captures the essential elements of PtM systems, enabling faster, better, and operation-informed investment decisions for innovative technologies to support the ongoing energy transition. These findings indicate that PtM technologies can be a viable solution for asset repurposing, grid stabilization, and decarbonizing hard-to-abate sectors.

1. Introduction

A global effort towards energy transition is driving a shift from traditional fossil fuel-based power plants to renewable energy sources. A significant milestone in this initiative was reached when the United Kingdom closed its last coal power station, Ratcliffe-on-Soar, near Nottingham, ending a 142-year reliance on coal power [1]. Similarly, mainland Europe is implementing plans to phase out coal, with the goal of achieving climate neutrality. This requires the closure of 72% of coal-fired power plants (CFPPs) by 2025. However, this transition carries the risk of losing the monetary value of stranded assets, which can be as high as EUR 40.47 billion if this phase-out is completed by 2030 and drops down to EUR 1.13 billion if coal phase-out occurs by 2038 [2]. Despite these challenges, the phase-out presents opportunities to repurpose existing infrastructures for emerging technologies [3]. One such prospect is the development of e-fuel production plants at closed coal power plant sites. Reusing existing infrastructure for e-fuel production can significantly reduce initial investment costs associated with infrastructure such as connections to the electrical and gas grids, water treatment stations, water demineralization units, storage facilities, transport infrastructure, buildings, etc. [4].

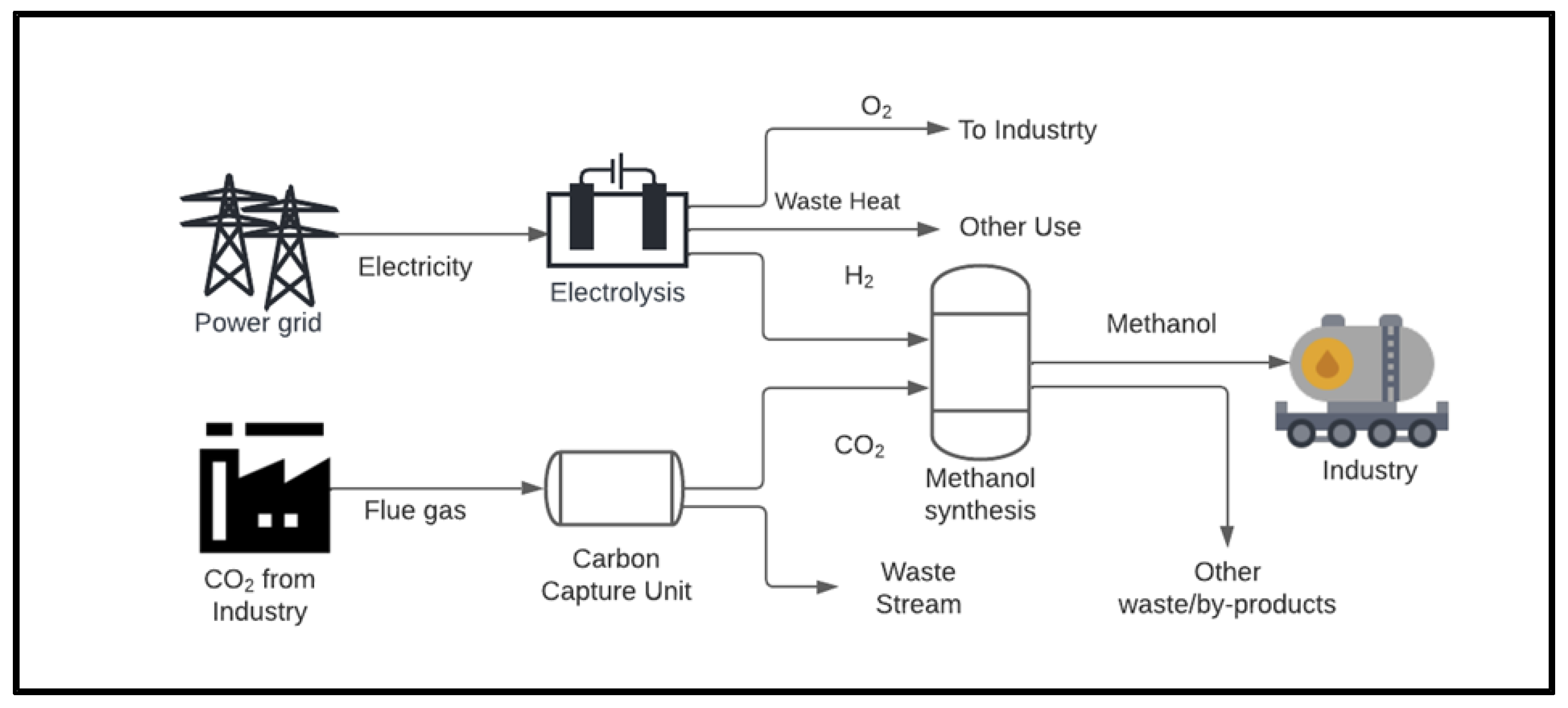

The power-to-methanol concept represents a strategic avenue for the storage of renewable energy and the decarbonization of sectors traditionally reliant on high-density fuels, such as aviation, shipping, and heavy transportation. By converting the negative residual load from renewable electricity production into methanol through the combination of CO2 from industrial sources and hydrogen obtained from water electrolysis, this technology facilitates the integration of intermittent energy sources into the energy system, also offering a viable solution to grid stabilization challenges. Furthermore, methanol’s role extends beyond fuel applications, serving as a critical feedstock in the chemical industry, thereby contributing to a reduction in the carbon intensity of industrial processes. The advancement and deployment of power-to-methanol technologies are imperative for transitioning towards a more sustainable and resilient energy framework, particularly in hard-to-abate sectors, necessitating concerted efforts in research and development to enhance system efficiencies and economic feasibility [5,6].

2. State of Research

In the domain of new power-to-fuel or similar facilities classified under the category of power-to-X, investment planning and operational optimization emerges as a critical consideration. This consideration is predominantly addressed through the mixed-integer linear programming (MILP) and mixed-integer non-linear programming (MINLP) methodologies, as evidenced in the existing literature.

For instance, Urbanucci [7] presents a comprehensive review of the state of the art in using MILP for optimizing polygeneration energy systems and discusses the challenges of using mixed-integer linear programming (MILP) for optimizing polygeneration systems, particularly in dealing with non-linearity, high dimensionality, and the need to consider both discrete and continuous variables over a full time horizon. It highlights limitations such as computational intensity and scalability issues and suggests decomposition strategies and piecewise linearization techniques to address these complexities. Other works such as Schmeling et al. [8] have developed a methodology for the optimal sizing and operation of a Power-to-Gas-to-Power (PtGtP) system within a hybrid energy system and used the open-source tool oemof.solph for modeling the energy system. The authors in Beerbühl et al. [9] presented a combined scheduling and capacity planning model for an electricity-to-hydrogen-to-ammonia plant that integrates the distinct non-linear characteristics using a heuristic approach. This, however, increases the computational effort compared to that of linear modeling. Likewise, Marocco et al. [10] used the MILP-based optimization methodology and metaheuristic techniques with ruled-based operational strategies to determine the optimal design and operation of a standalone renewable power system in an off-grid village. Similarly, Allman et al. [11] introduced a scheduling-informed design (SID) method for optimizing the design of chemical plants with time-varying operations, specifically focusing on wind-powered ammonia production. The authors identified a need to further refine and generalize the SID method for combined investment and operational scheduling optimization. Further, Zheng et al. [12] have discussed optimal sizing and operation strategies for wind-electrolyzer systems in the context of hydrogen production. The authors presented a two-stage multi-objective optimization framework for incorporating optimal operation strategies into investment planning. Zhang et al. [13] proposed a multiscale mixed-integer linear programming model for the integrated optimal design and operation of renewable-based fuels and power production networks. Gabrielli et al. [14] introduced an optimization framework for electrochemical devices, integrating first-principles models with simplified implementations in mixed-integer linear programming (MILP) using piecewise affine, affine, and linear approximations. This study finds that while linear approximations do not significantly impact the accuracy, they simplify the optimization process. Wassermann et al. [15] used a methodology using mixed-integer linear programming to model hydrogen supply systems, emphasizing the importance of considering the power supply and hydrogen demand separately. Mitra et al. [16,17] proposed a MILP formulation integrating operational and strategic decisions for power-intensive processes under time-sensitive electricity prices, comparing deterministic and stochastic demand models. It discusses the trade-off between capital and operating expenditures. Moreover, studies such as Yang et al. [18] have proposed multi-stage coordinated dispatching frameworks for electricity–hydrogen integrated energy systems, leveraging the operational flexibility of hydrogen systems within day-ahead and intra-day dispatch models. By incorporating advanced methods like chance-constrained optimization and deep reinforcement learning to handle uncertainties, these approaches further underscore the importance of integrating operational flexibility and uncertainty management into the optimization of energy systems.

On the other hand, approaches such as MINLP are also used in the literature. For instance, Mucci et al. [19] utilized a mixed-integer non-linear programming (MINLP) model to address the combined design and scheduling optimization problems in the power-to-methanol plant, ensuring the consideration of operating limits for each unit and maximizing the benefits of flexible operation. This study also indicates that overall global optimality cannot be guaranteed when using the MINLP model and adopts the representative days approach to approximate annual operations with a focus on the short-term optimization period. The MINLP approach, while comprehensive, often presents computational challenges in encompassing year-long operations. Also, these investigations often presuppose a fixed size or design of the system; thus, the investment and operational optimization typically occur as distinct characteristics, meaning that one is optimized while the other is fixed, as described by Zheng et al. [12]. Although MINLP allows for modeling non-linear relationships, MILP is often favored due to its distinct computational benefits. MILP’s advantages, extensively documented in the literature, include its computational efficiency, supported by established methodologies like the simplex method and branch-and-cut algorithms, which optimize performance robustly, as presented by Grossman et al. [20]. Furthermore, the predictability of the MILP solver performance is a considerable advantage, as linear relationships within MILP models ensure consistent scalability with problem size, unlike in MINLP, where the solver performance can vary significantly due to non-linearities. MILP also provides guarantees of global optimality for convex problems and has a wide availability of efficient commercial solvers, a feature not readily achievable in nonconvex MINLP scenarios without employing more resource-intensive global optimization. While there are limitations to the MILP framework, various strategies, such as decomposition and piecewise linearization, are presented to overcome these challenges, particularly for addressing non-linear dynamics and high dimensionality in energy systems. Consequently, MILP remains the preferred approach for optimizing polygeneration systems, despite its noted constraints. For instance, Urbanucci [7] provides a thorough review of the existing literature, consolidating the current knowledge on MILP applications in energy system optimization. It extends the body of knowledge by discussing the limits and potentials of MILP methods and by proposing solutions to enhance MILP’s applicability to real-world problems.

Based on the potential benefits of using mixed-integer linear programming (MILP) methods over mixed-integer non-linear programming (MINLP), as discussed in the previous paragraph, this work employs MILP for the optimization of power-to-methanol plants. In the literature, investment optimization and operational optimization are often considered separate attributes. However, recent work such as that by Mucci et al. [19] and Zheng et al. [12] has highlighted the importance of a combined approach to achieve more integrated and efficient outcomes. Several other research studies have explored the simultaneous optimization of investment and operational factors to enhance the system efficiency and sustainability across various industries. Halmschlager et al. [21] developed a mixed-integer linear programming (MILP) approach that links models for the optimal retrofit design of heat recovery systems and energy supply systems in industrial applications. Angarita et al. [22] proposed a MILP-based optimization model incorporating stochastic programming to determine the optimal investment and operation of microgrids, focusing on technologies like combined heat and power (CHP), boilers, photovoltaics (PVs), and battery energy storage systems (BESSs) to minimize the expected annual operational costs. Yin et al. [23] introduced an integrated framework for water network management that combines investment and operational optimization to minimize both capital expenditures (CAPEX) and operational expenditures (OPEX), addressing issues like pipe bursts and physical losses. Kiptoo et al. [24] developed an integrated planning model using MILP to combine capacity sizing and operational scheduling for standalone microgrids with high renewable energy penetration, incorporating demand response strategies with dynamic pricing to improve system flexibility. Zhang et al. [25] employed a combined agent-based demand modeling and stochastic optimization approach, using representative demand scenarios generated through simulation and clustering to optimize the design and dispatch strategy of integrated energy systems via MILP. De-Almeida-e-Pais et al. [26] proposed an integrated life cycle assessment method that optimizes investments in maintenance, technology, sustainability, and upgrades, aiming to extend the asset life and promote the circular economy by developing new econometric methods. Nabavi-Pelesaraei et al. [27] evaluated the integration of life cycle assessment (LCA) and data envelopment analysis (DEA) to optimize energy consumption and reduce environmental impacts in agricultural production. Shoaei et al. [28] conducted a comprehensive 4E (energy, exergy, economy, and environment) analysis and optimized a novel integrated energy system based on solar and geothermal resources using a multi-objective optimization algorithm (NSGA-II), aiming to enhance the exergy efficiency and reduce capital costs.

The adaption of the MILP optimization approach requires the modeling of individual components of the power-to-methanol system accordingly. The concept of incorporating operational flexibility within the design optimization of power-to-methanol systems has been the topic of some recent research. Commercial methanol synthesis plants, at present, operate continuously throughout the year with scheduled maintenance and tend to operate at full-load capacity [29]. In the recent years, there has been increasing research interest in studying the flexibility of methanol synthesis plants, such as in [30], where Chen et al. investigated a flexible methanol synthesis plant operation with intermediate storage for crude methanol. These studies, though in their early phases, suggest that flexibility in operation can offer significant advantages. However, they are not considered in this study due to their preliminary nature.

In contrast, the operational flexibility in the hydrogen production phase in power-to-methanol systems has been demonstrated in commercial systems as well. Also, electrolysis has emerged as the most energy- and cost-intensive component of this system. While numerous studies assume constant efficiency for electrolyzers, there is a growing body of research that includes part-load behaviors (operational flexibility) in system sizing determinations. Proton exchange membrane (PEM) electrolyzers exhibit part-load attributes, suggesting their potential for flexible operation. The integration of an electrolyzer with hydrogen storage systems could offer the requisite adaptability, especially in scenarios characterized by fluctuating electricity prices. However, the efficiency curve at partial loads for these systems is inherently non-linear. Raheli et al. [31] have performed an extensive discussion on different approaches adopted in the literature for modeling the efficiency curve of electrolyzers. The authors have identified that techniques such as piecewise linearization and piecewise affine linearization can be used to represent non-linear behaviors. Similarly, Li et al. [32] have employed hybrid Model Predictive Control (MPC) and Approximate Dynamic Programming (ADP) [33] for the real-time stochastic operation of grid-tied multi-energy microgrids [34], using piecewise linear functions to handle uncertainties and optimize operation costs. This approach underscores the effectiveness of integrating advanced control strategies and linear approximations. Other works such as Buttler et al. [35] and Gabrielli et al. [14] have also recognized the effectivity of the use of piecewise linearization for the linear representation and approximation of non-linear curves such as the part-load efficiency curve of electrolyzers. Currently, there is no widely accepted model for the hydrogen efficiency curve that is both accurate and efficient, so research often uses simplified models. In some recent works on the topic of the combined investment and operational optimization approach, the part-load operational dynamics of electrolyzers are instrumental in determining the system size. In the literature, two-stage stochastic programming is frequently employed for system planning and operation. Nevertheless, these models, which frequently depend on simplified assumptions and are primarily oriented towards economic optimization, encounter limitations in flexibility and might necessitate a thorough reassessment to accommodate diverse operational objectives. For instance, Zheng et al. [12] have focused on a typical hybrid wind–hydrogen system and offers flexible multi-objective two-stage optimization considering both planning and operation. Other authors such as Mucci et al. [19] address the problem through an MINLP framework but limited its scope to 1200 time steps. Most of these investigations have focused on Alkaline Electrolysis (AEL), which, while not markedly different in technical terms, can significantly influence the outcomes of the optimization process. Beerbühl et al. [9] have also developed a combined scheduling and capacity planning model for a power-to-ammonia plant using a heuristic procedure that enables the integration of non-linear operational characteristics into the model, leading to a convex and continuous non-linear programming (NLP) formulation. This approach, however, has a higher computational demand and only approximates the global optimum.

This study introduces a one-step MILP-based combined approach to investment and operational optimization, specifically aimed at assessing new investments in green technologies such as power-to-methanol aimed at replacing coal power plants and repurposing former coal power plant sites. Traditional economic models and optimization techniques typically rely on assumptions of constant efficiencies and linear system behaviors, which do not accurately capture the dynamic and non-linear operational characteristics of power-to-methanol processes. While non-linear programming approaches can model these complexities, they are typically time-consuming and computationally intensive, making them impractical for large-scale applications. Our research bridges this gap by adopting an intermediate modeling approach that balances detail and computational efficiency. Instead of exhaustively modeling every system component, we focus on key elements that significantly impact the system flexibility, namely, the electrolyzer and hydrogen storage. By incorporating the electrolyzer’s part-load efficiency into our MILP model, we enable efficient load adjustments in response to fluctuating electricity prices. This directly influences the optimal sizing of these capital-intensive components, leading to more cost-effective and realistic investment decisions. This nuanced approach not only enhances the accuracy of the optimization but also provides a practical and efficient pathway for advancing green technology investments.

In this context, this research aims to address the following research questions in the following sections of this study:

- How can a combined design and operational optimization approach be modeled using MILP?

- How does the incorporation of part-load behaviors in electrolyzers impact the combined sizing and operational optimization of power-to-fuel systems?

- What are the effects of different input parameters on the levelized cost and operational dynamics of methanol production, and which are crucial for optimizing combined investment and operational strategies?

The structure of this paper is organized as follows: Section 3 details the methodology employed in this study, providing a comprehensive framework for the research approach and indicating where specific additions related to the selection and integration of technologies such as PEM electrolysis, carbon capture, and hydrogen storage are incorporated. Section 4 describes the optimization model setup, highlighting the inclusion of a combined investment and operational optimization approach using the Open Energy Modelling Framework (oemof). In Section 5, a case study is presented, contextualizing the model presented within the repurposing of a closed coal power plant site in Austria, utilizing existing infrastructure and sourcing CO2 from a nearby industrial source. Section 6 discusses the optimization setup, including specific solver configurations and computational strategies employed to address the optimization problem. Section 7 presents the results, offering an analysis of the findings and emphasizing the impact of the operational flexibility of the electrolyzer and hydrogen storage on the optimal capacity and operation of the power-to-methanol plant. Section 8 provides a general discussion on the assumptions and impact of different input parameters using a sensitivity analysis. Finally, Section 9 provides the conclusion, summarizing the key insights of this work and suggesting avenues for future research, such as assessing the economic feasibility.

3. Methodology

In the initial phase of this study, the methodology encompassed the selection of optimal technologies and the establishment of a modeling framework. PEM electrolysis demonstrates a remarkable capability for operating across a full range of partial loads. However, as a relatively nascent technology with limited market penetration, its investment costs remain higher than those associated with Alkaline Electrolysis (AEL) [36]. Despite the higher initial investment when compared to AEL, PEM electrolysis’s wide-ranging operational flexibility makes it a pertinent subject for evaluation in this research. An expert elicitation study projected that by 2030, PEM electrolysis will emerge as the preferred technology in scenarios where electrolysis is coupled with renewable energy sources, attributed to its anticipated cost reduction and enhanced operational flexibility [37]. Moreover, PEM electrolyzers can operate at higher pressures required for downstream hydrogen sinks, i.e., methanol synthesis, which helps reduce the size and operating cost of the compression unit [19]. Consequently, this study will further explore the application and modeling of PEM electrolyzers in the context of the combined investment and operational optimization of power-to-methanol plants.

For carbon capture technology, post-combustion carbon capture stood out because of its relatively easier integration properties and higher Technology Readiness Level (TRL) level. It separates CO2 from flue gases (a typical low concentration of CO2 of 4–4%) produced from large-scale fossil fuel combustion in the industry sector. To facilitate CO2 separation and reach the necessary concentration of 95.5% for transportation and storage, there is a significant demand for energy and equipment. Furthermore, as has been carried out for several power plants, post-combustion CC units can be added directly to already-existing power plants with minimal retrofitting [38,39]. In this study, the carbon capture plant is not explicitly modeled. Rather, a point source for CO2 input is considered and the costs associated with carbon capture plant construction and operation are calculated for the size of the CO2 stream. A separate investigation is performed on potential CO2 sources available within the vicinity of the evaluated closed power plant use case. Subsequently, the size of the carbon capture plant and associated investment and operation costs are calculated to serve as an input for the optimization model developed in the study.

Further, for hydrogen storage, the present study assumes a physical-based storage method as this is most advanced and widely implemented [40]. Liquid storage increases the energy density and reduces the storage size, but it is complex and costly due to the need for a liquefaction plant. Gaseous storage is simpler, requiring only a compression unit, and can be conducted in vessels above ground or in underground caverns. The latter method, however, is dependent on specific geographical conditions. For this application, we have assumed above-ground storage using pressurized vessels because it is not limited by location. Among the types of vessels available, type I vessels are identified as most appropriate for the target pressure range (up to 200 bar) for stationary applications and relevant costs are used as an input for the optimization model. Moreover, hydrogen storage is not explicitly modeled, rather, an existing model for generic storage is used.

Moreover, for methanol (MeOH) production, the direct conversion process of CO2 and H2 to methanol is selected based on the latest research on this process and on its relevance to the geographical location. The conventional MeOH synthesis pathway from natural gas or coal may cause water shortages and increase GHG emissions. Hence, alternative routes to synthesize MeOH are of great interest.

The aim of this study is to investigate the integration and operation of power-to-fuel (Ptf) units in a cost-optimized way. Therefore, the focus is to study the interaction of these technologies at the level of an energy system model. For a combined investment and operational optimization, utilizing the Open Energy Modelling Framework [41] is deemed suitable. The identification of relevant use cases and scenarios followed this. The mathematical foundation of this model is built on mixed-integer linear programming techniques. The essential elements of the power-to-methanol system, such as the PEM electrolyzer, hydrogen storage, and methanol synthesis, were created utilizing integrated oemof components. Parameters such as the input variables, constraints, assumptions, and boundary conditions were derived from existing work [42,43,44]. A piecewise linear method is used to linearize the PEM electrolyzer’s part-load efficiency curve, as detailed in [45]. Moreover, the electricity price profile used in each scenario is obtained from the work of [2]. The CO2 input profile is use-case-dependent and will be discussed later. The optimization model used the Gurobi solver, with solver options for nonconvex problems and establishing a MIP gap tolerance of 5%. Furthermore, additional information is provided in the Appendix A.

4. Optimization Model

The optimization model for the power-to-methanol plant is set up using the Open Energy Modelling Framework (oemof) [19,41]. The oemof is a versatile, Python-based tool tailored for energy system optimization. It facilitates a modular approach where the energy system is defined as a network of various interconnected components, including sources, converters, sinks, and storage units. Each component is modeled as a node, and the connections representing energy flows are defined by edges, which are constrained by a combination of physical, technical, and economic parameters.

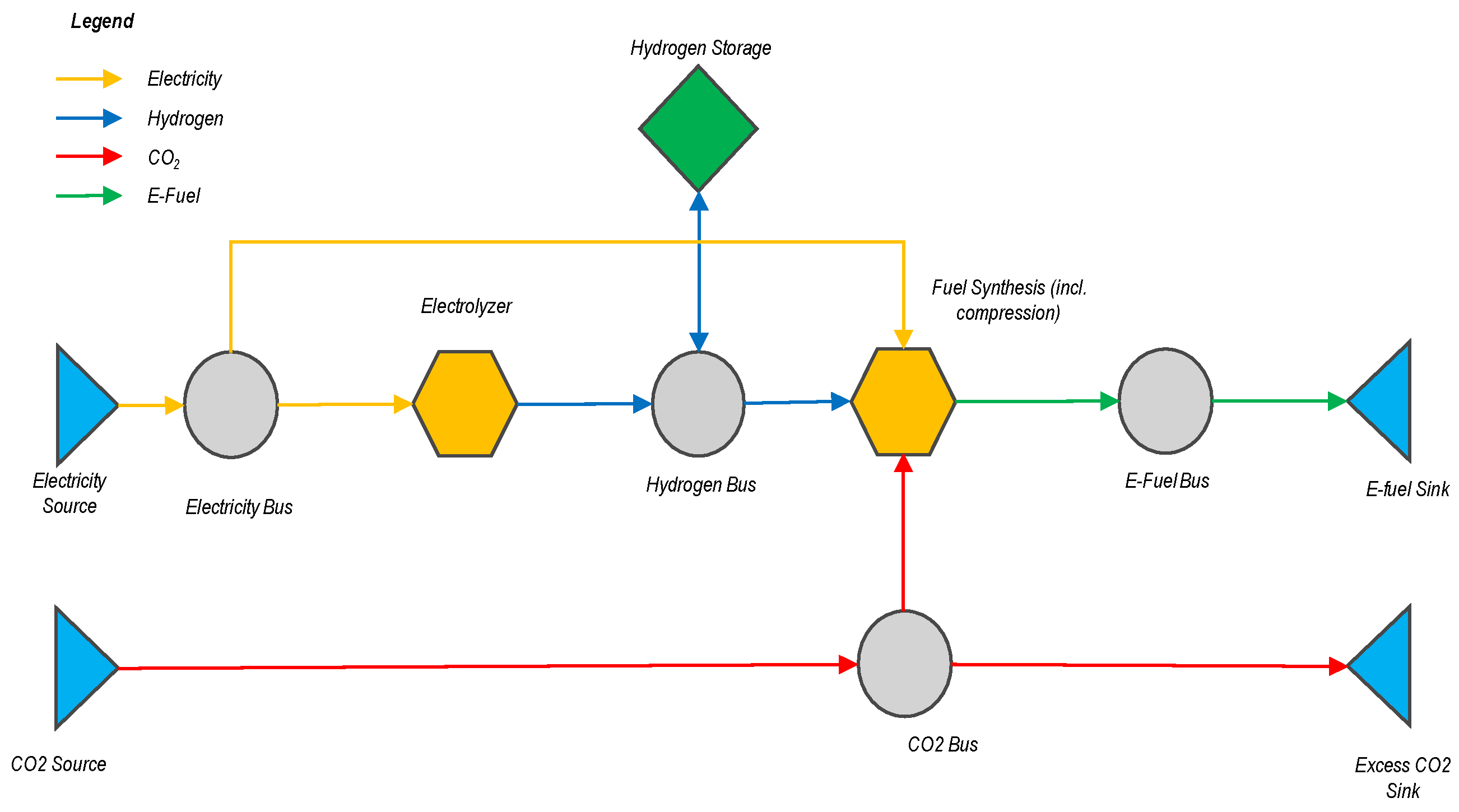

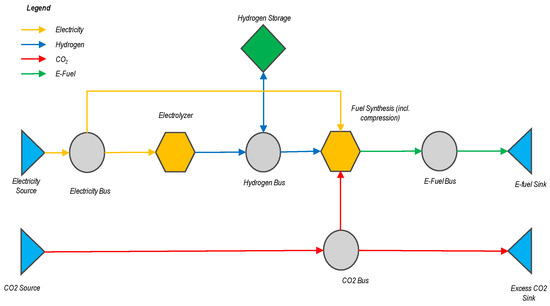

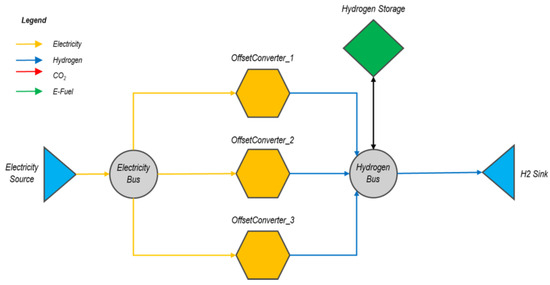

The components of the PtM plant are modeled as interconnected oemof components, i.e., buses, sources, converters, sinks, and storage units, as seen in Figure 1. Buses (electric bus, CO2 bus, hydrogen bus and e-fuel bus), depicted as circles, function as central nodes facilitating the connection and distribution of flows between different system components. Converters (PEM electrolyzer and Fuel Synthesis Unit), illustrated as hexagons, are responsible for converting flows from one form to another, reflecting efficiency losses in the process. Sources (electricity and CO2 source) and sinks (e-fuel and excess CO2 sink), represented by triangles, denote the inflows and outflows, respectively. The diamond shape (hydrogen storage) represents a storage component that can store excess hydrogen or act as a buffer and release it when required to balance the supply and demand. The connections between these components are depicted with color-coded arrows indicating the direction of different flows: yellow arrows show electricity flow; red arrows represent CO2 flow; green arrows denote e-fuel flow; and blue arrows illustrate the flow of hydrogen.

Figure 1.

Schematic representation of power-to-methanol plant model in oemof.

In the following section, how individual components are modeled is described in detail.

4.1. PEM Electrolyzer

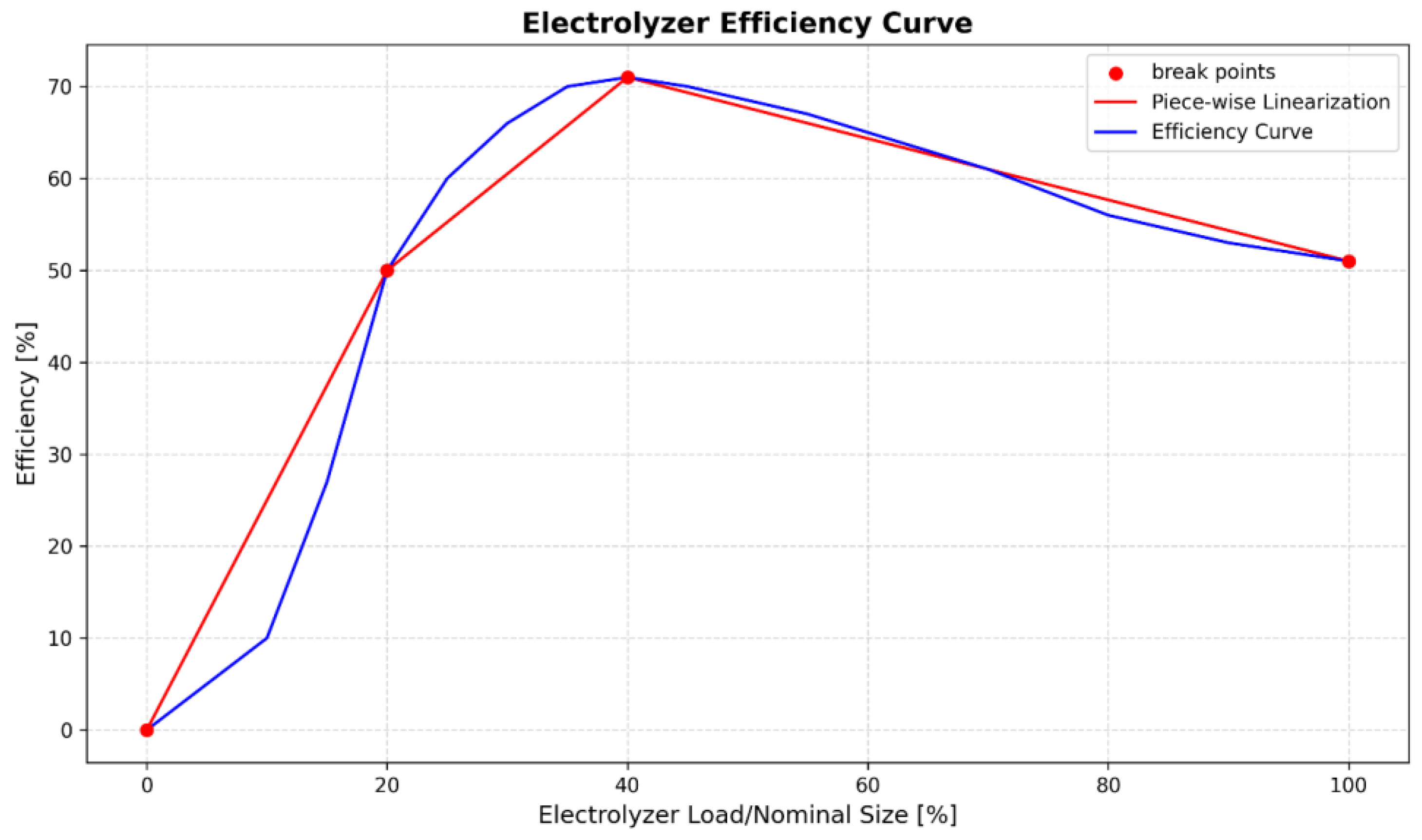

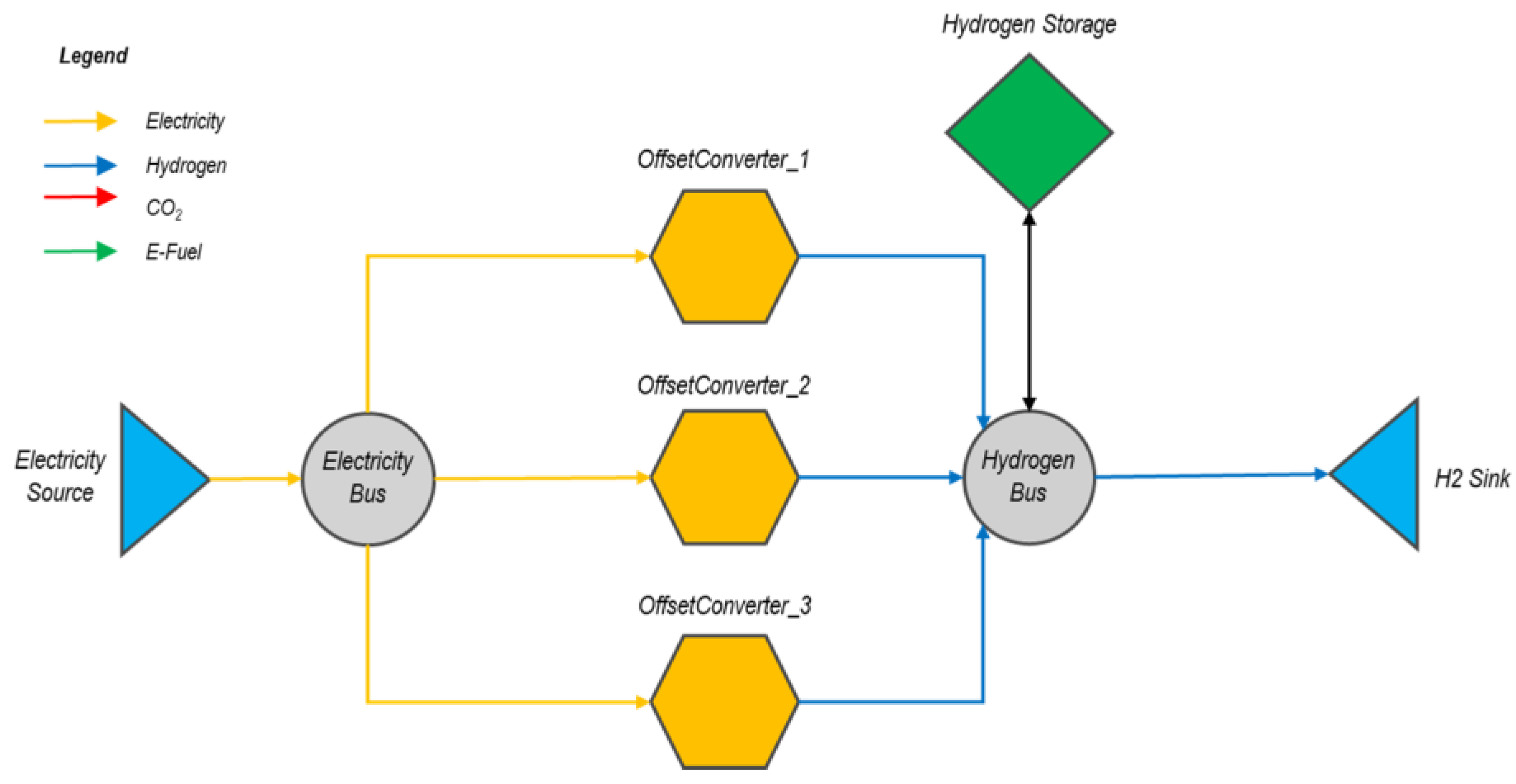

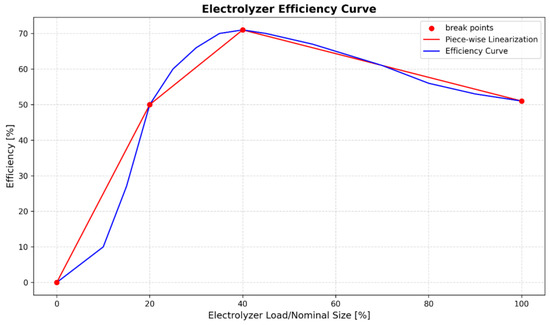

The PEM electrolyzer for commercial applications consists of multiple modules added for the total size of the PEM system. In this work, the PEM electrolyzer size is considered as a continuous variable. A piecewise linear approximation of the load-efficiency curve is used in this work. A piecewise linear approximation of the PEM efficiency curve based on [46] is adopted, as shown in Figure 2. This piecewise linear approximation shown in Figure 2 is implemented in oemof using three ‘OffsetConverter’ components, each representing a different segment of the load–efficiency curve, i.e., 0–20%, 20–40%, and 40–100%, as shown in Figure 3. The ‘OffsetConverter’ object [46] enables the creation of a converter whose efficiency varies based on the part-load condition. To achieve this, one flow must be defined as a nonconvex flow, and a minimum load must be specified.

Figure 2.

Piecewise linear representation of electrolyzer system efficiency curve.

Figure 3.

PEM electrolyzer model in oemof with three offset converters to represent the piecewise linear segments.

Each ‘OffsetConverter’, which represents the PEM electrolyzern is expressed by the piecewise function of its load, ‘L’, defined by the minimum and maximum loads (Lmin and Lmax), and the corresponding efficiencies, as shown in Table 1.

Table 1.

PEM Electrolyzer parameters.

As the combined investment and operational optimization option in the oemof is used for this model, two important oemof objects are considered: The ‘Investment’ object within the ‘OffsetConverter’ for the determination of the optimal capacity to be installed, subject to a maximum investment cap. The variable costs of operation and the capital costs represented by the equivalent periodical costs (EPCs) of investment are included. The other ‘NonConvex’ object signifies that the model includes binary variables, allowing the optimization to decide between discrete operational states of the electrolyzer, such as on/off conditions, within the piecewise linear performance curve. Moreover, additional constraints are applied to the offset converters to ensure a realistic representation of a single PEM electrolyzer. These constraints are as follows:

- Equality of Investment Variables: This constraint ensures that the investment decisions across multiple electrolyzer operation modes are equal.

- Limit Active Flow Count: This constraint ensures that only one operation mode of the PEM electrolyzers can be active at any given time.

These constraints are implemented in this optimization model to control the investment strategy and operational scheduling of the electrolyzers, respectively. The equate_variables function from solph.constraints is used to apply the equality constraint, while the limit_active_flow_count method limits the number of active flows according to the defined lower and upper limits, effectively enforcing the operational constraint.

4.2. Hydrogen Storage

The hydrogen storage is modeled using the oemof ‘GenericStorage’ component. This component is versatile and can be adapted to various storage scenarios, including hydrogen storage. Theoretically, ‘GenericStorage’ in the oemof.solph models the storage dynamics based on a number of key parameters that are listed in the Appendix A.

Theoretically, this modeling approach enables the representation of the hydrogen storage’s physical and economic characteristics, integrating it seamlessly into the broader energy system model for optimization.

where the elements are defined as follows:

- Mstorage (t) is the mass of hydrogen in the storage at time t.

- Δt is the time step duration.

- in (t) is the mass flow rate of hydrogen into the storage at time t.

- out (t) is the mass flow rate of hydrogen out of the storage at time t.

- Losses (t) represents any losses from the storage, which could include leakage or other forms of loss.

This equation depicts the hydrogen storage system by accounting for the flow of hydrogen in and out of the storage, as well as any losses, across discrete time steps. The losses considered in this model are self-discharge losses, which may occur over time due to leakage or diffusion through the storage container. Unlike batteries, where self-discharge involves chemical reactions, hydrogen self-discharge is primarily a physical phenomenon. Hydrogen, being the smallest and lightest molecule, can diffuse through many materials, even metals, especially at high pressures. This diffusion can lead to a gradual loss of hydrogen over time. High-pressure tanks made from advanced composite materials are designed to minimize this leakage, but it cannot be entirely eliminated. The self-discharge loss rate for pressurized hydrogen storage systems is generally very low compared to that of other energy storage systems like batteries. Studies suggest that the self-discharge rate for well-designed pressurized hydrogen storage tanks is very low. This means that for a large-scale storage system, only a small fraction of the stored hydrogen is lost daily, making it suitable for long-term storage applications [47].

4.3. Methanol Synthesis

The methanol synthesis plant is usually modeled using specialized chemical engineering software such as Aspen Plus. However, these models are too complex for an optimizer. A simplified model with key information from the literature [48,49] is therefore implemented in the oemof using the generic component ‘Converter’. Moreover, the ‘Investment mode’ option is used for this component as well, which means that no maximum value is assigned, and the optimizer can freely choose the optimal capacity for the methanol synthesis unit. In addition, the capacity factor of methanol production is assumed to be 90%, which reflects the industry standards for well-optimized plants, accounting for typical operational efficiencies and downtimes. Conversion factors for input and output streams derived from the literature are used in the oemof model, which are representative of the results of complex models described in those works. The following equations mathematically represent these conversion factors:

Hydrogen is a key reactant in the production of methanol. This equation indicates that for every unit of methanol produced, 0.20 units of hydrogen are required. This ratio helps in determining the hydrogen demand based on the desired production rate of methanol.

Carbon dioxide is another crucial reactant in methanol production. According to this equation, for every unit of methanol produced, 1.48 units of carbon dioxide are consumed. This relationship is essential for calculating the CO2 requirements for methanol synthesis.

This equation provides the electrical energy requirement (PMeOH) for methanol production. It means that for every kilogram of methanol produced, 0.335 kWh of electrical energy is needed.

This equation quantifies the thermal energy required for the methanol production process. For every kilogram of methanol produced, 1.38 kWh of heat energy is needed. This helps in designing and managing the heat supply system for the production process.

The costs associated with methanol synthesis and other components are sourced from the literature or are calculated, and are listed in the Appendix A section of this work.

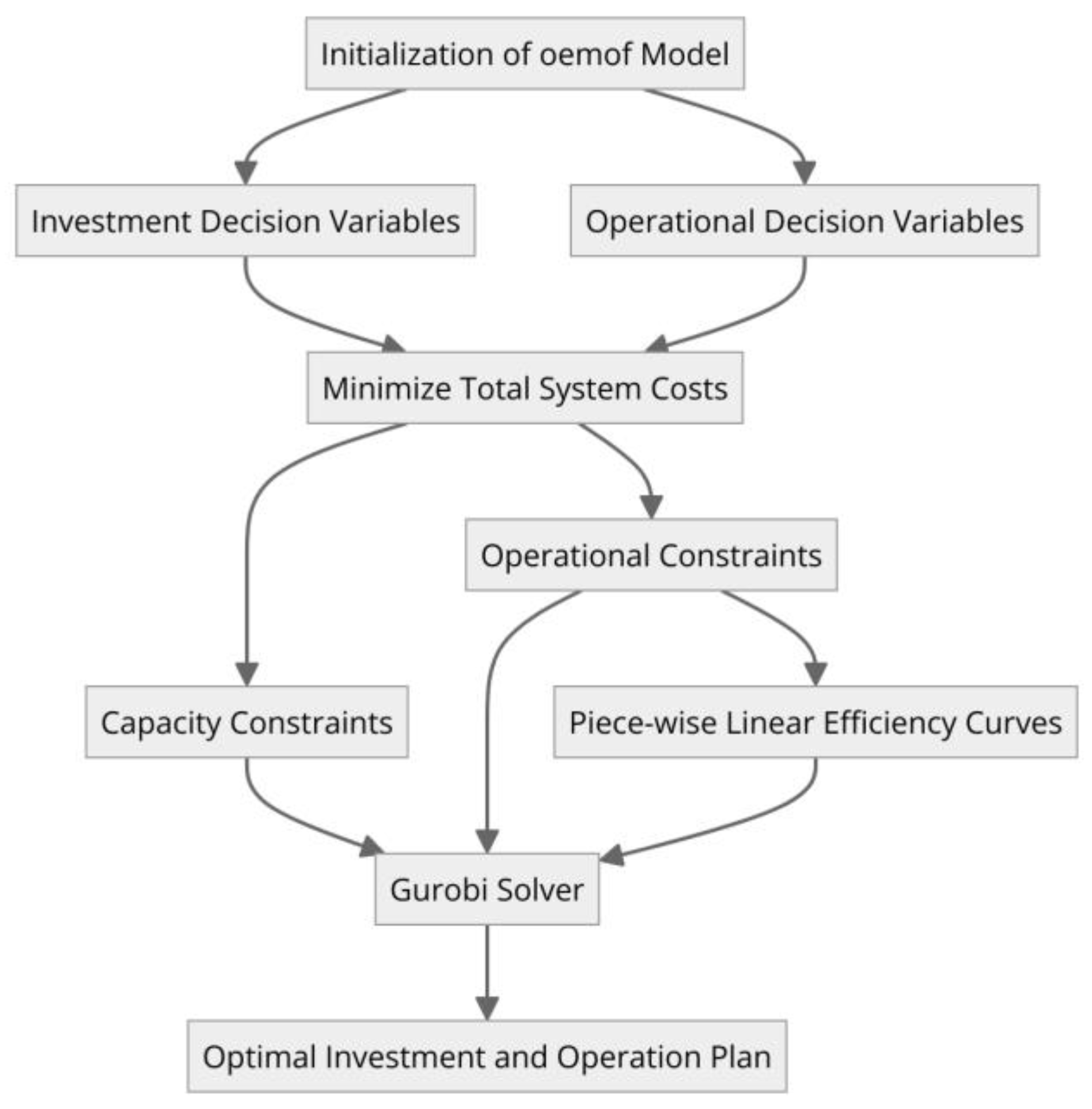

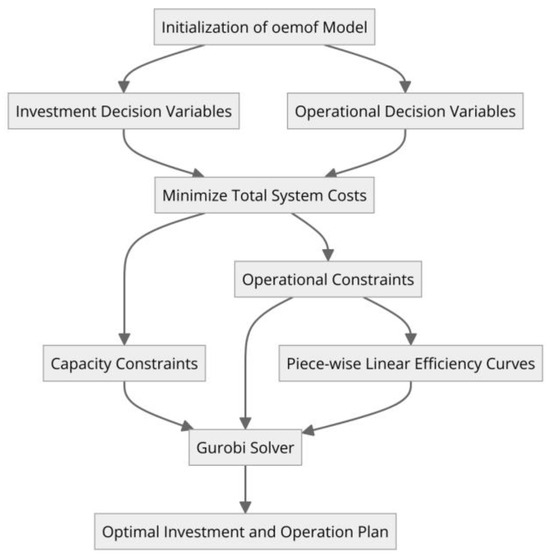

Within the oemof, the oemof.solph library provides a flexible environment for formulating linear and mixed-integer linear programming models, allowing for both operational and investment optimization in energy system analyses. Figure 4 elucidates how the oemof.solph concurrently determines investment and operational optimization. First, the model is initialized by defining the energy system components, such as sources, sinks, transformers, and storage units. Investment decision variables pertain to capacity additions or enhancements, while operational decision variables relate to the system’s temporal operations, including energy flows, generation, and consumption. The primary goal or the objective function is to minimize the total costs, which consist of the sum of variable costs for all the flows over time and the investment costs multiplied by the equivalent periodic costs for investments. The first term accounts for the operational costs while the second term accounts for the capital investment costs. This is mathematically represented as

Figure 4.

Modeling approach used in oemof.

Equation (9) represents the calculation of the equivalent periodic costs (epcosts) from capital expenditures (capex), weighted average cost of capital (WACC), and the asset’s lifetime. It essentially converts the upfront capital expenditure into a series of equal annual costs, factoring in the cost of capital over the asset’s lifetime.

Several constraints are considered in this optimization process. Operational constraints ensure that the system operates within the feasible limits of its components, such as ensuring that generation meets demand and that storage units operate within their capacity limits. Capacity constraints define the maximum and minimum capacities for investment decisions, preventing over-investment or under-investment in infrastructure. Additionally, the piecewise linear efficiency curves capture the non-linear efficiencies of components, such as the PEM electrolyzer.

The optimization problem, formulated as a mixed-integer linear programming (MILP) problem, is solved using the Gurobi solver (Gurobi Optimization, LLC, Houston, TX, USA). This solver identifies the optimal set of investment and operational decisions that minimize the total costs subject to the constraints. The outcome is an optimal configuration for the energy system, including both the necessary investments and the operational strategy over the considered time horizon.

Additionally, the optimization problem is subjected to the following constraints:

In this formulation, Xi are the investment decision variables, Yj,t are the operational decision variables, ηk,j represents the efficiency of component j in segment k. By integrating these elements, oemof.solph effectively combines investment planning with operational optimization, ensuring a cost-efficient and feasible energy system configuration.

5. Case Study

The repurposing of a closed coal power plant site to power-to-methanol was investigated using the model described in the previous section. The methodology for the optimal sizing and operation of the electrolyzer and hydrogen storage was evaluated for the case study and scenarios considered in the following section.

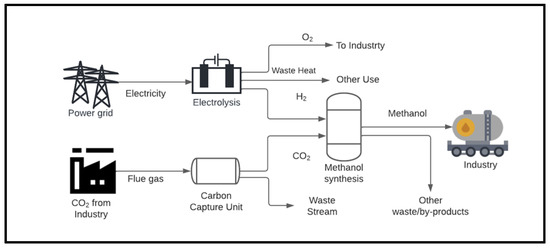

The considered use case is a closed coal power plant site located in the south of Austria. Due to its modern infrastructure, such as connections to the most important electricity transmission grids with different grid levels, the gas grid, and the district heating grid, as well as access to the cooling water capacities of a nearby river, the site is suited for repurposing to a power-to-methanol plant. The transportation infrastructure around the proposed site is also very good, with railway and highway connections nearby. The CO2 is sourced from a nearby industrial source, i.e., a cement plant. The investigated CO2 source was identified after an evaluation study was performed for potential CO2 sources in the vicinity of the coal plant. The electricity for the process was provided using the electricity grid, which is assumed to be renewable for this study. A graphical representation of the use-case is shown in Figure 5.

Figure 5.

Use case: power-to-methanol synthesis with industrial CO2 source.

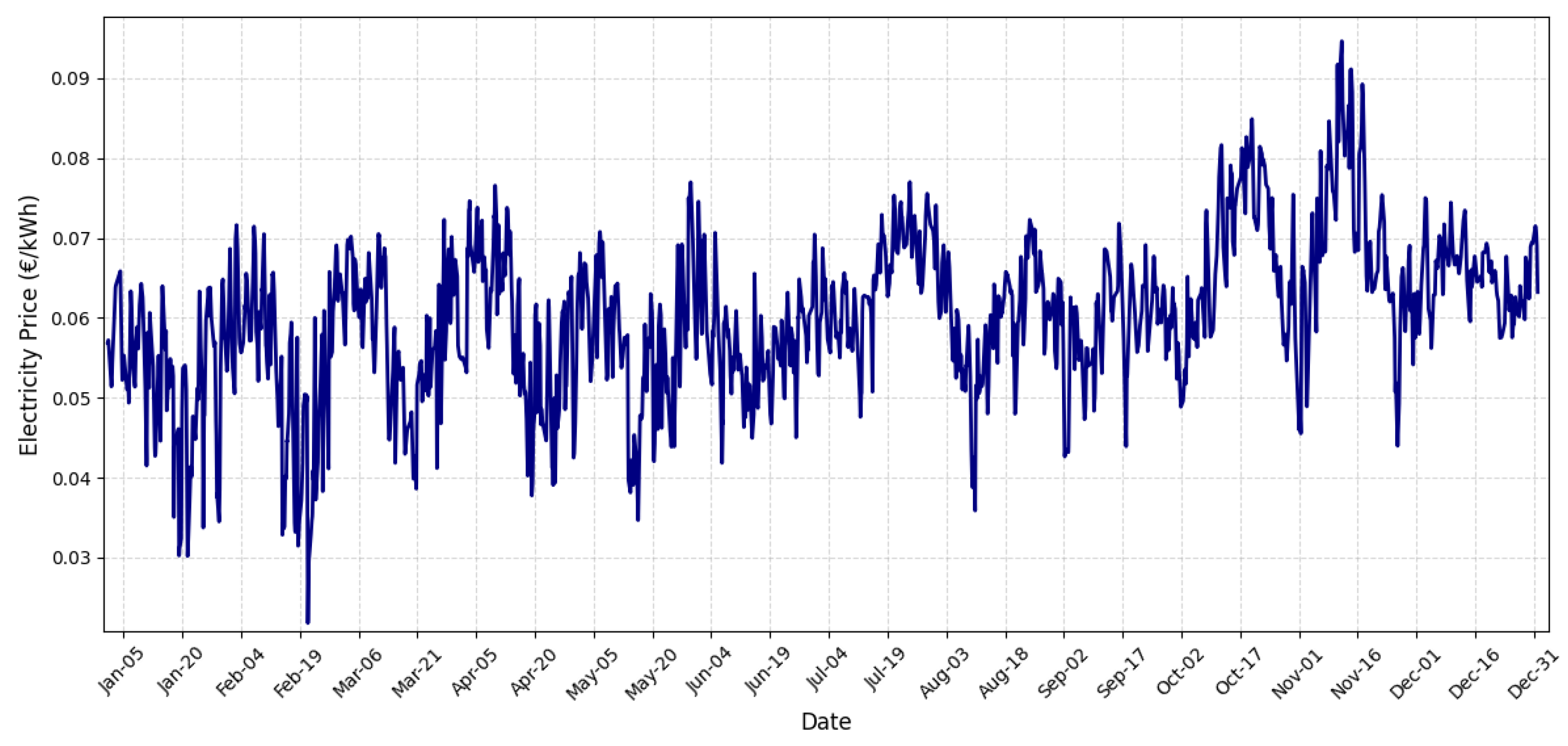

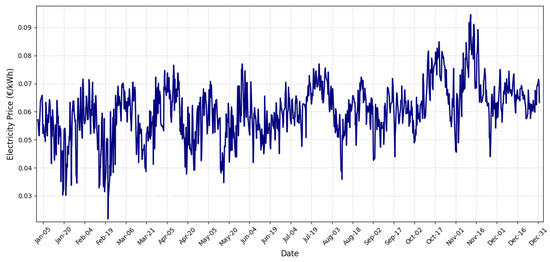

For the purposes of investment and operational optimization, the system is modeled by discrete time intervals of 1 h, yielding 8760 time steps for the considered time horizon of one year. This time frame allows us to take into account the seasonal behavior of hydrogen storage and scheduled maintenance breaks during the year for the equipment. The fact that this combined sizing and operational optimization problem can be solved in a reasonable time period is a benefit of the MILP-based model over a non-linear model, where we must use a short time frame for optimization. It is also assumed that there are no limitations in terms of the power availability. The annual electricity price curve for 2030 is obtained from [2], as shown in Figure 6, whose authors used curve-fitting on scaled 2020 data from the Energy Exchange Austria power exchange. The renewable sources on-site are not considered separately, as the on-site renewable potential for this site is negligible. For the current site location in Austria, the high penetration of renewables in the electricity grid is assumed. Moreover, heat integration between the processes is assumed. The heat integration is not explicitly modeled, but given the calculations performed for the availability of waste heat in the processes considered and their operation schedule, it can be said that the required heat for the relevant component can be sourced from the neighboring components and processes. In the case of the carbon capture unit, it is assumed that the heat can be supplied by the relevant industry where the plant is installed. For this specific use case, a carbon capture unit is installed at a cement factory which can provide heat for the process. For methanol synthesis, the heat can be supplied via the waste heat recovered from the PEM electrolyzer, where 14–15% of the electricity input to the stack can be utilized as heat [50]. Additional transportation expenses between energy system nodes are disregarded (no spatial resolution) and perfect foresight is assumed concerning time indexed parameters. The annualized cost of methanol production (CMeOH) is used as a metric to compare different scenarios.

Figure 6.

Annual electricity price curve for 2030.

6. Optimization Setup

The combined investment and operation optimization problem was formulated as a MILP problem in oemof v0.5.2 and solved on an AMD Ryzen 5 2400G 3.6 GHz CPU with 47 GB RAM (Advanced Micro Devices, Inc. (AMD), Santa Clara, CA, USA) with the Gurobi solver to tackle a complex problem characterized by 306,614 constraints and 236,533 variables with 744,621 non-zero elements. The solver parameters were specifically adjusted to meet the demands of the problem, including setting the nonconvex parameter to 2 to manage nonconvexity and reducing the MipGap to 0.05 to tighten the optimality gap. Significant enhancements in the solver performance were achieved through strategic modifications such as adjusting the Seed to 123 for better control over heuristic methods and fine-tuning additional parameters like AggFill and BarConvTol. The presolve process effectively reduced the problem size from its original scale to 145,070 rows and 93,041 columns, demonstrating the solver’s capability to simplify complex matrices efficiently. Additionally, the model includes a variety of variable types, with one quadratic constraint, illustrating the comprehensive utilization of continuous and binary integer variables. The solver’s resource management was optimized by using 4 computation threads, ensuring a balanced distribution of computational load. The detailed presolve and root barrier logs used aided in enhanced computational efficiency and potentially improved the solution quality for this model.

7. Results and Discussion

In this section, the results for the optimization of the case study described in the preceding section are discussed. At first, the general model behavior is discussed following with the optimized capacities. The discussion is carried out based on the perspective of repurposing the former coal power plant site and from a potential new investment in a power-to-fuel plant, since this paper provides prospective data for former coal power plant owners to forecast new investments in power-to-methanol plants with due consideration given to the operational flexibility provided by the electrolyzer and hydrogen storage. The chosen MILP approach allows for a longer time frame to be considered during the optimization process, enabling the better optimization of the operational behavior and opens prospective avenues for capturing the seasonal behavior of plants specially when on-site renewable energy input is considered.

7.1. General Model Behavior

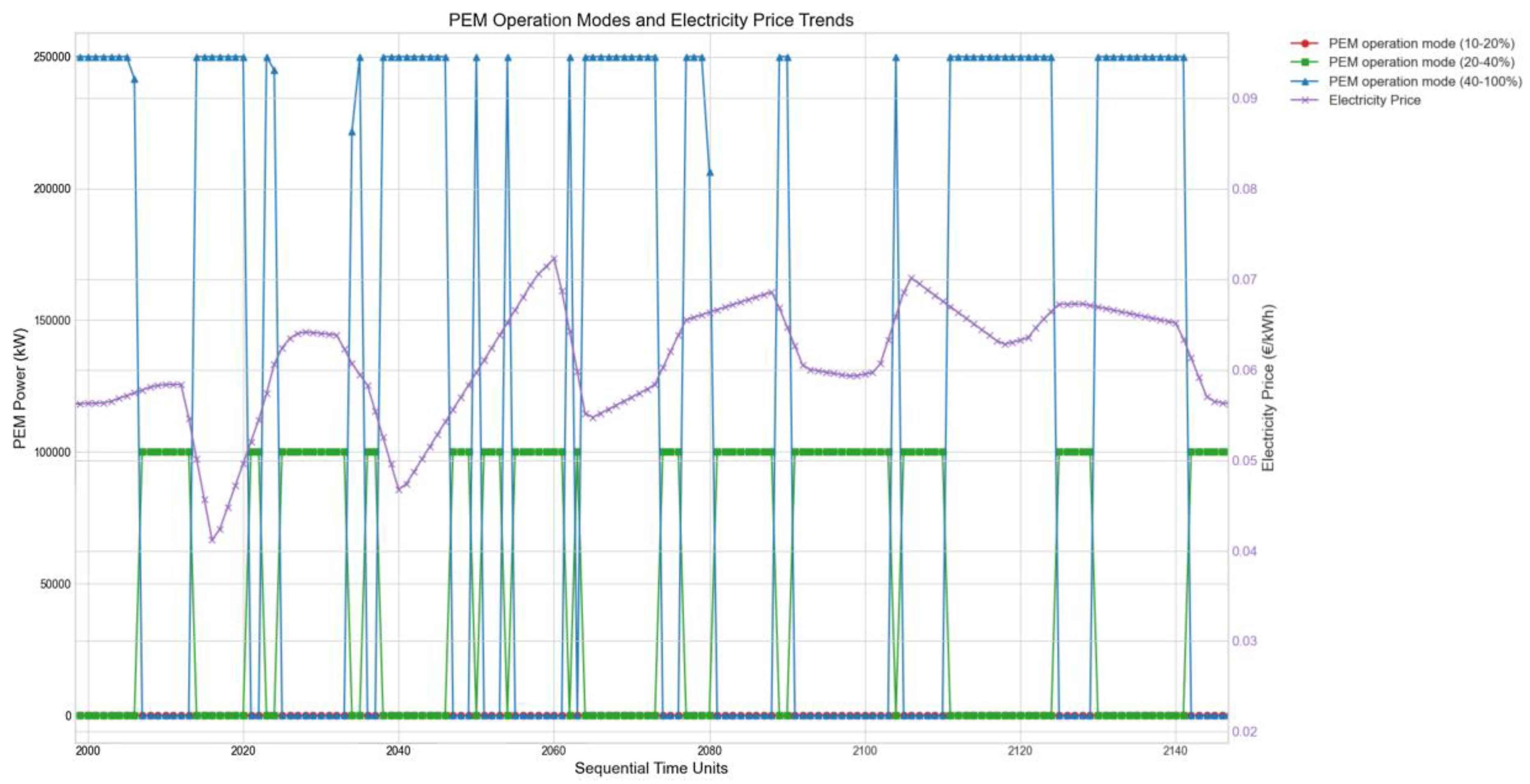

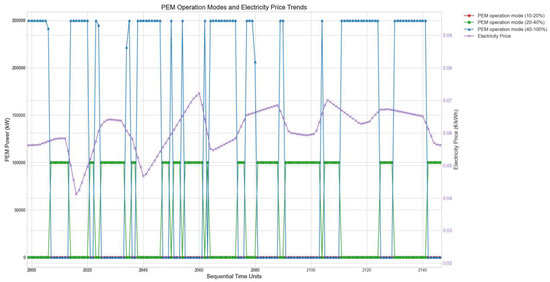

In order to analyze the behavior of the system, the calculation is performed over a full year of operation (8760 time steps). For clarity, only segments of the behavior of the model are discussed in this section that are representative of the operation for the rest of the time steps. The dispatch curve of the electrolyzer is shown in Figure 7. The part-load characteristics of the PEM electrolyzer are represented by three different operation modes in the model. It is observed that the electrolyzer operation is affected with the variation in electricity prices. When the electricity price is high, especially at its peak, the electrolyzer exhibits significant part-load behavior for more efficient operation. Similarly, at a lower electricity price, the electrolyzer tends to operate at full load to reach its maximum production. Collectively, this behavior underscores the interplay between the operational modes of the PEM systems and electricity market fluctuations.

Figure 7.

Dispatch curve for PEM electrolyzer.

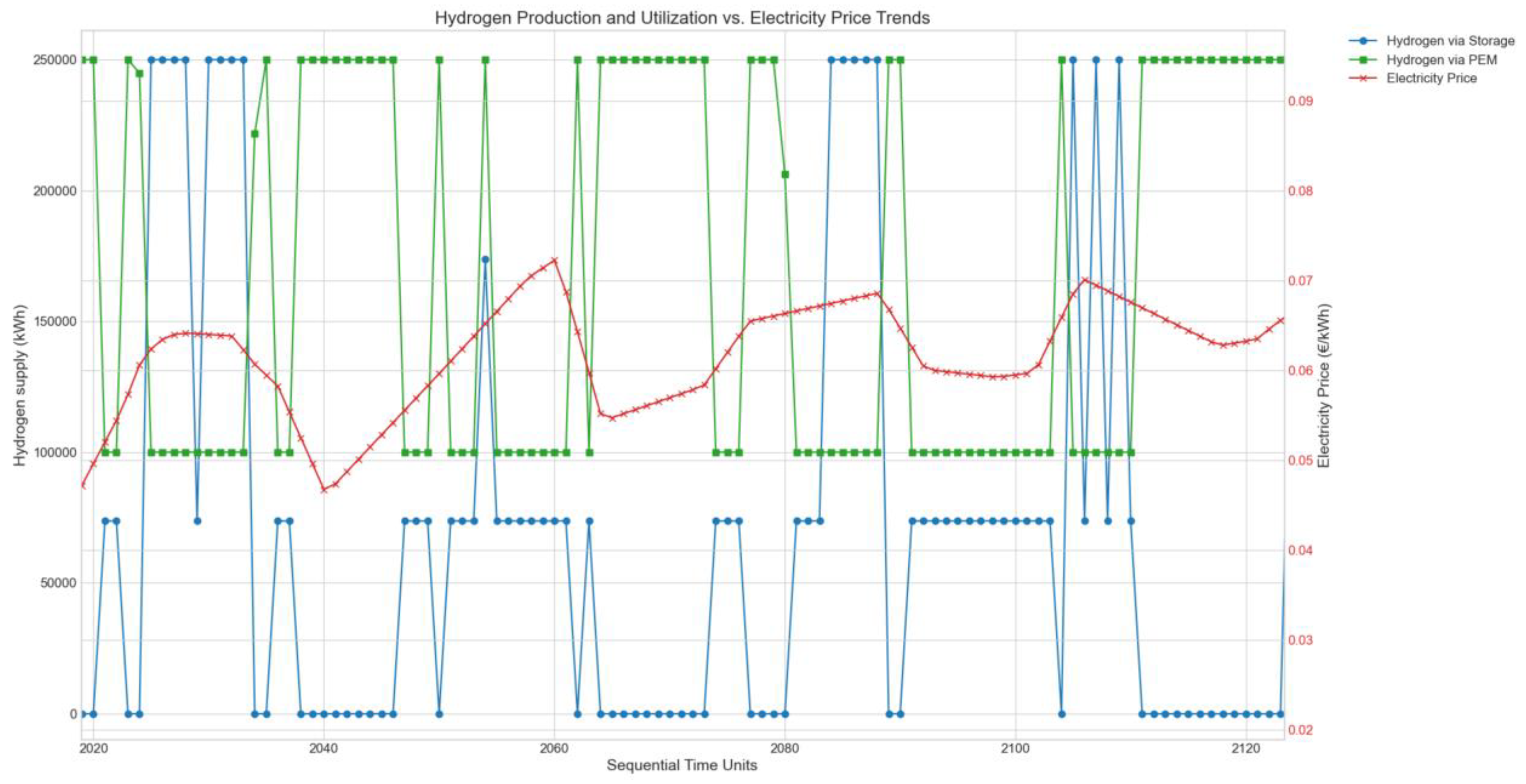

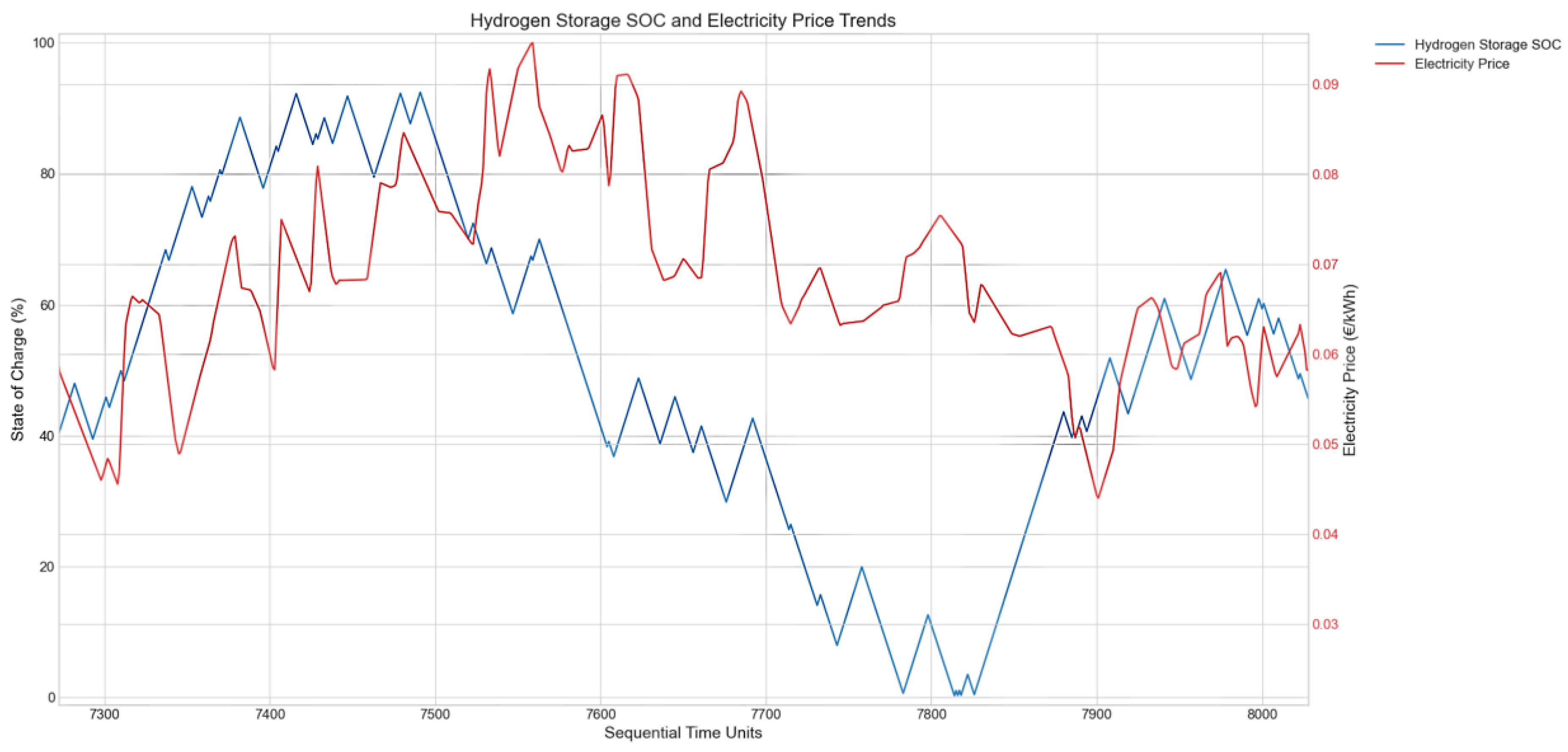

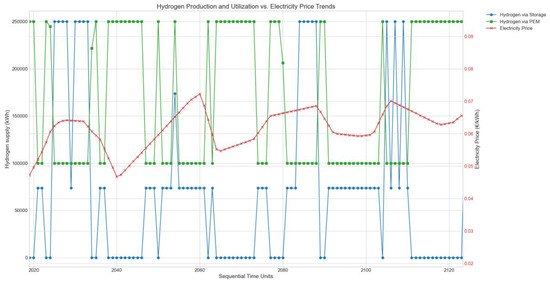

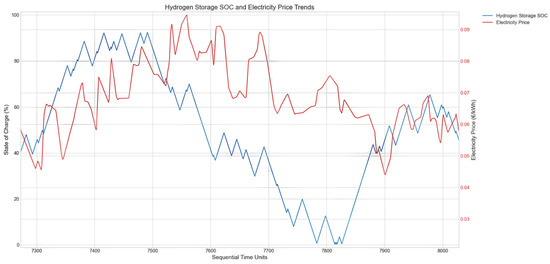

Figure 8 shows the H2 dispatch from the PEM electrolyzer and hydrogen storage depending on the need of the methanol production and electricity price trend. It can be observed that the storage takes advantage of the low electricity prices and discharges when the electricity prices are relatively higher. In some instances, the PEM electrolyzer shifts its production to part-load and supply from the hydrogen storage kicks in when the electricity peaks are observed. Figure 9 represents the state of charge with respect to the electricity prices. It can be observed that the state of charge (SOC) for hydrogen storage corresponds to the electricity price trend, i.e., charging during relatively low-price periods and vice versa. However, in some cases, the SOC seems to consider the future electricity price trend to keep itself charged or discharged. This is because the whole year of operation is optimized by the optimization model; therefore, in some cases, the hydrogen storage is charged or discharged at an unusual time, but the optimizer foresees that this is optimal from the upcoming electricity price trend.

Figure 8.

Hydrogen dispatch from PEM electrolyzer and storage.

Figure 9.

State of charge (SOC) of hydrogen storage with respect to electricity price.

7.2. Optimized Capacities and Operation

In this section, the results for the combined investment and operational optimization performed for the use case are described. These results are calculated for a set of input parameters suitable for the use case at hand and might differ for other use cases so they should be chosen by the user of the optimization model depending on the use case at hand. The dependence of the results on the input parameters and sensitivity will be discussed in the next section of this work.

For the current use case, a total of 318.035 kt/a of CO2 is captured and utilized for methanol production. The model is un-constrained as far as the capacity selection for the individual components is concerned. As a result, the optimizer determined that the optimal capacity for the methanol synthesis plant is 214.889 kt/a with a PEM electrolyzer sized at 434.283 MW and no hydrogen storage necessary at a cost of EUR 1.564/kg of methanol, as shown in Table 2.

Table 2.

Optimal capacities and operation for MILP model.

An iterative analysis with constrained capacities revealed that higher costs are incurred when the capacities are constrained under different operational patterns. In certain scenarios, it may be necessary to impose capacity constraints, prompting the optimizer to adjust the results according to these new conditions. For lower nominal capacities, a CO2 penalty is applied because not all of the captured CO2 is utilized. It is observed that the optimal capacity determined operates at approximately 8000 part-load hours annually. This behavior is attributed to the higher efficiency achieved during part-load operation. However, bear in mind that the calculated cost of methanol production is highly dependent on the scenarios and input data used for the optimization model. However, the cost of methanol production for this case study is within a range comparable to other works [19,51,52]. Also, this optimization model can be tailored according to the needs of the user and constrained accordingly. For instance, a use case where the maximum allowed capacity for the PEM electrolyzer is constrained or hydrogen storage is a must-have can be defined.

7.3. Comparison with Linear Model

A comparative analysis revealed a higher cost of methanol production when using a linear programming (LP) model in contrast to a mixed-integer linear programming (MILP) model as shown in Table 3. This section explains the potential reasons behind this result and its implications for the modeling of methanol production systems.

Table 3.

Optimal capacity and operation for linear model.

In our investigation, the linear programming (LP) model demonstrated a higher cost primarily due to the simplification of the constraints, which did not account for the possibility of the highly efficient part-load behavior of the PEM electrolyzer’s operation. This approach leads to an underestimation of the practical operational costs. In contrast, the mixed integer linear programming (MILP) model, by incorporating detailed and restrictive constraints, more accurately captures the complexities and discrete decisions involved in operations, resulting in lower cost projections. These findings suggest that the MILP model can also be utilized effectively for a broad preliminary analysis and scenario exploration due to its ability to capture more detail at a comparable computational expense when compared to a linear model. In addition, the MILP model offers a more detailed and pragmatic approach for the strategic planning and robust operation of methanol production facilities, making it suitable also for detailed planning and investment decision-making in deploying efficient and economically viable systems.

8. General Discussion

The optimization model developed in this study effectively minimizes the total cost of methanol production by integrating capital expenditures (CAPEX), operational expenditures (OPEX), and carbon emission penalties into its objective function. This comprehensive approach significantly influences decisions regarding the optimal capacity of the proton exchange membrane (PEM) electrolyzer and its operational scheduling. By accounting for short-term variability in electricity prices and the availability of input resources, the model dynamically adjusts the operation of the PEM electrolyzer to capitalize on periods when electricity is most economical. Notably, considering the PEM electrolyzer’s efficiency at varying load levels ensures accurate performance modeling and alignment with cost-effective operational periods.

For the specific use case analyzed, the model identifies an optimal PEM electrolyzer capacity of 434 MW, effectively balancing the trade-off between higher CAPEX associated with larger capacities and the limitations of smaller capacities in meeting peak demands or fully exploiting low electricity prices. This capacity allows the system to operate flexibly, adjusting between full-load and part-load operations to align with periods of low electricity prices and high efficiency. The decision to exclude hydrogen storage is notable; the model determines that the additional capital costs of storage infrastructure outweigh the benefits of mitigating electricity price fluctuations. This finding suggests that, under the given market conditions and cost parameters, investing in a larger electrolyzer capacity is more economically advantageous than incorporating storage solutions.

The model’s ability to dynamically adjust operations and strategically invest in capacities demonstrates its potential for practical application in the methanol production industry. By identifying the “sweet spot” where capacity and operational strategy minimize costs, producers can enhance profitability while contributing to carbon emission reduction efforts. The exclusion of hydrogen storage in the optimal solution suggests that investments might be better allocated toward increasing the electrolyzer capacity or improving the operational flexibility.

However, the model’s performance is predicated on the assumption of perfect foresight of electricity prices, which is unrealistic due to the inherent unpredictability of electricity markets influenced by factors such as weather variability, demand fluctuations, regulatory changes, and market dynamics. This assumption likely results in an optimistically efficient operational schedule that may not fully reflect real-world conditions. Consequently, the model’s strategies might underperform when subjected to actual market volatility, potentially impacting the economic viability and operational feasibility.

Additionally, the model assumes constant methanol demand and fixed technological parameters, which may not hold true over time. Environmental impacts other than carbon emissions, such as water usage or land requirements, are not considered, potentially overlooking important sustainability factors.

To address these limitations, future models should incorporate uncertainty quantification and probabilistic forecasting to better capture the market volatility. Techniques such as stochastic optimization or robust optimization can account for uncertainties in electricity prices and other critical parameters. Incorporating real-time data updates and enhancing market responsiveness would improve the model’s practical applicability. Leveraging machine learning and artificial intelligence methodologies could enhance the accuracy of electricity price forecasts, enabling more realistic operational planning.

Given that the optimization model’s outcomes are highly dependent on specific constraints and assumptions, caution is warranted when adapting it to different scenarios. The most critical constraints—such as the nominal capacity of the PEM electrolyzer, CO2 emission costs, methanol selling price, and PEM CAPEX—significantly influence the results. The effects of these constraints on the model’s performance are analyzed in the following subsections.

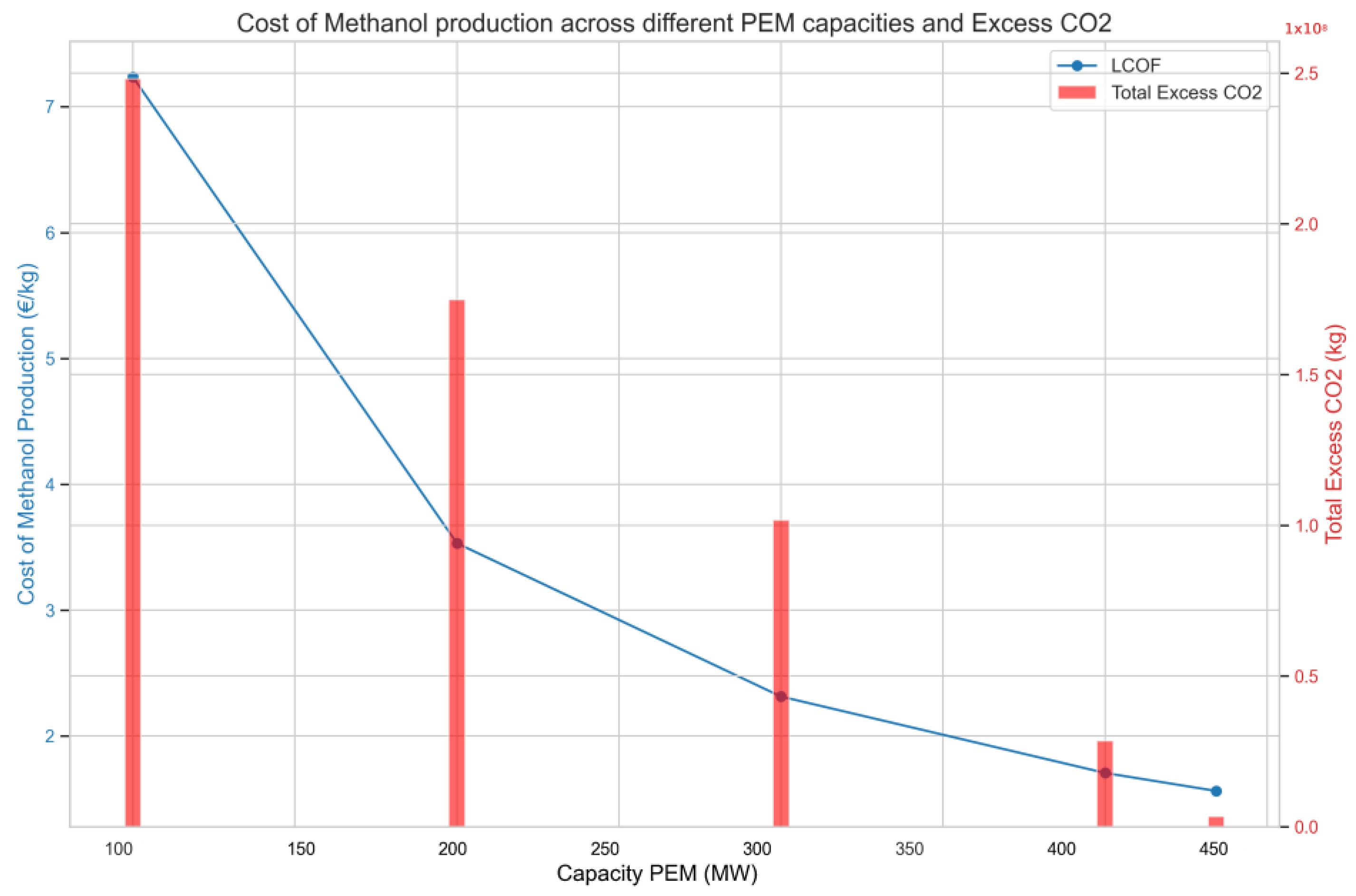

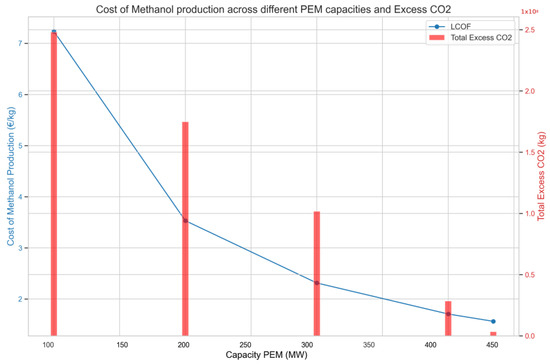

8.1. Effect of Nominal Value of Electrolyzer Capacity

The option to operate at part-load leads the optimizer to choose a larger electrolyzer size when using the combined sizing and operational approach. It is observed that the cost of methanol production varies significantly when only the capacity constraint is applied, and other input variables remain the same, as seen in Figure 10. This, on one hand, verifies that the optimization model is working accurately; thus, there are higher costs for any capacity other than the optimal one. This is since excess CO2 and the costs associated with it are accounted for at lower capacities. An un-constrained model with respect to the nominal capacity of the PEM electrolyzer tends to opt for an electrolyzer with a capacity of 434 MW, which operates at mostly part-load. On the other hand, when the nominal capacity is constrained, the operation behavior changes with increased full-load hours. All of the available CO2 is not used for methanol production and excess CO2 costs are incurred.

Figure 10.

Cost of methanol production across PEMs of different capacities and excess CO2.

8.2. Effect of Excess CO2 cost and Methanol Selling Price

This constraint is tested in combination with the methanol selling price. Constraints such as the cost of emitting CO2 and the incentive to produce methanol have an impact on the behavior of the optimization model. An iterative analysis was performed to assess the sensitivity for this purpose. With a low CO2 excess price, the model tends to produce no methanol at all since it is too expensive to do so when compared to dumping CO2 into an excess sink. With this approach, it can be said that for methanol production to be economically feasible, the cost of emitting CO2 should be higher. At a CO2 price of EUR 100/ton, the model returned a minimum methanol selling price of EUR 1.4/kg, which is higher than that of conventionally produced methanol, suggesting that, under this carbon pricing scenario, power-to-methanol remains less competitive. However, as the CO2 price increases, the methanol price decreases significantly. At a CO2 price of EUR 400/ton, the methanol price drops to EUR 1/kg, indicating a notable improvement in competitiveness. Further increasing the CO2 price to EUR 500/ton results in a methanol price of EUR 0.8/kg, approaching the price of conventionally produced methanol. These findings demonstrate an inverse relationship between the CO2 price and methanol selling price, where higher carbon prices incentivize lower production costs for power-to-methanol, making it more economically viable. The results suggest that a CO2 price of EUR 400/ton or higher is a critical threshold for making power-to-methanol competitive with conventional methanol. Thus, substantial increases in carbon pricing are essential for incentivizing the adoption of green methanol production, reinforcing the role of carbon pricing policies in promoting e-fuel technologies. This analysis aligns with the findings from similar studies, reinforcing the importance of high carbon pricing in fostering the adoption of green methanol production [53]. Further detailed analyses, including a deeper exploration of alternative scenarios and economic sensitivities, will be addressed in future studies, as this falls outside the scope of the current work.

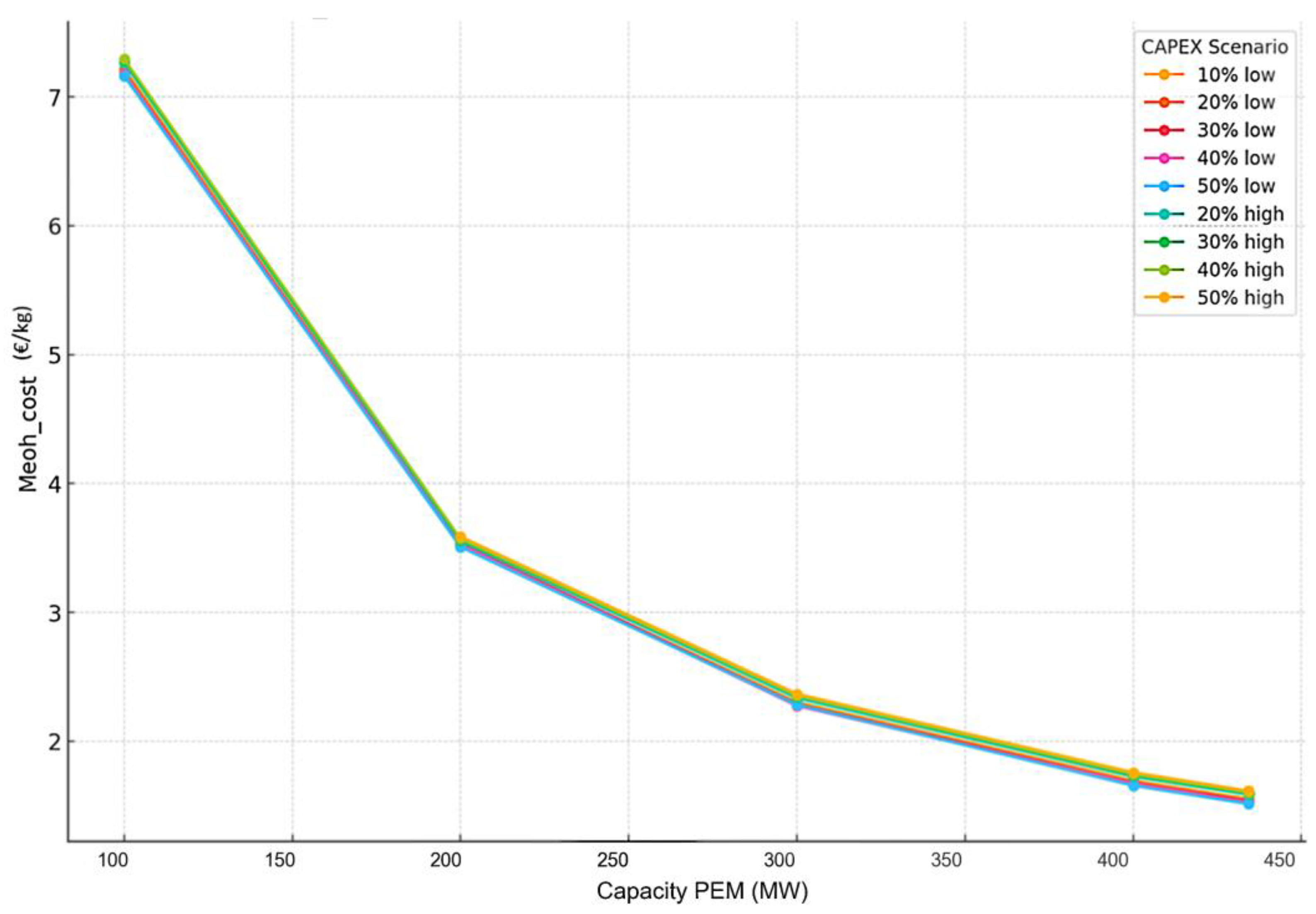

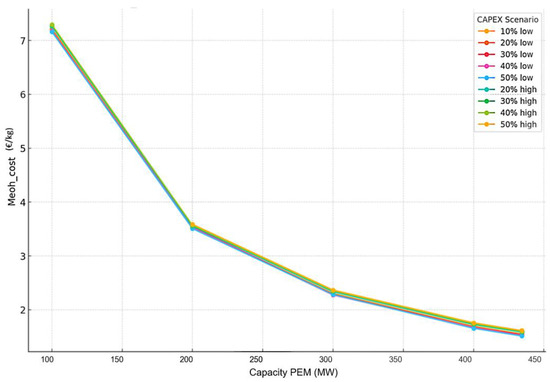

8.3. Effect of PEM CAPEX on Optimization Results

In this section, the relationship between the PEM-specific CAPEX scenarios and the cost of methanol is investigated. Across various CAPEX scenarios, the methanol cost shows minimal variation as shown in Figure 11, indicating that the PEM capacity has a far more substantial impact on reducing costs than changes in the capital expenditure. This suggests that strategic investments in scaling up the PEM capacity are crucial for achieving cost-efficient methanol production, making it a key focus area for advancing the green hydrogen economy. The findings highlight the robustness of PEM systems against CAPEX fluctuations, emphasizing the importance of capacity expansion in driving down production costs. The varying CAPEX scenarios (low to high) also serve as a risk assessment tool. Projects with low sensitivity to CAPEX changes (as observed with methanol cost) are likely more resilient to market fluctuations in capital costs. This resilience is a critical consideration for long-term investments in green hydrogen and methanol production infrastructure. Furthermore, this sensitivity analysis also revealed that a provision of hydrogen storage can be added when the CAPEX PEM increases by 30%.

Figure 11.

Sensitivity analysis for PEM investment cost.

8.4. Computation Efficiency

In the context of solving mixed-integer linear programming (MILP), especially when employing frameworks like the oemof in combination with the Gurobi solver, the computational efficiency is markedly improved, with typical solution times ranging from seconds to minutes, with results meeting the criteria of the desired optimality gap of 1%. This is a significant enhancement compared to the extensive computational durations required for mixed-integer non-linear programming (MINLP), which often span hours or even days. For instance, at the optimal capacity of 435 MW determined for the use case described in the previous section, Table 4 represents the computational results.

Table 4.

Computational results for the use case.

For example, Mucci et al. [19] imposed a 12-h CPU time limit, yet in most cases, the relative difference between the upper bound (the best feasible solution found) and the lower bound (the best possible solution) failed to meet the desired optimality gap within this period, precluding the assurance of global optimality. In contrast, the present model accomplishes similar tasks within a few minutes, underscoring its superior capability to deliver rapid results. It should be noted that the introduction of constraints, such as the PEM capacity constraint, may impact the computational time limit. For instance, when a capacity restriction of 250 MW is applied, the model takes approximately 120 min to deliver the results.

9. Conclusions and Future Work

This study introduces and elaborates on a hybrid strategy that integrates investment and operational optimization for power-to-methanol (PtM) systems, employing mixed-integer linear programming (MILP) models for faster run times. This paper presents a robust framework that encapsulates the essential elements of PtM systems, setting the stage for further research into a holistic optimization methodology. Our discussion underscores that the optimal capacity and operation of PtM facilities are intricately linked to a variety of technical and economic factors, which are, in turn, informed by prior techno-economic assessments. It can also be concluded that constraints such as the nominal value of the electrolyzer capacity, excess CO2 costs, and the selling price of methanol can have a substantial impact on the results of the optimization model. Other input parameters, such as electricity prices, have a significant effect on the model’s operational behavior. The results indicate that larger nominal capacities are preferred over smaller capacities when the system can operate flexibly and with part-load characteristics. It is also discussed how a large electrolyzer capacity with part-load characteristics provides a stable and predictable load for grid management, aiding load forecasting, distribution planning, and grid stabilization, crucial for ensuring system stability and integrating renewable energy sources efficiently, thereby supporting the transition to a sustainable energy system. This integrated optimization approach is pertinent to PtM plants and holds potential applicability across other synthetic fuel production processes, including synthetic natural gas and Fischer–Tropsch fuels. Future explorations may delve into assessing the economic feasibility of such ventures, considering potential revenue streams from the sale of synthetic fuels and carbon credits. Moreover, considering the volatility of electricity market prices and the integration of renewable energy sources, a critical analysis of return on investment will augment our understanding of the economic dynamics influencing the PtM process. Market dynamics, including the projection of synthetic fuel demand, distribution strategy development, and the influence of local global market trends on energy policy, constitute significant factors that merit comprehensive investigation. Future research can also investigate the large-scale integration and economic optimization of power-to-methanol technologies within existing energy systems to enhance grid resilience and diversify energy sources.

Author Contributions

Conceptualization, N.A. and T.K.; methodology, N.A. and T.K.; software, N.A.; validation, N.A. and T.K.; formal analysis, N.A.; investigation, N.A.; data curation, N.A.; writing—original draft preparation, N.A.; writing—review and editing, T.K.; visualization, N.A; supervision, T.K.; project administration, N.A.; funding acquisition, T.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Research Fund for Coal and Steel under Grant Agreement No. 101034035. The APC was funded by Montanuniversität Leoben.

Data Availability Statement

The datasets presented in this article are not readily available because of data protection reasons. Requests to access the datasets should be directed to the corresponding author.

Acknowledgments

The authors would like to thank David Banasiak and Thomas Kurz for the fruitful discussions during the development of this work.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of the data; in the writing of the manuscript, or in the decision to publish the results.

Appendix A

Table A1.

Cost parameters for different technologies.

Table A1.

Cost parameters for different technologies.

| Technology | Sp. Investment Costs | Variable Cost Factor | Other Cost/Cost Factor | Additional Parameters | Reference |

|---|---|---|---|---|---|

| PEM | EUR 519.39/kW | 0.04 × EPCPEM | 1.75 | Lifetime: 20 y Interest rate: 7% | [19] |

| Methanol | EUR 0.350/kg | 0.535 × EPCMeoh | EUR 0.001/MWh | Lifetime: 20 y Interest rate: 7% | [19,49] |

| Hydrogen storage | EUR 13.50/kWh | - | - | Pressure: 160 bar | [19,54,55] |

| Compressor | EUR 360/kW | - | - | Compressor size 5000 kW (calculated) | [56] |

| CO2 capture | EUR 0.025/kg | - | - | - | [calculated] |

Table A2.

Nominal capacities assumed for technologies.

Table A2.

Nominal capacities assumed for technologies.

| Component | Value | Unit | Description |

|---|---|---|---|

| Max grid electricity supply | 1,000,000 | kW | Maximum capacity of electricity supply from the grid |

| CO2 supply | 1 × Cflow | kg/s | Maximum CO2 supply capacity from CCU |

| PEM electrolyzer capacity | 500,000 | kW | Maximum electrical input capacity of the PEM electrolyzer |

| Hydrogen storage capacity | 500,000 | kW | Maximum hydrogen storage capacity |

| Hydrogen compressor capacity | 500,000 | kW | Maximum capacity of the hydrogen compressor |

| Methanol synthesis capacity | Unlimited | kg/h | Maximum capacity of the methanol synthesis unit (assumed unlimited) |

| Methanol demand | 30,000 | kg/h | Methanol demand at the sink (market demand or offtake agreement) |

| Compressor power | 5000 | kW | Rated power of the hydrogen compressor |

References

- Mark, P.; Esme, S. UK to Close Last Coal Power Station after 142 Years. BBC News [Online]. 30 September 2024. Available online: https://www.bbc.com/news/articles/c5y35qz73n8o (accessed on 20 November 2024).

- Traupmann, A.; Greiml, M.; Steinegger, J.; Kühberger, L.; Kienberger, T. Analysing sector coupling technologies for Re-purposing coal-fired power plants–Case study for the ENTSO-E grid. IET Energy Syst. Integr. 2023, 5, 95–118. [Google Scholar] [CrossRef]

- Qvist, S.; Gładysz, P.; Bartela, Ł.; Sowiżdżał, A. Retrofit Decarbonization of Coal Power Plants—A Case Study for Poland. Energies 2021, 14, 120. [Google Scholar] [CrossRef]

- Nouman, A.; Thomas, K.; Julia, B.; Lorenz, J. Combined Investment and Operational Optimization of Power-to-Fuel Plants at Closed Coal Power Plant Sites. In Proceedings of the 3rd International Sustainable Energy Conference (ISEC) 2024, Graz, Austria, 10–11 April 2024. [Google Scholar]

- Dieterich, V.; Buttler, A.; Hanel, A.; Spliethoff, H.; Fendt, S. Power-to-liquid via synthesis of methanol, DME or Fischer–Tropsch-fuels: A review. Energy Environ. Sci. 2020, 13, 3207–3252. [Google Scholar] [CrossRef]

- Brown, T.; Hampp, J. Ultra-long-duration energy storage anywhere Methanol with carbon cycling. Joule 2023, 7, 2414–2420. [Google Scholar] [CrossRef]

- Urbanucci, L. Limits and potentials of Mixed Integer Linear Programming methods for optimization of polygeneration energy systems. Energy Procedia 2018, 148, 1199–1205. [Google Scholar] [CrossRef]

- Schmeling, L.; Buchholz, A.A.I.; Heineke, H.; Klement, P.; Hanke, B.; Maydell, K.V. Planning, Optimisation and Evaluation of Small Power-to-Gas-to-Power Systems: Case Study of a German Dairy. Available online: https://www.mdpi.com/2071-1050/14/10/6050/htm#B22-sustainability-14-06050 (accessed on 7 October 2022).

- Schulte Beerbühl, S.; Fröhling, M.; Schultmann, F. Combined scheduling and capacity planning of electricity-based ammonia production to integrate renewable energies. Eur. J. Oper. Res. 2015, 241, 851–862. [Google Scholar] [CrossRef]

- Marocco, P.; Ferrero, D.; Martelli, E.; Santarelli, M.; Lanzini, A. An MILP approach for the optimal design of renewable battery-hydrogen energy systems for off-grid insular communities. Energy Convers. Manag. 2021, 245, 114564. [Google Scholar] [CrossRef]

- Allman, A.; Palys, M.J.; Daoutidis, P. Scheduling-informed optimal design of systems with time-varying operation: A wind-powered ammonia case study. AIChE J. 2019, 65, e16434. [Google Scholar] [CrossRef]

- Zheng, Y.; You, S.; Bindner, H.W.; Münster, M. Incorporating optimal operation strategies into investment planning for wind/electrolyser system. CSEE J. Power Energy Syst. 2022, 8, 347–359. [Google Scholar] [CrossRef]

- Zhang, Q.; Martín, M.; Grossmann, I.E. Integrated design and operation of renewables-based fuels and power production networks. Comput. Chem. Eng. 2019, 122, 80–92. [Google Scholar] [CrossRef]

- Gabrielli, P.; Gazzani, M.; Mazzotti, M. Electrochemical conversion technologies for optimal design of decentralized multi-energy systems: Modeling framework and technology assessment. Appl. Energy 2018, 221, 557–575. [Google Scholar] [CrossRef]

- Wassermann, T.; Mühlenbrock, H.; Kenkel, P.; Thöming, J.; Zondervan, E. Optimization of hydrogen supply from renewable electricity including cavern storage. Phys. Sci. Rev. 2023, 8, 4981–5021. [Google Scholar] [CrossRef]

- Mitra, S.; Pinto, J.M.; Grossmann, I.E. Optimal multi-scale capacity planning for power-intensive continuous processes under time-sensitive electricity prices and demand uncertainty. Part I: Modeling. Comput. Chem. Eng. 2014, 65, 89–101. [Google Scholar] [CrossRef]

- Mitra, S.; Pinto, J.M.; Grossmann, I.E. Optimal multi-scale capacity planning for power-intensive continuous processes under time-sensitive electricity prices and demand uncertainty. Part II: Enhanced hybrid bi-level decomposition. Comput. Chem. Eng. 2014, 65, 102–111. [Google Scholar] [CrossRef]

- Yang, Z.; Ren, Z.; Li, H.; Sun, Z.; Feng, J.; Xia, W. A multi-stage stochastic dispatching method for electricity-hydrogen integrated energy systems driven by model and data. Appl. Energy 2024, 371, 123668. [Google Scholar] [CrossRef]

- Mucci, S.; Mitsos, A.; Bongartz, D. Cost-Optimal Power-to-Methanol: Flexible Operation or Intermediate Storage. 2023. Available online: https://arxiv.org/pdf/2305.18338.pdf (accessed on 6 October 2023).

- Grossmann, I.E.; Biegler, L.T. Part II. Future perspective on optimization. Comput. Chem. Eng. 2004, 28, 1193–1218. [Google Scholar] [CrossRef]

- Halmschlager, D.; Beck, A.; Knöttner, S.; Koller, M.; Hofmann, R. Combined optimization for retrofitting of heat recovery and thermal energy supply in industrial systems. Appl. Energy 2022, 305, 117820. [Google Scholar] [CrossRef]

- Angarita, J.L.; Jafari, H.; Mohseni, M.; Al-Sumaiti, A.S.; Heydarian-Forushani, E.; Kumar, R. Optimal investment and operation of a microgrid to provide electricity and heat. IET Renew. Power Gen. 2021, 15, 2586–2595. [Google Scholar] [CrossRef]

- Yin, H.; Rossi, A.; Rondot, G.; Tobar, D.; Cantone, J.; van Becelaere, T. Performance and Operational Transformation for Effective Water Network Management. Environ. Sci. Proc. 2023, 21, 86. [Google Scholar] [CrossRef]

- Kiptoo, M.K.; Adewuyi, O.B.; Howlader, H.O.R.; Nakadomari, A.; Senjyu, T. Optimal Capacity and Operational Planning for Renewable Energy-Based Microgrid Considering Different Demand-Side Management Strategies. Energies 2023, 16, 4147. [Google Scholar] [CrossRef]

- Zhang, Z.; Jing, R.; Lin, J.; Wang, X.; van Dam, K.H.; Wang, M.; Meng, C.; Xie, S.; Zhao, Y. Combining agent-based residential demand modeling with design optimization for integrated energy systems planning and operation. Appl. Energy 2020, 263, 114623. [Google Scholar] [CrossRef]

- Almeida Pais, J.E.d.; Raposo, H.D.N.; Farinha, J.T.; Cardoso, A.J.M.; Marques, P.A. Optimizing the Life Cycle of Physical Assets through an Integrated Life Cycle Assessment Method. Energies 2021, 14, 6128. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Saber, Z.; Mostashari-Rad, F.; Ghasemi-Mobtaker, H.; Chau, K. Chapter 14-Coupled life cycle assessment and data envelopment analysis to optimize energy consumption and mitigate environmental impacts in agricultural production. In Methods in Sustainability Science: Assessment, Prioritization, Improvement, Design and Optimization; Ren, J., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 227–264. ISBN 978-0-12-823987-2. [Google Scholar]

- Shoaei, M.; Hajinezhad, A.; Moosavian, S.F. Design, energy, exergy, economy, and environment (4E) analysis, and multi-objective optimization of a novel integrated energy system based on solar and geothermal resources. Energy 2023, 280, 128162. [Google Scholar] [CrossRef]

- Cui, X.; Kær, S.K.; Nielsen, M.P. Energy analysis and surrogate modeling for the green methanol production under dynamic operating conditions. Fuel 2022, 307, 121924. [Google Scholar] [CrossRef]

- Chen, C.; Yang, A.; Bañares-Alcántara, R. Renewable methanol production: Understanding the interplay between storage sizing, renewable mix and dispatchable energy price. Adv. Appl. Energy 2021, 2, 100021. [Google Scholar] [CrossRef]

- Raheli, E.; Werner, Y.; Kazempour, J. A conic model for electrolyzer scheduling. Comput. Chem. Eng. 2023, 179, 108450. [Google Scholar] [CrossRef]

- Li, Z.; Wu, L.; Xu, Y.; Moazeni, S.; Tang, Z. Multi-Stage Real-Time Operation of a Multi-Energy Microgrid With Electrical and Thermal Energy Storage Assets: A Data-Driven MPC-ADP Approach. IEEE Trans. Smart Grid 2022, 13, 213–226. [Google Scholar] [CrossRef]

- Lee, J.H.; Wong, W. Approximate dynamic programming approach for process control. J. Process Control 2010, 20, 1038–1048. [Google Scholar] [CrossRef]

- Fan, H.; Yuan, Q.; Cheng, H. Multi-Objective Stochastic Optimal Operation of a Grid-Connected Microgrid Considering an Energy Storage System. Appl. Sci. 2018, 8, 2560. [Google Scholar] [CrossRef]

- Buttler, A.; Spliethoff, H. Current status of water electrolysis for energy storage, grid balancing and sector coupling via power-to-gas and power-to-liquids: A review. Renew. Sustain. Energy Rev. 2018, 82, 2440–2454. [Google Scholar] [CrossRef]

- Tremel, A. Electricity-Based Fuels; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Schmidt, O.; Gambhir, A.; Staffell, I.; Hawkes, A.; Nelson, J.; Few, S. Future cost and performance of water electrolysis: An expert elicitation study. Int. J. Hydrog. Energy 2017, 42, 30470–30492. [Google Scholar] [CrossRef]

- Wilberforce, T.; Olabi, A.G.; Sayed, E.T.; Elsaid, K.; Abdelkareem, M.A. Progress in carbon capture technologies. Sci. Total Environ. 2021, 761, 143203. [Google Scholar] [CrossRef] [PubMed]

- Song, C.; Liu, Q.; Deng, S.; Li, H.; Kitamura, Y. Cryogenic-based CO2 capture technologies: State-of-the-art developments and current challenges. Renew. Sustain. Energy Rev. 2019, 101, 265–278. [Google Scholar] [CrossRef]

- Moradi, R.; Groth, K.M. Hydrogen storage and delivery: Review of the state of the art technologies and risk and reliability analysis. Int. J. Hydrog. Energy 2019, 44, 12254–12269. [Google Scholar] [CrossRef]

- Open Energy Modelling Framework (Oemof)—Oemof Documentation. Available online: https://oemof.readthedocs.io/en/latest/ (accessed on 25 October 2022).

- Pérez-Fortes, M.; Schöneberger, J.C.; Boulamanti, A.; Tzimas, E. Methanol synthesis using captured CO2 as raw material: Techno-economic and environmental assessment. Appl. Energy 2016, 161, 718–732. [Google Scholar] [CrossRef]

- Gabrielli, P.; Flamm, B.; Eichler, A.; Gazzani, M.; Lygeros, J.; Mazzotti, M. Modeling for Optimal Operation of PEM Fuel Cells and Electrolyzers. Available online: https://ieeexplore.ieee.org/document/7555707 (accessed on 31 July 2023).

- Danish Energy Agency. Technology Data for Renewable Fuels. Available online: https://ens.dk/en/our-services/projections-and-models/technology-data/technology-data-renewable-fuels (accessed on 28 March 2024).

- Philipp, L. Efficiency–Electrolysis White Paper. 2021. Available online: https://assets.siemens-energy.com/siemens/assets/api/uuid:5342163d-2333-4c8d-ae85-2a0e8d45db56/white-paper-efficiency-en.pdf (accessed on 5 July 2023).

- User’s Guide—Oemof.Solph 0.5.4a1 Documentation. Available online: https://oemof-solph.readthedocs.io/en/latest/usage.html#offsetconverter-component (accessed on 16 July 2024).

- Pellow, M.A.; Emmott, C.J.M.; Barnhart, C.J.; Benson, S.M. Hydrogen or batteries for grid storage? A net energy analysis. Energy Environ. Sci. 2015, 8, 1938–1952. [Google Scholar] [CrossRef]

- Mucci, S.; Mitsos, A.; Bongartz, D. Power-to-X processes based on PEM water electrolyzers: A review of process integration and flexible operation. Comput. Chem. Eng. 2023, 175, 108260. [Google Scholar] [CrossRef]

- Van-Dal, É.S.; Bouallou, C. Design and simulation of a methanol production plant from CO2 hydrogenation. J. Clean. Prod. 2013, 57, 38–45. [Google Scholar] [CrossRef]

- van der Roest, E.; Bol, R.; Fens, T.; van Wijk, A. Utilisation of waste heat from PEM electrolysers–Unlocking local optimisation. Int. J. Hydrog. Energy 2023, 48, 27872–27891. [Google Scholar] [CrossRef]

- Chen, C.; Yang, A. Power-to-methanol: The role of process flexibility in the integration of variable renewable energy into chemical production. Energy Convers. Manag. 2021, 228, 113673. [Google Scholar] [CrossRef]

- Kang, S. Innovation Outlook: Renewable Methanol; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2021; ISBN 9789292603205. [Google Scholar]

- Lee, G.G.; Ham, S.-W. Prediction of Carbon Price in EU-ETS Using a Geometric Brownian Motion Model and Its Application to Analyze the Economic Competitiveness of Carbon Capture and Storage. Energies 2023, 16, 6333. [Google Scholar] [CrossRef]