Hybrid Energy Storage Modeling and Control for Power System Operation Studies: A Survey

Abstract

1. Introduction

1.1. Background and Motivation

1.2. Contributions

- Providing an in-depth and systematic review of the HESS’s role in enhancing power system stability, security, and reliability.

- Extensive analysis of the multi-dimensional decision criteria for HESS selection.

- Reviewing and evaluating the modeling and control schemes applied to HESSs.

- Assessing the crucial role of HESSs in the context of net zero transitioning, a key consideration in today’s changing energy landscape.

1.3. Organization

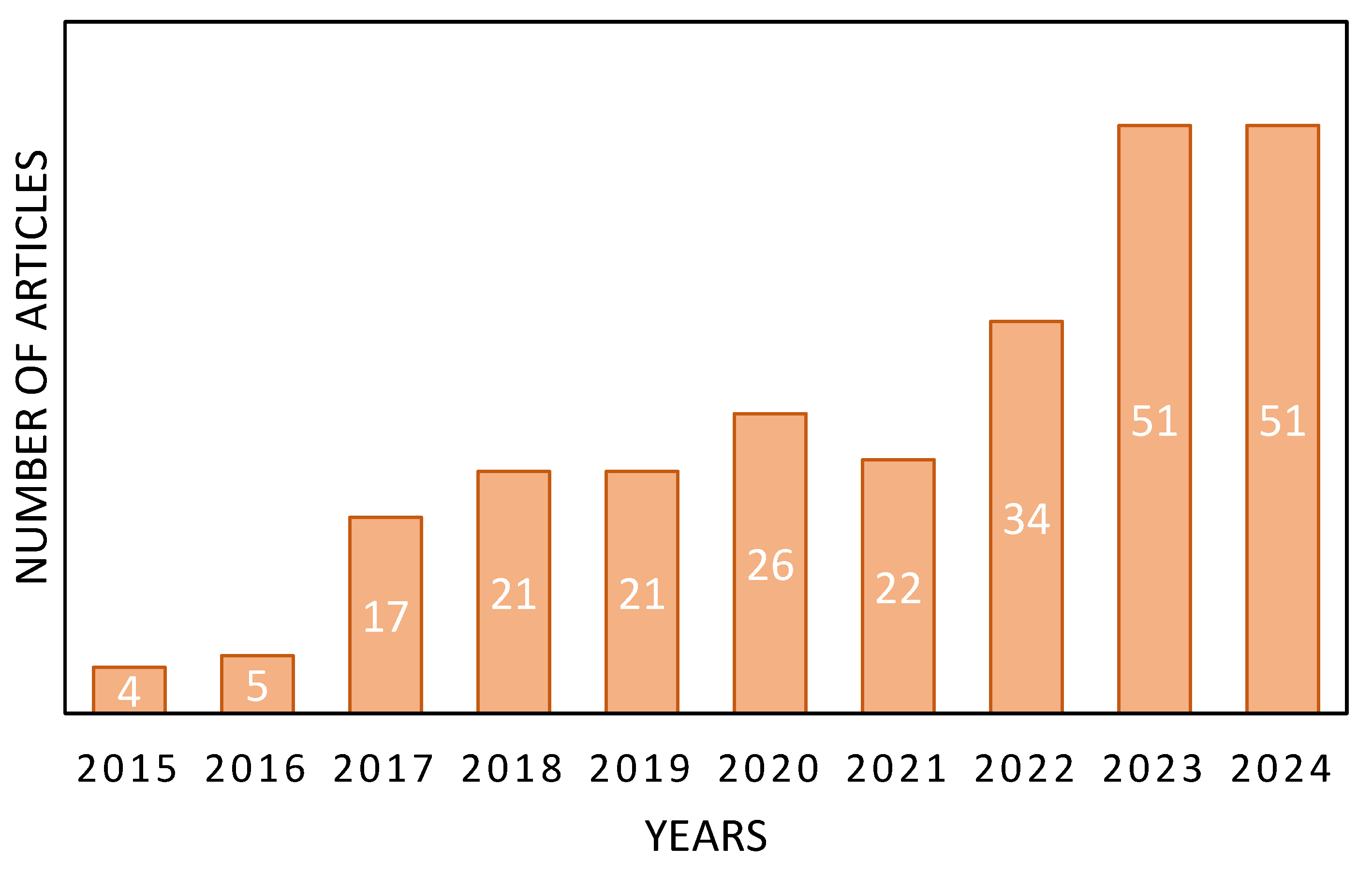

2. Literature Review Methodology

- The emerging and advanced nature of HESS technology.

- Changes in power system operation due to the increasing penetration of renewables in the last ten years.

- To collect and evaluate the most recent information in the HESS domain and power system applications of HESSs.

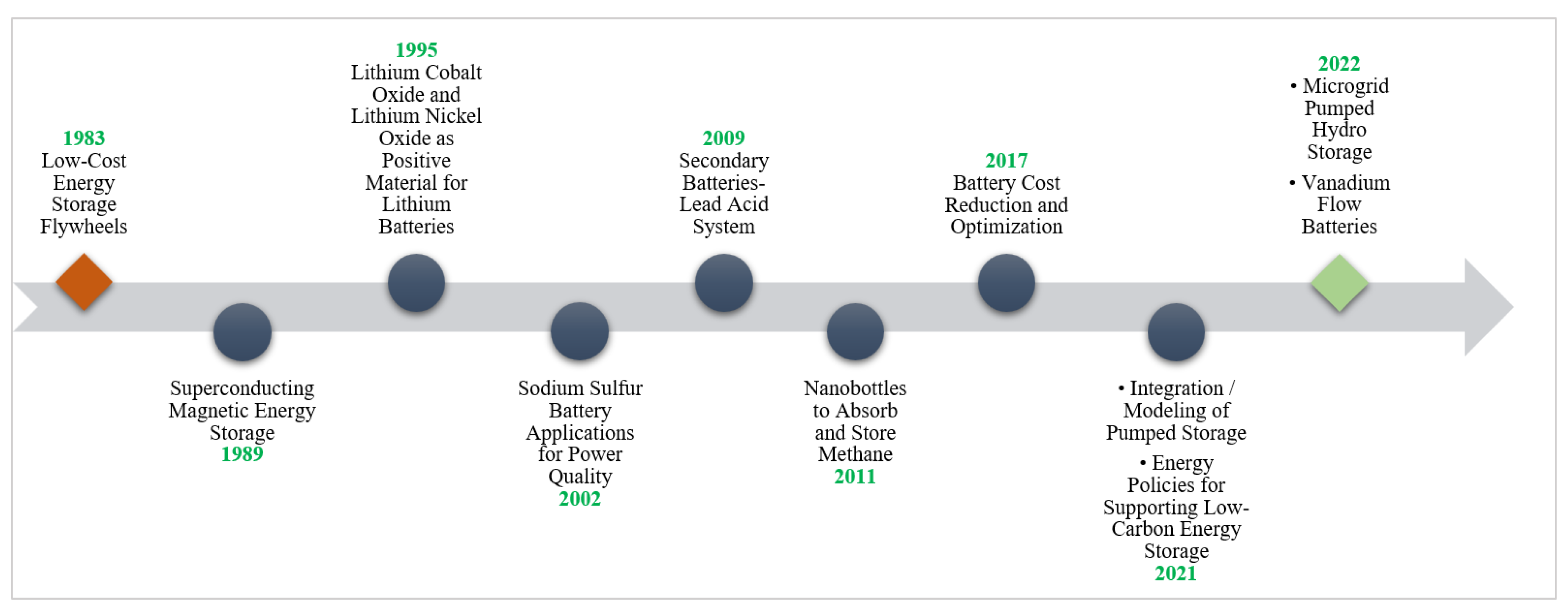

3. Energy Storage System (ESS)

3.1. Overview and Comparison of Various Energy Storage Systems

3.1.1. Pumped Storage (PS)

3.1.2. Flywheel Energy Storage (FES)

3.1.3. Compressed Air Energy Storage (CAES)

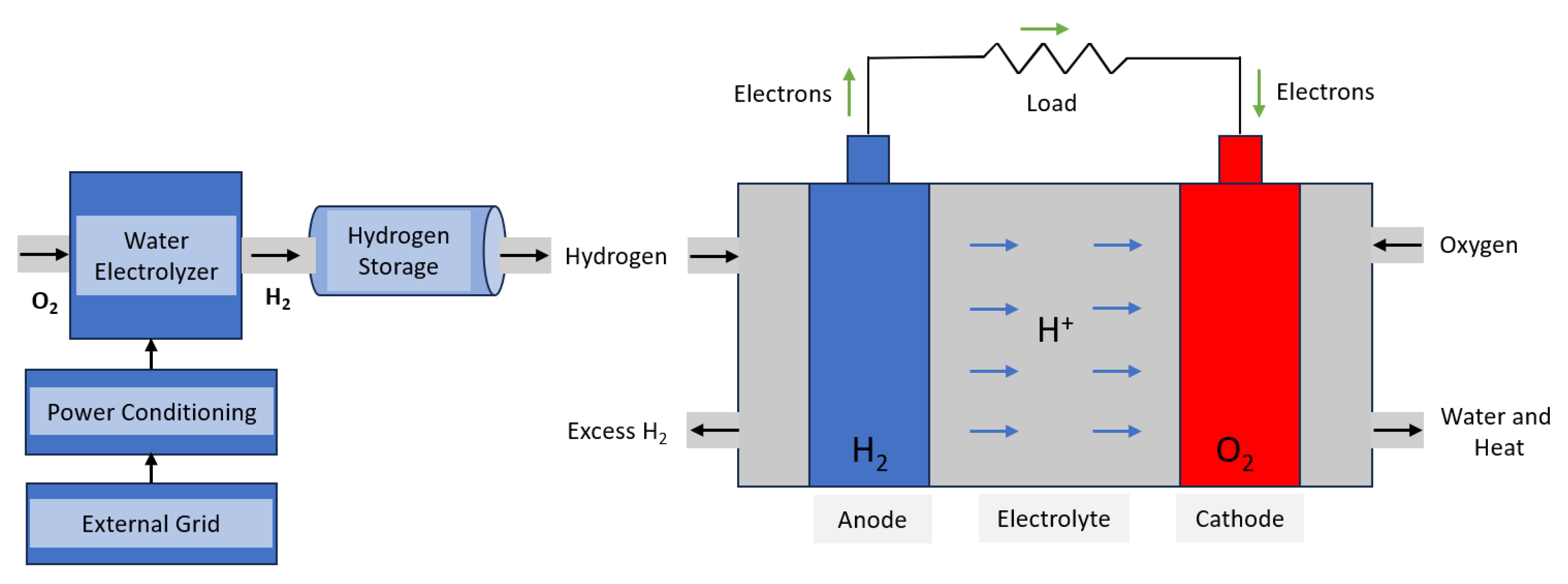

3.1.4. Hydrogen Fuel Cell (HFC)

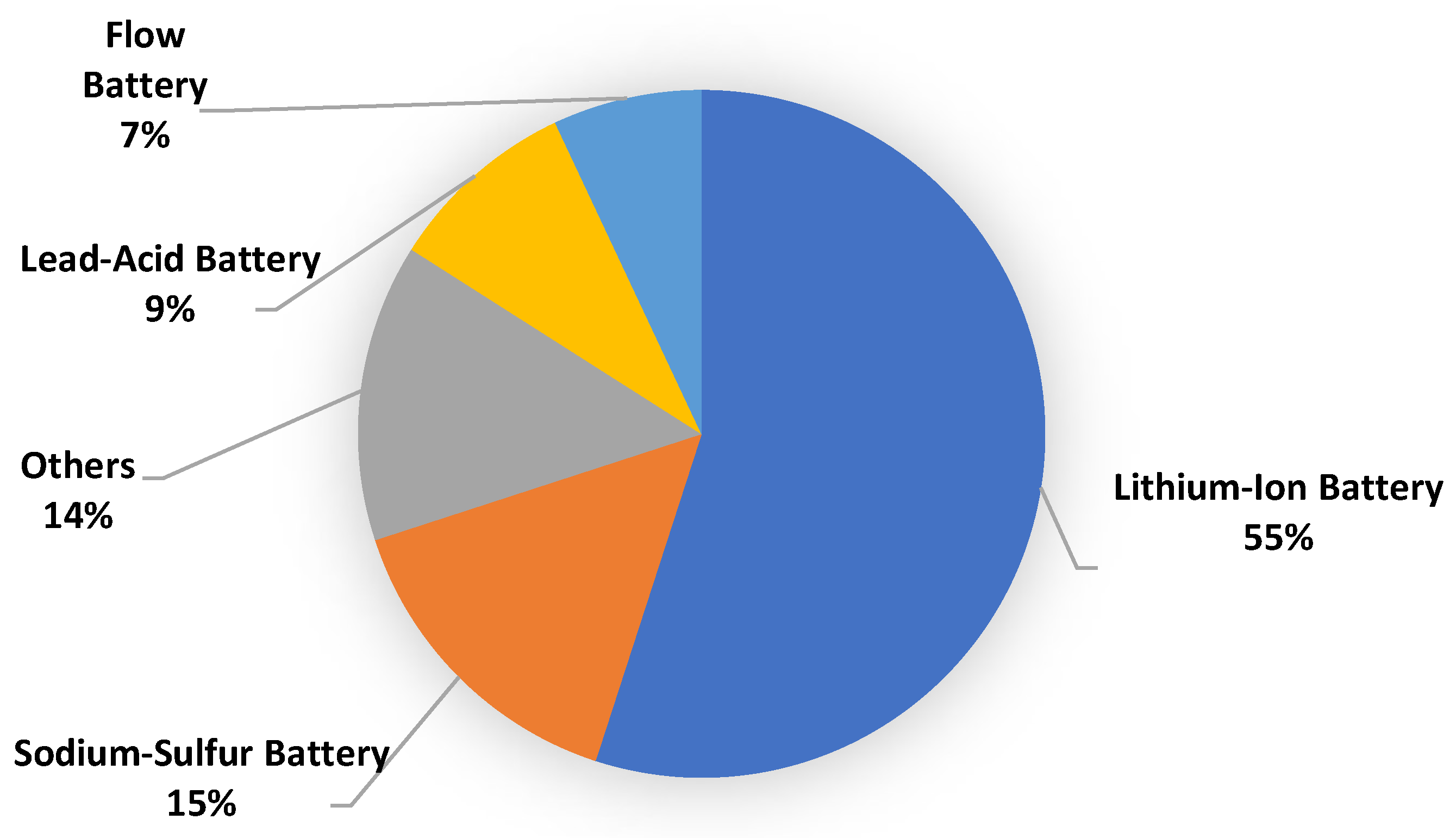

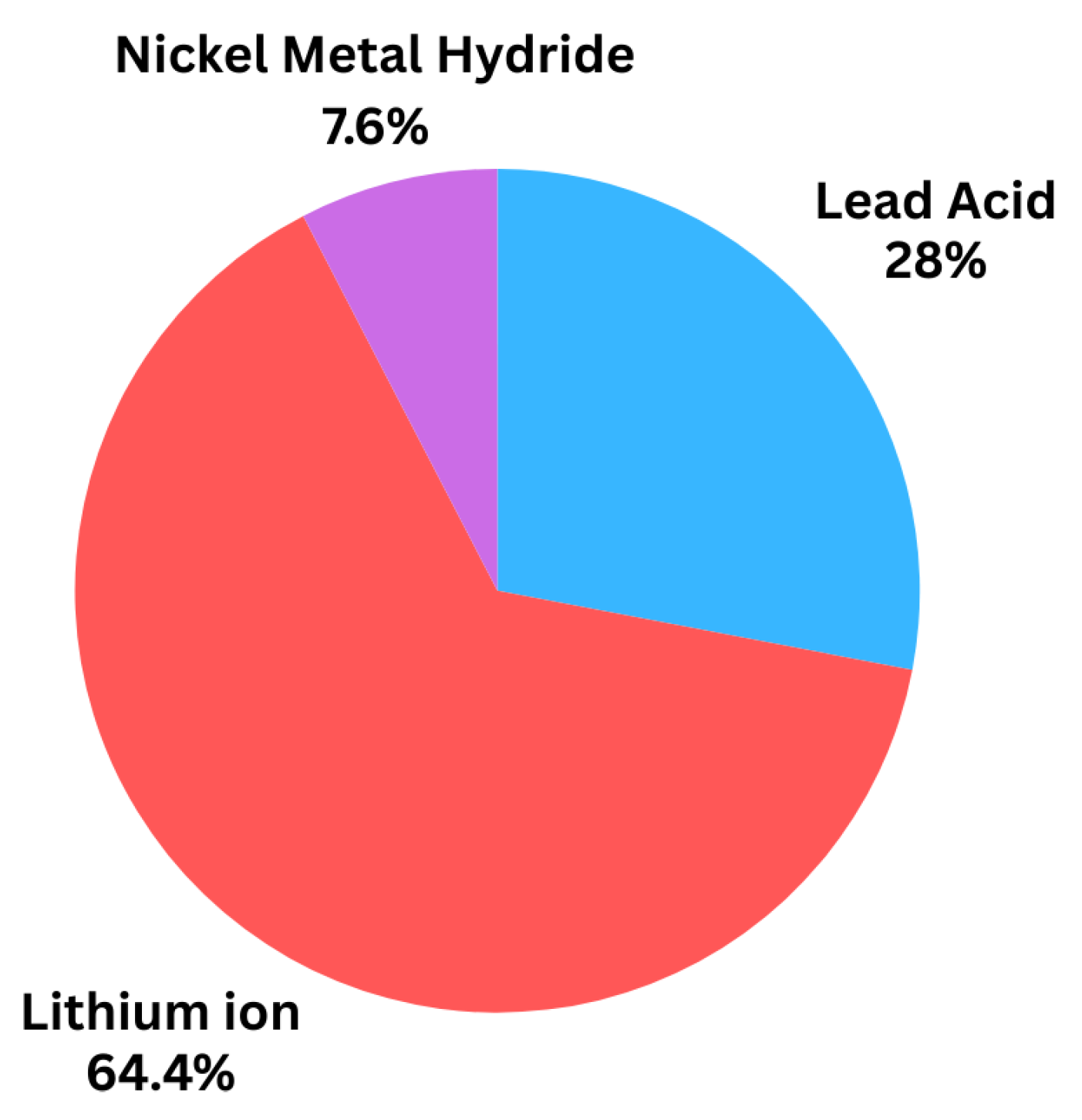

3.1.5. Battery Energy Storage System (BESS)

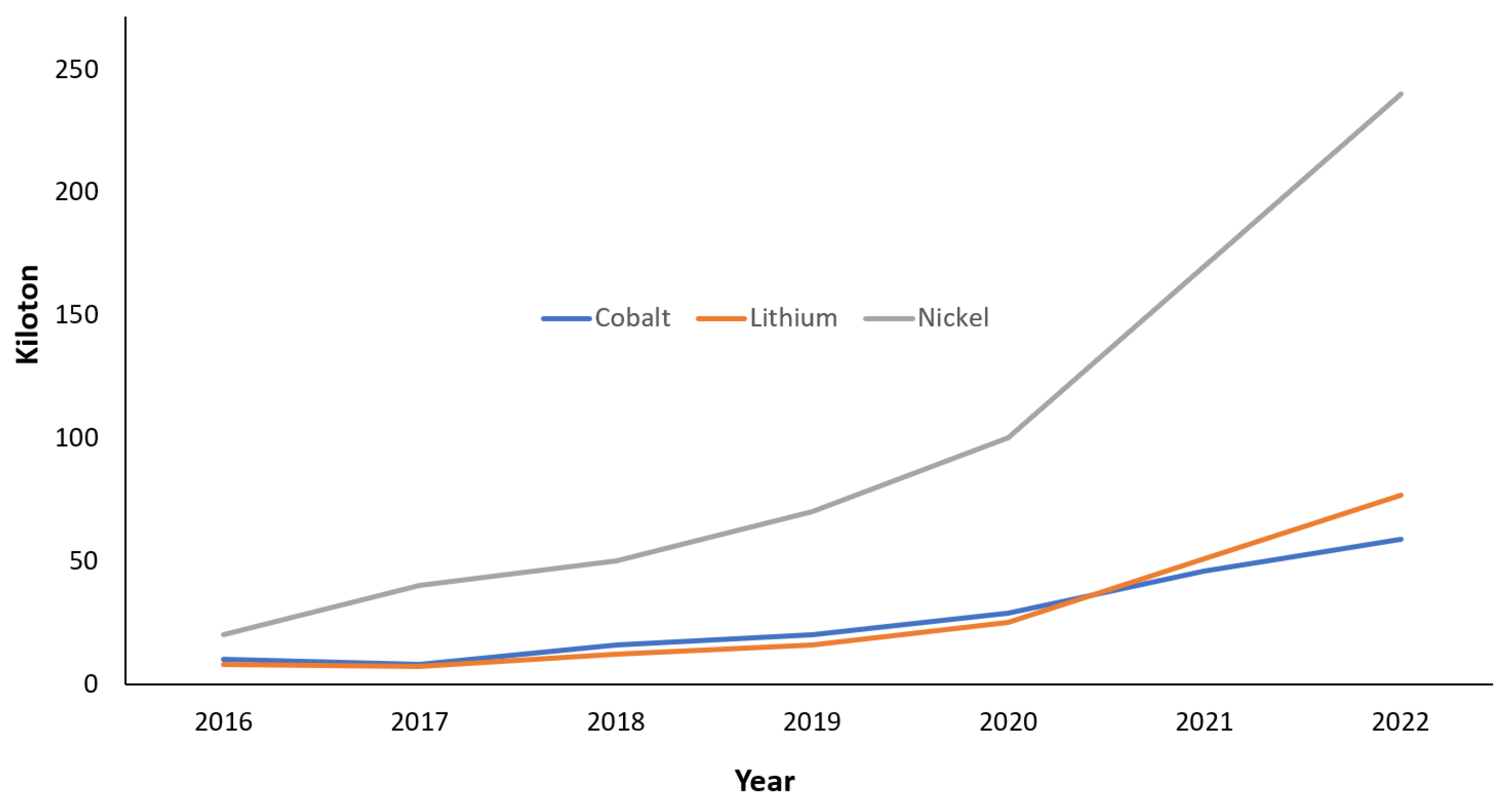

- Lithium-Ion Battery (LIB)

- 2.

- Lead–Acid Battery

- 3.

- Vanadium Redox Flow Battery (VRFB)

3.1.6. Supercapacitor (SC)

3.1.7. Superconducting Magnetic Energy Storage (SMES)

3.2. Why Use Hybrid Energy Storage Systems?

3.3. Overview of Some Common HESSs

3.3.1. SC–BESS

3.3.2. FES–BESS

3.3.3. SMES–BESS

3.3.4. BESS–BESS

3.3.5. HSS–BESS

| HESS Type | Advantages | Limitations | Applications |

|---|---|---|---|

| SC–BESS |

|

| |

| FES–BESS |

|

| |

| SMES–BESS |

|

| |

| BESS–BESS (HBESS [59]) |

|

|

|

| HSS–BESS |

|

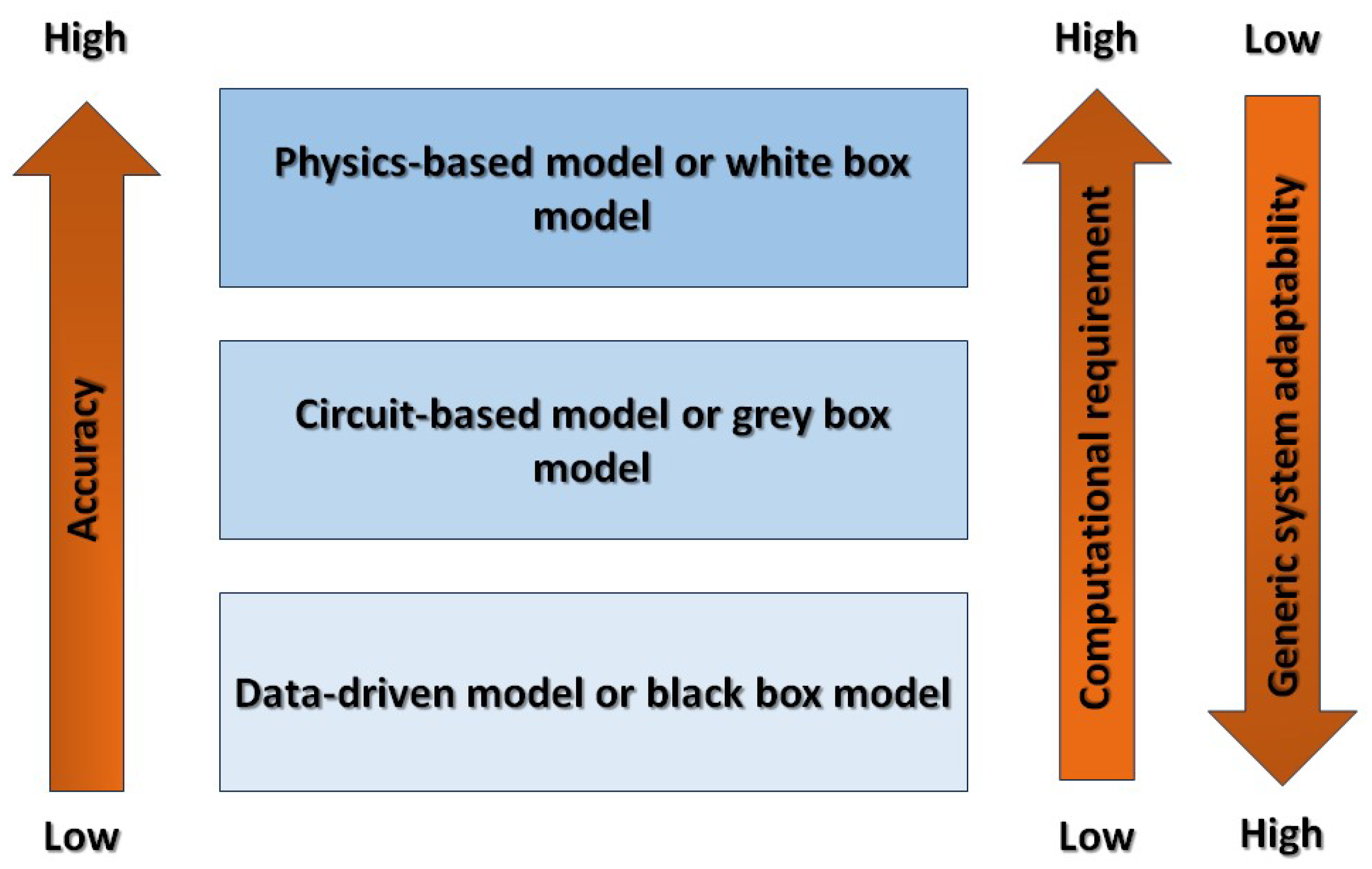

3.4. HESS Modeling and Control

3.4.1. HESS Modeling Overview

- (1)

- Physics-based model or white box model.

- (2)

- Circuit-based model or grey box model.

- (3)

- Data-driven model or black box model.

3.4.2. Hybridization Approaches and Architectures

Active Topology

Passive Topology

Semi-Active Topology

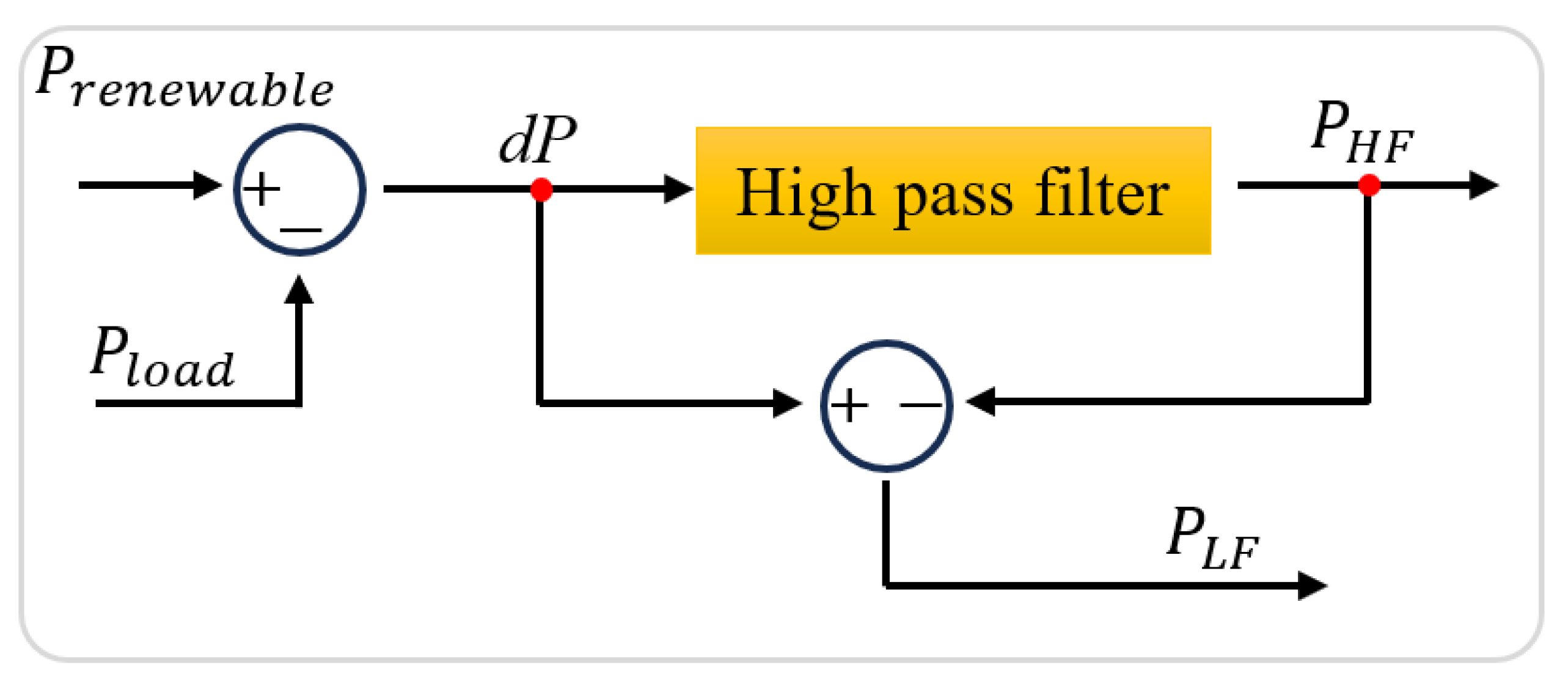

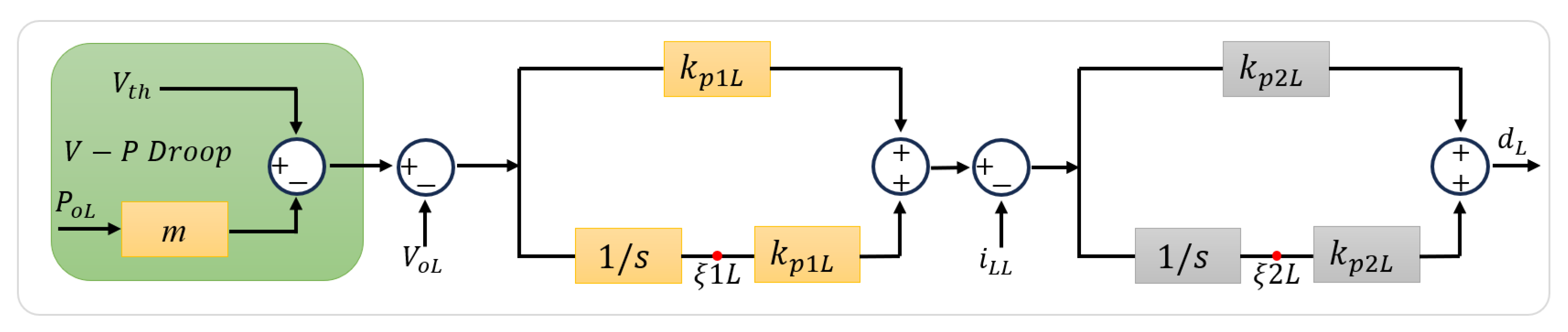

3.4.3. Control Design

3.5. Application of Optimization and AI in Modeling and Control of HESSs

3.5.1. Optimization-Based Modeling and Control

3.5.2. AI-Based Modeling and Control

4. Application of HESSs in Power System Operation

4.1. Role of HESSs in Addressing the Challenges in Power System Stability

4.2. Role of HESSs in Meeting Net Zero Transitioning Requirements

4.2.1. Extending Storage Lifetime

4.2.2. Reducing Storage Cost

4.2.3. Overcoming Intermittencies in RESs

5. Selection Criteria for Hybrid Energy Storage Systems

5.1. Power and Energy Density

5.2. Lifetime Enhancement

5.3. Geographical Limitations

5.4. Financial Factors

5.5. Ramping Capability

5.6. Efficiency and Energy Loss

5.7. Suitability for Intended Objective

6. Conclusions and Future Research Directions

- (a)

- A proper HESS design is important to make it more efficient than a single ESS. In this regard, the selection of an appropriate combination of ESSs is crucial. The HESS selection criteria have been presented and discussed in this paper. Sizing the individual ESSs of a HESS should be carefully performed using appropriate optimization methods. State-of-the-art relevant optimization examples have been provided in this review.

- (b)

- A BESS is mostly integrated with a SMES and SC to form a HESS. Very few works have considered the formation of a HESS with thermal storage. However, with the extension of energy hubs and multi-carrier energy systems, this can be a suitable research direction for future studies.

- (c)

- HESSs formed by combining multiple (more than two) ESSs need further investigation on their optimum design and efficacy in providing ancillary services. While these HESSs may be able to provide higher storage capability and flexibility, their design and implementation may encounter more complexities. Thus, evaluating the benefits of these HESSs requires further study.

- (d)

- HESSs can be effective in improving the voltage and frequency stability status of a power system, as can be seen from the literature works. However, the impacts of HESSs on other stability issues (such as control interactions and sub-synchronous and super-synchronous oscillations), as well as other types of stability emerging in renewable energy-integrated power systems (such as converter-driven stability), need further study.

- (e)

- HESSs can play a particularly useful role in net zero transitioning by providing a flexible storage capacity to overcome the intermittency of renewable generation and providing cost-effective grid services for the stable operation of the power system. However, although ESSs are integrated for advancing towards net zero emission targets, the hidden environmental impacts of the manufacturing process of ESSs, such as batteries, should be considered and analyzed while selecting the optimum combinations of ESSs for a HESS. Alternative storage systems should replace ESSs that result in high emissions during their manufacturing process.

- (f)

- There are very few grid codes for HESSs in practical power systems, while it is a key issue for the extensive use of HESSs in practice. Further research needs to be conducted in this area.

- (g)

- Simplified degradation models for ESSs have been used in many studies. In the future, instead of using simplified degradation models for ESSs, more accurate and dynamic models that can cover the relevant constraints and factors involved in ESS lifetime degradation and ESS replacement costs should be considered to determine the most economical combination of ESSs for forming a HESS or to perform the cost-benefit analysis of a HESS.

- (h)

- Multi-objective optimization and multi-criteria decision-making for HESSs can be considered in future research to simultaneously meet the technical, economic, and environmental objectives of HESS planning.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ADP | Adaptive Dynamic Programming | IMC | Internal Model Control |

| ADRC | Active Disturbance Rejection Control | INN | Intelligent Neural Network |

| AGC | Automatic Generation Control | ITAE | Integral Time Absolute Error |

| ANN | Artificial Neural Network | LADRC | Linear ADRC |

| BESS | Battery Energy Storage System | LFC | Load Frequency Control |

| CAES | Compressed Air Energy Storage | LIB | Lithium-Ion Battery |

| CBC | Composite Backstepping Control | LPF | Low-Pass Filter |

| CIG | Converter-Interfaced Generation | LPSP | Loss Of Power Supply Probability |

| CPL | Constant Power Load | NSCAS | Network Support and Control Ancillary Services |

| DAEs | Differential Algebraic Equations | NSGA | Non-Dominating Sorting Genetic Algorithm |

| DFIG | Doubly Fed Induction Generator | PCC | Point of Common Coupling |

| DIS | Dynamic Interaction Stabilization | PED | Power Electronic Devices |

| DOD | Depth of Discharge | PEMFC | Proton Exchange Membrane Fuel Cell |

| EEI | Energy Export Index | PHEV | Plug-In Hybrid Electric Vehicles |

| EMD | Empirical Mode Decomposition | PI | Proportional-Integral |

| EMS | Energy Management System | PLL | Phase Locked Loop |

| ESS | Energy Storage System | PMS | Power Management System |

| EV | Electric Vehicle | PS | Pumped Storage |

| FB | Filtration-Based | PSO | Particle Swarm Optimization |

| FC | Fuel Cell | RES | Renewable Energy Source |

| FCAS | Frequency Control Ancillary Services | ROCOF | Rate of Change of Frequency |

| FES | Flywheel Energy System | RTDS | Real-Time Dynamic Simulation |

| FOC | Fractional Order Controller | SC | Supercapacitor |

| GA | Genetic Algorithm | SMES | Superconducting Magnetic Energy Storage |

| GFM | Grid-Forming | SOC | State Of Charge |

| HES | High-Energy Storage | SOFC | Solid Oxide Fuel Cell |

| HESC | Hybrid Energy Storage Converter | THD | Total Harmonic Distortion |

| HESS | Hybrid Energy Storage System | UC | Ultracapacitor |

| HFC | Hydrogen Fuel Cell | V2G | Vehicle-To-Grid |

| HPS | High-Power Storage | VCD | Virtual Capacitance Droop |

| HSS | Hydrogen Storage System | VIDC | Virtual Inertia and Damping Control |

| HWPF | Hybrid Wind/PV Farm | VMD | Variational Mode Decomposition |

| IBC | Interleaved Boost Converter | VRD | Virtual Resistance Droop |

| IDA-PBC | Interconnection Damping Assessment Passivity-Based Controller | VRFB | Vanadium Redox Flow Battery |

| IEH | Integrated Energy Hub | VSC | Voltage Source Converter |

| iLADRC | Improved LADRC | VSG | Virtual Synchronous Generator |

References

- Renewable Energy–Powering a Safer Future. Available online: https://www.un.org/en/climatechange/raising-ambition/renewable-energy (accessed on 29 July 2024).

- Global Greenhouse Gas Emissions Data. Available online: https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data (accessed on 29 July 2024).

- Ippolito, M.G.; Di Silvestre, M.L.; Riva Sanseverino, E.; Zizzo, G.; Graditi, G. Multi-objective Optimized Management of Electrical Energy Storage Systems in an Islanded Network with Renewable Energy Sources under Different Design Scenarios. Energy 2014, 64, 648–662. [Google Scholar] [CrossRef]

- Emrani, A.; Berrada, A. A Comprehensive Review on Techno-economic Assessment of Hybrid Energy Storage Systems Integrated with Renewable Energy. J. Energy Storage 2024, 84, 111010. [Google Scholar] [CrossRef]

- Qin, X.; Xu, B.; Lestas, I.; Guo, Y.; Sun, H. The Role of Electricity Market Design for Energy Storage in Cost-efficient Decarbonization. Joule 2023, 7, 1227–1240. [Google Scholar] [CrossRef]

- Wangmo; Helwig, A.; Bell, J. What Energy Storage Technologies will Australia Need as Renewable Energy Penetration Rises? J. Energy Storage 2024, 95, 112701. [Google Scholar] [CrossRef]

- Reveles-Miranda, M.; Ramirez-Rivera, V.; Pacheco-Catalán, D. Hybrid Energy Storage: Features, Applications, and Ancillary Benefits. Renew. Sustain. Energy Rev 2024, 192, 114196. [Google Scholar] [CrossRef]

- Kandari, R.; Neeraj, N.; Micallef, A. Review on Recent Strategies for Integrating Energy Storage Systems in Microgrids. Energies 2023, 16, 317. [Google Scholar] [CrossRef]

- Shyni, R.; Kowsalya, M. HESS-based Microgrid Control Techniques Empowered by Artificial Intelligence: A Systematic Review of Grid-connected and Standalone Systems. J. Energy Storage 2024, 84, 111012. [Google Scholar]

- Elalfy, D.A.; Gouda, E.; Kotb, M.F.; Bureš, V.; Sedhom, B.E. Comprehensive Review of Energy Storage Systems Technologies, Objectives, Challenges, and Future Trends. Energy Strategy Rev. 2024, 54, 101482. [Google Scholar] [CrossRef]

- Zhang, Z.; Ding, T.; Zhou, Q.; Sun, Y.; Qu, M.; Zeng, Z.; Ju, Y.; Li, L.; Wang, K.; Chi, F. A Review of Technologies and Applications on Versatile Energy Storage Systems. Renew. Sustain. Energy Rev 2021, 148, 111263. [Google Scholar] [CrossRef]

- Shekhawat, M.; Bansal, H.O. An Extensive Review on Hybrid Electric Vehicles Powered by Fuel cell-enabled Hybrid Energy Storage System. Environ. Sci. Pollut. Res. 2023, 30, 119750–119771. [Google Scholar] [CrossRef]

- Nkwanyana, T.B.; Siti, M.W.; Wang, Z.; Toudjeu, I.; Mbungu, N.T.; Mulumba, W. An Assessment of Hybrid-energy storage Systems in the Renewable Environments. J. Energy Storage 2023, 72, 108307. [Google Scholar] [CrossRef]

- Kumaresan, N.; Rammohan, A. A Comprehensive Review on Energy Management Strategies of Hybrid Energy Storage Systems for Electric Vehicles. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 146. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, Z.; Yao, J.; Guo, T.; Yang, F.; Zhang, Z.; Ren, J.; Jiang, L.; Li, B. An Overview of Application-oriented Multifunctional Large-scale Stationary Battery and Hydrogen Hybrid Energy Storage System. Energy Rev. 2024, 3, 100068. [Google Scholar] [CrossRef]

- Wali, S.B.; Hannan, M.A.; Abd Rahman, M.S.; Alghamdi, H.A.; Mansor, M.; Ker, P.J.; Tiong, S.K.; Mahlia, T.M.I. Usage Count of Hydrogen-based Hybrid Energy Storage Systems: An Analytical Review, Challenges and Future Research Potentials. Int. J. Hydrogen Energy 2023, 48, 34836–34861. [Google Scholar] [CrossRef]

- Jing, W.; Hung Lai, C.; Wong, S.H.W.; Wong, M.L.D. Battery-supercapacitor Hybrid Energy Storage System in Standalone DC Microgrids: A Review. IET Renew. Power Gener. 2017, 11, 461–469. [Google Scholar] [CrossRef]

- Papageorgiou, P.G.; Oureilidis, K.O.; Christoforidis, G.C. A Systematic Review of Hybrid Superconducting Magnetic/battery energy storage systems: Applications, Control Strategies, Benefits, Limitations and Future Prospects. Renew. Sustain. Energy Rev. 2023, 183, 113436. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Li, M.; Chen, Z. A Review of Key Issues for Control and Management in Battery and Ultracapacitor Hybrid Energy Storage Systems. eTransportation 2020, 4, 100064. [Google Scholar] [CrossRef]

- Ji, W.; Hong, F.; Zhao, Y.; Liang, L.; Du, H.; Hao, J.; Fang, F.; Liu, J. Applications of Flywheel Energy Storage System on Load Frequency Regulation Combined with Various Power Generations: A Review. Renew. Energy 2024, 223, 119975. [Google Scholar] [CrossRef]

- Sutikno, T.; Arsadiando, W.; Wangsupphaphol, A.; Yudhana, A.; Facta, M. A Review of Recent Advances on Hybrid Energy Storage System for Solar Photovoltaics Power Generation. IEEE Access 2022, 10, 42346–42364. [Google Scholar] [CrossRef]

- Babu, T.S.; Vasudevan, K.R.; Ramachandaramurthy, V.K.; Sani, S.B.; Chemud, S.; Lajim, R.M. A Comprehensive Review of Hybrid Energy Storage Systems: Converter Topologies, Control Strategies and Future Prospects. IEEE Access 2020, 8, 148702–148721. [Google Scholar] [CrossRef]

- Hajiaghasi, S.; Salemnia, A.; Hamzeh, M. Hybrid Energy Storage System for Microgrids Applications: A Review. J. Energy Storage 2019, 21, 543–570. [Google Scholar] [CrossRef]

- Chong, L.W.; Wong, Y.W.; Rajkumar, R.K.; Rajkumar, R.K.; Isa, D. Hybrid Energy Storage Systems and Control Strategies for Stand-alone Renewable Energy Power Systems. Renew. Sustain. Energy Rev 2016, 66, 174–189. [Google Scholar] [CrossRef]

- Lin, X.; Zamora, R. Controls of Hybrid Energy Storage Systems in Microgrids: Critical Review, Case Study and Future Trends. J. Energy Storage 2022, 47, 103884. [Google Scholar] [CrossRef]

- Jiang, Z.; Luo, Z.; Shen, K. Analysis and Prediction on the Development Potential of Pumped Storage Hydroelectricity in China in Ten Years (2022–2032). Highlights Sci. Eng. Technol. 2022, 26, 34–40. [Google Scholar] [CrossRef]

- Arseneaux, J. 20 MW Flywheel Frequency Regulation Plant; US Department of Energy: Washington, DC, USA, 2015. [Google Scholar]

- Murray, C. World’s Largest Compressed Air Energy Storage Project Connects to the Grid in China. Available online: https://www.energy-storage.news/worlds-largest-compressed-air-energy-storage-project-connects-to-the-grid-in-china/ (accessed on 29 July 2024).

- Energy Storage News. The Energy Storage Report Taking stock of the energy storage market in Europe and the US as the buildout accelerates. In Energy Storage Summit, 9th ed.; Energy Storage News: London, UK, 2024; Available online: https://www.energy-storage.news/resources/the-energy-storage-report-2024/ (accessed on 29 July 2024).

- The World’s Largest Capacity 5 MW Supercapacitor Energy Storage System Is Put into Operation. Available online: http://yhcarbon.com/index.php?m=home&c=View&a=index&aid=94 (accessed on 29 July 2024).

- Olabi, A.G.; Wilberforce, T.; Abdelkareem, M.A.; Ramadan, M. Critical Review of Flywheel Energy Storage System. Energies 2021, 14, 2159. [Google Scholar] [CrossRef]

- Hossain, E.; Faruque, H.M.R.; Sunny, M.S.H.; Mohammad, N.; Nawar, N. A Comprehensive Review on Energy Storage Systems: Types, Comparison, Current Scenario, Applications, Barriers, and Potential Solutions, Policies, and Future Prospects. Energies 2020, 13, 3651. [Google Scholar] [CrossRef]

- Amiryar, M.E.; Pullen, K.R. A Review of Flywheel Energy Storage System Technologies and Their Applications. Appl. Sci. 2017, 7, 286. [Google Scholar] [CrossRef]

- Zoupalis, K.; Amiri, A.; Sugden, K.; Kendall, M.; Kendall, K. Micro solid oxide fuel cell thermal dynamics: Incorporation of experimental measurements and model-based estimations for a multidimensional thermal analysis. Energy Convers. Manag. 2023, 277, 116650. [Google Scholar] [CrossRef]

- Rahman, M.A.; Kim, J.H.; Hossain, S. Recent Advances of Energy Storage Technologies for Grid: A Comprehensive Review. Energy Storage 2022, 4, e322. [Google Scholar] [CrossRef]

- Dehghani-Sanij, A.R.; Tharumalingam, E.; Dusseault, M.B.; Fraser, R. Study of energy storage systems and environmental challenges of batteries. Renew. Sustain. Energy Rev. 2019, 104, 192–208. [Google Scholar] [CrossRef]

- Unterreiner, L.; Jülch, V.; Reith, S. Recycling of Battery Technologies—Ecological Impact Analysis Using Life Cycle Assessment (LCA). Energy Procedia 2016, 99, 229–234. [Google Scholar] [CrossRef]

- Qudaih, S.; Bektas, Z.; Guven, D.; Kayakutlu, G.; Kayalica, M.Ö. Technology Assessment of Hydrogen Storage: Cases Enabling the Clean Energy Transition. IEEE Trans. Eng. Manag. 2024, 71, 5744–5756. [Google Scholar] [CrossRef]

- IEA. Global Installed Energy Storage Capacity by Scenario, 2023 and 2030; IEA: Paris, France, 2024; Available online: https://www.iea.org/data-and-statistics/charts/global-installed-energy-storage-capacity-by-scenario-2023-and-2030 (accessed on 29 July 2024).

- O’Farrell, K.; Kinrade, P.; Jones, P.; Roser, L. Australian Battery Market Analysis. Battery Stewardship Council, June 2020. Available online: https://bcycle.com.au/wp-content/uploads/2024/02/BSC-Australian-battery-market-analysis-Project-report-2020.pdf (accessed on 29 July 2024).

- IEA. Global EV Outlook 2023; IEA: Paris, France, 2023; Available online: https://www.iea.org/reports/global-ev-outlook-2023 (accessed on 29 July 2024).

- Yang, Y.; Xu, Y.; Zhang, H.; Yang, F.; Ren, J.; Wang, X.; Jin, P.; Huang, D. Research on the Energy Management Strategy of Extended Range Electric Vehicles based on a Hybrid Energy Storage System. Energy Rep. 2022, 8, 6602–6623. [Google Scholar] [CrossRef]

- Xiao, G.; Xu, F.; Tong, L.; Xu, H.; Zhu, P. A Hybrid Energy Storage System based on Self-adaptive Variational Mode Decomposition to Smooth Photovoltaic Power Fluctuation. J. Energy Storage 2022, 55, 105509. [Google Scholar] [CrossRef]

- Liu, L.; Sheng, J.; Liang, H.; Yang, J.; Ye, H.; Jiang, J. Moth-flame-optimisation based Parameter Estimation for Model-predictive-controlled Superconducting Magnetic Energy Storage-battery Hybrid Energy Storage System. IET Smart Grid 2023, 7, 241–250. [Google Scholar] [CrossRef]

- Amir, M.; Deshmukh, R.G.; Khalid, H.M.; Said, Z.; Raza, A.; Muyeen, S.M.; Nizami, A.-S.; Elavarasan, R.M.; Saidur, R.; Sopian, K. Energy storage technologies: An integrated survey of developments, global economical/environmental effects, optimal scheduling model, and sustainable adaption policies. J. Energy Storage 2023, 72, 108694. [Google Scholar] [CrossRef]

- Bharatee, A.; Ray, P.K.; Ghosh, A. Power Distribution Technique and Small-signal Modeling of Grid-integrated Solar PV System with Hybrid Energy Storage systems. J. Energy Storage 2023, 73, 109316. [Google Scholar] [CrossRef]

- Bocklisch, T. Hybrid Energy Storage Systems for Renewable Energy Applications. Energy Procedia 2015, 73, 103–111. [Google Scholar] [CrossRef]

- Alessandro, S.; Mario, P.; Alfonso, D. A Novel Highly Integrated Hybrid Energy Storage System for Electric Propulsion and Smart Grid Applications. Adv. Energy Storage Technol. 2018, 71, 79–101. [Google Scholar]

- Leon, J.I.; Dominguez, E.; Wu, L.; Alcaide, A.M.; Reyes, M.; Liu, J. Hybrid Energy Storage Systems: Concepts, Advantages, and Applications. IEEE Ind. Electron. Mag. 2021, 15, 74–88. [Google Scholar] [CrossRef]

- Dougal, R.A.; Liu, S.; White, R.E. Power and Life Extension of Battery-Ultracapacitor Hybrids. IEEE Trans. Compon. Packag. Technol. 2002, 25, 120–131. [Google Scholar] [CrossRef]

- Podder, A.K.; Chakraborty, O.; Islam, S.; Kumar, N.M.; Alhelou, H.H. Control Strategies of Different Hybrid Energy Storage Systems for Electric Vehicles Applications. IEEE Access 2021, 9, 51865–51895. [Google Scholar] [CrossRef]

- Trovão, J.P.; Roux, M.A.; Ménard, É.; Dubois, M.R. Energy- and Power-split Management of Dual Energy Storage System for a Three-Wheel Electric Vehicle. IEEE Trans. Veh. Technol. 2017, 66, 5540–5550. [Google Scholar] [CrossRef]

- Ahmad Hamidi, S.; Ionel, D.M.; Nasiri, A. Modeling and Management of Batteries and Ultracapacitors for Renewable Energy Support in Electric Power Systems–An Overview. Electr. Power Compon. Syst. 2015, 43, 1434–1452. [Google Scholar] [CrossRef]

- Ortenzi, F.; Andrenacci, N.; Pasquali, M.; Villante, C. On the Hybridization of Microcars with Hybrid Ultracapacitors and Li-ion Batteries Storage Systems. Energies 2020, 13, 3230. [Google Scholar] [CrossRef]

- Shen, L.; Cheng, Q.; Cheng, Y.; Wei, L.; Wang, Y. Hierarchical Control of DC Micro-grid for Photovoltaic EV Charging Station based on Flywheel and Battery Energy Storage System. Electr. Power Syst. Res. 2020, 179, 106079. [Google Scholar] [CrossRef]

- Wang, J.; Yao, L.; Cao, D.; Yin, D.; Zhai, D.; Wang, J.; Mao, B.; Xie, B. A Coordinated Control Strategy for Integrated Wind power-flywheel-battery System to Participate in Grid Frequency Regulation. In Proceedings of the Energy Storage Conference 2023 (ESC 2023), Glasgow, UK, 15–16 November 2023. [Google Scholar]

- Taheri, B.; Shahhoseini, A. Direct current (DC) Microgrid Control in the Presence of Electrical Vehicle/Photovoltaic (EV/PV) Systems and Hybrid Energy Storage Systems: A Case Study of Grounding and Protection Issue. IET Gener. Transm. Distrib. 2023, 17, 3084–3099. [Google Scholar] [CrossRef]

- He, J.; Shi, C.; Wei, T.; Jia, D. Stochastic Model Predictive Control of Hybrid Energy Storage for Improving AGC Performance of Thermal Generators. IEEE Trans. Smart Grid 2022, 13, 393–405. [Google Scholar] [CrossRef]

- Hasan, M.M.; Berseneff, B.; Meulenbroeks, T.; Cantero, I.; Chakraborty, S.; Geury, T.; Hegazy, O. A Multi-Objective Co-design Optimization Framework for Grid-Connected Hybrid Battery Energy Storage Systems: Optimal Sizing and Selection of Technology. Energies 2022, 15, 5355. [Google Scholar] [CrossRef]

- Dascalu, A.; Sharkh, S.; Cruden, A.; Stevenson, P. Performance of a Hybrid Battery Energy Storage System. Energy Rep. 2022, 8, 1–7. [Google Scholar] [CrossRef]

- Wang, P.; Lu, J.; Wu, Y.; Xu, L.; Li, J.; Mao, H.; Tian, Y.; Xu, B.; Huang, J. A Novel Cooperative Control for SMES/Battery Hybrid Energy Storage in PV Grid-Connected System. IEEE Trans. Appl. Supercond. 2024, 34, 5401605. [Google Scholar] [CrossRef]

- Zhang, X.; Feng, G. MMC-Based PV Grid-Connected System with SMES-Battery Hybrid Energy Storage System. IEEE Trans. Appl. Supercond. 2024, 34, 5702004. [Google Scholar] [CrossRef]

- Khan, I.A.; Mokhlis, H.; Mansor, N.N.; Illias, H.A.; Usama, M.; Daraz, A.; Wang, L.; Awalin, L.J. Load Frequency Control Using Golden Eagle Optimization for Multi-Area Power System Connected through AC/HVDC Transmission and Supported with Hybrid Energy Storage Devices. IEEE Access 2023, 11, 44672–44695. [Google Scholar] [CrossRef]

- Li, C.; Cao, Y.; Li, B.; Wang, S.; Chen, P. A Novel Power Control Scheme for Distributed DFIG based on Cooperation of Hybrid Energy Storage System and Grid-side Converter. Int. J. Electr. Power Energy Syst. 2024, 157, 109801. [Google Scholar] [CrossRef]

- Liu, Y.; Li, P.; Xing, Z.; Han, X.; Fu, Q.; Jiang, Z. Research on Microgrid Superconductivity-Battery Energy Storage Control Strategy Based on Adaptive Dynamic Programming. IEEE Trans. Appl. Supercond. 2024, 34, 5701604. [Google Scholar] [CrossRef]

- Sivadanam, N.; Bhookya, N.; Maheswarapu, S. Stochastic and Iterative Based Optimization for Enhancing Dynamic Performance of Interconnected Power System with Hybrid Energy Storage. Front. Energy Res. 2022, 10, 845686. [Google Scholar] [CrossRef]

- Polat, H.; Unamuno, E.; Cabezuelo, D.; Geury, T.; Hegazy, O. Development and Comparison of Rule- and Machine Learning-Based EMS for HESS Providing Grid Services. IEEE Access 2024, 12, 53224–53233. [Google Scholar] [CrossRef]

- Faydi, Y.; Djdiaa, A.; Laabassi, H.; Ait Omar, A.; Bouzekri, H. Contribution of Green Hydrogen Vector to Guarantee Electricity Feeding in Remote Areas-Case Study. Renew. Energy 2024, 222, 119880. [Google Scholar] [CrossRef]

- Phu, P.V.; Huy, T.H.B.; Park, S.; Kim, D. An IGDT Approach for the Multi-objective Framework of Integrated Energy Hub with Renewable Energy Sources, Hybrid Energy Storage Systems, and Biomass-to-hydrogen Technology. J. Energy Storage 2024, 89, 111488. [Google Scholar] [CrossRef]

- Adeyemo, A.A.; Amusan, O.T. Modelling and Multi-objective Optimization of Hybrid Energy Storage Solution for Photovoltaic Powered Off-grid Net zero Energy Building. J. Energy Storage 2022, 55, 105273. [Google Scholar] [CrossRef]

- Behera, M.K.; Saikia, L.C. A Novel Resilient Control of Grid-Integrated Solar PV-Hybrid Energy Storage Microgrid for Power Smoothing and Pulse Power Load Accommodation. IEEE Trans. Power Electron. 2023, 38, 3965–3980. [Google Scholar] [CrossRef]

- Tamilselvi, S.; Gunasundari, S.; Karuppiah, N.; Razak RK, A.; Madhusudan, S.; Nagarajan, V.M.; Sathish, T.; Shamim, M.Z.M.; Saleel, C.A.; Afzal, A. A Review on Battery Modelling Techniques. Sustainability 2021, 13, 10042. [Google Scholar] [CrossRef]

- Ibrahim, H.; Ilinca, A.; Perron, J. Energy storage systems—Characteristics and comparisons. Renew. Sustain. Energy Rev 2008, 12, 1221–1250. [Google Scholar] [CrossRef]

- Farhadi, M.; Mohammad, O. Energy Storage Technologies for High-Power Application. IEEE Trans. Ind. Appl. 2016, 52, 1953–1961. [Google Scholar] [CrossRef]

- Calero, F.; Canizares, C.; Bhattacharya, K. Dynamic Modelling of Battery Energy Storage and Applications in Transmission Systems. IEEE Trans. Smart Grid 2021, 12, 589–598. [Google Scholar] [CrossRef]

- Krpan, M.; Kuzle, I.; Radovanovic, A.; Milanovic, J. Modelling of Supercapacitor Banks for Power System Dynamics Studies. IEEE Trans. Power Syst. 2021, 36, 3987–3996. [Google Scholar] [CrossRef]

- Gouda, E.; Abd-Alaziz, A.; El-Saadawi, M. Design Modeling and Control of Multi-stage SMES Integrated with PV System. J. Energy Storage 2020, 29, 101399. [Google Scholar] [CrossRef]

- Rouholamini, M.; Wang, C.; Nehrir, H.; Hu, X.; Hu, Z.; Aki, H.; Zhao, B.; Miao, X.; Strunz, K. A Review of Modelling Management and Applications of Grid Connected Li-ion Battery Storage Systems. IEEE Trans. Smart Grid 2022, 13, 4515–4525. [Google Scholar] [CrossRef]

- Avadhanula, A.K.; Kulkarni, S.S. Comparative Study of Mathematical Models and Data Driven Models for Battery Performance Parameter Estimation. In Proceedings of the 2020 Third International Conference on Advances in Electronics, Computers and Communications (ICAECC), Bengaluru, India, 11–12 December 2020; pp. 1–5. [Google Scholar]

- Gilbert Zequera, R.; Rassõlkin, A.; Vaimann, T.; Kallaste, A. Overview of battery energy storage systems readiness for digital twin of electric vehicles. IET Smart Grid 2023, 6, 5–16. [Google Scholar] [CrossRef]

- Bajpai, P.; Dash, V. Hybrid renewable energy systems for power generation in stand-alone applications: A review. Renew. Sustain. Energy Rev. 2012, 16, 2926–2939. [Google Scholar] [CrossRef]

- Sayed, K.; Kassem, A.; Saleeb, H.; Alghamdi, A.S.; Abo-Khalil, A.G. Energy-Saving of Battery Electric Vehicle Powertrain and Efficiency Improvement during Different Standard Driving Cycles. Sustainability 2020, 12, 10466. [Google Scholar] [CrossRef]

- Zaheeruddin; Manas, M. Renewable Energy Management through Microgrid Central Controller Design: An Approach to Integrate Solar, Wind and Biomass with Battery. Energy Rep. 2015, 1, 156–163. [Google Scholar] [CrossRef]

- Manandhar, U.; Tummuru, N.R.; Kollimalla, S.K.; Ukil, A.; Beng, G.H.; Chaudhari, K. Validation of Faster Joint Control Strategy for Battery- and Supercapacitor-Based Energy Storage System. IEEE Trans. Ind. Electron. 2018, 65, 3286–3295. [Google Scholar] [CrossRef]

- Kollimalla, S.K.; Mishra, M.K.; Ukil, A.; Gooi, H.B. DC Grid Voltage Regulation Using New HESS Control Strategy. IEEE Trans. Sustain. Energy 2017, 8, 772–781. [Google Scholar] [CrossRef]

- Hossain, M.J.; Pota, H.R.; Mahmud, M.A.; Aldeen, M. Robust Control for Power Sharing in Microgrids with Low-inertia Wind and PV Generators. IEEE Trans. Sustain. Energy 2015, 6, 1067–1077. [Google Scholar] [CrossRef]

- Lahyani, A.; Venet, P.; Guermazi, A.; Troudi, A. Battery/Supercapacitors Combination in Uninterruptible Power Supply (UPS). IEEE Trans. Power Electron. 2013, 28, 1509–1522. [Google Scholar] [CrossRef]

- Jone, P.B.; Lakeman, J.B.; Mepsted, G.O.; Moore, J.M. A Hybrid Power Sources for Pulsed Current Applications. J. Power Sources 1999, 80, 242–247. [Google Scholar] [CrossRef]

- Raveendhra, D.; Poojitha, R.; Narasimharaju, B.L.; Dreglea, A.; Liu, F.; Panasetsky, D.; Pathak, M.; Sidorov, D. Part-I: State-of-the-Art Technologies of Solar Powered DC Microgrid with Hybrid Energy Storage Systems-Architecture Topologies. Energies 2023, 16, 923. [Google Scholar] [CrossRef]

- Song, Z.; Hofmann, H.; Li, J.; Han, X.; Zhang, X.; Ouyang, M. A Comparison Study of Different Semi-active Hybrid Energy Storage System Topologies for Electric Vehicles. J. Power Sources 2015, 274, 400–411. [Google Scholar] [CrossRef]

- Gee, A.M.; Robinson, F.V.P.; Dunn, R.W. Analysis of Battery Lifetime Extension in a Small-Scale Wind-Energy System Using Supercapacitors. IEEE Trans. Energy Convers. 2013, 28, 24–33. [Google Scholar] [CrossRef]

- Behera, P.K.; Pattnaik, M. Performance Enhancement of a Modified Filtration based Control Scheme for Hybrid Energy Storage System in Low Voltage Direct Current Microgrid. J. Power Sources 2024, 610, 234698. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, D.; Zou, J.; Shen, Z. Opposite Vector Modulation-based Bidirectional Power Allocation for Single-Stage Multi-port Inverter-Connected Hybrid Energy Storage System. IEEE Trans. Power Electron. 2024, 39, 12200–12212. [Google Scholar] [CrossRef]

- Kollimalla, S.K.; Mishra, M.K.; Narasamma, N.L. Design and Analysis of Novel Control Strategy for Battery and Supercapacitor Storage System. IEEE Trans. Sustain. Energy 2014, 5, 1137–1144. [Google Scholar] [CrossRef]

- Behera, P.K.; Pattnaik, M. Hybrid Energy Storage Integrated Wind Energy fed DC Microgrid Power Distribution Control and Performance Assessment. IEEE Trans. Sustain. Energy 2024, 15, 1502–1514. [Google Scholar] [CrossRef]

- Mendis, N.; Muttaqi, K.M.; Perera, S. Active power management of a super capacitor-battery hybrid energy storage system for standalone operation of DFIG based wind turbines. In Proceedings of the 2012 IEEE Industry Applications Society Annual Meeting, Las Vegas, NV, USA, 7–11 October 2012; pp. 1–8. [Google Scholar]

- Wang, B.; Li, Z.; Fan, H.; Wan, X.; Xian, L.; Zhang, M.; Xu, Q. Higher Order Sliding Mode Observer Based Fast Composite Backstepping Control for HESS in DC Microgrids. IEEE Trans. Sustain. Energy 2024, 15, 1627–1639. [Google Scholar] [CrossRef]

- Paucara, J.D.; Peña, J.C.U.; Sal Y Rosas, D. HESS Management for Virtual Inertia, Frequency, and Voltage Support through Off-Board EV Bidirectional Chargers. IEEE Open J. Ind. Electron. Soc. 2024, 5, 376–385. [Google Scholar] [CrossRef]

- Yim, J.; You, S.; Blaabjerg, F.; Lee, Y.; Gui, Y.; Kim, W. Energy Management Systems for Forecasted Demand Error Compensation using Hybrid Energy Storage System in Nanogrid. Renew. Energy 2024, 221, 119744. [Google Scholar] [CrossRef]

- Guttula, Y.; Samanta, S. Enhanced Energy Management Algorithm for Battery/Ultra-Capacitor based Hybrid Energy Storage System using Interleaved DC-DC Converter. IEEE J. Emerg. Sel. Top. Power Electron. 2024, 12, 5004–5012. [Google Scholar] [CrossRef]

- Lin, G.; Li, Y.; Han, Y.; Wang, S.; Rehtanz, C.; Liu, J. Dynamic Interaction Stabilization Method for Multi-Parallel Hybrid Energy Storage Supplied Electric Vehicle DC Charging Station. IEEE Trans. Transp. Electrif. 2024, 1–12. [Google Scholar] [CrossRef]

- Zhang, X.; Yi, H.; Wen, Y.; Li, Q.; Wang, Z.; Luo, Y.; Zhuo, F. Decentralized Control of Multiple Supercapacitors for Hybrid Energy Storage Converter in Off-grid Mode under Power Fluctuations and Short-time High Power. IEEE Trans. Ind. Appl. 2024, 60, 7225–7239. [Google Scholar] [CrossRef]

- Song, G.; Liu, X.; Xiao, G.; Chen, B.; Wang, P. Decentralized Adaptive Control Strategy of DC-DC Boost Converter for Hybrid Energy Storage Systems Feeding CPLs. IEEE J. Emerg. Sel. Top. Power Electron. 2024, 12, 3663–3674. [Google Scholar] [CrossRef]

- Li, Z.; Wang, B.; Xian, L.; Zhang, M.; Xu, Q. Decentralized Active Disturbance Rejection Control for Hybrid Energy Storage System in DC Microgrid. IEEE Trans. Ind. Electron. 2024, 71, 14232–14243. [Google Scholar] [CrossRef]

- Li, X.; Wang, M.; Jiang, W.; Dong, C.; Xu, Z.; Wu, X. An Autonomous Finite-Time Backstepping Control for Decentralized Automatic Power Sharing of Hybrid Energy Storage Systems in DC Microgrids. IEEE Trans. Smart Grid 2024, 15, 3348–3360. [Google Scholar] [CrossRef]

- Surulivel, N.; Sunny, A.C.; Dev, D.; Samanta, A.K.; Debnath, D. A Novel Four-Port Converter with All Bi-Directional Ports Having Common Ground for Photo-Voltaic Hybrid Energy Storage DC System. IEEE Trans. Circuits Syst. II Express Briefs 2024, 71, 4571–4575. [Google Scholar] [CrossRef]

- Wang, L.; Ke, W.J.Y.; Wu, R.X.; Tripathy, M.; Mokhlis, H.; Chua, K.H.; Prokhorov, A.V.; Nguyen, T.H.; Farid, M.M.; Subiantoro, A.; et al. Stability Evaluation of a Grid-tied Hybrid Wind/PV Farm Joined with a Hybrid Energy Storage System. Sustain. Environ. Res. 2023, 33, 21. [Google Scholar] [CrossRef]

- Li, J.; Han, Y.; Zhou, S.; Li, Z.; Fan, H.; Wang, B. Improved Linear Active Disturbance Rejection Control with Dynamic Event-triggered Mechanism for Hybrid Energy Storage System. IEEE Trans. Transp. Electrif. 2023, 10, 2533–2546. [Google Scholar] [CrossRef]

- Lin, P.; Wang, P.; Xu, Q.; Xiao, J.; Nutkani, I.U.; Choo Fook, H. An integral-droop based dynamic power sharing control for hybrid energy storage system in DC microgrid. In Proceedings of the 2017 IEEE 3rd International Future Energy Electronics Conference and ECCE Asia (IFEEC 2017—ECCE Asia), Kaohsiung, Taiwan, 3–7 June 2017; pp. 338–343. [Google Scholar]

- Lizana, R.; Rivera, S.; Figueroa, F.; Flores-Bahamonde, F.; Rodriguez, J.; Goetz, S.M. Hybrid Energy Storage System based on a Multioutput Multilevel Converter. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 3864–3873. [Google Scholar] [CrossRef]

- Ghorashi Khalil Abadi, S.A.; Bidram, A. Effective Utilization of Grid-forming Cloud Hybrid Energy Storage Systems in Islanded Clustered DC Nano-grids for Improving Transient Voltage Quality and Battery Lifetime. IET Gener. Transm. Distrib. 2023, 17, 1836–1856. [Google Scholar] [CrossRef]

- Shaban, M.; Mosa, M.A.; Ali, A.A.; Abdel-Latif, K.M. Effect of Power Sharing Control Techniques of Hybrid Energy Storage System During Fault Conditions in DC Microgrid. J. Energy Storage 2023, 72, 108249. [Google Scholar] [CrossRef]

- Bhogaraju, I.; Forestieri, J.N.; Malisoff, M.; Farasat, M. Delay Compensating Stabilizing Feedback Controller for a Grid-connected PV/Hybrid Energy Storage System. IEEE Trans. Control Syst. Technol. 2023, 31, 1875–1883. [Google Scholar] [CrossRef]

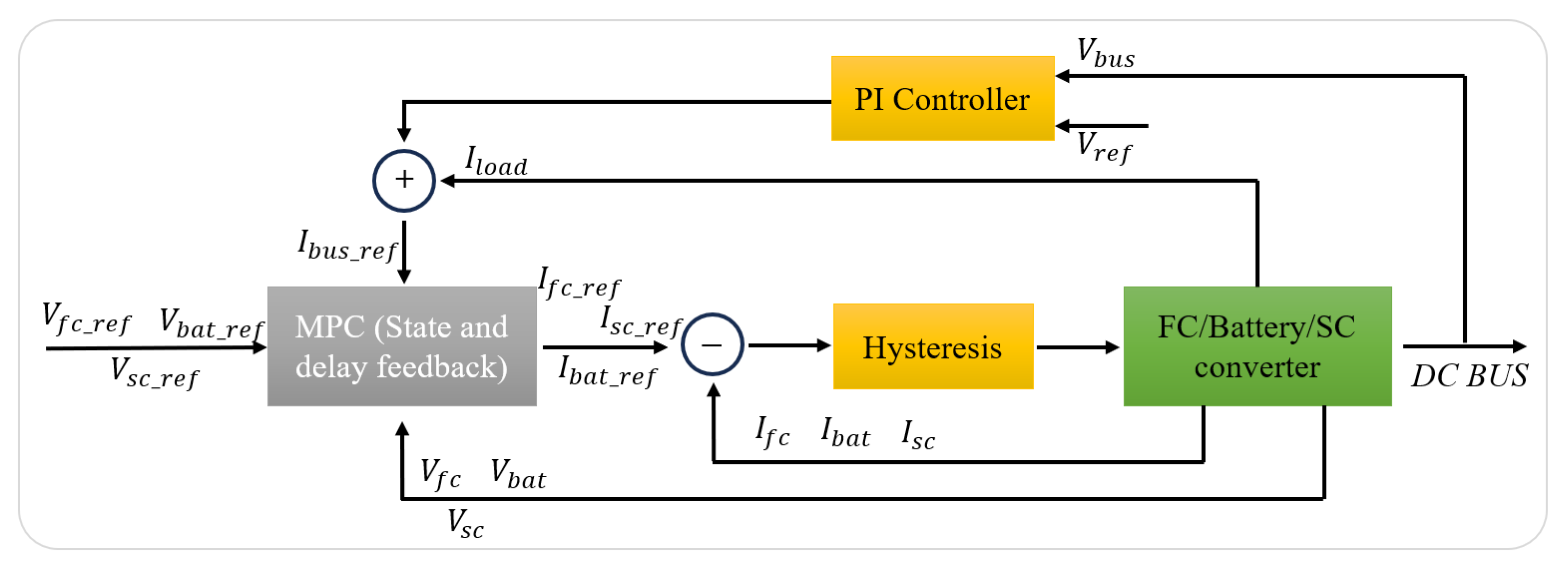

- Amin; Bambang, R.T.; Rohman, A.S.; Dronkers, C.J.; Ortega, R.; Sasongko, A. Energy Management of Fuel cell/battery/supercapacitor Hybrid Power Sources using Model Predictive Control. IEEE Trans. Ind. Inform. 2014, 10, 1992–2002. [Google Scholar] [CrossRef]

- Latorre, A.; Martinez, W.; Cortes, C.A. Average Current Control with Internal Model Control and Real-time Frequency Decoupling for Hybrid Energy Storage Systems in Microgrids. J. Mod. Power Syst. Clean Energy 2023, 11, 511–522. [Google Scholar] [CrossRef]

- Kasari, P.R.; Bhattacharjee, S. An HESS Based on a Modified MMCC-TSBC Converter Integrating Energy Storages. CSEE J. Power Energy Syst. 2023, 9, 1698–1709. [Google Scholar]

- Tan, P.; Huang, L.; Chen, M.; Li, Y.; Wei, L.; Ma, R. A Robust Faster Joint Control of a Direct-Drive Wave Energy Converter Combined with Supercapacitor and Battery Energy Storage. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 5417–5429. [Google Scholar] [CrossRef]

- Lee, Y.L.; Lin, C.H.; Chang, C.H.; Liu, H.D.; Chen, C.C. A Novel Hybrid Energy Storage System with an Adaptive Digital Filter−based Energy Management Strategy for Electric Vehicles. IEEE Trans. Transp. Electrif. 2023, 10, 5131–5142. [Google Scholar] [CrossRef]

- Yuming, C.; Peng, J.; Gaojun, M.; Yao, W.; Tiantian, L. Optimal Capacity Configuration of Hybrid Energy Storage System Considering Smoothing Wind Power Fluctuations and Economy. IEEE Access 2022, 10, 101229–101236. [Google Scholar] [CrossRef]

- Makrygiorgou, J.J.; Alexandridis, A.T. Unified Modeling, Control, and Stability for a Vehicle-to-Grid and Plug-In EV System. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 3284–3301. [Google Scholar] [CrossRef]

- Amaro Pinazo, M.; Romeral Martinez, J.L. Intermittent Power Control in Wind Turbines Integrated into a Hybrid Energy Storage System based on a New State-of-charge Management Algorithm. J. Energy Storage 2022, 54, 105223. [Google Scholar] [CrossRef]

- Kumar, K.; Bae, S. Dynamic Power Management based on Model Predictive Control for Hybrid-energy-storage-based Grid-Connected Microgrids. Int. J. Electr. Power Energy Syst. 2022, 143, 108384. [Google Scholar] [CrossRef]

- Kumar, G.V.B.; Palanisamy, K. Energy Management of Renewable Energy-based Microgrid System with HESS for Various Operation Modes. Front. Energy Res. 2022, 10, 995034. [Google Scholar] [CrossRef]

- Peng, H.; Huang, S.; Wei, J.; Wei, C.; Wu, Q.; Shen, F.; Zhang, W.; Wang, P. Two-stage Decentralized Optimal Voltage Control in Wind Farms with Hybrid ESSs. IEEE Trans. Power Syst. 2024, 39, 6552–6565. [Google Scholar] [CrossRef]

- Farrokhi, E.; Ghoreishy, H.; Ahmadi Ahangar, R. Optimization-based Power Management for Battery/supercapacitor Hybrid Energy Storage System with Load Estimation Capability in a DC Microgrid. Int. J. Electr. Power Energy Syst. 2024, 155, 109665. [Google Scholar] [CrossRef]

- Aktas, A.; Onar, O.C.; Asa, E.; Ozpineci, B.; Tolbert, L.M. Genetic Algorithm-Based Optimal Sizing of Hybrid Battery/Ultracapacitor Energy Storage System for Wave Energy Harvesting Applications. IEEE Access 2024, 12, 125572–125584. [Google Scholar] [CrossRef]

- Ding, Y.; Xu, Q.; Hao, L.; Xia, Y.; Li, D.; Chen, J. Day-ahead Robust Dispatch of Interconnected Multi-microgrids Considering Two-stage Model of Hybrid Energy Storage. J. Energy Storage 2024, 92, 112120. [Google Scholar] [CrossRef]

- Abdelghany, M.B.; Al-Durra, A.; Gao, F. A Coordinated Optimal Operation of a Grid-Connected Wind-Solar Microgrid Incorporating Hybrid Energy Storage Management Systems. IEEE Trans. Sustain. Energy 2024, 15, 39–51. [Google Scholar] [CrossRef]

- Wang, W.; Chen, P.; Ren, G.; Liu, J.; Fang, F.; Chen, Z. Zero-phase CARIMA Filtering and Application in Wind-storage System Sizing and Power Dispatch Optimization. CSEE J. Power Energy Syst. 2023, 1–14. [Google Scholar]

- Chen, X.; Yang, Y.; Song, J.; Wang, J.; He, G. Hybrid Energy Storage System Optimization with Battery Charging and Swapping Coordination. IEEE Trans. Autom. Sci. Eng. 2023, 21, 4094–4105. [Google Scholar] [CrossRef]

- Roy, P.; Liao, Y.; He, J.B. Economic Dispatch for Grid-Connected Wind Power with Battery-Supercapacitor Hybrid Energy Storage System. IEEE Trans. Ind. Appl. 2023, 59, 1118–1128. [Google Scholar] [CrossRef]

- Roy, P.; Karayaka, H.B.; He, J.; Yu, Y.H. Cost Investigation of Battery-supercapacitor Hybrid Energy Storage System for Grid-Connected Hourly Dispatching Wave Energy Converter Power. J. Energy Storage 2023, 72, 108347. [Google Scholar] [CrossRef]

- Khosravi, M.; Afsharnia, S.; Farhangi, S. Stochastic Power Management Strategy for Optimal Day-ahead Scheduling of Wind-HESS Considering Wind Power Generation and Market Price Uncertainties. Int. J. Electr. Power Energy Syst. 2022, 134, 107429. [Google Scholar] [CrossRef]

- Díaz-González, F.; Chillón-Antón, C.; Llonch-Masachs, M.; Galceran-Arellano, S.; Rull-Duran, J.; Bergas-Jané, J.; Bullich-Massagué, E. A Hybrid Energy Storage Solution based on Supercapacitors and Batteries for the Grid Integration of Utility Scale Photovoltaic Plants. J. Energy Storage 2022, 51, 104446. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Xue, L.; Liu, C.; Song, F.; Sun, Y.; Liu, Y.; Che, B. Research on Planning Optimization of Integrated Energy System based on the Differential Features of Hybrid Energy Storage System. J. Energy Storage 2022, 55, 105368. [Google Scholar] [CrossRef]

- Sepehrzad, R.; Mahmoodi, A.; Ghalebi, S.Y.; Moridi, A.R.; Seifi, A.R. Intelligent Hierarchical Energy and Power Management to Control the Voltage and Frequency of Micro-grids based on Power Uncertainties and Communication Latency. Electr. Power Syst. Res. 2022, 202, 107567. [Google Scholar] [CrossRef]

- Cao, Y.; Wu, Q.; Zhang, H.; Li, C. Optimal Sizing of Hybrid Energy Storage System Considering Power Smoothing and Transient Frequency Regulation. Int. J. Electr. Power Energy Syst. 2022, 142, 108227. [Google Scholar] [CrossRef]

- Fukaume, S.; Nagasaki, Y.; Tsuda, M. Stable Power Supply of an Independent Power Source for a Remote Island using a Hybrid Energy Storage System Composed of Electric and Hydrogen Energy Storage Systems. Int. J. Hydrogen Energy 2022, 47, 13887–13899. [Google Scholar] [CrossRef]

- Feng, L.; Zhang, X.; Li, X.; Li, B.; Li, Y.; Xu, Y.; Guo, H.; Zhou, X.; Chen, H. Performance Analysis of Hybrid Energy Storage Integrated with Distributed Renewable Energy. Energy Rep. 2022, 8, 1829–1838. [Google Scholar] [CrossRef]

- Saxena, A.; Shankar, R. Improved Load Frequency Control Considering Dynamic Demand Regulated Power System Integrating Renewable Sources and Hybrid Energy Storage System. Sustain. Energy Technol. Assess. 2022, 52, 102245. [Google Scholar] [CrossRef]

- Tang, Z.; Liu, J.; Zeng, P. A Multi-Timescale Operation Model for Hybrid Energy Storage System in Electricity Markets. Int. J. Electr. Power Energy Syst. 2022, 138, 107907. [Google Scholar] [CrossRef]

- Li, B.; Wang, H.; Tan, Z. Capacity Optimization of Hybrid Energy Storage System for Flexible Islanded Microgrid based on Real-time Price-based Demand Response. Int. J. Electr. Power Energy Syst. 2022, 136, 107581. [Google Scholar] [CrossRef]

- Abbassi, A.; Mehrez, R.B.; Abbassi, R.; Saidi, S.; Albdran, S.; Jemli, M. Improved Off-grid Wind/Photovoltaic/Hybrid Energy Storage System based on New Framework of Moth-Flame Optimization Algorithm. Int. J. Energy Res. 2022, 46, 6711–6729. [Google Scholar] [CrossRef]

- Wang, Q.; Luo, Y. Research on a New Power Distribution Control Strategy of Hybrid Energy Storage System for Hybrid Electric Vehicles based on the Subtractive Clustering and Adaptive Fuzzy Neural Network. Clust. Comput. 2022, 25, 4413–4422. [Google Scholar] [CrossRef]

- Li, C.; Liu, X.; Wang, R.; Zhang, Y.; Zhang, L. An Improved Dual-Loop Feedforward Control Method for the Enhancing Stability of Grid-Connected PV and Energy Storage System under Weak Grids. Front. Energy Res. 2022, 10, 939376. [Google Scholar] [CrossRef]

- Yi, F.; Lu, D.; Wang, X.; Pan, C.; Tao, Y.; Zhou, J.; Zhao, C. Energy Management Strategy for Hybrid Energy Storage Electric Vehicles Based on Pontryagin’s Minimum Principle Considering Battery Degradation. Sustainability 2022, 14, 1214. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, J.; Qin, B.; Guo, L. Coordinated Control of Wind Turbine and Hybrid Energy Storage System based on Multiagent Deep Reinforcement Learning for Wind Power Smoothing. J. Energy Storage 2023, 57, 106297. [Google Scholar] [CrossRef]

- Liu, Y.; Han, X.; Xing, Z.; Li, P.; Liu, H.; Jiang, Z. Research on Control Strategy of Hybrid Superconducting Energy Storage based on Reinforcement Learning Algorithm. IEEE Trans. Appl. Supercond. 2024, 34, 5701404. [Google Scholar] [CrossRef]

- Jena, C.J.; Ray, P.K. Power Allocation Scheme for Grid Interactive Microgrid with Hybrid Energy Storage System using Model Predictive Control. J. Energy Storage 2024, 81, 110401. [Google Scholar] [CrossRef]

- Ankar, S.J.; Pinkymol, K.P. Optimal Sizing and Energy Management of Electric Vehicle Hybrid Energy Storage Systems with Multi-Objective Optimization Criterion. IEEE Trans. Veh. Technol. 2024, 73, 11082–11096. [Google Scholar] [CrossRef]

- Li, J.; Yao, F.; Yang, Q.; Wei, Z.; He, H. Variable Voltage Control of a Hybrid Energy Storage System for Firm Frequency Response in the U.K. IEEE Trans. Ind. Electron. 2022, 69, 13394–13404. [Google Scholar] [CrossRef]

- Hu, L.; Tian, Q.; Zou, C.; Huang, J.; Ye, Y.; Wu, X. A Study on Energy Distribution Strategy of Electric Vehicle Hybrid Energy Storage System Considering Driving Style based on Real Urban Driving Data. Renew. Sustain. Energy Rev. 2022, 162, 112416. [Google Scholar] [CrossRef]

- Zhang, X.; Pei, W.; Mei, C.; Deng, W.; Tan, J.; Zhang, Q. Transform from Gasoline Stations to Electric-Hydrogen Hybrid Refueling Stations: An Islanding DC Microgrid with Electric-Hydrogen Hybrid Energy Storage System and its Control Strategy. Int. J. Electr. Power Energy Syst. 2022, 136, 107684. [Google Scholar] [CrossRef]

- Ghasemi, A.; Sedighizadeh, M.; Fakharian, A.; Nasiri, M.R. Intelligent Voltage and Frequency Control of Islanded Micro-Grids based on Power Fluctuations and Communication System Uncertainty. Int. J. Electr. Power Energy Syst. 2022, 143, 108383. [Google Scholar] [CrossRef]

- Fallah Ghavidel, H.; Mousavi-G, S.M. Modeling Analysis, Control, and Type-2 Fuzzy Energy Management Strategy of Hybrid Fuel cell-Battery-Supercapacitor Systems. J. Energy Storage 2022, 51, 104456. [Google Scholar] [CrossRef]

- Yan, L.; Shui, T.; Xue, T.; Wang, M.; Ma, N.; Li, K. Comprehensive Control Strategy Considering Hybrid Energy Storage for Primary Frequency Modulation. Energies 2022, 15, 4079. [Google Scholar] [CrossRef]

- Dai, K.; Xiong, W.; Yuan, X.; Zheng, H.; Feng, Q.; Xu, Y.; Cai, Y.; Guo, D. Additional Compound Damping Control to Suppress Low-Frequency Oscillations in a Photovoltaic Plant with a Hybrid Energy Storage System. Energies 2022, 15, 9044. [Google Scholar] [CrossRef]

- Mohamed, M.M.; El Zoghby, H.M.; Sharaf, S.M.; Mosa, M.A. Optimal Virtual Synchronous Generator Control of Battery/Supercapacitor Hybrid Energy Storage System for Frequency Response Enhancement of Photovoltaic/Diesel Microgrid. J. Energy Storage 2022, 51, 104317. [Google Scholar] [CrossRef]

- Chankaya, M.; Ahmad, A.; Hussain, I. Path-Finder Optimization Based Control of Grid-Tied PV Hybrid Energy Storage System. IETE J. Res. 2023, 69, 5289–5306. [Google Scholar] [CrossRef]

- Ohara, K. Evaluation of climate model performance. In Climate Change in the Anthropocene; Elsevier: Amsterdam, The Netherlands, 2022; pp. 41–62. [Google Scholar]

- UN Environment Programme. Emissions Gap Report 2023: Broken Record (Temperatures Hit New Highs, Yet World Fails to Cut Emissions (Again)); UN Environment Programme: Nairobi, Kenya, 2023. [Google Scholar]

- Shahzad, S.; Abbasi, M.A.; Shahid, M.B.; Guerrero, J.M. Unlocking the Potential of Long-duration Energy Storage: Pathways to Net-zero Emissions through Global Innovation and Collaboration. J. Energy Storage 2024, 97, 112904. [Google Scholar] [CrossRef]

- Fam, A.; Fam, S. Review of the US 2050 Long term Strategy to Reach Net Zero Carbon Emissions. Energy Rep. 2024, 12, 845–860. [Google Scholar] [CrossRef]

- Bahloul, M.; Khadem, S.K. Impact of Power Sharing Method on Battery Life Extension in HESS for Grid Ancillary Services. IEEE Trans. Energy Convers. 2019, 34, 1317–1327. [Google Scholar] [CrossRef]

- Vulturescu, B.; Butterbach, S.; Forgez, C. Experimental Considerations on the Battery Lifetime of a Hybrid Power Source Made of Ultracapacitors and Lead-Acid Batteries. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 701–709. [Google Scholar] [CrossRef]

- Lakshmi, D.; Ravi, C.N.; Zahira, R.; Palanisamy, S.; Chenniappan, S. Introduction to renewable energy sources and bulk power system. In Power Systems Operation with 100% Renewable Energy Sources; Chenniappan, S., Padmanaban, S., Palanisamy, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 1–13. [Google Scholar]

- Younghyun, K.; Yanzhi, W.; Naehyuck, C.; Massoud, P. Computer-Aided Design and Optimization of Hybrid Energy Storage Systems; Foundation and Trade in Electronic Design Automation: Wien, Austria, 2013; pp. 247–338. [Google Scholar]

- Ibrahim, H.; Rezkallah, M.; Ilinca, A.; Ghandour, M. Hybrid energy storage systems. In Hybrid Renewable Energy Systems and Microgrids; Kabalci, E., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 351–372. [Google Scholar]

- Masood, U.; Azeem, M.K.; Ahmad, I.; Jabbar, A.U. Robust Adaptive Nonlinear Control of Plugin Hybrid Electric Vehicles for Vehicle to Grid and Grid to Vehicle Power Flow with Hybrid Energy Storage System. ISA Trans. 2023, 139, 406–424. [Google Scholar] [CrossRef]

| Storage Technology | Name of the Project | Country | Power (MW) | Energy (MWh) |

|---|---|---|---|---|

| PS [6] | Pioneer-Burdekin pumped storage | Australia | 5000 | 120,000 |

| PS [26] | Fengning pumped storage | China | 3600 | 40,000 |

| FES [27] | Hazle spindle FES by Beacon Power | USA | 20 | - |

| CAES [28] | Hubei Yingchang | China | 300 | 1500 |

| BESS [29] | Edwards & Sanborn solar-plus-storage project | USA | - | 3287 |

| SC [30] | - | China | 5 | - |

| Storage Technology | Ranking Points 1 |

|---|---|

| LIB | 3 |

| VRFB | 4 |

| Lead–acid Battery | 1 |

| Storage Technology | Charge Time | Discharge Time | Leakage (%/Day) | Response Time | Lifetime (Years) |

|---|---|---|---|---|---|

| PS | h–month | h–days | very small | min | 40–60 |

| FES | s–min | s–min | 20%/h | ms–s | 15–20 |

| CAES | h–month | h–days | 0.5–1 | 1–15 min | 20–40 |

| HFC | h–month | s–days | 0.003–0.03 | ms–min | 20–30 |

| LIB | min–day | min–24 h | 0.1–5 | ms–s | 5–16 |

| VRFB | h–month | s–h | very small | s | 5–20 |

| Lead-acid Battery | h–month | s–h | 0.1–0.3 | s | 5–15 |

| SC | s–h | s–1.2 h | 5–40 | ms | 10–30 |

| SMES | min–h | ms–30 min | 10–15 | ms | 20–30 |

| Storage Technology | Stored Energy | Power Range (MW) | Energy Range (MWh) | Power Density (W/L) | Energy Density (Wh/L) |

|---|---|---|---|---|---|

| PS | Mechanical | 10–5000 | 180–120,000 | 0.5–1.5 | 0.5–1.5 |

| FES | Mechanical | 0.25–20 | 0.0052–5 | 1000–2000 | 20–80 |

| CAES | Thermal | 5–300 | 580–1500 | 0.5–2 | 3–6 |

| HFC | Chemical | 0–58.5 | 0.312–39 | 0.2–20 | 500–3000 |

| LIB | Electro-chemical | 0–100 | 0.004–10 | 500–2000 | 200–480 |

| VRFB | Electro-chemical | 0.3–3 | <60 | 0.5–2 | 16–33 |

| Lead-Acid Battery | Electro-chemical | 0–40 | 0.001–40 | 10–400 | 50–80 |

| SC | Electro-chemical | 0–5 | 0.0005 | 500–5000 | 2.5–15 |

| SMES | Electrical | 0.1–10 | 0.0008–0.015 | 1000–4000 | 0.5–15 |

| Reference | HESS | Solving Technique | Objectives/Advantages |

|---|---|---|---|

| [124] | SC–BESS | An online gradient projection-based iterative algorithm | Minimize voltage deviation in reactive power control |

| [125] | SC–BESS | Adaptive Kalman filter | Voltage regulation |

| [150] | SC–BESS | Non-dominating sorting genetic algorithm III (NSGA-III) | Battery life improvement, size reduction |

| [126] | UC–BESS | GA | Battery life improvement, size reduction |

| [127] | Thermal and electrical | Combination of column-and-constraint generation and analytical target cascading algorithm | Minimization of day-ahead energy cost |

| [69] | BESS–HSS | Information Gap Decision Theory-based normalized weighted-sum approach | Reduction of financial cost, carbon emissions, EEI |

| [128] | BESS–HSS | GA | HESS maintenance, cost-saving, and enhanced battery lifetime |

| [129] | UC–BESS | The zero-phase controlled Auto-Regressive Integrated Moving Average filter algorithm | Reduction in size |

| [63] | SMES–VRFB | Golden Eagle optimization | Improved settling time for frequency, reduced frequency overshoot and undershoot (objective function is Integral Time Absolute Error) |

| [130] | BESS–BESS | PSO | Maximize revenue through arbitrage |

| [131] | SC–BESS | PSO | Minimize lifecycle cost of BESS |

| [132] | SC–BESS | PSO | Minimize lifecycle cost of BESS |

| [133] | SC–BESS | Mixed integer linear programming | Optimizing day-ahead market profit |

| [58] | FES–BESS | Quadratic programming | Improved AGC of thermal generators |

| [70] | HSS–BESS | NSGA-II | Annualized cost of system, LPSP, and potential energy waste probability |

| [152] | SC–BESS | Gray wolf optimization | Battery life extension and energy loss minimization |

| [135] | SC–BESS–heat | GA | Power smoothing, reducing financial cost |

| [137] | SC–BESS | Linear weighted method and generalized Benders’ decomposition | HESS capacity |

| [138] | SC–HSS | Kalman filter | Transient stability, financial cost |

| [139] | SC–BESS–CAES | GA | Optimal capacity allocation and cost |

| [140] | SC–BESS | Quasi-oppositional Harris Hawks optimization | Power system demand response regulation |

| [43] | SC–BESS | Self-adaptive VMD | Reduction in HESS lifecycle cost |

| [141] | Generic model of power-based ESS (SC) and energy-based ESS (BESS) | Integrating progressive hedging and dual decomposition algorithms | Increase storage lifetime and ensure proper scheduling |

| [154] | SC–BESS | PSO in primary controller | Precise and efficient voltage and frequency control |

| [142] | SC–BESS | m-II | Comprehensive operating cost and flexibility insufficiency rate |

| [66] | BESS–SMES | PSO | Optimizing economic cost |

| [143] | SC–BESS | Modified moth–flame optimization algorithm | Minimizing total cost of electricity |

| [144] | Power battery–SC | Subtractive clustering | Improve energy storage performance of hybrid electric vehicles |

| [146] | SC–BESS | Pontryagin’s minimum principle optimization | Reduced energy usage rate and slower battery degradation |

| Reference | HESS | AI Algorithm | Objectives/Advantages |

|---|---|---|---|

| [126] | BESS–SMES | ADP based on reinforcement learning | Power system reliability improvement and reduction in power fluctuations |

| [64] | BESS–SMES | ADP based on reinforcement learning | Reduction in power fluctuations |

| [149] | BESS–SC | Fuzzy logic rule-based power sharing strategy | Power smoothing and voltage stability |

| [150] | SC–BESS | Sugeno-type fuzzy logic controller | Battery life improvement, size reduction |

| [61] | BESS–SMES | Two-layer control, upper layer is fuzzy logic-controlled | Battery life improvement, enhanced system voltage stability |

| [147] | SC–BESS | Multi-agent deep reinforcement learning | Optimal power allocation |

| [151] | SC–BESS | Fuzzy logic combined with a dynamic filtering method to devise a power management strategy | Enhanced SC utilization and low converter cost |

| [155] | SC–BESS | Type 2 fuzzy strategy | Enhanced asymptotic stability, fast tracking DC-bus voltage regulation, and signal noise reduction |

| [153] | HSS–BESS | Fuzzy logic controller for power allocation | DC-bus voltage stability |

| [136] | SC–BESS | INN (for secondary control) | Voltage and frequency stability |

| [154] | SC–BESS | Fuzzy logic in primary controller and INN in secondary controller | Precise and efficient voltage and frequency control |

| [144] | Power battery–SC | Adaptive fuzzy neural network | Improve energy storage performance of hybrid electric vehicles |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aslam, M.U.; Shakhawat, N.S.B.; Shah, R.; Amjady, N.; Miah, M.S.; Amin, B.M.R. Hybrid Energy Storage Modeling and Control for Power System Operation Studies: A Survey. Energies 2024, 17, 5976. https://doi.org/10.3390/en17235976

Aslam MU, Shakhawat NSB, Shah R, Amjady N, Miah MS, Amin BMR. Hybrid Energy Storage Modeling and Control for Power System Operation Studies: A Survey. Energies. 2024; 17(23):5976. https://doi.org/10.3390/en17235976

Chicago/Turabian StyleAslam, Muhammad Usman, Nusrat Subah Binte Shakhawat, Rakibuzzaman Shah, Nima Amjady, Md Sazal Miah, and B. M. Ruhul Amin. 2024. "Hybrid Energy Storage Modeling and Control for Power System Operation Studies: A Survey" Energies 17, no. 23: 5976. https://doi.org/10.3390/en17235976

APA StyleAslam, M. U., Shakhawat, N. S. B., Shah, R., Amjady, N., Miah, M. S., & Amin, B. M. R. (2024). Hybrid Energy Storage Modeling and Control for Power System Operation Studies: A Survey. Energies, 17(23), 5976. https://doi.org/10.3390/en17235976