The Role of Underground Salt Caverns in Renewable Energy Peaking: A Review

Abstract

1. Introduction

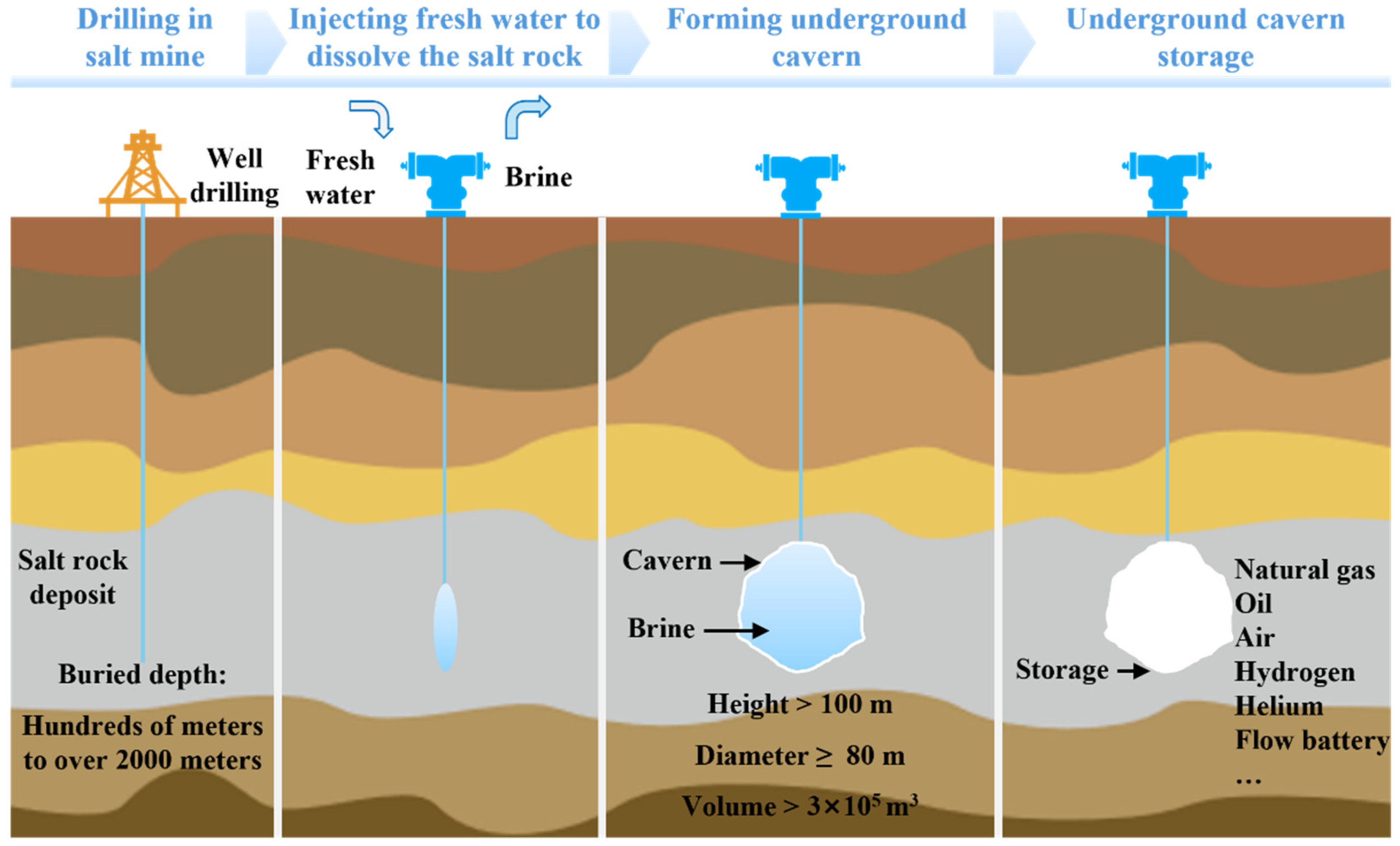

2. Pathways for Renewable Energy Storage Utilizing Salt Caverns

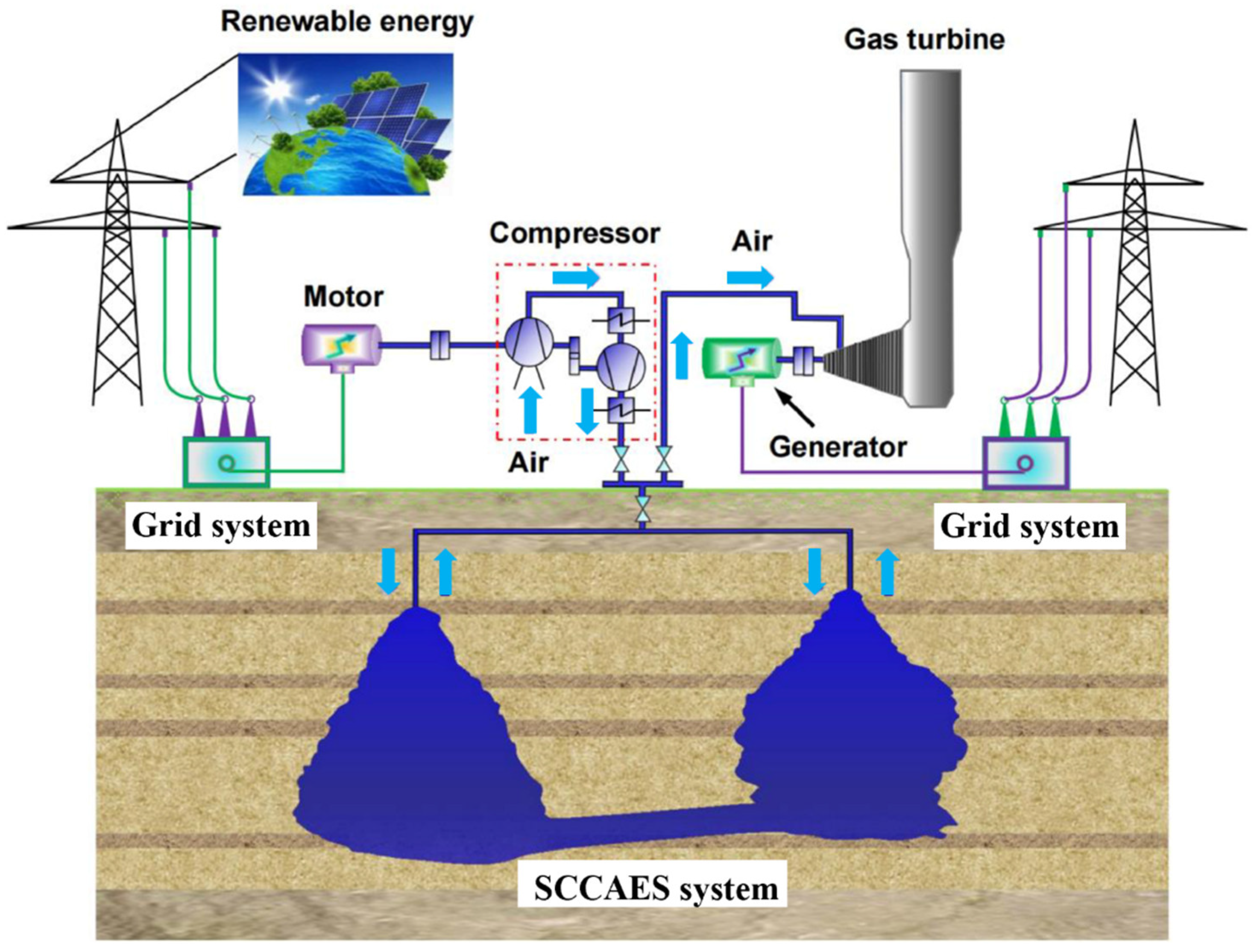

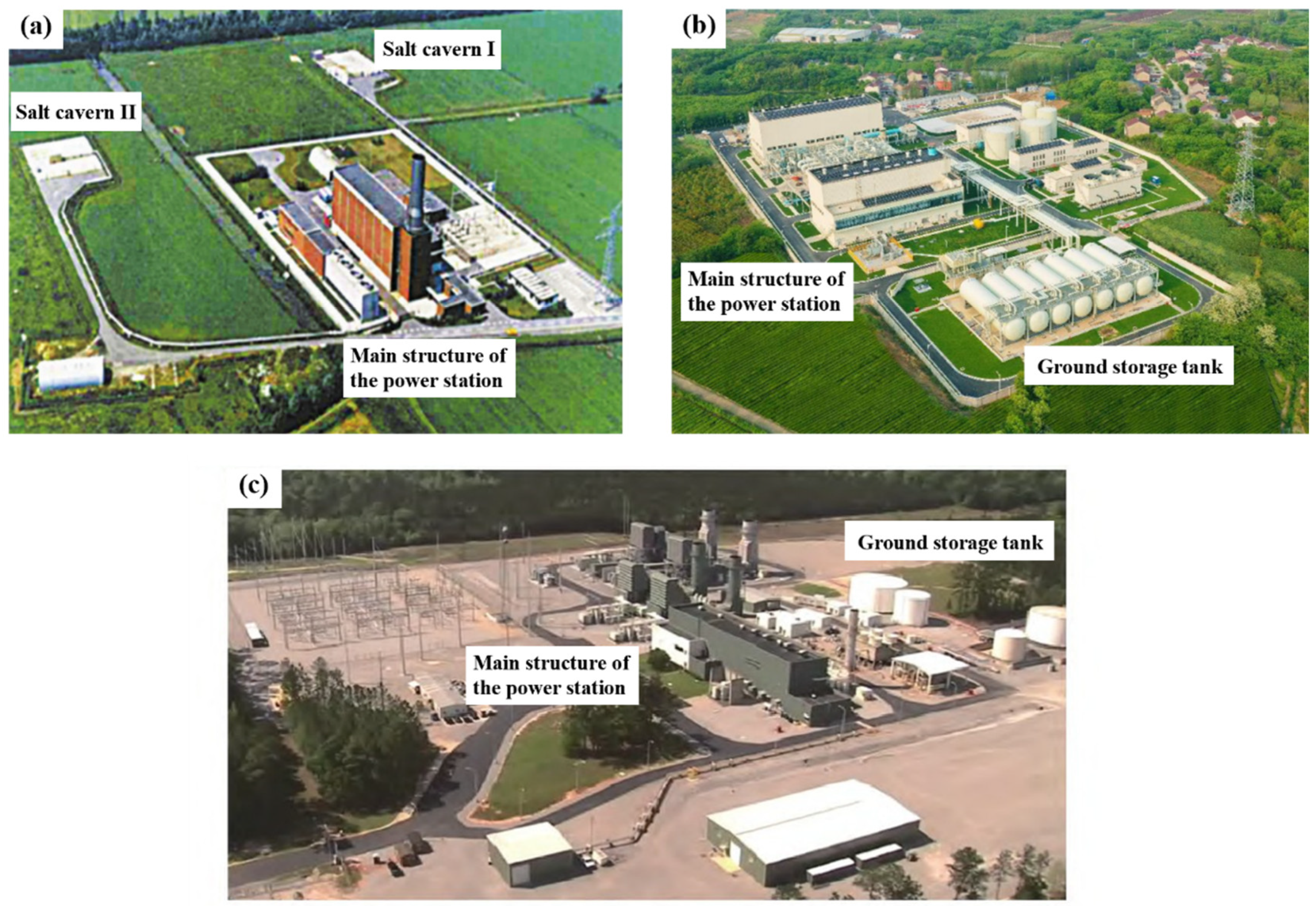

2.1. Salt Cavern Compressed Air Energy Storage

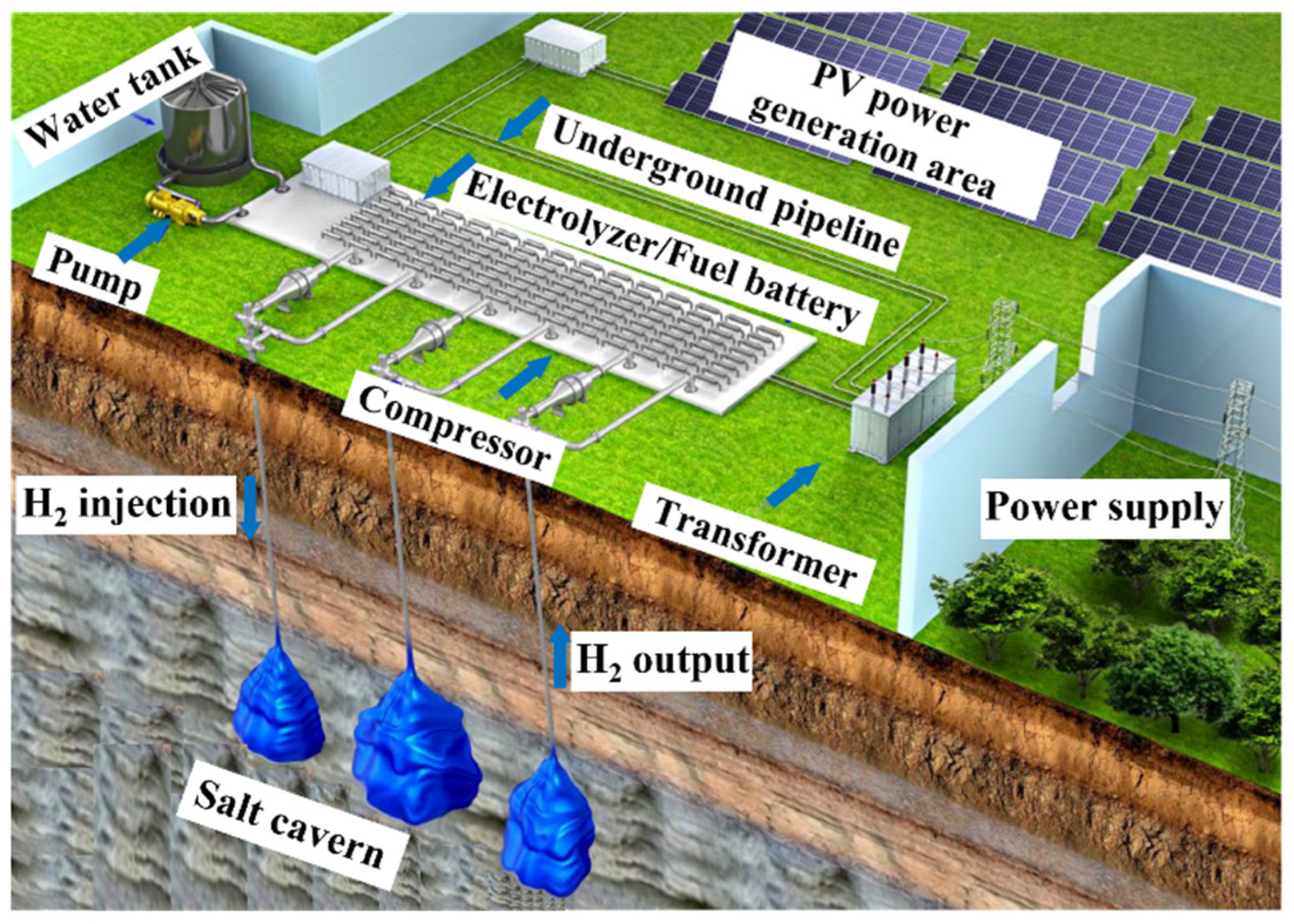

2.2. Salt Cavern Hydrogen Storage

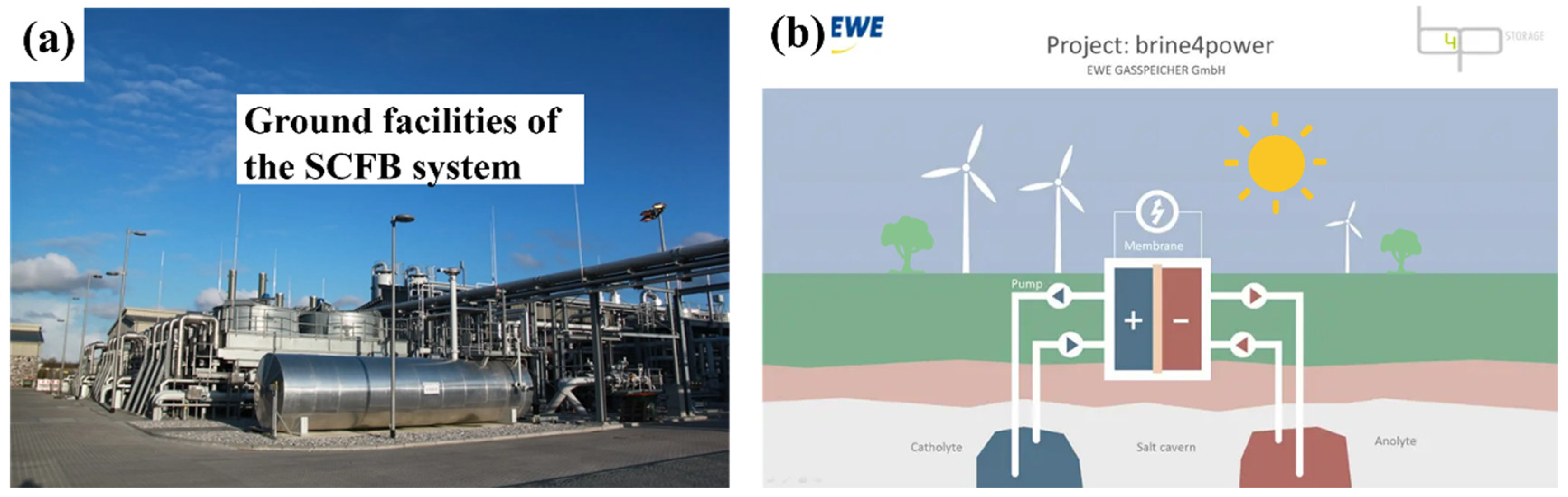

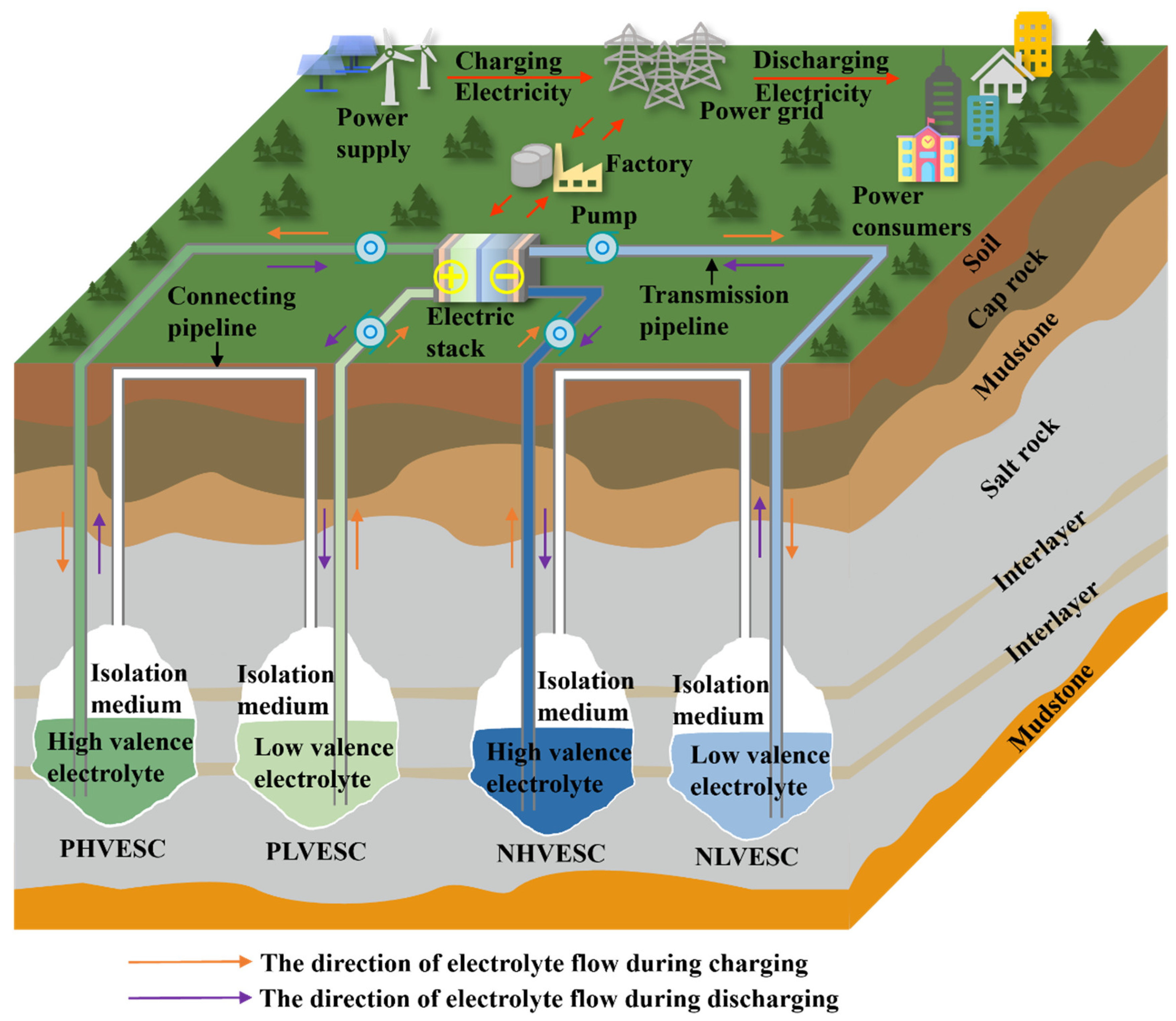

2.3. Salt Cavern Flow Battery

3. Key Technical Challenges of Different Salt Cavern Energy Storage Methods

3.1. Key Challenges of SCCAES

3.2. Key Challenges of SCHS

3.3. Key Challenges of SCFB

4. Comparison of Underground Large-Scale Energy Storage Methods

4.1. Environmental and Safety Risk Analysis of Salt Cavern Energy Storage

4.2. Comparative Analysis with Alternative Energy Storage Technologies

5. Conclusions

- (1)

- The key challenge of SCCAES is that its overall energy efficiency is only about 60%. It is recommended to develop more advanced core equipment, such as compressors, energy storage systems, and control systems, which play a critical role in improving energy efficiency. Reducing the cost of ground equipment should be the focus of future research. Based on the considerations of tightness and output power for SCCAES, it is recommended that the burial depth of the salt cavern should range from 500 to 1000 m.

- (2)

- Unlike natural gas and air, hydrogen has extremely high compression and diffusion coefficients. This makes the biggest challenge for SCHS the risk of hydrogen leakage. Conducting in-depth research on the diffusion and permeation mechanisms of hydrogen in the surrounding rock of salt caverns, which could also serve as the theoretical foundation for the development of SCHS pipeline materials, is recommended. The development of new materials should be directed toward superior tightness and corrosion resistance. Due to the relatively low volumetric energy density of hydrogen, it is recommended that the operating pressure of SCHS should be appropriately widened, which can help reduce the storage cost per unit volume of salt caverns.

- (3)

- The key challenge of SCFB is the low and uneven distribution of active materials within the huge salt caverns. This challenge can be addressed by deploying two salt caverns at each of the positive or negative electrodes of the SCFB to store the electrolyte before and after the redox reaction. It is essential to thoroughly investigate the impact of impurity ions (such as K+, Ca2+, Mg2+, CO32−, SO42−, and Fe2+) in the salt cavern on the electrochemical performance of the SCFB. Considering the temperature conditions of the electrolyte working environment, it is recommended that the burial depth of the salt cavern range from 500 to 1500 m. Developing electrolytes with better electrochemical properties is key to facilitating SCFB development.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wegener, L. Can the Paris Agreement Help Climate Change Litigation and Vice Versa? Transnatl. Environ. Law 2020, 9, 17–36. [Google Scholar] [CrossRef]

- Yun, G. China’s response to climate change issues after Paris Climate Change Conference. Adv. Clim. Chang. Res. 2016, 7, 235–240. [Google Scholar]

- Feng, Y.; Yang, C.-Y.; Lu, C.-C.; Tang, P.-Y. Measuring Pollution Control and Environmental Sustainable Development in China Based on Parallel DEA Method. Energies 2022, 15, 5697. [Google Scholar] [CrossRef]

- Worek, J.; Badura, X.; Biaas, A.; Chwiej, J.; Kawoń, K.; Styszko, K. Pollution from Transport: Detection of Tyre Particles in Environmental Samples. Energies 2022, 15, 2816. [Google Scholar] [CrossRef]

- Erickson, P.; Lazarus, M.; Piggot, G. Limiting fossil fuel production as the next big step in climate policy. Nat. Clim. Chang. 2018, 8, 1037–1043. [Google Scholar] [CrossRef]

- McGlade, C.; Ekins, P. The geographical distribution of fossil fuels unused when limiting global warming to 2 degrees C. Nature 2015, 517, 187–190. [Google Scholar] [CrossRef]

- Lacis, A.A.; Schmidt, G.A.; Rind, D.; Ruedy, R.A. Atmospheric CO2: Principal Control Knob Governing Earth’s Temperature. Science 2010, 330, 356–359. [Google Scholar] [CrossRef] [PubMed]

- Guan, D.; Liu, Z.; Geng, Y.; Lindner, S.; Hubacek, K. The gigatonne gap in China’s carbon dioxide inventories. Nat. Clim. Chang. 2012, 2, 672–675. [Google Scholar] [CrossRef]

- Tan, K.M.; Babu, T.S.; Ramachandaramurthy, V.K.; Kasinathan, P.; Solanki, S.G.; Raveendran, S.K. Empowering smart grid: A comprehensive review of energy storage technology and application with renewable energy integration. J. Energy Storage 2021, 39, 102591. [Google Scholar] [CrossRef]

- Gangopadhyay, A.; Seshadri, A.K.; Sparks, N.J.; Toumi, R. The role of wind-solar hybrid plants in mitigating renewable energy-droughts. Renew. Energy 2022, 194, 926–937. [Google Scholar] [CrossRef]

- Preston, B.J. The Influence of the Paris Agreement on Climate Litigation: Causation, Corporate Governance and Catalyst (Part II). J. Environ. Law 2020, 33, 227–256. [Google Scholar] [CrossRef]

- Berrich, O.; Mafakheri, F.; Dabbou, H. Renewable Energy Transition and the Paris Agreement: How Governance Quality Makes a Difference? Energies 2024, 17, 4238. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, X.D.; Zhong, J.T.; Guo, L.F.; Guo, S.Y.; Wang, D.Y.; Miao, C.H.; Zhang, X.L.; Zhang, X.Y. A representative CO2 emissions pathway for China toward carbon neutrality under the Paris Agreement’s 2 °C target. Adv. Clim. Chang. Res. 2023, 14, 941–951. [Google Scholar] [CrossRef]

- Shu, Z.; Jin, J.; Zhang, J.; Wang, G.; Lian, Y.; Liu, Y.; Bao, Z.; Guan, T.; He, R.; Liu, C.; et al. 1.5 °C and 2.0 °C of global warming intensifies the hydrological extremes in China. J. Hydrol. 2024, 635, 131229. [Google Scholar] [CrossRef]

- Chen, L.; Msigwa, G.; Yang, M.; Osman, A.; Fawzy, S.; Rooney, D.; Yap, P. Strategies to achieve a carbon neutral society a review. Environ. Chem. Lett. 2022, 20, 2277–2310. [Google Scholar] [CrossRef]

- Guo, Q.; Xi, X.; Yang, S.; Cai, M. Technology strategies to achieve carbon peak and carbon neutrality for China’s metal mines. Int. J. Miner. Metall. Mater. 2022, 29, 626–634. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, K.; Kang, J.; Chen, W.; Wang, X.; Zhang, X. Policy and Management of Carbon Peaking and Carbon Neutrality: A Literature Review. Engineering 2022, 14, 52–63. [Google Scholar] [CrossRef]

- Zhao, F.; Liu, X.; Zhang, L.W. Automobile Industry under China’s Carbon Peaking and Carbon Neutrality Goals: Challenges, Opportunities, and Coping Strategies. J. Adv. Transp. 2022, 2022, 5834707. [Google Scholar] [CrossRef]

- Liu, Q.; Lei, Q.; Xu, H.; Yuan, J. China’s energy revolution strategy into 2030. Resour. Conserv. Recycl. 2018, 128, 78–89. [Google Scholar] [CrossRef]

- Qiu, S.; Lei, T.; Wu, J.; Bi, S. Energy Demand and Supply Planning of China through 2060. Energy 2021, 234, 121193. [Google Scholar] [CrossRef]

- Feng, T.; Sun, L.; Zhang, Y. The relationship between energy consumption structure, economic structure and energy intensity in China. Energy Policy 2009, 37, 5475–5483. [Google Scholar] [CrossRef]

- Sun, J.; Li, G.; Wang, Z. Optimizing China’s Energy Consumption Structure under Energy and Carbon Constraints. Struct. Chang. Econ. Dyn. 2018, 47, 57–72. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, H. Strategies for development of clean energy in China. Pet. Sci. 2008, 5, 183–188. [Google Scholar] [CrossRef]

- Liang, J.; Langbein, L. Performance Management, High-Powered Incentives, and Environmental Policies in China. Int. Public Manag. J. 2015, 18, 346–385. [Google Scholar] [CrossRef]

- Liu, H.; Liang, D. A review of clean energy innovation and technology transfer in China. Renew. Sustain. Energy Rev. 2013, 18, 486–498. [Google Scholar] [CrossRef]

- Bai, W.; Shi, X.; Yang, C.; Zhu, S.; Wei, X.; Li, Y.; Liu, X. Assessment of the potential of salt mines for renewable energy peaking in China. Energy 2024, 300, 131577. [Google Scholar] [CrossRef]

- Chen, X.H.; Tee, K.; Elnahass, M.; Ahmed, R. Assessing the environmental impacts of renewable energy sources: A case study on air pollution and carbon emissions in China. J. Environ. Manag. 2023, 345, 118525. [Google Scholar] [CrossRef]

- Liu, L.Q.; Wang, Z.X.; Zhang, H.Q.; Xue, Y.C. Solar energy development in China-A review. Renew. Sustain. Energy Rev. 2010, 14, 301–311. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, Q.; Hu, S.; Xu, H.; Rasmussen, C.N. Review of energy storage system for wind power integration support. Appl. Energy 2015, 137, 545–553. [Google Scholar] [CrossRef]

- Rehman, S.; Al-Hadhrami, L.M.; Alam, M.M. Pumped hydro energy storage system: A technological review. Renew. Sustain. Energy Rev. 2015, 44, 586–598. [Google Scholar] [CrossRef]

- Barbier, E. Geothermal energy technology and current status: An overview. Renew. Sustain. Energy Rev. 2002, 6, 3–65. [Google Scholar] [CrossRef]

- Ellahi, M.; Abbas, G.; Khan, I.; Koola, P.M.; Nasir, M.; Raza, A.; Farooq, U.; Sciubba, E. Recent Approaches of Forecasting and Optimal Economic Dispatch to Overcome Intermittency of Wind and Photovoltaic (PV) Systems: A Review. Energies 2019, 12, 4392. [Google Scholar] [CrossRef]

- Marouani, I.; Guesmi, T.; Hadj Abdallah, H.; Alshammari, B.M.; Alqunun, K.; Alshammari, A.S.; Rahmani, S. Combined Economic Emission Dispatch with and without Consideration of PV and Wind Energy by Using Various Optimization Techniques: A Review. Energies 2022, 15, 4472. [Google Scholar] [CrossRef]

- Gowrisankaran, G.; Reynolds, S.S.; Samano, M. Intermittency and the Value of Renewable Energy. J. Political Econ. 2016, 124, 1187–1234. [Google Scholar] [CrossRef]

- Aflaki, S.; Netessine, S. Strategic Investment in Renewable Energy Sources: The Effect of Supply Intermittency. Msom-Manuf. Serv. Oper. Manag. 2015, 19, 489–507. [Google Scholar] [CrossRef]

- Castillo, A.; Gayme, D.F. Grid-scale energy storage applications in renewable energy integration: A survey. Energy Convers. Manag. 2014, 87, 885–894. [Google Scholar] [CrossRef]

- Shamsi, S.S.M.; Barberis, S.; Maccarini, S.; Traverso, A. Large scale energy storage systems based on carbon dioxide thermal cycles: A critical review. Renew. Sustain. Energy Rev. 2024, 192, 114245. [Google Scholar] [CrossRef]

- Sayed, E.; Olabi, A.; Alami, A.; Radwan, A.; Mdallal, A.; Rezk, A.; Abdelkareem, M. Renewable Energy and Energy Storage Systems. Energies 2023, 16, 1415. [Google Scholar] [CrossRef]

- Olabi, A.G.; Onumaegbu, C.; Wilberforce, T.; Ramadan, M.; Abdelkareem, M.A.; Al-Alami, A.H. Critical review of energy storage systems. Energy 2020, 214, 118987. [Google Scholar] [CrossRef]

- Wu, F.; Gao, R.; Li, C.; Liu, J. A comprehensive evaluation of wind-PV-salt cavern-hydrogen energy storage and utilization system: A case study in Qianjiang salt cavern, China. Energy Convers. Manag. 2023, 277, 116633. [Google Scholar] [CrossRef]

- Liu, W.; Li, Q.; Yang, C.; Shi, X.; Wan, J.; Jurado, M.J.; Li, Y.; Jiang, D.; Chen, J.; Qiao, W.; et al. The role of underground salt caverns for large-scale energy storage: A review and prospects. Energy Storage Mater. 2023, 63, 103045. [Google Scholar] [CrossRef]

- Matos, C.R.; Carneiro, J.F.; Silva, P.P. Overview of Large-Scale Underground Energy Storage Technologies for Integration of Renewable Energies and Criteria for Reservoir Identification. J. Energy Storage 2019, 21, 241–258. [Google Scholar] [CrossRef]

- Wu, F.; Gao, R.; Zou, Q.; Chen, J.; Liu, W.; Peng, K. Long-term strength determination and nonlinear creep damage constitutive model of salt rock based on multistage creep test: Implications for underground natural gas storage in salt cavern. Energy Sci. Eng. 2020, 8, 1592–1603. [Google Scholar] [CrossRef]

- Huang, L.; Fang, Y.; Hou, Z.; Xie, Y.; Wu, L.; Luo, J.; Wang, Q.; Guo, Y.; Sun, W. A preliminary site selection system for underground hydrogen storage in salt caverns and its application in Pingdingshan, China. Deep. Undergr. Sci. Eng. 2023, 3, 117–128. [Google Scholar] [CrossRef]

- Jiang, D.; Wang, Y.; Liu, W.; Li, L.; Qiao, W.; Chen, J.; Li, D.; Li, Z.; Fan, J. Construction simulation of large-spacing-two-well salt cavern with gas blanket and stability evaluation of cavern for gas storage. J. Energy Storage 2022, 48, 103932. [Google Scholar] [CrossRef]

- Shi, X.; Liu, W.; Chen, J.; Jiang, D.; Wu, F.; Zhang, J.; Jinyang, F. Softening model for failure analysis of insoluble interlayers during salt cavern leaching for natural gas storage. Acta Geotech. 2018, 13, 801–816. [Google Scholar] [CrossRef]

- Wei, X.; Shi, X.; Li, Y.; Li, P.; Ban, S.; Zhao, K.; Ma, H.; Liu, H.; Yang, C. A comprehensive feasibility evaluation of salt cavern oil energy storage system in China. Appl. Energy 2023, 351, 121807. [Google Scholar] [CrossRef]

- Kuang, X.; Jiao, J.; Zheng, C.; Cherry, J.A.; Li, H. A review of specific storage in aquifers. J. Hydrol. 2020, 581, 124383. [Google Scholar] [CrossRef]

- Heidarabad, R.G.; Shin, K. Carbon Capture and Storage in Depleted Oil and Gas Reservoirs: The Viewpoint of Wellbore Injectivity. Energies 2024, 17, 1201. [Google Scholar] [CrossRef]

- Saigustia, C.; Robak, S. Review of Potential Energy Storage in Abandoned Mines in Poland. Energies 2021, 14, 6272. [Google Scholar] [CrossRef]

- Dong, X.; Karrech, A.; Basarir, H.; Elchalakani, M.; Seibi, A. Energy Dissipation and Storage in Underground Mining Operations. Rock Mech. Rock Eng. 2019, 52, 229–245. [Google Scholar] [CrossRef]

- Uliasz-Misiak, B.; Misiak, J. Underground Gas Storage in Saline Aquifers: Geological Aspects. Energies 2024, 17, 1666. [Google Scholar] [CrossRef]

- Li, H.; Lu, C.; Werner, A.D.; Irvine, D.J.; Luo, J. Impacts of Heterogeneity on Aquifer Storage and Recovery in Saline Aquifers. Water Resour. Res. 2022, 58, e2021WR031306. [Google Scholar] [CrossRef]

- Xia, P.; Hu, X.; Ying, C.; Wu, S.; Xu, C.; Wang, X.; Chen, H.; Duan, H. Study on Shear Strength Characteristics of Basalt-Concrete Bonding Interface Based on in-situ Direct Shear Test. J. Earth Sci. 2024, 35, 553–567. [Google Scholar] [CrossRef]

- Morstyn, T.; Chilcott, M.; Mcculloch, M.D. Gravity energy storage with suspended weights for abandoned mine shafts. Appl. Energy 2019, 239, 201–206. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Cai, Z.; Zhu, G.; Zhou, J.; Yao, W. Mechanical Behaviors of Anchorage Interfaces in Layered Rocks with Fractures under Axial Loads. J. Earth Sci. 2023, 34, 354–368. [Google Scholar] [CrossRef]

- Wang, M.; Liu, L.; Chen, L.; Zhang, X.; Ji, C. Cold Load and Storage Functional Backfill for Cooling Deep Mine. Adv. Civ. Eng. 2018, 2018, 5435214. [Google Scholar] [CrossRef]

- Thoraval, A.; Lahaie, F.; Brouard, B.; Berest, P. A generic model for predicting long-term behavior of storage salt caverns after their abandonment as an aid to risk assessment. Int. J. Rock Mech. Min. Sci. 2015, 77, 44–59. [Google Scholar] [CrossRef]

- Song, H.; Zhu, S.; Li, J.; Wang, Z.; Li, Q.; Ning, Z. Design Criteria for the Construction of Energy Storage Salt Cavern Considering Economic Benefits and Resource Utilization. Sustainability 2023, 15, 6870. [Google Scholar] [CrossRef]

- Dong, Z.; Li, Y.; Li, H.; Wang, Z.; Shi, X.; Chen, X.; Lu, Q. Experimental Study on the Influence of Temperature on Rock Salt Creep. Rock Mech. Rock Eng. 2023, 56, 3499–3518. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Q.; Song, Z.; Feng, S.; Zhang, Y. Nonlinear creep model of salt rock used for displacement prediction of salt cavern gas storage. J. Energy Storage 2022, 48, 103951. [Google Scholar] [CrossRef]

- Minougou, J.D.; Gholami, R.; Poirier, S. A one-dimensional diffusive transport model to evaluate H2S generation in salt caverns hydrogen storage sites. Gas Sci. Eng. 2024, 126, 205336. [Google Scholar] [CrossRef]

- Feng, K.; Li, W.; Nan, X.; Yang, G. Salt Cavern Thermal Damage Evolution Investigation Based on a Hybrid Continuum-Discrete Coupled Modeling. Sustainability 2023, 15, 8718. [Google Scholar] [CrossRef]

- Wan, L.; Wang, B.; Xie, M.; Hu, C.; Wen, Y. Prediction of corrosion life of nitrogen blanket casing in salt cavern gas storage. Energy Sci. Eng. 2022, 10, 3044–3056. [Google Scholar] [CrossRef]

- Wang, J.; Xie, H.; Leung, C.; Li, X. A research on excavation compensation theory for large deformation disaster control and a review on the multiphysical–multiscale responses of salt rock for underground gas storage. Deep. Undergr. Sci. Eng. 2023, 2, 103–104. [Google Scholar] [CrossRef]

- Chen, J.; Lu, D.; Liu, W.; Fan, J.; Jiang, D.; Yi, L.; Kang, Y. Stability study and optimization design of small-spacing two-well (SSTW) salt caverns for natural gas storages. J. Energy Storage 2020, 27, 101131. [Google Scholar] [CrossRef]

- Wei, X.; Shi, X.; Li, Y.; Ban, S.; Liu, X.; Xue, T.; Ma, H.; Liu, H.; Yang, C. Optimization of engineering for the salt cavern oil storage (SCOS) during construction in China. Geoenergy Sci. Eng. 2024, 233, 212567. [Google Scholar] [CrossRef]

- Zhao, T.; He, Y.; Deng, J. Effect of geothermal heat transfer on performance of the adiabatic compressed air energy storage systems with the salt cavern gas storage. Appl. Therm. Eng. 2024, 249, 123386. [Google Scholar] [CrossRef]

- Zhu, S.; Shi, X.; Yang, C.; Bai, W.; Wei, X.; Yang, K.; Li, P.; Li, H.; Li, Y.; Wang, G. Site selection evaluation for salt cavern hydrogen storage in China. Renew. Energy 2024, 224, 120143. [Google Scholar] [CrossRef]

- Ding, B.; Chen, J.; He, Y.; Liu, W.; Chen, L.; Xu, J.; Rui, Y. Feasibility analysis of underground flow battery storage in bedded salt rocks of China. J. Energy Storage 2023, 68, 107520. [Google Scholar] [CrossRef]

- Shi, X.; Chen, Q.; Ma, H.; Li, Y.; Zhang, C. Geomechanical investigation for abandoned salt caverns used for solid waste disposal. Bull. Eng. Geol. Environ. 2020, 80, 1205–1218. [Google Scholar] [CrossRef]

- Soubeyran, A.; Rouabhi, A.; Coquelet, C. Thermodynamic analysis of carbon dioxide storage in salt caverns to improve the Power-to-Gas process. Appl. Energy 2019, 242, 1090–1107. [Google Scholar] [CrossRef]

- Li, W.; Chen, G.; Ding, S.; Zhang, Y. A method for assessing the gas capacity based on thermodynamic state analysis for salt cavern during operation. J. Energy Storage 2022, 50, 104316. [Google Scholar] [CrossRef]

- Li, J.; Wan, J.; Liu, H.; Jurado, M.J.; He, Y.; Yuan, G.; Xia, Y. Stability Analysis of a Typical Salt Cavern Gas Storage in the Jintan Area of China. Energies 2022, 15, 4167. [Google Scholar] [CrossRef]

- Mortazavi, A.; Nasab, H. Analysis of the behavior of large underground oil storage caverns in salt rock. Int. J. Numer. Anal. Methods Geomech. 2017, 41, 602–624. [Google Scholar] [CrossRef]

- Zhao, H.; Hao, X. Risk assessment of zero-carbon salt cavern compressed air energy storage power station. J. Clean. Prod. 2024, 468, 143002. [Google Scholar] [CrossRef]

- Mou, J.; Shang, H.; Ji, W.; Wan, J.; Xing, T.; Ma, H.; Peng, W. Feasibility Analysis of Compressed Air Energy Storage in Salt Caverns in the Yunying Area. Energies 2023, 16, 7171. [Google Scholar] [CrossRef]

- Osman, A.I.; Nasr, M.; Eltaweil, A.S.; Hosny, M.; Farghali, M.; Al-Fatesh, A.S.; Rooney, D.W.; Abd El-Monaem, E.M. Advances in hydrogen storage materials: Harnessing innovative technology, from machine learning to computational chemistry, for energy storage solutions. Int. J. Hydrogen Energy 2024, 67, 1270–1294. [Google Scholar] [CrossRef]

- Schainker, R.B. Executive overview: Energy storage options for a sustainable energy future. In Proceedings of the IEEE Power Engineering Society General Meeting, Denver, CO, USA, 6–10 June 2004; pp. 2309–2314. [Google Scholar]

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J. Overview of current development in electrical energy storage technologies and the application potential in power system operation. Appl. Energy 2015, 137, 511–536. [Google Scholar] [CrossRef]

- Bachand, A.; Doyon, B.; Raymond, J. Thermo-physical numerical model for hydrogen storage in underground tanks and caverns. Int. J. Hydrogen Energy 2024, 66, 66–80. [Google Scholar] [CrossRef]

- Raju, M.; Khaitan, S.K. Modeling and simulation of compressed air storage in caverns: A case study of the Huntorf plant. Appl. Energy 2012, 89, 474–481. [Google Scholar] [CrossRef]

- Migliari, L.; Micheletto, D.; Cocco, D. Performance Analysis of a Diabatic Compressed Air Energy Storage System Fueled with Green Hydrogen. Energies 2023, 16, 7023. [Google Scholar] [CrossRef]

- Wan, J.; Ji, W.; He, Y.; Li, J.; Gao, Y. Pitting and Strip Corrosion Influence on Casing Strength of Salt Cavern Compressed Air Energy Storage. Energies 2023, 16, 5362. [Google Scholar] [CrossRef]

- Ebere, F.O.; Jabbari, H. Unlocking underground hydrogen storage potential: Geochemical characterization of North Dakota’s geological formation. Int. J. Hydrogen Energy 2024, 93, 250–272. [Google Scholar] [CrossRef]

- Song, S.; Lin, H.; Sherman, P.; Yang, X.; Mcelroy, M.B. Production of hydrogen from offshore wind in China and cost-competitive supply to Japan. Nat. Commun. 2021, 12, 6953. [Google Scholar] [CrossRef] [PubMed]

- Westlake, S.; John, C.H.D.; Cox, E. Perception spillover from fracking onto public perceptions of novel energy technologies. Nat. Energy 2023, 8, 149–158. [Google Scholar] [CrossRef]

- Beaucour, R.; Lamaison, N. Operational long-term management of a salt cavern for industry targeted green H2 production. Energy 2024, 311, 133332. [Google Scholar] [CrossRef]

- Ge, L.; Gong, X.; Wang, Z.; Zhao, L.; Wang, Y.; Wang, M. Insight of anode reaction for CWS (coal water slurry) electrolysis for hydrogen production. Energy 2016, 96, 372–382. [Google Scholar] [CrossRef]

- Pan, W.; Chen, K.; Ai, N.; Lu, Z.; Jiang, S.P. Mechanism and kinetics of Ni-Y2O3-ZrO2 hydrogen electrode for water electrolysis reactions in solid oxide electrolysis cells. J. Electrochem. Soc. 2016, 163, F106–F114. [Google Scholar] [CrossRef]

- Li, Y.; Yang, G.; Yu, S.; Kang, Z.; Mo, J.; Han, B.; Talley, D.A.; Zhang, F.Y. In-situ investigation and modeling of electrochemical reactions with simultaneous oxygen and hydrogen microbubble evolutions in water electrolysis. Int. J. Hydrogen Energy 2019, 44, 28283–28293. [Google Scholar] [CrossRef]

- Bade, S.O.; Taiwo, K.; Ndulue, U.F.; Tomomewo, O.S.; Aisosa Oni, B. A review of underground hydrogen storage systems: Current status, modeling approaches, challenges, and future prospective. Int. J. Hydrogen Energy 2024, 80, 449–474. [Google Scholar] [CrossRef]

- Méndez-Vázquez, S.; Soage, A.; Navarrina, F.; París, J.; Colominas, I.; Cueto-Felgueroso, L.; Juanes, R. Effect of a gunite lining on the stability of salt caverns in bedded formations for hydrogen storage. Int. J. Hydrogen Energy 2024, 90, 298–316. [Google Scholar] [CrossRef]

- Zamani, O.A.M.; Knez, D. Well Integrity in Salt Cavern Hydrogen Storage. Energies 2024, 17, 3586. [Google Scholar] [CrossRef]

- Ozarslan, A. Large-scale hydrogen energy storage in salt caverns. Int. J. Hydrogen Energy 2012, 37, 14265–14277. [Google Scholar] [CrossRef]

- Caglayan, D.G.; Weber, N.; Heinrichs, H.U.; Linen, J.; Stolten, D. Technical potential of salt caverns for hydrogen storage in Europe. Int. J. Hydrogen Energy 2020, 45, 6793–6805. [Google Scholar] [CrossRef]

- Wallace, R.L.; Cai, Z.; Zhang, H.; Zhang, K.; Guo, C. Utility-scale subsurface hydrogen storage: UK perspectives and technology. Int. J. Hydrogen Energy 2021, 46, 25137–25159. [Google Scholar] [CrossRef]

- Huang, S.; Li, Y.; Shi, X.; Liu, Y.; Ma, H.; Li, P.; Liu, Y.; Liu, X.; Xu, M.; Yang, C. Key Issues of Salt Cavern Flow Battery. Energies 2024, 17, 5190. [Google Scholar] [CrossRef]

- Chen, Q.; Lv, Y.; Yuan, Z.; Li, X.; Yu, G.; Yang, Z.; Xu, T. Organic Electrolytes for pH-Neutral Aqueous Organic Redox Flow Batteries. Adv. Funct. Mater. 2021, 32, 2108777. [Google Scholar] [CrossRef]

- Beh, E.S.; De Porcellinis, D.; Gracia, R.L.; Xia, K.T.; Gordon, R.G.; Aziz, M.J. A Neutral pH Aqueous Organic–Organometallic Redox Flow Battery with Extremely High Capacity Retention. ACS Energy Lett. 2017, 2, 639–644. [Google Scholar] [CrossRef]

- Hu, B.; DeBruler, C.; Rhodes, Z.; Liu, T.L. Long-Cycling Aqueous Organic Redox Flow Battery (AORFB) toward Sustainable and Safe Energy Storage. J. Am. Chem. Soc. 2017, 139, 1207–1214. [Google Scholar] [CrossRef]

- Wang, H.; Li, D.; Xu, J.; Wu, Y.; Cui, Y.; Chen, L. An unsymmetrical two-electron viologens anolyte for salt cavern redox flow battery. J. Power Sources 2021, 492, 229659. [Google Scholar] [CrossRef]

- Fang, J.; Ma, H.; Yang, C.; Li, H.; Zeng, Z.; Zhu, S.; Wang, X.; Nong, X. Airtightness evaluation of compressed air energy storage (CAES) salt caverns in bedded rock salt. J. Energy Storage 2024, 102, 114100. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L.; Hu, S. Underground hydrogen storage in depleted gas fields: Progress, challenges, and outlook. J. Energy Storage 2024, 102, 113842. [Google Scholar] [CrossRef]

- Zhu, S.; Shi, X.; Yang, C.; Li, Y.; Li, H.; Yang, K.; Wei, X.; Bai, W.; Liu, X. Hydrogen loss of salt cavern hydrogen storage. Renew. Energy 2023, 218, 119267. [Google Scholar] [CrossRef]

- Portarapillo, M.; Di Benedetto, A. Risk Assessment of the Large-Scale Hydrogen Storage in Salt Caverns. Energies 2021, 14, 2856. [Google Scholar] [CrossRef]

- Davies, E.; Ehrmann, A.; Schwenzfeier-Hellkamp, E. Safety of Hydrogen Storage Technologies. Processes 2024, 12, 2182. [Google Scholar] [CrossRef]

- Taiwo, G.O.; Tomomewo, O.S.; Oni, B.A. A comprehensive review of underground hydrogen storage: Insight into geological sites (mechanisms), economics, barriers, and future outlook. J. Energy Storage 2024, 90, 111844. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, W.; Guo, Q.; Duan, X.; Li, Y.; Wang, T. Tightness evaluation and countermeasures for hydrogen storage salt cavern contains various lithological interlayers. J. Energy Storage 2022, 50, 104454. [Google Scholar] [CrossRef]

| Project Information | Geological Structure | Purity/% | Operating Condition | Depth/m | Volume/m3 | Current Condition |

|---|---|---|---|---|---|---|

| Teesside/Britain | Salt layer | 95 | 45 MPa | 365 | 210,000 | Operating |

| Clemens/U.S. | Salt dome | 95 | 7–13.7 MPa | 1000 | 580,000 | Operating |

| Moss Bluff/U.S. | Salt dome | 95 | 5.5–15.2 MPa | 1200 | 566,000 | Operating |

| Spindletop/U.S. | Salt dome | 95 | 6.8–20.2 MPa | 1340 | 906,000 | Operating |

| Kiel/Germany | Salt cavern | 60 | 8–10 MPa | / | 32,000 | Closing |

| Energy Storage Method | Overall Efficiency | Cost | Construction Cost | Operating Cost | Maintenance Cost | Scalability | Advantage | Disadvantage |

|---|---|---|---|---|---|---|---|---|

| Salt cavern | 60–80% | USD 50–USD 100/MWh | Moderate, RMB 300–800/m3 | Low to moderate | Low | Excellent | High efficiency, proven technology, large-scale energy storage | Higher construction costs and geographically limited resources |

| Depleted oil and gas reservoir | 50–75% | USD 60–USD 120/MWh | Moderate, RMB 200–600/m3 | Moderate | Moderate | Moderate | Use of existing facilities, low initial costs | Less efficient, limited resources, uncertain long-term stability |

| Aquifer | 50–70% | USD 70–USD 150/MWh | Low to moderate, RMB 200–600/m3 | Low to moderate | Moderate | Moderate | Wide distribution of resources, low initial costs | Inefficiency, limited by aquifer conditions, risk of contamination |

| Lining chamber | 55–75% | USD 100–USD 200/MWh | High, RMB 300–800/m3 | High | High | Moderate | Large space, high safety | High construction costs, limited by geological conditions |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; Li, Y.; Shi, X.; Bai, W.; Huang, Y.; Hong, Y.; Liu, X.; Ma, H.; Li, P.; Xu, M.; et al. The Role of Underground Salt Caverns in Renewable Energy Peaking: A Review. Energies 2024, 17, 6005. https://doi.org/10.3390/en17236005

Huang S, Li Y, Shi X, Bai W, Huang Y, Hong Y, Liu X, Ma H, Li P, Xu M, et al. The Role of Underground Salt Caverns in Renewable Energy Peaking: A Review. Energies. 2024; 17(23):6005. https://doi.org/10.3390/en17236005

Chicago/Turabian StyleHuang, Si, Yinping Li, Xilin Shi, Weizheng Bai, Yashuai Huang, Yang Hong, Xiaoyi Liu, Hongling Ma, Peng Li, Mingnan Xu, and et al. 2024. "The Role of Underground Salt Caverns in Renewable Energy Peaking: A Review" Energies 17, no. 23: 6005. https://doi.org/10.3390/en17236005

APA StyleHuang, S., Li, Y., Shi, X., Bai, W., Huang, Y., Hong, Y., Liu, X., Ma, H., Li, P., Xu, M., & Xue, T. (2024). The Role of Underground Salt Caverns in Renewable Energy Peaking: A Review. Energies, 17(23), 6005. https://doi.org/10.3390/en17236005