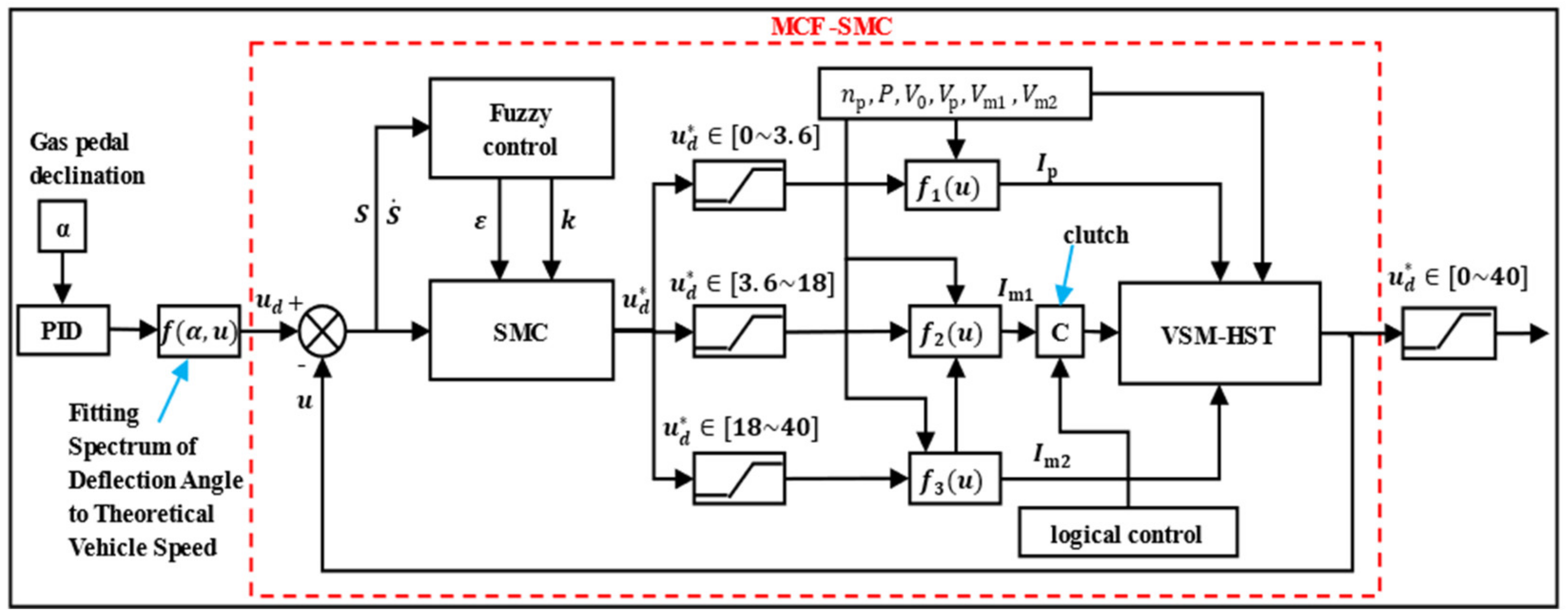

3.2. MCF–SMC

The MCF–SMC control strategy comprises Sliding Mode Control (SMC) and Multivariable Fuzzy Control (MCF). The following explanations are based on the system’s dynamic equations derived in

Section 3.1. The first-order differentiation of

in Equation (22) gives the output as a function of the three inputs as in Equation (23).

When

is fixed, the inputs

,

, and

all affect the output of the vehicle’s speed. However, based on the analysis of the control characteristics in

Section 2.2, it is determined that in different speed ranges of the loader, only one input has the maximum influence on the output. Therefore, the vehicle speed is segmented into ranges, with one primary input dominating each range, while the other inputs remain constant and are deemed disturbances that have no impact on the vehicle’s speed. Specifically, when

, the dominant input is

; when

, the dominant input is

; and when

, the dominant input is

. This relationship is expressed by Equation (24):

SMC, a nonlinear control technique, employs the real-time state of the system and experiences continuous regular changes to steer complex nonlinear systems by enforcing a desired state trajectory, referred to as the sliding mode surface. This approach delivers effective control performance with high-frequency and small fluctuations. To implement this method, two tasks must be completed: designing the sliding mode surface for the system and designing a control law that will move the system state to the sliding mode surface.

The tracking error

is the difference between the ideal vehicle speed

and the actual vehicle speed

, as shown in Equation (22).

According to Equation (21), the sliding mode surface is defined as Equation (26).

where

and

are constants greater than zero whose values can be determined by having pole configurations that satisfy the requirements of the Laws criterion [

26].

From Equations (22)–(26), the system control rate can be derived as shown in Equation (27).

where

is the a priori expected speed,

,

.

The

in Equation (27) is indeterminate. To ensure a smooth reaching of the system state to the sliding mode surface, the design of the convergence rate also needs to adapt to the external perturbation. In this paper, an exponential convergence rate was adopted, as shown in Equation (28).

where

,

and

are constants greater than zero, whose magnitude determines the switching and convergence speeds. Because the time constants of the pumps and motors are 0.1 s, let

. From Equations (27) and (28), the final system sliding mode control rate is Equation (29).

where

is the approximation function of

as shown in Equation (27), and

is the compensation function about

, and good robustness and stability of the system can be realized by controlling the values of

and

reasonably.

In control theory, the Lyapunov function is used to determine the stability of the system [

27]. For the control objective

, if there exists a continuous function

that satisfies Equations (30) and (31), the system will be stable at the equilibrium point

, that is

.

Let

, which clearly satisfies the first condition of Lyapunov stability [

28]. Taking the derivative of

yields:

When , the system satisfies the second condition of Lyapunov stability, so the system will eventually stabilize near the sliding mode surface, and the two variables will eventually reach equilibrium.

But for practical engineering problems, the time required for stability and the stability after interference also need to be considered. It has been proven above that the system is stable, so let

directly, where

represents the upper limit of system error and the proof process is as follows:

The above equation proves that the system will reach stability within a finite time, and the stability time is:

Therefore, it is necessary to add a constraint to

as Equation (34).

When the system is affected by external interference

, where

is the upper bound of the interference [

29], then there is Equation (35)

In summary, under the condition of meeting the limited conditions, through reasonable control, the values of and can achieve good robustness and stability of the system.

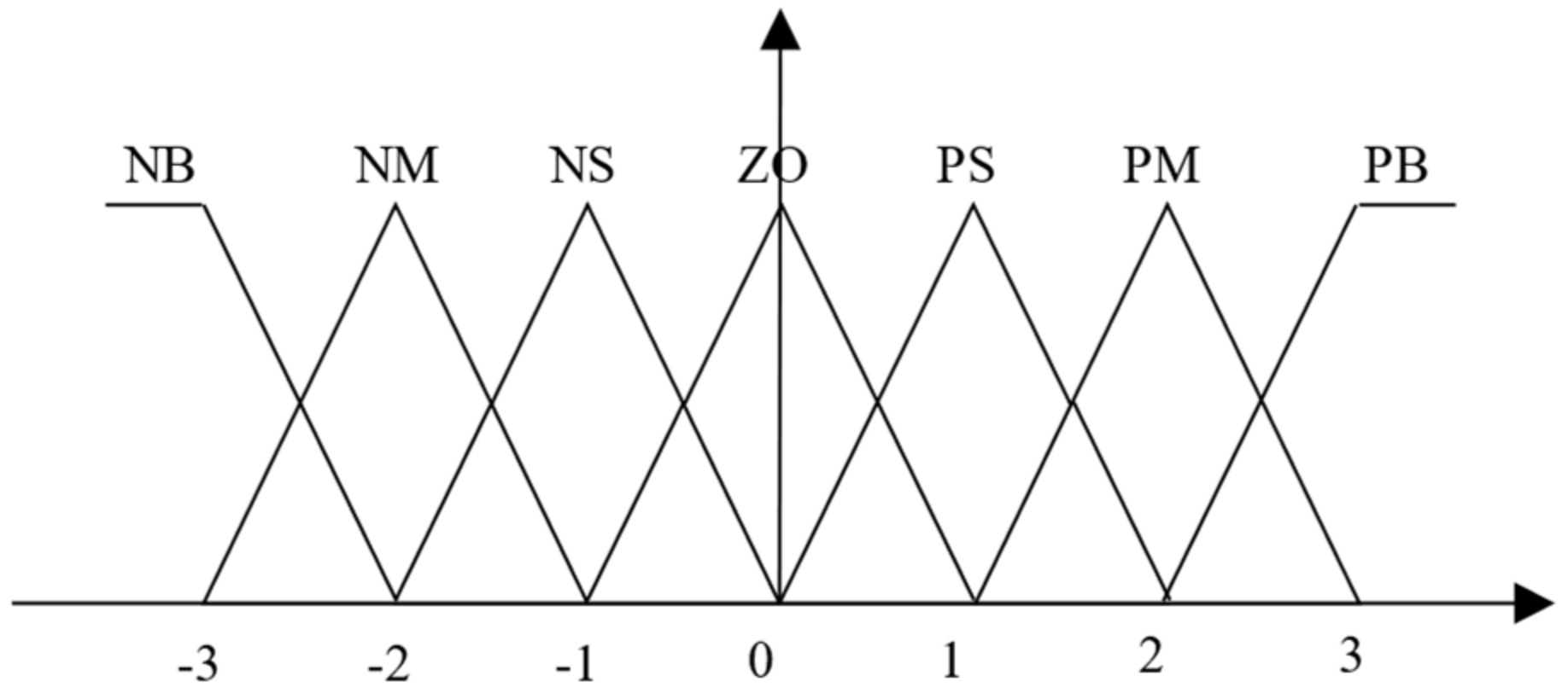

MCF is a rule-based control algorithm that, when combined with SMC, can minimize jitter resulting from abrupt and rapid system parameter adjustments. The input variables for MCF are

and

, representing the relative distances between the state point and the sliding mode surface and the state point’s speed relative to the sliding mode surface, respectively. The output quantity,

is adjusted based on the fuzzy rules that guarantee the establishment of

. The linguistic variables and their ranges were selected as {−3 −2 −1 0 1 2 3} for both the controller’s input and output. The associated linguistic terms for these variables are NB, NM, NS, ZO, PS, PM, and PB, which stand for Negative Big, Negative Medium, Negative Small, Zero, Positive Small, Positive Medium, and Positive Big, respectively. The controller’s input–output mapping applies triangular membership functions to the linguistic terms by the design guidelines outlined in references [

30,

31,

32]. An illustration of these triangular membership functions can be found in

Figure 6.

The control logic equation is formulated as shown in Equation (30).

The paper utilizes the widely accepted weighted average method for defuzzification, which has been previously outlined in studies [

33,

34,

35]. Equation (31) presents the calculation formula for this method.

where

is the defuzzification value,

is the value of the affiliation function, and

is the center of mass of the affiliation function. Under the condition that the inequality

is met, the control rules for the output variable ε were designed based on empirical knowledge, as illustrated in

Table 5.

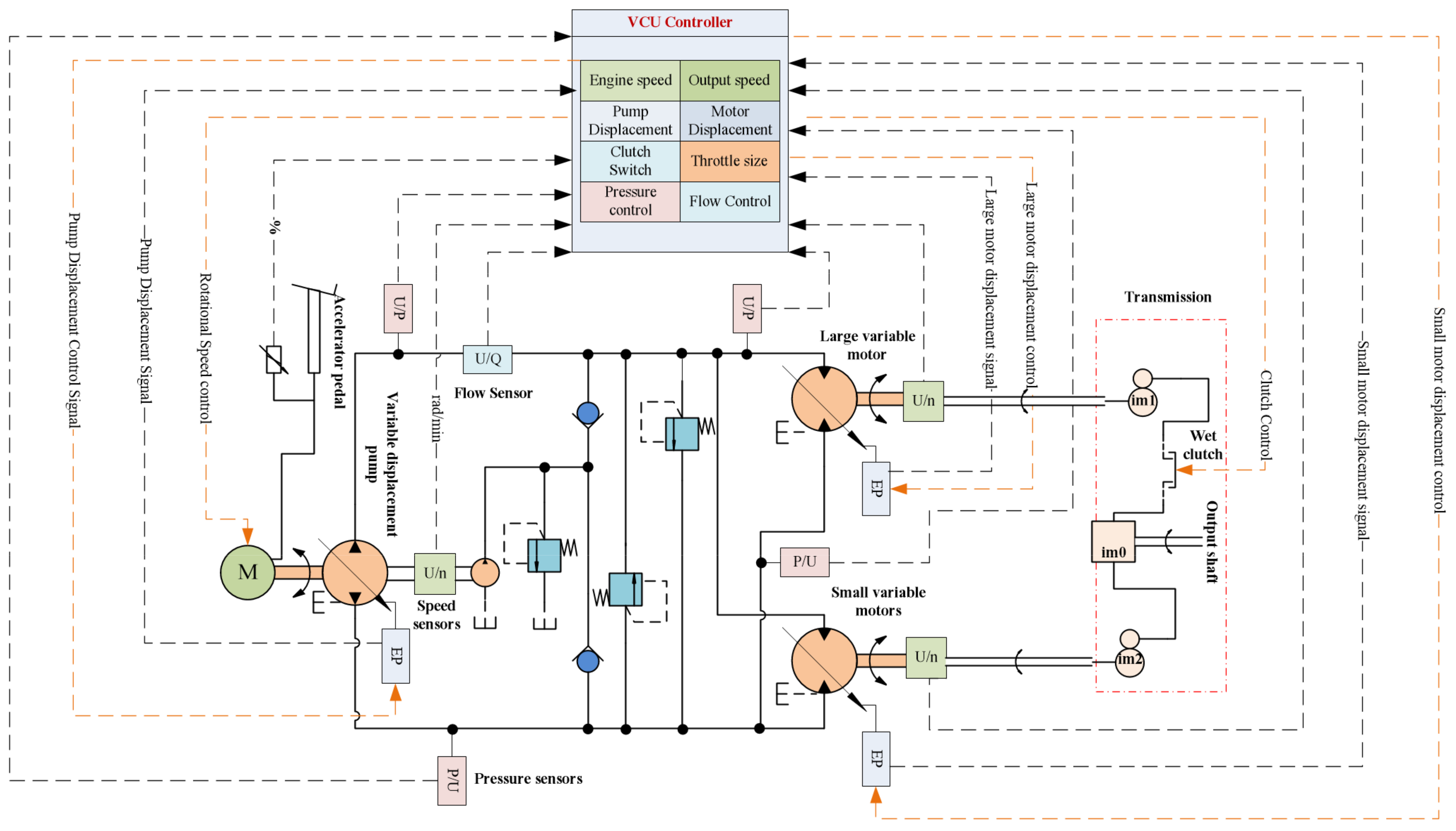

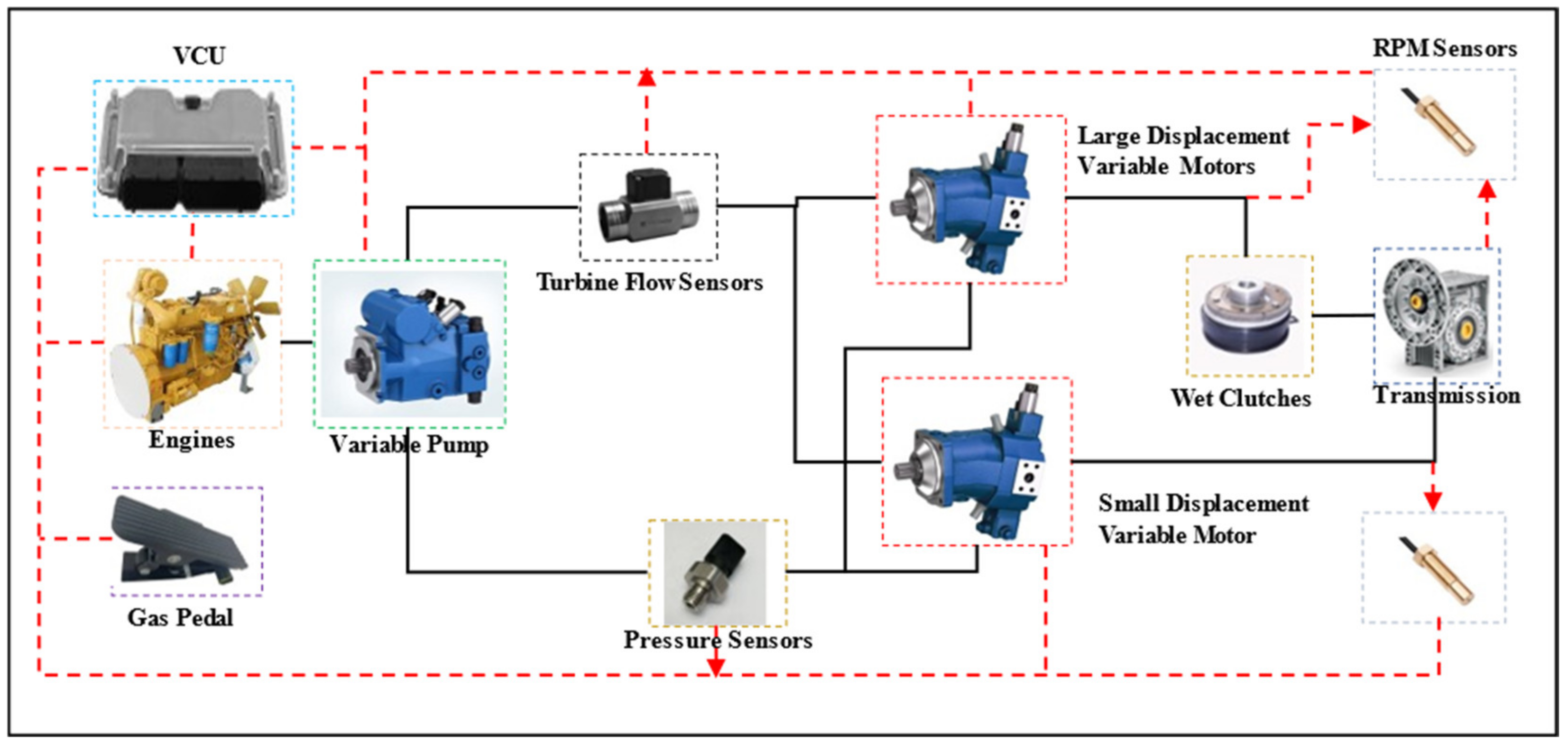

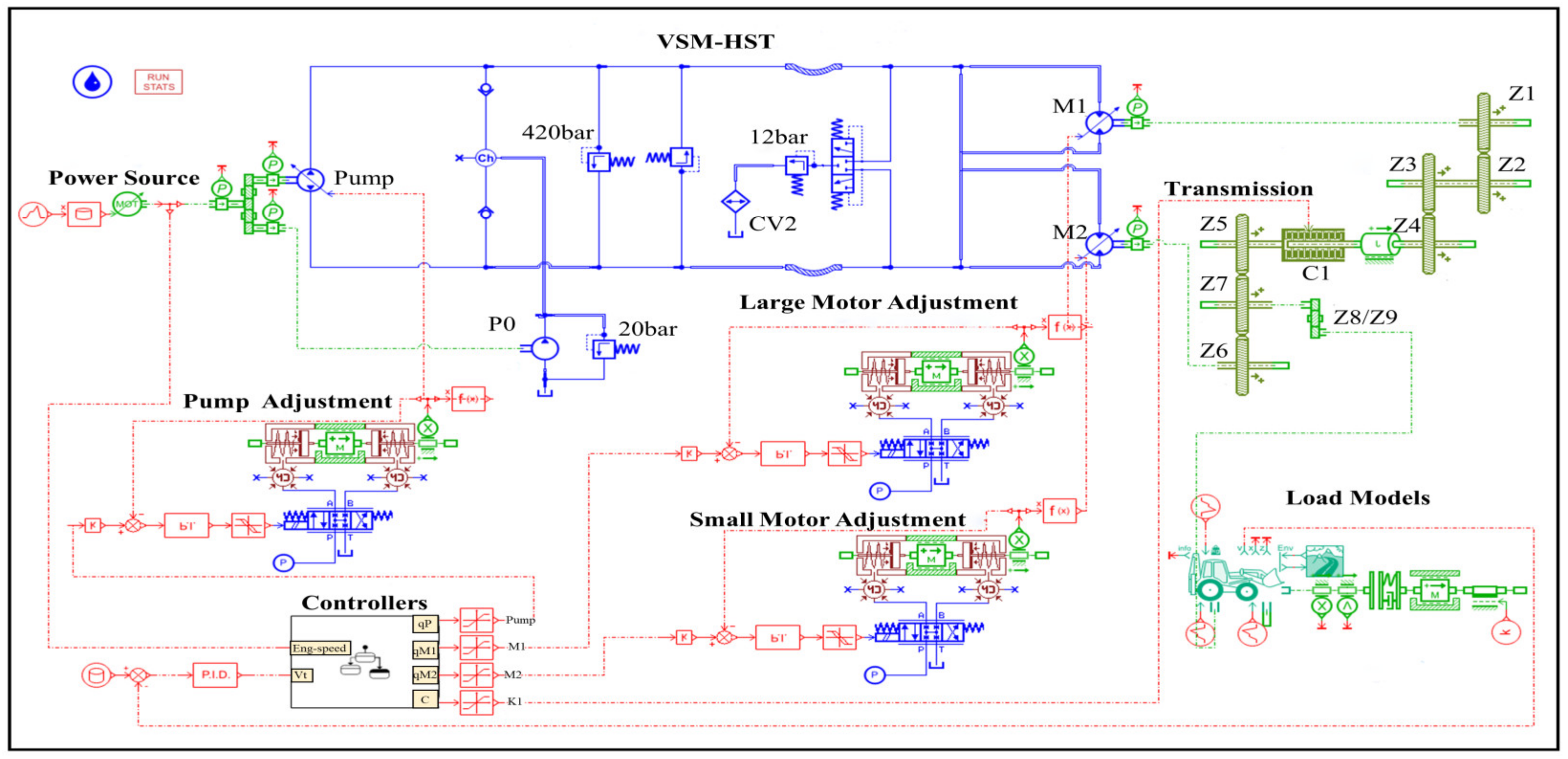

Due to the variable-structure nature of the VSM-HST system involving structural switching, in conjunction with the analysis of operational conditions, the automatic shifting mode was divided into low-speed mode and high-speed mode based on the transition of the transmission structure. When the vehicle transitions from low-speed mode to high-speed mode, the transmission structure shifts automatically, ensuring a smooth transition of speed ranges. However, drivers can switch between these modes manually. Typically, the low-speed mode is utilized for loading, short-distance transport and heavy transportation, while the high-speed mode is reserved for long-distance transport and high-speed travel. The vehicle starts in the low-speed mode by default. In this mode, both M1 and M2 operate simultaneously, with M2 maintaining maximum displacement. When the driver enables travel, the vehicle moves at idle speed, with the pump set to minimum displacement and the motor maintaining maximum displacement, resulting in a travel speed of 1 km/h. Upon receiving a signal indicating an increase in throttle pedal movement, the engine speed gradually increases until the rate of change becomes zero.

As engine speed increases, pump displacement also increases, resulting in a gradual increase in travel speed. At the same time, M1 displacement decreases in response to the increase in speed, further enhancing travel speed. This process continues until the system stabilizes and the desired travel speed is achieved within an acceptable margin of error. If a further increase in travel speed is required, the system will automatically exit the low-speed mode and enter the high-speed mode. As M1’s displacement approaches zero, the clutch disengages between M1 and the output shaft. Decreasing M2’s displacement further increases the travel speed. Once M2’s displacement reaches the set minimum, the pump attains maximum displacement. The control logic’s schematic representation is shown in

Figure 7.

3.3. Simulation Results

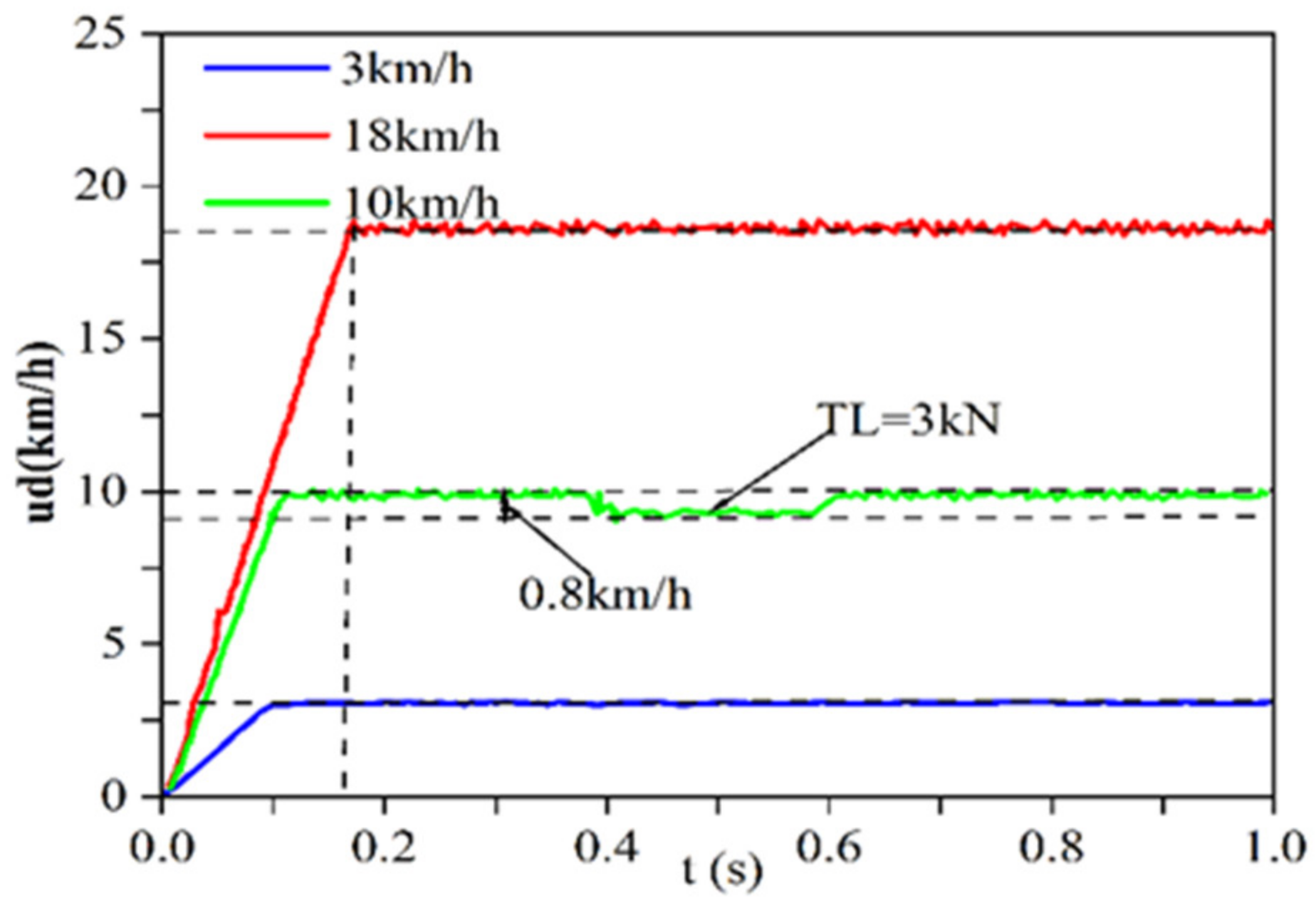

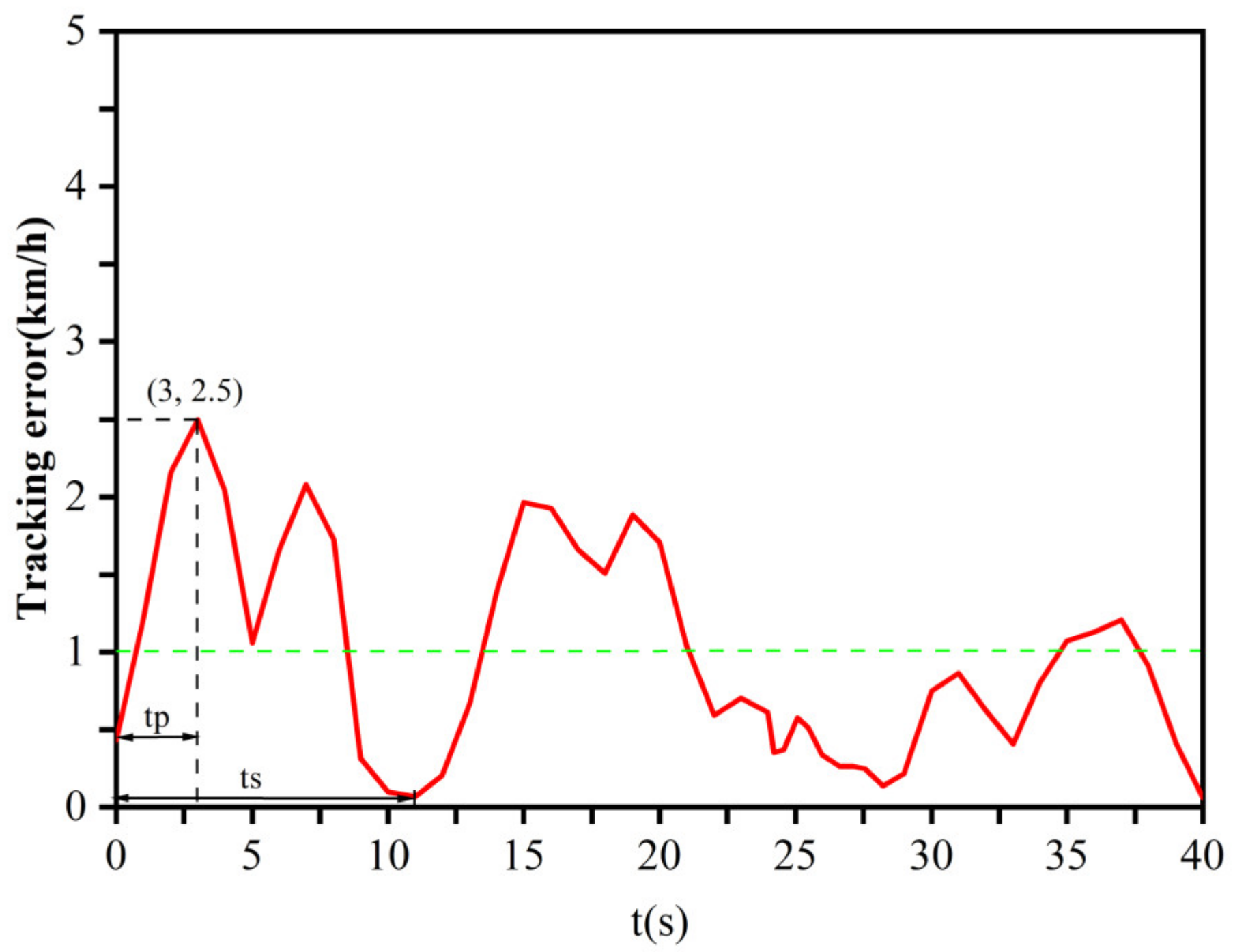

In the simulation scenario with a load of , constant engine speed , and other parameters remaining the same, three different target speeds were set: 3 km/h, 10 km/h, and 18 km/h. An additional impact load of was applied at 0.4 s of the simulation for the experimental group with a target vehicle speed of 10 km/h.

This simulation was carried out under ideal conditions, where the control current range for both the pump and motors was within (−400 mA, 400 mA). The displacement control signals can be directly controlled by amplifying the current through a current amplifier or a similar mechanism. The MCF–SMC parameters are provided in

Table 6.

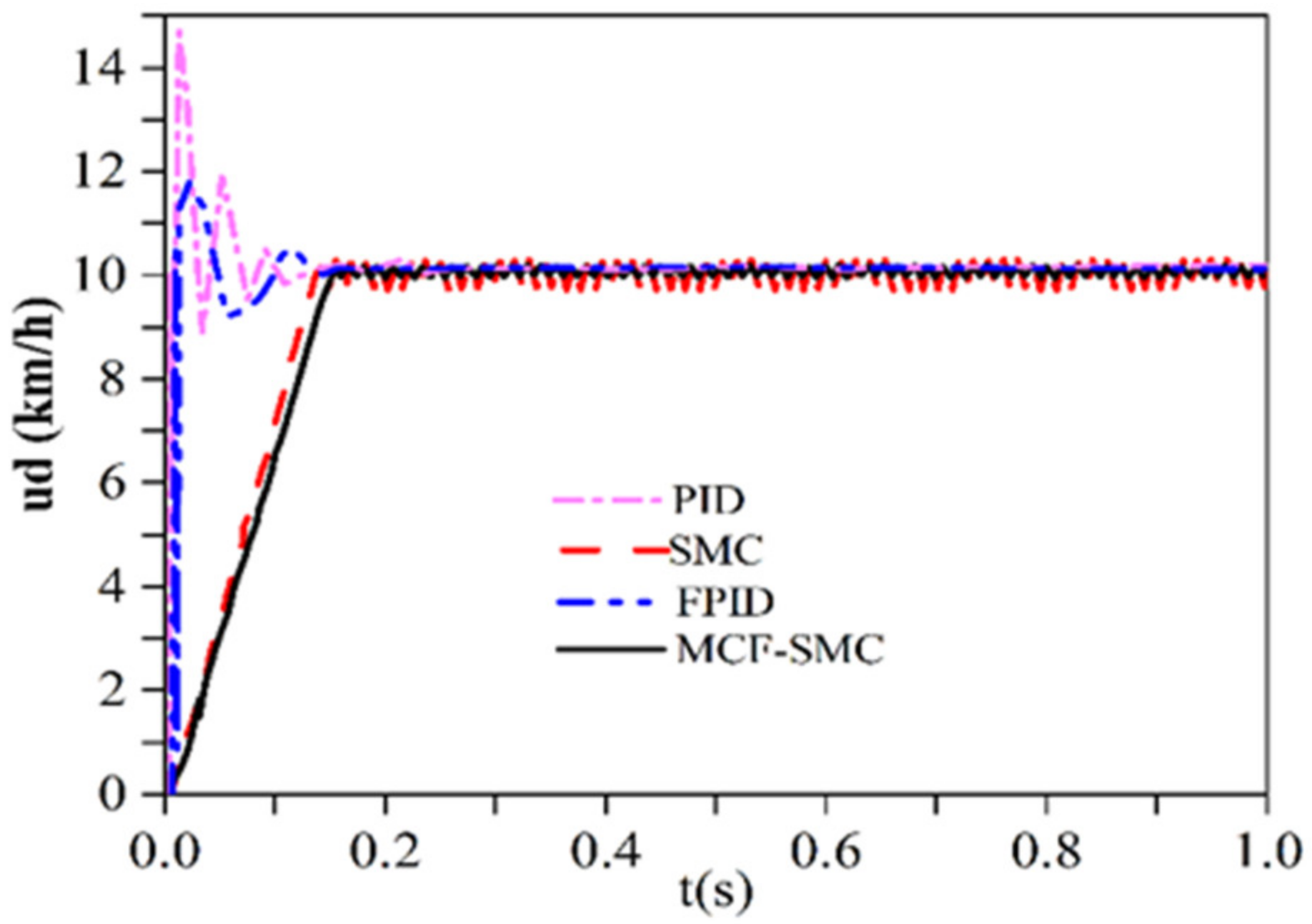

The results are shown in

Figure 8. The simulation results demonstrate that the control strategy effectively tracks and predicts the target speeds. In the presence of a sudden 3 kN load disturbance, the speed variation is around 0.8 km/h, which is less than 1 km/h. Furthermore, the speed quickly returns to the target value after the disturbance disappears, indicating that the control strategy can handle load disturbances well and ensure the stability of the system control.

To assess the efficacy of the MCF–SMC, simulations were conducted and its performance to typical control algorithms employed in electro-hydraulic servo systems was compared.

Figure 9 illustrates the actual speed output curve obtained at an external load of

, an engine speed of

, and a target speed of

.

In the simulation comparison test, the pre-experimental control algorithm only replaced the fuzzy control and SMC parts depicted in

Figure 7. The control logic and VSM-HST settings were unaltered. During the experiment, severe overshoot was observed in numerous experiments when using the PID algorithm. After implementing the widely-used integral separation and anti-integral saturation methods, the system was still affected, although to a lesser degree, by overshoot, and the PID control output generated the vehicle speed curve illustrated in

Figure 9. The PID was further enhanced with the fuzzy control strategy. The integral coefficient in the variable integral strategy was adjusted based on deviation size. Faster integration occurs for smaller deviations, while slower integration takes place for larger deviations. If the deviation surpasses a specific threshold, the integral term is set to zero. The resulting FPID experimental curve is represented in

Figure 9. Despite numerous attempts to debug, the vehicle’s speed output still experiences oscillations during the initial start-up phase. The use of SMC control eliminates initial stage oscillations, but small amplitude oscillations persist near the target vehicle speed after system convergence. Incorporating a fuzzy control strategy effectively suppresses these vibrations, improving control quality. MCF–SMC appears to be a more suitable strategy for VSM-HST system control compared to other alternatives.