Selected Issues, Methods, and Trends in the Energy Consumption of Industrial Robots

Abstract

1. Introduction

- RQ1: What methods are currently used to reduce the energy consumption of industrial robots?

- RQ2: What are the current trends in the development of methods for reducing energy consumption in robotics?

2. Fundamentals of Energy Consumption Optimization for Industrial Robots

- PTP—Point to Point, also called “Joint”: The TCP (Tool Center Point) moves along the fastest trajectory. The movement is fast and repeatable.

- CP—Continuous Path (Linear or Circular Motion)—The Continuous Path is used when the movement needs to be controlled to precisely follow the programmed path. The TCP is moved along the specified trajectory. The robot controller automatically (at a specified frequency) memorizes the current positions.

3. IoT Usage in Industrial Robot Systems

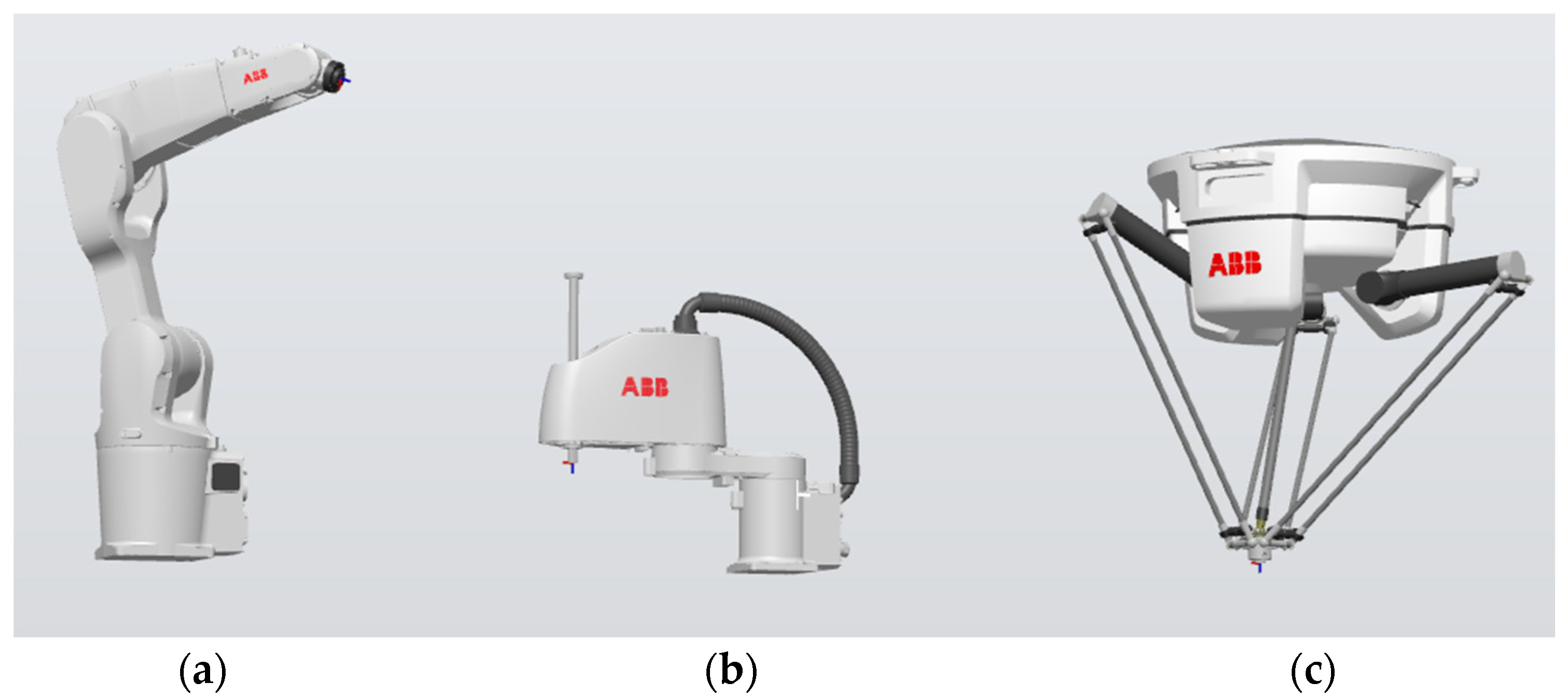

4. Energy Efficiency in Robotics: Reducing Industrial Robots’ Power Consumption

- The robot type;

- Equipment replacement;

- The addition of equipment.

- Trajectory optimization;

- Operation planning.

5. Trends in Robotics Energy Consumption

- Efficient motion planning is the primary focus, with an emphasis on smooth and optimally timed trajectories;

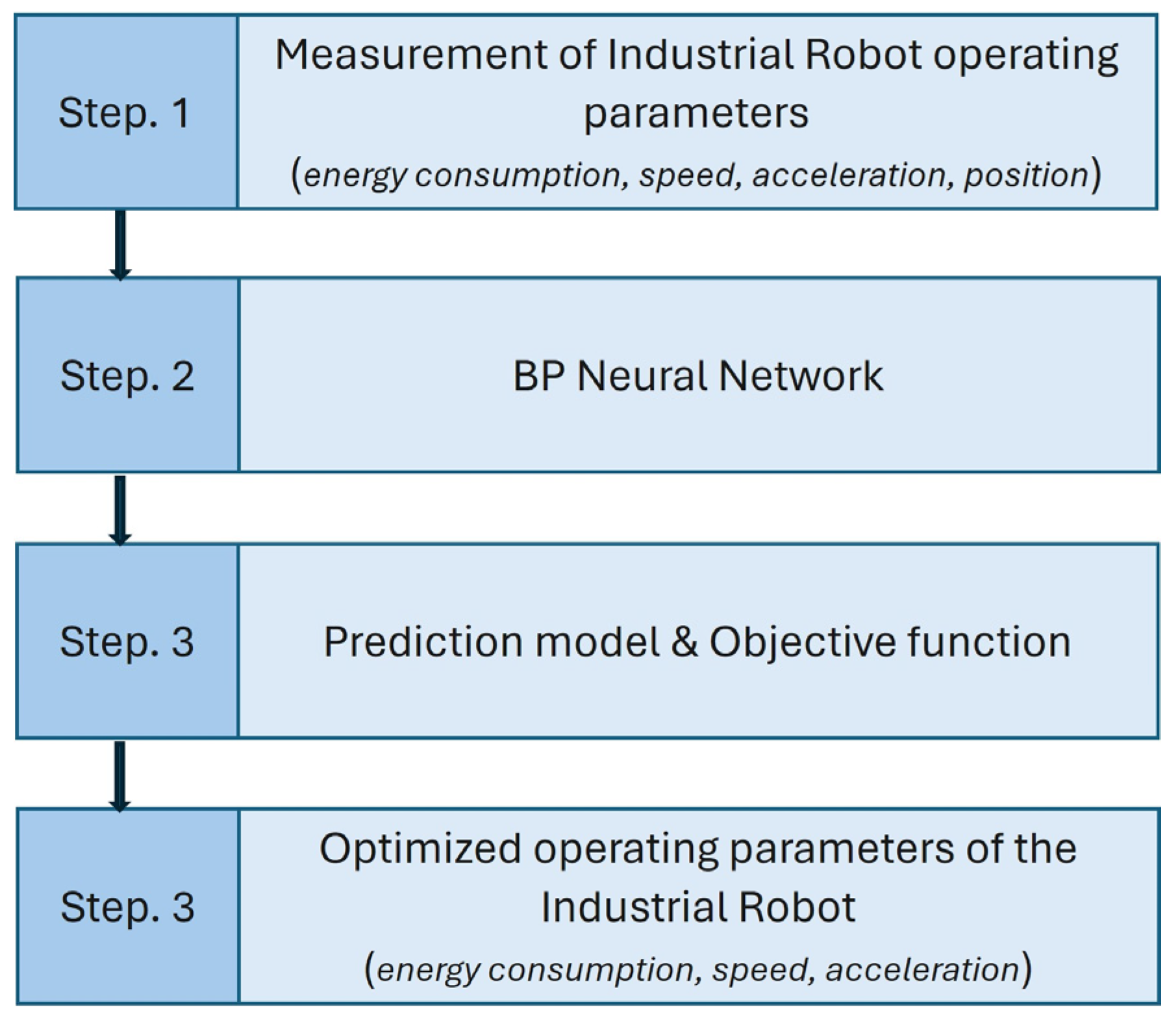

- Optimizing the operational parameters of industrial robots can be achieved through an experimental approach and computer modeling and simulation;

- Planning tasks for industrial robots involves optimizing the sequence of movements and minimizing the number of starts and stops. This includes various factors that need to be considered, such as the efficiency of the robot’s movements and the time required to complete the task.

- Increased energy efficiency: Methods for recovering electrical energy resulting from kinetic energy transformation will be developed, and smart-power-saving modes will be introduced to increase energy efficiency. Energy monitoring will become standard.

- Reshoring aims to shorten the distance between the manufacturer and the recipient of components needed for production: This leads to the increased implementation of robotic systems by expanding companies, as many things can be produced on-site without the need for long-distance transport.

- Ease of use: Technologies that lower the entry threshold in terms of robot programming, such as “low code” or “no code” techniques, will be implemented to improve ease of use. Emphasis will be placed on solution flexibility and easy configuration. For example, it will be possible to equip a heavy industrial robot with sensors and software that enable collaborative work.

- Utilization of artificial intelligence: AI development will primarily support the optimization of robotic processes, enabling better management of variable or unpredictable events.

- Second life of industrial robots: The ability to repair and upgrade used industrial robots is environmentally friendly and cost-effective. Modernization can also contribute to reducing the energy consumption of refurbished robots.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| AR | Augmented reality |

| CCTV | Closed-circuit television |

| EC | Electronic commerce |

| GUI | Graphical user interface |

| IoT | Internet of Things |

| IIoT | Industrial Internet of Things/Industrial Internet |

| IoRT | Internet of Robotic Things |

| SCARA | Selective Compliance Assembly Robot Arms |

| SLAM | Simultaneous localization and mapping |

| SNS | Social networking services |

| UI | User interface |

| VR | Virtual reality |

| WSDL | Web service description language |

References

- Ghobakhloo, M.; Fathi, M.; Iranmanesh, M.; Maroufkhani, P.; Morales, M.E. Industry 4.0 Ten Years On: A Bibliometric and Systematic Review of Concepts, Sustainability Value Drivers, and Success Determinants. J. Clean. Prod. 2021, 302, 127052. [Google Scholar] [CrossRef]

- Suleiman, Z.; Shaikholla, S.; Dikhanbayeva, D.; Shehab, E.; Turkyilmaz, A. Industry 4.0: Clustering of Concepts and Characteristics. Cogent. Eng. 2022, 9, 2034264. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Aoun, A.; Ilinca, A.; Ghandour, M.; Ibrahim, H. A Review of Industry 4.0 Characteristics and Challenges, with Potential Improvements Using Blockchain Technology. Computers 2021, 162, 107746. [Google Scholar] [CrossRef]

- European Parliament. Available online: https://www.europarl.europa.eu/ (accessed on 8 September 2023).

- International Federation of Robotics. Executive Summary World Robotics 2023 Industrial Robots. IFR 2023. Available online: https://ifr.org/free-downloads/ (accessed on 16 October 2023).

- Borys, S.; Kaczmarek, W.; Laskowski, D.; Polak, R. Experimental Study of the Vibration of the Spot Welding Gun at a Robotic Station. Appl. Sci. 2022, 12, 12209. [Google Scholar] [CrossRef]

- Guo, Q.; Su, Z. The Application of Industrial Robot and the High-Quality Development of Manufacturing Industry: From a Sustainability Perspective. Sustainability 2023, 15, 12621. [Google Scholar] [CrossRef]

- Singh, G.; Banga, V.K. Robots and Its Types for Industrial Applications. Mater. Today Proc. 2022, 60, 1779–1786. [Google Scholar] [CrossRef]

- Kaczmarek, W.; Borys, S.; Panasiuk, J.; Siwek, M.; Prusaczyk, P. Experimental Study of the Vibrations of a Roller Shutter Gripper. Appl. Sci. 2022, 12, 9996. [Google Scholar] [CrossRef]

- Herrmann, C.; Thiede, S.; Zein, A.; Ihlenfeldt, S.; Blau, P. Energy Efficiency of Machine Tools: Extending the Perspective. In Proceedings of the 42nd CIRP International Conference on Manufacturing Systems, Grenoble, France, 3–5 June 2009. [Google Scholar]

- Pellegrinelli, S.; Borgia, S.; Pedrocchi, N.; Villagrossi, E.; Bianchi, G.; Tosatti, L.M. Minimization of the Energy Consumption in Motion Planning for Single-Robot Tasks. Procedia CIRP 2015, 29, 354–359. [Google Scholar] [CrossRef]

- Mohammed, A.; Schmidt, B.; Wang, L.; Gao, L. Minimizing Energy Consumption for Robot Arm Movement. Procedia CIRP 2015, 29, 354–359. [Google Scholar] [CrossRef]

- Chemnitz, M.; Schreck, G.; Krüger, J. Analyzing Energy Consumption of Industrial Robots. In Proceedings of the IEEE Conference on Emerging Technologies & Factory Automation, Toulouse, France, 5–9 September 2011; pp. 1–4. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Wang, X.V.; Wang, L. Energy-Efficient Trajectory Planning for an Industrial Robot Using a Multi-Objective Optimization Approach. Procedia Manuf. 2018, 25, 517–525. [Google Scholar] [CrossRef]

- Garriz, C.; Domingo, R. Trajectory Optimization in Terms of Energy and Performance of an Industrial Robot in the Manufacturing Industry. Sensors 2022, 22, 7538. [Google Scholar] [CrossRef] [PubMed]

- Otani, T.; Nakamura, M.; Kimura, K.; Takanishi, A. Energy Efficient Path and Trajectory Optimization of Manipulators with Task Deadline Constraints. IEEE Access 2023, 11, 107441–107450. [Google Scholar] [CrossRef]

- Paes, K.; Dewulf, W.; Vander Elst, K.; Kellens, K.; Slaets, P. Energy Efficient Trajectories for an Industrial ABB Robot. Procedia CIRP 2014, 15, 105–110. [Google Scholar] [CrossRef]

- Peta, K.; Wlodarczyk, J.; Maniak, M. Analysis of Trajectory and Motion Parameters of an Industrial Robot Cooperating with Numerically Controlled Machine Tools. J. Manuf. Process. 2023, 101, 1332–1342. [Google Scholar] [CrossRef]

- Paryanto, P.M.B.; Kohl, J.; Merhof, J.; Spreng, S.; Franke, J. Energy Consumption and Dynamic Behavior Analysis of a Six-Axis Industrial Robot in an Assembly System. Procedia CIRP 2014, 23, 131–136. [Google Scholar] [CrossRef]

- Carabin, G.; Wehrle, E.; Vidoni, R. A Review on Energy-Saving Optimization Methods for Robotic and Automatic Systems. Robotics 2017, 6, 39. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Optimization of Energy Consumption in Industrial Robots, a Review. Cogn. Robot. 2023, 3, 142–157. [Google Scholar] [CrossRef]

- Yaskawa Robotics. Available online: https://www.yaskawa.eu.com/products/robot (accessed on 3 November 2023).

- Uhlmann, E.; Reinkober, S.; Hollerbach, T. Energy Efficient Usage of Industrial Robots for Machining Processes. Procedia CIRP 2016, 48, 206–211. [Google Scholar] [CrossRef]

- Sekala, A.; Kost, G.; Banas, W.; Gwiazda, A.; Grabowik, C. Modelling and Simulation of Robotic Production Systems. J. Phys. Conf. Ser. 2022, 2198, 012065. [Google Scholar] [CrossRef]

- Liu, A.; Liu, H.; Yao, B.; Xu, W.; Yang, M. Energy consumption modeling of industrial robot based on simulated power data and parameter identification. Adv. Mech. Eng. 2018, 10, 1–11. [Google Scholar] [CrossRef]

- Pollak, A.; Temich, S.; Ptasiński, W.; Kucharczyk, J.; Gąsiorek, D. Prediction of Belt Drive Faults in Case of Predictive Maintenance in Industry 4.0 Platform. Appl. Sci. 2021, 11, 10307. [Google Scholar] [CrossRef]

- Farnell. Amazon—A Prime Example of an IoT Implementation; Farnell: Chicago, IL, USA, 2017; Available online: https://pl.farnell.com/amazon-a-prime-example-of-an-iot-implementation (accessed on 16 October 2023).

- Ray, P.P. Internet of Robotic Things: Concept, Technologies, and Challenges. IEEE Access 2017, 4, 9489–9500. [Google Scholar] [CrossRef]

- Waters, M.; Waszczuk, P.; Ayre, R.; Dreze, A.; McGlinchey, D.; Alkali, B.; Morison, G. Open Source IIoT Solution for Gas Waste Monitoring in Smart Factory. Sensors 2022, 22, 2972. [Google Scholar] [CrossRef]

- Cropp, C. Technological Trends Driving Advances in the Mining Industry. 2021. Available online: https://info.vercator.com/blog/technological-advancements-in-mining-industry (accessed on 3 July 2023).

- Cañizares, E.; Valero, F.A. Analyzing the Effects of Applying IoT to a Metal-Mechanical Company. J. Ind. Eng. Manag. 2018, 11, 308–317. [Google Scholar] [CrossRef]

- Palomba, I.; Wehrle, E.; Carabin, G.; Vidoni, R. Minimization of the Energy Consumption in Industrial Robots through Regenerative Drives and Optimally Designed Compliant Elements. Appl. Sci. 2020, 10, 7475. [Google Scholar] [CrossRef]

- Krejčí, J.; Babiuch, M.; Babjak, J.; Suder, J.; Wierbica, R. Implementation of an Embedded System into the Internet of Robotic Things. Micromachines 2023, 14, 113. [Google Scholar] [CrossRef]

- Wójcicki, K.; Biegańska, M.; Paliwoda, B.; Górna, J. Internet of Things in Industry: Research Profiling, Application, Challenges and Opportunities—A Review. Energies 2022, 15, 1806. [Google Scholar] [CrossRef]

- Farhan, L.; Shukur, S.T.; Alissa, A.E.; Alrweg, M.; Raza, U.; Kharel, R. A survey on the challenges and opportunities of the Internet of Things (IoT). In Proceedings of the 2017 Eleventh International Conference on Sensing Technology (ICST), Sydney, Australia, 4–6 December 2017; pp. 1–5. [Google Scholar]

- Chen, Y. Challenges and opportunities of internet of things. In Proceedings of the 17th Asia and South Pacific Design Automation Conference, Sydney, Australia, 30 January–2 February 2012; pp. 383–388. [Google Scholar]

- Peng, C.; Peng, T.; Liu, Y.; Geissdoerfer, M.; Evans, S.; Tang, R. Industrial Internet of Things enabled supply-side energy modelling for refined energy management in aluminium extrusions manufacturing. J. Clean. Prod. 2021, 301, 126882. [Google Scholar] [CrossRef]

- Tabaa, M.; Monteiro, F.; Bensag, H.; Dandache, A. Green Industrial Internet of Things from a smart industry perspectives. Energy Rep. 2020, 6, 430–446. [Google Scholar] [CrossRef]

- Kumar, N.M.; Chand, A.A.; Malvoni, M.; Prasad, K.A.; Mamun, K.A.; Islam, F.; Chopra, S.S. Distributed energy resources and the application of AI, IoT, and blockchain in smart grids. Energies 2020, 13, 5739. [Google Scholar] [CrossRef]

- Elahi, H.; Munir, K.; Eugeni, M.; Atek, S.; Gaudenzi, P. Energy Harvesting towards Self-Powered IoT Devices. Energies 2020, 13, 5528. [Google Scholar] [CrossRef]

- Boscariol, P.; Scalera, L.; Gasparetto, A. Task-Dependent Energetic Analysis of a 3 dof Industrial Manipulator. In Proceedings of the International Conference on Robotics in Alpe-Adria Danube Region, Kaiserslautern, Germany, 19–21 June 2019; pp. 162–169. Available online: https://www.academia.edu/39317276/Task_dependent_energetic_analysis_of_a_3_d_o_f_industrial_manipulator (accessed on 17 October 2023).

- Zhang, M.; Yan, J. A data-driven method for optimizing the energy consumption of industrial robots. J. Clean. Prod. 2021, 285, 124862. [Google Scholar] [CrossRef]

- Benotsmane, R.; Kovács, G. Optimization of Energy Consumption of Industrial Robots Using Classical PID and MPC Controllers. Energies 2023, 16, 3499. [Google Scholar] [CrossRef]

- Scalera, L.; Boscariol, P.; Carabin, G.; Vidoni, R.; Gasparetto, A. Enhancing Energy Efficiency of a 4-DOF Parallel Robot Through Task-Related Analysis. Machines 2020, 8, 10. [Google Scholar] [CrossRef]

- Heredia, J.; Schlette, C.; Kjærgaard, M.B. Breaking Down the Energy Consumption of Industrial and Collaborative Robots: A Comparative Study. In Proceedings of the 2023 IEEE 28th International Conference on Emerging Technologies and Factory Automation (ETFA), Sinaia, Romania, 12–15 September 2023; pp. 1–8. [Google Scholar]

- Garcia, R.R.; Bittencourt, A.C.; Villani, E. Relevant Factors for the Energy Consumption of Industrial Robots. J Braz. Soc. Mech. Sci. Eng. 2018, 40, 464. [Google Scholar] [CrossRef]

- Rassõlkin, A.; Hõimoja, H.; Teemets, R. Energy Saving Possibilities in the Industrial Robot IRB 1600 Control. In Proceedings of the 2011 7th International Conference-Workshop Compatibility and Power Electronics (CPE), Tallinn, Estonia, 1–3 June 2011; pp. 226–229. [Google Scholar]

- Gadaleta, M.; Pellicciari, M.; Berselli, G. Optimization of the Energy Consumption of Industrial Robots for Automatic Code Generation. Robot. Comput. Integr. Manuf. 2019, 57, 452–464. [Google Scholar] [CrossRef]

- Gadaleta, M.; Berselli, G.; Pellicciari, M.; Grassia, F. Extensive Experimental Investigation for the Optimization of the Energy Consumption of a High Payload Industrial Robot with Open Research Dataset. Robot. Comput. Integr. Manuf. 2021, 68, 102046. [Google Scholar] [CrossRef]

- Riazi, S.; Bengtsson, K.; Wigström, O.; Vidarsson, E.; Lennartson, B. Energy Optimization of Multi-Robot Systems. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24–28 August 2015; pp. 1345–1350. [Google Scholar]

- Vergnano, A.; Thorstensson, C.; Lennartson, B.; Falkman, P.; Pellicciari, M.; Yuan, C.; Biller, S.; Leali, F. Embedding Detailed Robot Energy Optimization into High-Level Scheduling. In Proceedings of the 2010 IEEE International Conference on Automation Science and Engineering, Auckland, New Zealand, 26–30 August 2010; pp. 386–392. [Google Scholar]

- Stuhlenmiller, F.; Jungblut, J.; Clever, D.; Rinderknecht, S. Combined Analysis of Energy Consumption and Expected Service Life of a Robotic System. In Proceedings of the 2020 6th International Conference on Mechatronics and Robotics Engineering (ICMRE), Barcelona, Spain, 12–15 February 2020; pp. 53–57. [Google Scholar]

- Meike, D.; Pellicciari, M.; Berselli, G.; Vergnano, A.; Ribickis, L. Increasing the Energy Efficiency of Multi-Robot Production Lines in the Automotive Industry. In Proceedings of the 2012 IEEE International Conference on Automation Science and Engineering (CASE), Seoul, Republic of Korea, 20–24 August 2012; pp. 700–705. [Google Scholar]

- Heredia, J.; Schlette, C.; Kjargaard, M.B. Sizing up Energy Consumption in Lightweight Robots: A Comprehensive Assessment. In Proceedings of the 2023 7th International Conference on Automation, Control and Robots (ICACR), Kuala Lumpur, Malaysia, 4–6 August 2023; pp. 31–38. [Google Scholar]

- Meike, D.; Ribickis, L. Energy Efficient Use of Robotics in the Automobile Industry. In Proceedings of the 2011 15th International Conference on Advanced Robotics (ICAR), Tallinn, Estonia, 20–23 June 2011; pp. 507–511. [Google Scholar]

- Pellicciari, M.; Berselli, G.; Leali, F.; Vergnano, A. A Method for Reducing the Energy Consumption of Pick-and-Place Industrial Robots. Mechatronics 2013, 23, 326–334. [Google Scholar] [CrossRef]

- Meike, D.; Pellicciari, M.; Berselli, G. Energy Efficient Use of Multirobot Production Lines in the Automotive Industry: Detailed System Modeling and Optimization. IEEE Trans. Automat. Sci. Eng. 2014, 11, 798–809. [Google Scholar] [CrossRef]

- Hovgard, M.; Lennartson, B.; Bengtsson, K. Energy reduction of stochastic time-constrained robot stations. Robot. Comput. Integr. Manuf. 2023, 81, 102511. [Google Scholar] [CrossRef]

- Vodovozov, V.; Raud, Z.; Petlenkov, E. Intelligent Control of Robots with Minimal Power Consumption in Pick-and-Place Operations. Energies 2023, 16, 7418. [Google Scholar] [CrossRef]

- Barnett, N.; Costenaro, D.; Rohmund, I. Direct and indirect impacts of robots on future electricity load. In Proceedings of the ACEEE Summer Study on Energy Efficiency in Industry, Denver, CO, USA, 15–18 August 2017; pp. 1–9. Available online: https://www.aceee.org/files/proceedings/2017/data/polopoly_fs/1.3687904.1501159084!/fileserver/file/790278/filename/0036_0053_000029.pdf (accessed on 17 October 2023).

- 3 Trends in Robotics Energy Consumption. Robotics Tomorrow. Available online: https://roboticstomorrow.com/story/2021/03/3-trends-in-robotics-energy-consumption/16385/ (accessed on 3 October 2023).

- Ogbemhe, J.; Mpofu, K.; Tlale, N.S. Achieving Sustainability in Manufacturing Using Robotic Methodologies. Procedia Manuf. 2017, 8, 440–446. [Google Scholar] [CrossRef]

- Yao, M.; Shao, Z.; Zhao, Y. Review on Energy Consumption Optimization Methods of Typical Discrete Manufacturing Equipment. In Intelligent Robotics and Applications; Liu, X.-J., Nie, Z., Yu, J., Xie, F., Song, R., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 48–58. [Google Scholar]

- Wang, E.-Z.; Lee, C.-C.; Li, Y. Assessing the Impact of Industrial Robots on Manufacturing Energy Intensity in 38 Countries. Energy Econ. 2022, 105, 105748. [Google Scholar] [CrossRef]

- Paryanto; Brossog, M.; Bornschlegl, M.; Franke, J. Reducing the Energy Consumption of Industrial Robots in Manufacturing Systems. Int. J. Adv. Manuf. Technol. 2015, 78, 1315–1328. [Google Scholar] [CrossRef]

- Vavra, C. Five Robot Trends for 2023. Available online: https://www.controleng.com/articles/five-robot-trends-for-2023/ (accessed on 25 October 2023).

- Evjemo, L.D.; Gjerstad, T.; Grøtli, E.I.; Sziebig, G. Trends in Smart Manufacturing: Role of Humans and Industrial Robots in Smart Factories. Curr. Robot. Rep. 2020, 1, 35–41. [Google Scholar] [CrossRef]

- Izagirre, U.; Arcin, G.; Andonegui, I.; Eciolaza, L.; Zurutuza, U. Torque-Based Methodology and Experimental Implementation for Industrial Robot Standby Pose Optimization. Int. J. Adv. Manuf. Technol. 2020, 111, 2065–2072. [Google Scholar] [CrossRef]

- Vatankhah Barenji, A.; Liu, X.; Guo, H.; Li, Z. A Digital Twin-Driven Approach towards Smart Manufacturing: Reduced Energy Consumption for a Robotic Cell. Int. J. Comput. Integr. Manuf. 2021, 34, 844–859. [Google Scholar] [CrossRef]

- Yan, K.; Xu, W.; Yao, B.; Zhou, Z.; Pham, D.T. Digital Twin-Based Energy Modeling of Industrial Robots. In Methods and Applications for Modeling and Simulation of Complex Systems; Li, L., Hasegawa, K., Tanaka, S., Eds.; Springer: Singapore, 2018; pp. 333–348. [Google Scholar]

- Stan, L.; Nicolescu, A.F.; Pupăză, C.; Jiga, G. Digital Twin and Web Services for Robotic Deburring in Intelligent Manufacturing. J. Intell. Manuf. 2023, 34, 2765–2781. [Google Scholar] [CrossRef]

- Barreto, J.P.; Schöler, F.J.-F.; Corves, B. The Concept of Natural Motion for Pick and Place Operations. In New Advances in Mechanisms, Mechanical Transmissions and Robotics; Corves, B., Lovasz, E.-C., Hüsing, M., Maniu, I., Gruescu, C., Eds.; Springer International Publishing: Cham, Switzerland, 2017; Volume 46, pp. 89–98. ISBN 9783319454498. [Google Scholar]

- Stuhlenmiller, F.; Weyand, S.; Jungblut, J.; Schebek, L.; Clever, D.; Rinderknecht, S. Impact of Cycle Time and Payload of an Industrial Robot on Resource Efficiency. Robotics 2021, 10, 33. [Google Scholar] [CrossRef]

- Lv, H.; Shi, B.; Li, N.; Kang, R. Intelligent Manufacturing and Carbon Emissions Reduction: Evidence from the Use of Industrial Robots in China. Int. J. Environ. Res. Public Health 2022, 19, 15538. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Wang, Y.; Wei, X.; Zeng, C. Towards Low-Carbon Development: The Role of Industrial Robots in Decarbonization in Chinese Cities. J. Environ. Manag. 2023, 330, 117216. [Google Scholar] [CrossRef] [PubMed]

- Weidemann, C.; Mandischer, N.; van Kerkom, F.; Corves, B.; Hüsing, M.; Kraus, T.; Garus, C. Literature Review on Recent Trends and Perspectives of Collaborative Robotics in Work 4.0. Robotics 2023, 12, 84. [Google Scholar] [CrossRef]

| Vertical Plane | Horizontal Plane | |||||

|---|---|---|---|---|---|---|

| Motor | Energy (J) | Energy Reduction (%) | Energy (J) | Energy Reduction (%) | ||

| No ERD | ERD | No ERD | ERD | |||

| 1 | 10.15 | 2.06 | 79.70 | 5.62 | 1.88 | 66.59 |

| 2 | 9.43 | 2.29 | 75.69 | 7.31 | 2.14 | 70.63 |

| Total | 19.58 | 4.35 | 77.78 | 12.93 | 4.02 | 68.90 |

| Motor | Energy (J) | Energy Reduction (%) | |

|---|---|---|---|

| No ERD | ERD | ||

| 1 | 19.69 | 2.50 | 87.28 |

| 2 | 6.38 | 0.6689 | 89.53 |

| 3 | 19.68 | 14.30 | 27.35 |

| 4 | 1.97 | 1.50 | 24.03 |

| Total | 47.72 | 18.96 | 60.26 |

| Momentary Power Consumption | Operation/Charging Hours per Day | Energy Usage per Year | Lifetime (in Years) | |

|---|---|---|---|---|

| Average | 3000 | 20 | 21,915 | 14 |

| Units Sold (2014) | Units in Operation (2014) | Robot Load (GWh) 2014 | Predicted Robot Load (GWh) 2025 | Year-over-Year Growth (%) | |

|---|---|---|---|---|---|

| Industrial Manufacturing | 25,350 | 203,637 | 5058 | 15,954 | 10.4 |

| Automotive | 13,943 | 112,000 | 2782 | 8775 | 10.4 |

| Electronics | 3740 | 30,045 | 746 | 2354 | 10.4 |

| Rubber/Plastic | 1309 | 10,516 | 261 | 824 | 10.4 |

| Pharmaceutical | 187 | 1502 | 37 | 118 | 10.4 |

| Food/Beverage | 748 | 6009 | 149 | 471 | 10.4 |

| Metallurgical | 1683 | 13,520 | 336 | 1059 | 10.4 |

| Others | 3740 | 30,045 | 746 | 2354 | 10.4 |

| Solution: Hardware/Software/Mixed (Hardware and Software) | Energy Optimization Method | Article No. |

|---|---|---|

| Hardware | System Modernization Using Energy Recovery and Storage Devices, such as Regenerative Drives and Compatible Components | [33] |

| Software | Artificial Neural Network and Genetic Algorithm | [43] |

| Optimization of Trajectories and Optimal Control Strategies for Robot Arms | [44] | |

| Application of Dynamic and Electromechanical Models of Manipulators for the Best Relative Positioning of the Robot | [45] | |

| Optimal Trajectory Planning and Path Localization in the Workspace. Development of an Electromechanical Model of Actuators and the Inverse Dynamic Model of the Robot | [42] | |

| Optimization of Parameter and Software Values, such as Connection Speed, Acceleration, and Robot Payload | [47] | |

| Programming and Positioning of Robots | [48] | |

| Modeling of Motor Energy Consumption, which Changes with the Robot’s Trajectory, and Optimization of the Robot’s Speed | [26] | |

| Robot Parameter Optimization—Speed, Payload | [20] | |

| Software | Simulation Tool that Allows for Automatic Calculation of Optimal Energy Parameters of Motion | [49] |

| Optimization of Programmable Robot Parameters (including trajectory, speed) | [50] | |

| Optimization Algorithms for Sequence of Operations and Motion Trajectories | [51] | |

| Scaling of Reference Trajectories | [52] | |

| Optimization of Trajectories | [53] | |

| Optimization of the Target Location of the Robot’s Path | [13] | |

| Trajectory Optimization Using Time Scaling, Earlier Release of Actuator Brake During Robot Standby. | [54] | |

| Optimization of Parameters including Motion Commands, Trajectory Planning, Acceleration Constraints, and Speed Limitations | [55] | |

| Trajectory Optimization | [57] | |

| Trajectory Optimization and Earlier Release of Actuator Brakes | [58] | |

| Optimization of Execution Times and Operation Sequence | [59] | |

| Trajectory Optimization | [60] | |

| Mixed | Various Methods of Energy Optimization including Brake Management, Temporary Storage of Kinetic Energy of the Robot, and Energy Exchange between Robot Controllers | [56] |

| Designing More Efficient Electronics—Effective Allocation of Computational Tasks Between System Resources | [46] | |

| IIoT—Application of Sensors for Energy Monitoring | [35] | |

| IIoT and Energy Modeling Methods | [38] |

| Advantages | Disadvantages |

|---|---|

| IIoT—Application of Sensors for Energy Monitoring: | |

|

|

| IIoT and Energy-Modeling Methods: | |

|

|

| Artificial Neural Network and Genetic Algorithm: | |

|

|

| Optimization of Trajectories and Optimal Control Strategies for Robot Arms: | |

|

|

| System Modernization Using Energy Recovery and Storage Devices: | |

|

|

| Application of Dynamic and Electromechanical Models of Manipulators: | |

|

|

| Optimal Trajectory Planning and Path Localization: | |

|

|

| Designing More Efficient Electronics: | |

|

|

| Optimization of Parameter and Software Values: | |

|

|

| Programming and Positioning of Robots: | |

|

|

| Modeling of Motor Energy Consumption: | |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sękala, A.; Blaszczyk, T.; Foit, K.; Kost, G. Selected Issues, Methods, and Trends in the Energy Consumption of Industrial Robots. Energies 2024, 17, 641. https://doi.org/10.3390/en17030641

Sękala A, Blaszczyk T, Foit K, Kost G. Selected Issues, Methods, and Trends in the Energy Consumption of Industrial Robots. Energies. 2024; 17(3):641. https://doi.org/10.3390/en17030641

Chicago/Turabian StyleSękala, Agnieszka, Tomasz Blaszczyk, Krzysztof Foit, and Gabriel Kost. 2024. "Selected Issues, Methods, and Trends in the Energy Consumption of Industrial Robots" Energies 17, no. 3: 641. https://doi.org/10.3390/en17030641

APA StyleSękala, A., Blaszczyk, T., Foit, K., & Kost, G. (2024). Selected Issues, Methods, and Trends in the Energy Consumption of Industrial Robots. Energies, 17(3), 641. https://doi.org/10.3390/en17030641